Patents

Literature

222 results about "Brick clamp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A brick clamp is a traditional method of baking bricks, done by stacking the unbaked bricks with fuel under or among them and then setting the fuel on fire. The clamp is considered a type of kiln. If the clamp is insulated by packing earth or mud around it, it becomes a scove kiln.

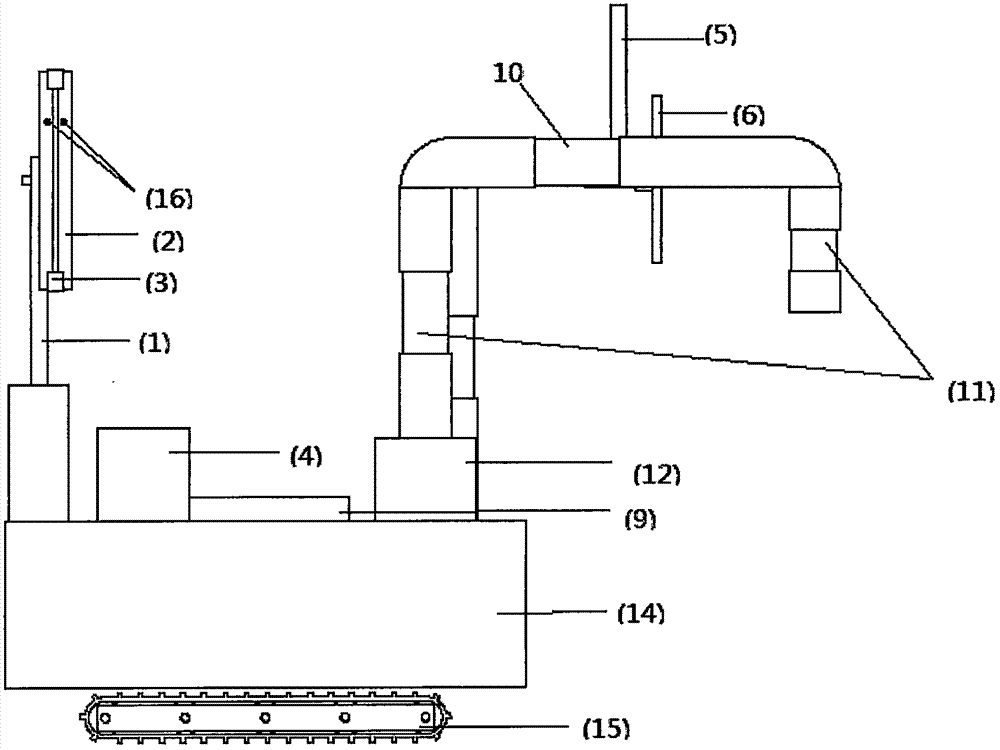

Rotary brick laying machine

The invention discloses a rotary brick laying machine. The rotary brick laying machine is mainly composed of a travelling device, a rotation device, a brick clamp, a suspension device and a support device, wherein a shovelling device is arranged at the front end of the travelling device, and a levelling plate is arranged at the rear end of the travelling device; the rotation device is arranged at the middle part above a chassis frame, a fixed disc at the lower end of the rotation device is fixedly connected with the chassis frame, the support device is arranged above a rotation sleeve disc of the rotation device, a support chassis is fixedly connected with the rotation sleeve disc, a support oil cylinder and a support arm are installed on the support chassis, and the suspension device is installed at the upper end of the support arm and the upper end of the support oil cylinder; and the brick clamp is arranged below a telescopic arm of the suspension device. The rotary brick laying machine disclosed by the invention is capable of flexibly laying floor bricks on a fan-shaped laying surface, and adaptive to lay floor bricks on curve road surfaces, large-radian road surfaces or floors, road surfaces and floors with dead angles, and other complex road surfaces and floors.

Owner:桑胜军

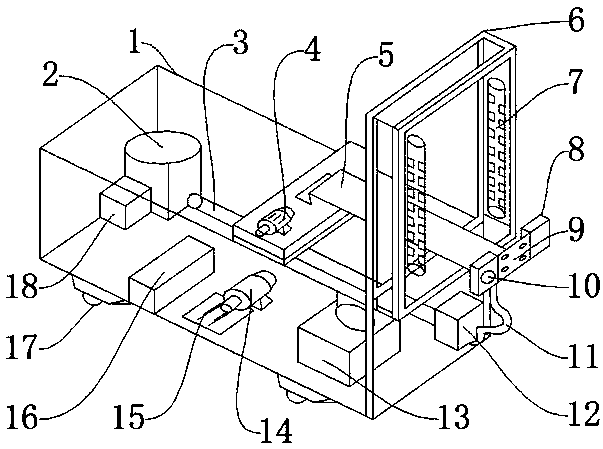

Wall building robot and working method thereof

PendingCN107443353APrecise positioningReduce mistakesProgramme-controlled manipulatorGripping headsDrive motorTransfer mechanism

A wall building robot comprises a workbench body. The workbench body is provided with a brick car transferring mechanism, a double-four-axis linkage control system, an automatic claying machine, a hydraulic brick cutting machine, a brick clamping pallet, and a lifting and translation mechanism. The brick car transferring mechanism moves up and down on a workbench through a first workbench body guide rail and a second workbench body guide rail. The double-four-axis linkage control system conducts spatial positioning and moving on a brick taking manipulator. The automatic claying machine and the hydraulic brick cutting machine are parallel to each other and are both arranged across the brick clamping pallet. The automatic claying machine is connected with the workbench body through a hopper supporting plate and provided with a hopper, an impeller, and a driving motor. The hydraulic brick cutting machine is provided with a cutting blade bracket. The lifting and translation mechanism is arranged on a hollow position between a workbench body base in the workbench body and a workbench top supporting frame. The wall building robot can replace manpower to carry out brick taking, claying, brick cutting, wall building and other action, and is high in automation degree and efficiency and convenient to use.

Owner:洛阳海特智能科技有限公司

Automatic bricklaying device

InactiveCN105544998AHigh bricklaying precisionEasy to operateBuilding material handlingBrick clampEngineering

An automatic bricklaying device comprises a guide rail mechanism having a pedestal; a vertical first transmission mechanism is arranged on the pedestal, and connected with a second transmission mechanism vertical to the first transmission mechanism and capable of moving up-down along the first transmission mechanism; the second transmission mechanism is connected with a brick clamp manipulator capable of horizontally moving along the second transmission mechanism; the pedestal is provided with a brick conveyer used for placing to-be laid bricks, and a controller controlling the first and second transmission mechanisms and the brick clamp manipulator to move; the controller is respectively connected with the first and second transmission mechanisms and the brick clamp manipulator; when the automatic bricklaying device works, the first transmission mechanism drives the second transmission mechanism to move up and down; the second transmission mechanism is controlled by the controller to drive the brick clamp manipulator to horizontally move, so the brick clamp manipulator can move above the brick conveyer so as to clamp bricks; the brick clamp manipulator clamps the brick, is controlled by the controller to move to a to-be laid position, and drops the brick.

Owner:ZHEJIANG KEWANG ROBOT CO LTD

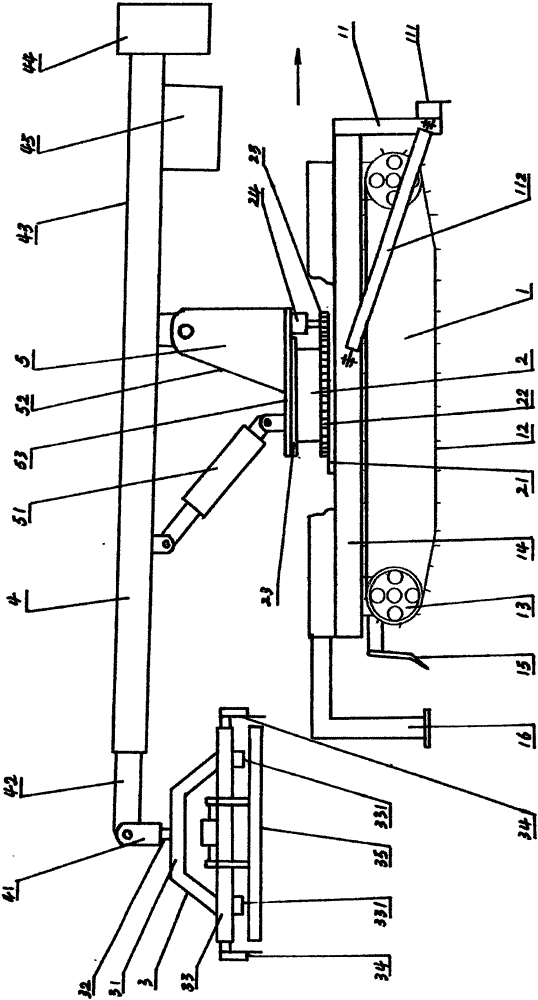

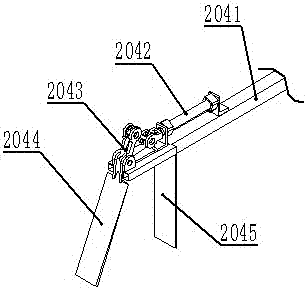

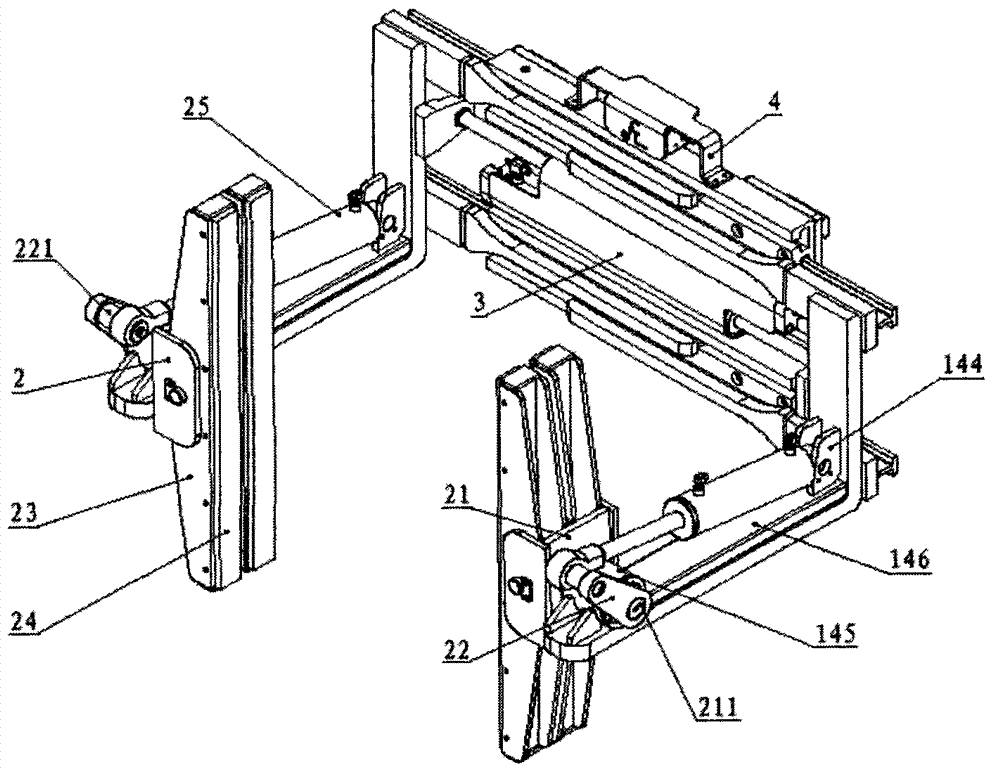

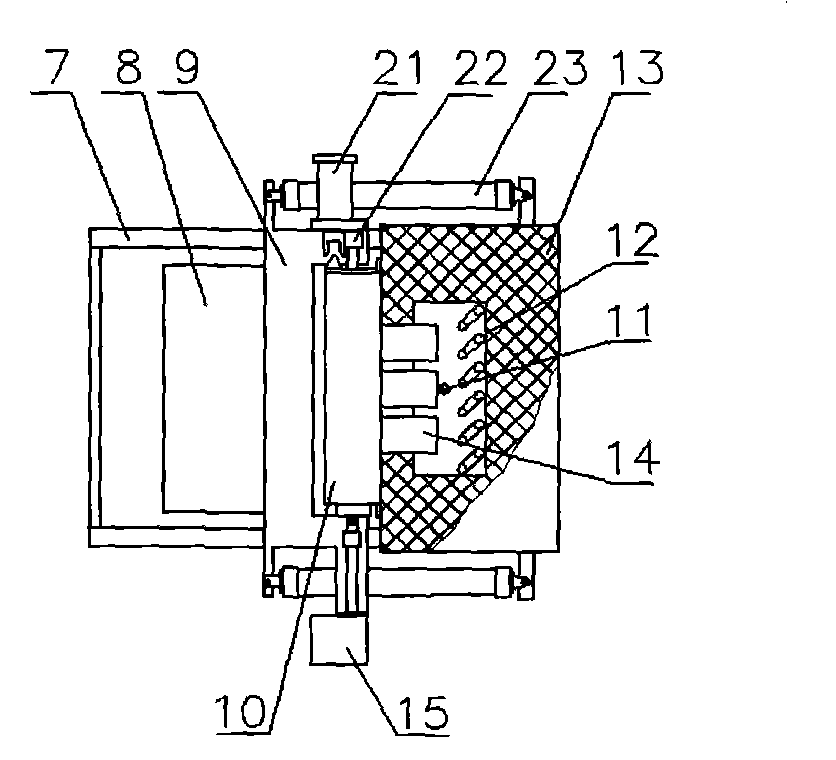

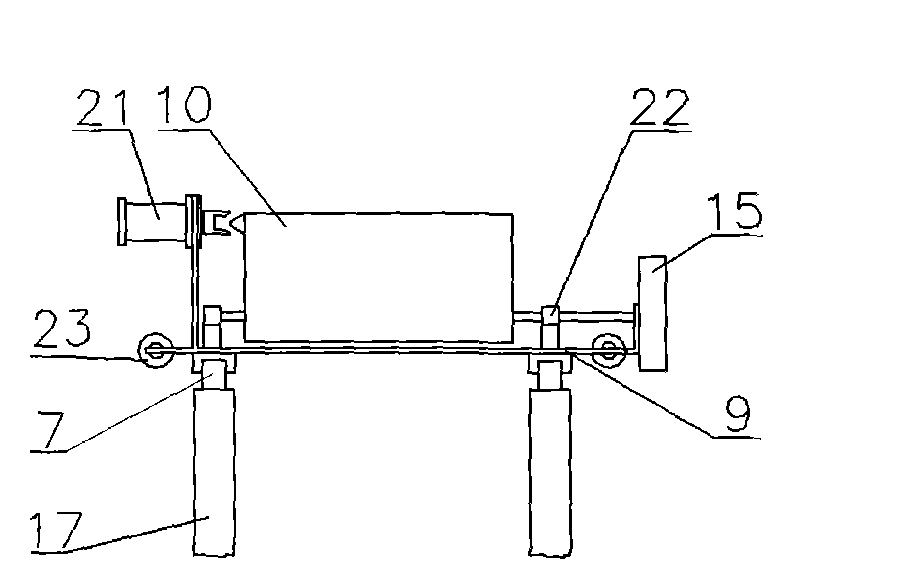

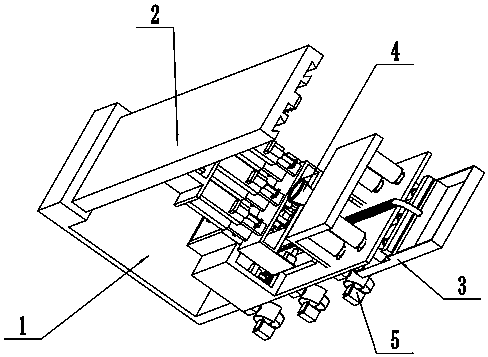

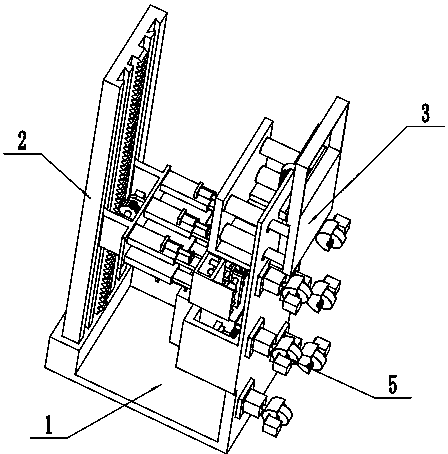

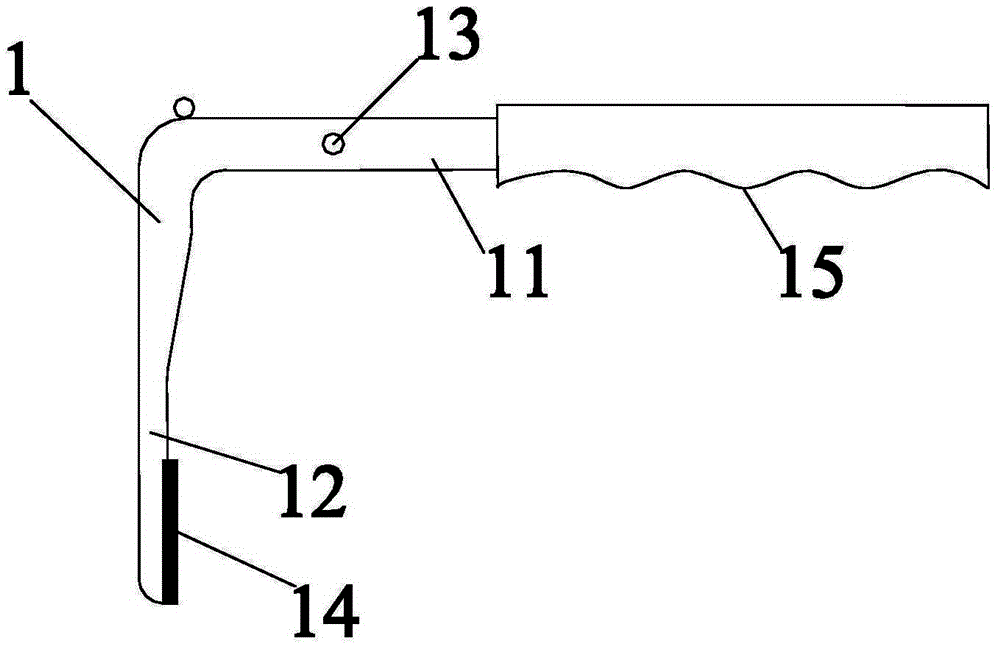

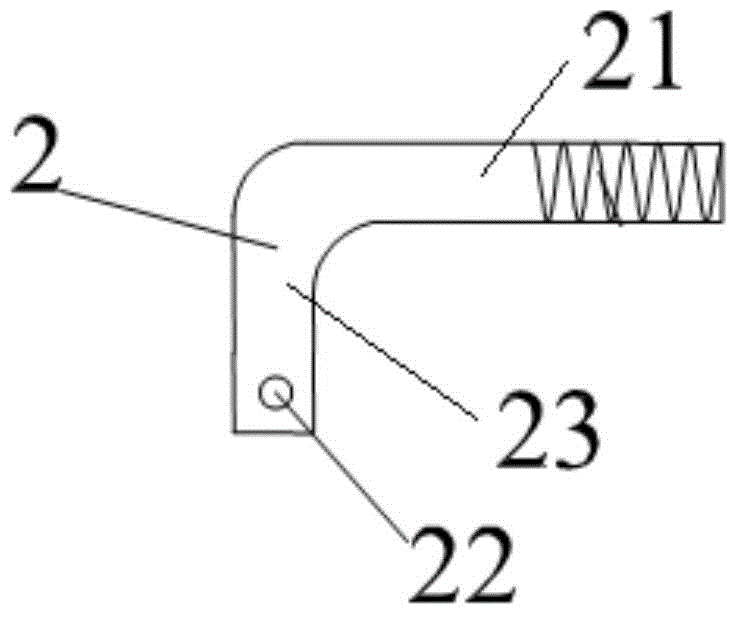

Sideways-moving tilting brick clamp

InactiveCN102730606AAchieve mechanical propertiesFully automatedLifting devicesExpanded clay aggregateBrick clamp

The invention discloses a sideways-moving tilting brick clamp. The sideways-moving tilting brick clamp comprises a sideways-moving clamping mechanism (1) which consists of a bottom plate assembly, a sideways-moving clamping cylinder, a left clamping arm assembly and a right clamping arm assembly, a left rotating arm mechanism (2) and a right rotating arm mechanism (2) which consist of a tilting cylinder, a turning fixture and a clamping arm respectively, and a hydraulic control valve, wherein under the action of hydraulic oil, the sideways-moving clamping cylinder (12) can drive left and right clamping arm assemblies (14 and 15) to loosen or clamp bricks and move sideways from left to right or from right to left simultaneously; and under the action of the hydraulic oil, the tilting cylinder (25) can drive the clamping arms to turn forwards and backwards in the range of 0 to 90 degrees around a revolving shaft. By using the sideways-moving tilting brick clamp, manual handling is not needed in the whole process of demoulding, turning, cutting, stacking and loading large aerated blocks and ceramsite hollow building blocks, thus aims of realizing mechanized and automatic operation and improving the working efficiency are fulfilled; and besides, the sideways-moving tilting brick clamp is reasonable, complete, compact and simple in structure and high in stability and firmness.

Owner:HEFEI HANDBAROW APPURTENANCES TECH

Wall building machine

InactiveCN107217859ARaise the level of modernizationFast and preciseBuilding material handlingRobotic armControl system

The invention relates to a wall-laying machine, which is mainly composed of a control system, a brick grabbing device, a cement spraying hose, a smoothing device, a motor, a positioning device, an adjusting device, a box platform and a moving system based on dynamics and power transmission. . Wherein the brick grasping device is composed of a mechanical arm, a sliding clamping groove, a brick clamp and a brick clamping positioning device. The cement spraying hose is composed of a hose horizontal adjustment device, a hose vertical adjustment device and a hose positioning device. Wherein the smoothing device is composed of a smoothing plate, a smoothing level adjustment device, a smoothing vertical adjustment device and a smoothing positioning device. The box platform is used to hold cement and support brick grabbing device, cement spraying hose and troweling device. Under the program control of the detection and positioning device and the specially compiled computer application software, the invention can quickly and accurately complete the wall-building operation, and its efficiency far exceeds that of manual operation. Not only has the quality of the wall been greatly improved, but also the construction progress has been accelerated and the labor cost has been reduced. The promotion and application of this technology and products will effectively improve the modernization level of the public facilities industry and create good economic effects for the society.

Owner:CHONGQING JIAOTONG UNIVERSITY

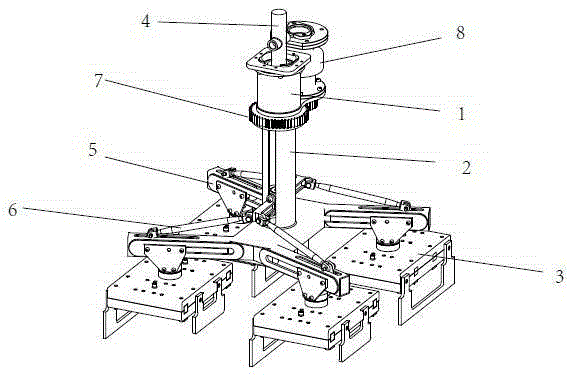

Multifunctional robot gripper for piling of special-shaped bricks

ActiveCN106041985AAvoid damageMeet the needs of code bricksGripping headsStacking articlesBrick clampGrippers

The invention discloses a multifunctional robot gripper for piling of special-shaped bricks. The multifunctional robot gripper comprises a substrate, wherein two parallel substrate guiderails are fixed on the bottom surface of the substrate along the left and right sides; a fixed gripper connection block is fixed at the middle part of each of the two substrate guiderails; substrate sliding blocks are connected with the substrate guiderail on two sides of each fixed gripper connection block in a sliding manner; a gripper connection plate is fixed on each of the substrate sliding blocks and the fixed gripper connection blocks; a brick placing air cylinder fixing plate is connected with each of every two left-right symmetrically arranged gripper connection plates; and a finger component is connected with each of the brick placing air cylinder fixing plates on the front and rear sides. According to the multifunctional robot gripper for piling of special-shaped bricks, the brick clamping direction of the gripper is perpendicular to the length direction of the substrate, so that two bricks can be combined during the piling and then the brick piling demand can be better satisfied. The multifunctional robot gripper not only can be used for piling special-shaped bricks, but also can be used for piling flat-bottom bricks through directly replacing a clamping plate.

