Patents

Literature

36results about How to "Large floating amount" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

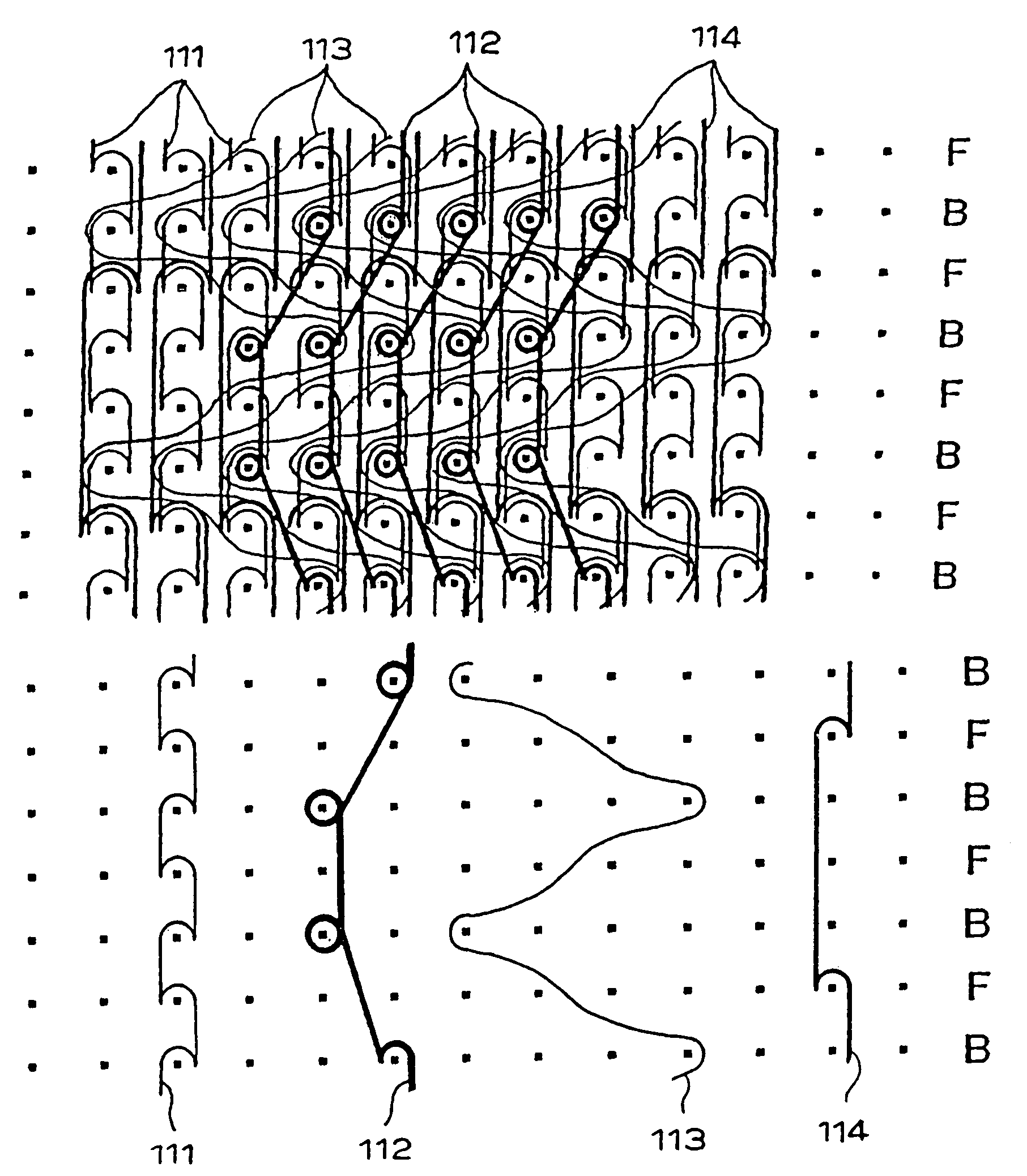

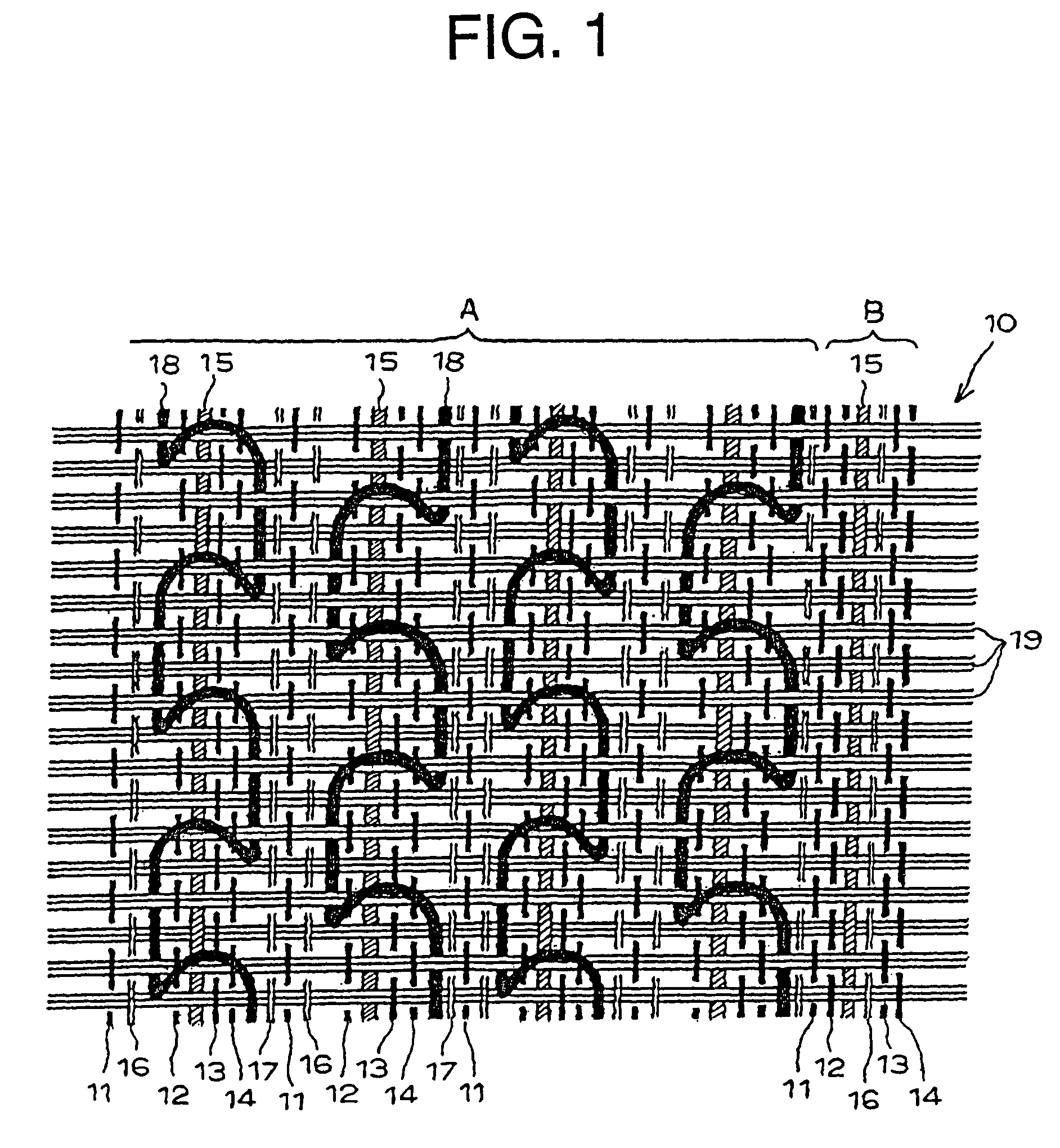

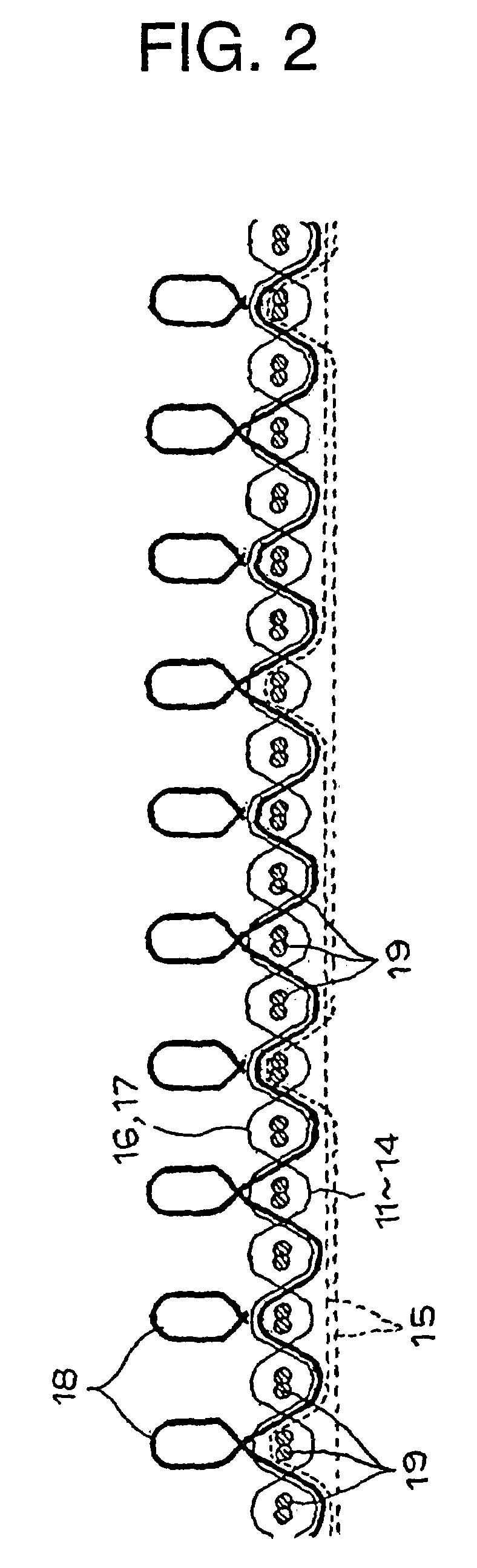

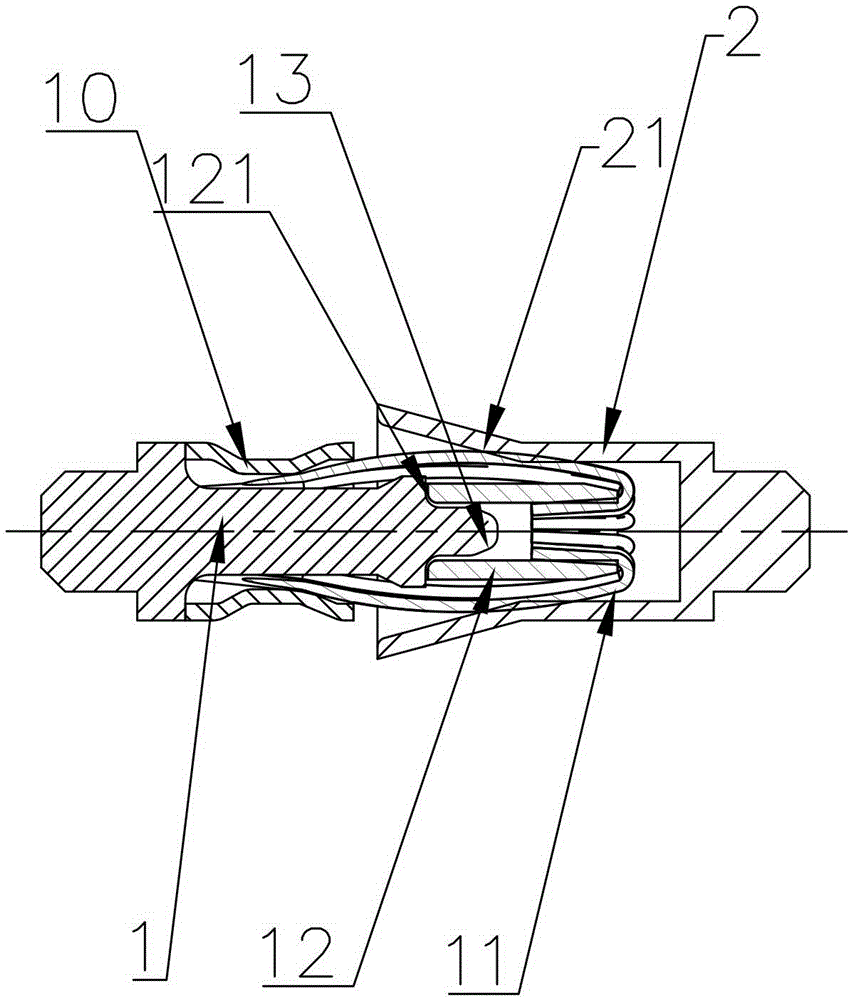

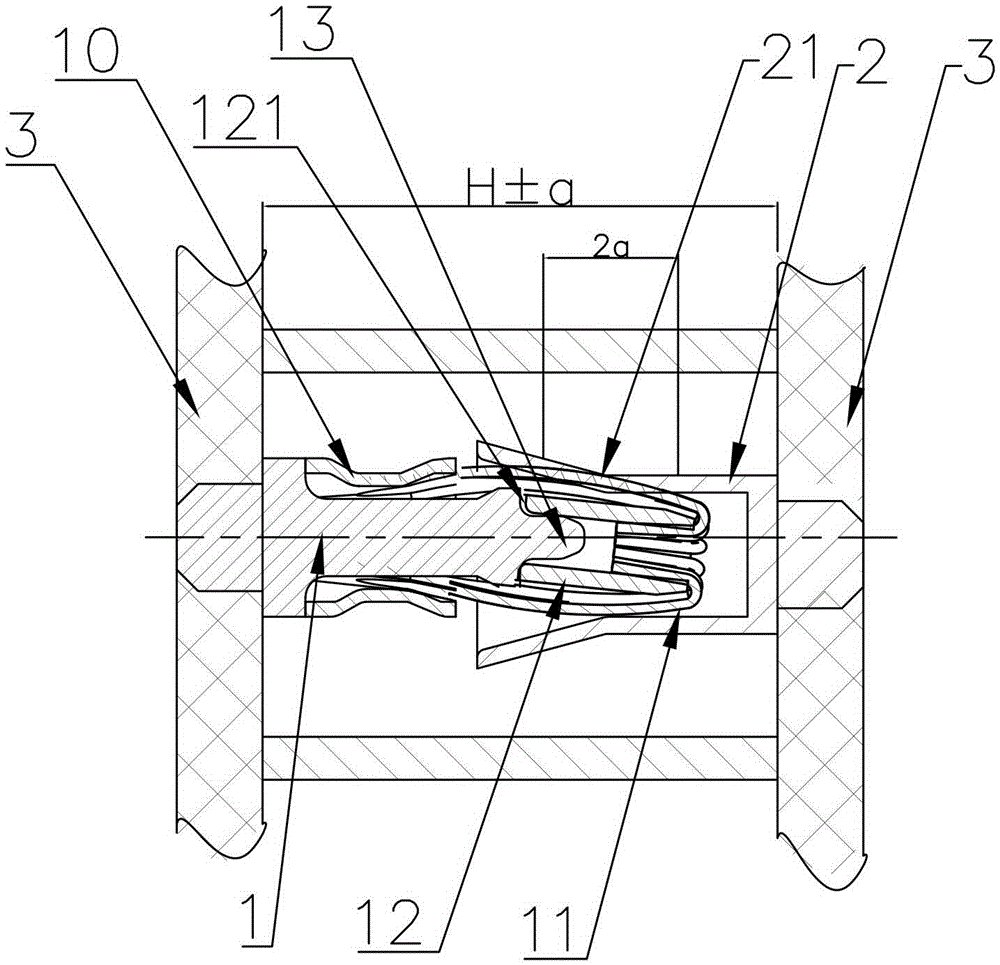

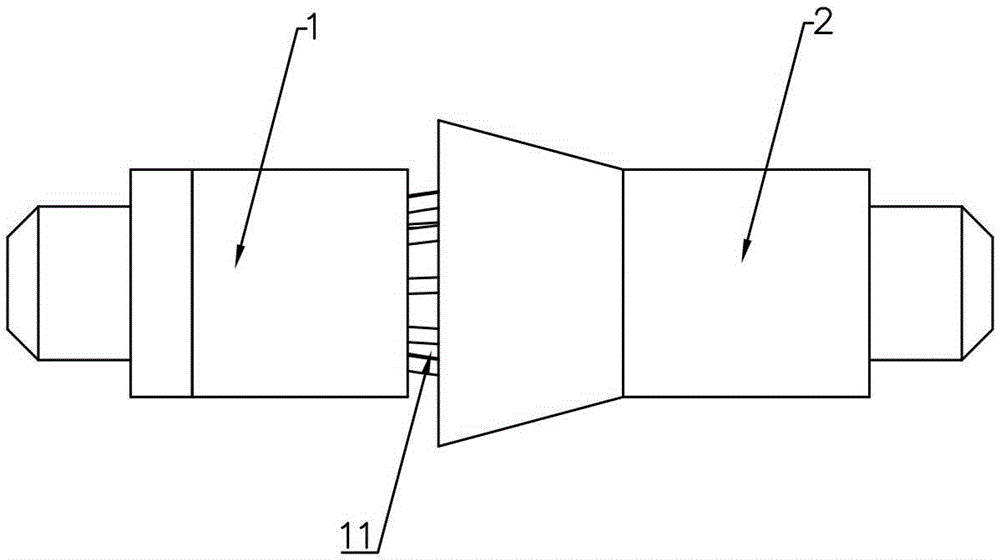

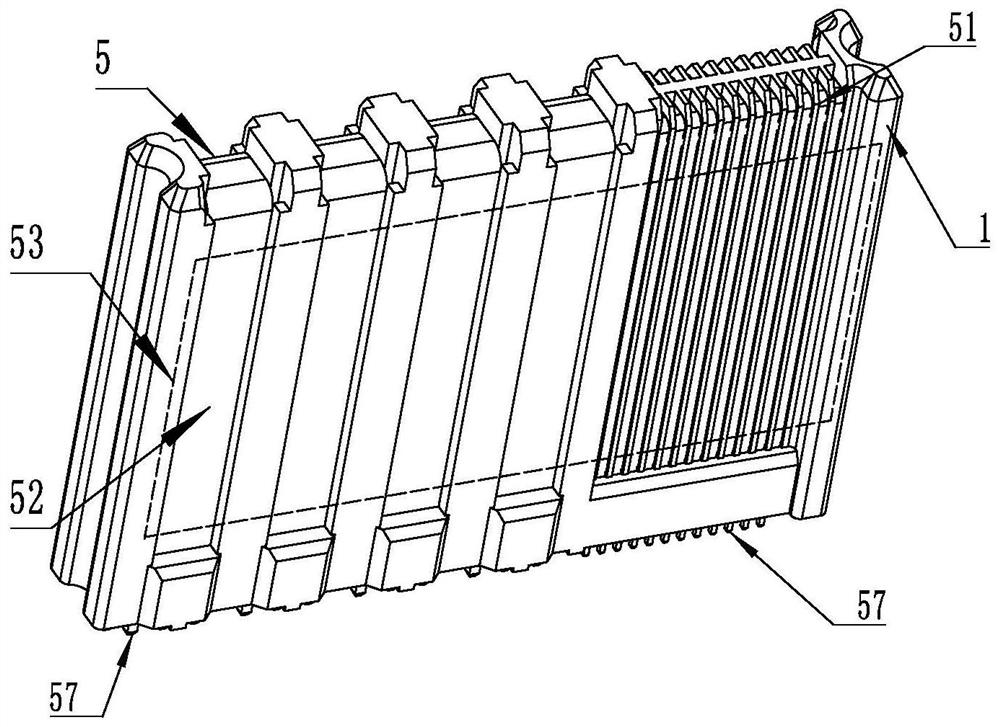

Fiber-made surface fastener

InactiveUS7207195B2Extreme softness feelingImprove plasticityOrnamental textile articlesWoven fabricsFiberYarn

A fiber-made surface fastener having on its back a covering of soft fiber yarns excellent in softness and in a function and durability as a surface fastener and including a multiplicity of engaging elements woven or knitted simultaneously with weaving or knitting of a substrate woven or knitted fabric (10) and projecting from a surface of the same woven or knitted fabric (10). Warp yarns (11 to 17, 111, 114) of the substrate woven or knitted fabric (10) contain finished yarns (15, 114) partially. The finished yarns (15, 114) are woven or knitted into the substrate woven or knitted fabric (10) such that the yarn floating from a rear surface of the same substrate woven or knitted fabric (10) and a substantially entire surface of the rear surface of the substrate woven or knitted fabric (10, 110) is covered with the same finished yarns (15, 114). Preferably, these finished yarns (15, 114) are bulky finished yarns composed of multifilaments.

