Full-automatic bulk cargo storage yard stacking and taking method

A fully automatic, yard technology, applied in transportation and packaging, loading/unloading, etc., can solve the problems of low degree of automation, low operation efficiency, and high labor intensity of operators, and achieve the effect of overcoming low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

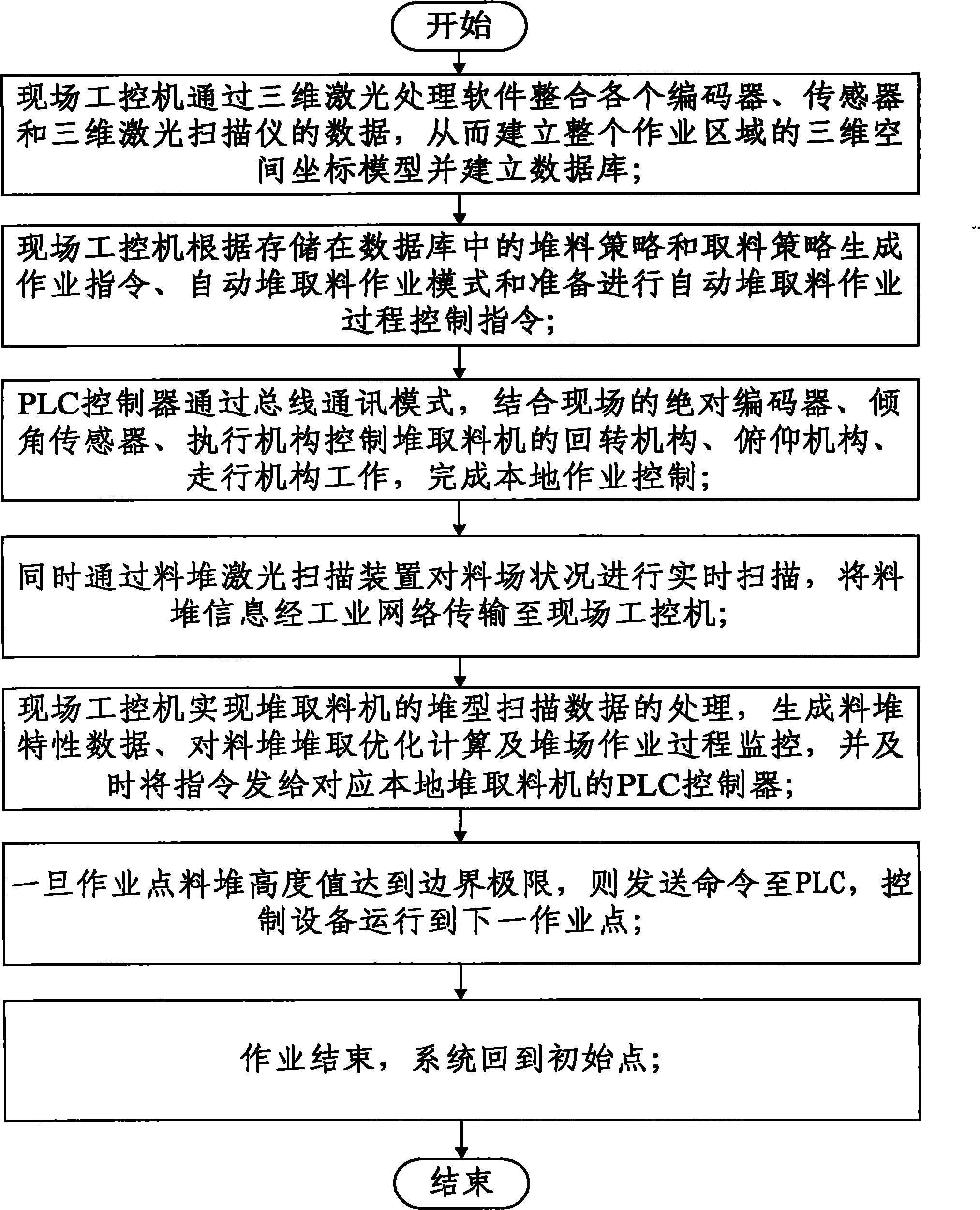

[0022] like figure 1 The shown full-automatic bulk cargo yard stacking method comprises the following steps:

[0023] (1) The 3D laser scanner and the PLC controller are connected to the on-site industrial computer through TCP / IP. The on-site industrial computer integrates the data of each encoder, sensor and 3D laser scanner through the 3D laser processing software to establish a 3D image of the entire operation area. Space coordinate model, 3D laser processing software calculates the best initial point of stacking and reclaiming, and inputs it into the database of the on-site industrial computer;

[0024] (2) The on-site industrial computer generates operation instructions, automatic stacking and retrieving operation modes and preparations for automatic stacking and retrieving operation process control instructions according to the stacking strategy and retrieving strate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com