Intelligent brick clamping machine

A brick clamping machine and intelligent technology, applied in the stacking of objects, destacking, transportation and packaging of objects, etc., can solve the problems of unable to change the direction of clamping bricks, unable to unload bricks automatically, etc., and achieve fast and reliable unloading of bricks. , easy to promote, good general effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but is not limited to the content described below.

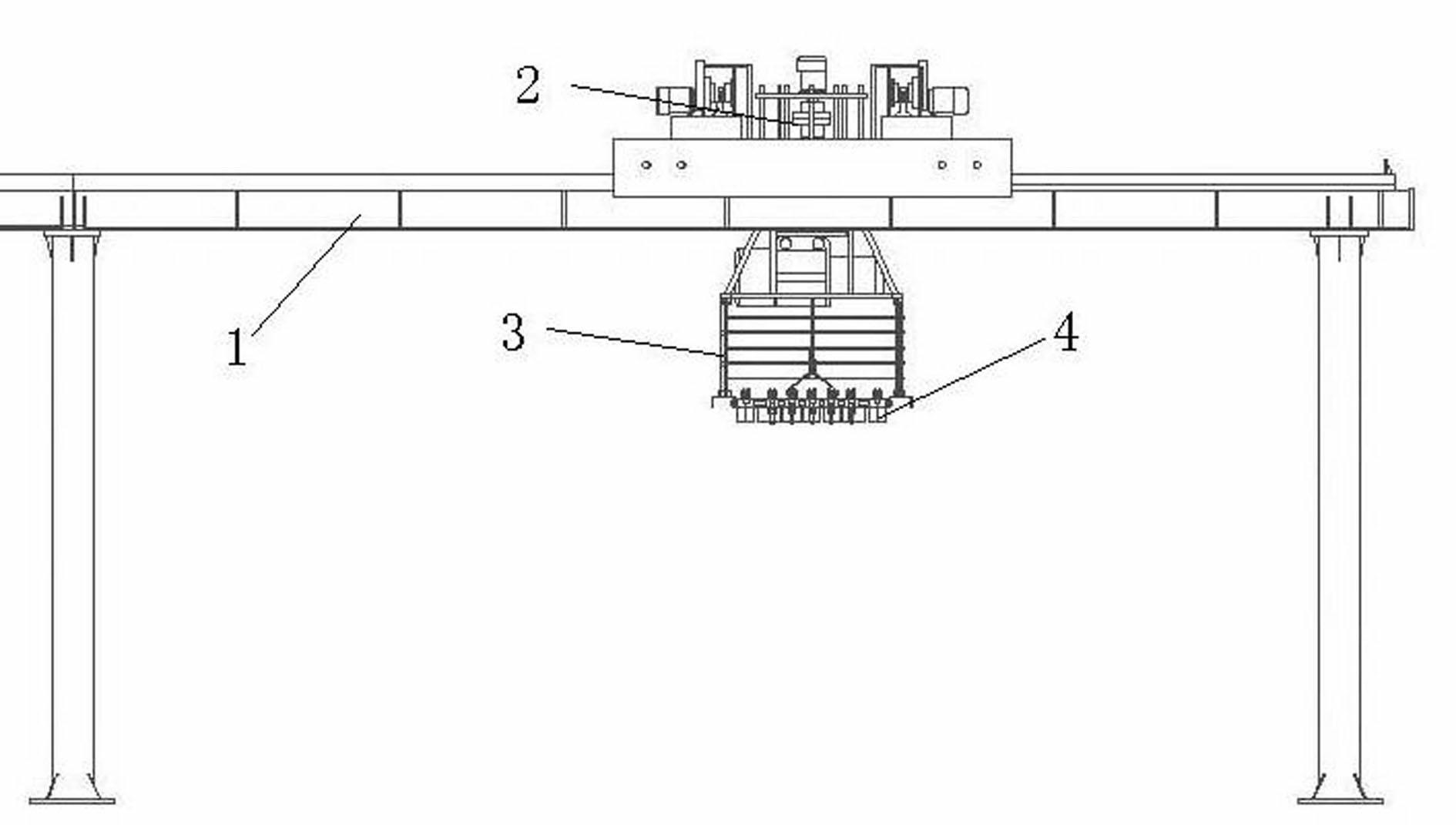

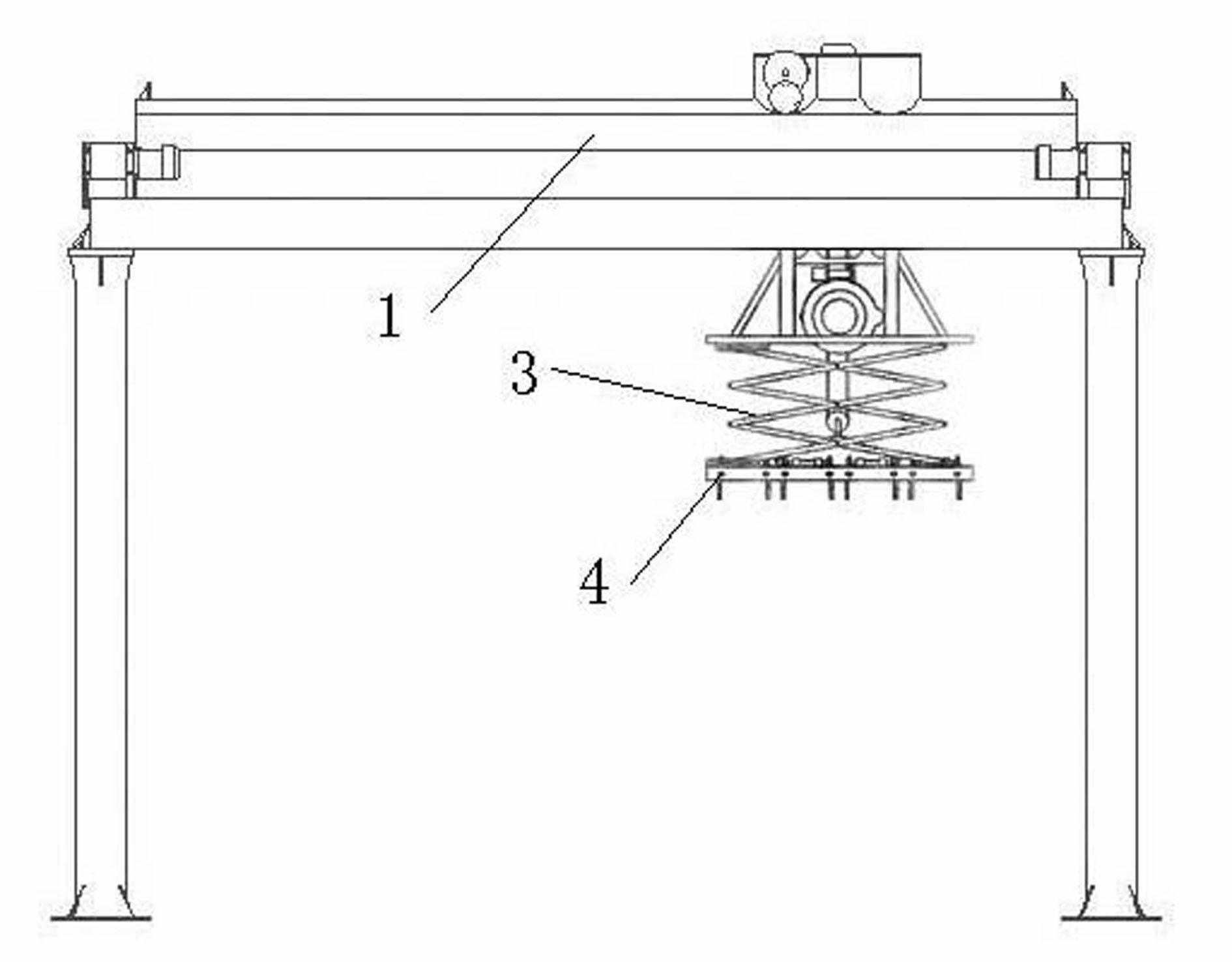

[0030] The intelligent brick clamping machine provided by the invention has a structure such as figure 1 and figure 2 As shown, it is mainly composed of a crane 1, a rotating mechanism 2, a lifting mechanism 3 and a brick unloading fixture 4, and is controlled by a PLC programmable controller and a hydraulic mechanism. 1, the lifting mechanism 3 is connected to the lower end of the rotating mechanism 2, and the brick unloading clamp 4 is connected to the lower end of the lifting mechanism 3, and each mechanism is controlled by a PLC programmable controller.