Owner:THE OHIO STATES UNIV +1

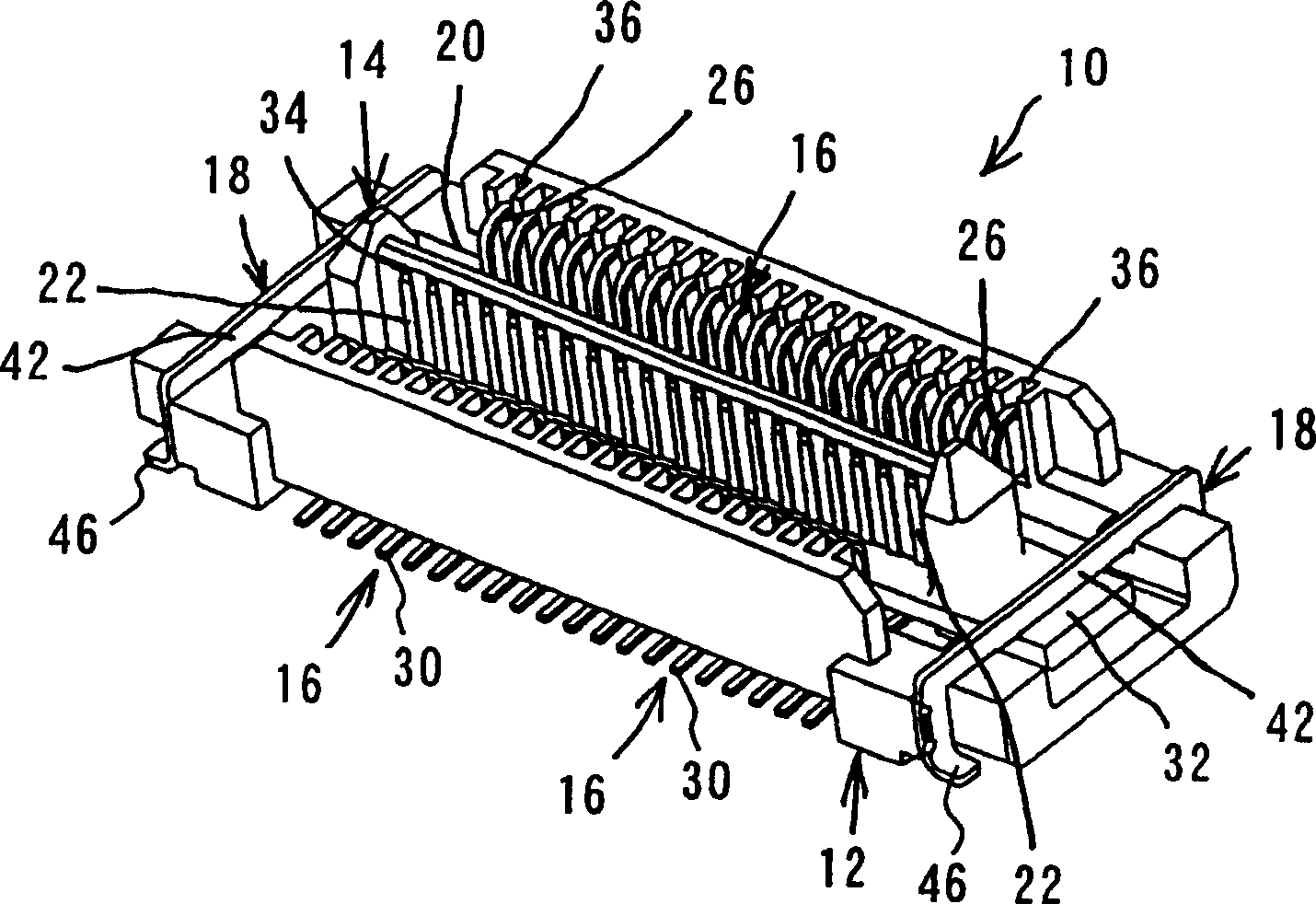

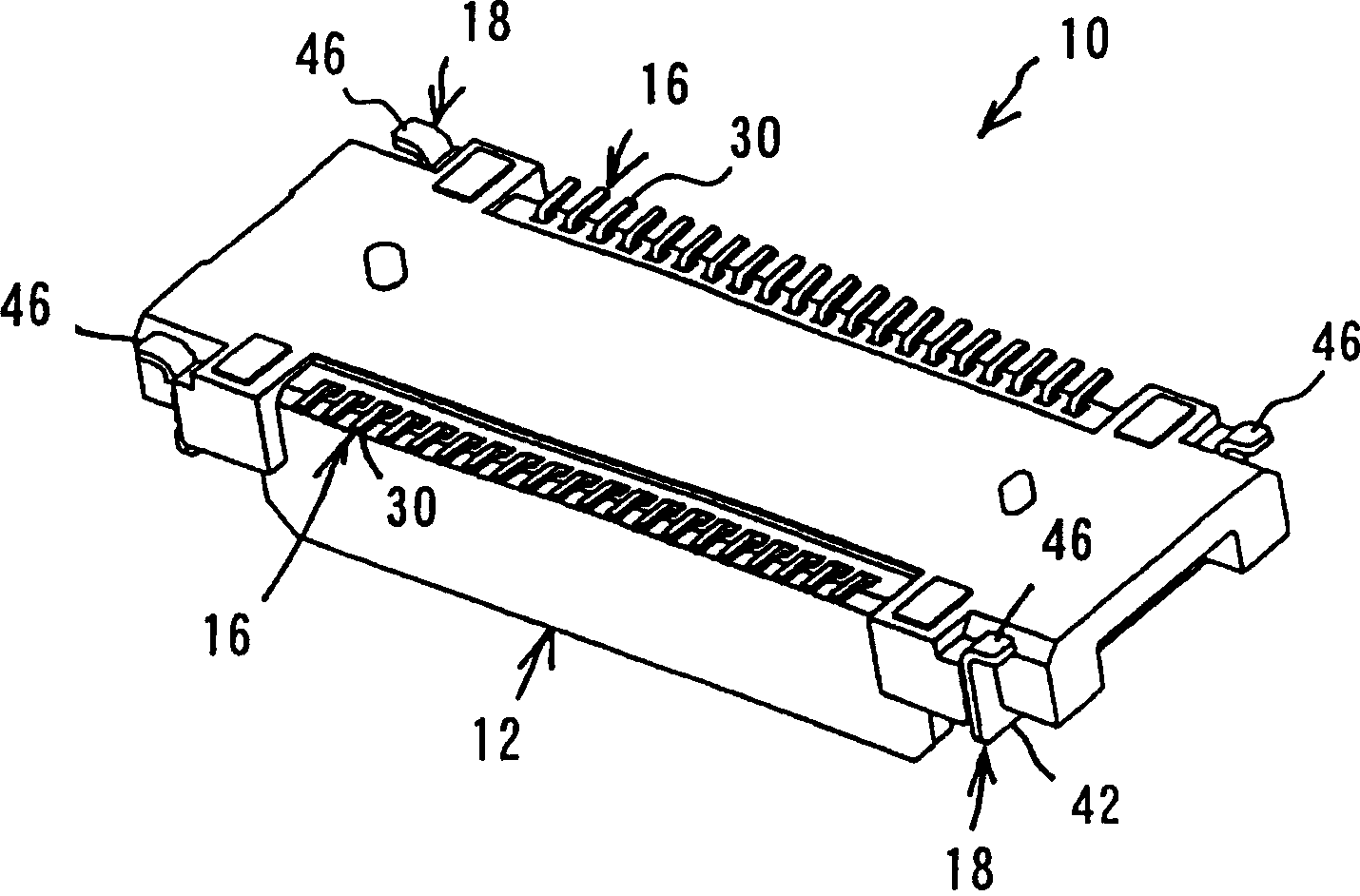

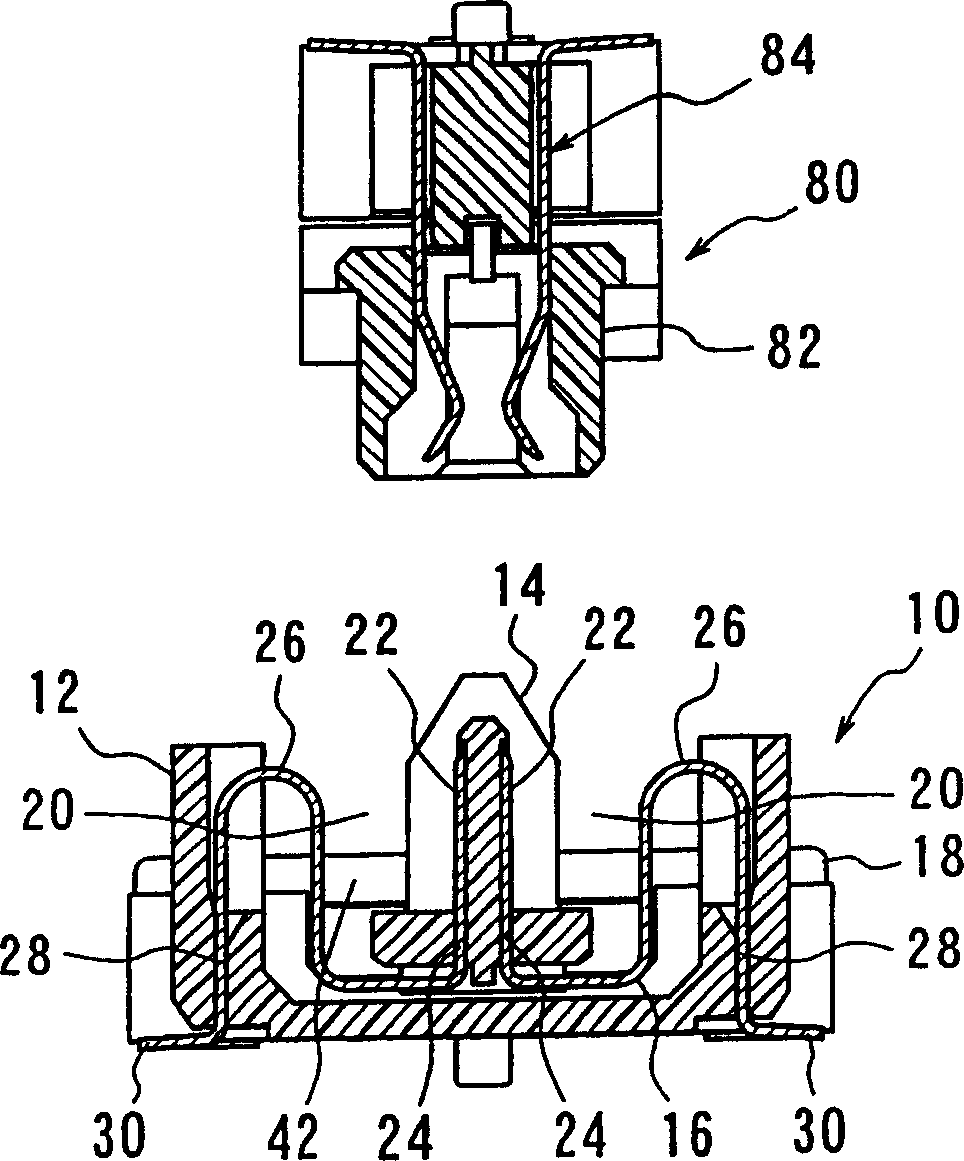

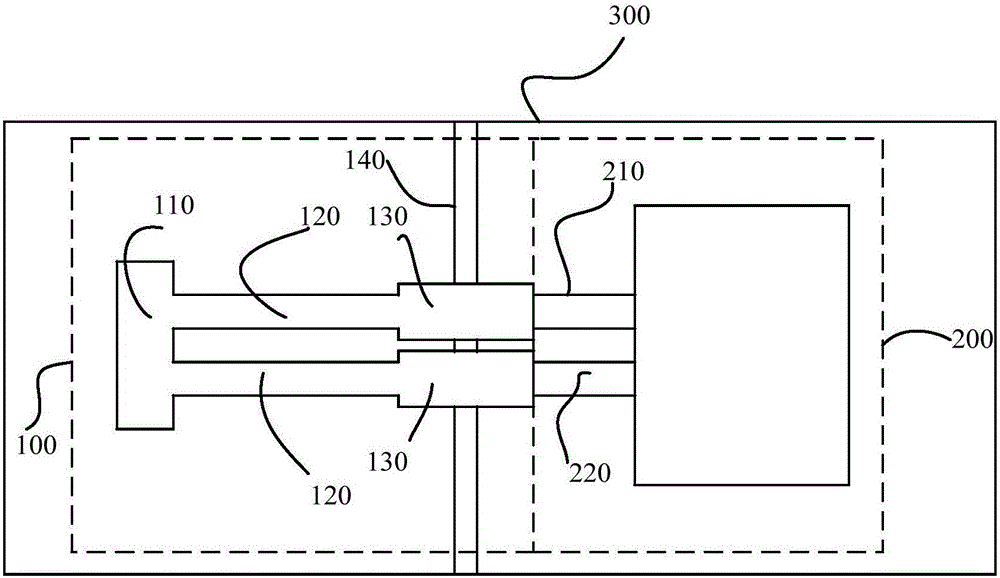

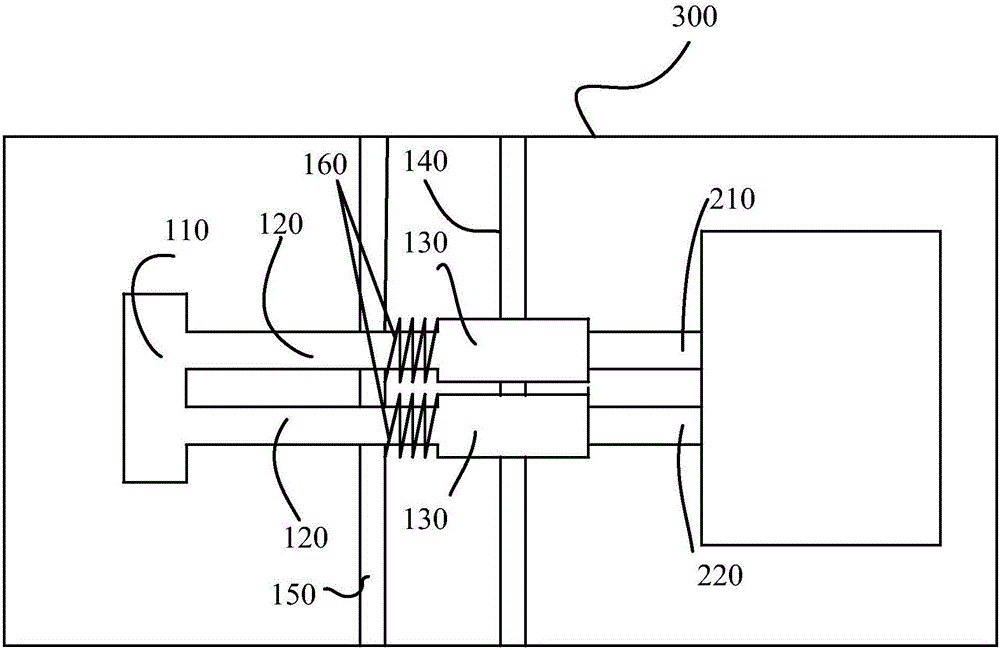

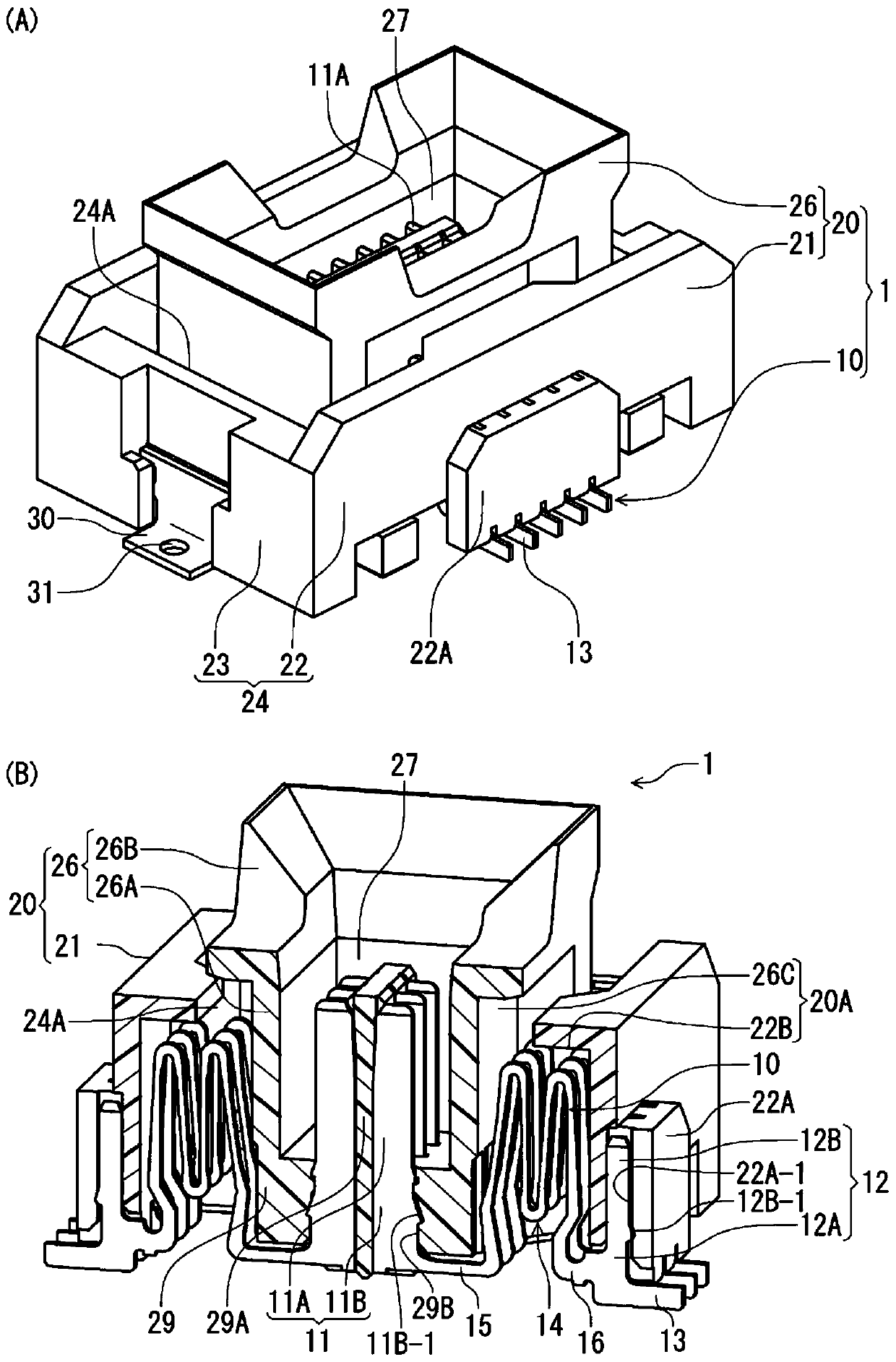

Connector

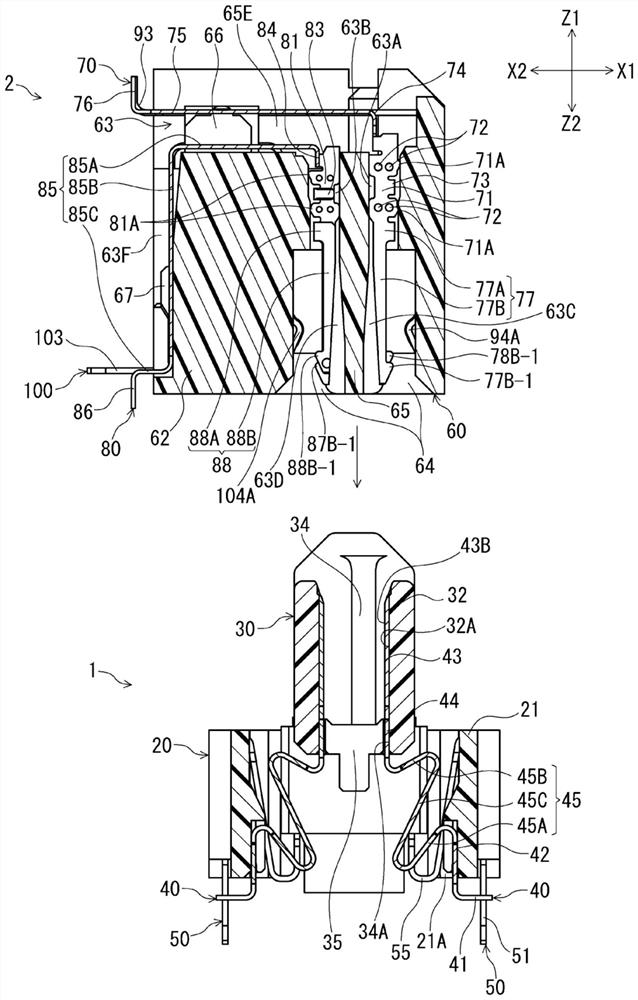

ActiveCN1893199AReliable electrical connectionPrevent disengagementCoupling contact membersTwo-part coupling devicesMechanical engineeringShort circuit

A connector includes contacts and an insulator. Each contact includes a contact portion, a first fixed portion, an elastic portion substantially in the form of a crank, a second fixed portion and a connection portion. The insulator includes a fixation block to which the second fixed portions are fixed, and a movable housing to which the first fixed portions are fixed. The movable housing is fixed only to the contacts and held by the elastic portions in a floating condition away from the bottom surface of the fixation block. The fixation block has a wall for preventing short circuit when the connector is being mounted on a substrate. A floating amount of more than 0.7 mm can be achieved with a simple construction without causing short circuit with a substrate when the connector is being fitted with a mating connector and without causing any failed connection.

Owner:DDK LTD

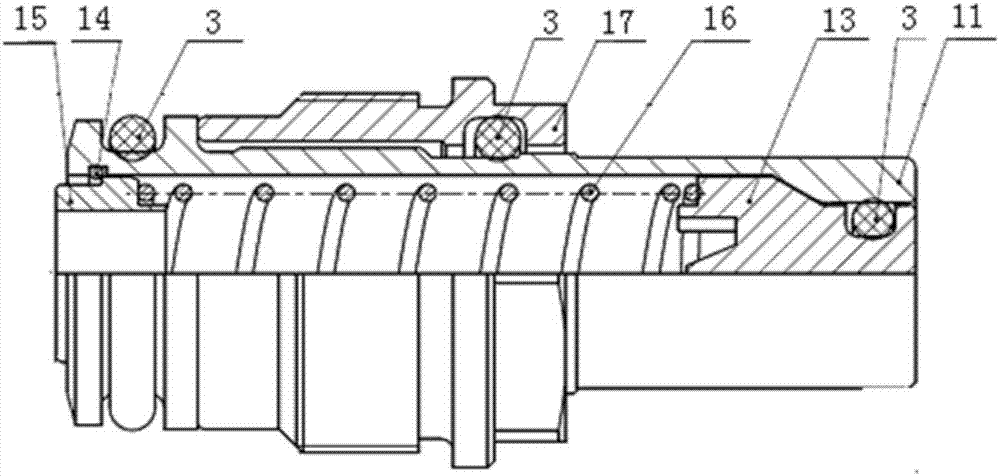

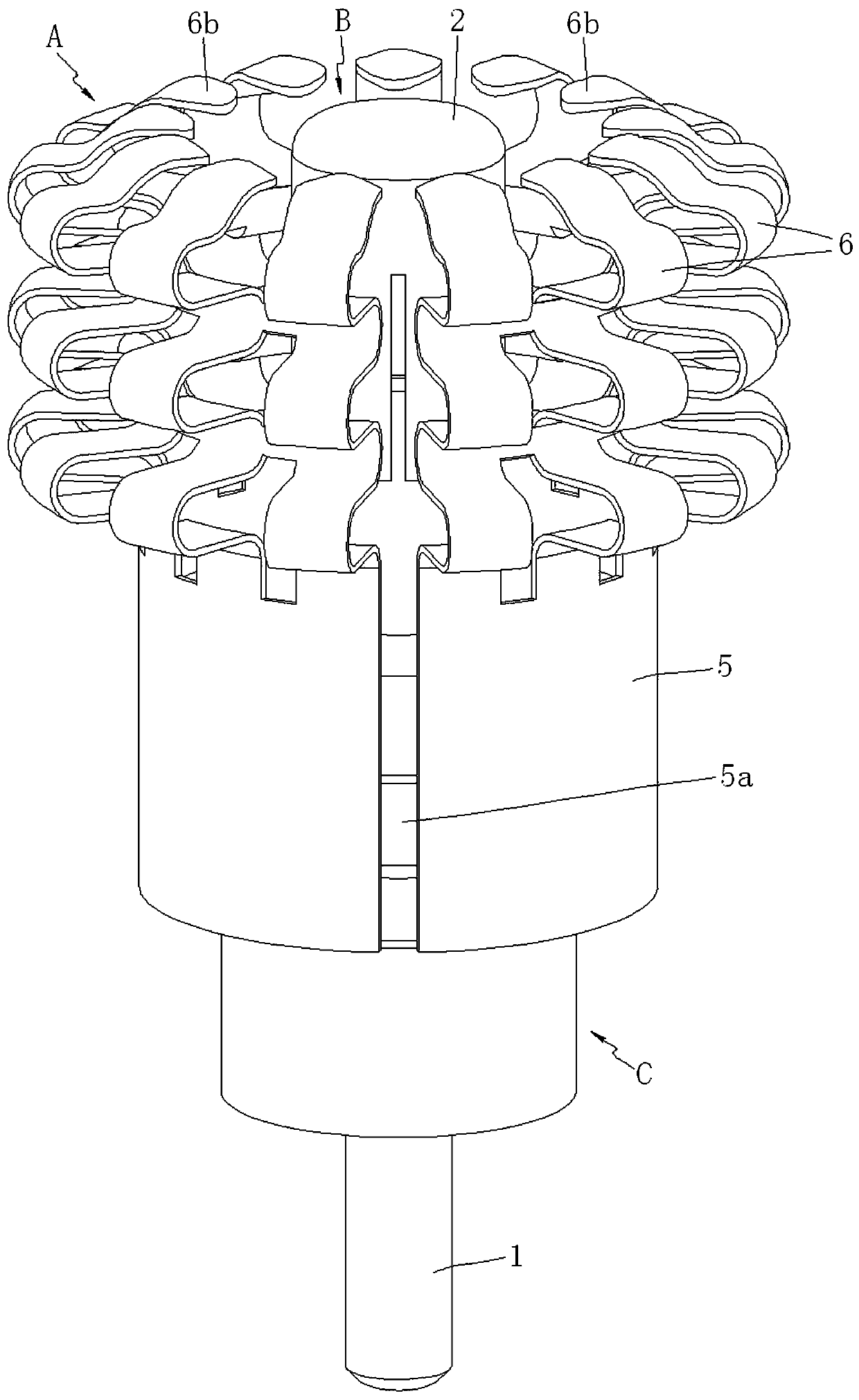

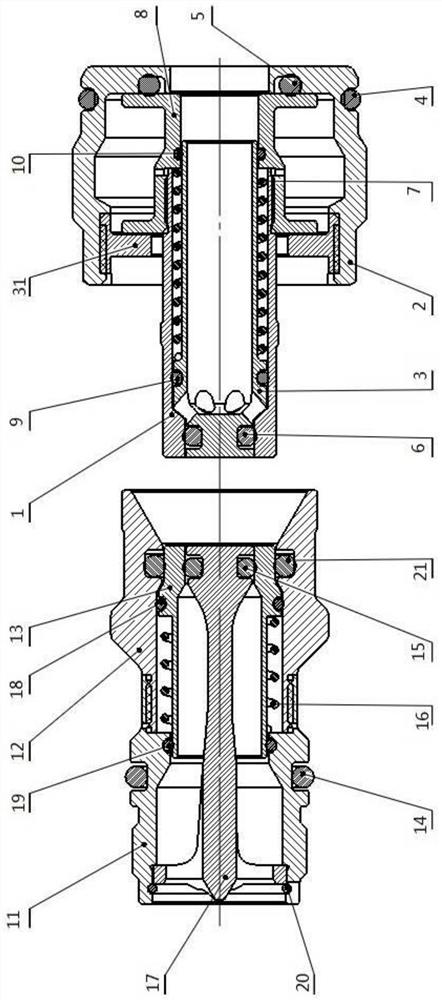

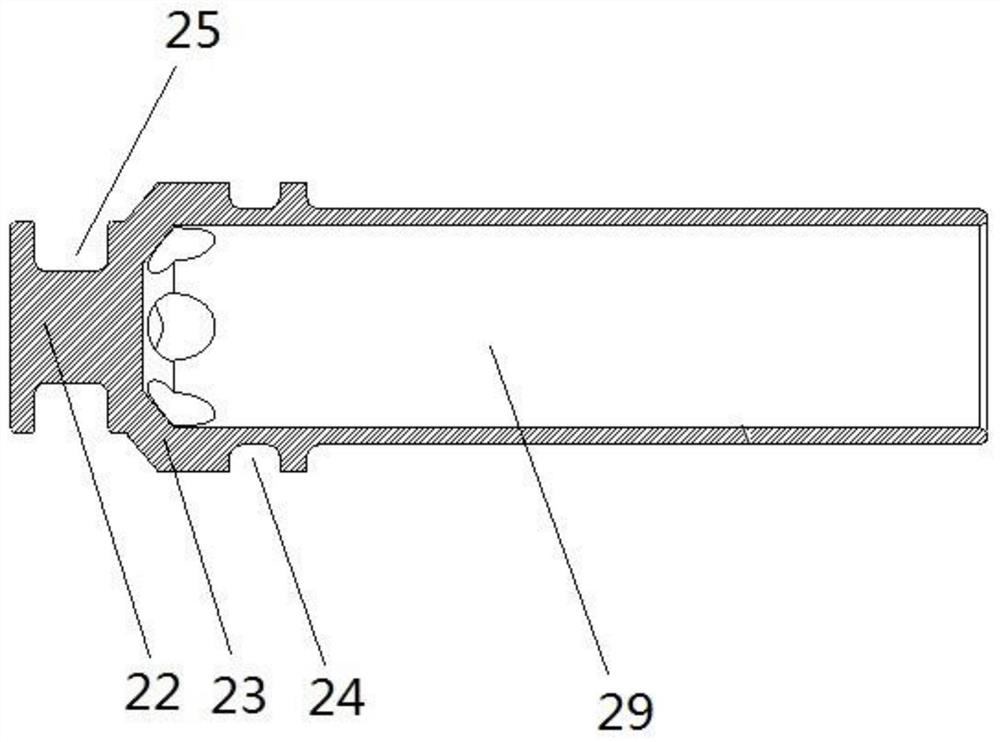

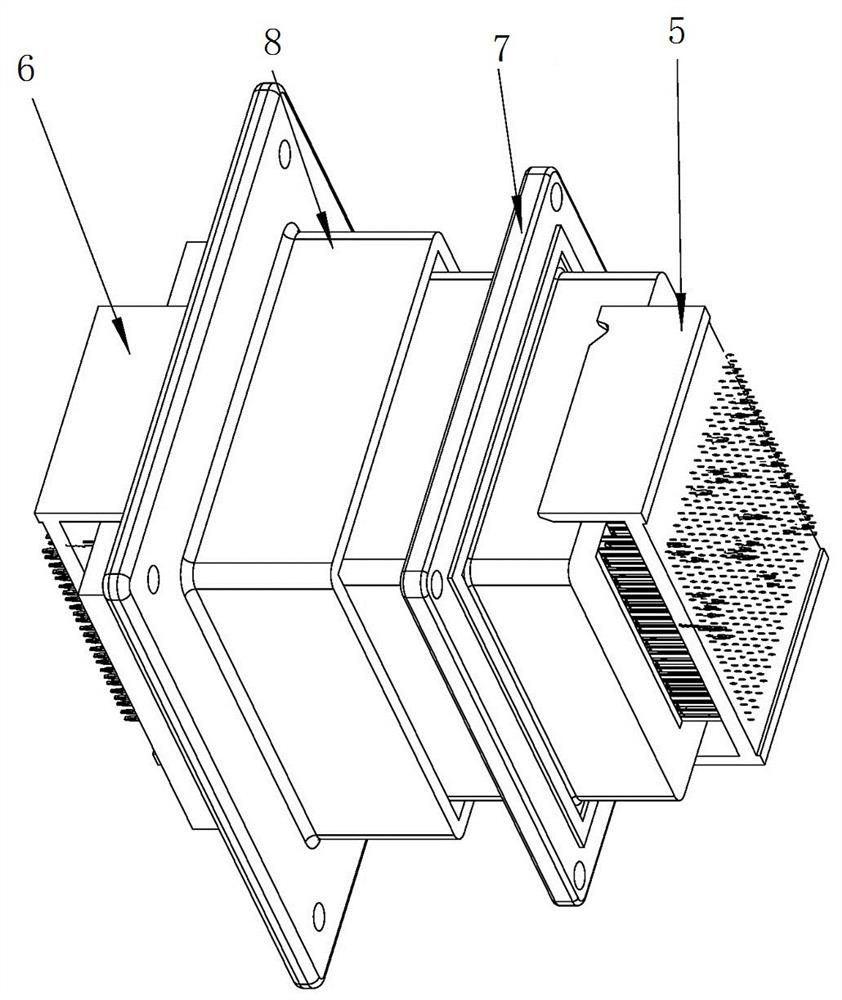

Floating blind-mating fluid connector

ActiveCN106931261AGuaranteed tightnessLarge floating amountCouplingsStructural engineeringMechanical engineering

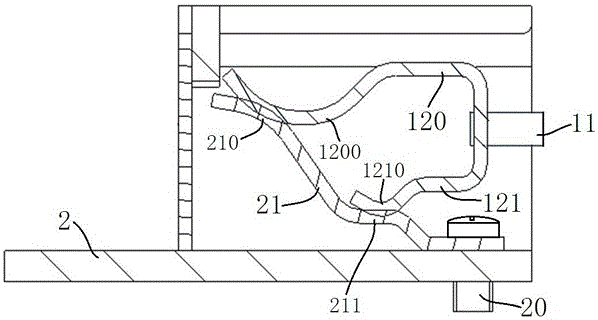

The invention discloses a floating blind-mating fluid connector. The floating blind-mating fluid connector comprises a plug and a socket. When the plug is not plugged in the socket, a side wall of a first valve element sealing ring is abutted to a side wall of a first valve element sealing hole in a contact manner to seal a first valve; and meanwhile, a second valve element inner sealing ring and a second valve element outer sealing ring are respectively abutted to the inner side wall and the outer side wall of a second valve element in a contact manner to seal a second valve, so that liquid in a pipeline cannot flow out. When the plug is plugged in the socket, the first valve and the second valve element are extruded to each other, the first valve is separated from a first valve element, a gap is formed between the first valve and the first valve element, meanwhile, a gap is formed between the second valve element and a flow guiding column, the pipeline is switched on, and fluid flows through the gaps. Original oscillating floating is changed into movable floating, floating can be implemented without the aid of deformation of the sealing rings, the sealing effect is guaranteed, floating displacement is increased, the machining dimensional precision is reduced, and costs are saved.