Owner:TIANJIN YANGTIAN TECH CO LTD

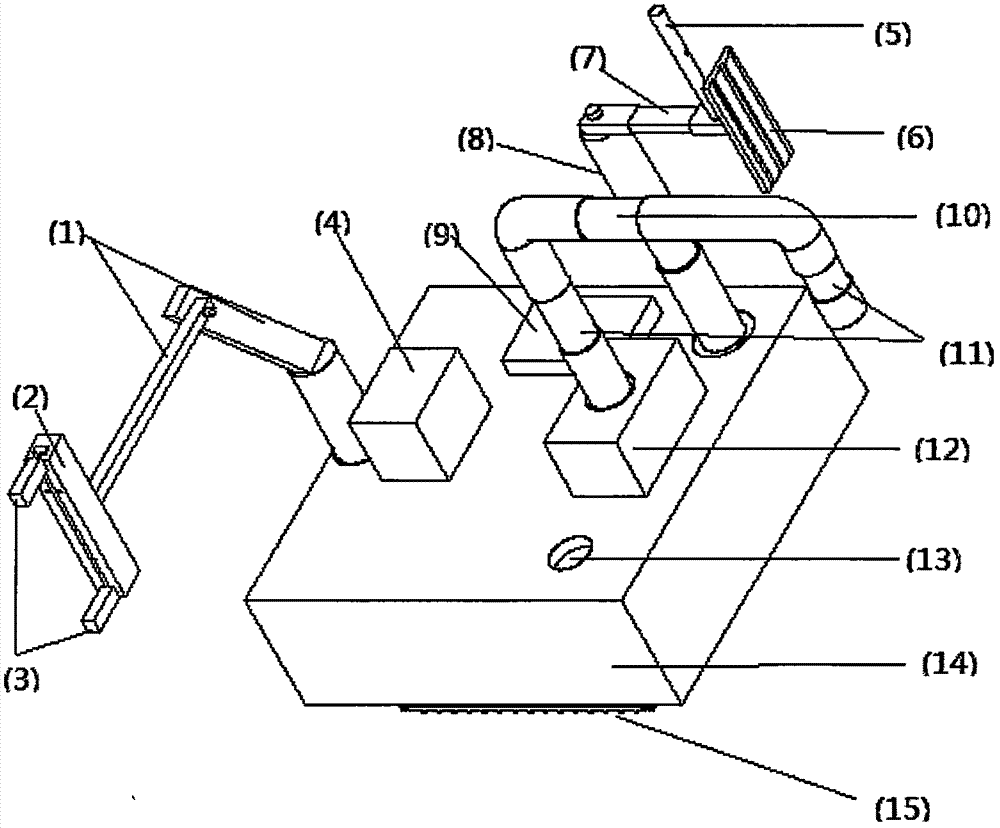

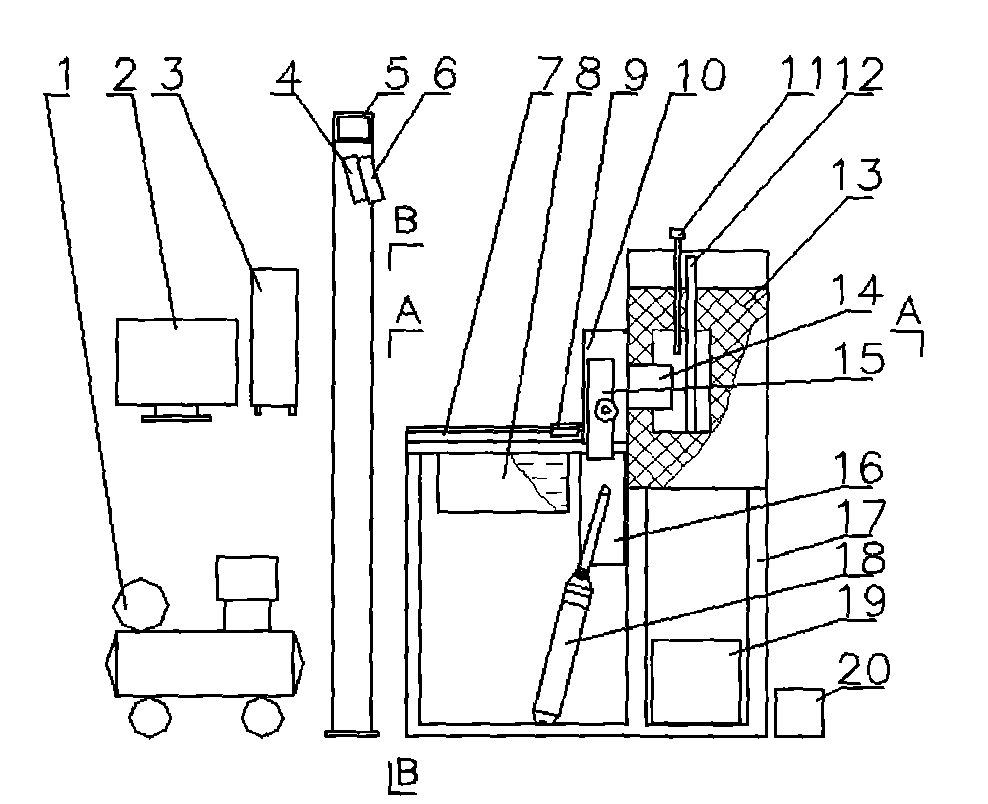

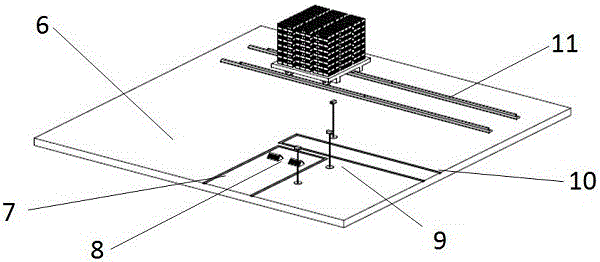

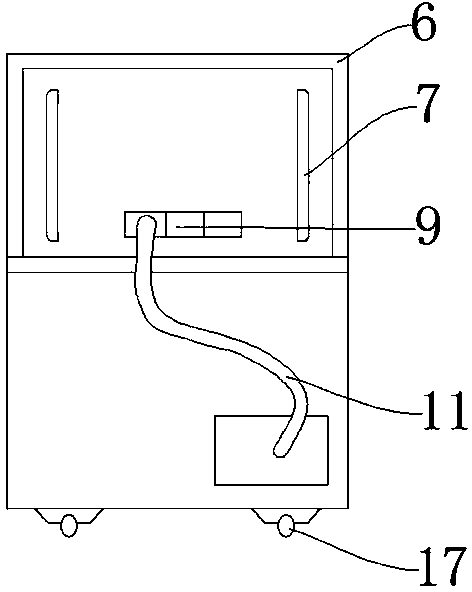

Testing device for high temperature thermal shock resistance of refractory material and application method thereof

The invention relates to a testing device for high temperature thermal shock resistance of a refractory material and an application method thereof. The invention adopts the technical scheme that a heating body 12 and a thermocouple 11 are installed in a heating furnace 13, a cooling water tank 8, a slide rail 7 and a camera 6 are arranged at the front of the heating furnace, a sliding frame 9 is arranged on the slide rail 7, a brick clamping device 10 is installed on the sliding frame 9, a sample 14 is placed in the brick clamping device 10, an original image of the measured surface of the sample 14 is collected through the camera 6, the sample 14 is sent into the heating furnace 13 for heating and heat preservation after the heating and the heat preservation of the heating furnace 13, water cooling is carried out for the sample 14 after being discharged from the furnace, then the sample 14 is placed in the air for cooling, the image of the measured surface of the sample 14 after testing is collected through the camera 6, the area and the breakage rate of the measured surface of the sample 14 are computed, and the high temperature thermal shock resistance of the sample 14 is measured according to the rule of YB / T 376.1-1995. The testing device has the characteristics of high automation degree, accurate test result and high testing efficiency.

Owner:WUHAN UNIV OF SCI & TECH

Brick pile packaging and loading mechanical integrated system equipment

InactiveCN105731089ACollection of bricks improvedEasy to packPackagingStacking articlesBrick clampEngineering

The utility model relates to an integrated system equipment for brick packing and loading mechanization, which belongs to the field of machinery. The equipment includes a brick packing machine, a brick collecting platform, a brick clamping machine, a car loading machine and a floor. The brick clamping machine includes the main beam frame, the brick clamping assembly and the brick clamping machine small sports car. The brick clamp assembly includes the folding arm of the brick clamp machine, the rotating frame and the movable brick clamp group. The folding arm is connected with the small sports car of the brick clamping machine. The folding arm of the brick clamping machine is connected to the frame through the rotating frame, and the brick clamping box is installed on the frame of the rotating frame. Brick stacking baler includes baler, push baler and delivery roller frame. The baler includes a column, a lifting platform, a lead screw, a base and a baler set brick table. The lifting platform uses the power of the control box to make the lead screw reciprocate up and down to drive the lifting platform up and down. The car loading machine includes machine beams, columns, small sports car frame, car loading machine brick clamps, sports car working platform, hoist, hydraulic power unit and control box. The invention integrates bricks, packing and loading into one body, and improves the efficiency of brick collection, packing and loading in a brick factory.

Owner:张利平 +1

Clamping device and brick clamping machine using same

ActiveCN102815645ASolve many inconvenient problems such as time-consuming and laboriousIncrease forceLifting devicesBrick clampEngineering

The invention discloses a clamping device and a brick clamping machine using the same. The clamping device comprises a rack and a hanging bracket which is hinged on the top of the rack and can swing forward and backward, wherein a clamp is assembled on the hanging bracket; the hanging bracket comprises a hanging bracket body hinged on the rack, and a slide carriage which is movably assembled on the hanging bracket under the guidance in leftward and rightward directions; and the clamp is assembled on the slide carriage. Leftward and rightward movement of the clamp is realized, so that left and right deviations between the clamp and brick stack loading and unloading positions can be further adjusted, and loading and unloading operation is more convenient.

Owner:河南三和水工机械有限公司

Vertical type automatic wall brick sticking device for building construction

The invention discloses a vertical type automatic wall brick sticking device for building construction. The vertical type automatic wall brick sticking device comprises a belt, an equipment bracket, aconcrete box, a lifting bracket, a laser sensor and a hydraulic lift; a brick sticking arm is arranged above the equipment bracket, a first motor is arranged above the brick sticking arm, and a pressing plate is arranged at the end, away from the first motor, of the brick sticking arm; a concrete spraying head is arranged on the side, close to the first motor, of the pressing plate; the laser sensor is arranged on the other side of the pressing plate, the lifting bracket is arranged above the pressing plate, two wall brick clamps are parallelly arranged in the lifting bracket, and the hydraulic lift is arranged below the lifting bracket; and a hose is arranged below the concrete spraying head, and a pressurizing pump is arranged below the hose. The vertical type automatic wall brick sticking device has the beneficial effects that the wall brick sticking speed is increased, the labor intensity of workers is reduced, the construction time is reduced, and the wall brick position is determined through laser, so that the sticking effect is better, more order and more attractive.

Owner:江苏阿尔博装饰工程有限公司

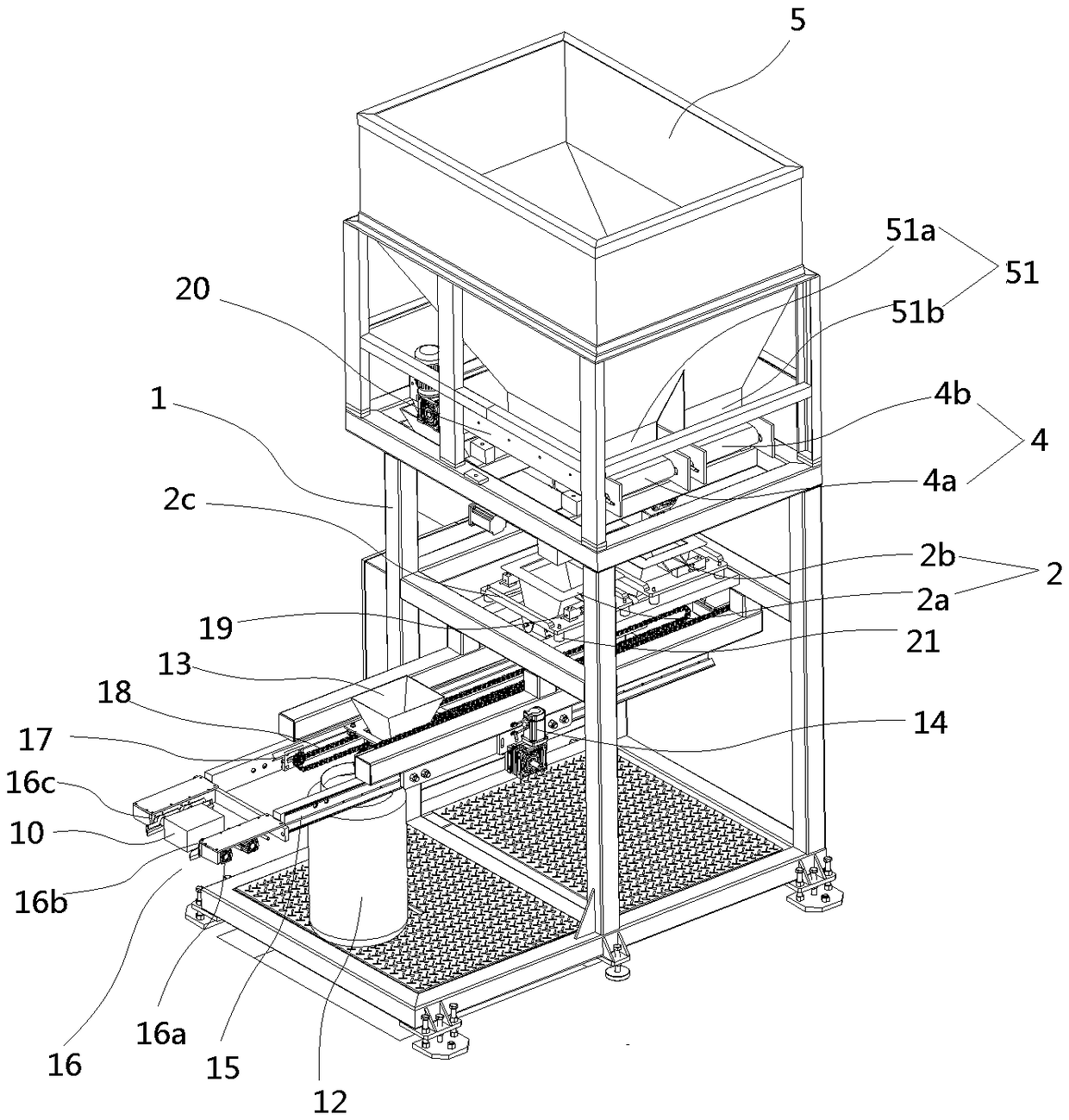

Refractory brick production equipment

ActiveCN109049283AAvoid instabilityReduce laborDischarging arrangementFeeding arrangmentsBrick clampEngineering

The invention discloses refractory brick production equipment. The refractory brick production equipment comprises a distributing device, a press and detecting device which are sequentially arranged,wherein the distributing device comprises a rack, a raw material bin and a weighing packing auger; a conveyor belt is arranged on the rack; a packing auger weighing sensor is arranged in the weighingpacking auger; a weighing hopper is arranged on a position, below a discharge hole of the weighing packing auger, of the rack; a hopper weighing sensor is arranged on the weighing hopper; a hopper isarranged on a position, below the weighing hopper, on the rack; the detecting device comprises a table rack and a clamping slide table which is in sliding fit to the top of the table rack; a conveyingchain for conveying a refractory brick is arranged on the table rack; a brick clamping mechanism for clamping the refractory brick to a charge end of the conveying chain from the press is arranged onthe clamping slide table; a detecting sensor is arranged on a position, above the conveying chain, of the table rack; and a mechanical hand for taking out the refractory brick from the discharge endof the conveying chain is arranged at one side of the table rack. The invention aims to provide refractory brick production equipment which saves labor power, and improves production efficiency.

