An embedded fluid connector that can be floated and the spring is not exposed to the flow channel

An embedded and connector technology, which is applied in the connection with fluid cut-off device, coupling, pipe/pipe joint/pipe fitting, etc., which can solve the problems of large axial space occupation, complex design and processing, and relatively high requirements for spring materials. Problems, to achieve the effect of cost saving, large floating amount, and reduce the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

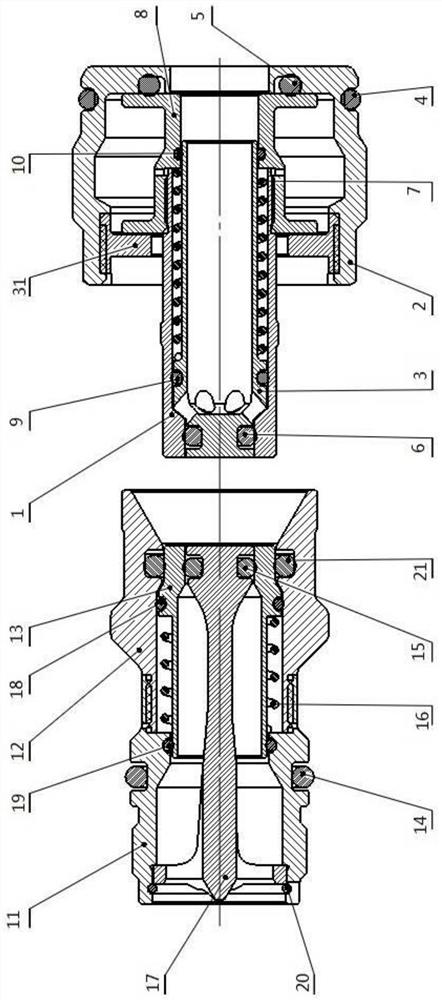

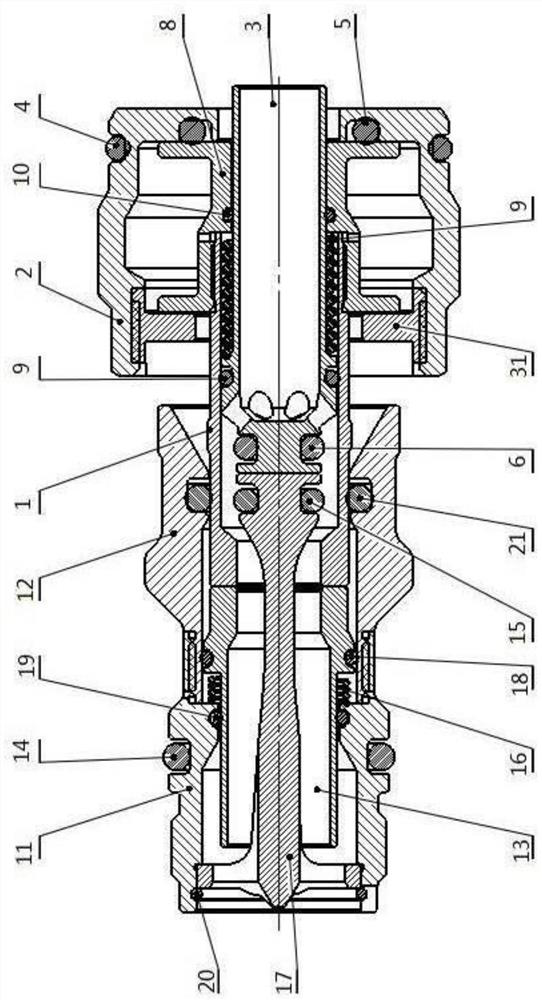

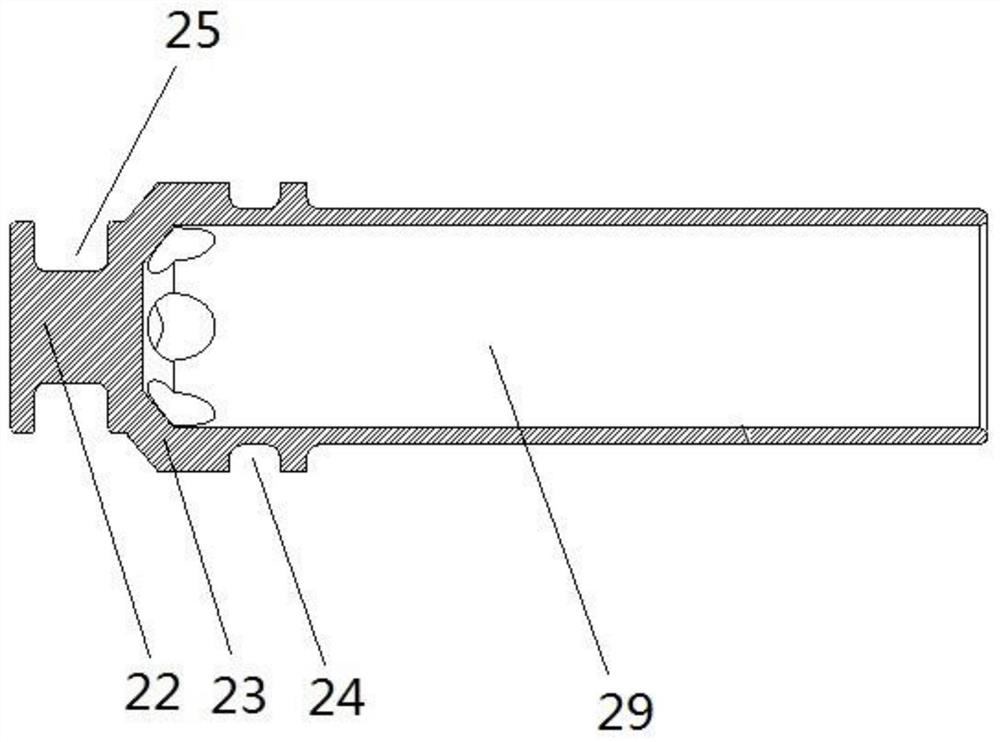

[0028] Such as Figure 1 to Figure 5 As shown, the present invention is an embedded fluid connector that can be floated and the spring is not exposed to the flow channel, including a male end connector and a female end connector. The male end connector includes a male end main shaft sleeve 1 and a male end Install the nut 2, the male end main shaft sleeve 1 is provided with a first passage and a second passage, the first passage communicates with the second passage, the diameter of the first passage is smaller than that of the second passage, and the diameter of the first passage and the second passage is connected. The connection is a tapered surface; the male end main shaft sleeve 1 is further provided with a male end floating ring 8 at the end far away from the female end connector, and the male end floating ring 8 is connected with the male end main shaft sleeve 1 through threads, and the male end The floating ring 8 is provided with a third channel communicating with the ...

Embodiment 2

[0037] Such as Figure 1 to Figure 4 As shown, on the basis of Embodiment 1, several first vent holes are also provided on the floating ring 8 of the male end, and one end of the first vent hole communicates with the spring 7 of the male end, and the other end communicates with the floating gap. The first female end main shaft sleeve 11 is also provided with some second air holes, and the second air holes communicate with the female end spring 16, and the first air hole and the second air hole provided can ensure that the female end spring 16 and the male end The spring 7 can maintain a communication state with the external air pressure, so as to ensure the normal compression and rebound of the spring; the male end mounting nut 2 is also provided with a ninth groove, and the ninth groove is provided with a first sealing ring 4, so The outer wall of the male mounting nut 2 is also provided with threads, the male mounting nut 2 is used to connect with external equipment, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com