Owner:中国电子科技集团公司第四十研究所

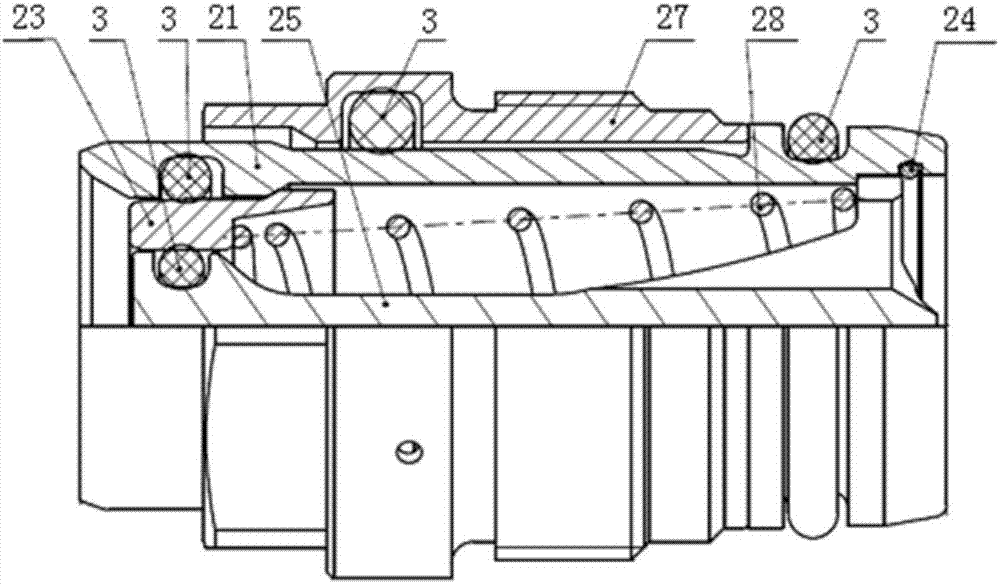

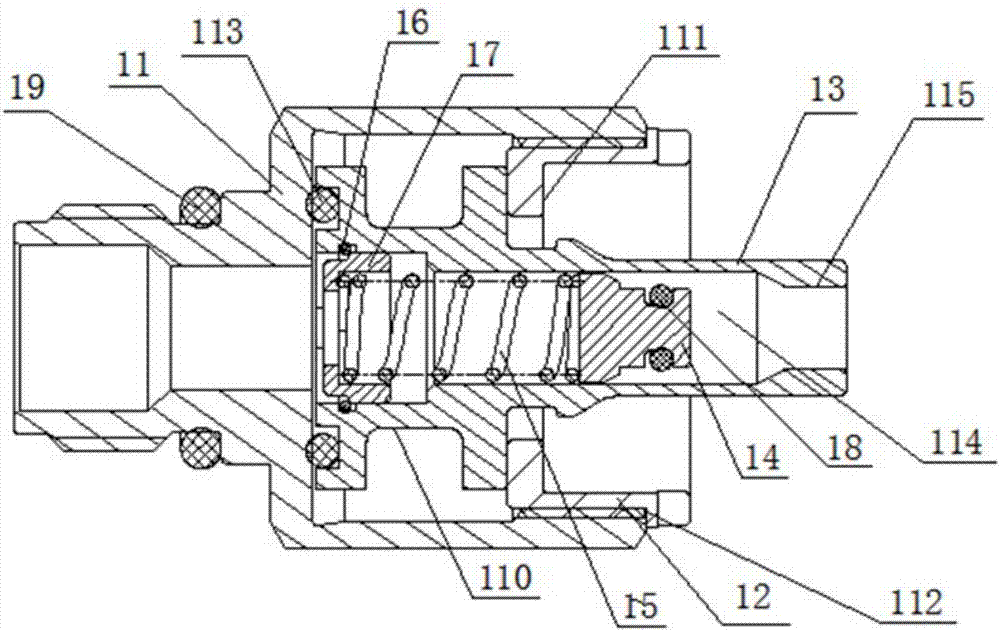

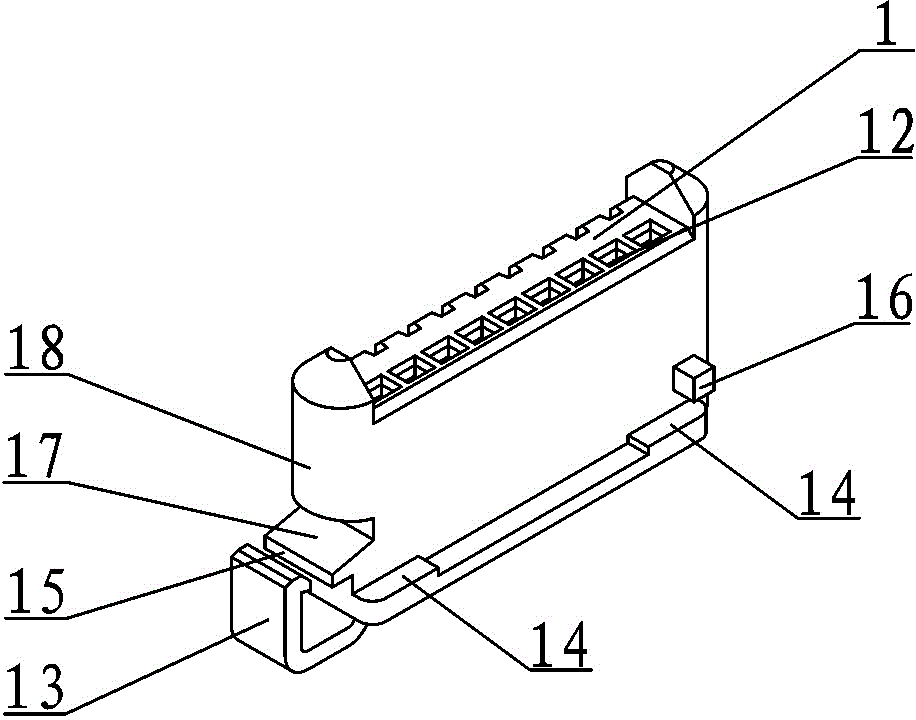

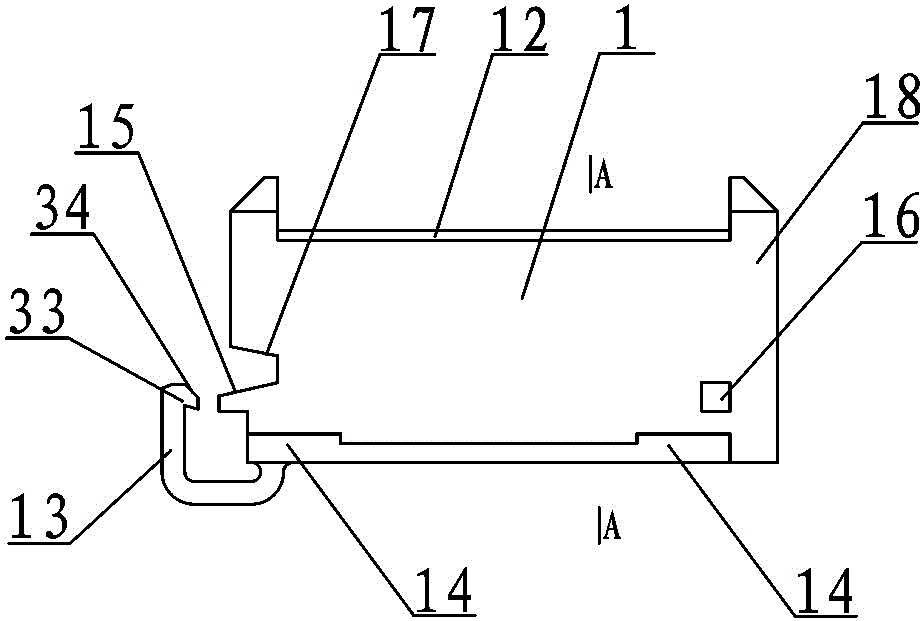

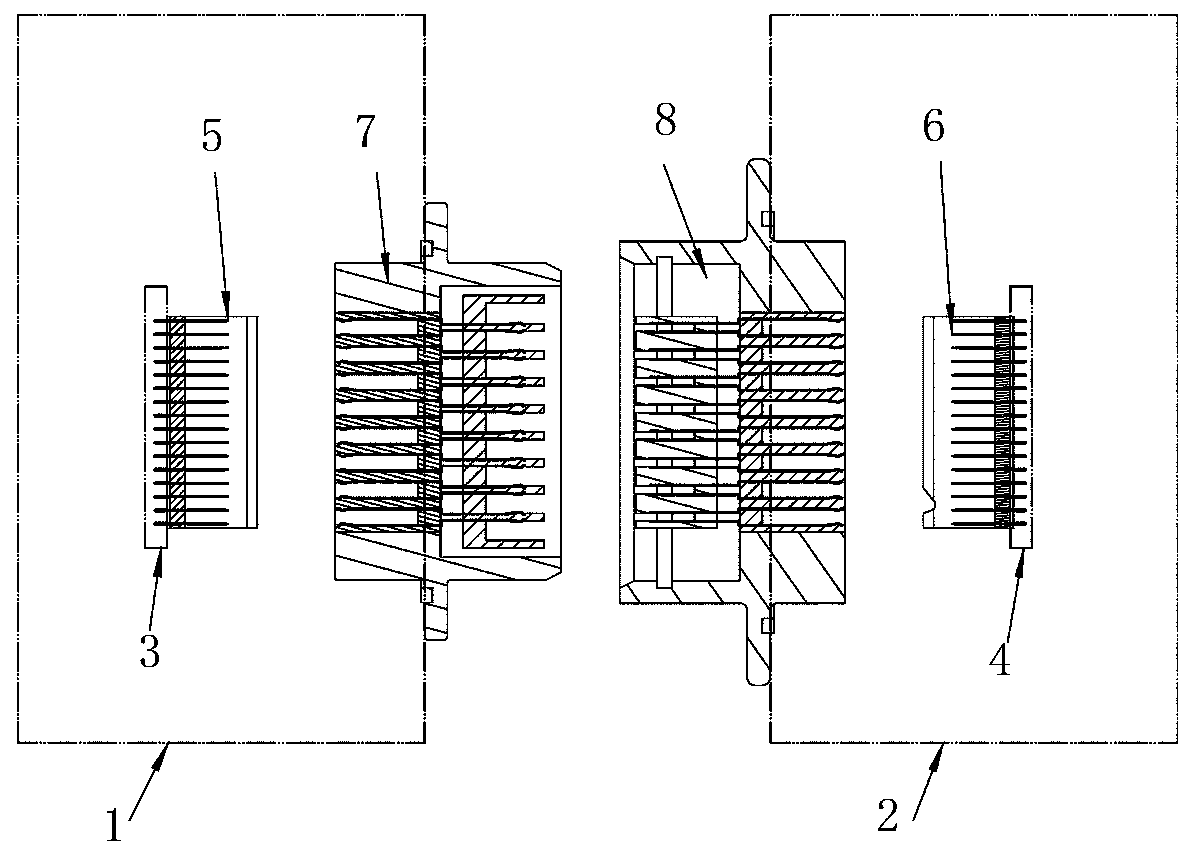

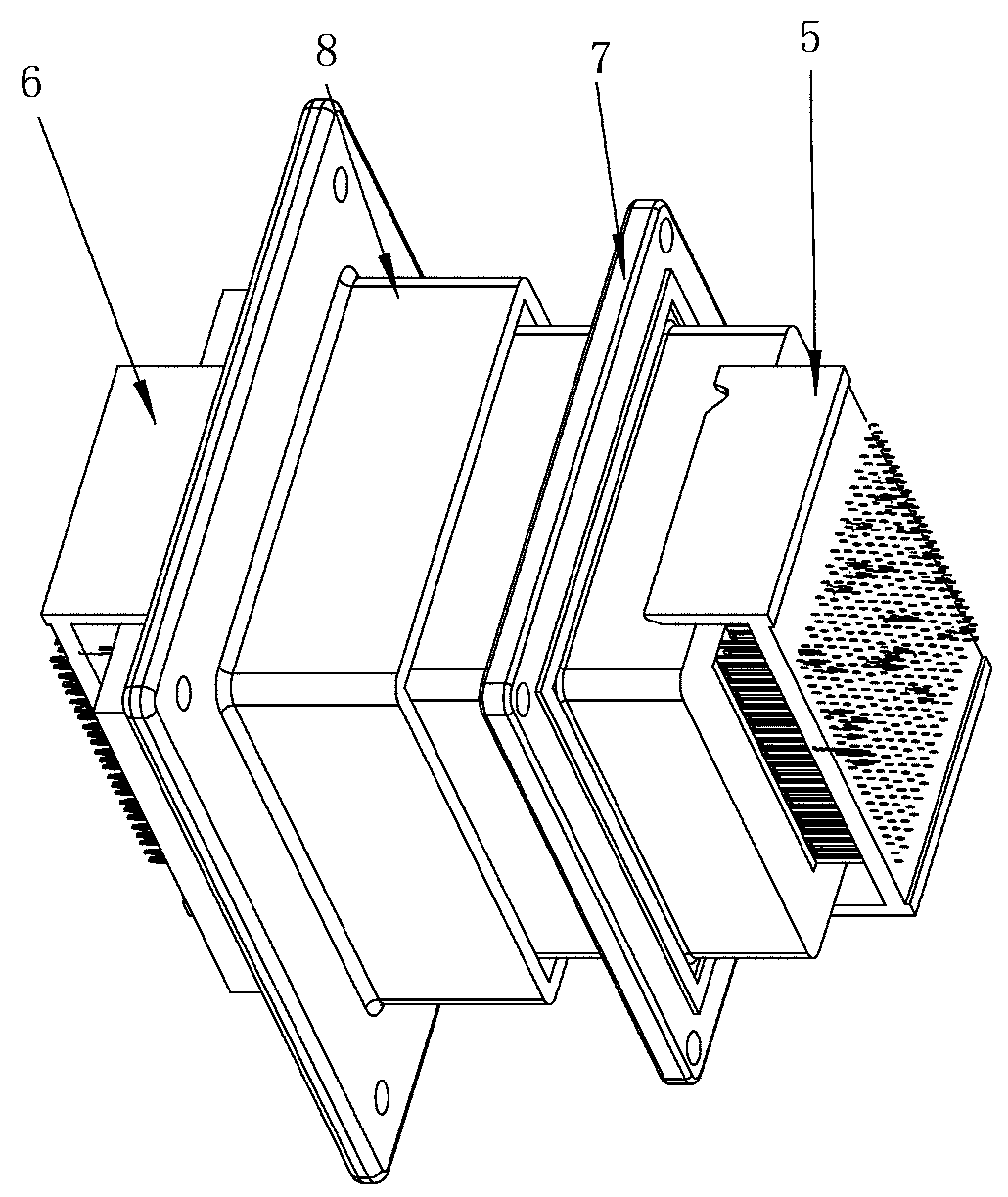

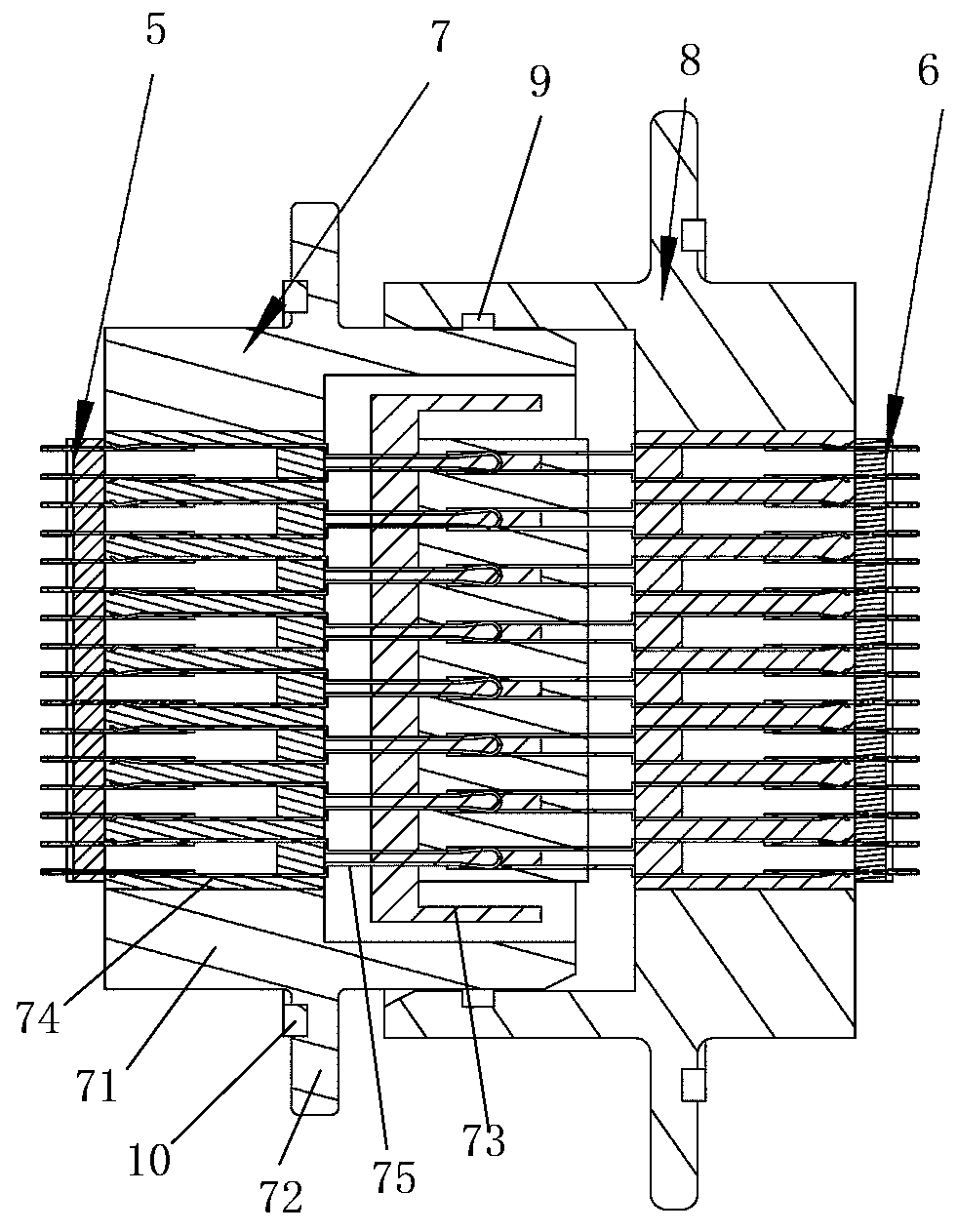

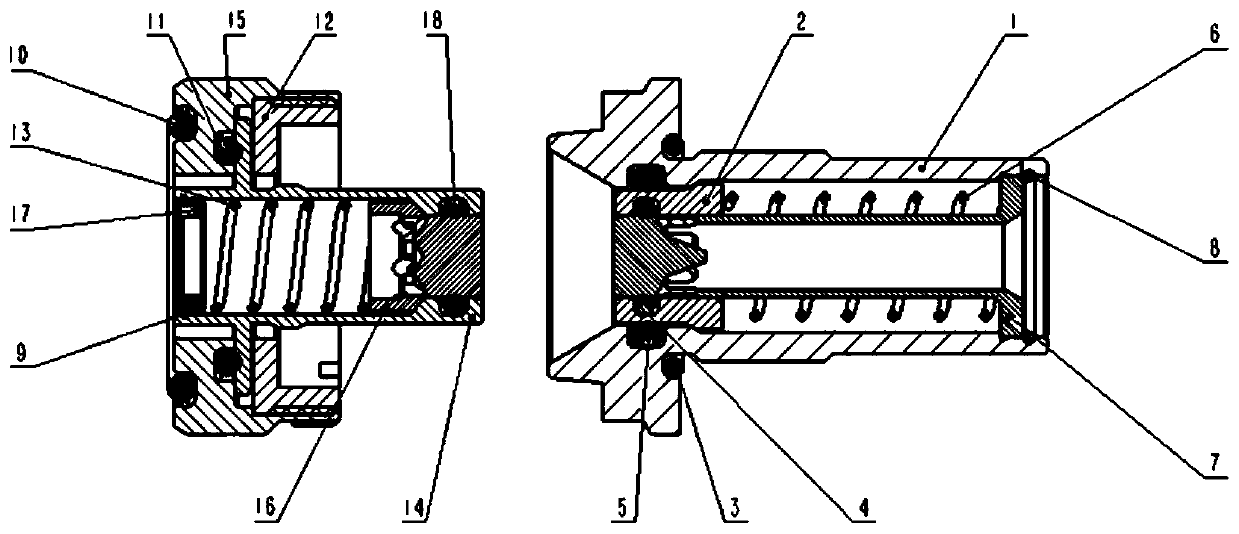

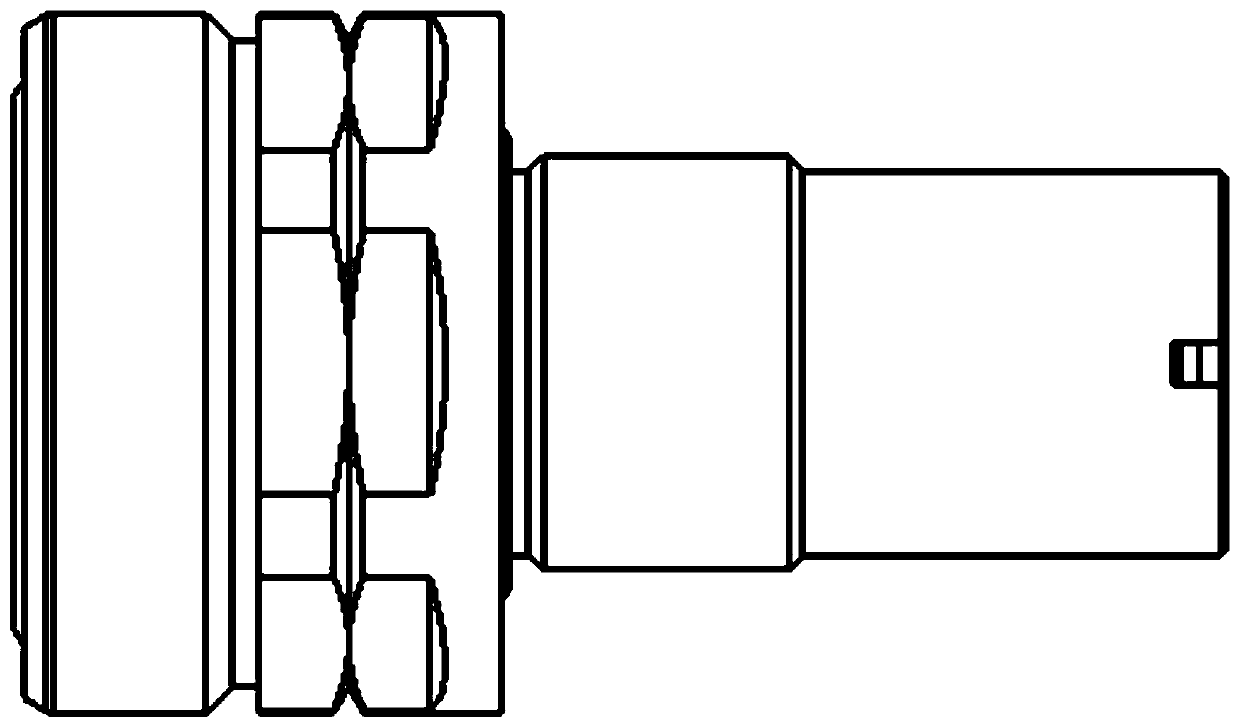

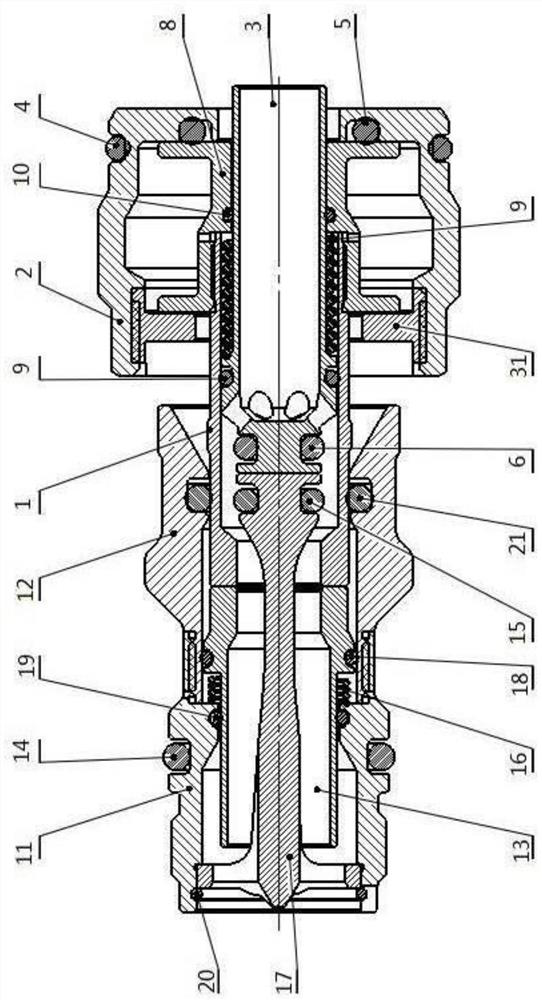

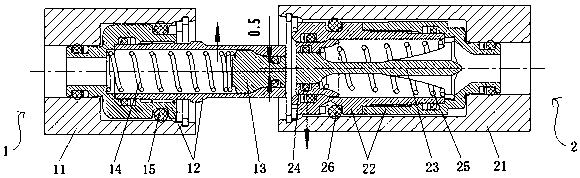

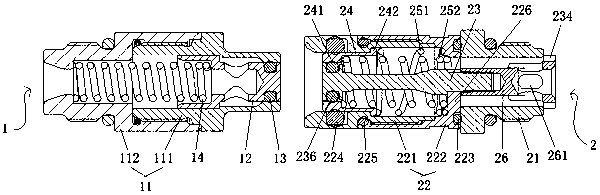

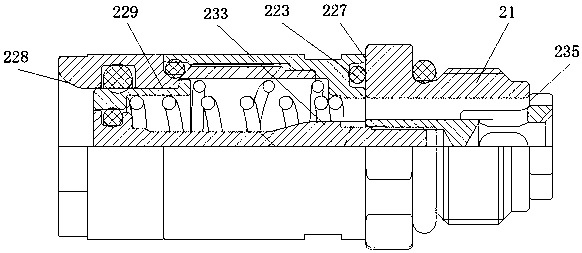

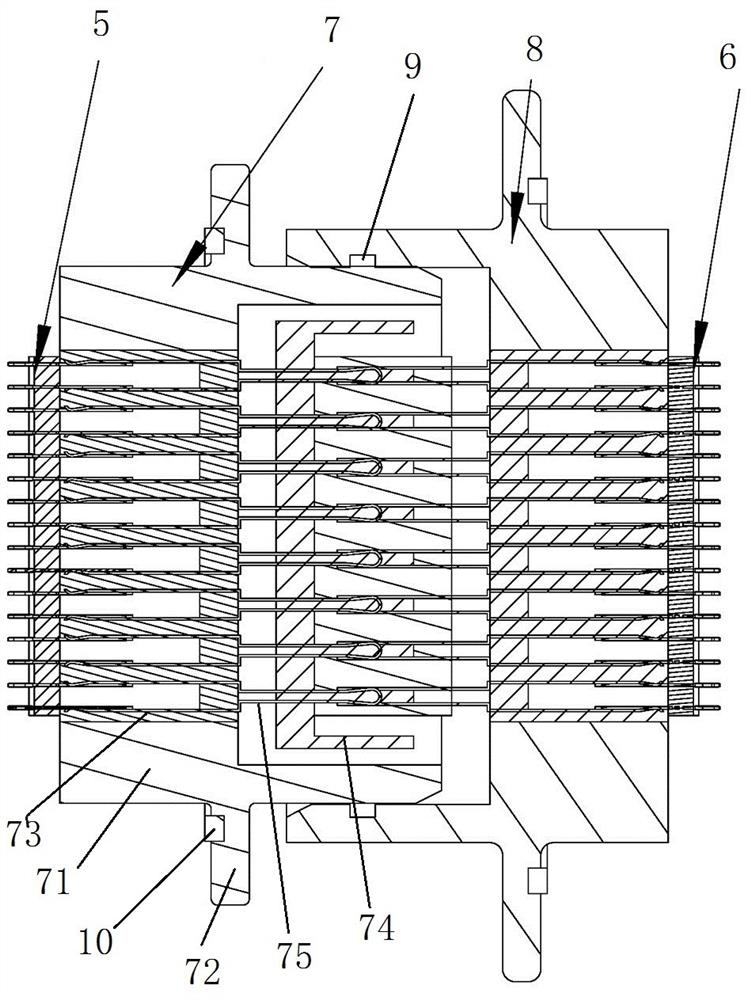

Elastic pierced radio frequency coaxial connector with radial and axial floating function