Owner:CHANGXING RONGLI MACHINERY

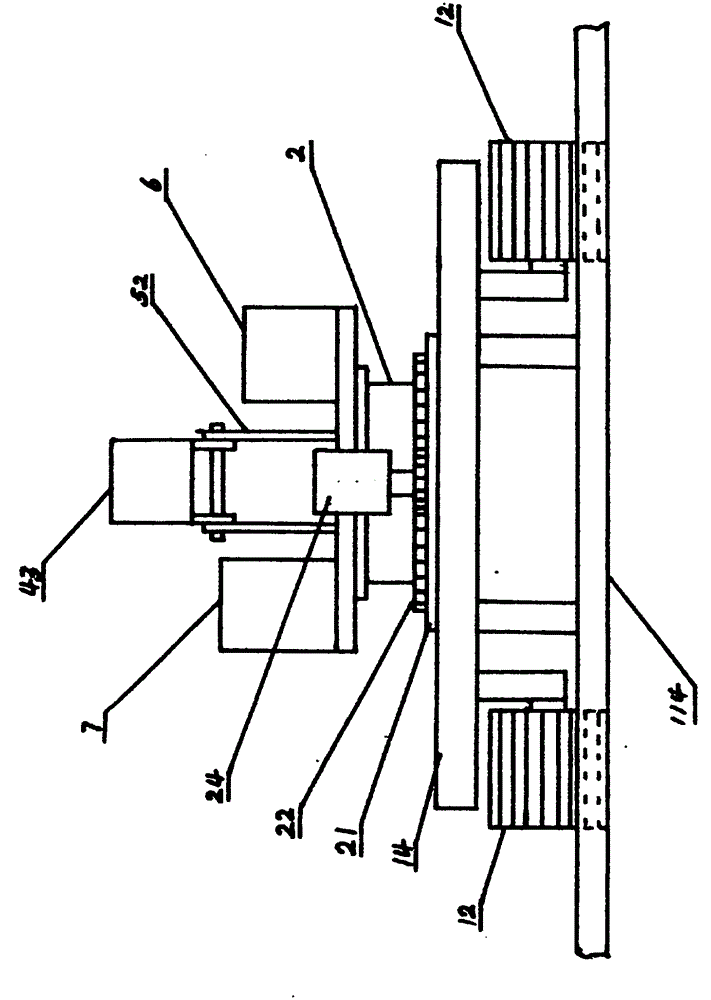

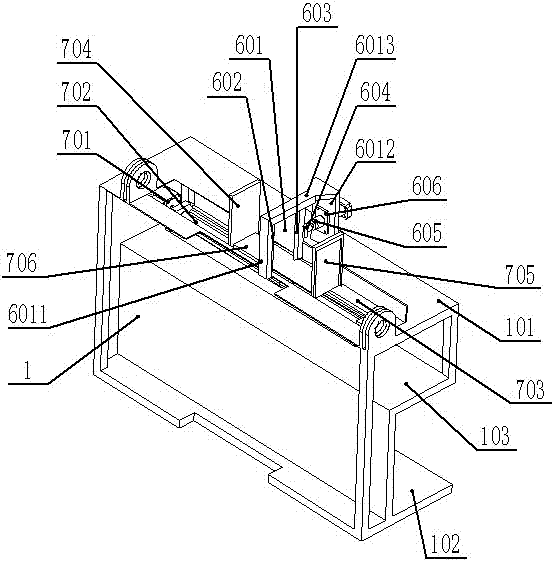

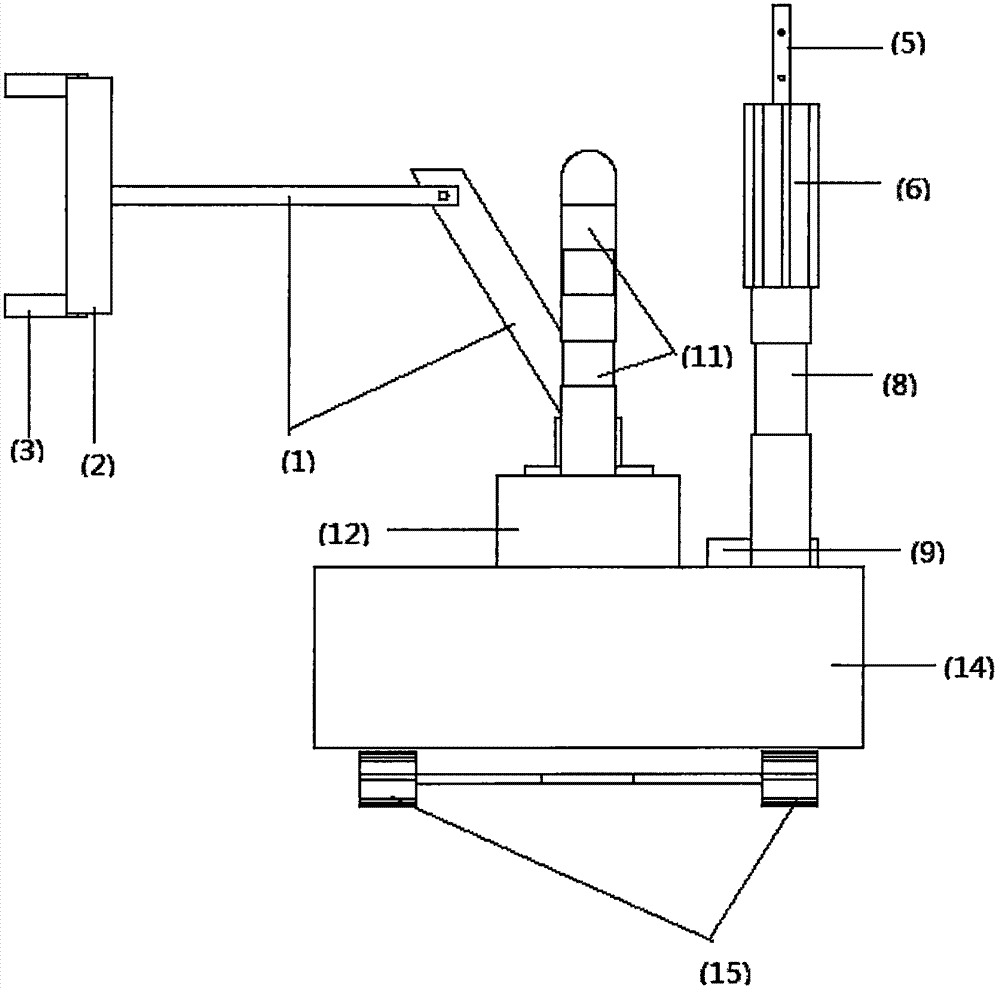

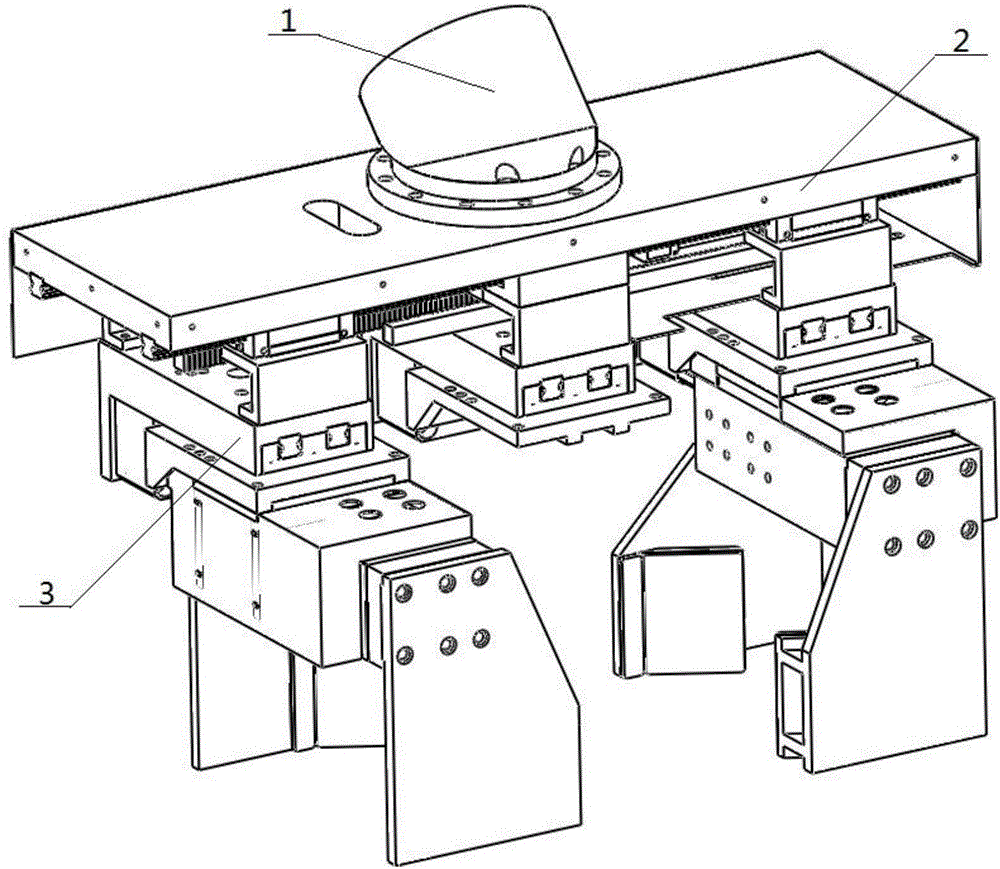

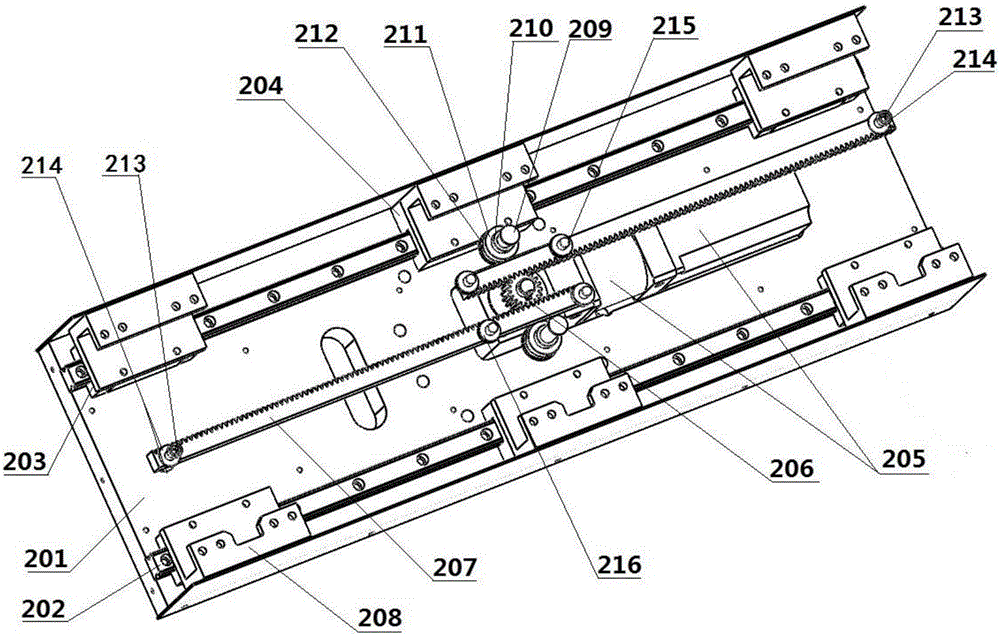

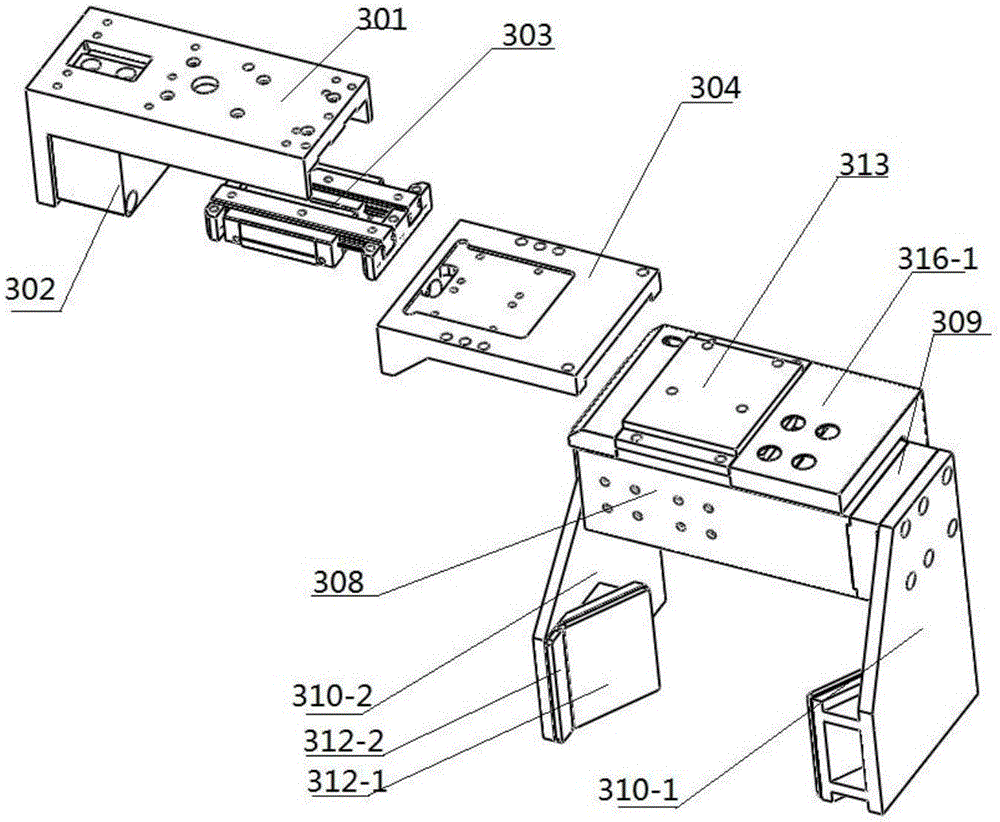

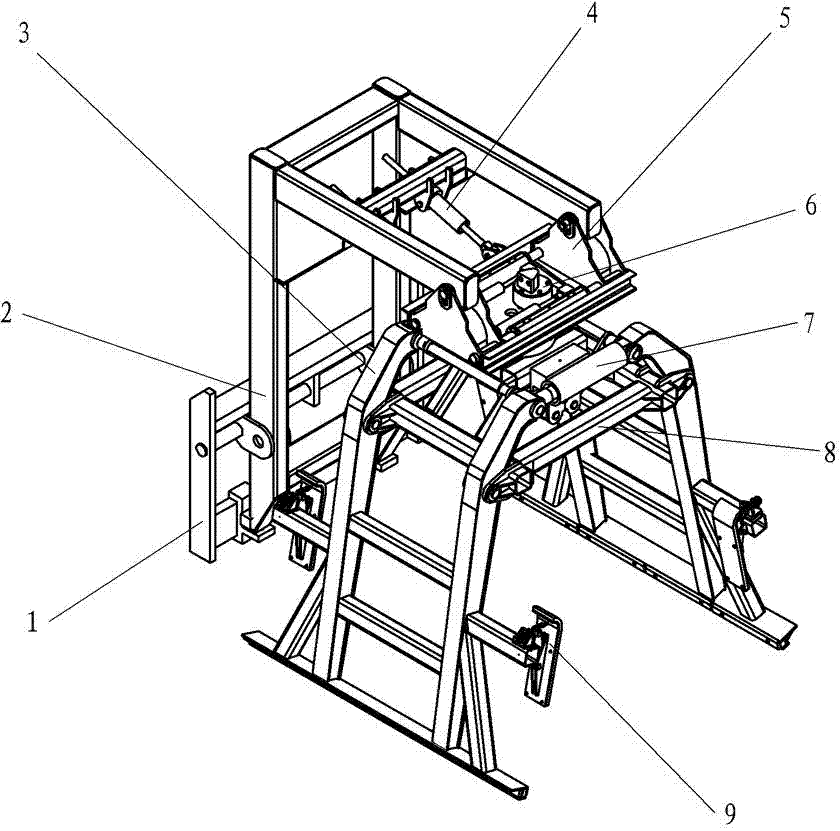

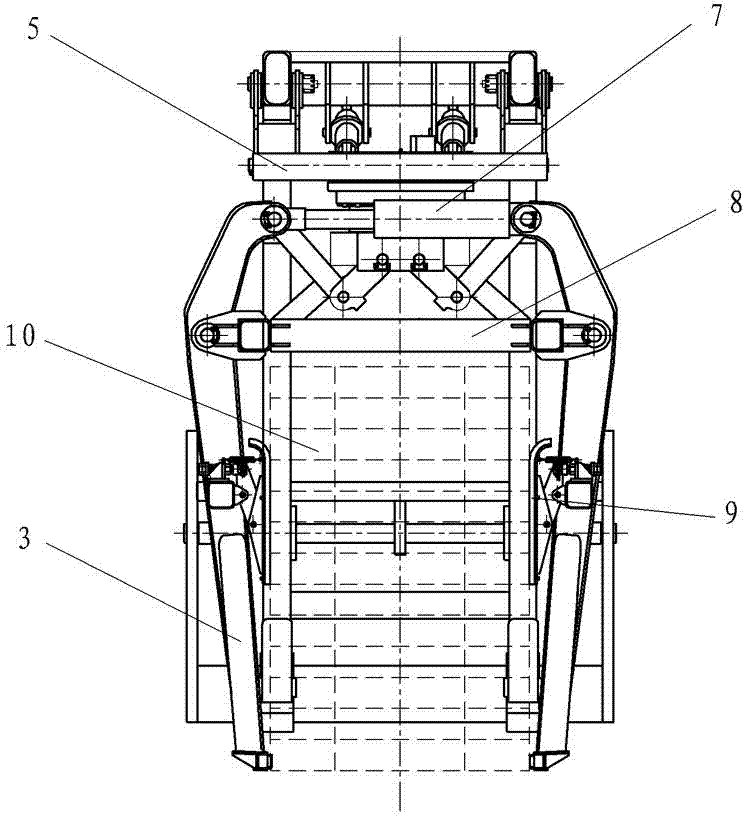

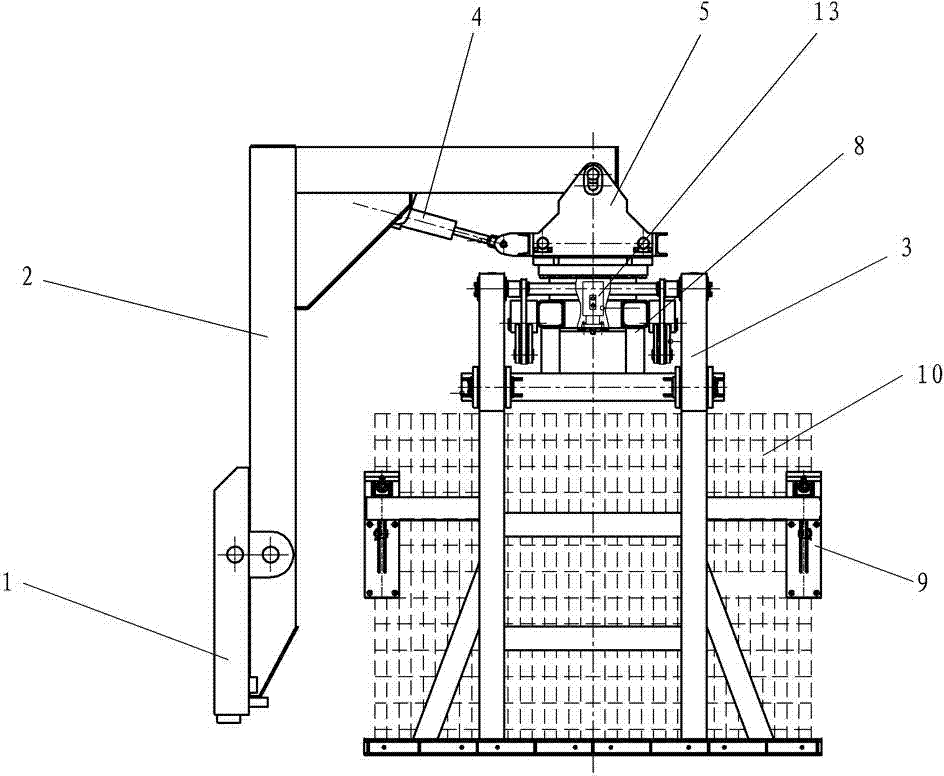

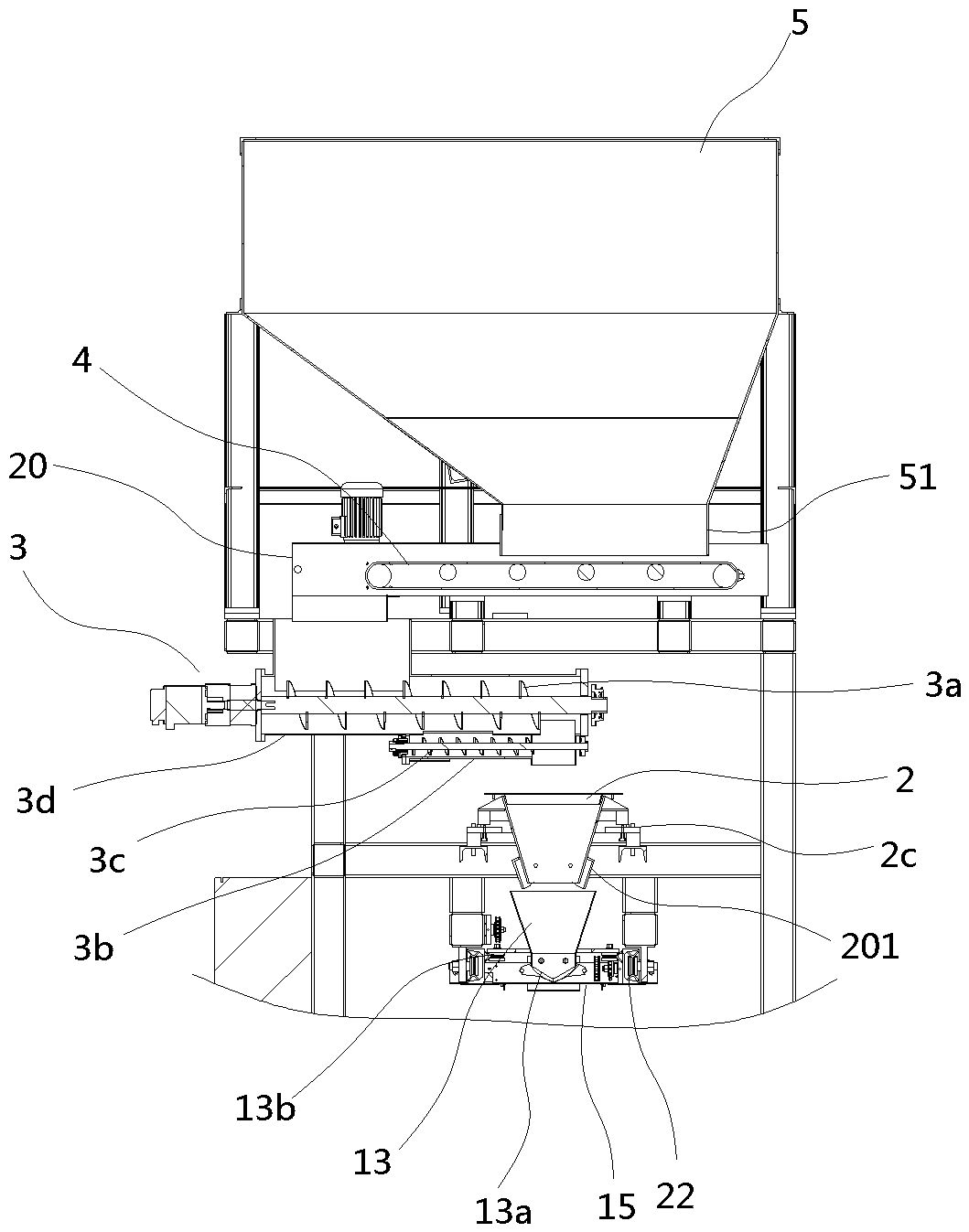

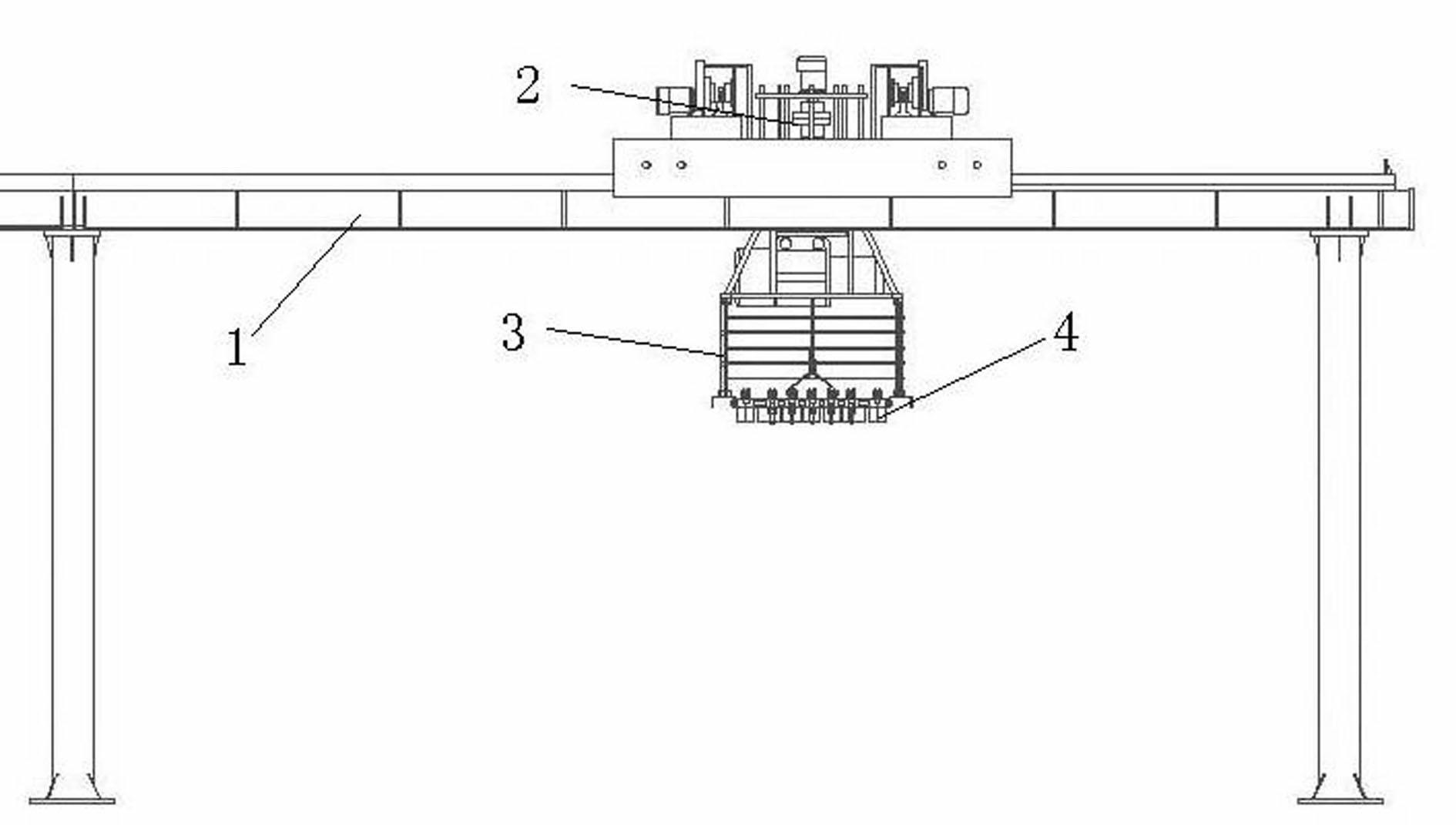

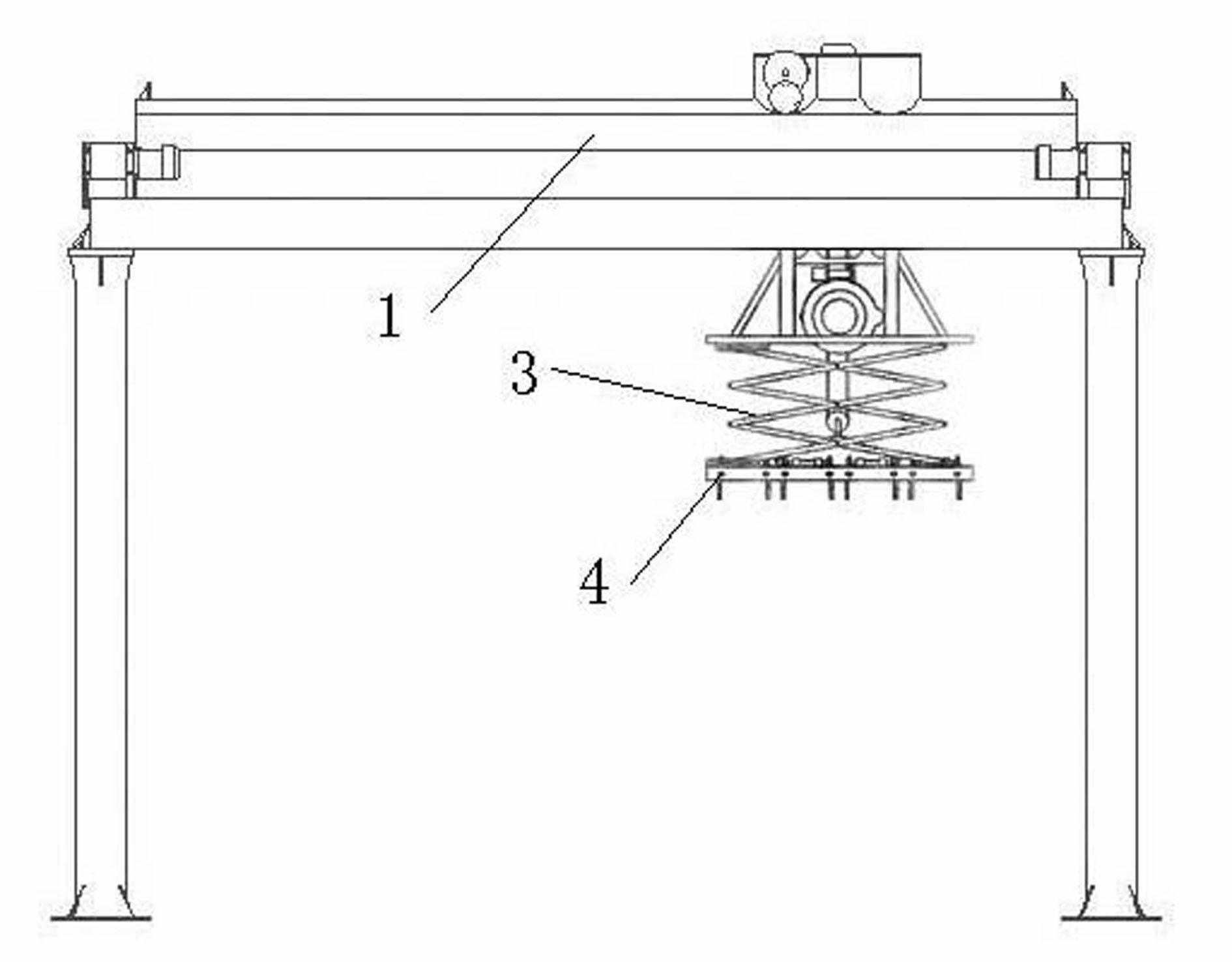

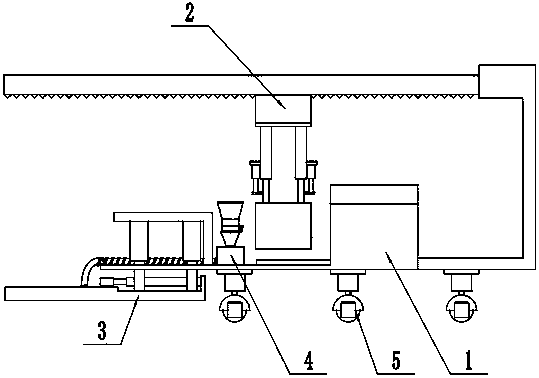

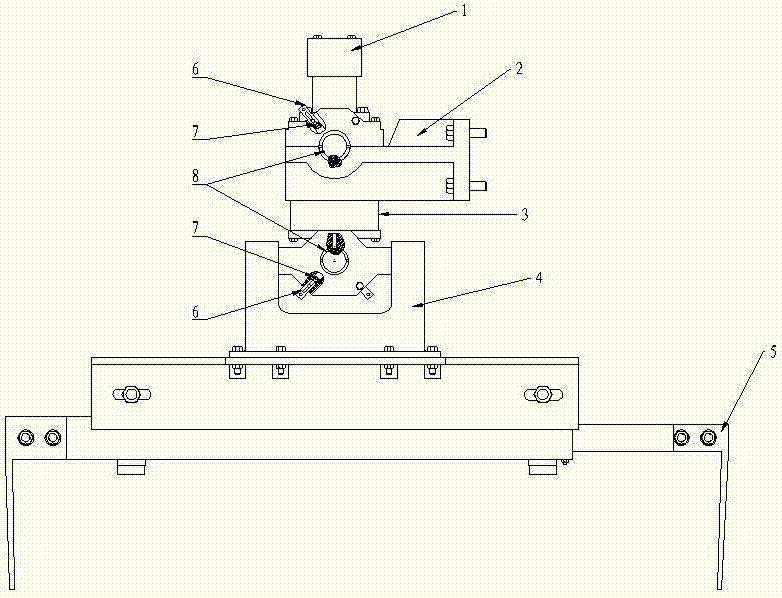

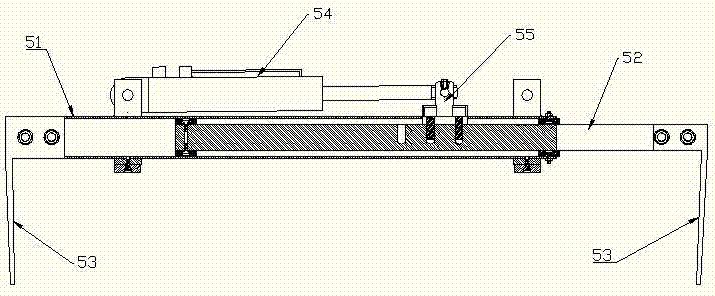

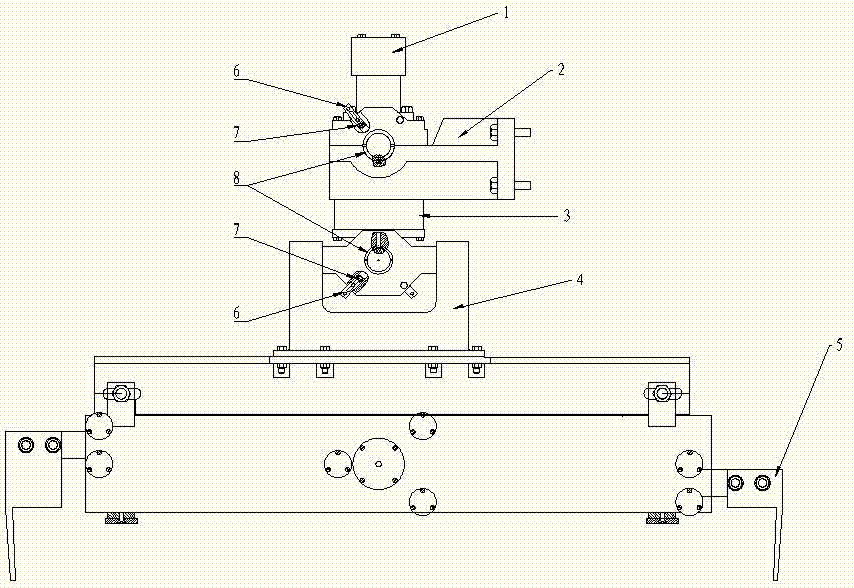

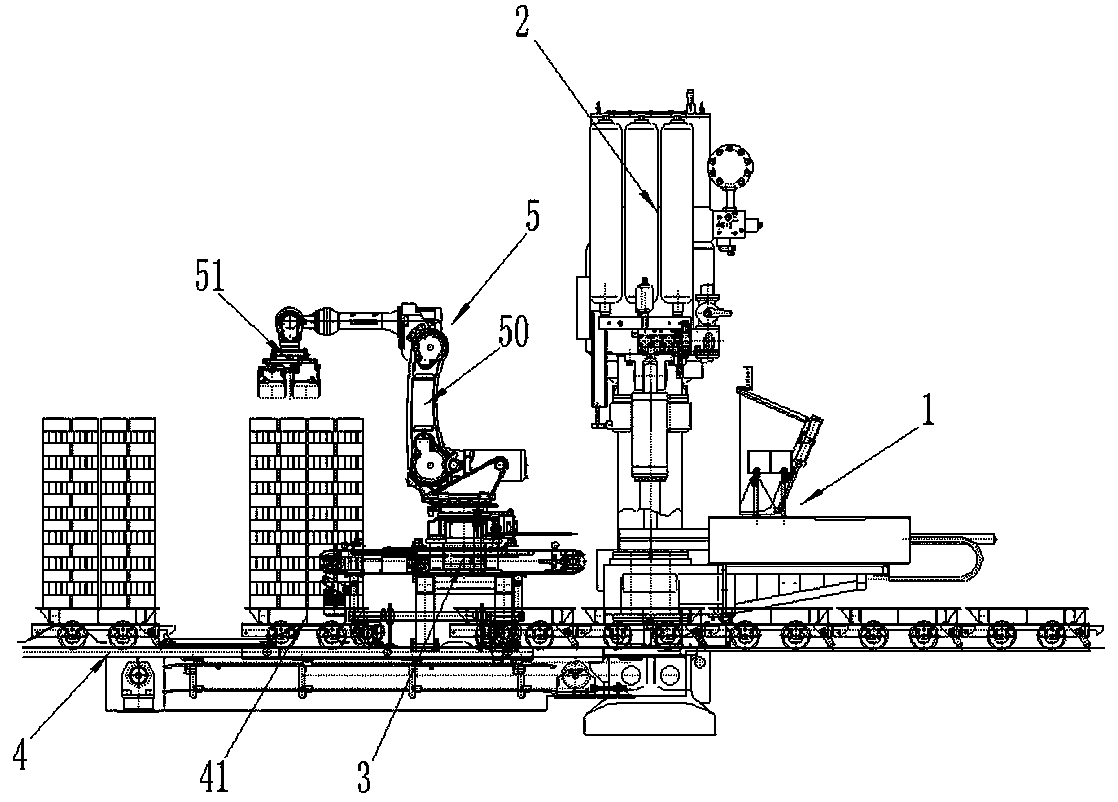

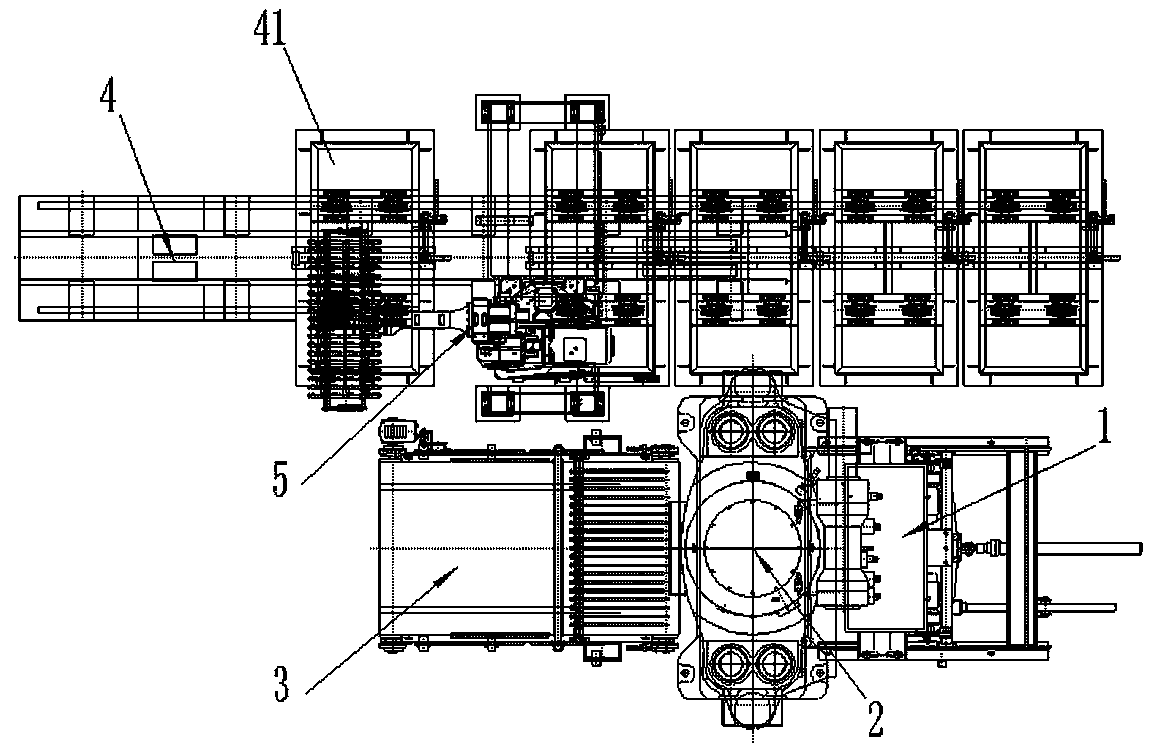

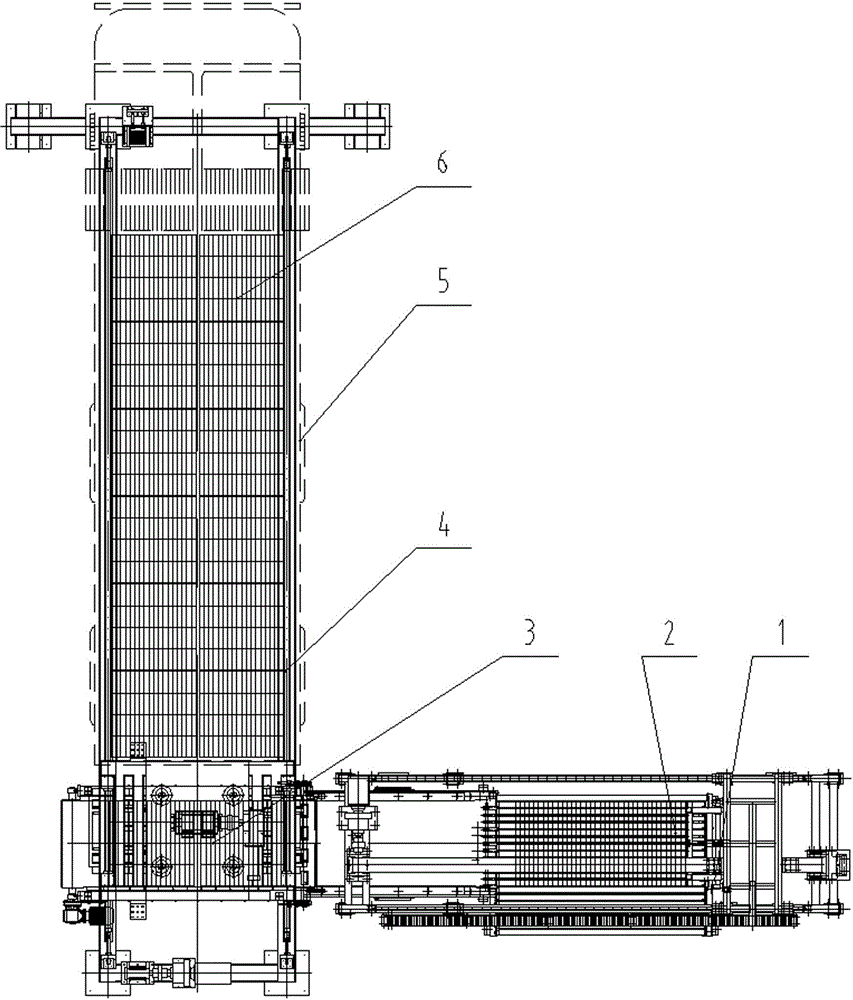

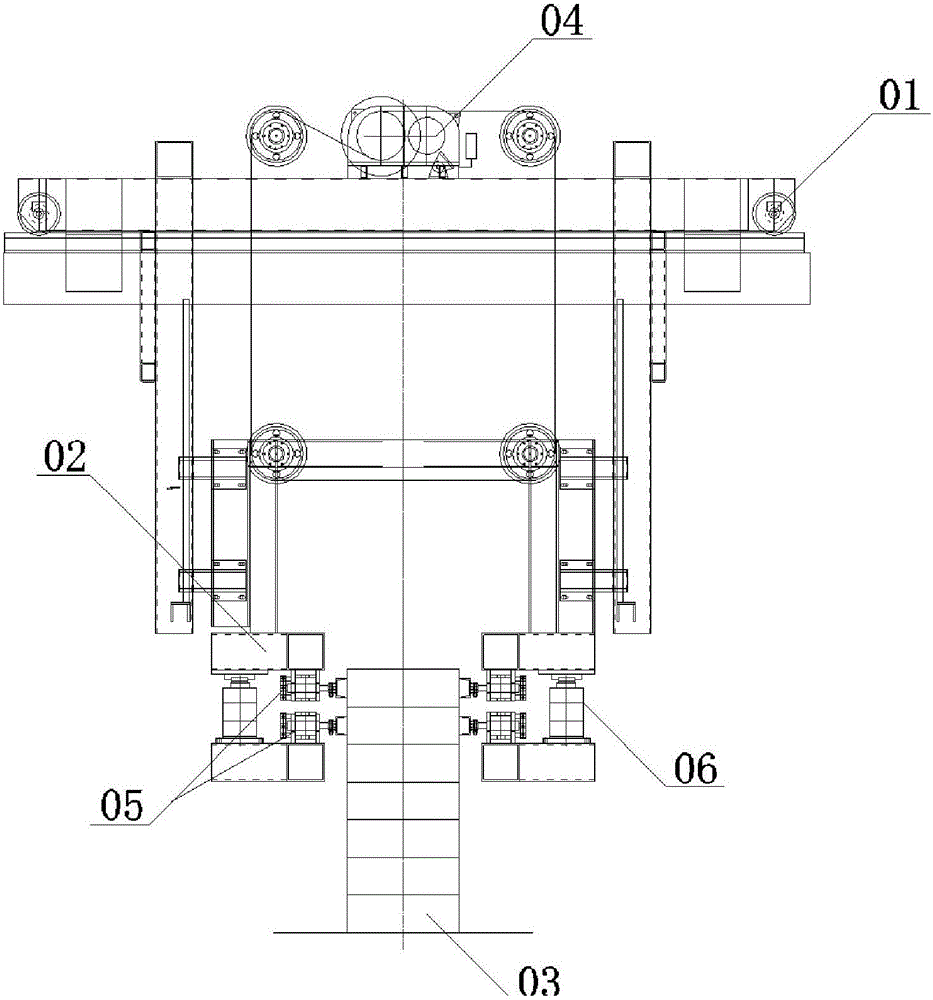

Intelligent brick clamping machine

InactiveCN102633130AFast and reliable brick unloadingRealize automatic brick unloadingStacking articlesDe-stacking articlesProgrammable logic controllerBrick clamp