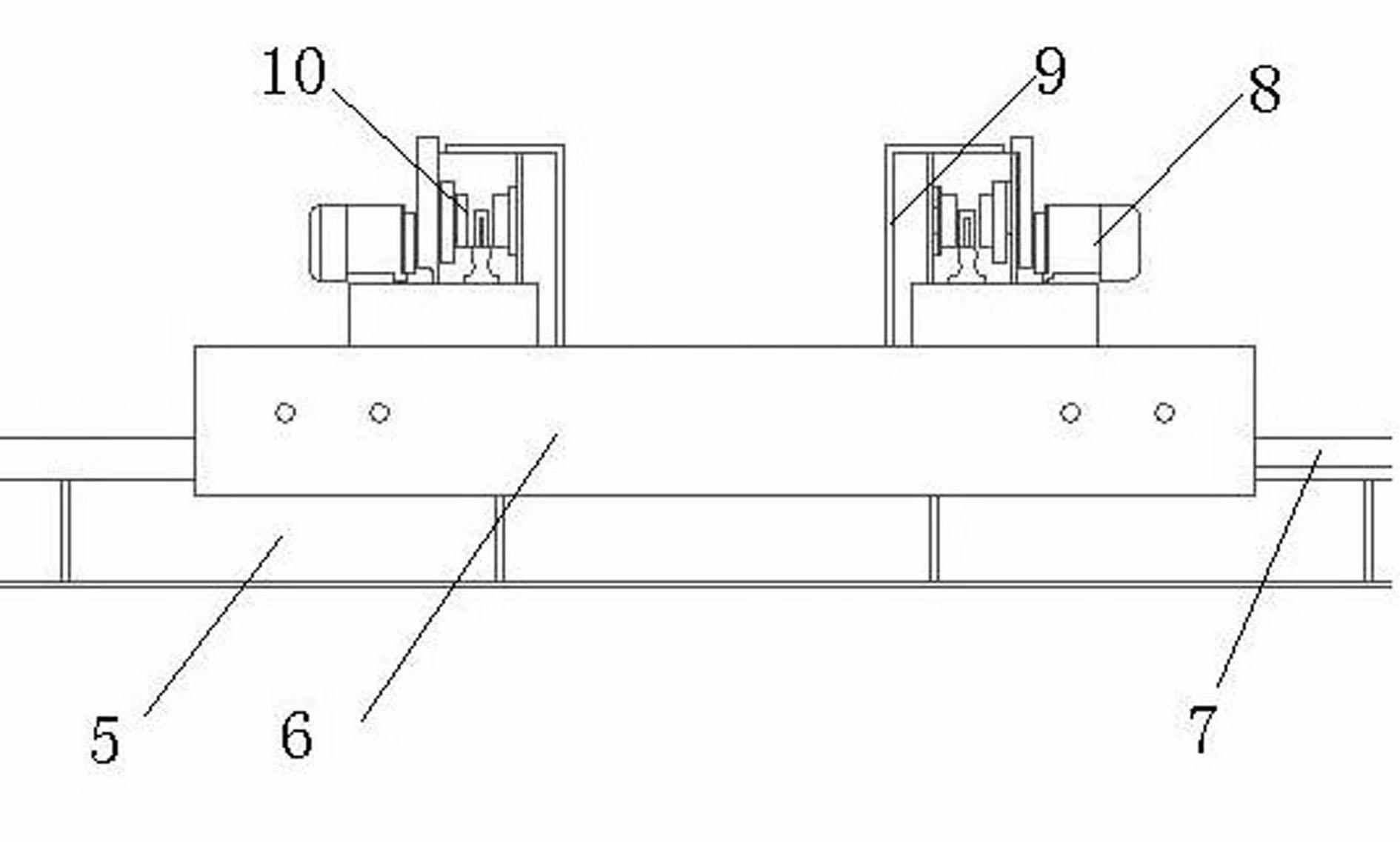

[0031] The crane 1 is a double-girder structure, including a main beam 5 and an auxiliary beam 6, supported by a column 12, and the specific structure is as follows: image 3 and Figure 4 As shown, the main girder light rail 7 is laid on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com