ActiveCN105281122AIncrease contactLarge floating amountCoupling contact membersTwo-part coupling devicesCable transmissionMultiple forms

The invention discloses an elastic pierced radio frequency coaxial connector with a radial and axial floating function. The elastic pierced radio frequency coaxial connector comprises a plug and a socket. The socket and the plug are plugged. The elastic pierced radio frequency coaxial connector is characterized in that the plug is composed of a pressure tube, spring wires, an internal sleeve and an internal rod. The head part of the internal rod is "omega"-shaped. The internal sleeve is "H"-shaped. The pressure tube is fixed on the internal rod. There are multiple spring wires which are evenly distributed on the internal sleeve circumferentially. The spring wires and the internal sleeve are integrally plugged in the internal rod and fixed in the internal rod by the pressure tube. The elastic pierced radio frequency coaxial connector is used for the board-to-board occasion of electronic communication equipment and devices. Higher radial and axial floating quantity is provided by an elastic pierced part in the use process so that great contact of the connector can be guaranteed, and stable and reliable butting can be provided. The elastic pierced radio frequency coaxial connector can be a high-power connector and can be used for multiple forms of PCB transmission, cable transmission and adapter connection of different interfaces. The elastic pierced radio frequency coaxial connector is a two-body type elastic pierced radio frequency coaxial connector so that the elastic pierced radio frequency coaxial connector is high in floating quantity, great in butting performance, simple and practicable in structure and economical in cost in comparison with a three-body type floating blind plugging connector.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

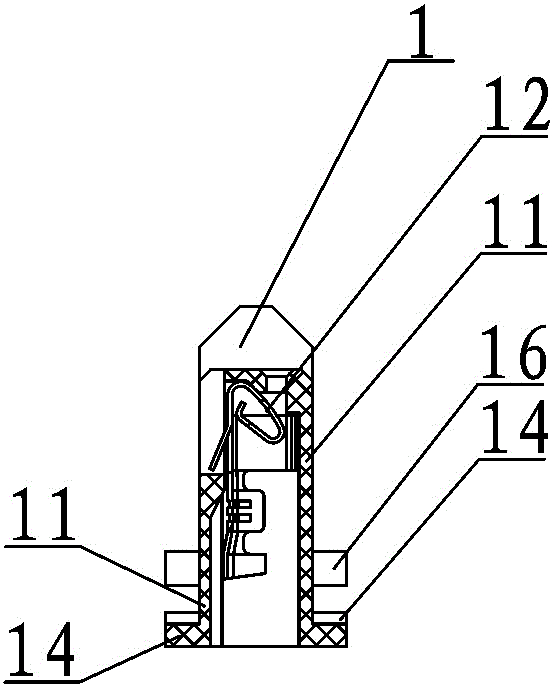

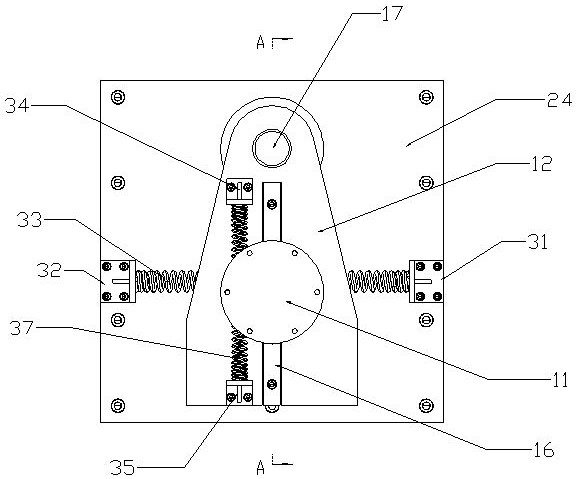

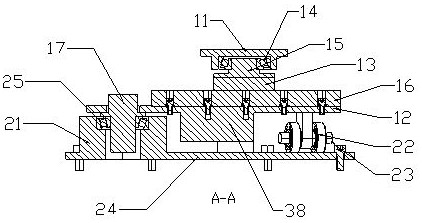

Floating connector

ActiveCN103633492ALow installation requirementsEasy to guideCoupling device detailsCoil springEngineering

Owner:GUIZHOU SPACE APPLIANCE CO LTD

Blind-mate manifold branch system and liquid-cooled system

ActiveCN105764306ASolve unreliable connectionReduce forceCooling/ventilation/heating modificationsSingle plateEngineering

The invention discloses a blind-mate manifold branch system and a liquid-cooled system. The blind-mate manifold branch system comprises a main tube, a plurality pairs of elastic branch tubes, a plurality pairs of tube connection heads and limiting assemblies, wherein one end of each elastic branch tube is communicated with the main tube, one end of each tube connection head is communicated with the other end of a corresponding elastic branch tube, the other end of a first tube connection head and the other end of a second tube connection head in each pair of tube connection heads are respectively communicated with an inlet opening and an outlet opening of a single plate which is pluggable along a slide way of a machine cabinet, a flow can flow in the blind-mate manifold branch system in a circulating manner, and heat dissipation of the single plate can be realized; the limiting assembly is fixedly connected with the machine cabinet and used for limiting distance that each tube connection head can move toward a single plate plugging direction. The blind-mate manifold branch system and the liquid-cooled system in an embodiment of the invention can improve connection reliability when the single plate is plugged into the blind-mate manifold branch system.

Owner:HUAWEI TECH CO LTD

Floating connector

InactiveCN103986016AImprove reliabilitySmall spatial structureCoupling device detailsMarine engineeringSpatial structure

The invention discloses a floating connector which comprises a panel and a plug. An insulation base of the plug is provided with an elastic arm, an upper positioning block and a lower positioning block, and the panel is provided with an installation groove and a window. The floating connector is characterized in that a wedge-shaped insertion groove is formed above the upper positioning block, the elastic arm is provided with a hook, the distance between an upper positioning convex block and the bottom of the insertion groove is smaller than or equal to the distance between an opening to a rectangular frame of the installation groove, the width and the length of the insertion groove are larger than those of the plug, an insertion gap formed among the upper positioning block, the upper positioning convex block and the lower positioning block allows the plug to be inserted into the panel, the elastic arm of the plug is buckled to the window through the hook, and the insulation base is connected with the panel in a sliding mode. Compared with the prior art, the floating connector has the advantages of being small in space structure due to three-dimensional floating connection, large in floating degree, low in manufacturing cost, high in reliability, convenient to install and use and capable of achieving the largest floating degree in the effective space structure.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

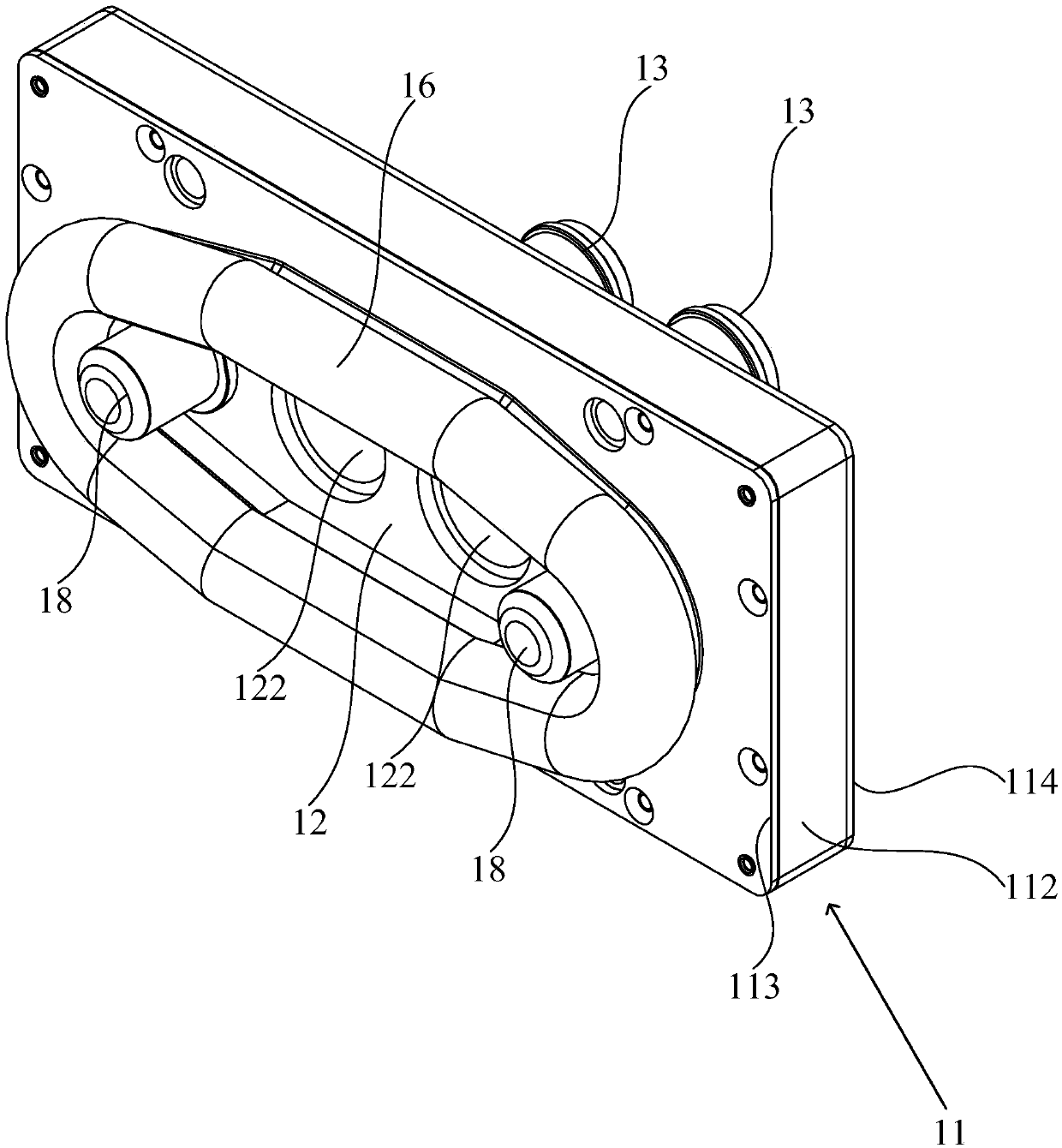

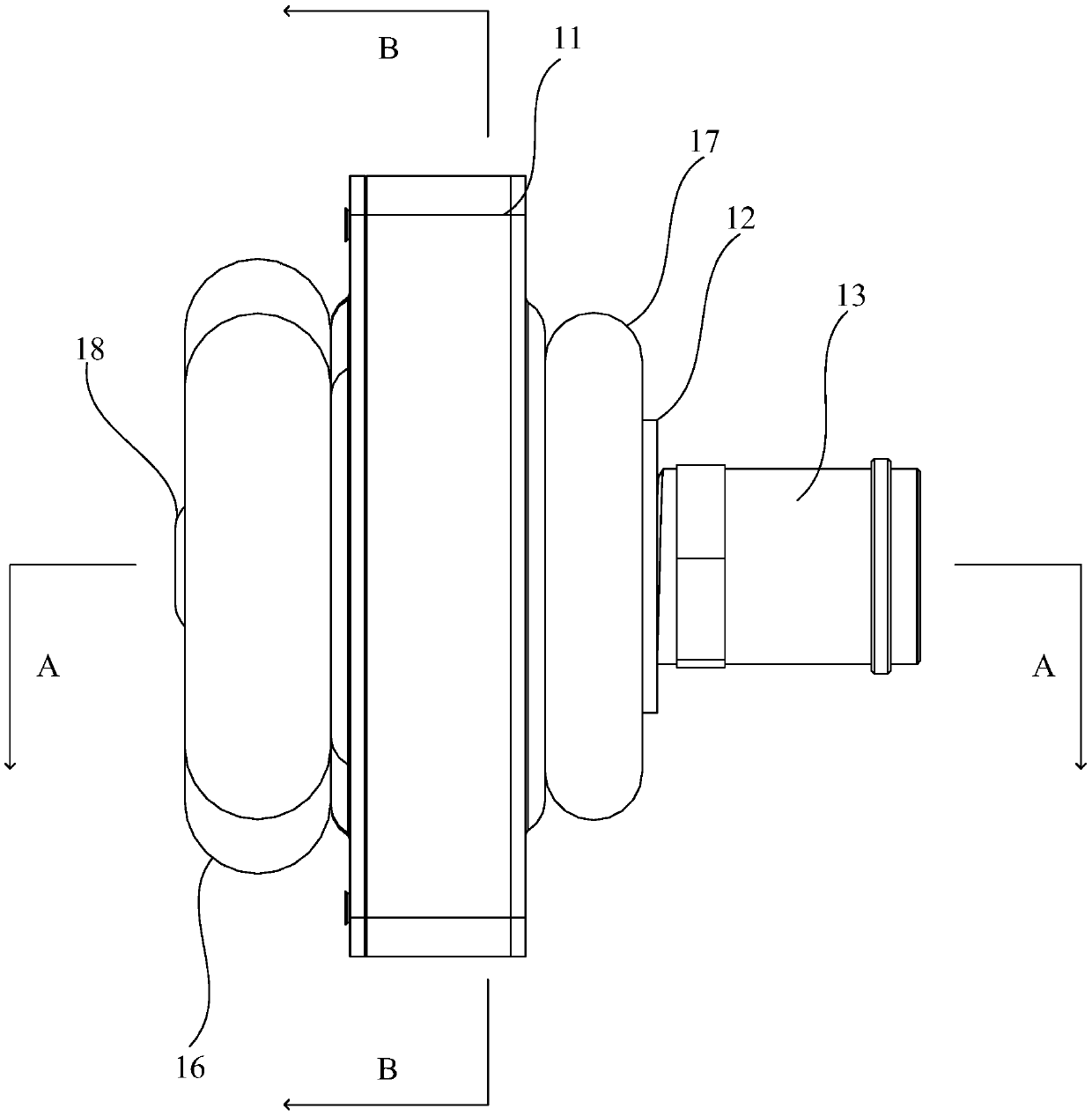

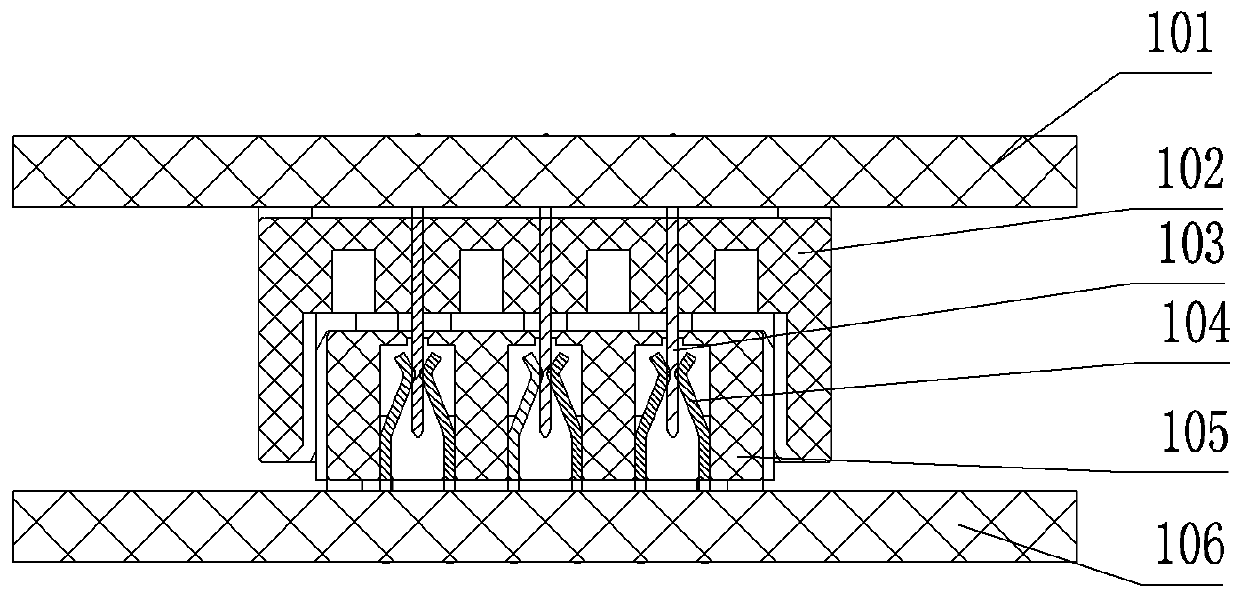

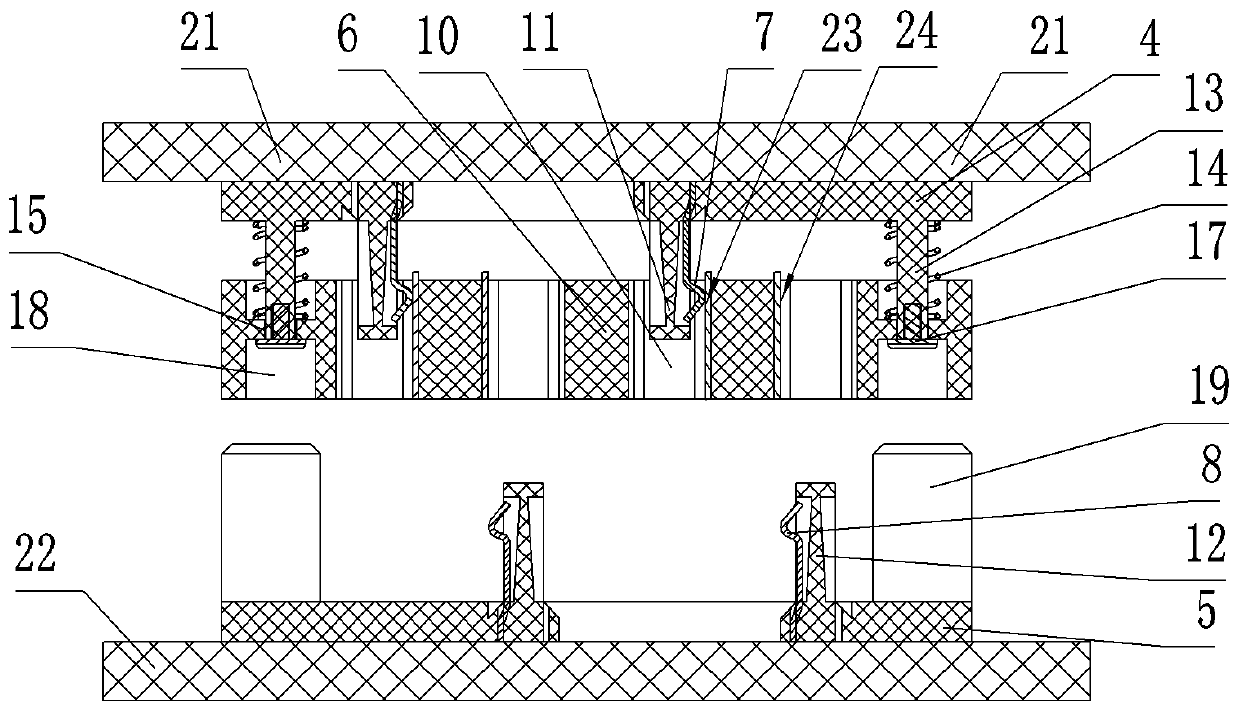

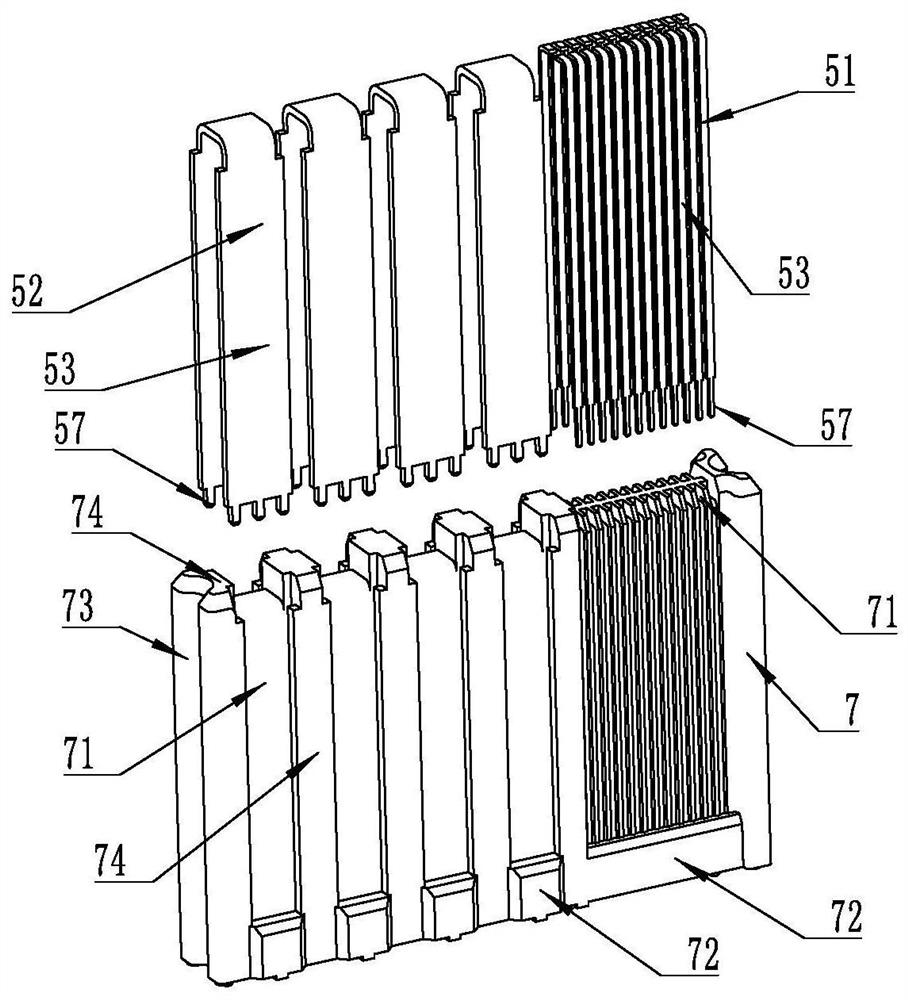

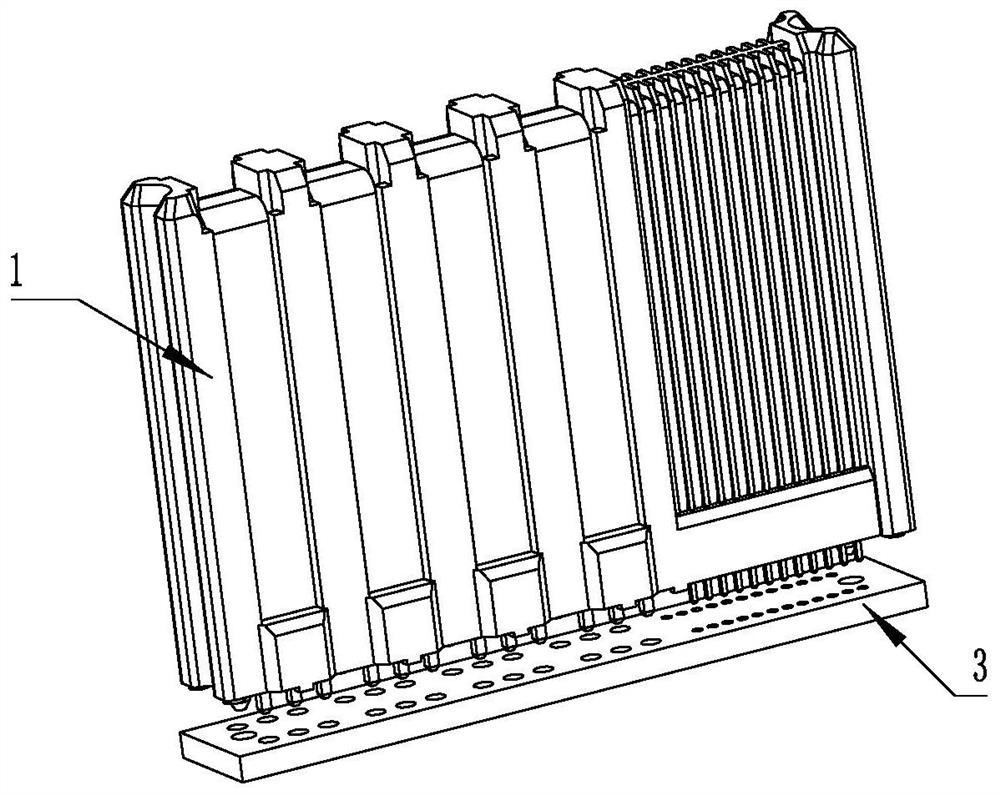

Liquid cooling plug-in assembly, liquid cooling plug-in device and battery pack assembly

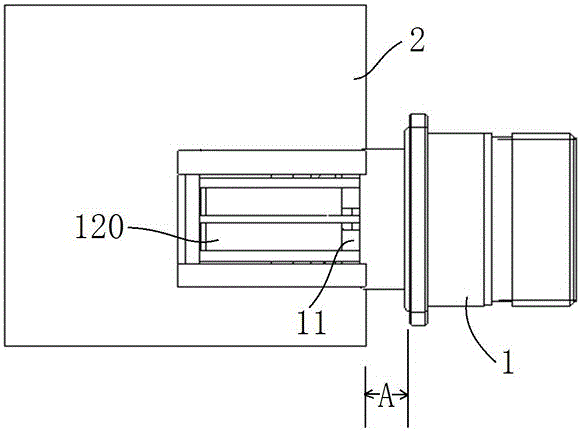

PendingCN111384467ALarge floating amountImprove stabilityCoupling device detailsSecondary cellsEngineeringMechanical engineering

The invention discloses a liquid cooling plug-in assembly, a liquid cooling plug-in device and a battery pack assembly. The liquid cooling plug-in assembly comprises a first fixed plate, a floating plate, at least one first elastic piece and a plurality of plug-in pieces; and the plurality of connectors are all connected to the floating plate, a movable cavity is formed in the first fixed plate, the floating plate and the first elastic piece are both located in the movable cavity, and the floating plate is in floating connection with the first fixed plate through the first elastic piece. The liquid cooling plug-in device comprises a matching plug-in assembly and the liquid cooling plug-in assembly, and the matching plug-in assembly is detachably connected to the liquid cooling plug-in assembly. The battery pack assembly comprises the liquid cooling plug-in device. The floating plate is in floating connection with the first fixed plate through the first elastic piece, so that the connector has a large floating amount, the connection stability is greatly enhanced, and the phenomena that liquid in the connector flows out and splashes are effectively avoided.