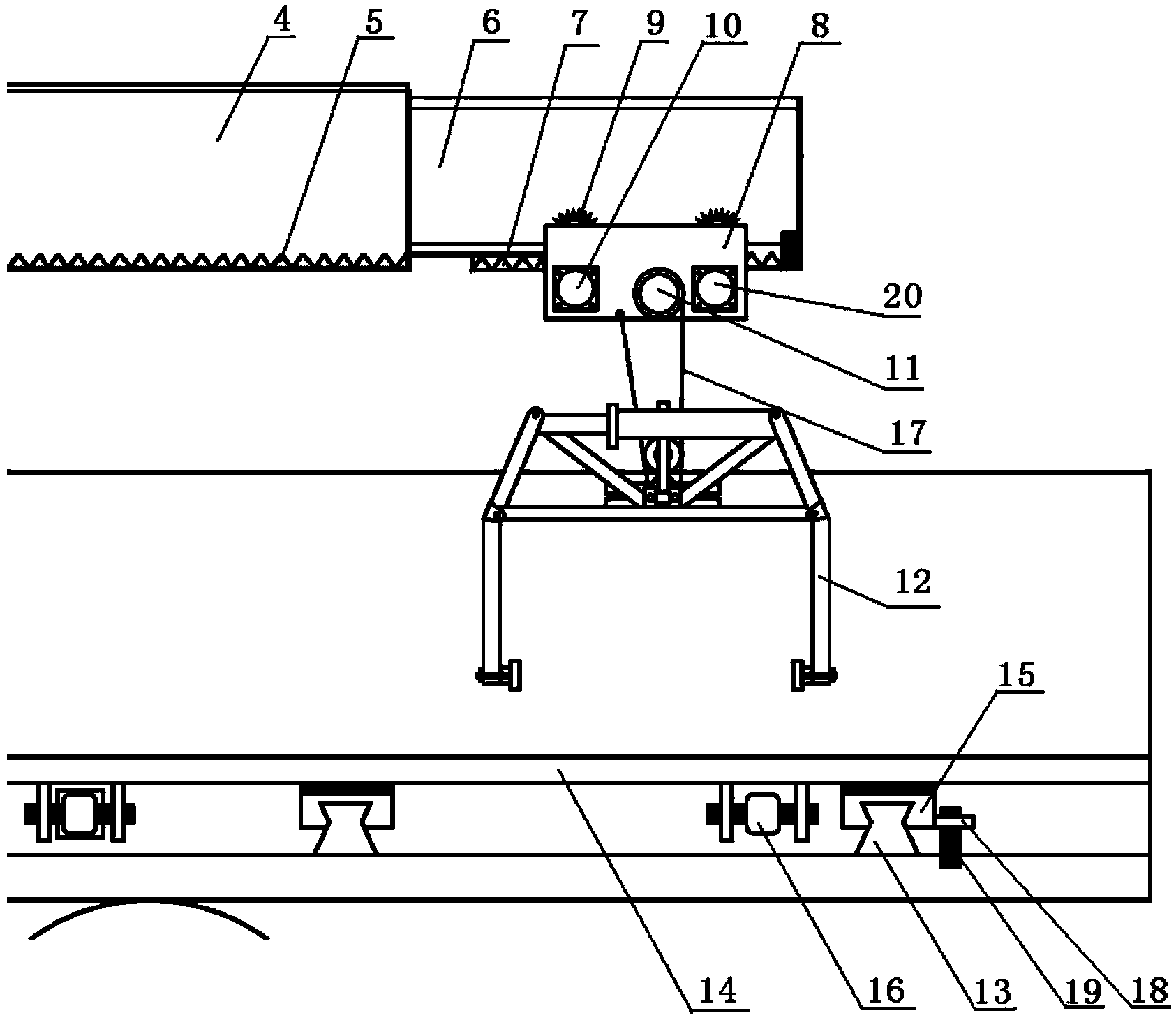

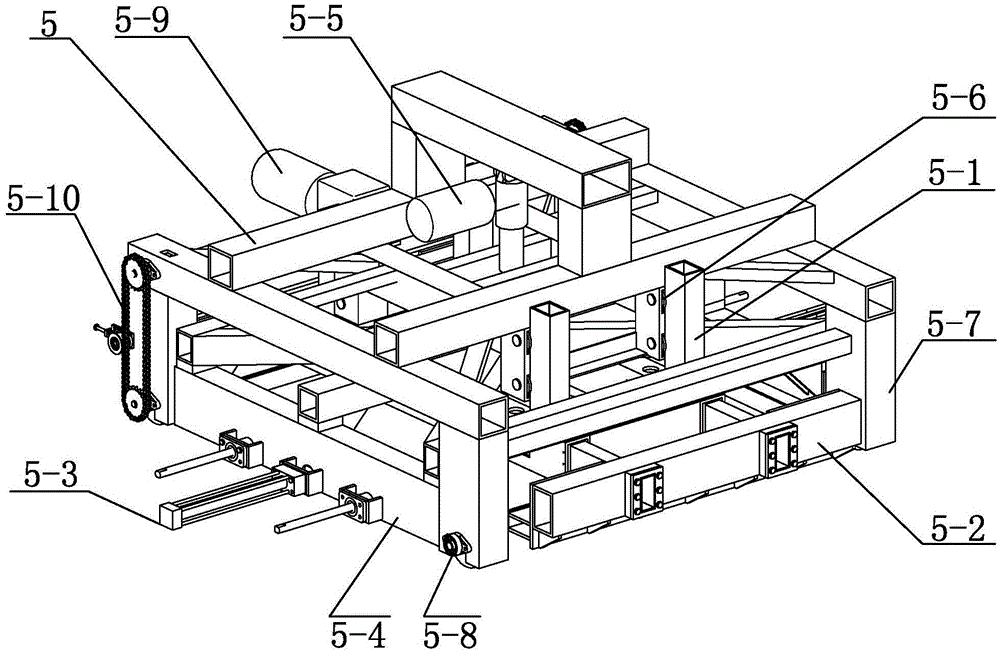

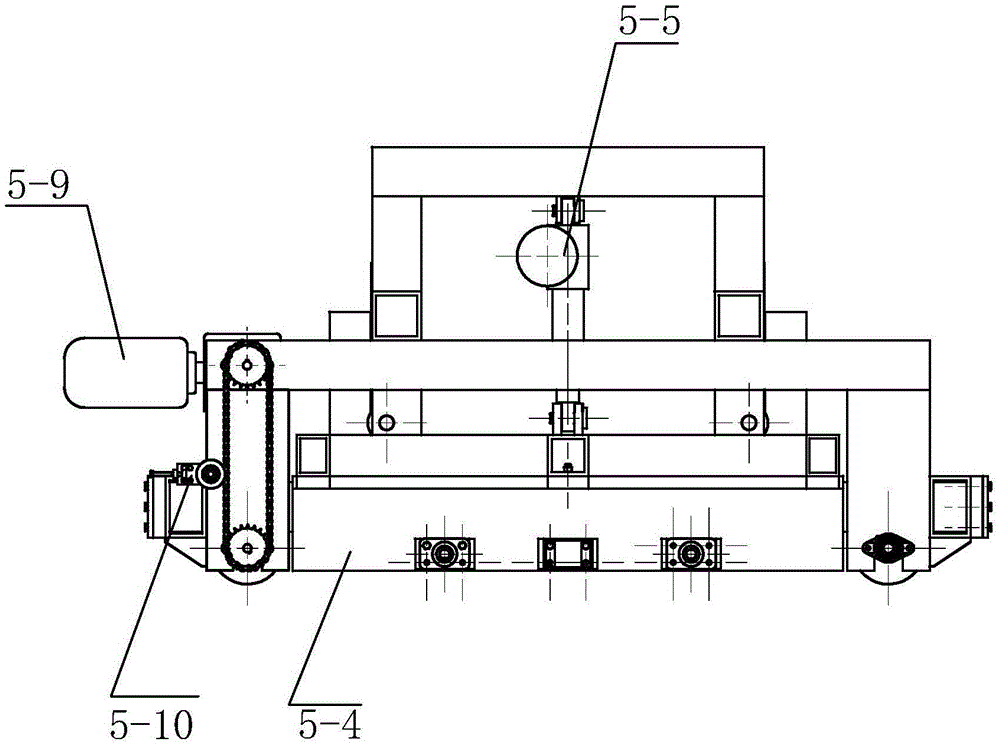

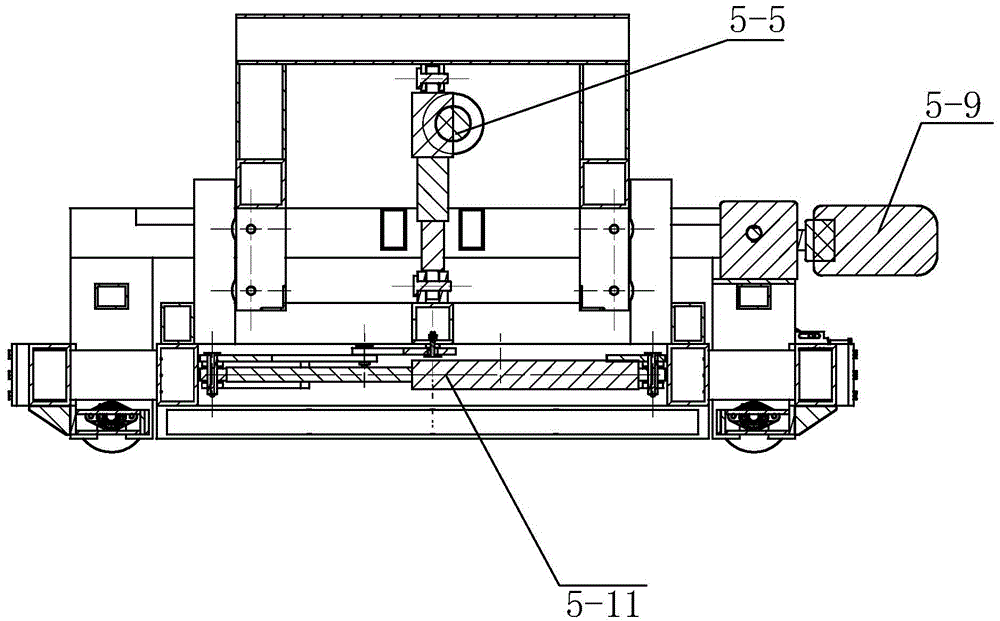

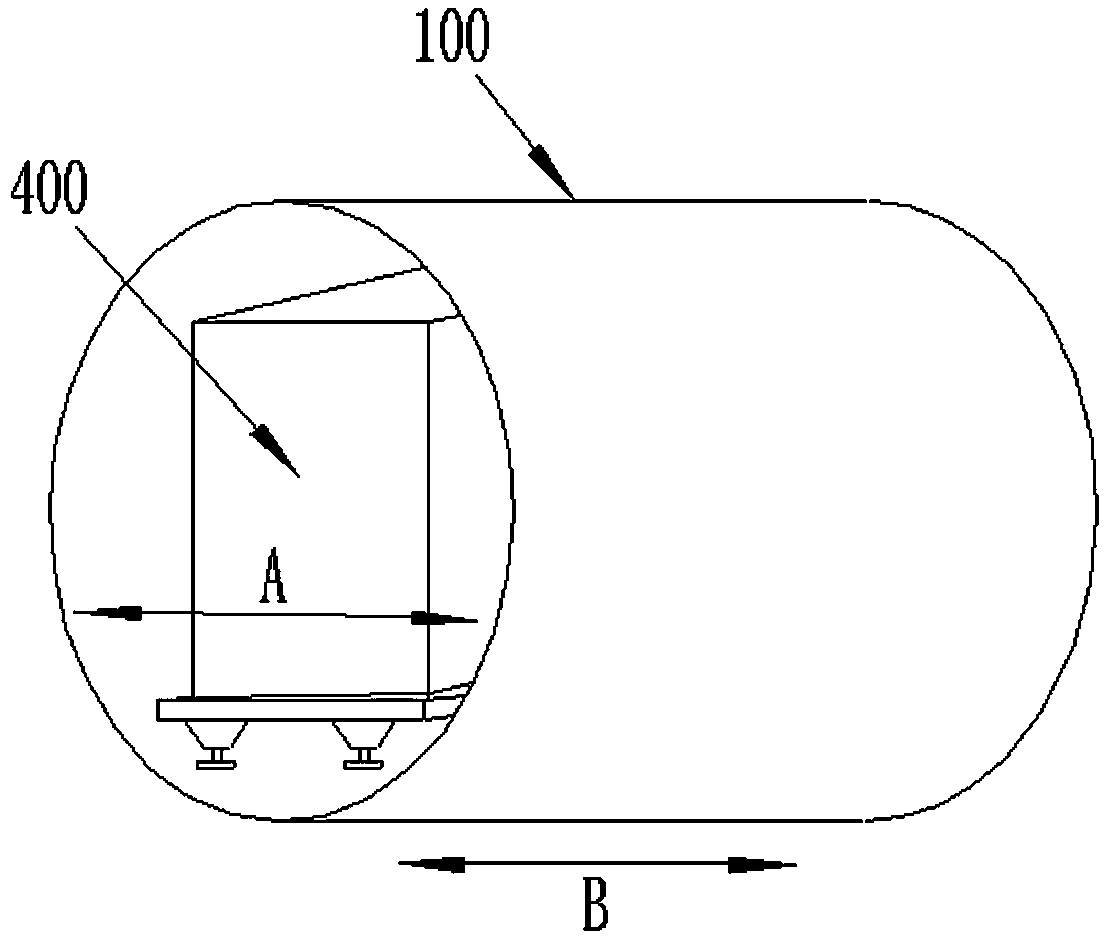

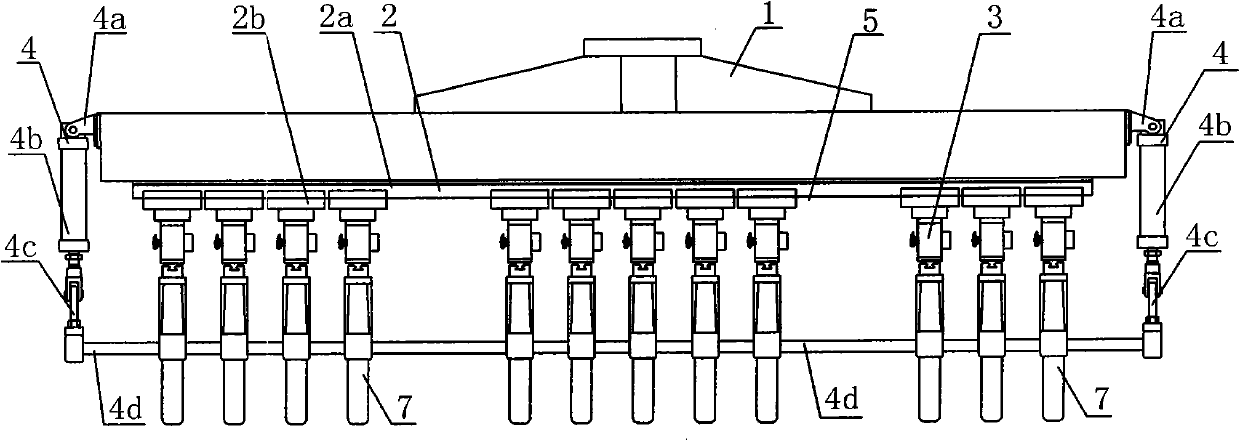

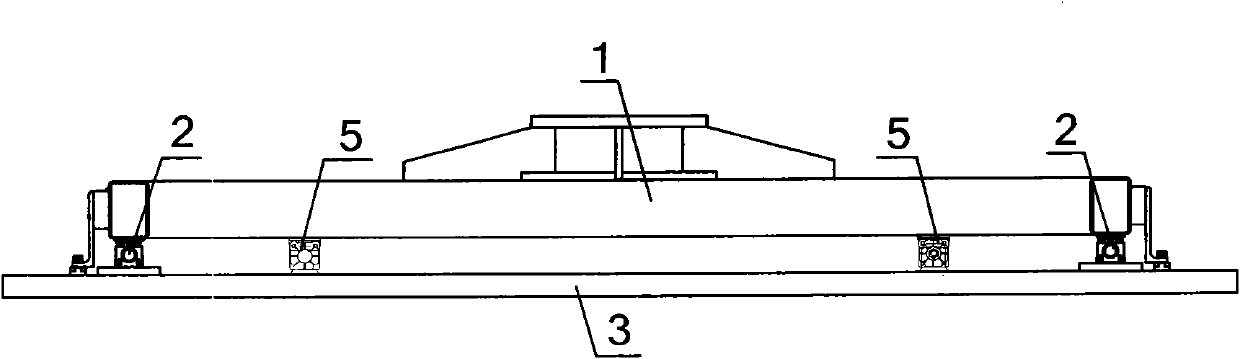

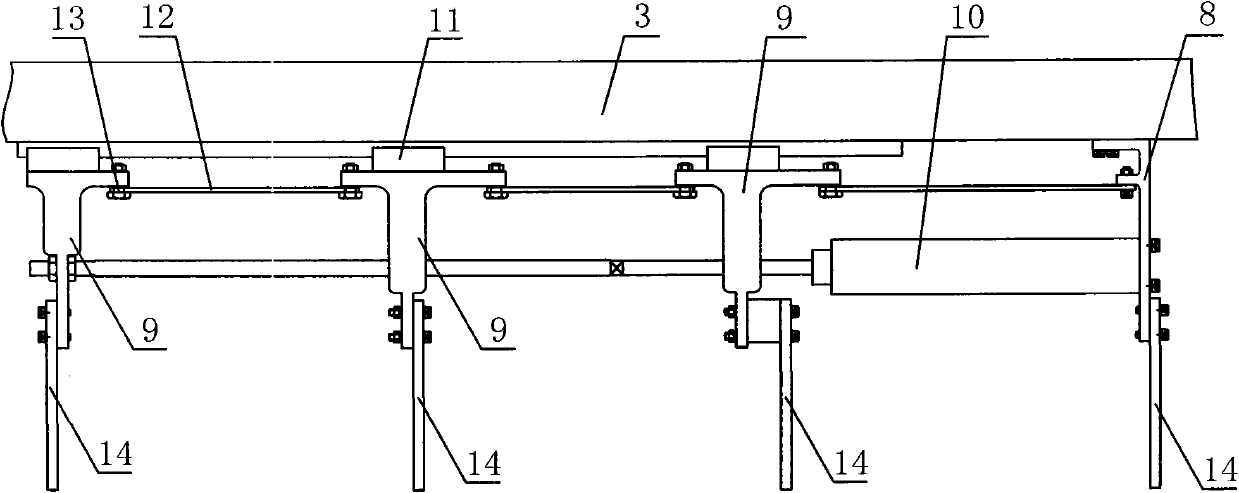

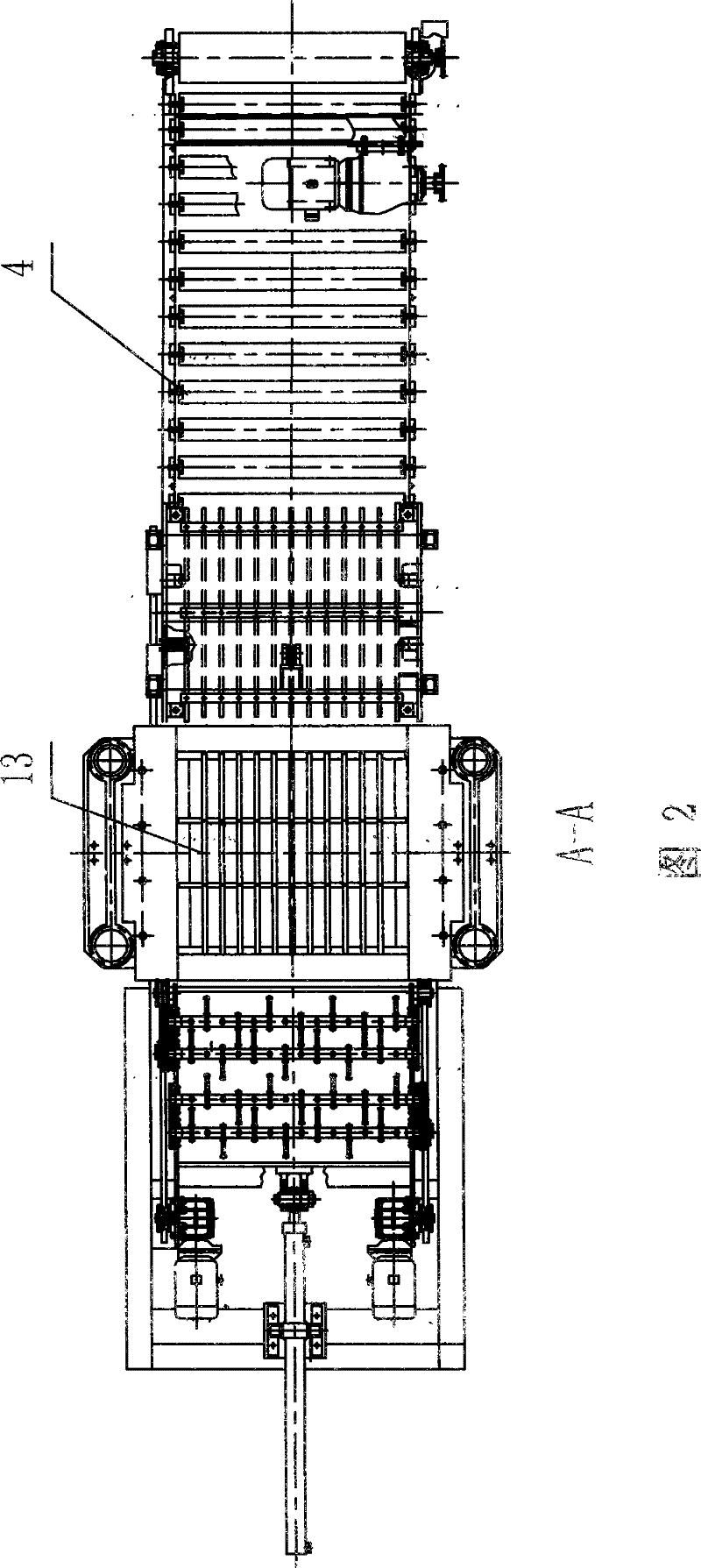

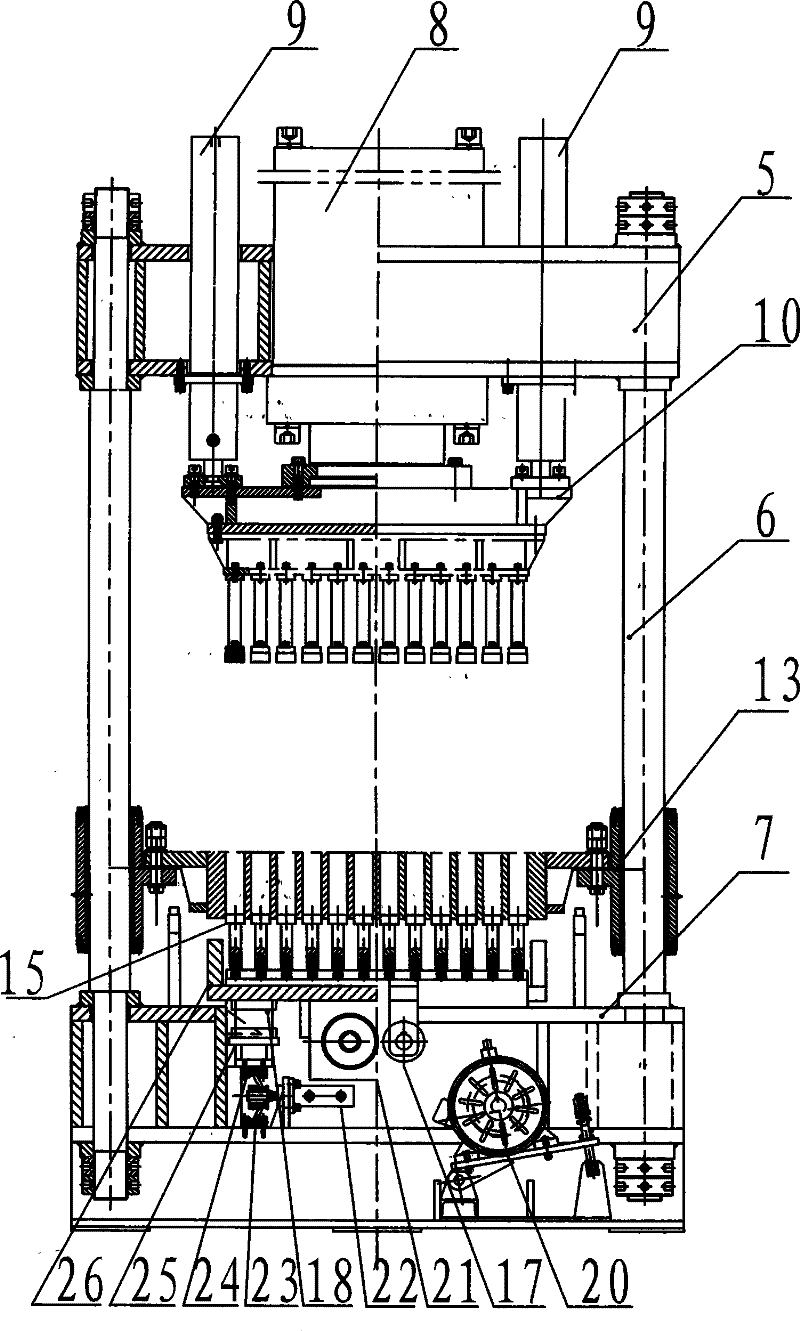

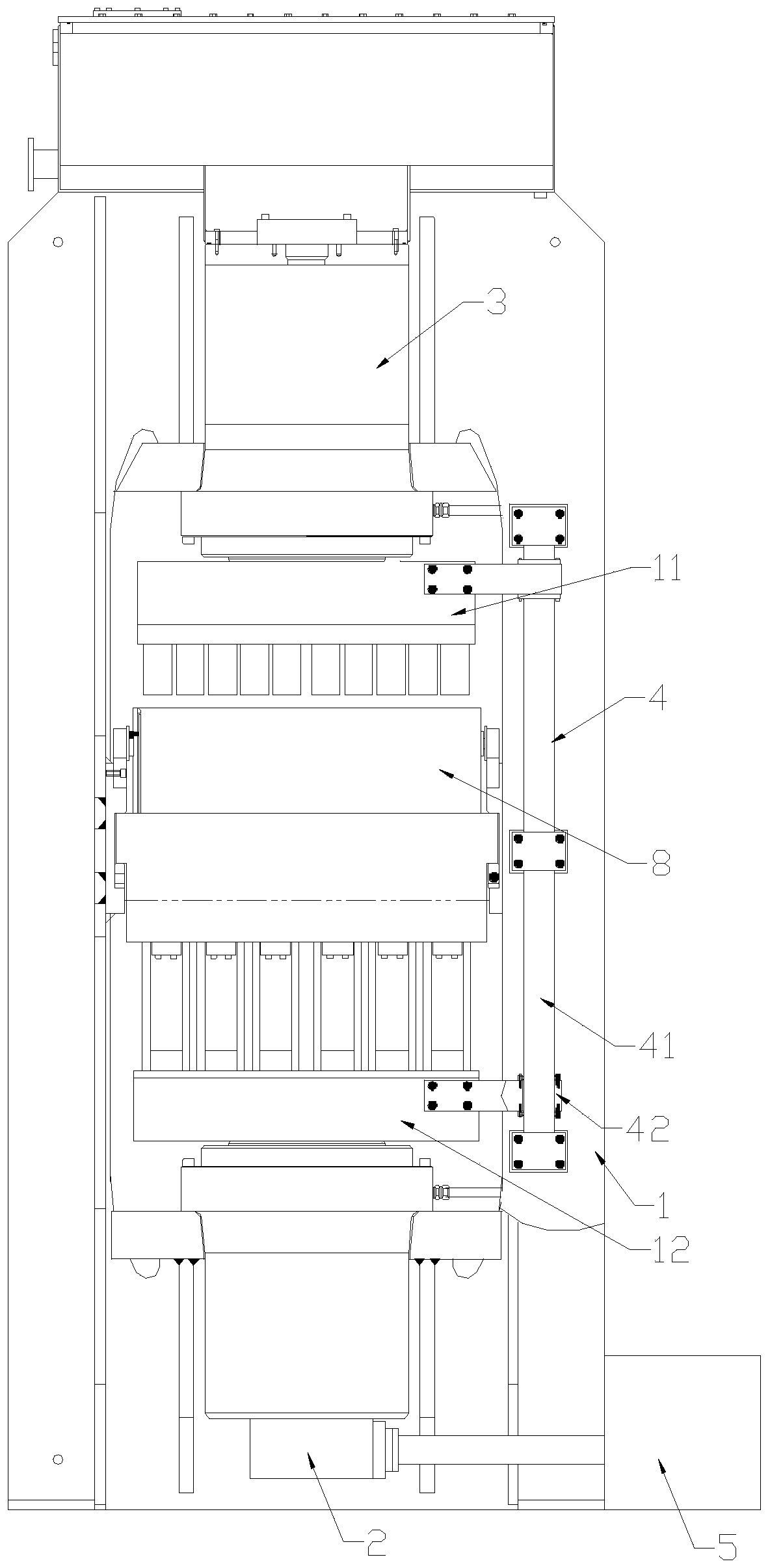

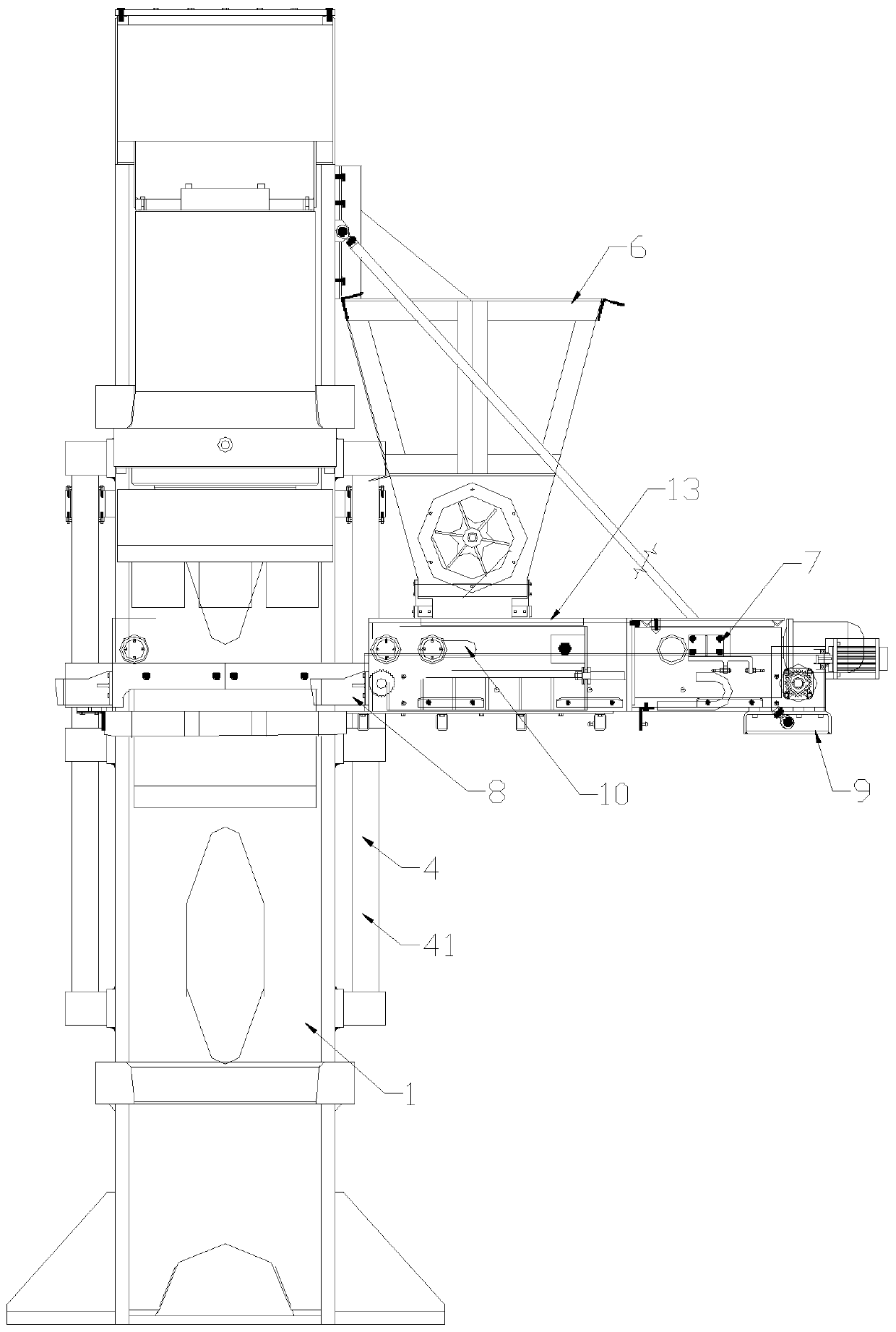

The invention provides an intelligent brick clamping machine which is composed of a travelling crane (1), a rotating mechanism (2), a hoisting mechanism (3) and a brick discharge clamp (4). The intelligent brick clamping machine is controlled by a PLC (Programmable Logic Controller) and a hydraulic mechanism. The travelling crane (1) spans over a kiln car, the rotating mechanism (2) is arranged on the travelling crane (1), the hoisting mechanism (3) is connected with the lower end of the rotating mechanism (2), and the brick discharge clamp (4) is connected at the lower end of the hoisting mechanism (3); and the intelligent brick clamping machine is controlled by the PLC. By simply adjusting the clamp, the intelligent brick clamping mechanism can ensure that each brick is clamped tightly in transportation and prevented from falling off and being left out, and simultaneously, the clamp also can rotate horizontally so as to adapt to different brick stacking modes automatically, and the intelligent brick clamping machine is accurate and quick in the brick discharge action and convenient to control, and can realize automatic brick discharge in an unattended manner.

Owner:WUHAN UNIV OF TECH +1

