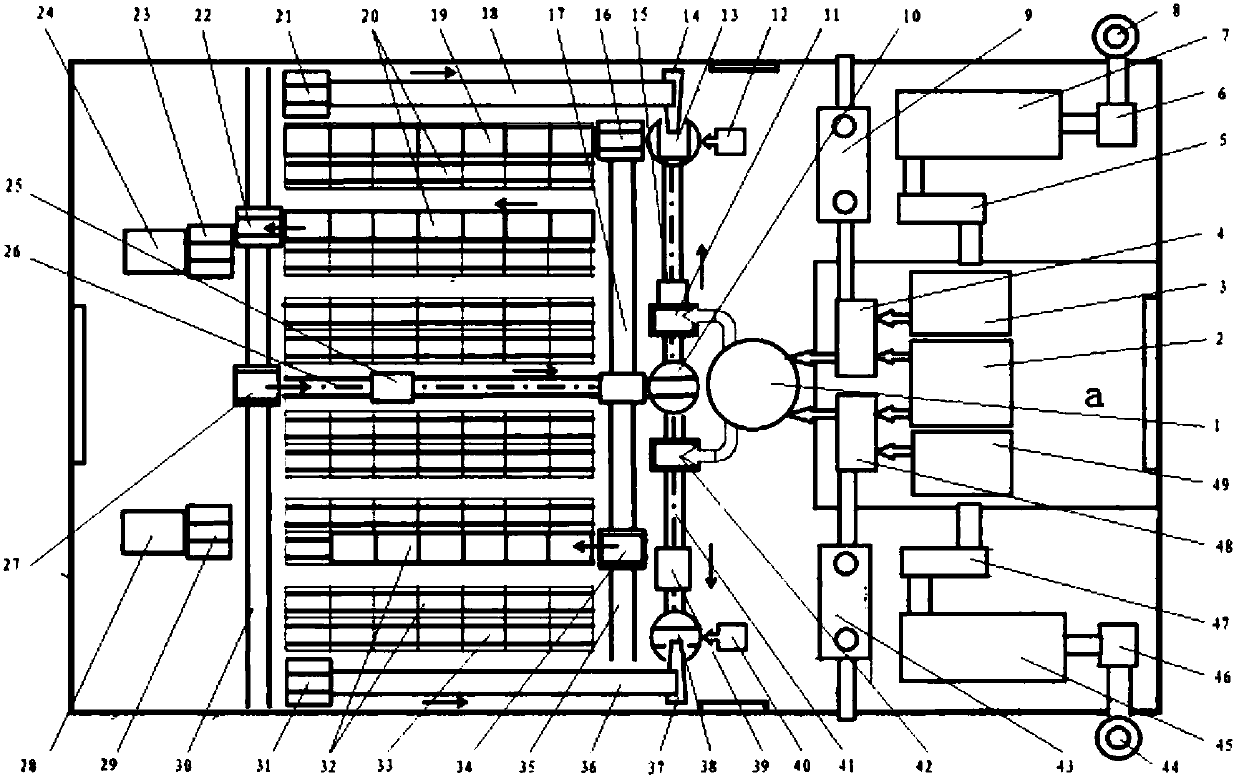

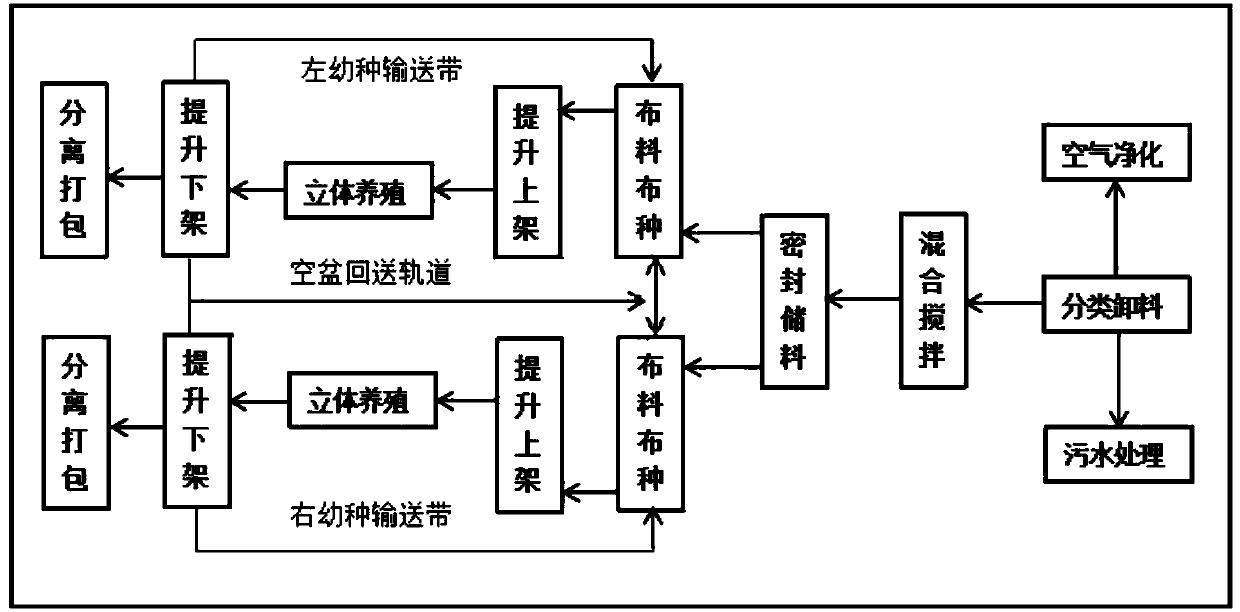

Automatic treatment system of organic waste bio-utilization technology

A technology of organic waste and treatment system, which is applied in the field of automatic biological treatment of organic waste, can solve the problems of high labor intensity, low processing capacity, and low production efficiency, and achieve the goal of overcoming high labor intensity, avoiding environmental pollution, and improving production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 is a single-cycle organic waste biological utilization technology automatic processing system, referring