Owner:AULTON NEW ENERGY AUTOMOTIVE TECHNOLOGY GROUP

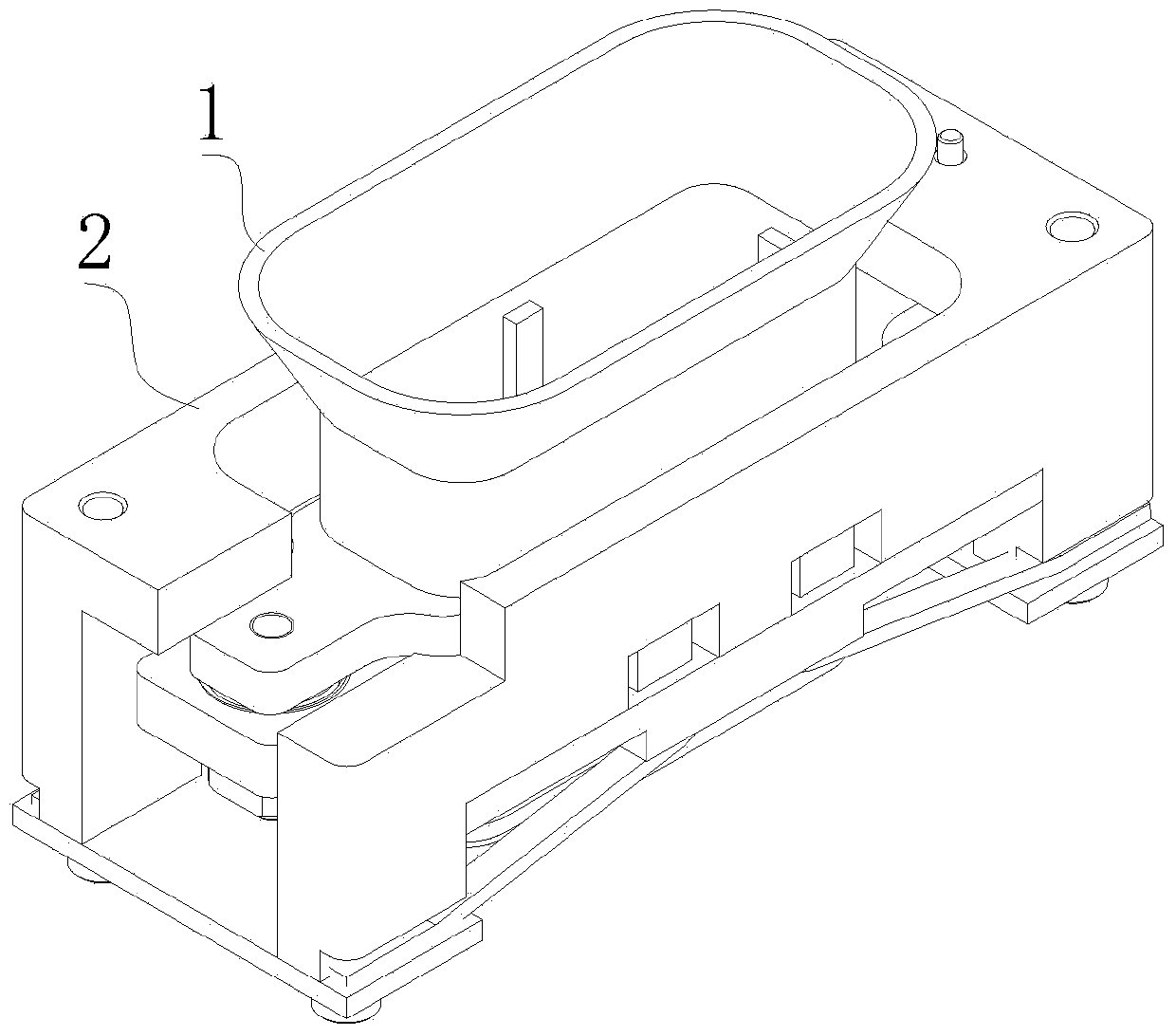

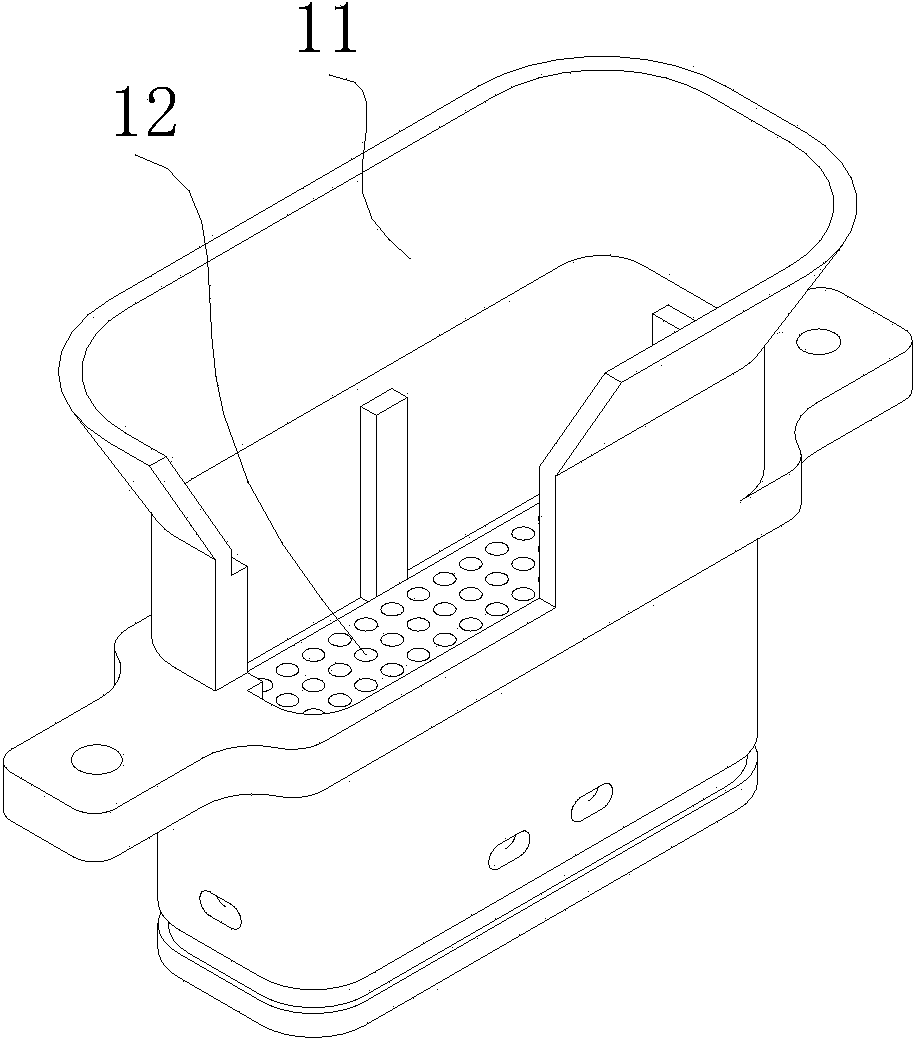

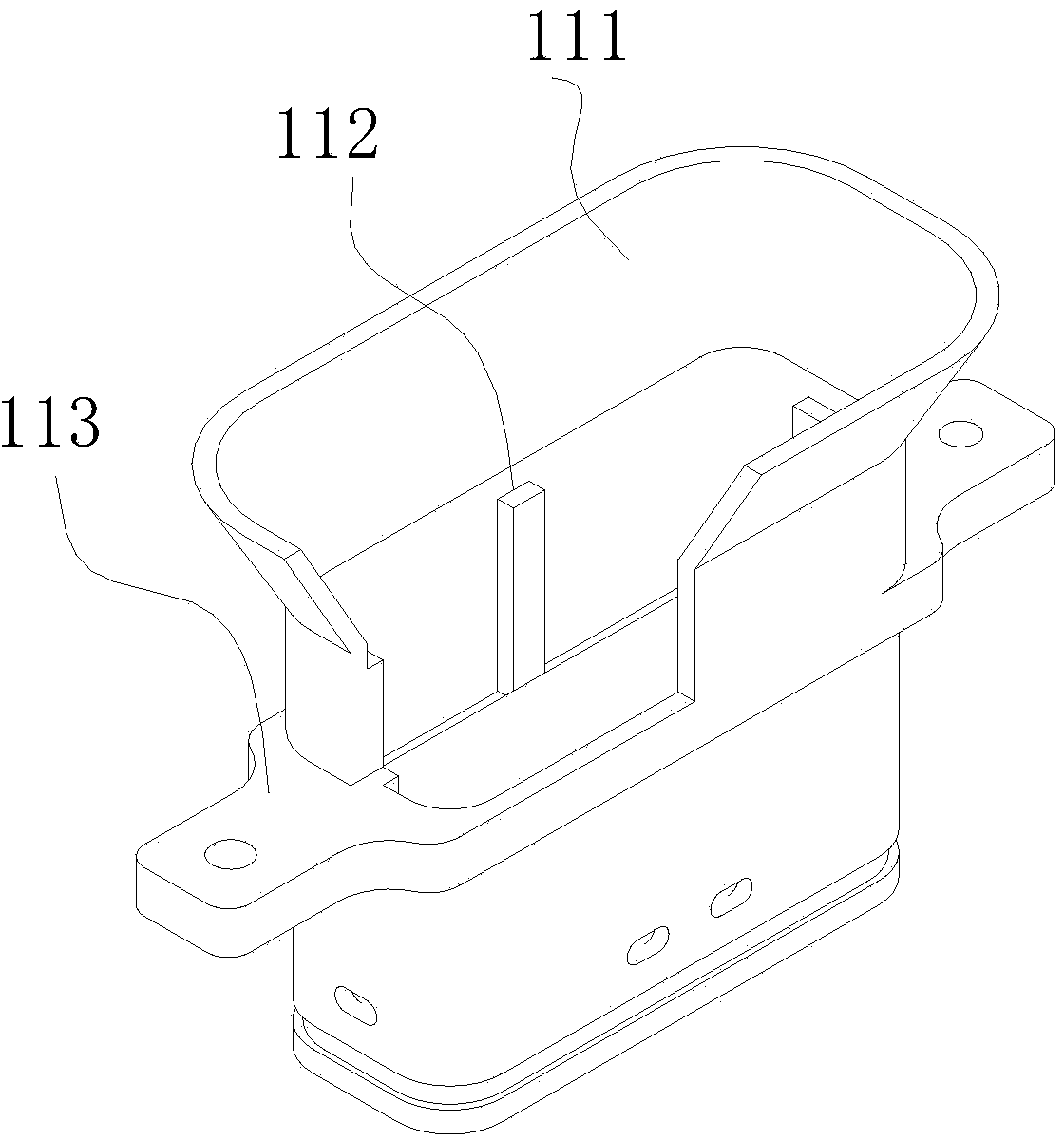

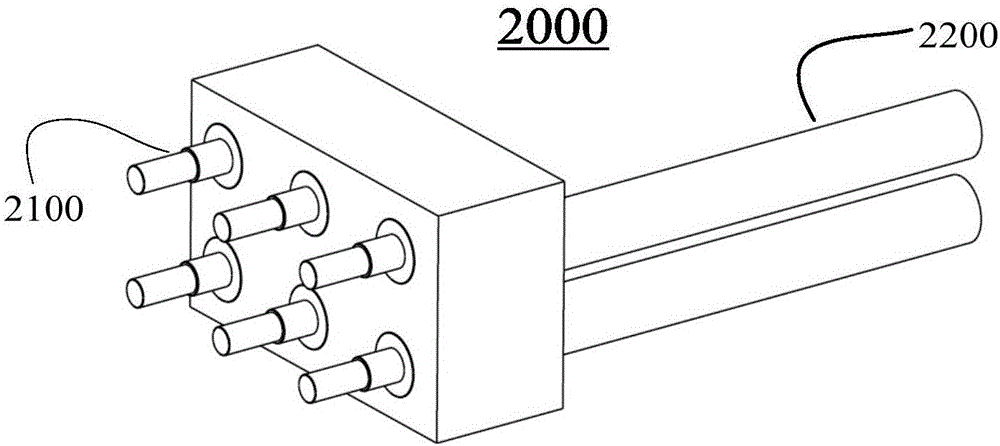

Electric connector assembly

ActiveCN111009752ALarge offsetReduce difficultySecuring/insulating coupling contact membersCoupling protective earth/shielding arrangementsMechanical engineeringPhysics

The invention relates to an electric connector assembly, which comprises a first connector and a second connector, the first connector and the second connector comprise shells and contact piece modules, the contact piece module comprises a contact piece, a floating insulator and a fixed insulator, the floating insulator and the fixed insulator are arranged at intervals front and back, and the fixed insulator is fixed in the shell; the contact piece is provided with a front connecting section, a rear connecting section and a middle deformation section, the front connecting section is fixedly connected with the floating insulator, the rear connecting section is fixedly connected with the fixed insulator, and the floating insulator moves relative to the fixed insulator in the direction perpendicular to the inserting direction of the contact piece through elastic deformation of the middle deformation section, so that the two connectors can be inserted in a floating mode; and the front endsof the contact piece modules of the first connector and the second connector are mutually inserted. According to the invention, the front end of the contact module is set as the floating plugging end, and the floating plugging ends of the two connectors are plugged and matched with each other, so that the two connectors can allow a larger deviation value, and the signal transmission quality is further ensured.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

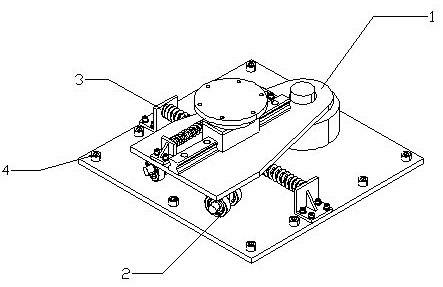

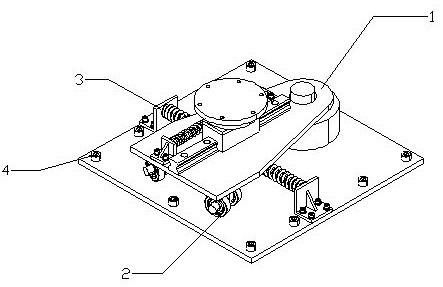

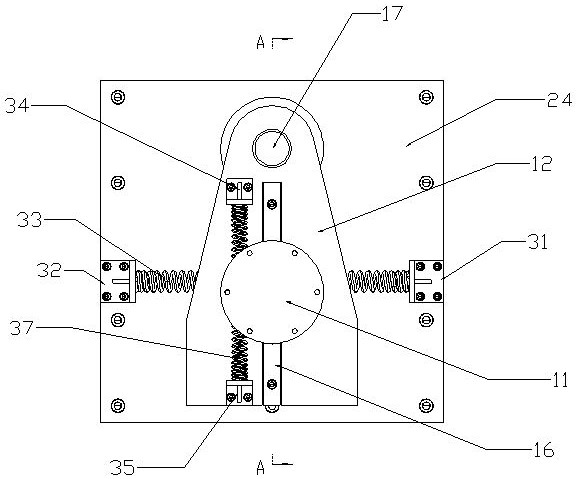

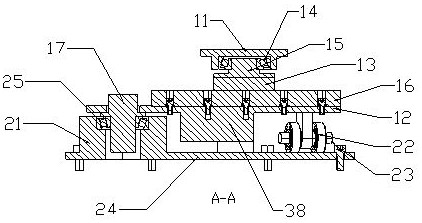

Floating adjusting device

ActiveCN112026957AImprove synchronicityImprove coordinationVehiclesControl theoryMechanical engineering

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

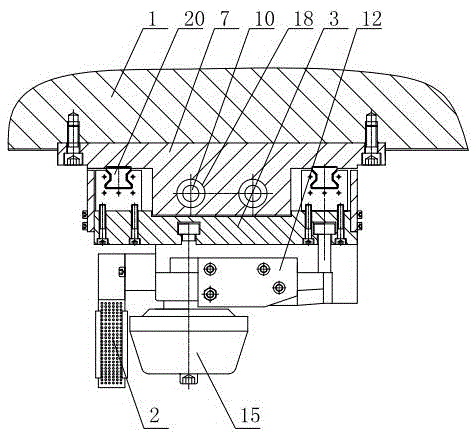

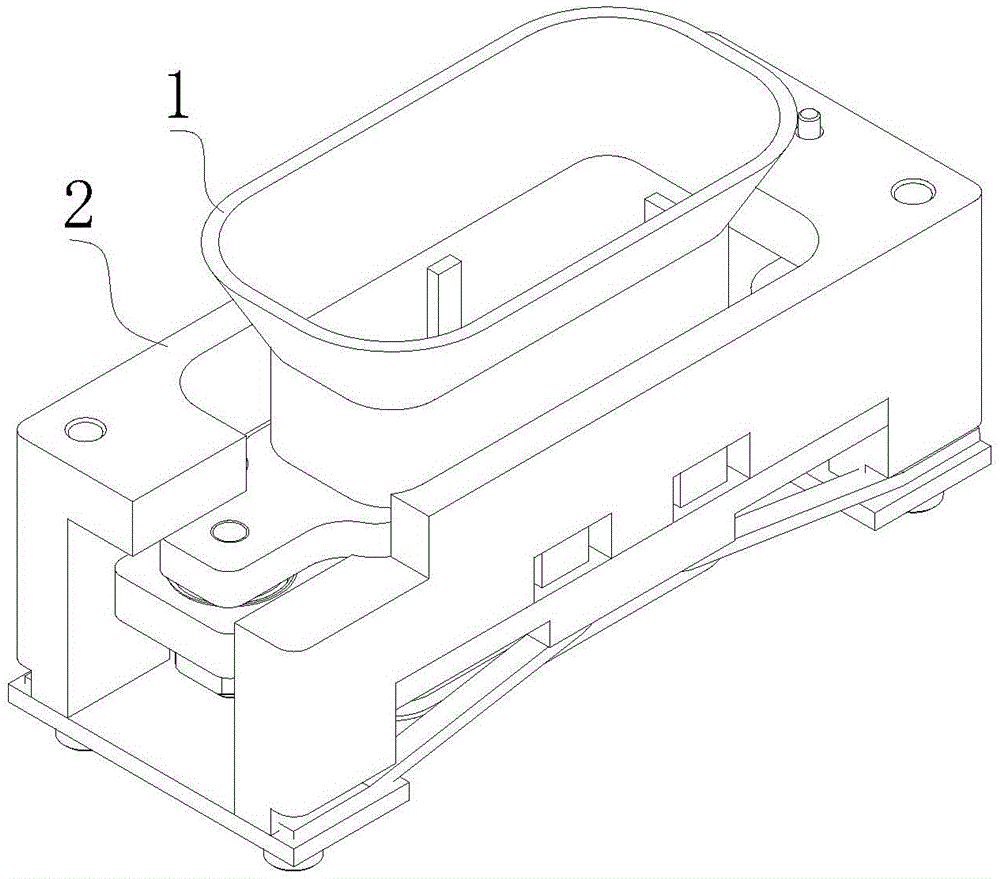

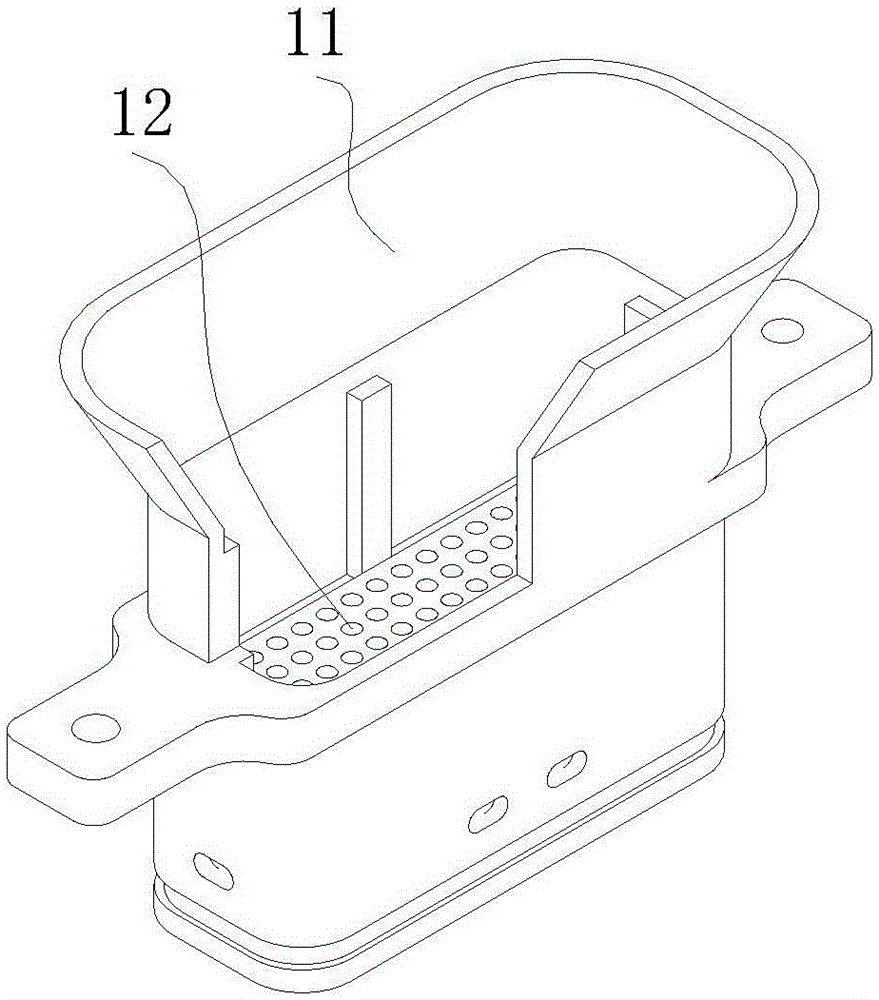

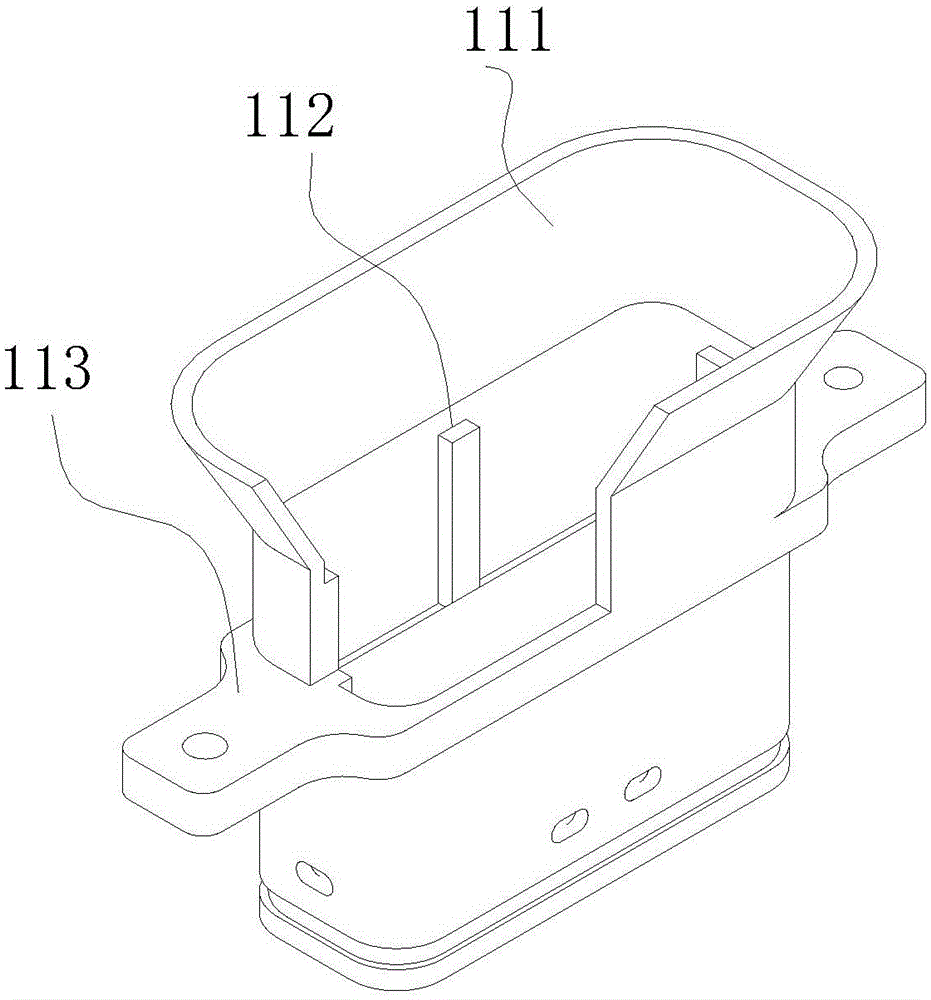

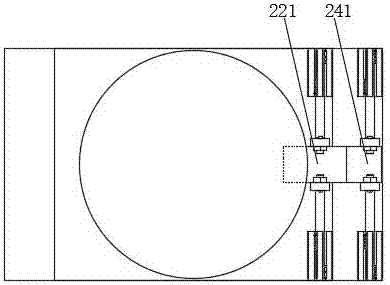

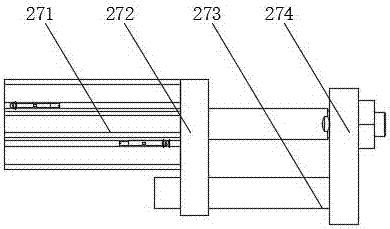

Flattop chamfering and cutting device

InactiveCN105562721AGood followabilityLarge floating amountAuxillary equipmentTurning machinesEngineeringMechanical engineering

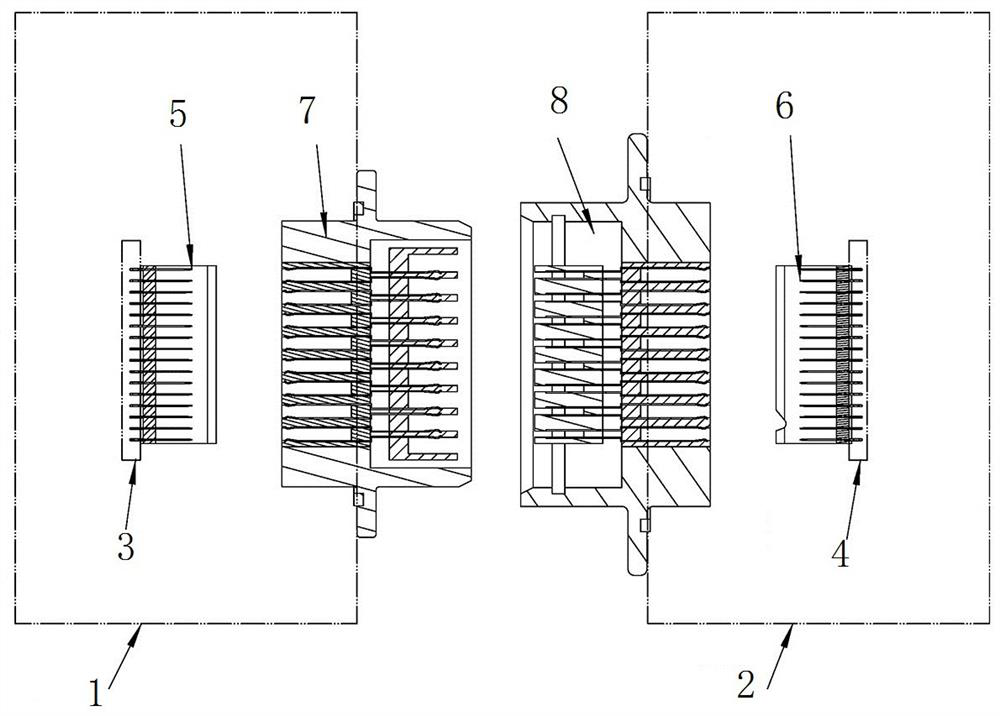

Disclosed is a flattop chamfering and cutting device. The flattop chamfering and cutting device comprises a cutter disc. A cutting device and a balance block are symmetrically disposed on the cutter disc. The cutting device comprises a bottom plate fixed to the cutter disc; linear guide ways are mounted at the two ends of the bottom plate correspondingly; a floating seat is disposed on the bottom plate through the linear guide ways; holes are symmetrically formed in the middle of the bottom plate; belleville springs are disposed in the holes correspondingly; guide rods are mounted in the middles of the belleville springs; guiding blocks are mounted on tops of the guide rods, and pre-tightening screws are mounted on tops of the guiding blocks; the floating seat slides along the linear guide ways; a T-shaped groove is formed in the floating seat; a sliding seat is mounted on the floating seat through a locking block; a beveled edge cutter seat is mounted on the upper portion of the sliding seat; a beveled edge blade is mounted on the beveled edge cutter seat; a depended wheel is arranged on the lower portion of the sliding seat through a shaft and locked through compression screws; a steel wire brush is mounted in the position, on one side of the depended wheel, of the sliding seat; a blunted edge cutter seat is further disposed on the lower portion of the sliding seat; and a blunted edge blade is disposed on the blunted edge cutter seat. The flattop chamfering and cutting device is good in cutting quality.