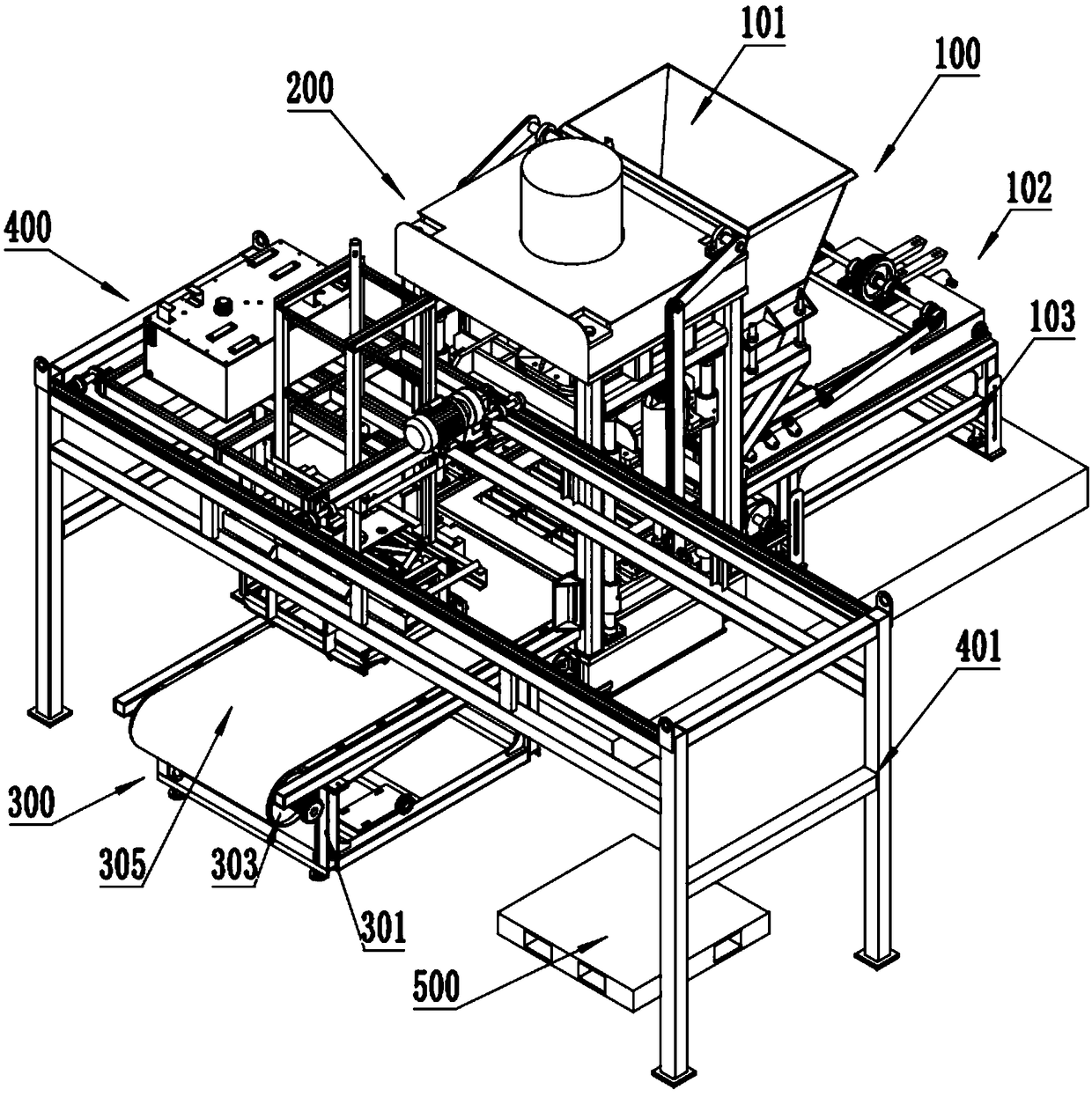

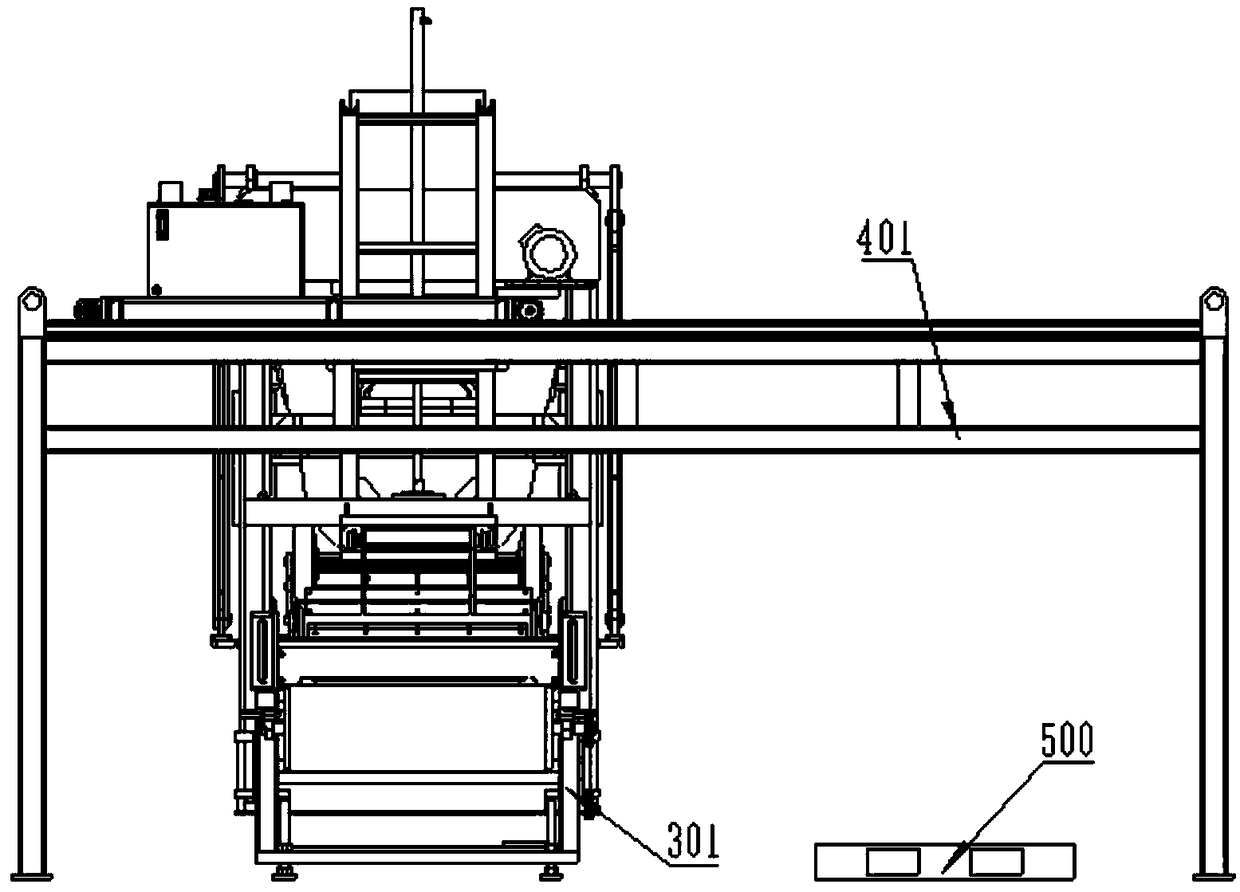

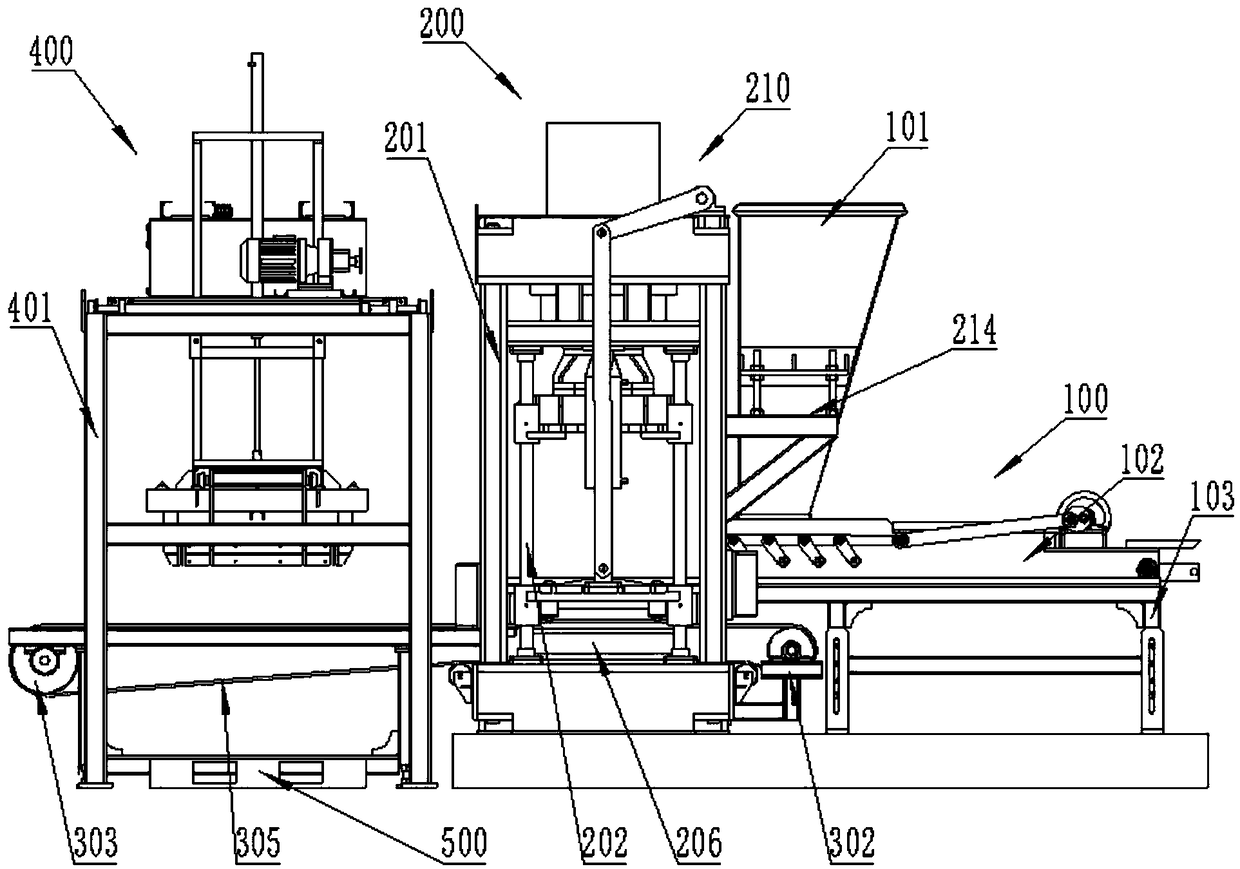

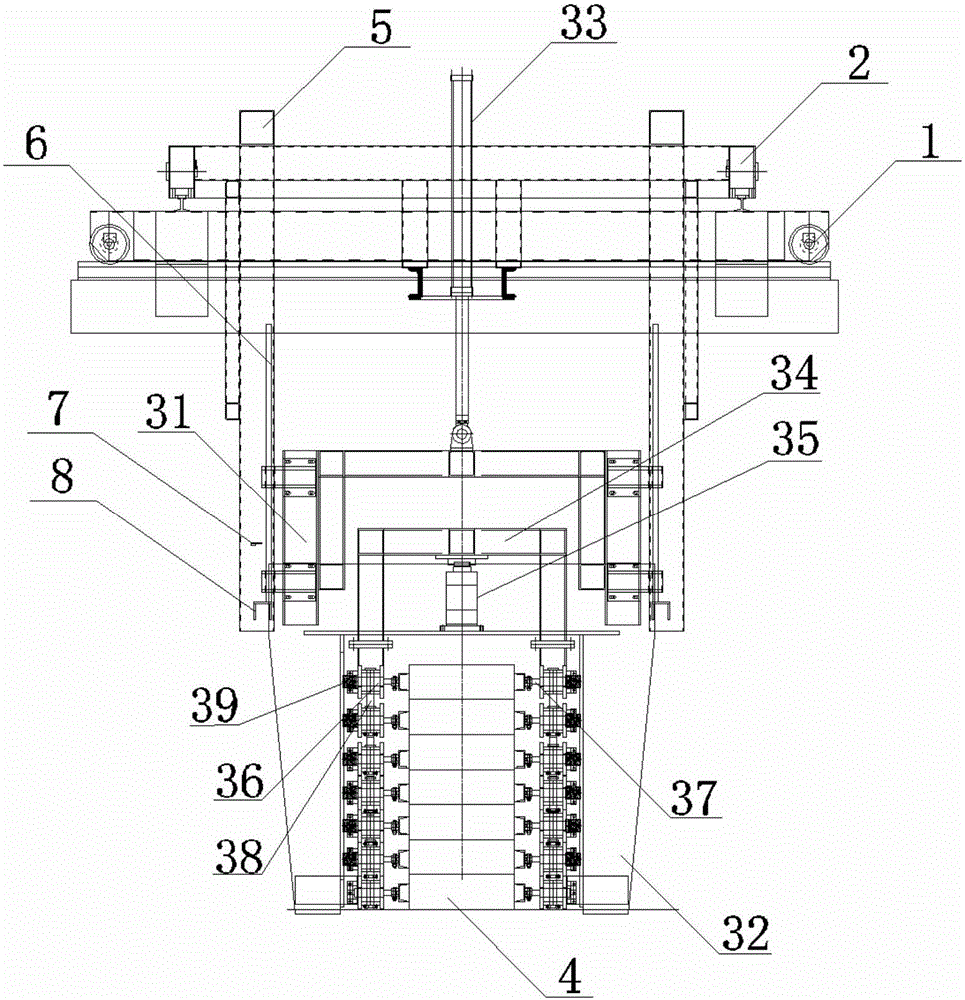

Support-plate-free static pressure building block forming machine

PendingCN108995017AReduce labor costsReduce manufacturing costDischarging arrangementMouldsBrick clampEngineering

The invention discloses a support-plate-free static pressure building block forming machine comprising a feeding device, a brick forming device, a support-plate-free conveying device and a brick clamping stacking device. The feeding device comprises a hopper and a distribution vehicle. The brick forming device comprises a main machine rack, a guide column, a pressure oil cylinder, an upper die assembly, a lower die assembly, a brick making platform and a die release oil cylinder. The support-plate-free conveying device comprises a driving roller support, a driven roller support, a driving roller, a driven roller, a conveying belt and a driving roller driving mechanism. The brick clamping stacking device comprises a stacking rack, a traveling mechanism and a brick clamping mechanism. The support-plate-free conveying device penetrates through the lower portion of the stacking rack. A first guide rail is fixedly arranged on the upper portion of the stacking rack. The traveling mechanism drives the brick clamping mechanism to move in the extending direction of the first guide rail. Support-plate-free building block production is achieved, equipment investment cost of the early period of building block production is reduced, labor cost of the later period of building block production is reduced, and then production cost of building blocks is lowered.

