Connector

A connector and transfer technology, applied in the direction of connection, connecting device parts, electrical components, etc., can solve the problems of small floating amount of the connector, inability to realize large tolerance connection, etc., and achieve small floating interval and large tolerance. Connect and ensure the effect of the installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

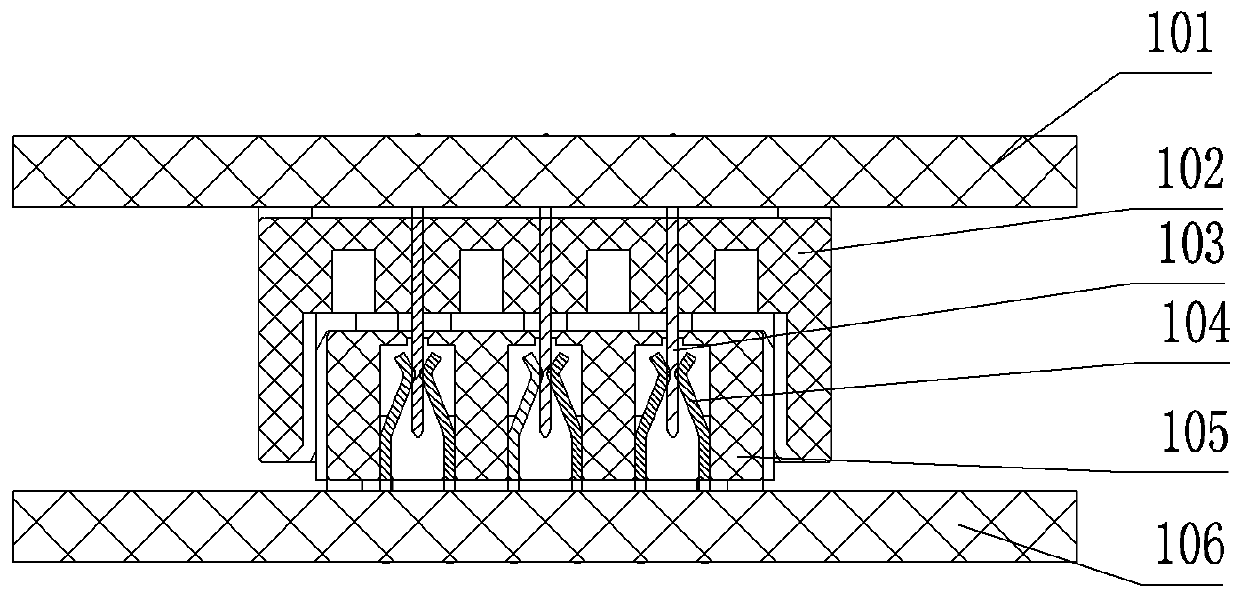

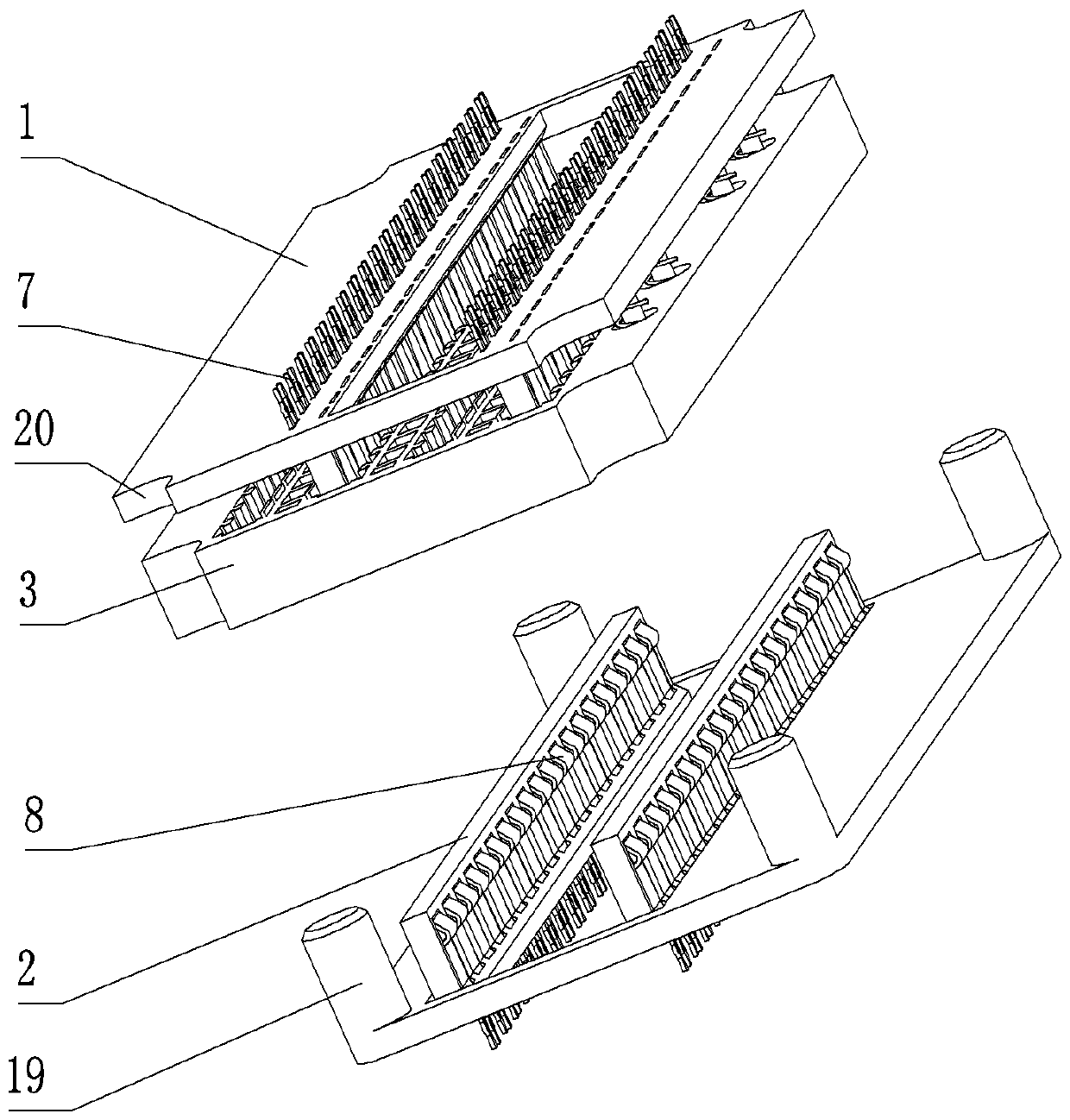

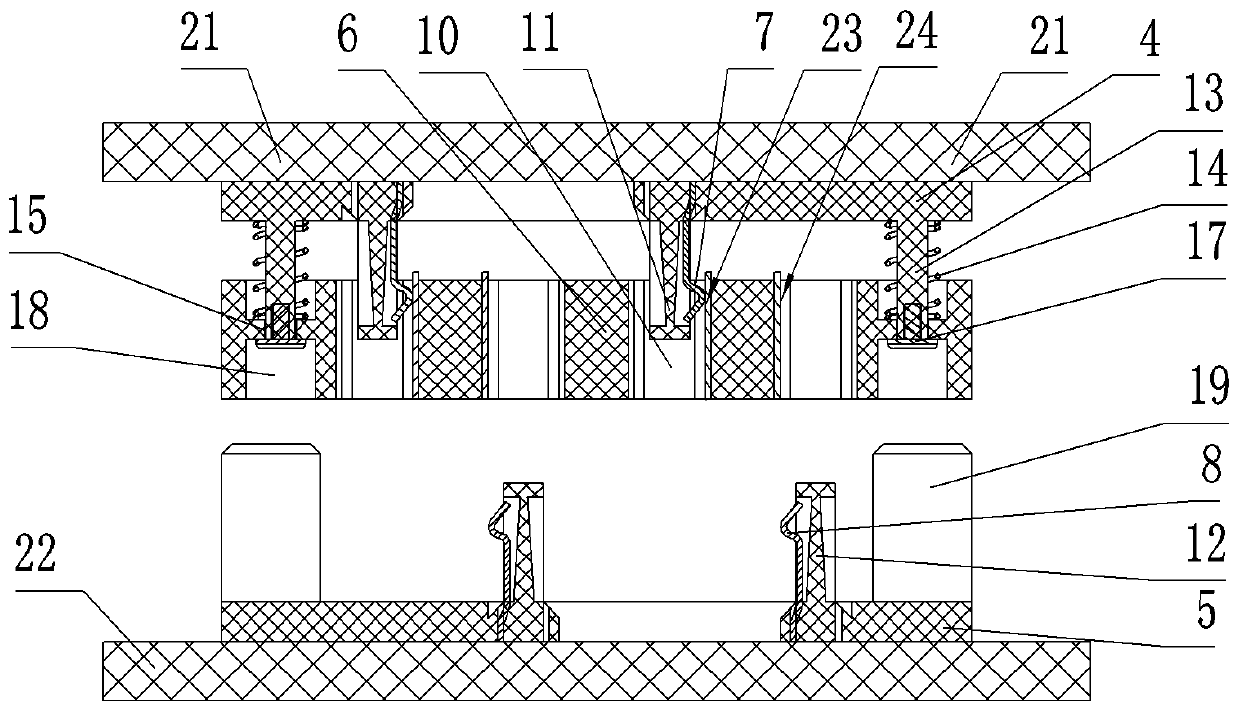

[0048] Such as figure 2 and image 3 As shown, the connector includes a first plug-in module 1, a second plug-in module 2 and an adapter module 3, the first printed board 21 is connected to the first plug-in module 1, and the second printed board 22 is connected to the second pair of plug-in modules. plug-in module connection. The adapter module 3 is arranged between the first plug-in module 1 and the second plug-in module 2 , and the first plug-in module 1 and the second plug-in module 2 are plugged on the adapter module 3 . The first plug-in module 1 and the adapter module 3 are provided with an arc-shaped guide groove 20, and the second plug-in module 2 is provided with an adapter guide column 19, and the adapter guide column 19 guides and cooperates with the arc-shaped guide groove 20, so as to Guaranteed installation location.

[0049] In order to illustrate this embodiment more clearly, with image 3 The up and down direction of the connector assembly is the up and ...

Embodiment 2

[0065] Embodiment 2 of the connector in the present invention, the difference between this embodiment and Embodiment 1 is that the stop position in Embodiment 1 is formed by the plug-in end face of the second plug-in module, and in this embodiment, A partial protrusion is provided on the second plug-in end surface, and the partial protrusion is used to form a stop position.

Embodiment 3

[0066] Embodiment 3 of the connector in the present invention, the difference between this embodiment and Embodiment 1 is that the first contact and the second contact in Embodiment 1 are spring-type structures, and the transfer contact is U-shaped. structure, but in this embodiment, the first contact and the second contact are pin-type structures, and the transfer contacts are reed-type structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com