Owner:SUNYO S&T CO LTD

a floating connector

ActiveCN103633492BLow installation requirementsEasy to guideCoupling device detailsCoil springElectrical and Electronics engineering

Owner:GUIZHOU SPACE APPLIANCE CO LTD

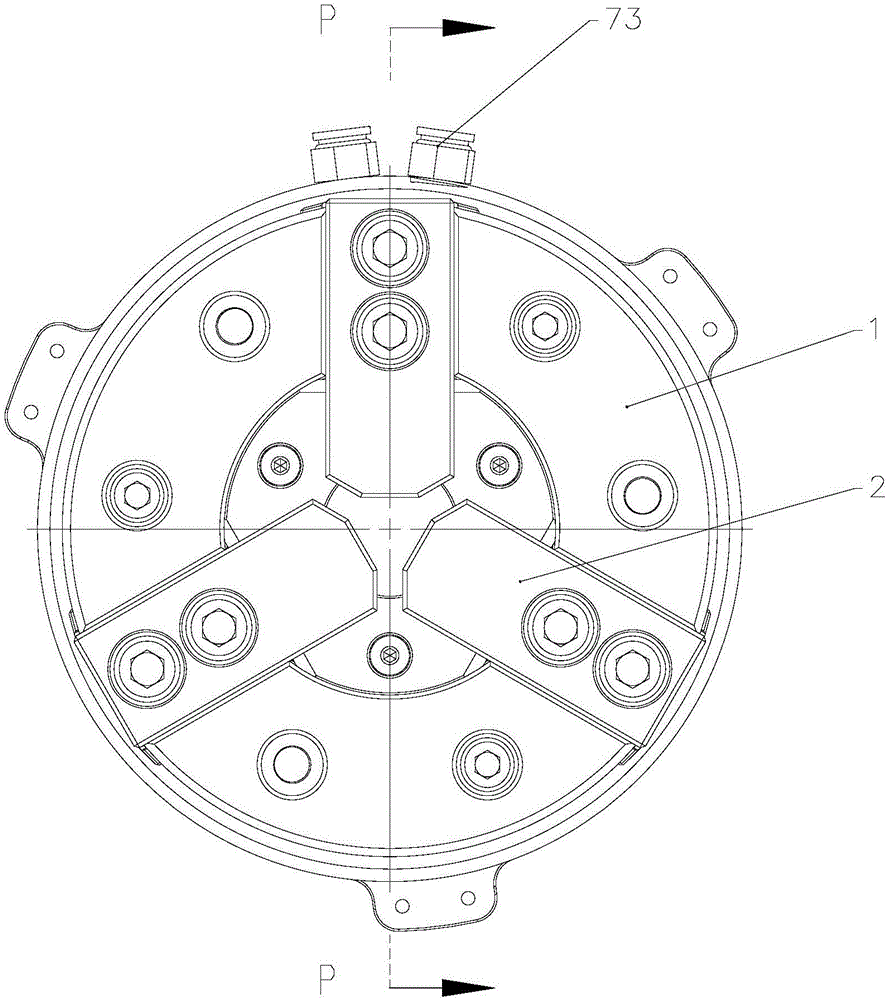

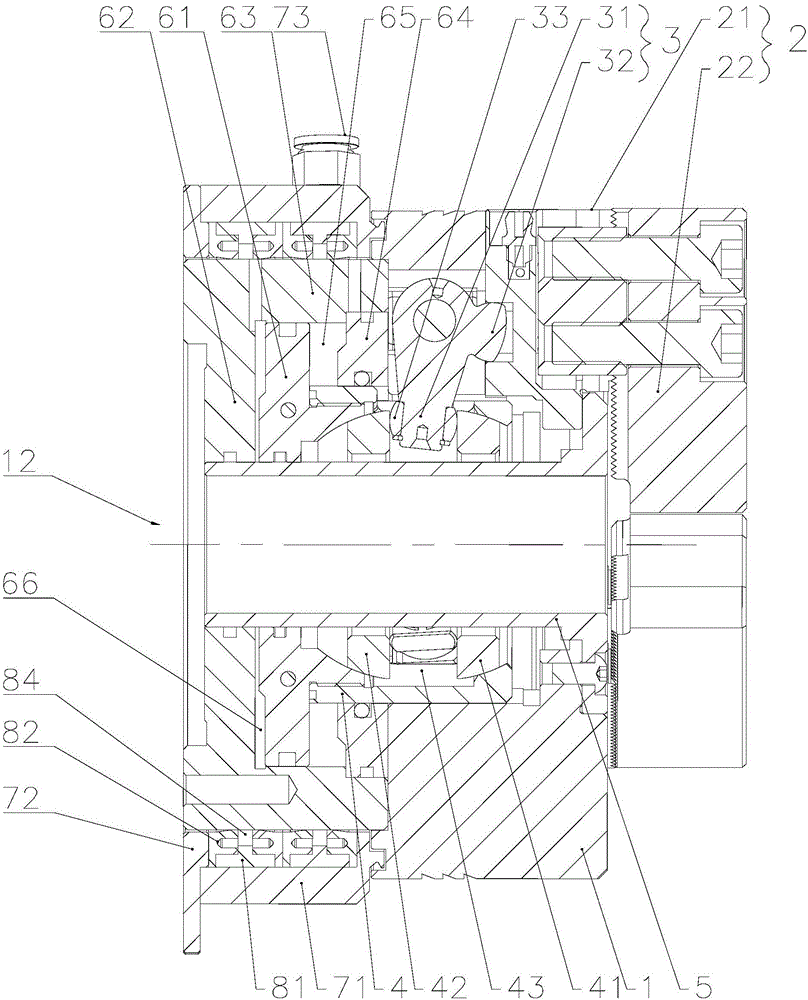

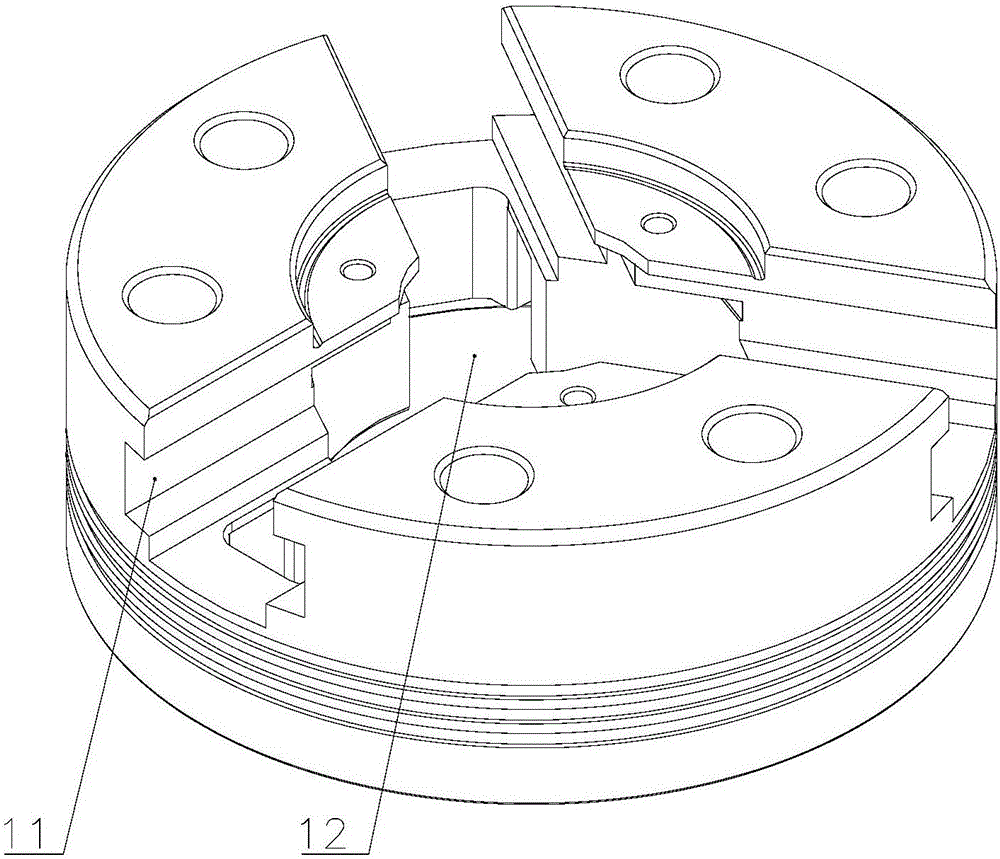

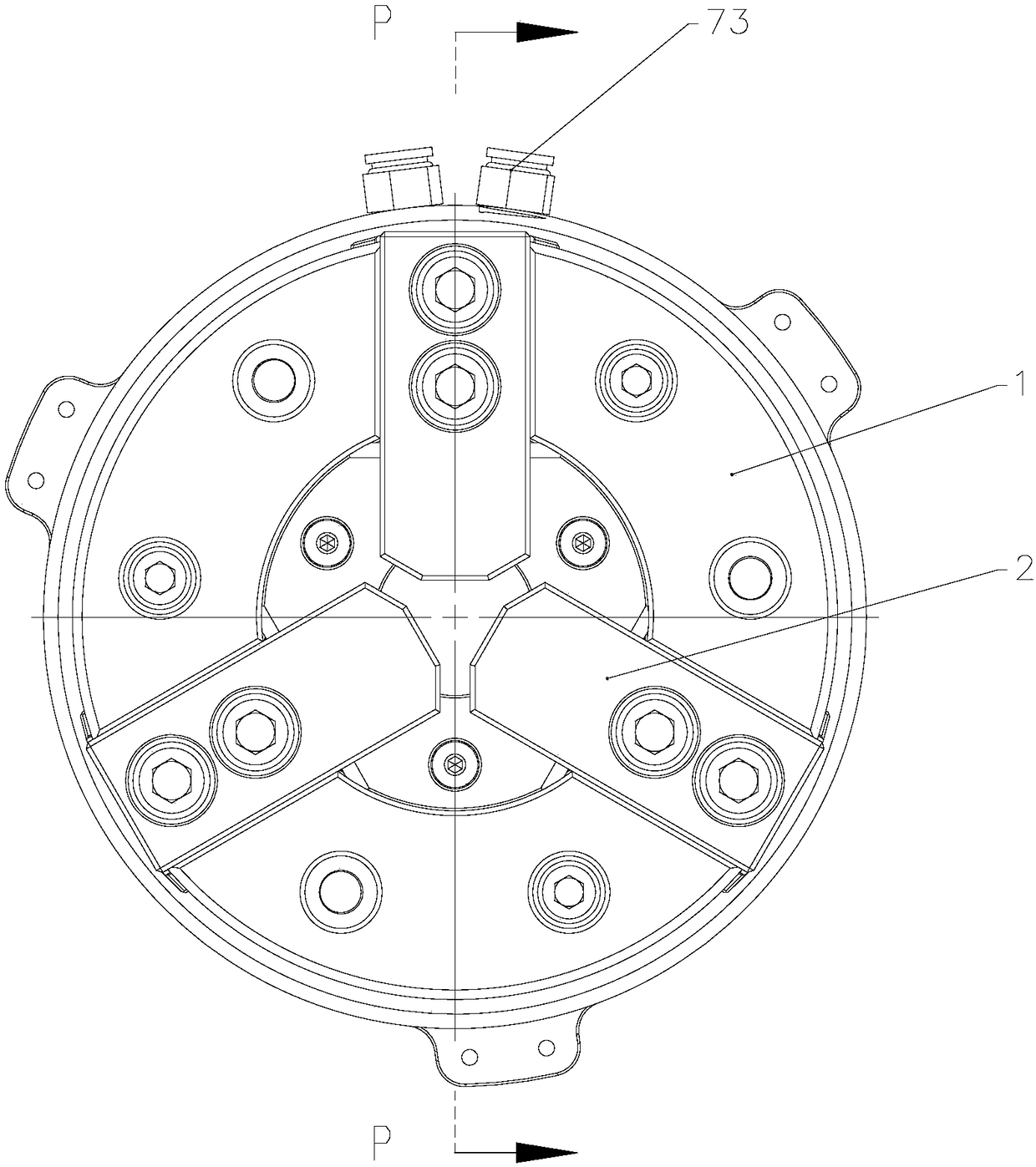

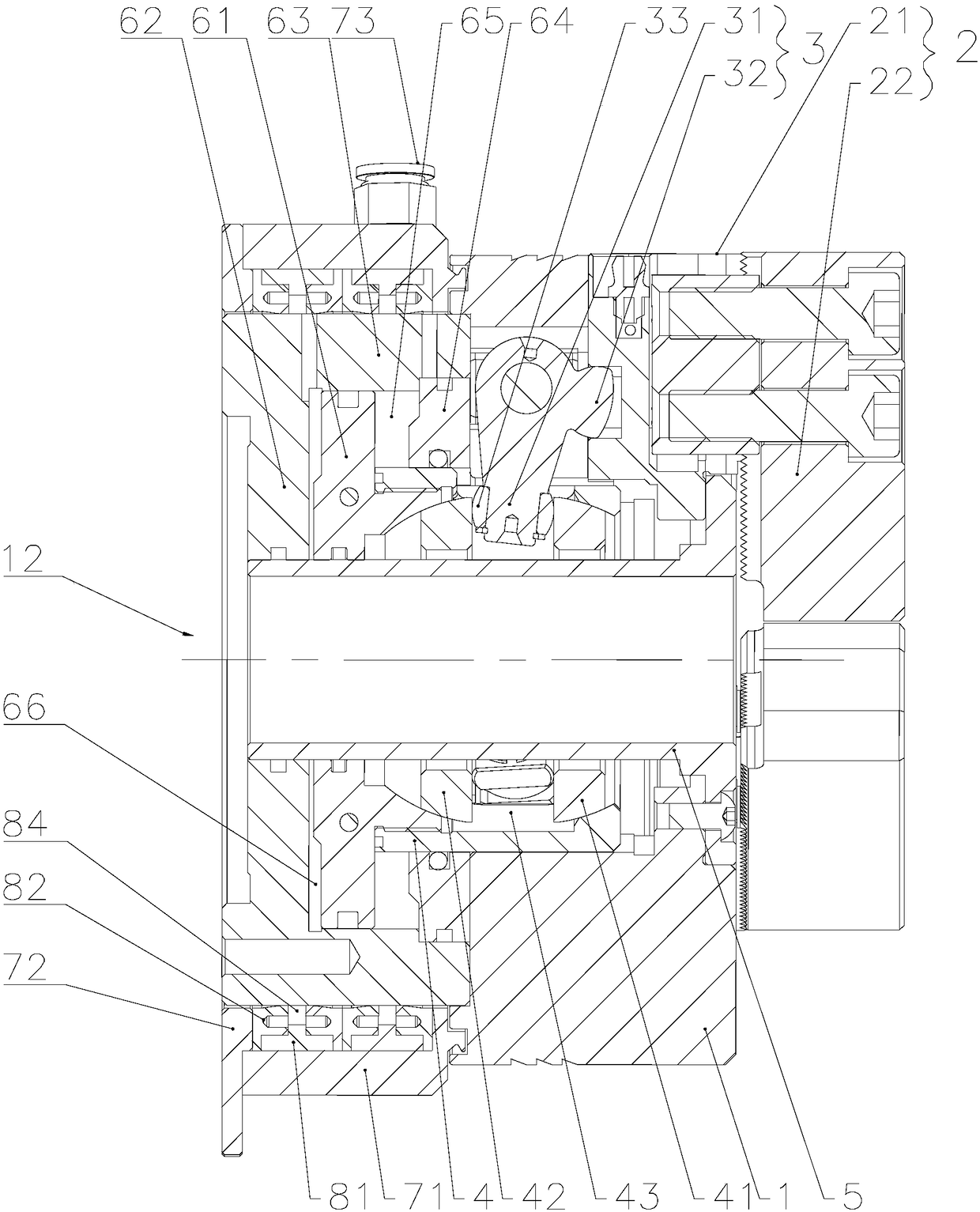

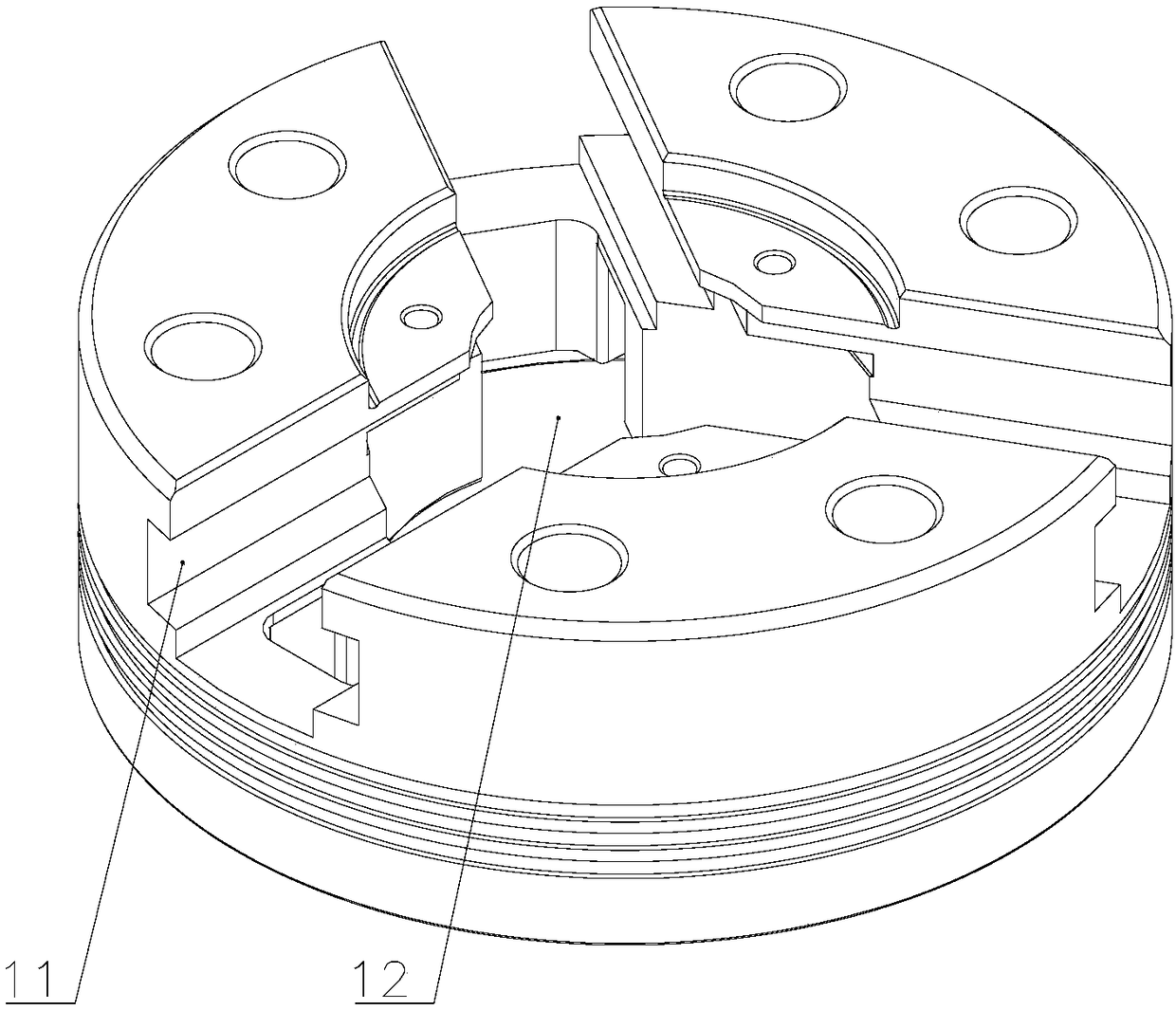

Floating jaw chuck of grinding machine

ActiveCN106392871AStrong self-alignment positioning abilityLarge floating amountGrinding drivesWork carriersEngineeringMachine tool

The invention relates to the technical field of jigs, in particular to a floating jaw chuck of a grinding machine. The floating jaw chuck comprises a chuck body, clamping jaws, a crank, an inner sleeve and a drive device; the included angle between an active section and a passive section of the crank is 70-110 degrees, and one end of the active section is fixedly connected to a spherical floating head; the clamping jaws are arranged in T-shaped grooves through bottom jaw sliding blocks in a sliding mode; the inner sleeve is arranged in a shaft hole of the chuck body in a sliding mode; the crank is hinged to the chuck body through the joint of the active section and the passive section so that the passive section can be arranged in drive grooves below bottom jaw plates, and the spherical floating head on the active section is arranged in a ball clamping space formed between an upper ball sleeve and a lower ball sleeve; and the drive device is fixed to the lower side of the chuck body and is used for driving the inner sleeve to move up and down. According to the floating jaw chuck of the grinding machine, after work-pieces to be machined are clamped, bottom jaws can deflect to a large extent due to large floating amount, and the positioning ability is high.

Owner:CHANGZHOU BEIDEFU MACHINERY SCI & TECH

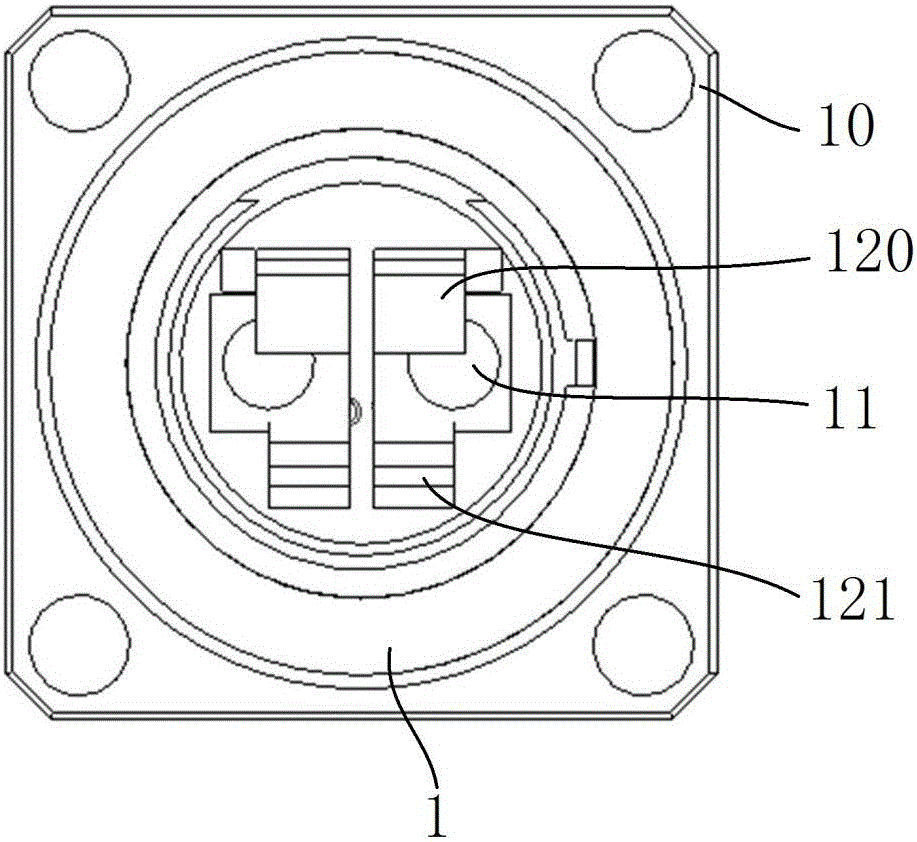

Connector

ActiveCN111509432ALarge floating amountSmall float intervalCoupling device detailsEngineeringContact element

The invention relates to a connector, which comprises a first plug-in module, a second plug-in module and a switching module, wherein the first plug-in module is provided with a first contact element,the second plug-in module is provided with a second contact element, and the switching module is provided with a switching contact element; the switching module is arranged on the first plug-in module in a guiding manner, and a reset spring is arranged between the switching module and the first plug-in module, so that the switching module can extend forwards relative to the first plug-in module;the first contact element and the second contact element are in sliding contact with the switching contact element; the second plug-in module is provided with a stop part, so that the switching modulecan retreat relative to the first plug-in module. Compared with a connector without a switching module in the prior art, the second contact element can be contacted with the switching contact elementearlier, so that a larger floating interval can be formed between the first plug-in module and the second plug-in module, the floating amount of the connector is increased, and large-tolerance connection is realized.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

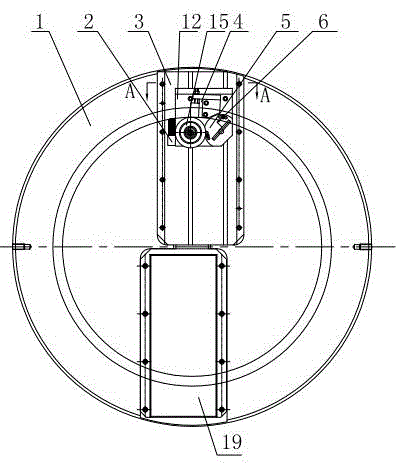

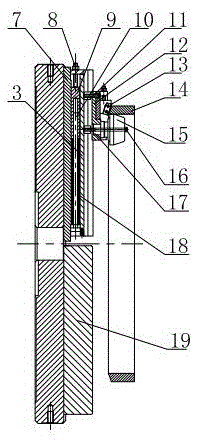

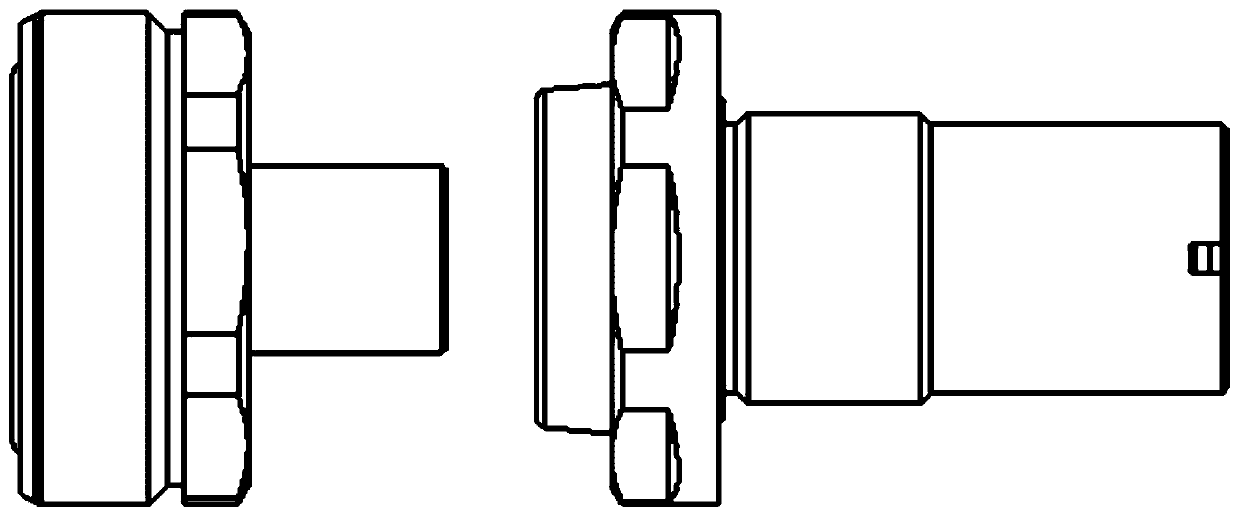

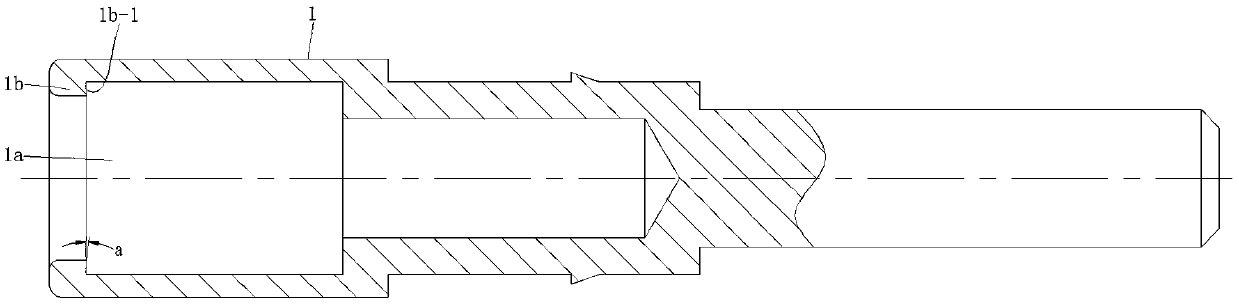

Embedded large floating fluid connector capable of plugging with pressure

PendingCN110440073ARealize plugging and unplugging under pressureWon't impactCouplingsMechanical engineering

The invention discloses an embedded large floating fluid connector capable of plugging with pressure. The fluid connector comprises a male-end connector and a female-end connector, wherein the left end of the female-end connector and the right end of the male-end connector are plug combined positions of the fluid connector; the male-end connector comprises a male-end main shaft sleeve, a male-endmounting sealing ring, a male-end floating sealing ring, a male-end mounting nut, a male-end floating retainer ring, a male-end spring, a male-end sealing ring, a male-end spring retainer ring, a male-end clamping ring and a male-end valve core; and the female-end connector comprises a female-end main shaft sleeve, a female-end mounting sealing ring, a female-end valve core shaft sleeve, a female-end spring, a female-end outer sealing ring, a female-end inner sealing ring, a female-end valve core and a wire clamp spring. According to the embedded large floating fluid connector capable of plugging with pressure, the fluid connector can be used for solving the problems that an existing connector is small in radial floating space, large in axial occupation space, incapable of carrying out plugging with pressure and complex in structure.