Owner:湖南中利福机械有限公司

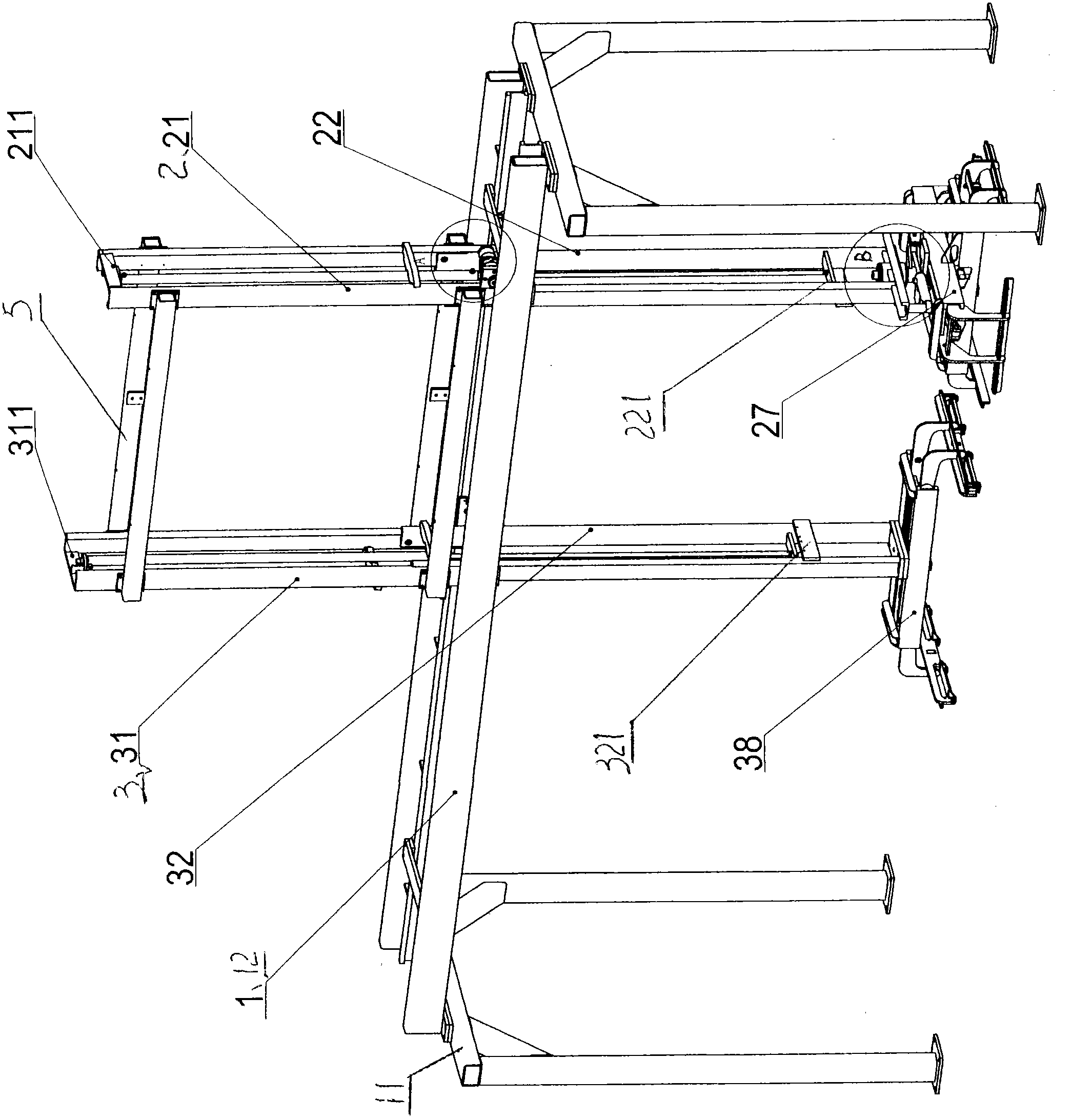

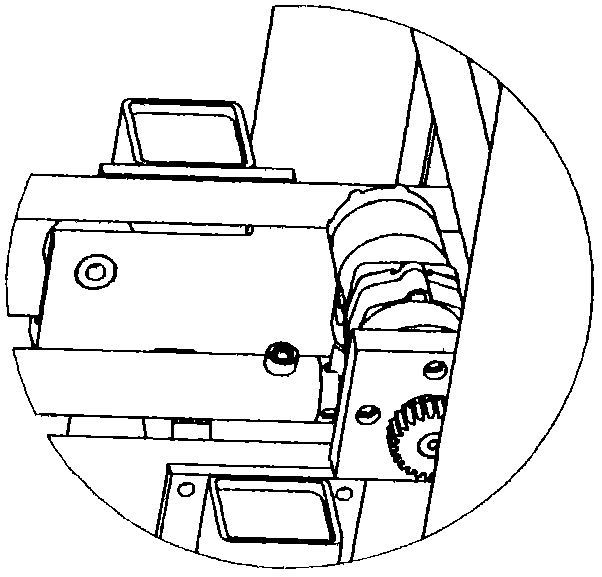

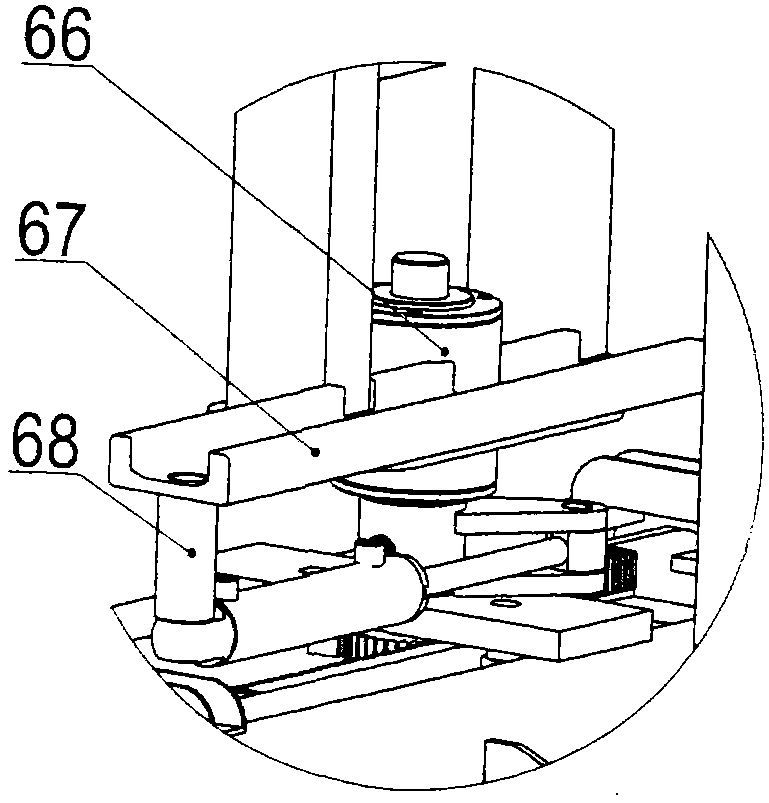

Brick and plate separating mechanism for conveying machine-made baking-free brick

InactiveCN102837862ATo achieve the purpose of staggered palletizingImprove work efficiencyArticle unpackingStacking articlesAutomatic controlFixed frame

The invention discloses a brick and plate separating mechanism for conveying a machine-made baking-free brick. The brick and plate separating mechanism consists of a base frame, a brick lifting device, a carrying plate lifting device, a translation device and an automatic control system, wherein the automatic control system consists of a programmable controller; lifting fixed frames in the brick lifting device (2) and the carrying plate lifting device (3) are connected into a whole through a connecting rod (5) between the frames, are movably arranged on a first guide rail and are driven by the translation device (7); the first guide rail is formed by two pieces of C-shaped parallel channel steel (12) with opposite notches in the base frame (1); lifting connecting frames in the brick lifting device and the carrying plate lifting device are movably arranged in the lifting fixed frames respectively and are connected by a hydraulic oil cylinder respectively; and the lower ends of the lifting connecting frames are connected with a brick clamp (27) and a carrying plate clamp (38) consisting of supporting frames, clamping arms and hydraulic oil cylinders respectively. The aims of brick and plate separation and stacking in a conveying process of the baking-free bricks are fulfilled; and the brick and plate separating mechanism has the advantages of working hour saving, labor saving, high working efficiency, simple structure and reliability in operation.

Owner:HEFEI HANDBAROW APPURTENANCES TECH

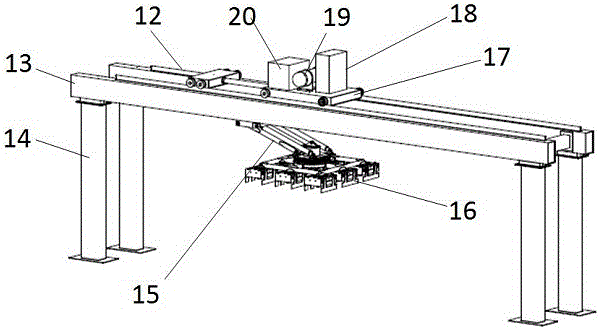

Universal ground brick laying robot

InactiveCN108560890AImprove work efficiencyAutomate tile layingBuilding constructionsHydraulic cylinderFixed frame

The invention relates to a universal ground brick laying robot. The robot comprises a base, a brick taking and laying part, a cement mold part, a cement stirring and delivering part and a walking part. The robot is characterized in that a second gear is driven by a second stepping motor to drive a brick taking and laying fixing frame to move to the position above a first bottom plate where groundbricks are placed, the ground bricks are clamped by a ground brick clamp by extending a piston rod of a second hydraulic cylinder forward, cement is stirred uniformly by the stirring device and flowsinto a cement mold passing through a delivering hose, the ground bricks are steadily placed onto laid cement through the cooperation of a first hydraulic cylinder and the second hydraulic cylinder, the ground bricks are in contact with a rubber hammer by extending a piston rod of a third hydraulic cylinder forward, the rubber hummer is driven by a vibrating device to generate vibration to level the ground bricks, the working efficiency is higher, different ground brick types can be adapted, the laid ground is smoother, automated brick laying is achieved, and the brick laying efficiency and quality are improved.

Owner:羊芳

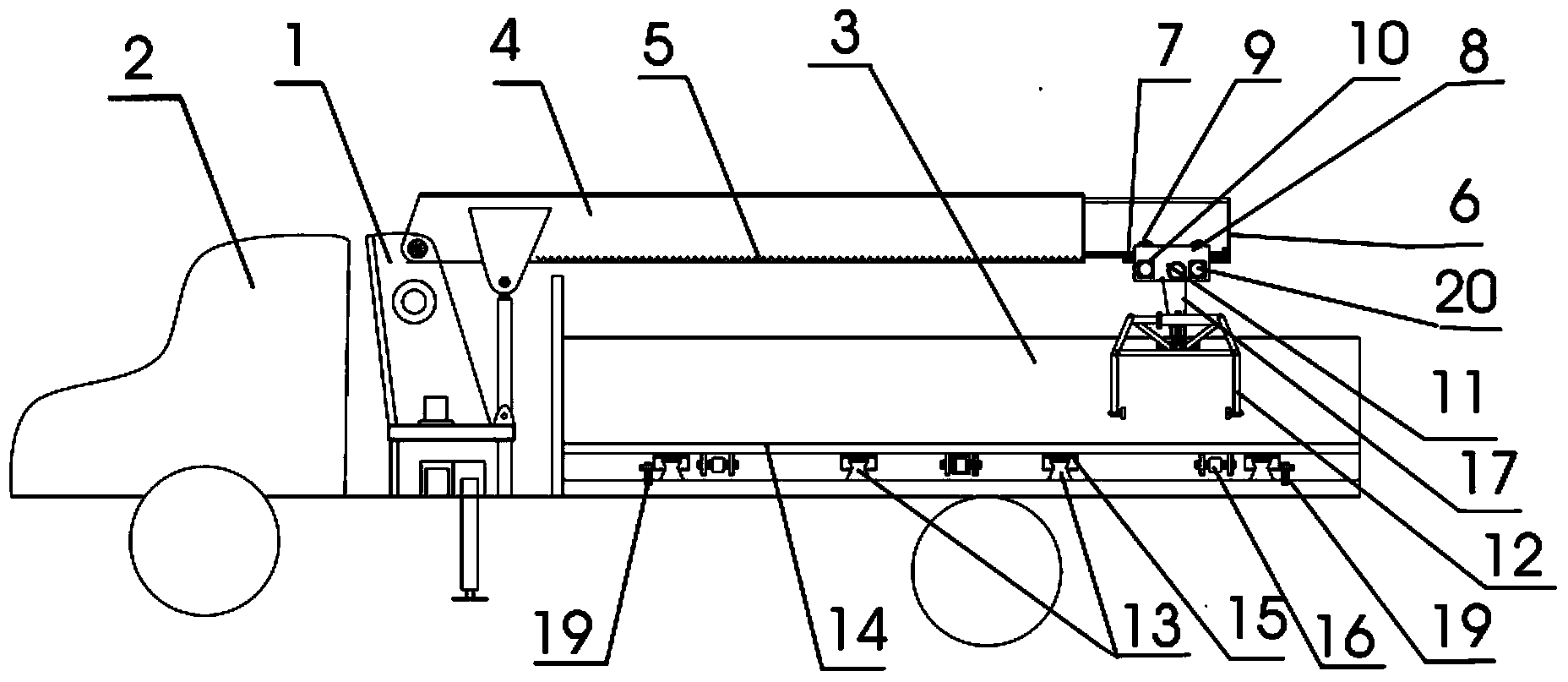

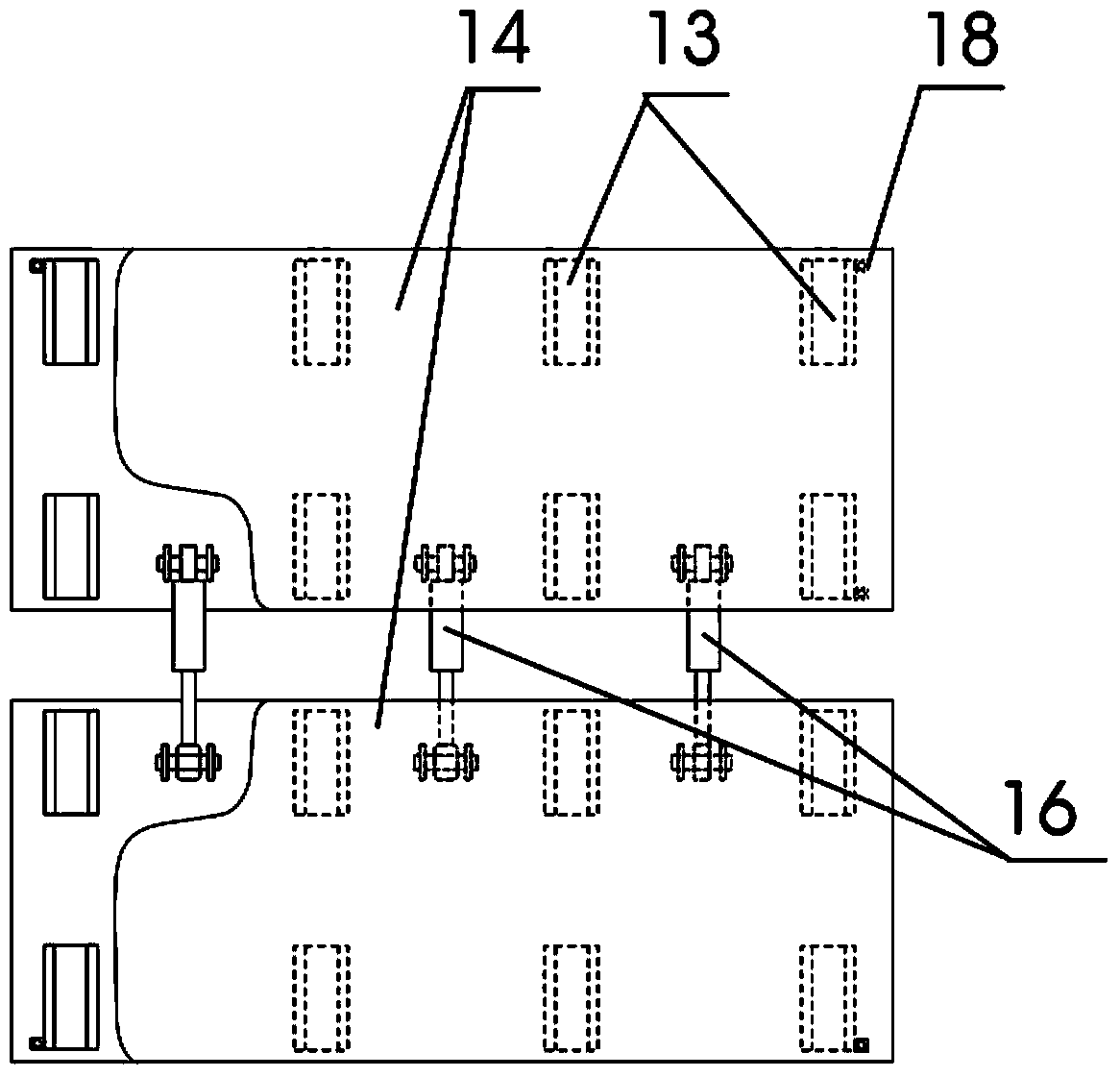

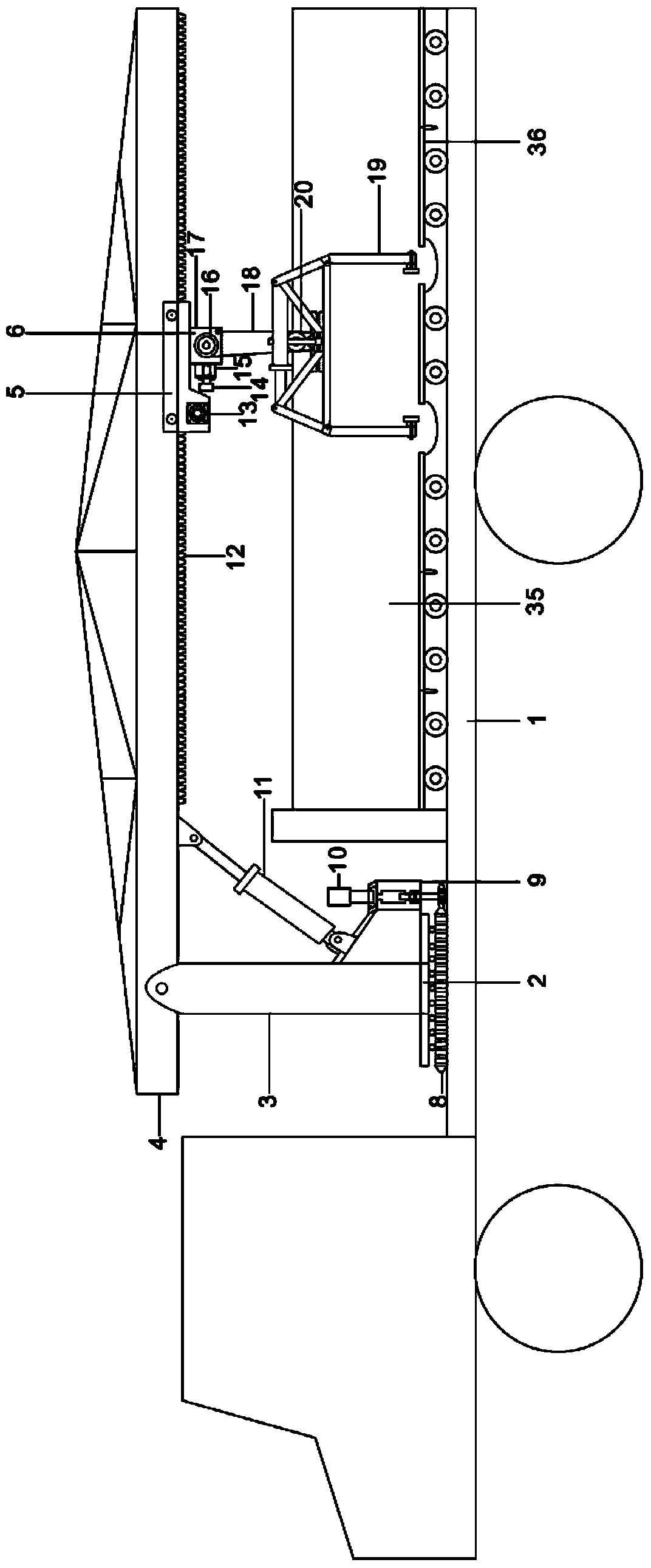

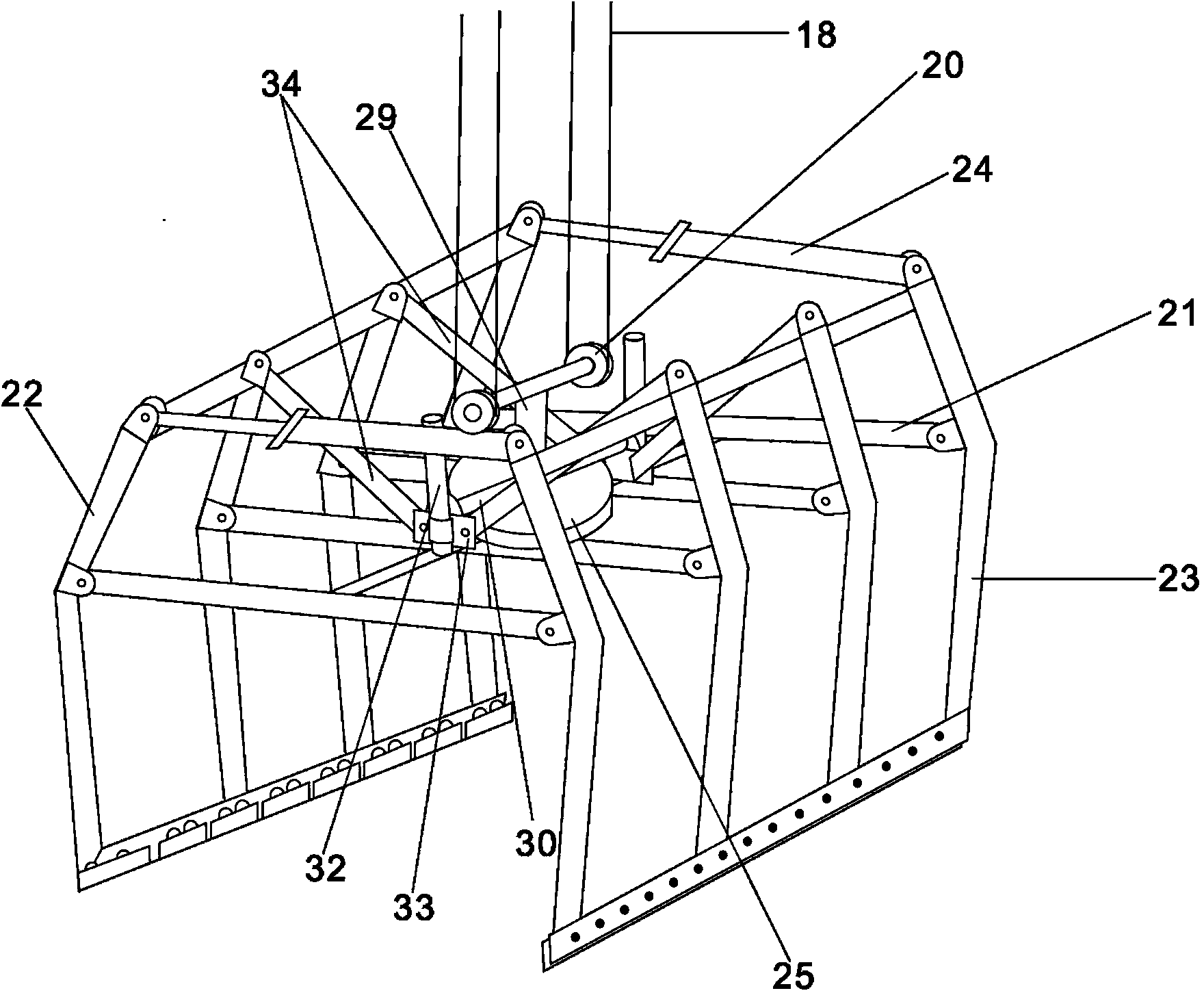

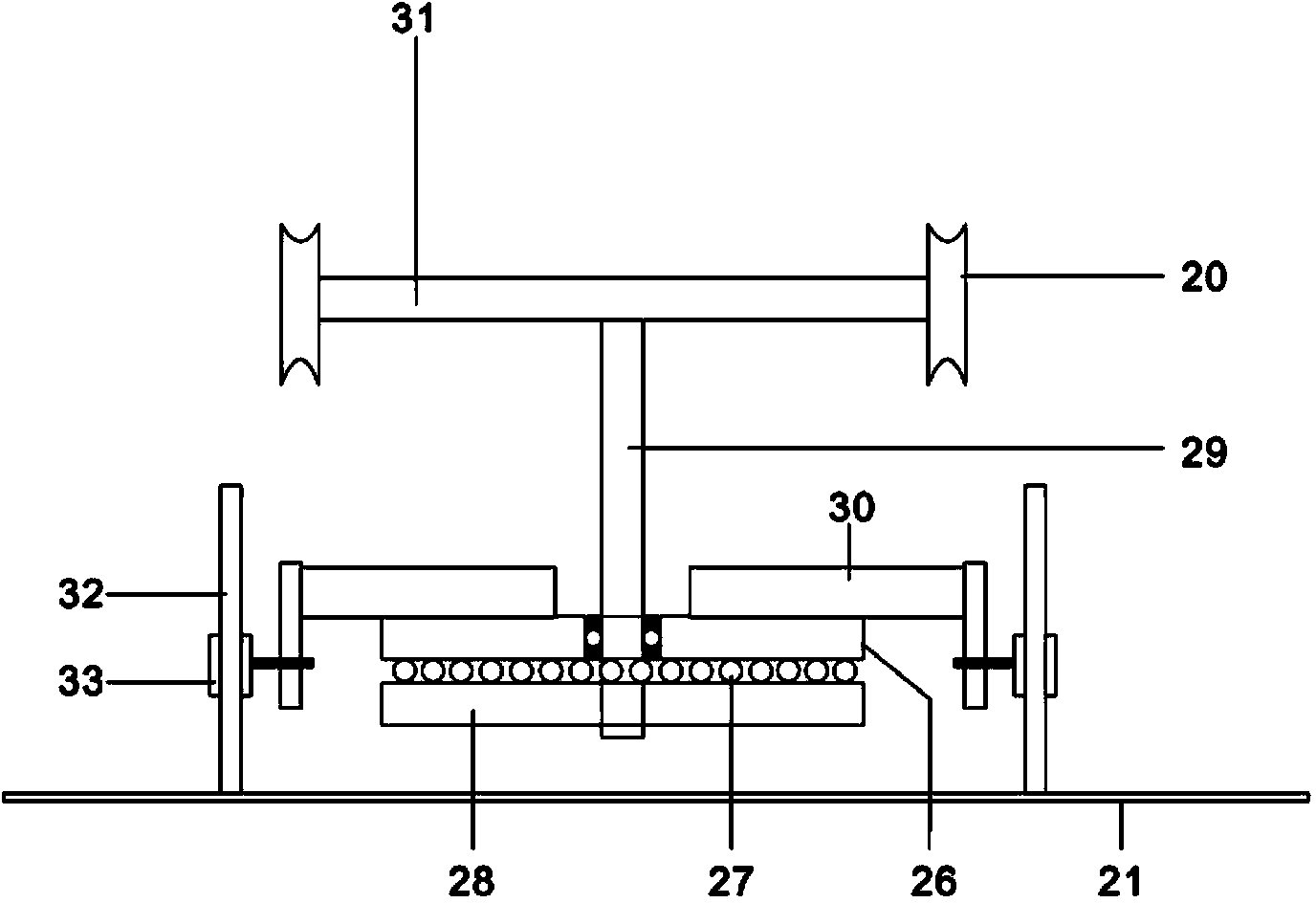

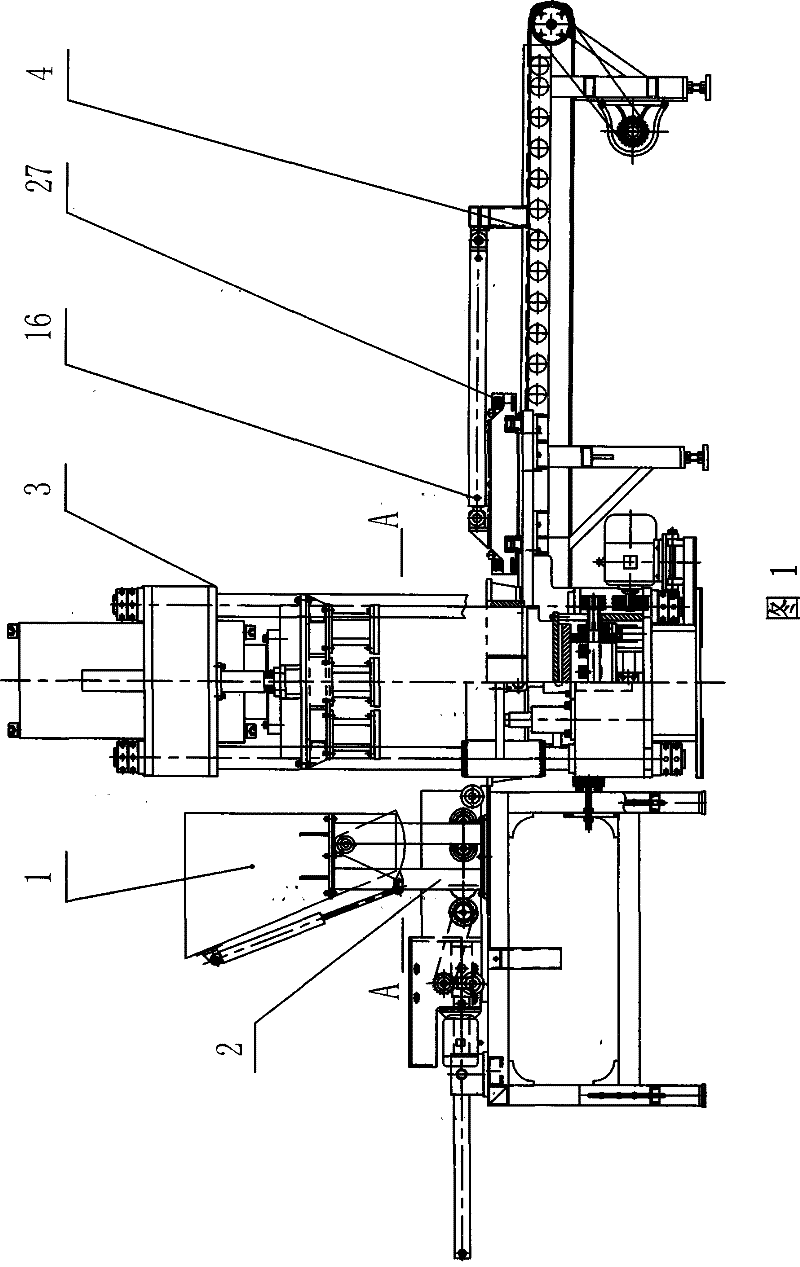

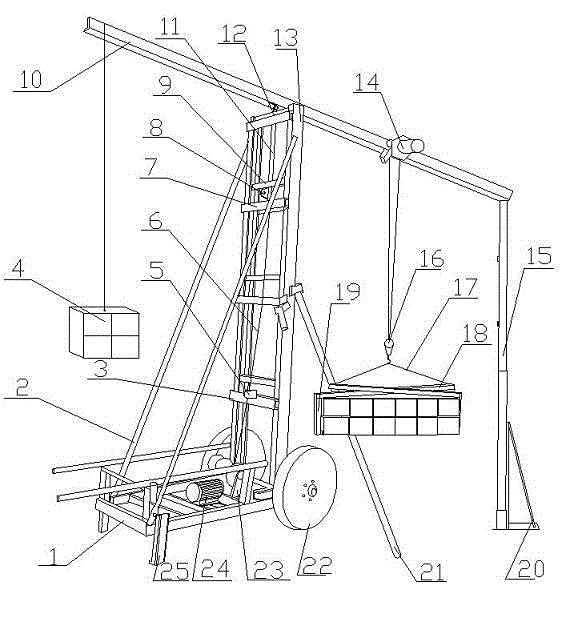

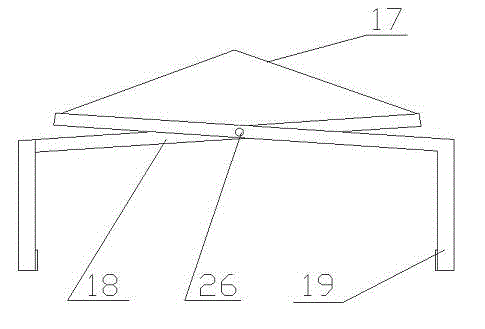

Automatic loading and unloading brick transport cart of truck-mounted crane

InactiveCN104139725AReduction in the space occupied by the rotarySmooth loading and unloadingVehicles with cranesCranesBrick clampEngineering

An automatic loading and unloading brick transport cart of a truck-mounted crane comprises the truck-mounted crane which is located between a cab and a compartment. The two sides of the lower end of a main boom of the truck-mounted crane are provided with racks I with tooth surfaces facing upwards. A telescopic suspension arm is installed in the main boom. The two sides of the lower end of the top of the suspension arm are provided with racks II with tooth surfaces facing upwards. The two racks II and the two racks I are in butt joint after the suspension arm retracts. The crane is installed on the two racks II through two pairs of gears and is driven by a hydraulic running motor to move along the two racks II. The crane is provided with a lifting winch which is driven by a hydraulic lifting motor. A brick clamp is suspended below the lifting winch through a steel wire rope. The automatic loading and unloading brick transport cart of the truck-mounted crane is provided with the telescopic suspension arm, so that the occupied space for rotation of the suspension arm is reduced greatly; a left movable bottom board and a right movable bottom board are adopted as compartment bottom boards, so that continuous loading and unloading are achieved, and the loading efficiency and unloading efficiency are improved.

