Grinder floating jaw chuck

A floating jaw and grinding machine technology, which is applied to the grinding drive device, grinding machine parts, grinding/polishing equipment, etc., can solve the problem of restricting the use of the chuck, the bottom jaw has no deflection, and the floating self-aligning function cannot be generated. and other problems, to achieve the effect of strengthening the self-aligning positioning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

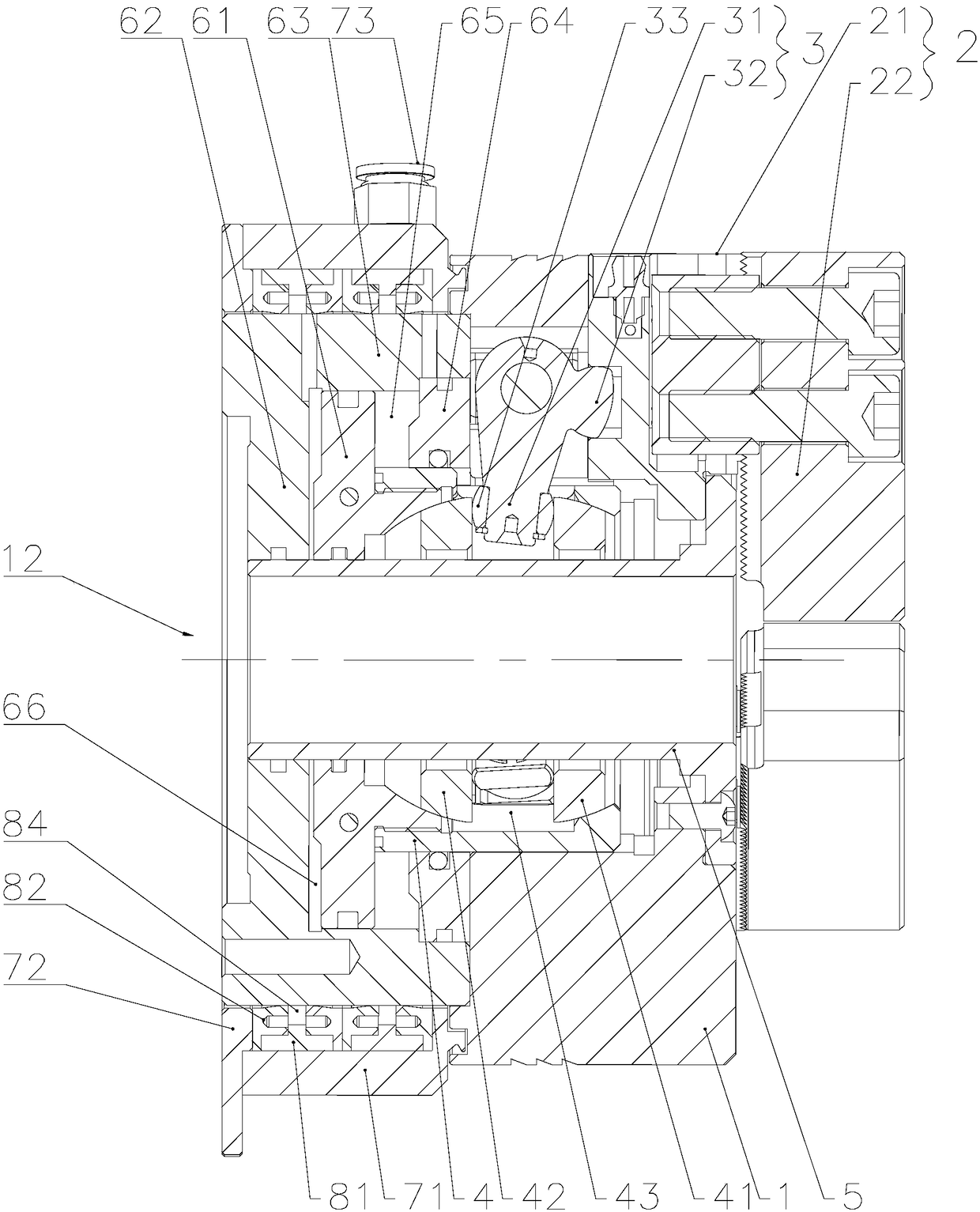

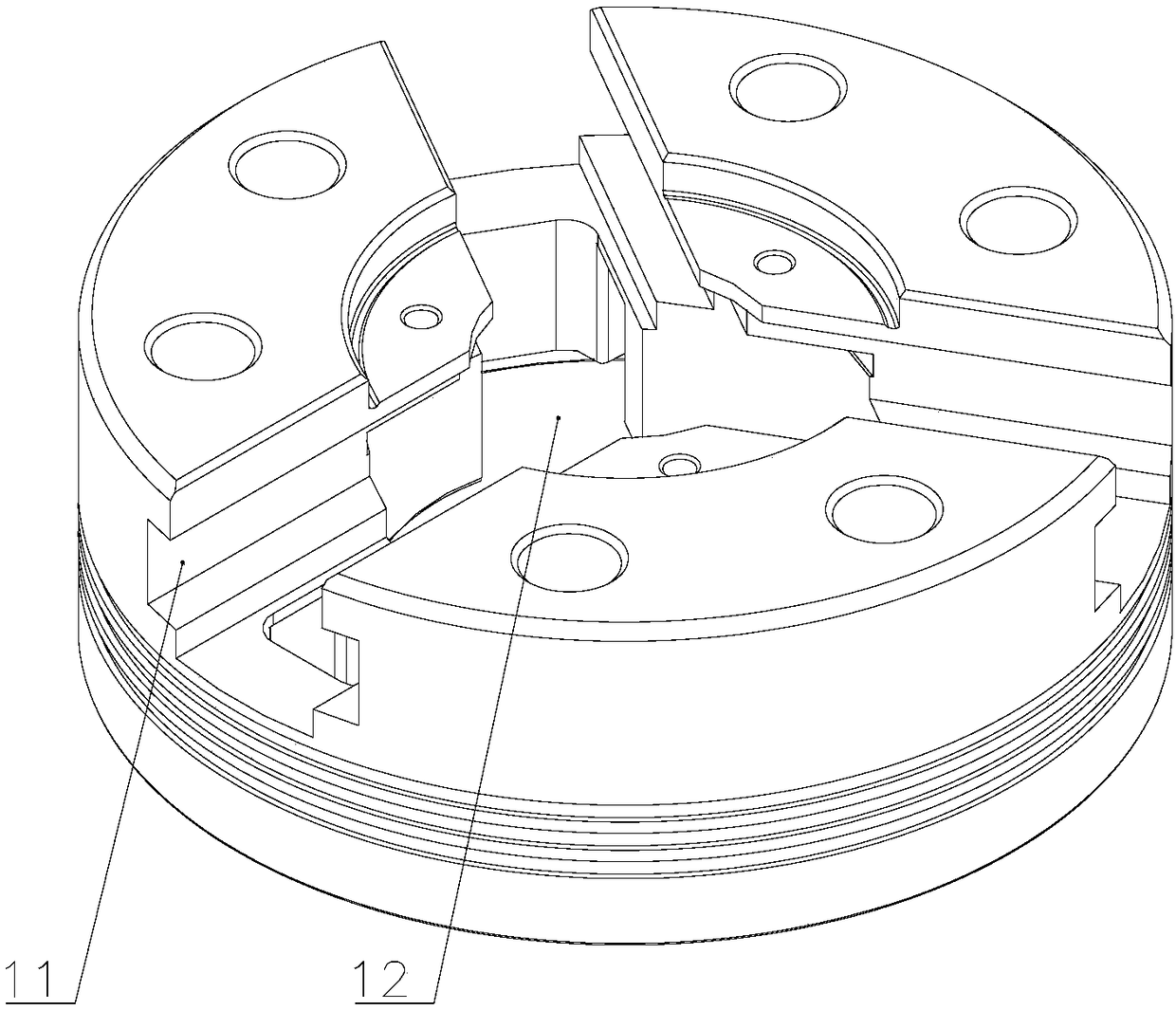

[0034] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention. Wherein the piston movement direction is the upward direction, the opposite direction is the downward direction, and the plane perpendicular to the upward direction is the horizontal plane.

