Contact, electric connector and contact piece assembly

A technology for contact parts and components, which is applied in the direction of contact parts, parts of connecting devices, connections, etc., can solve the problems of large heat generation, shortened service life of adapter sockets, and large resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

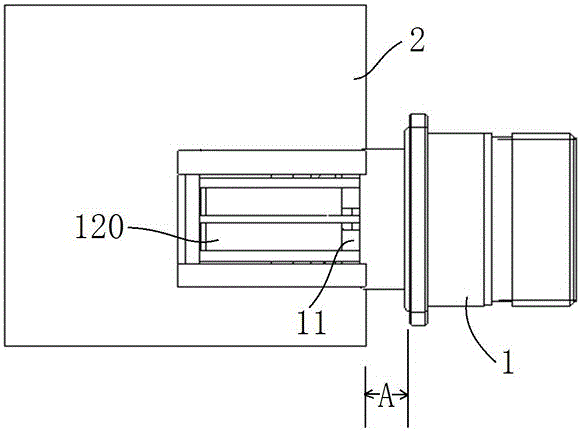

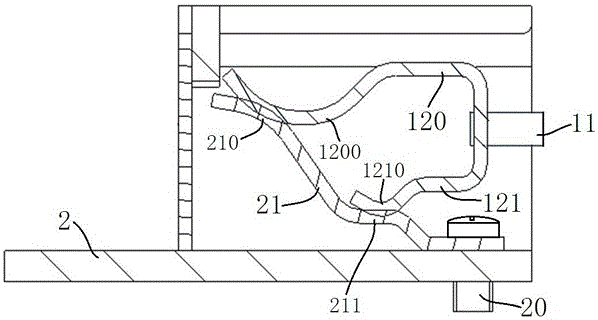

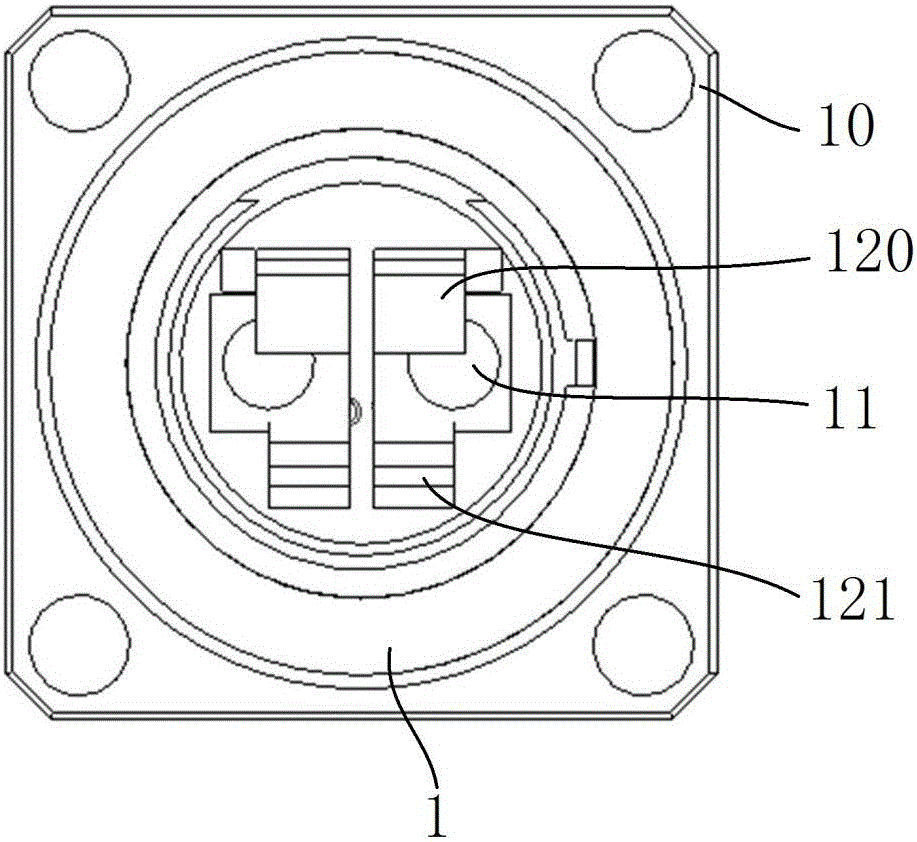

[0021] The first specific embodiment of the connector of the present invention is a transfer connector installed on the panel of the box body and used to realize the conversion of the printed board assembly in the box and the external plug connector. Specifically, it includes a connector housing 1, and a contact piece is arranged inside the connector housing 1. The contact piece includes a front contact section 11 extending forward and backward, and the front contact section 11 is a pin or a socket contact piece for matching with The plug connectors are mated with each other.

[0022] The contact also includes a rear contact section fixedly arranged at the rear end of the front contact section 11. When the connector is installed on the panel of the box body through the connecting flange 10 on the housing, the rear contact section extends into the box and contacts the printed board. The transition contacts on the component make conductive contact. Such as figure 1 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com