Owner:万硕(成都)航空科技有限公司

One-piece large tolerance radio frequency connector

ActiveCN109687240AIncrease contactImprove conductivityCoupling contact membersCouplings bases/casesElectrical conductorBroadband transmission

The invention discloses a one-piece large tolerance radio frequency connector. The one-piece large tolerance radio frequency connector comprises an outer conductor, an inner conductor and an insulator. The inner conductor comprises a main body, a conductive head and a spring, the inner conductor further comprises a positioning sleeve fixed in an inner hole of the conductive head, the positioning sleeve is cylindrical, an inner hole is formed in the rear end of the positioning sleeve, an outer convex barb is arranged on the outer circular wall surface of the rear end of the positioning sleeve,an inner convex barb is arranged on the inner hole wall surface at the front end of the main body, the front end surface of the outer convex barb abuts against the rear end surface of an inner convexbarb, and a gap is arranged between the outer circular wall surface of the outer convex barb and the inner hole wall surface of the main body. An annular protrusion is arranged on the inner hole wallsurface of the rear end of the conductive head, the front and rear end surfaces of the annular protrusion are chamfered or smooth circular arc surfaces, the annular protrusion of the conductive head is in sliding connection with the outer circular wall surface of the front end of the main body, and the front and rear end surfaces of the spring separately abut against the front end of the positioning sleeve or the front end of the conductive head and the rear end of an inner hole of the main body. The one-piece large tolerance radio frequency connector has excellent conductivity and good contact, ensures the requirement of broadband transmission, and realizes connection with small space and large tolerance.

Owner:CHANGZHOU XINSHENG ELECTRONICS

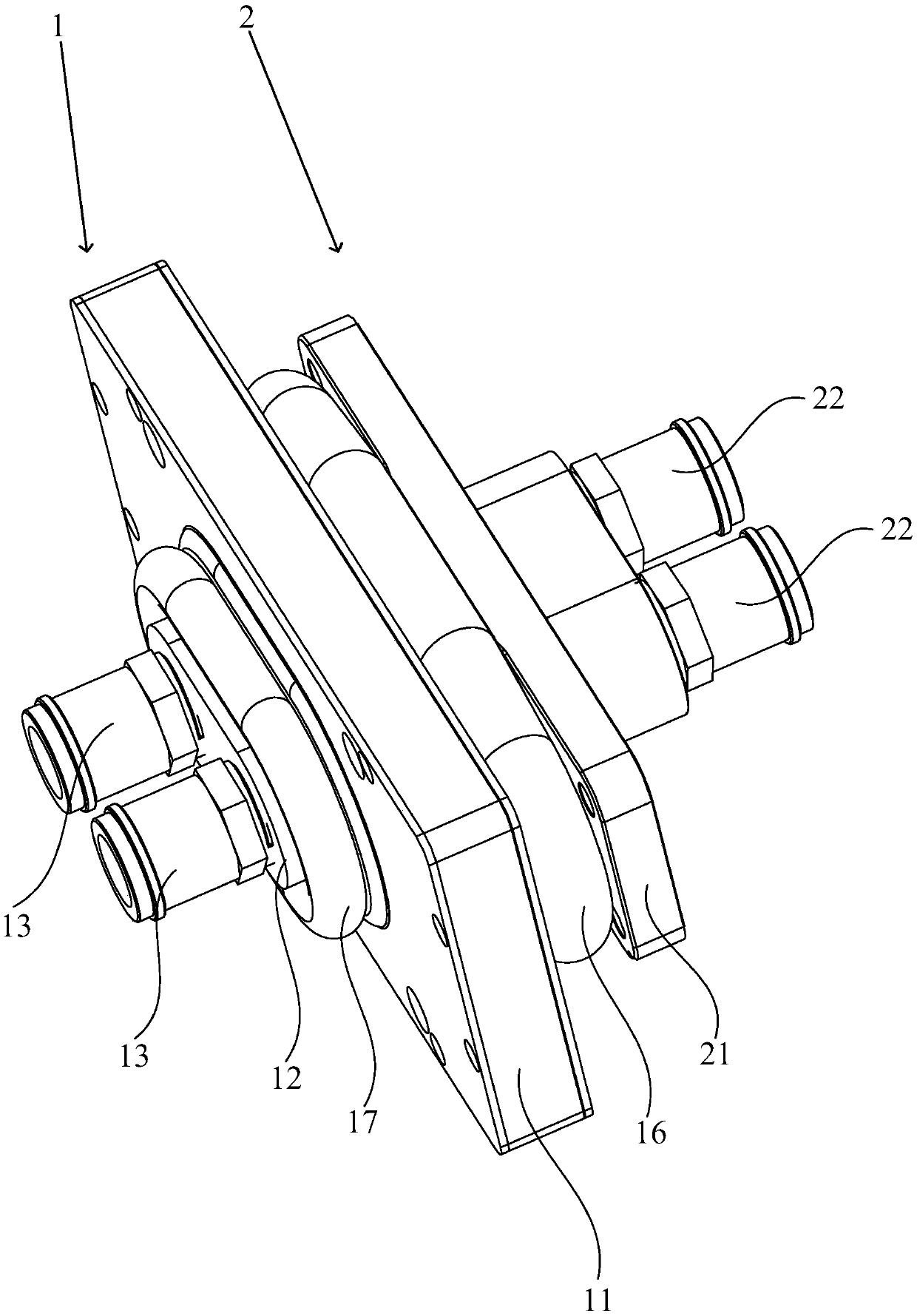

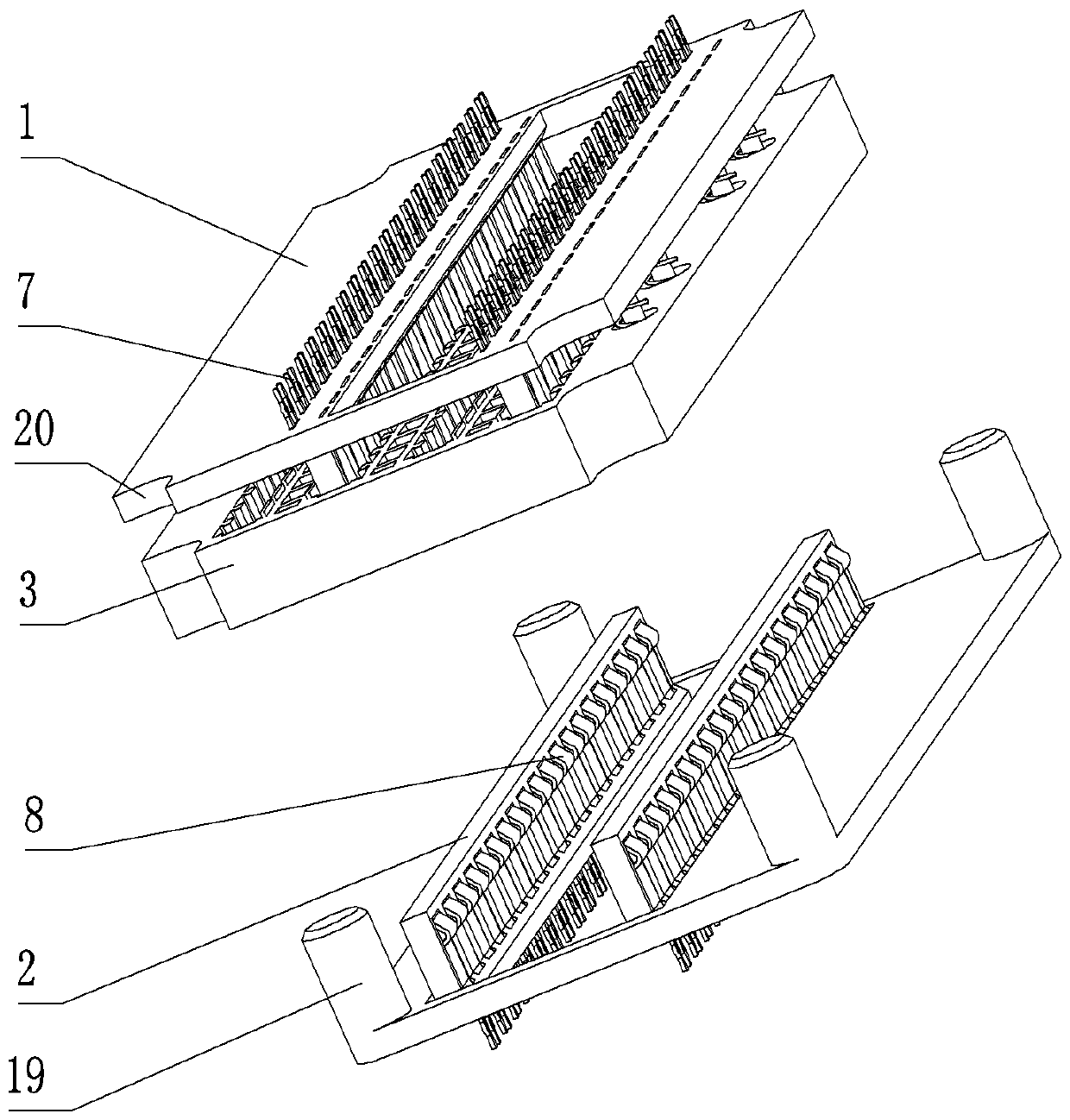

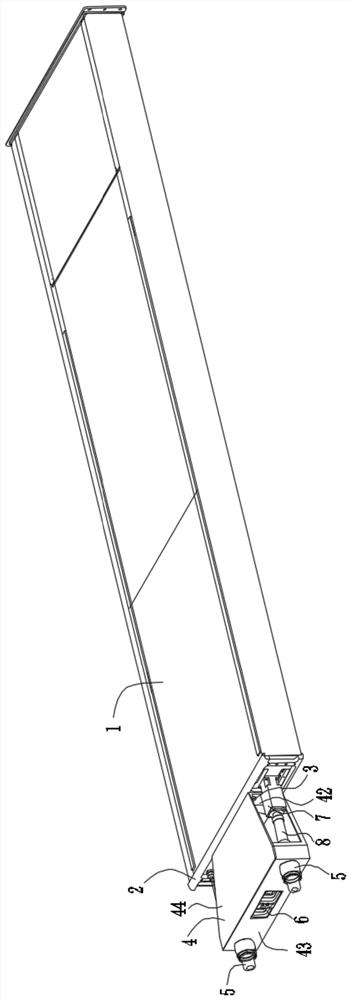

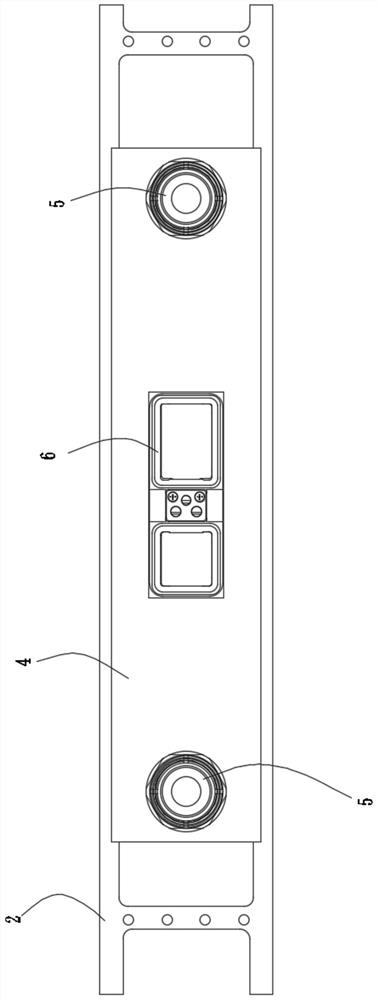

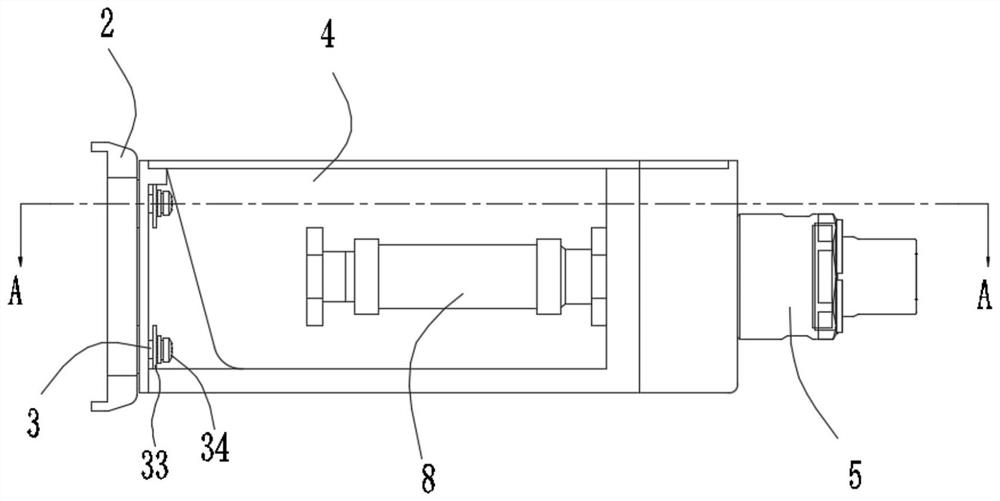

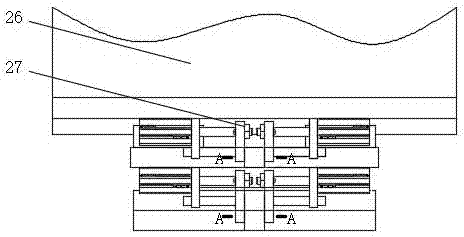

Blind-mating floating docking system for large-size equipment

PendingCN112531407ALarge floating amountPrecise dockingCoupling device detailsBranching pipesStructural engineeringElectrical and Electronics engineering

The invention relates to a blind-mating floating docking system for large-size equipment. The system comprises the equipment; an adapter plate which is mounted at one end of the equipment, and a floating part is fixed on the adapter plate; a box-shaped part which is provided with a liquid supply connector and a communication connector, the box-shaped part is connected with the adapter plate through the floating part, and the floating part is used for adjusting the relative position of the liquid supply connector and the equipment and the relative position of the communication connector and theequipment. According to the large-size equipment blind-mating floating butt joint system, the influence of installation errors of the communication connector and the liquid supply connector caused byequipment manufacturing and assembling can be offset, and reliable butt joint of the equipment blind-mating communication connector and the liquid supply connector is achieved.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

Floating clamping jaw self-adapting to bricking stack

ActiveCN107500197AAchieve floatingLarge floating amountLifting devicesBrick clampStructural engineering

The invention discloses a floating clamping jaw self-adapting to a bricking stack and relates to the field of clamping devices. The floating clamping jaw comprises a hanging frame, a floating device and a clamping device which are sequentially connected. The floating device comprises a base connected with the hanging frame, a linear floating plate slidably arranged on the base and a circular rotating floating plate which is rotatably arranged on the linear floating plate and connected with the clamping device. The sliding direction of the linear floating plate is parallel to the clamping direction of the clamping device, and a first limiting block is arranged on the side face, parallel to the sliding direction of the linear floating plate, of the linear floating plate; the base is provided with a first clamping mechanism for clamping and loosening the first limiting block; the rotating axis of the rotating floating plate is perpendicular to the end face of the linear floating plate, and the outer circle face of the rotating floating board is provided with a second limiting block; and a second clamping mechanism for clamping and loosening the second limiting block is arranged on the linear floating plate. The clamping device of a brick clamping machine can be self-adapted to tightly clamp floating in the direction of the bricking stack, and manually adjustment of an operator of a power vehicle for the clamping device is not needed.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

An embedded fluid connector that can be floated and the spring is not exposed to the flow channel

ActiveCN110131510BLow costLarge floating amountJoints with fluid cut-off meansCouplingsAnimal scienceMedicine

Owner:万硕(成都)航空科技有限公司

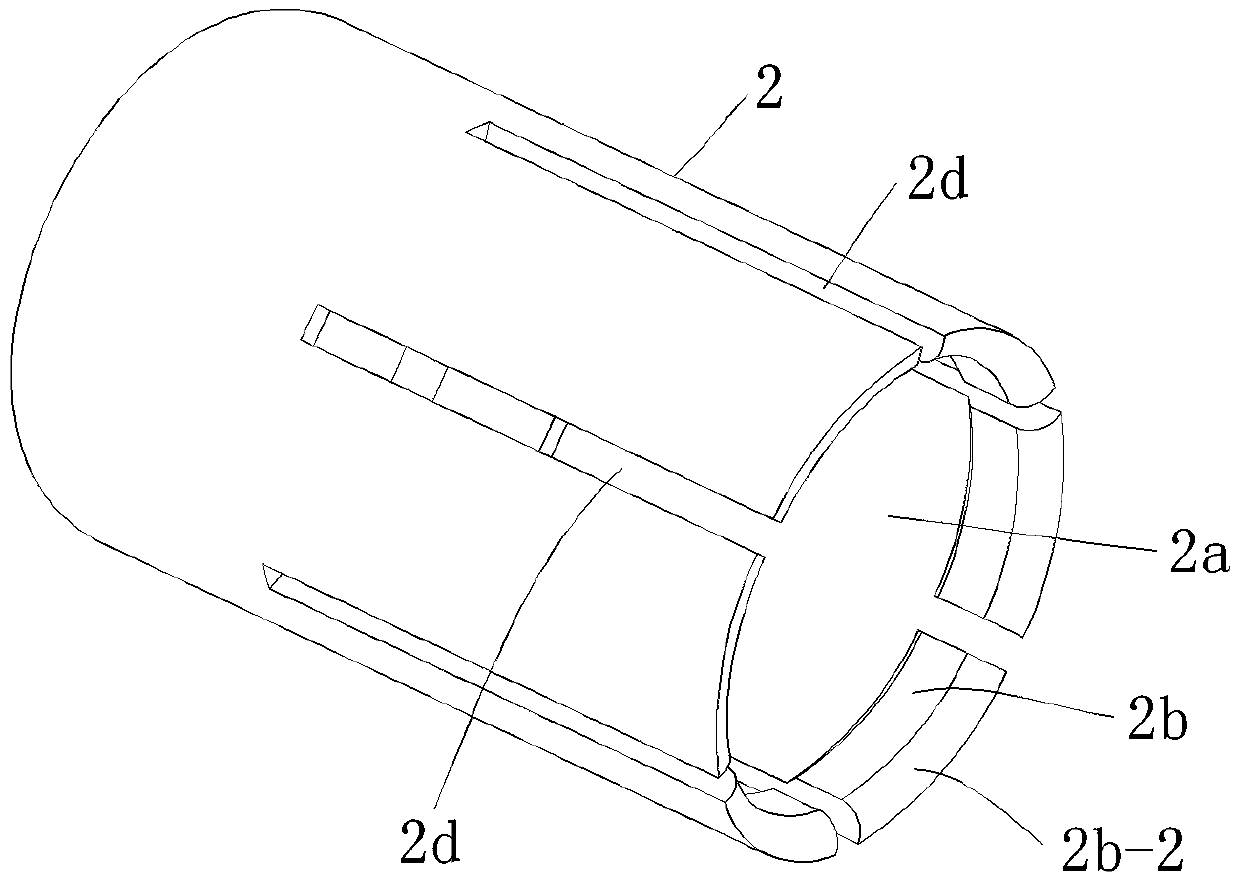

Fluid connector module and female end connector thereof

InactiveCN109140085ALarge floating amountLarge adjustment rangeJoints with fluid cut-off meansProcessing accuracyMachining

The invention relates to a fluid connector module and a female end connector thereof. The fluid connector module comprises a male end connector and the female end connector; the female end connector comprises a front end floating part, a back end fixing part, and a pull rod inserted in the two; the front end of the pull rod is connected with a floating part, and the back end is provided with a back end stop surface for forwards stopping the back end surface of the fixing part in the axial direction and capable of relatively sliding in the radial direction; the floating part is provided with afront end stop surface for backwards stopping the front end surface of the fixing part in the axial direction and capable of relatively sliding in the radial direction; and a sealing structure is arranged between the floating part and the fixing part. The floating part and the fixing part realize radial floating through relative sliding between the surfaces, so that the floating quantity is higher, the adjusting range is wider, the machining error between the male end connector and the female end connector can be compensated in a wider range, and the requirement of users on the machining precision of the fluid connector module is further reduced.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

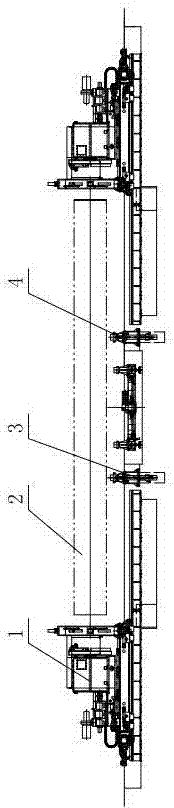

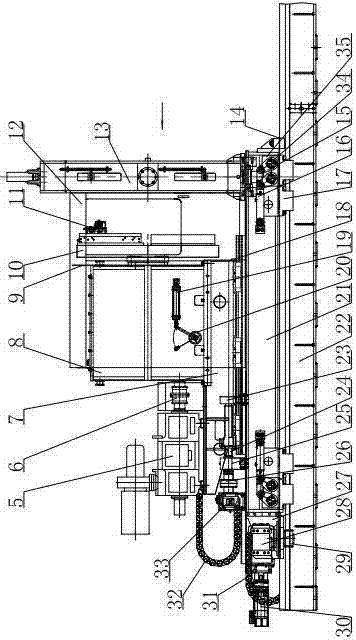

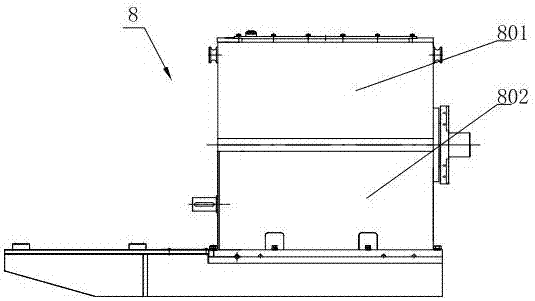

Automatic steel pipe chamfering machine

ActiveCN105522223BReasonable collection methodImprove technical levelLarge fixed membersPositioning apparatusCouplingEngineering

A fully automatic steel pipe chamfering machine includes a base. A large carriage is installed on the base. Hook plates are installed on both ends of the base. The hook plates are hooked tightly on the base. A base box is installed on the large carriage through slide rails. The base The bedside box is installed on the box through fasteners. The bedside box has a combined structure and is divided into an upper box and a lower box. The lower box is connected to the base box. The upper box is installed on the lower box. The lower box is inside the box. A gear transmission mechanism is installed, and a main motor is installed on the base box located at the lower part of the bedside box. The output end of the main motor is connected to the gear transmission mechanism in the bedside box through a first coupling; a knife is installed on the outside of the bedside box. A cutting device is installed on the cutter head; a clamping device is installed at one end of the large carriage; a first-layer drag chain is also installed at one end of the large carriage, and a second drag chain is installed on the top of the first-layer drag chain through a splint. Layer drag chain. High level of automation, strong processing capability, safe and reliable.

Owner:SUNYO S&T CO LTD

An electrical connector assembly

ActiveCN111009752BLarge offsetThe corresponding position is the sameSecuring/insulating coupling contact membersCoupling protective earth/shielding arrangementsElectrical connectorMechanical engineering

The invention relates to an electrical connector assembly, which includes a first connector and a second connector, and the two connections include a housing and a contact module, and the contact module includes a contact, a floating insulator and a fixed insulator, and the floating insulator and the fixed insulator are separated from each other Arrangement, the fixed insulator is fixed in the shell; the contact piece has a front connection section, a rear connection section and a middle deformation section, the front connection section is fixedly connected with the floating insulator, the rear connection section is fixedly connected with the fixed insulator, and the floating insulator passes through the elasticity of the middle deformation section The deformation moves relative to the fixed insulator along the direction perpendicular to the plugging direction of the contacts, so that the two connectors can be plugged in floatingly; the front ends of the contact modules of the first connector and the second connector are plugged into each other. In the present invention, by setting the front end of the contact module as a floating plug-in terminal, the floating plug-in terminals of the two connectors are mated with each other, so that the two connectors can allow a large offset value, thereby ensuring the quality of signal transmission .

