Cutting-free fast tearing butt coupler and butt joint piece

A kind of butt-fastening and fast technology, applied in the field of prefabricated fasteners and prefabricated parts manufacturing, which can solve the problems of no impact, unsatisfactory, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

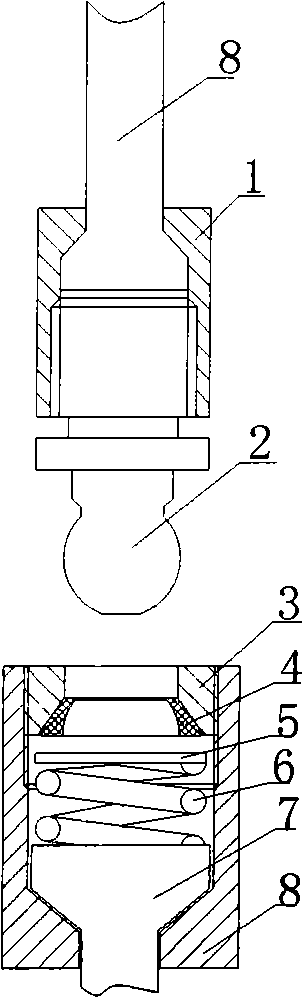

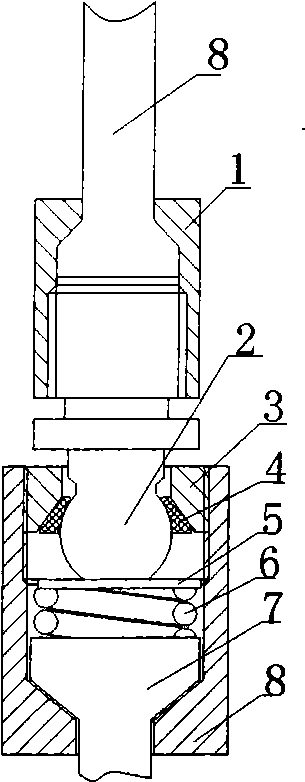

[0029] Embodiment 1: with reference to attached figure 1 and 2 . Non-shearing fast strong pull butt joint fastener, which includes an expansion nut 1 and a top pull nut 8, the expansion nut 1 and the top pull nut 8 are internal thread structures, and the internal thread is a strong pull thread buckle, the cap There is a steel bar hole in the center of the bottom, and the periphery of the steel bar hole is a steel bar heading card. The compression spring 6 is located in the top pull nut 8. One end of the compression spring 6 is located on the steel bar heading card. Multi-piece tapered sleeve 4 (generally two pieces constitute a tapered sleeve--the cavity of the sleeve is tapered and penetrates up and down, see the attached figure 1 and 2), the threaded sleeve 3 is screwed into the top pull nut 8 and the tapered sleeve 4 is shifted and positioned, the tail of the plug joint 2 is connected with the internal thread of the expansion nut 1, and the head of the plug joint 2 is sp...

Embodiment 2

[0030] Embodiment 2: On the basis of Embodiment 1, that is to say, the other end of the compression spring 6 is provided with a gasket 5, and the tapered sleeve 4 composed of two or more pieces is located on the gasket 5.

Embodiment 3

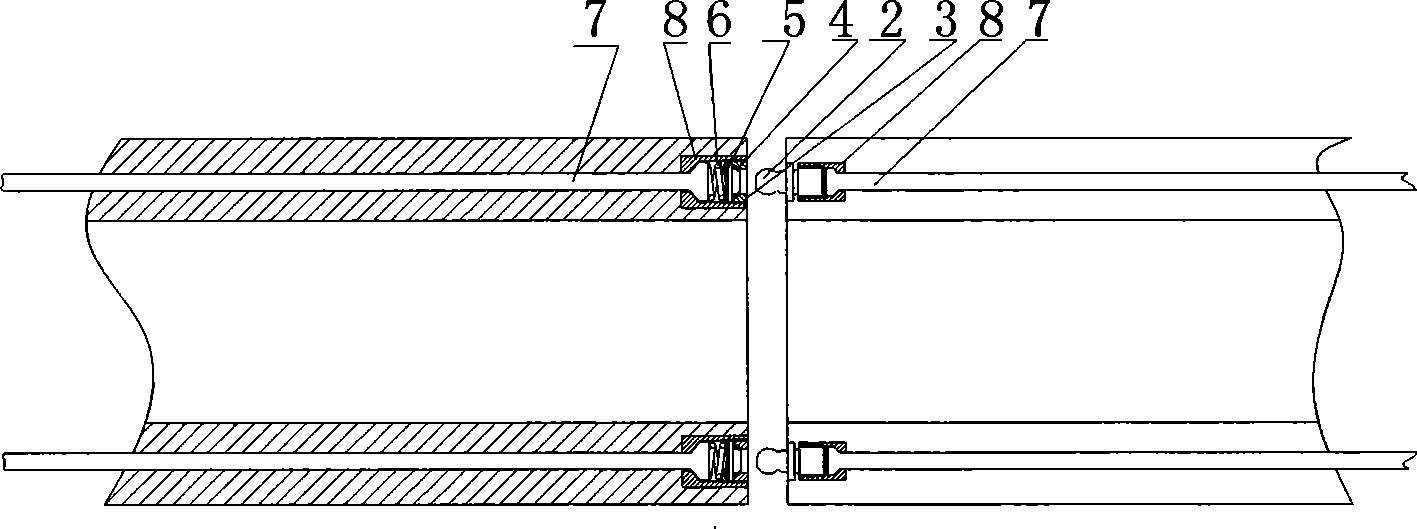

[0031] Embodiment 3: with reference to attached image 3 and 4 . On the basis of Example 1, the prefabricated part composed of non-shearing fast and strong butt joint fasteners is composed of tension nuts 1, top tension nuts 8 and prefabricated longitudinal steel bars 7 located at both ends of the prefabricated part, wherein, The tension nut 1 and the top pull nut 8 are of internal thread structure, the internal thread is a strong wire buckle, there is a steel bar hole in the center of the bottom of the cap, the periphery of the steel bar hole is a steel bar heading card, and the longitudinal steel bar 7 of the prefabricated part The two ends of the upsetting head are clamped on the upsetting head card table, the compression spring 6 is located in the top pull nut 8, one end of the compression spring 6 is located on the steel bar upsetting head, and the other end is equipped with two or more pieces. Tapered sleeve 4 (generally two pieces constitute a tapered sleeve----the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com