Owner:万红章

Small brick clamp trolley and brick stacker crane with small brick clamp trolley

The invention discloses a small brick clamp trolley and a brick stacker crane with the small brick clamp trolley. The clamp trolley comprises an inner frame, a front brick clamping arm, a rear brick clamping arm, a push-pull oil cylinder mechanism driving the front brick clamping arm and the rear brick clamping arm to move front and back, a left brick clamping arm, a right brick clamping arm, a telescopic oil cylinder mechanism driving the left brick clamping arm and the right brick clamping arm to move left and right, a lifting electric push-pull rod and a lifting guide wheel set. The front brick clamping arm, the rear brick clamping arm, the left brick clamping arm and the right brick clamping arm are correspondingly arranged on the front side, the rear side, the left side and the right side of the inner frame. The lifting electric push-pull rod is connected with the inner frame through the lifting guide wheel set so as to drive the inner frame to ascend and descend. According to the small brick clamp trolley, the movement of the front brick clamping arm, the rear brick clamping arm, the left brick clamping arm and the right brick clamping arm is controlled through the push-pull oil cylinder and the telescopic oil cylinder, clamping of a single layer of bricks is achieved, the strength of the small brick clamp trolley is uniform and controllable, and stable transferring of the single layer of bricks is achieved. In addition, the small brick clamp trolley can walk, and therefore the single layer of bricks can be clamped at the optimal angle.

Owner:GUANGXI YIPIN INVESTMENT

Automatic brick clamping device

The invention discloses an automatic brick clamping device comprising a support frame, a hydraulic rotation joint, a hydraulic motor, a buffer balance seat, a brick clamping mechanism and a hydraulic control mechanism, wherein the hydraulic rotation joint is suspended on the support frame, the hydraulic motor is fixed on an end cover of the hydraulic rotation joint and drives a valve plug of the hydraulic rotation joint to rotate, a through hole is formed in the lower end of the valve plug of the hydraulic rotation joint, a cross shaft passes through the through hole to be fixed on the valve plug, the buffer balance seat and the brick clamping mechanism are respectively installed on the two ends of the cross shaft, the buffer balance seat comprises a buffer block, a buffer seat, a spring and a balance seat, wherein the center of the buffer block is fixed on the cross shaft, the buffer block is installed in the buffer seat and is supported by the spring in the buffer seat, the balance seat is fixed below the buffer seat, and the brick clamping mechanism is installed on the balance seat. According to the automatic brick clamping device, the structure is simple, the operation is convenient, the clamping is stable, the work efficiency is high, the production efficiency is improved greatly, and the labor intensity is lowered.

Owner:张金平

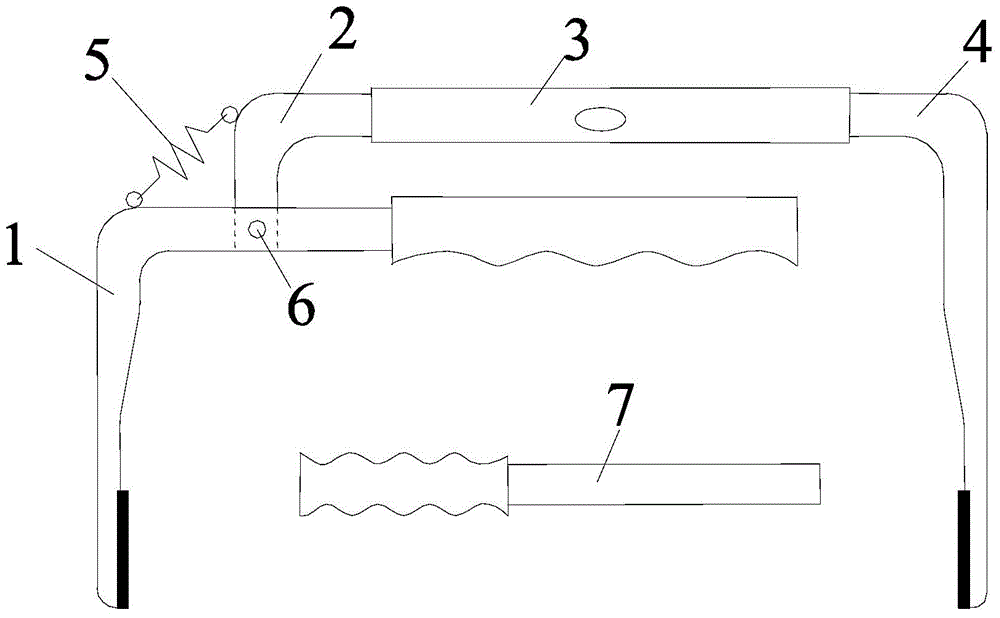

Two-way extending assembly brick clamp for shale-sintered thermal-insulating blocks

The invention discloses a two-way extending assembly brick clamp for shale-sintered thermal-insulating blocks. The two-way extending assembly brick clamp comprises a boosting clamping bar, a positive thread clamping bar, a sleeve and a negative thread clamping bar. All of the boosting clamping bar, the positive thread clamping bar and the negative thread clamping bar are L-shaped bars. The boosting clamping bar comprises a first brick clamp and a hand lever perpendicular to the first brick clamp, and the middle of the hand lever is provided with a round hole. The positive thread clamping bar comprises a clamping-bar connecting rod and a sleeve connecting screw rod perpendicular to the clamping-bar connecting rod; a round hole is formed at the tail end of the clamping-bar connecting rod which is connected onto the hand lever of the boosting clamping bar through a rotating shaft. The negative thread clamping bar comprises a screw rod and a second brick clamp perpendicular to the screw rod. One end of the sleeve is connected with the positive thread clamping bar while the other end of the sleeve is connected with the negative thread clamping bar. A clamping space is formed between the first brick clamp and the second brick clamp and used for allowing the clamped blocks to be disposed therein. By the brick clamp, the problem that the shale-sintered thermal-insulating blocks of different types cannot be carried with a single fixed-size brick clamp due to different sizes is solved, and block carrying and masonry construction are enabled to be more convenient.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

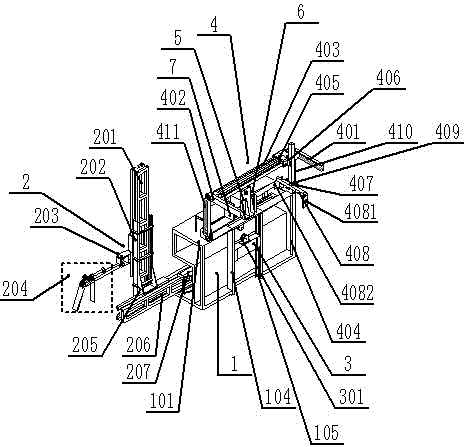

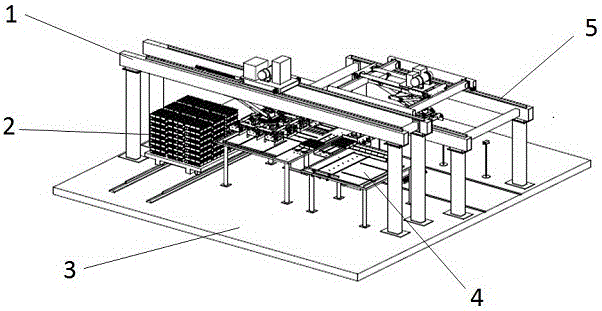

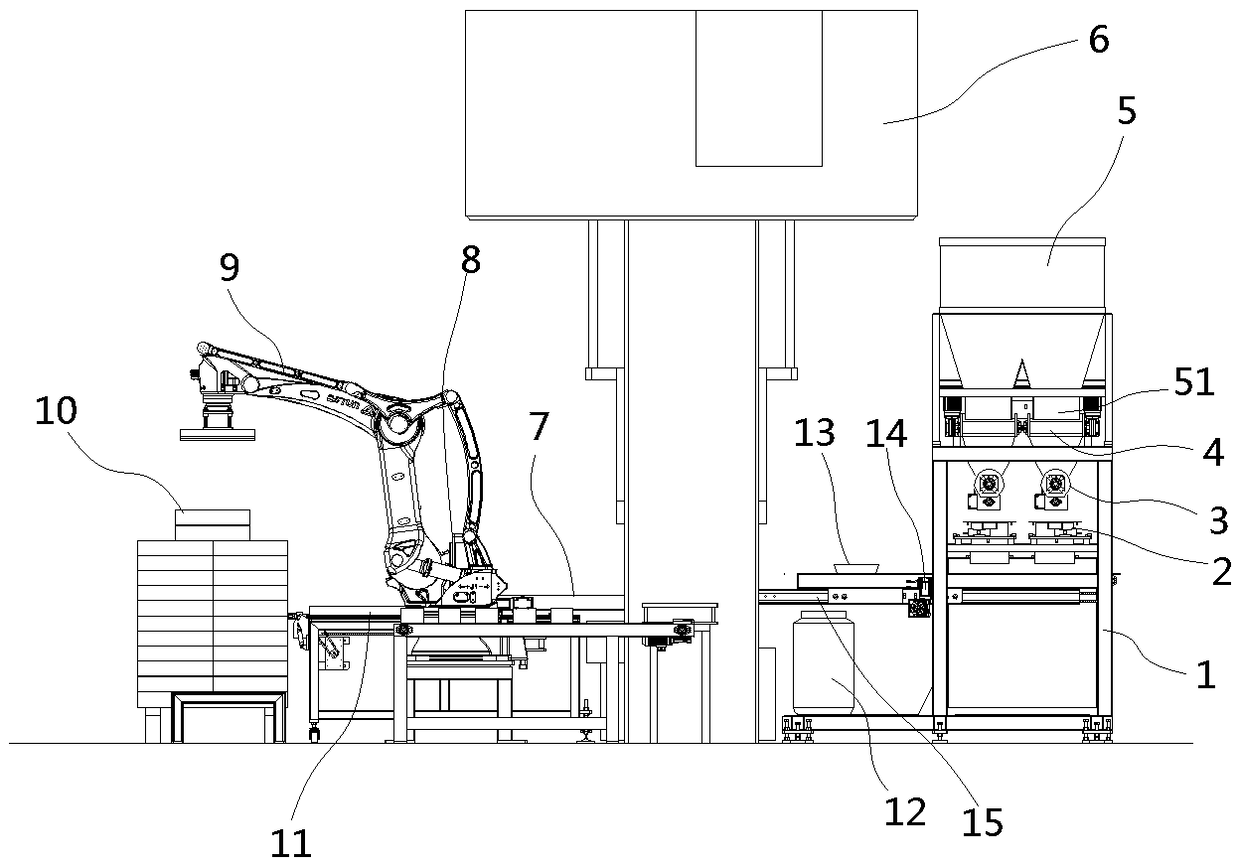

Automatic brick forming and stacking system and stacking method thereof

PendingCN108820907AHigh outputSave time at workCeramic shaping plantsAuxillary shaping apparatusCompression moldingBrick clamp

The invention relates to an automatic brick forming and stacking system and a stacking method thereof. The automatic brick forming and stacking system comprises a synchronous green brick clamping anddistributing device, a hydraulic brick pressing machine and a brick conveying mechanism which are all sequentially arranged. The hydraulic brick pressing machine comprises a hopper for feeding, a molding press for shaping raw materials in a pressing manner and an ejecting mechanism for ejecting formed bricks. The synchronous green brick clamping and distributing device comprises a movable distribution vehicle and a brick clamping mechanism. The distribution vehicle is provided with a material frame. After brick materials in the hopper of the hydraulic brick pressing machine are poured into thematerial frame, the molding press carries out compression molding from top to bottom so that brick blocks can be formed, the ejecting mechanism ejects the brick blocks from bottom to top, after the distribution vehicle returns, the brick clamping mechanism is located above a brick mold, the brick clamping mechanism clamps the brick blocks to the brick conveying mechanism, and meanwhile, and the material frame moves to the position below the molding press again so that distribution can be achieved. The automatic brick forming and stacking system further comprises a stacking robot and a green brick vehicle conveying mechanism, and the stacking robot clamps the bricks on the brick conveying mechanism through mechanical arms and carries out stacking on a green brick vehicle. The green brick vehicle conveying mechanism conveys the green brick vehicle to a still kettle.

Owner:FUJIAN HAIYUAN AUTOMATIC EQUIP CO LTD

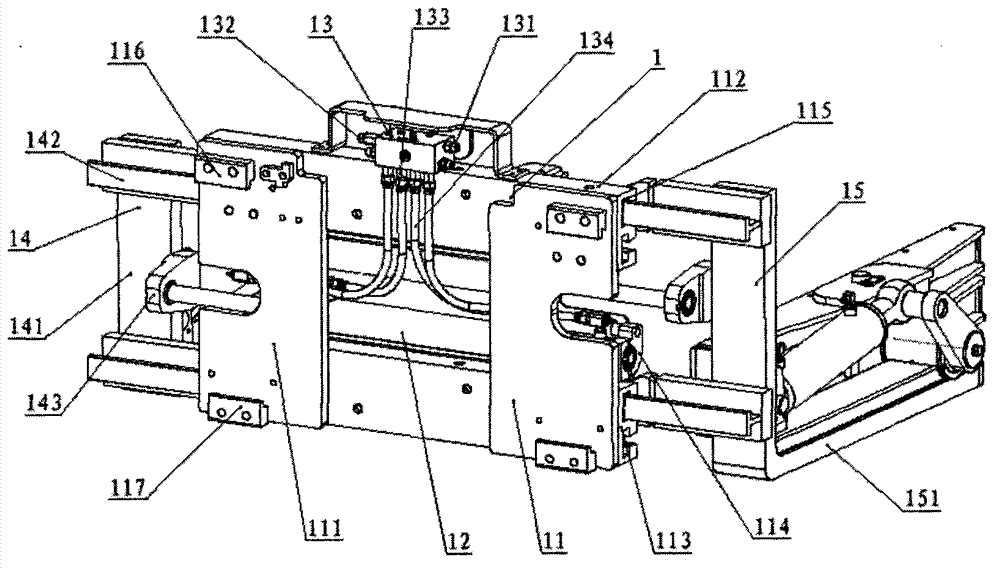

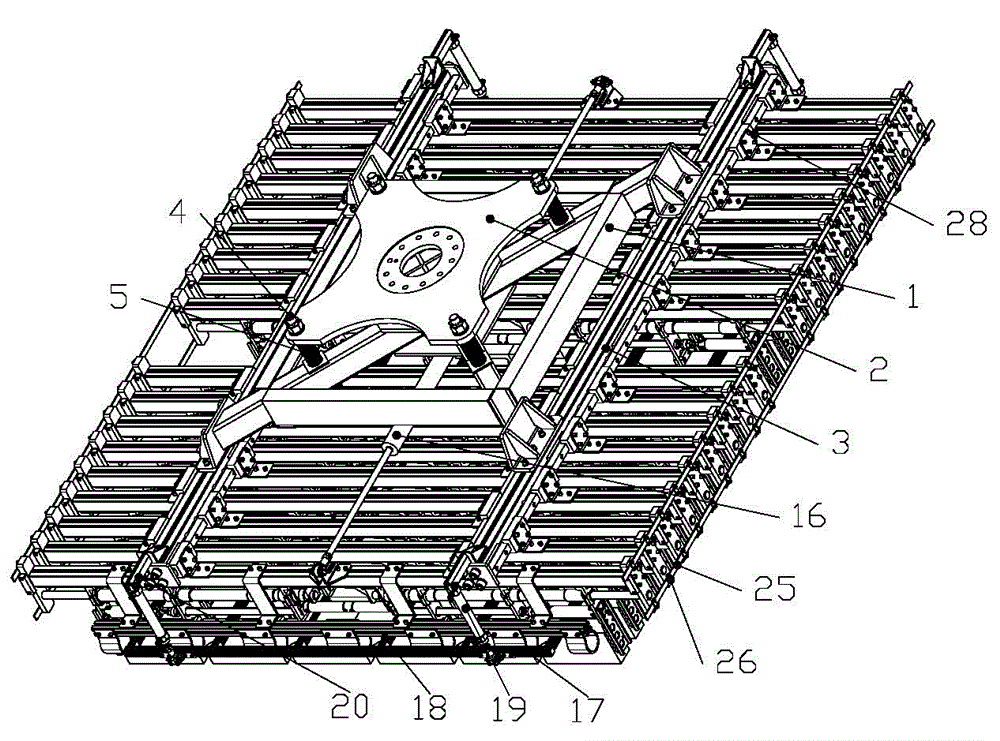

Grasping mechanism for automatic green brick stacking device

ActiveCN102167231AGuaranteed to be fixedWon't scratchStacking articlesDe-stacking articlesBrick clampEngineering

The invention provides a grasping mechanism for an automatic green brick stacking device. The grasping mechanism for the automatic green brick stacking device comprises a hanging bracket, a support rod and a brick clamping mechanism; the support rod is horizontally arranged at the bottom of the hanging bracket, and the support rod is provided with the brick clamping mechanism; the brick clamping mechanism comprises a fixed bracket, movable brackets, a clamping cylinder, sliding pairs, limit connecting plates, limit pins and clips; the upper end of the fixed bracket is fixed on the support rod; the upper end of each movable bracket is connected with the support rod via a sliding pair; the movable brackets are arranged on one side of the fixed bracket; the clamping cylinder is fixed on the fixed bracket; a piston rod of the clamping cylinder is connected with the movable bracket on the outermost side; the fixed bracket and the movable bracket adjacent to the fixed bracket, and the movable brackets are connected via the limit connecting plates; and the movable brackets are provided with strip guiding limit holes, the limit pins are arranged in the strip guiding limit holes, and the lower ends of the fixed bracket and the movable bracket are provided with clips respectively. The grasping mechanism has the advantages that: the structure is simple, the clamping force is precisely controlled, and the stacking position of the green brick is precisely located.

Owner:信阳雄狮装备科技股份有限公司

Automatic boom-type loading-unloading brick truck

InactiveCN103770686ASolve loading and unloading difficultiesSmooth loading and unloadingVehicles with cranesVehicle frameMotor drive

The invention relates to an automatic boom-type loading-unloading brick truck. A large turntable is installed in front of a truck frame, a gear ring is fixed in front of the truck frame, a large stand column is fixedly arranged on the center of the large turntable, and the top end of the large stand column is hinged to a boom; the large turntable is provided with a transmission case, a rotating motor drives the large turntable to rotate through the engagement of a gear and a gear ring on a power output shaft of the transmission case, and the large stand column is hinged to the boom through an adjusting oil cylinder; the boom is provided with a traveling crane through a roller, a rack is arranged below the boom, and a traveling crane is driven to move through the engagement of a gear and a rack on a traveling motor main shaft which is installed on the traveling crane; the bottom of the traveling crane is connected with an elevator consisting of a lifting motor, a gear case, a winding drum and an elevator shell, the lifting motor drives the winding drum through the gear case, one end of a wire rope is fixed on the elevator shell, and the other end is fixedly wound onto the winding drum after rounding a movable block on the top of a brick clamp. By adopting the automatic boom-type loading-unloading brick truck, no-dead-corner loading and unloading and success in loading and unloading in a narrow field can be realized.

Owner:万红章

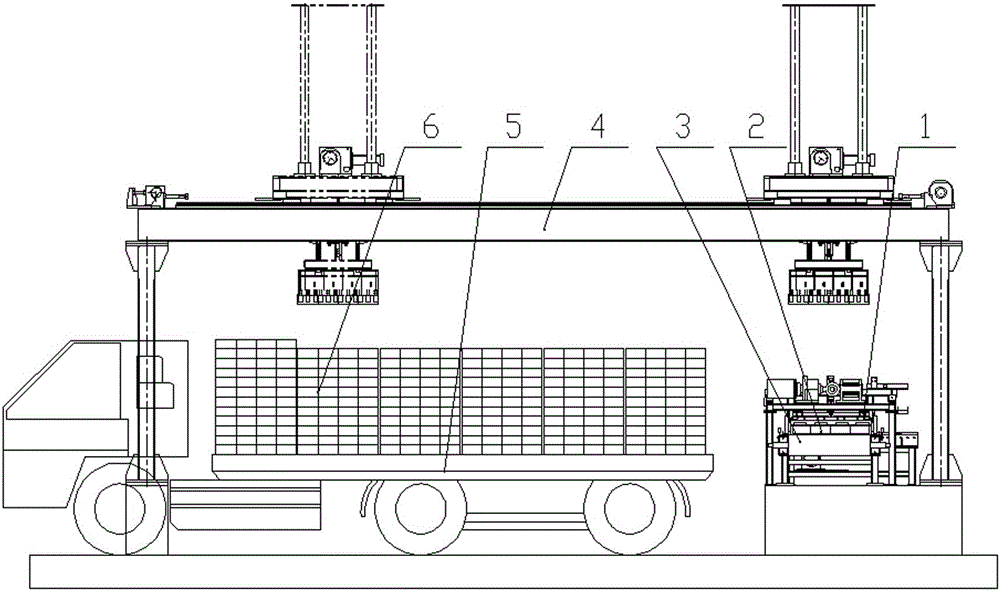

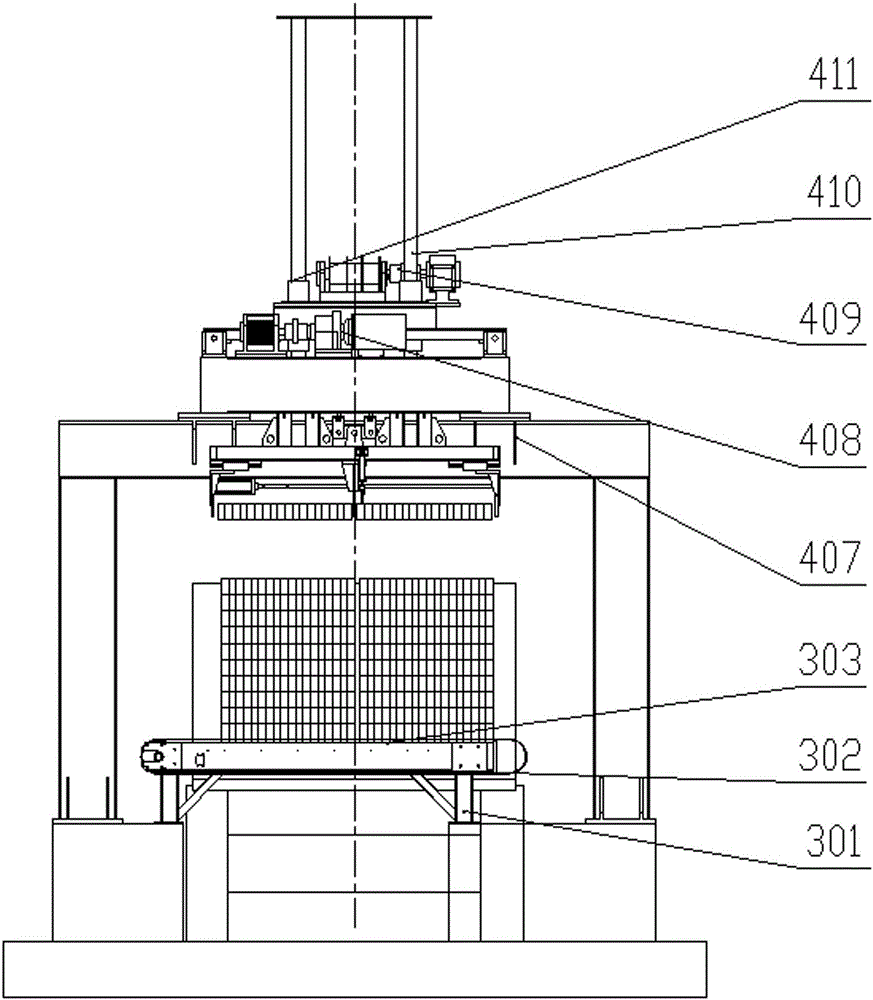

Automatic post-brick-unloading grouping and loading device and technology for baked bricks

InactiveCN105084042AImprove the full load factorImprove vehicle utilizationLoading/unloadingStack machineBrick clamp

The invention relates to an automatic post-brick-unloading grouping and loading device and technology for baked bricks. The device is provided with a grouping belt conveyor, a stacking machine and a brick-unloading unit transferring mechanism. The grouping belt conveyor is arranged at the tail end of the brick-unloading unit transferring mechanism. The baked bricks are gathered together by the brick-unloading unit transferring mechanism, and then grouped and conveyed to the grouping belt conveyor. According to the width of a transport vehicle, the baked bricks are grouped by grouping belt conveyor matched with the brick-unloading unit transferring mechanism. The stacking machine is arranged above the grouping belt conveyor. The grouped baked bricks are clamped and stacked up to the transport vehicle by the stacking machine. According to the device and the technology, direct mechanized automatic grouping and loading of finished bricks can be achieved; the problem that the multiple bricks are not firm to clamp is solved; the method is simple, practical and reliable. The problem of the gaps between brick stacks is solved; the load factor of the bricks and the utilization rate of the vehicle are improved; the damage rate in the transport process is reduced; a great deal of manpower is saved; the production efficiency is improved; the labor intensity of workers is lowered.