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

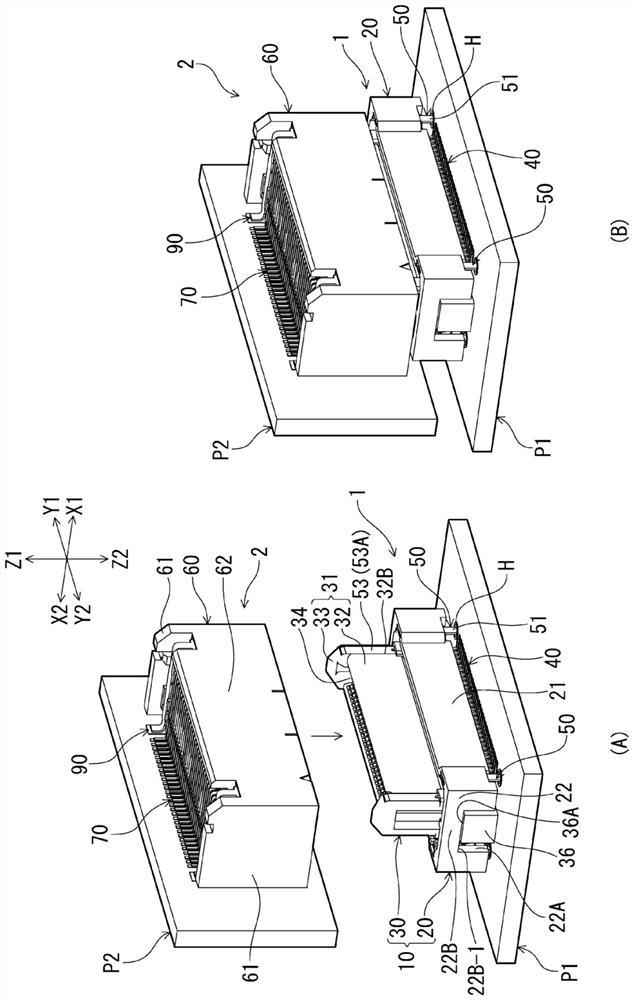

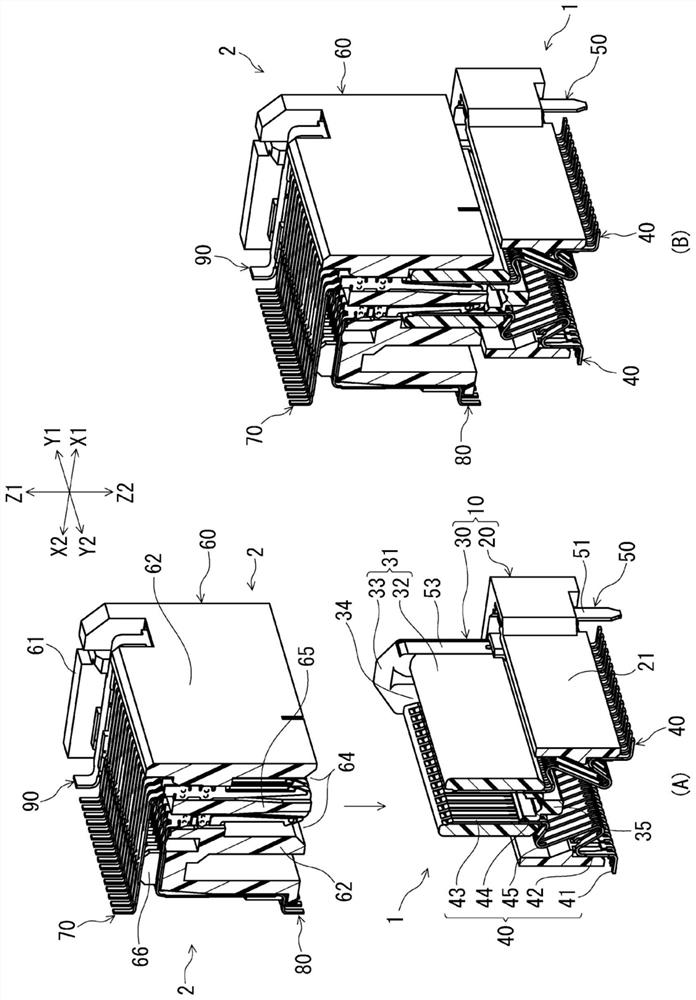

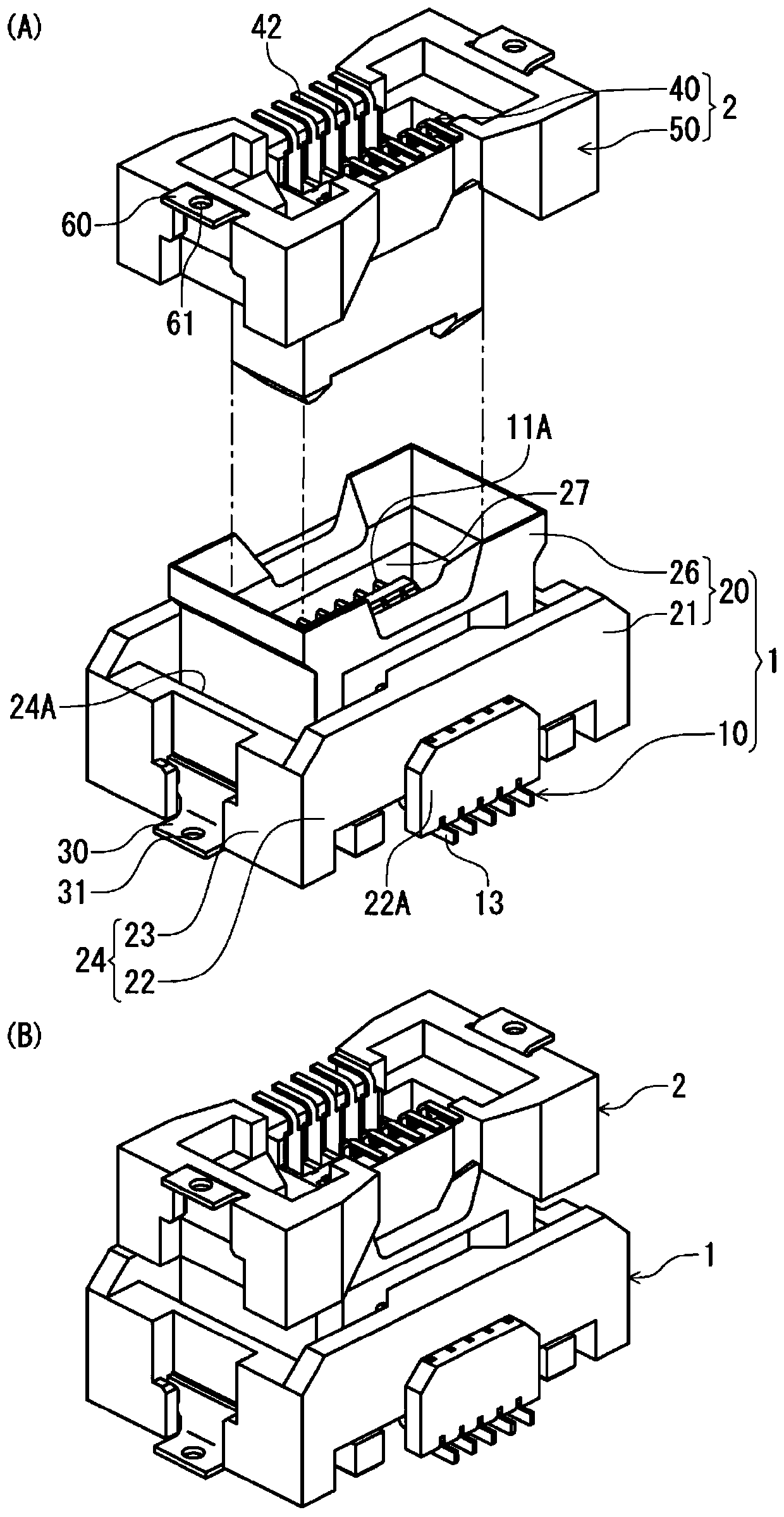

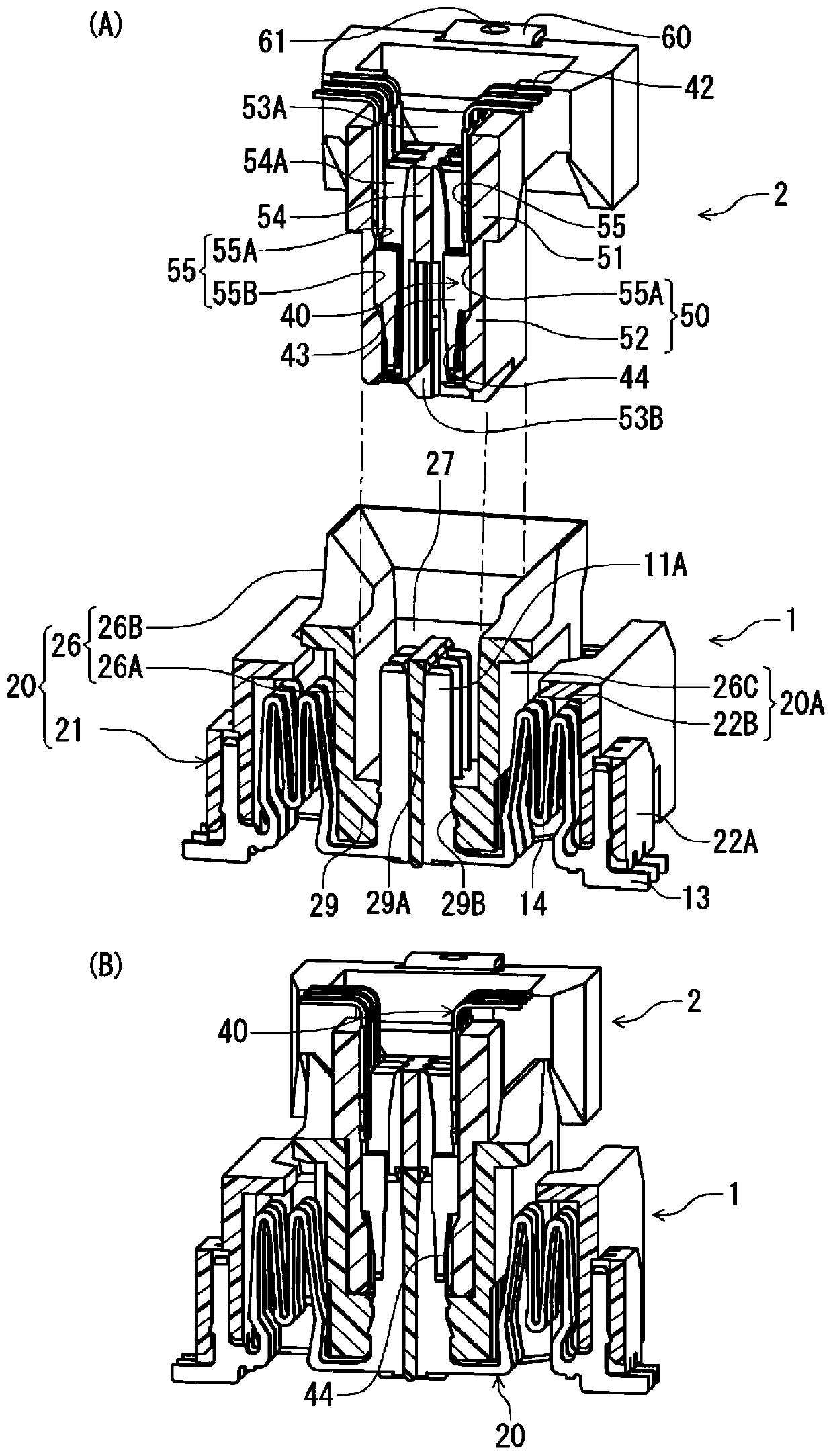

Electrical connectors for circuit boards

ActiveCN110416770BSmall sizeAchieve thinningCoupling contact membersTwo-part coupling devicesHemt circuitsStructural engineering

The present invention provides an electrical connector for a circuit board capable of securing a sufficient amount of floating, reducing the thickness of the connector, and minimizing degradation of high-speed transmission characteristics. The terminal (40) has: a fixed side held portion (42) held by the fixed case (20); a movable side held portion (44) held by the movable case (30); and an elastic portion (45) , arranged between the fixed-side held portion (42) and the movable-side held portion (44), the elastic portion (45) of the elastic portion (45) in the longitudinal direction of the terminal (40) A portion has bent portions (45A, 45B) bent so as to have portions repeatedly arranged in a connector height direction at right angles to the mounting surface of the circuit board.

Owner:HIROSE ELECTRIC GROUP

Contact, electric connector and contact piece assembly

ActiveCN106025631ALower resistanceExtended service lifeCoupling contact membersElectricityEngineering

The invention provides a contact, an electric connector and a contact piece assembly. The contact piece assembly comprises a back contact section which is fixedly arranged at the back end of a front contact section; the back contact section adopts a turnoff shunt-wound structure which comprises an upper contact cantilever and a lower contact cantilever that are arranged in parallel; the upper contact cantilever and the lower contact cantilever are provided with an upper contact part and a lower contact part respectively; the contact piece assembly also comprises an adaptive contact, wherein the adaptive contact is provided with a first adaptive contact part and a second adaptive contact part which are in conductive contact with the upper contact part and the lower contact part respectively. The back contact section is set to be the turnoff shunt-wound structure, so that the resistance of the back contact section is lowered; the heating amount is corresponding reduced; and the service life of the adapter socket is prolonged.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Float adjustment device

ActiveCN112026957BImprove synchronicityImprove coordinationVehiclesControl theoryMechanical engineering

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

Grinder floating jaw chuck

ActiveCN106392871BLarge floating amountLarge deflection functionGrinding drivesWork carriersEngineeringMachine tool

The invention relates to the technical field of jigs, in particular to a floating jaw chuck of a grinding machine. The floating jaw chuck comprises a chuck body, clamping jaws, a crank, an inner sleeve and a drive device; the included angle between an active section and a passive section of the crank is 70-110 degrees, and one end of the active section is fixedly connected to a spherical floating head; the clamping jaws are arranged in T-shaped grooves through bottom jaw sliding blocks in a sliding mode; the inner sleeve is arranged in a shaft hole of the chuck body in a sliding mode; the crank is hinged to the chuck body through the joint of the active section and the passive section so that the passive section can be arranged in drive grooves below bottom jaw plates, and the spherical floating head on the active section is arranged in a ball clamping space formed between an upper ball sleeve and a lower ball sleeve; and the drive device is fixed to the lower side of the chuck body and is used for driving the inner sleeve to move up and down. According to the floating jaw chuck of the grinding machine, after work-pieces to be machined are clamped, bottom jaws can deflect to a large extent due to large floating amount, and the positioning ability is high.

Owner:CHANGZHOU BEIDEFU MACHINERY SCI & TECH

Electrical connectors for circuit boards

The electrical connector for circuit boards provided by the present invention can ensure sufficient floating amount in the height and width directions of the connector without increasing the size of the connector in the height direction. The terminal (10) has a fixed-side held portion (12B) held by the fixed housing (21), a movable-side held portion (11B) held by the movable housing (26), and an elastically deformable elastic portion ( 14), the housing (20) forms a receiving space (20A) for receiving the elastic part (14) of the terminal between the fixed housing (21) and the movable housing (26), and the elastic part (14) forms a continuous The band-shaped portion continuously forms a wave-shaped portion through a plurality of flexion portions (14A), (14B), and (14C) that repeatedly reverse the flexion direction, and has a fixed side held portion (12B) and a movable side held portion. The opening width of the waveform of each adjacent waveform portion (11B) becomes wider as it moves away from the flexure portion.

Owner:HIROSE ELECTRIC GROUP

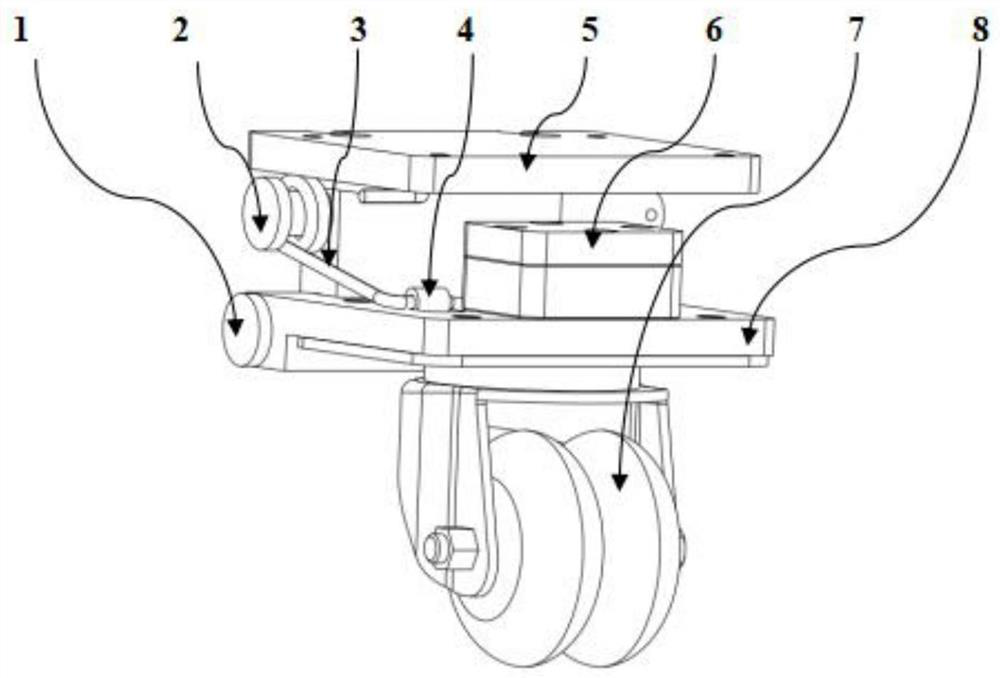

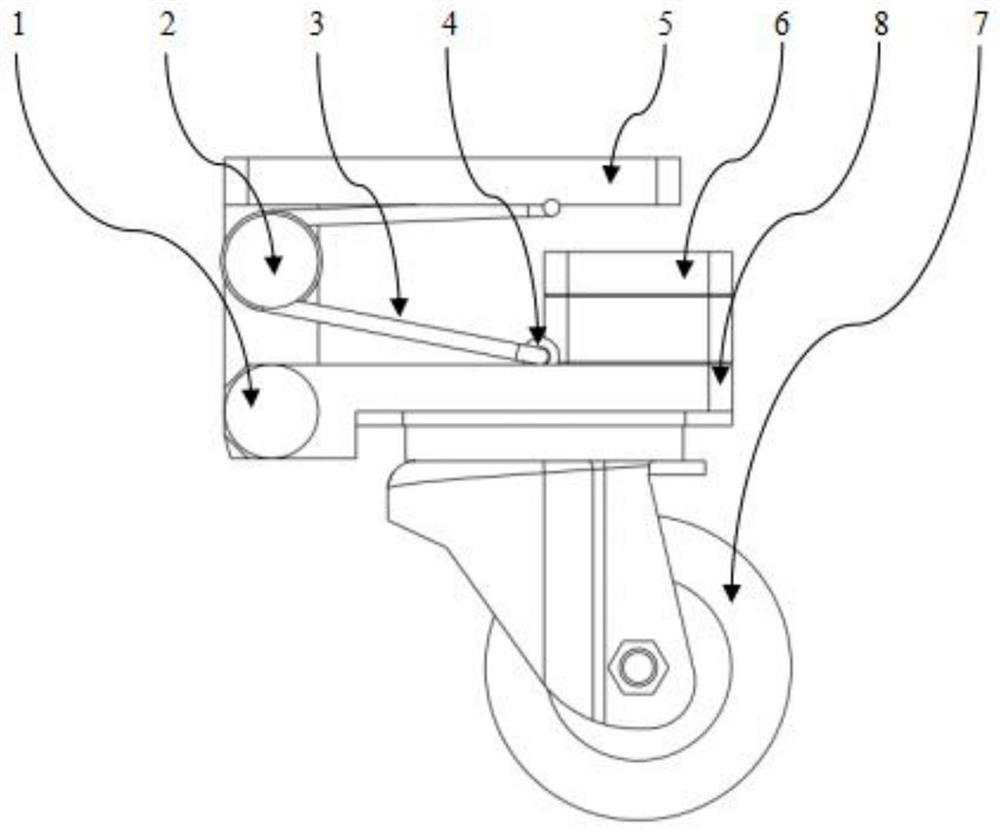

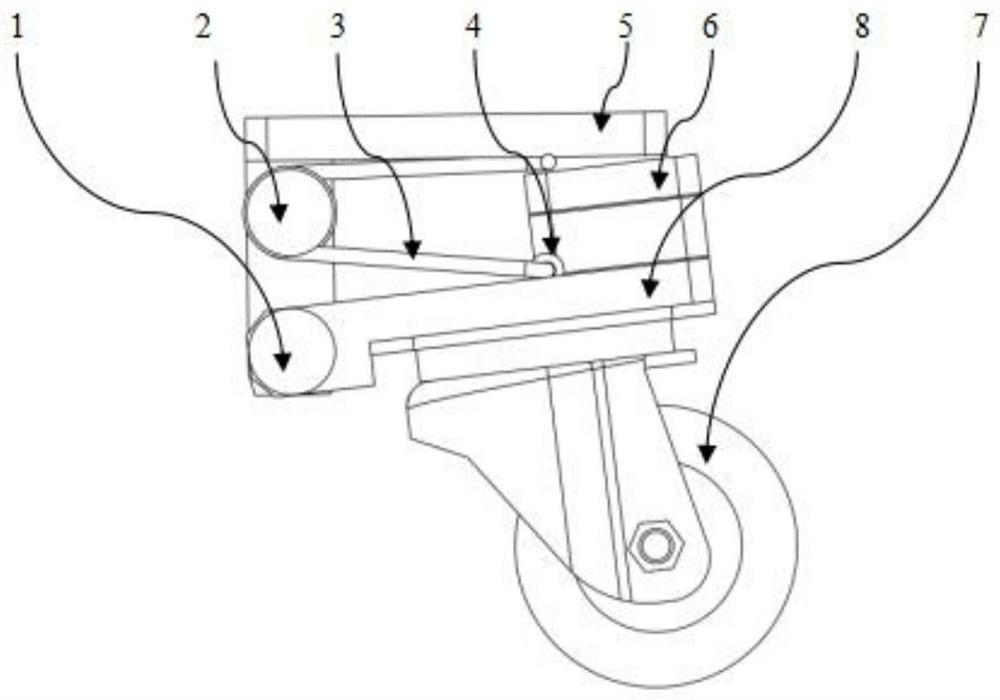

Driven wheel floating mechanism and AGV

PendingCN113335005AConstant positive pressureThe range of elastic variation is smallResilient suspensionsDrive wheelControl theory

The invention discloses a driven wheel floating mechanism and an AGV. The driven wheel floating mechanism comprises a mounting plate, a floating plate, an elastic piece and a trundle. The floating plate and the mounting plate form a relative space below the mounting plate, one side of the floating plate is hinged to the mounting plate, and the other side of the floating plate freely rotates clockwise or anticlockwise with the hinge point as the axis so as to compress or release the relative space of the floating plate and the mounting plate. And the elastic piece is arranged in the relative space of the mounting plate and the floating plate. The trundles are installed below the floating plate. When the relative space of the elastic piece is changed, the elastic piece elastically deforms, so that the trundle always has vertically downward positive pressure. The AGV comprises a driving wheel and a driven wheel, and the driven wheel comprises any one of the driven wheel floating mechanisms. According to the floating wheel, no track is arranged, the needed installation space is small, the situation that floating cannot be achieved due to dead pinning cannot occur, the torsional spring is adopted as an elastic piece, the elasticity change range of the torsional spring is small, and the positive pressure of the floating wheel on the ground can be kept relatively constant.

Owner:广东塔斯克机器人有限公司

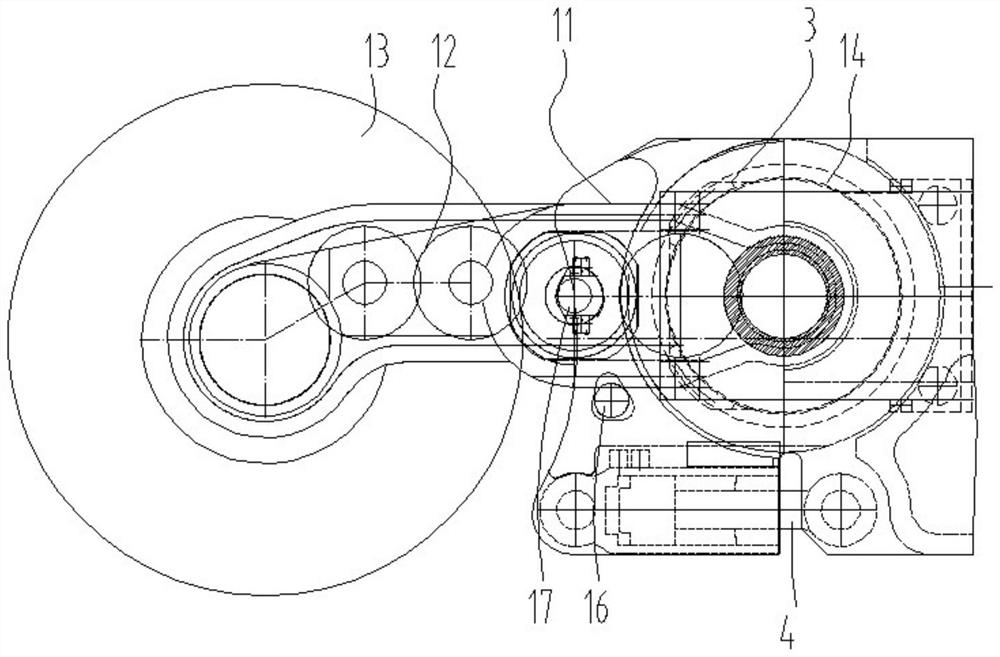

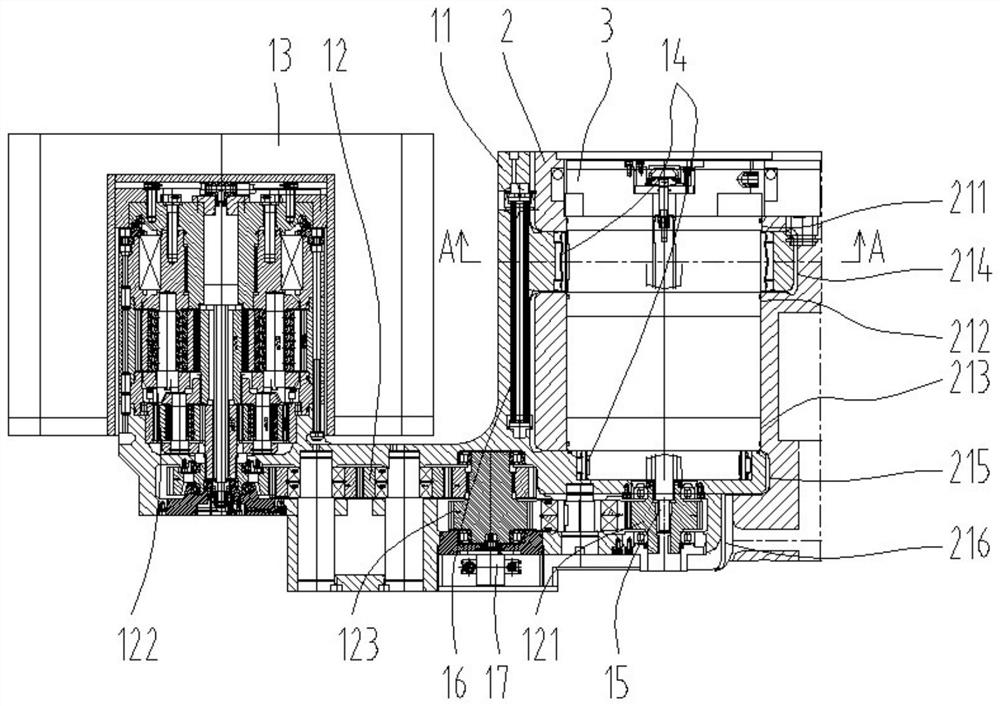

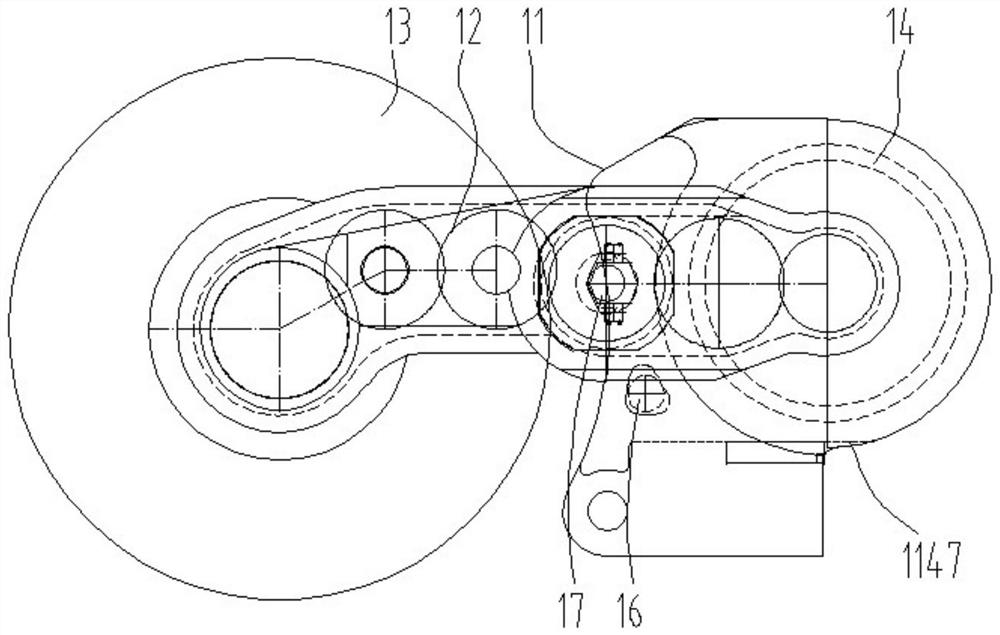

Cutting mechanism of thin seam short-span coal mining machine

PendingCN114396264AShorten the left and right lengthSimple structureSlitting machinesCutting machinesGear wheelElectric machinery

The invention relates to a thin seam short-span coal mining machine cutting mechanism which comprises a cutting motor, a swing arm shell and a front main body shell, a main body of the swing arm shell is an arm frame extending left and right, a connecting arm overhanging forwards is arranged in the middle of the arm frame, and a front arm overhanging leftwards or rightwards is arranged on the connecting arm. A first lug seat, a second lug seat and a connecting base are sequentially arranged on the right edge or the left edge of the front main body part shell from front to back, and the high-speed end of the front arm and the high-speed end of the arm frame are mutually inserted and hinged with the first lug seat, the second lug seat and the connecting base of the front main body part shell; an output shaft of the cutting motor is in coaxial transmission connection with an input end gear of a cutting transmission mechanism in the arm frame, and the cutting motor is fixedly connected and rotationally connected relative to the front main body part shell and the swing arm shell respectively. According to the invention, a larger mining range and larger cutting power can be provided, the machine body can be shortened, and the gravity center of the coal mining machine can be improved.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

BTB plug, BTB socket and BTB connector

PendingCN113193428AWidely used valueRealize high floating demandSecuring/insulating coupling contact membersCoupling contact membersMechanical engineeringPhysics

The invention relates to a BTB plug, a BTB socket and a BTB connector, the BTB connector comprises the BTB plug and the BTB socket, and plug terminals extending in the plugging direction are assembled on the two sides of a plug shell of the BTB plug; the BTB socket comprises a socket shell with an inner cavity with two open ends, and socket terminals assembled in the socket shell form a hollow cavity for the BTB plug to insert; and when the connector is plugged, any position of the contact area, extending along the axial direction, of the plug terminal can be contacted and conducted with the socket terminal, so that the connector can meet the floating requirement of different heights between printed boards through the axial relative sliding of the BTB plug and the BTB socket. The BTB plug and the BTB socket can meet the connection between printed boards with different board heights through axial floating, the product development types are reduced, the development cost is saved, and the development period is shortened.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com