to Figure 4 As shown, this system includes 1 set of cloth seed, lifting upper rack, three-dimensional breeding, lower rack unloading system and 1 empty pot return track;

Embodiment 2

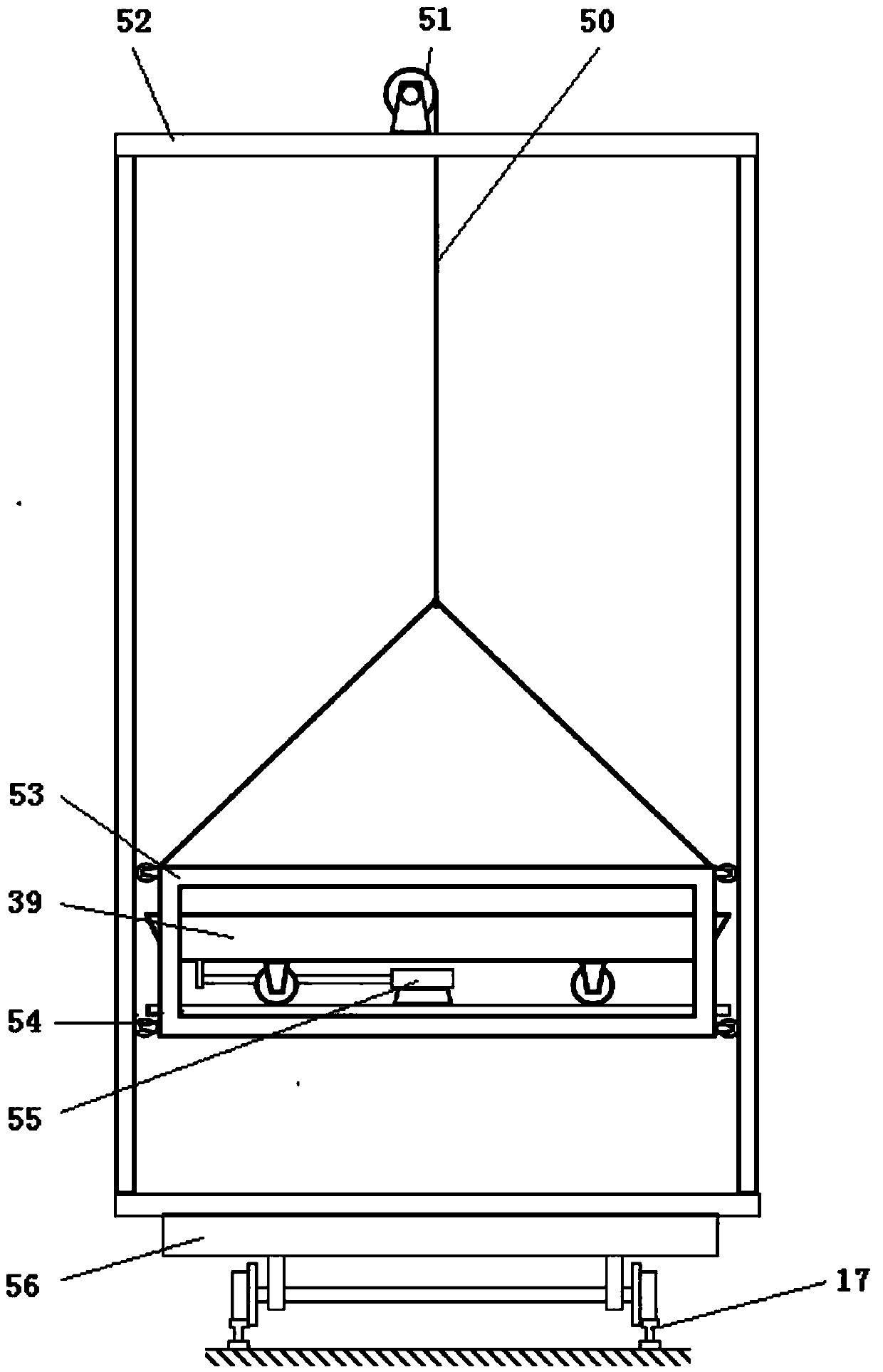

[0038] Embodiment 2 is a horizontal single-cycle organic waste biological utilization technology automatic processing system, referring to Figure 5 As shown, this system includes a set of fabric cloth, three-dimensional breeding, unloading from the rack and a horizontal lifting rack system, and the present embodiment is not provided with an empty basin return track.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com