Owner:LUOYANG ZHONGYE HEAVY IND GRP CO LTD

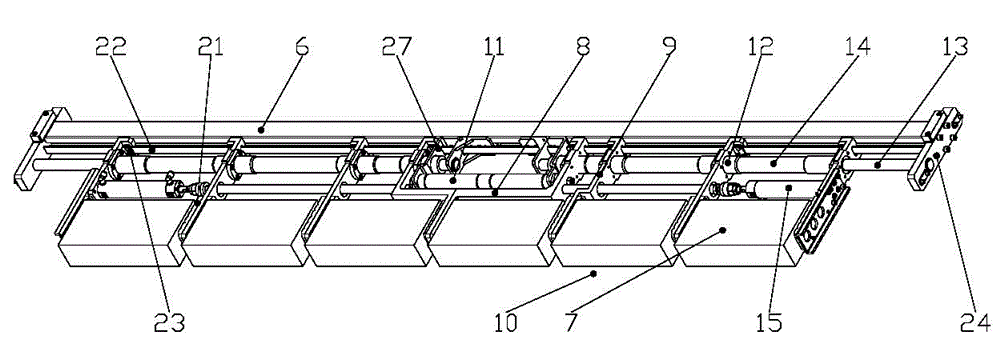

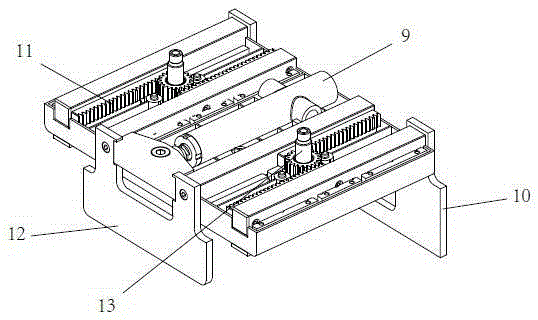

Brick clamp

The invention discloses a brick clamp which comprises a fork arm supporting frame, wherein a flange is arranged above the fork arm supporting frame; two parallel guide rails are arranged below the fork arm supporting frame; brick clamp units which are in sliding fit with the guide rails are mounted between the two guide rails at intervals. A double-stroke double-rod cylinder, a clamping clearance adjustment cylinder and a clamping clearance limiting sleeve are used for conveniently adjusting and limiting the width of a brick clamping clearance to enable the width of the brick clamping clearance meet the requirement for clamping of a finished brick product; furthermore, the double-stroke double-rod cylinder and the clamping clearance adjustment cylinder are used for clamping and fixing the brick; when the clamped bricks are transferred to a stacking position, the clearance adjustment cylinder is used for adjusting a distance between every two adjacent brick clamping units according to the stacking requirement for the bricks, so that the stacking distance between each two bricks can be adjusted; a brick push rod is downwards pushed by a brick push cylinder by properly reducing the clamping force between the double-stroke double-rod cylinder and the clamping clearance adjustment cylinder, so that the bricks clamped in the brick clamping clearance can be stably unloaded.

Owner:CHONGQING ROBOT

Wall brick pasting device for building construction

InactiveCN113073827APrevent fallingAvoid artificialBuilding constructionsArchitectural engineeringBrick clamp

The invention discloses a wall brick pasting device for building construction, and relates to the technical field of building construction. The problem that a single wall brick needs to be manually placed in a wall brick clamp in each time of operation, and manpower is consumed is solved. The wall brick pasting device specifically comprises a device body, a lifting structure is arranged on the inner wall of the top of the device body, a mounting plate is arranged on the outer wall of the top of the lifting structure, a mounting seat is arranged on the outer wall of the top of the mounting plate and is of an L-shaped structure, a protection plate is arranged on the outer wall of the top of the mounting seat, an air cylinder is arranged on the inner wall of one side of the mounting seat, and a pushing assembly is arranged at one end of the air cylinder; and the pushing assembly comprises a first spring and a pushing plate, four or more wall bricks are placed on the outer wall of the top of the mounting seat, a conveying belt assembly is arranged on the outer wall of the top of the mounting seat, and the conveying belt assembly comprises a conveying belt and a driving motor. The multiple wall bricks are placed at a time, pushing and conveying are facilitated one by one, manual sequential placement is avoided, and manpower is saved.

Owner:黄朝辉

Separator for aerated concrete light bricks

The invention relates to the technical field of brick making mechanical equipment, and discloses a separator for aerated concrete light bricks. The separator comprises a front-back sliding crown block, a left-right sliding crown block fixed to the front-back sliding crown block, and a machine body fixed to the left-right sliding crown block. The machine body comprises a lifting frame, a fixed plate fixed to the lifting frame, a lifting oil cylinder used for driving the lifting frame to move up and down, a brick clamping frame, a brick release oil cylinder connected with the lifting frame and the brick clamping frame, multiple sets of brick clamping bases with the number matched with that of the to-be-separated light bricks, and multiple sets of brick clamping oil cylinders correspondingly arranged on the brick clamping bases. The brick clamping bases include the first set of brick clamping bases fixed to the brick clamping frame, the last set of brick clamping bases fixed to the fixed plate, and at least one set of middle brick clamping bases. Each set of brick clamping bases are sequentially connected through coupling shafts. The first set of brick clamping bases and the middle brick clamping bases are each provided with a slide wheel. The slide wheels are connected with the fixed plate in a sliding manner. The separator is flexible to move, capable of achieving one-time brick release, high in work effect and low in cost.

Owner:佛山市南海蓝淇机械设备有限公司

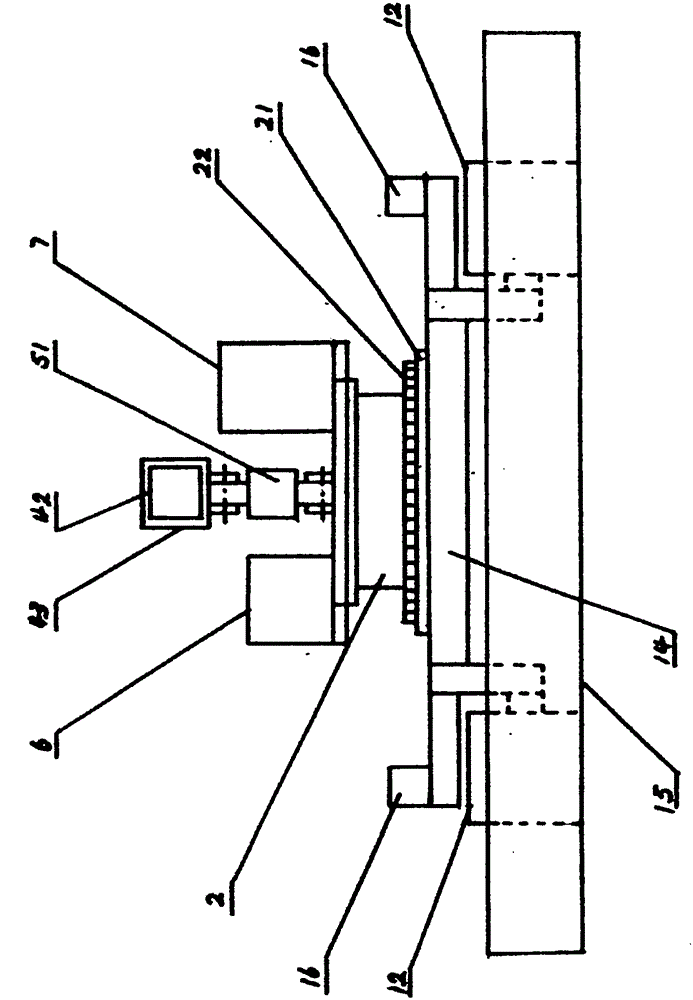

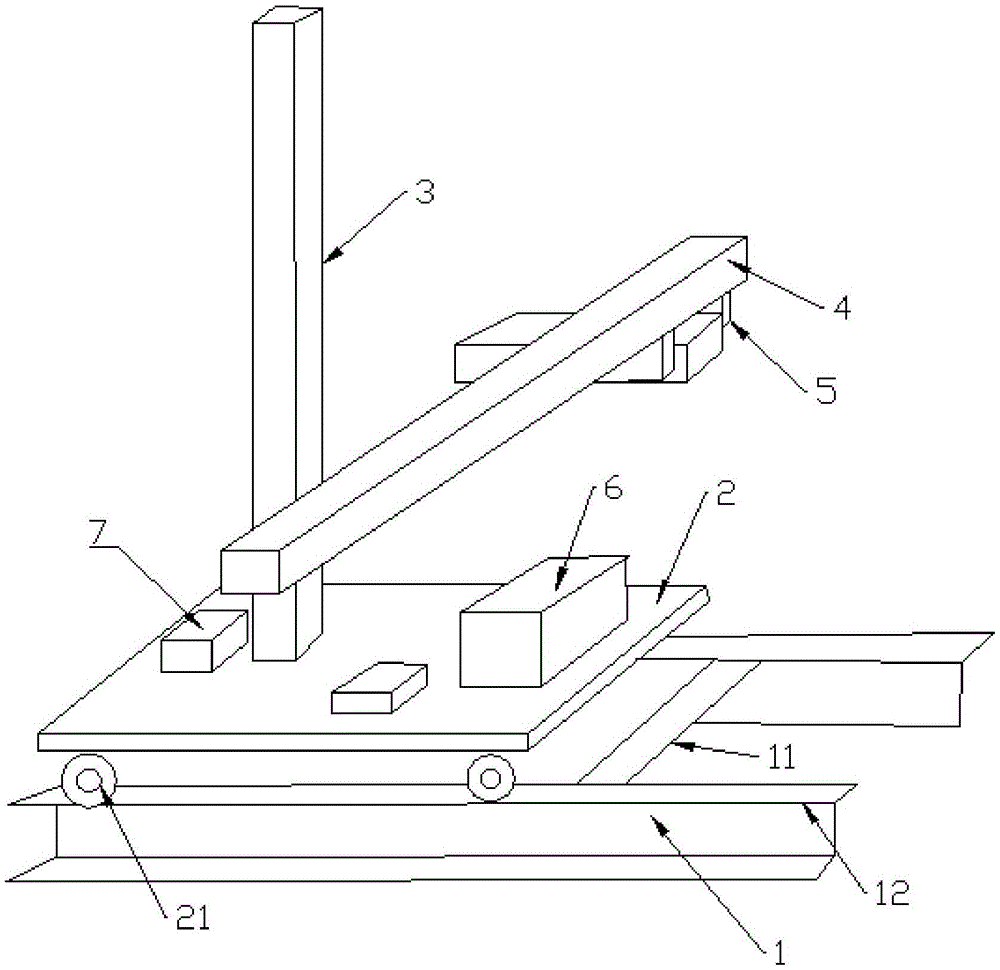

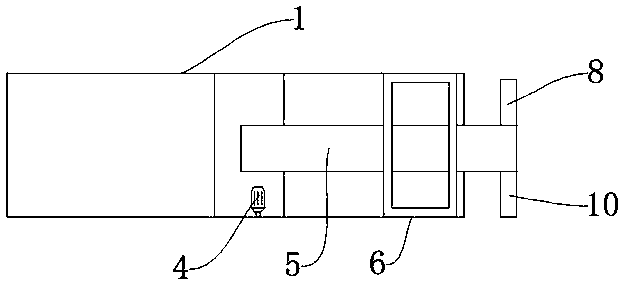

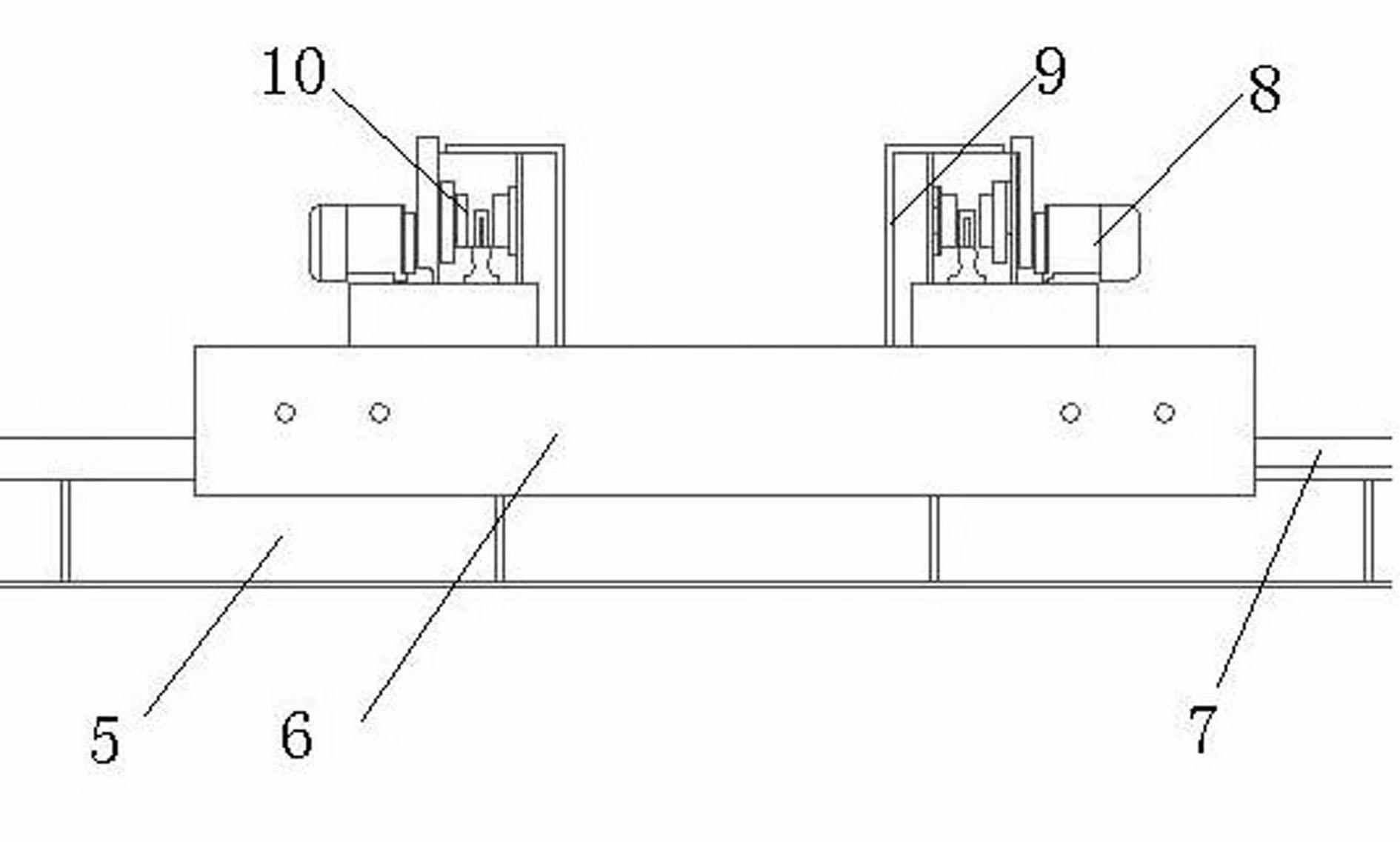

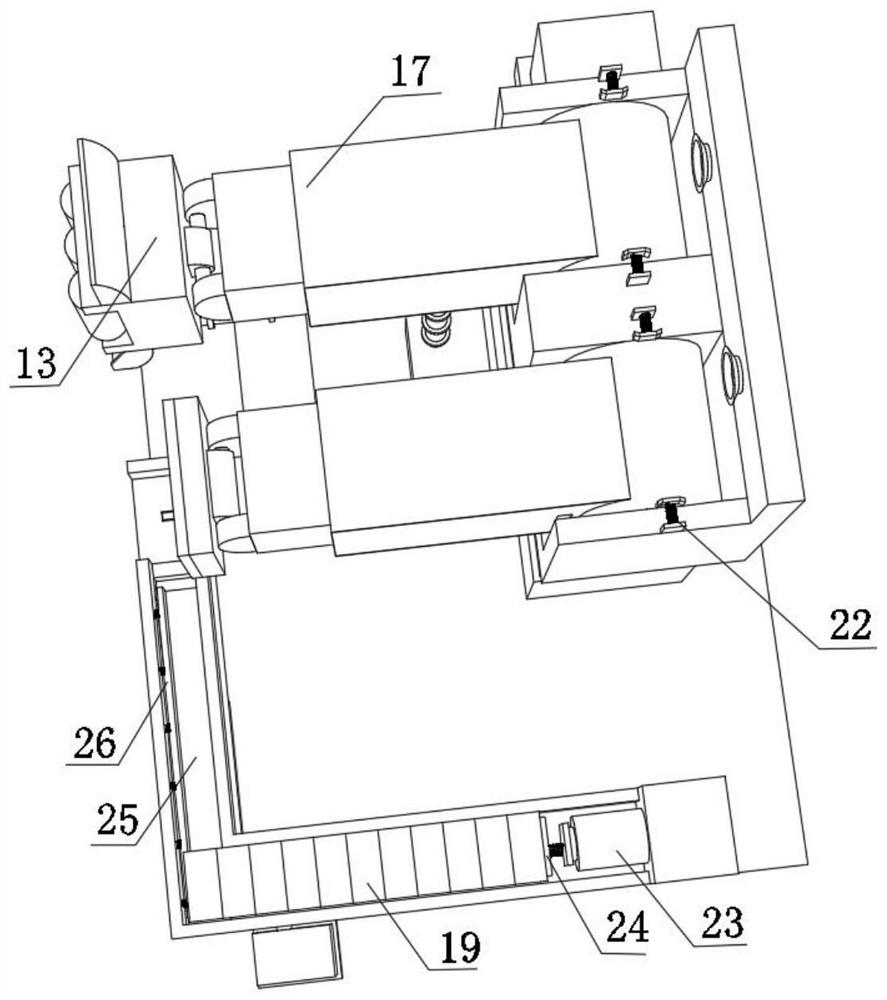

Automatic drawing brick clamping machine

InactiveCN105329662AImprove handling efficiencyFlexible rotationConveyor partsHydraulic cylinderReciprocating motion

The invention relates to the technical field of machines, in particular to an automatic drawing brick clamping machine. The brick clamping machine comprises a fixing rotation frame 1, a drawing guide rail 2, movable combined brick clamps 3, a hydraulic cylinder 4, drawing frames 5, pull rods 6, a rotating gear 7 and a speed reducer and drive gear 8. The drawing guide rail 2 is sleeved with the fixing rotation frame 1. The fixing rotation frame 1 is provided with the rotating gear 7. The gear 7 is meshed with a drive gear installed on a speed reducer shaft. The drawing frames 5 are installed in sliding grooves of the drawing guide rail 2. The drawing frames 5 are composed of the movable combined brick clamps 3 and the pull rods 6, are connected with a piston rod of the hydraulic cylinder 4 and do vertical drawing and expanding movement along the sliding grooves along with the reciprocating movement of the piston rod. The number of clamped and placed bricks is large, loading and unloading are flexible, the application range is wide, and the brick carrying efficiency is greatly improved.

Owner:张利平 +1

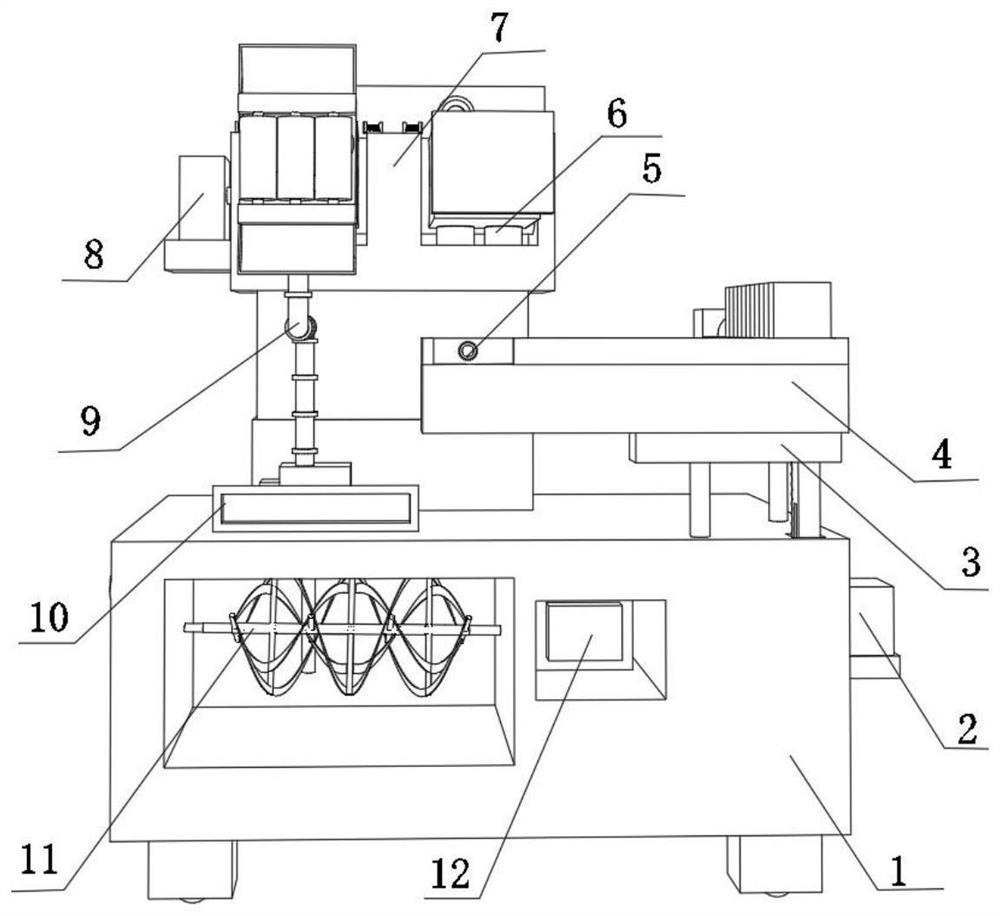

Multifunctional two-way pressure vibration brick making machine

InactiveCN101733824BStir quicklyAvoid unevennessCeramic shaping apparatusAutomatic controlMachine control

Owner:WUHAN BANDAO HEAVY IND

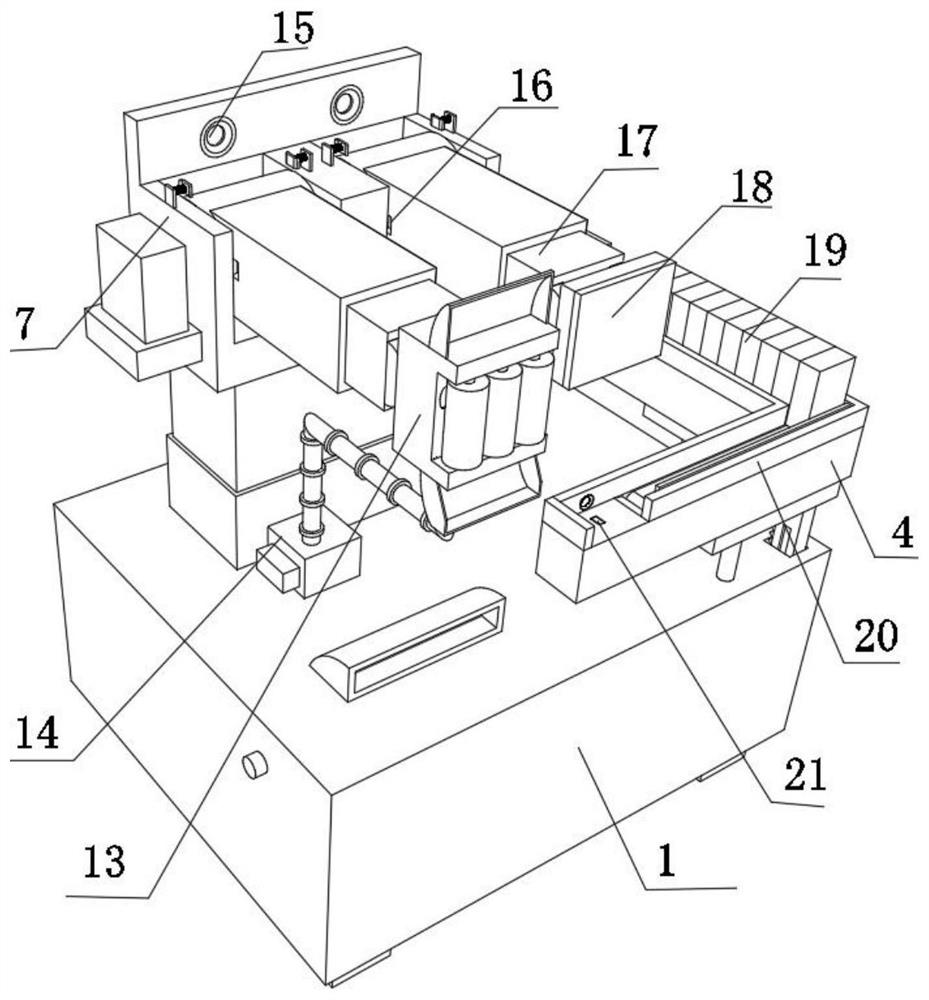

Bidirectional static pressure building block forming machine

InactiveCN110893641AAvoid cavitiesQuality improvementDischarging arrangementFeeding arrangmentsMolding machineBrick clamp

The invention discloses a bidirectional static pressure building block forming machine. A structure comprises a main rack, a lower oil cylinder, an upper oil cylinder, a guide device, an oil tank, a quantifying device, a material distribution vehicle, a brick clamping device, a material distribution vehicle support and a blank pushing and feeding sensor. A lower portion of the main rack is fixedlyconnected with the lower oil cylinder. An upper end of the lower oil cylinder is fixedly connected with a base of a lower die through a connecting frame. The upper portion of the main rack is fixedlyconnected with the upper oil cylinder. During a normal working process, after feeding is completed, the upper oil cylinder drives the upper die to move downwards; and the lower oil cylinder drives the lower die to move upwards, bricks can be pressed and formed after the upper die makes contact with the lower die, then the brick clamping device clamps the formed bricks out, and work of a next period can be performed. Cavities generated in the work process can be effectively avoided, product quality is improved, the upper die and the lower die move at the same time, and operation efficiency isimproved.

Owner:中科德冠(福建)科技有限公司

Cement brick loader

The invention discloses a cement brick loader, comprising a triangular support, a lifting mechanism, a suspension rod and a chain hoist, wherein the triangular support comprises a vertical support, a transverse support and two diagonal bracings; the vertical support comprises two vertical rods and a plurality of cross rods; the lifting mechanism comprises a positioning cross rod, an ejector rod, a winch, a steel wire rope and a pulley block, wherein the positioning cross rod is arranged between the two vertical rods and capable of moving along the vertical rod up and down, and also can be positioned on the vertical rod through a pin; the lower end of the ejector rod is connected with the middle part of the positioning cross rod, while the upper end thereof penetrates through the top of the vertical support and in rotational connection with the middle part of the suspension rod through a bearing; the pulley block comprises a fixed pulley and a movable block; the winch is arranged on the transverse support; one end of the steel wire rope is wound around the winch, while the other end thereof is connected with the positioning cross rod round the pulley block; the chain hoist is arranged at one side of the suspension rod; and the chain hoist catches on a cement brick clamp through a lifting hook. The cement brick loader provided by the invention is capable of clamping a plurality of cement bricks simultaneously; and as a result, the traditional manual carrying manner is changed and the labor efficiency is effectively improved.

Owner:零永孝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com