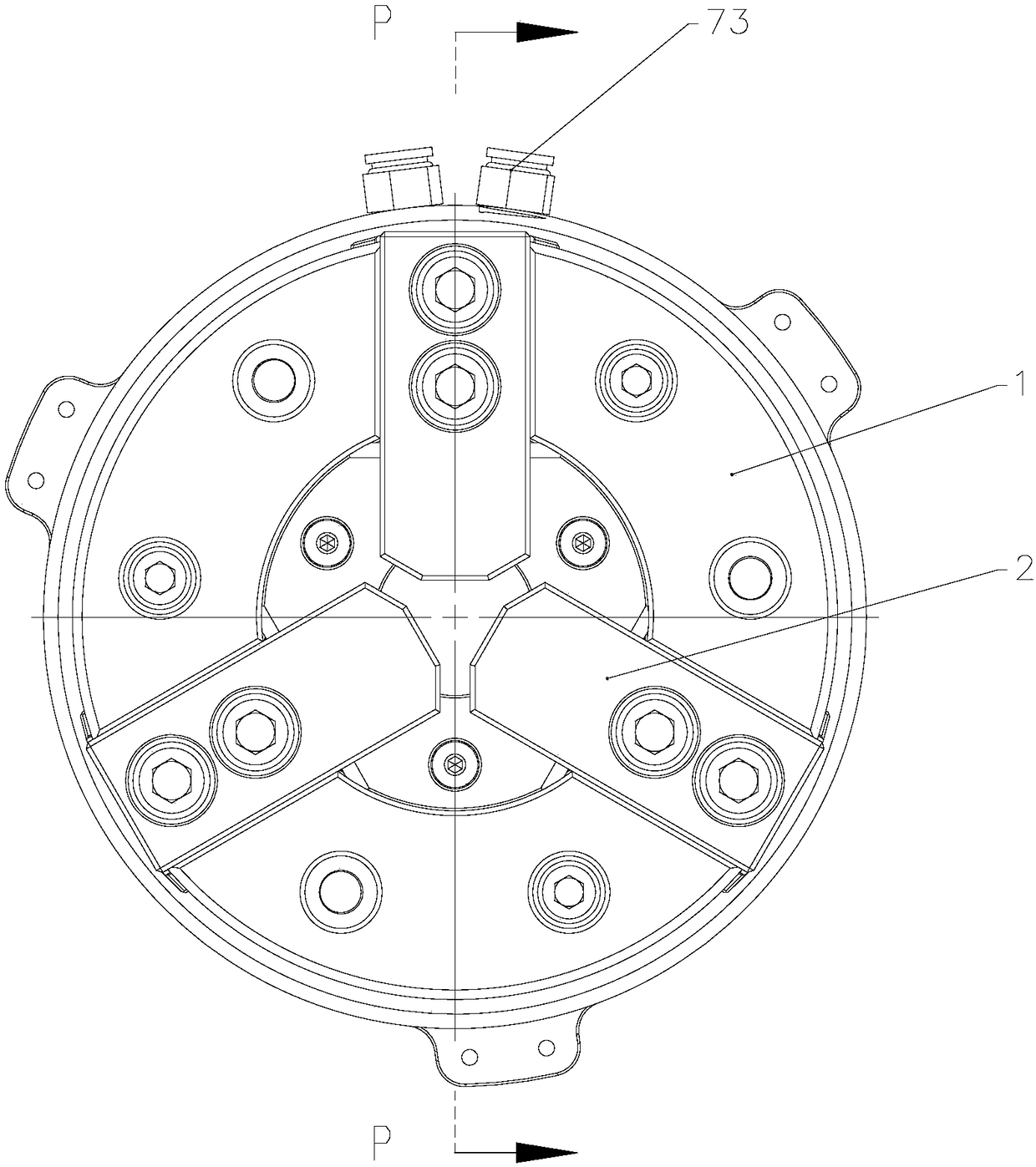

[0035] Such as Figure 1-5 Shown, a grinding machine floating jaw chuck, including:

[0036] The disc body 1 is provided with at least two T-shaped grooves 11 in the horizontal direction, and the disc body 1 has a shaft hole 12 in the center,

[0037] The claw 2, the claw 2 includes a fixed bottom claw 21 and an upper claw 22, the bottom claw 21 includes a bottom claw plate 211 and a driving groove 212 arranged at the bottom of the bottom claw plate 211, and the bottom cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com