Cutting box of slot milling machine

A slot milling machine and box technology, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of poor sealing performance, affecting the operation efficiency of underground diaphragm wall curtain wall construction quality, equipment failure of slot milling machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

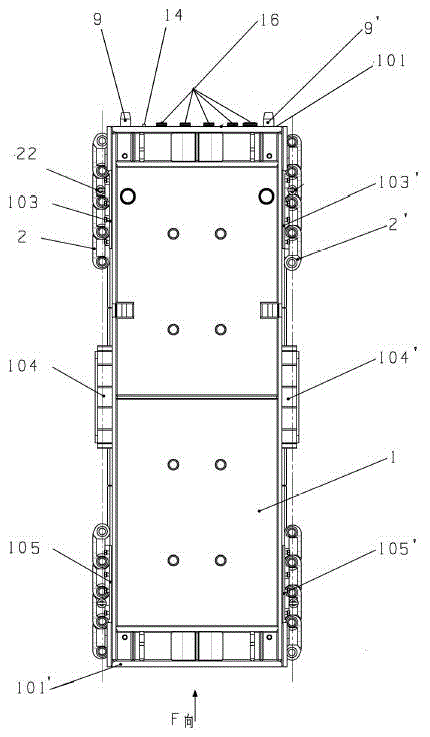

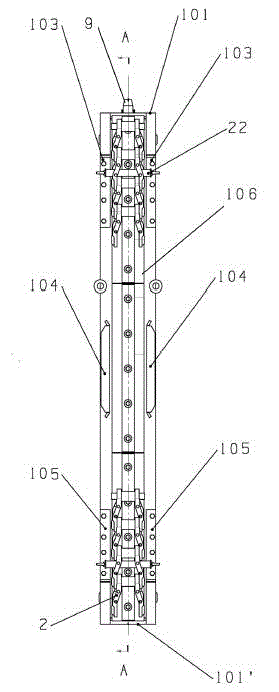

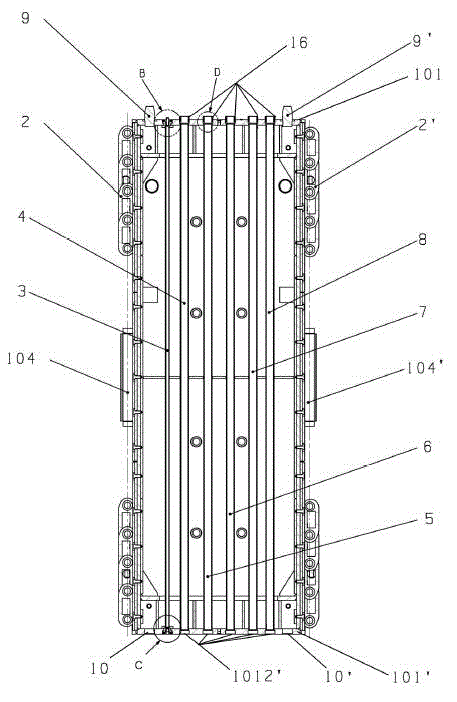

[0021] like Figure 1-Figure 8 As shown, a cutting box of a milling machine is composed of multiple unit cutting boxes, and each unit cutting box includes a box body 1, two chain groups 2, 2' located on the left and right sides of the box body, lubricating oil pipe 3, and conveying and transmission pipes , positioning pin 9, 9', positioning hole 10, 10', sealing seat 13, 13', quick joint 14, quick joint seat 15, sealing sleeve 16, the first O-ring 17 and the second O-ring 18 and the first Three O-shaped rings 19; it is characterized in that the box body 1 is a rectangular parallelepiped welded structure, and two upper fixing frames 103, 103' are arranged symmetrically from top to bottom on its left and right opposite sides. , guard plates 104, 104' and lower fixing frames 105, 105', which form guide grooves 106, 106' on the left and right sides of the box body 1; the two chain groups 2, 2' (each chain group includes rail joints , the pin shaft and the tool set on the rail joi...

Embodiment 2

[0025] The difference from Embodiment 1 is that the delivery and transmission pipeline includes a first air tube 4 , a first slurry tube 5 and a sensor cannula 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com