an x-ray source

An X-ray and emission component technology, applied in the field of X-ray generating devices, can solve the problems of reducing the accuracy of XPS experimental results, reducing the service life of filaments, and inconvenience to users, and achieves compact structure, adjustable X-ray intensity, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

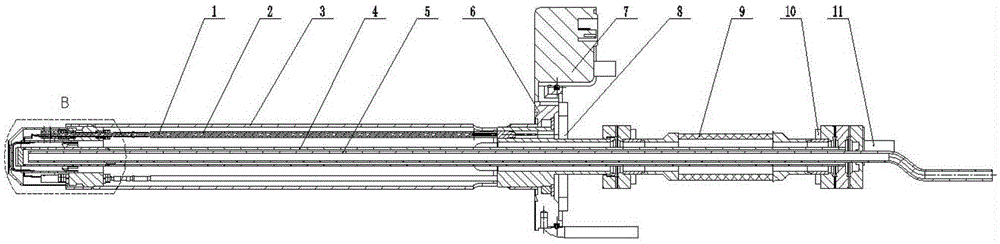

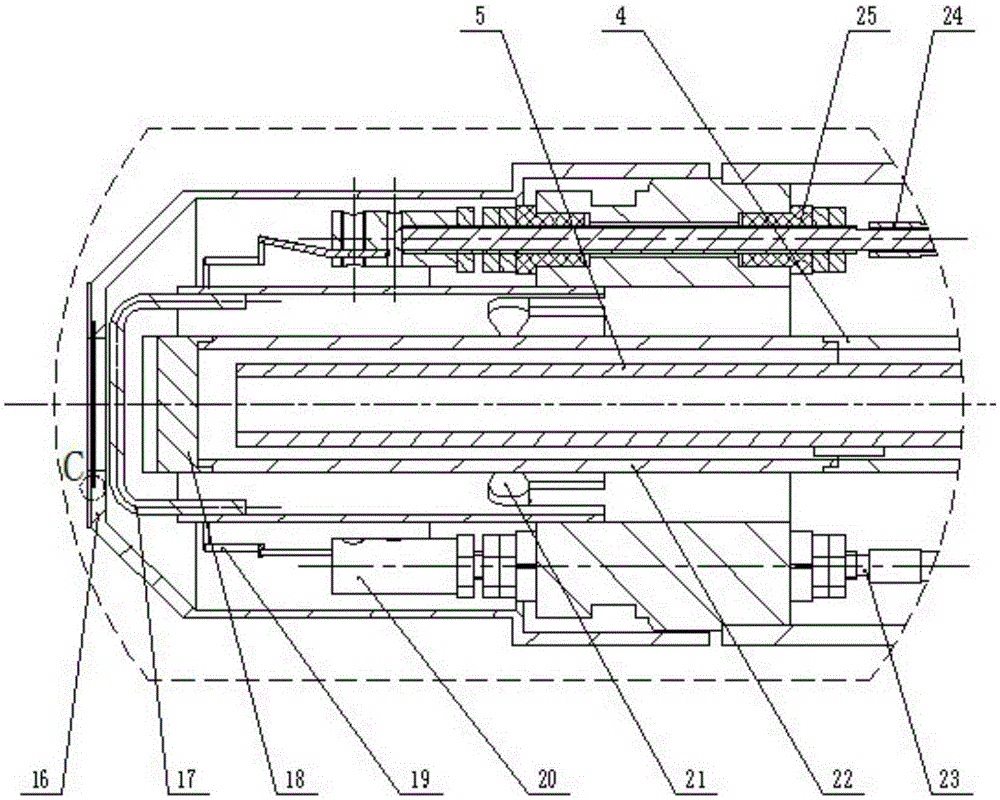

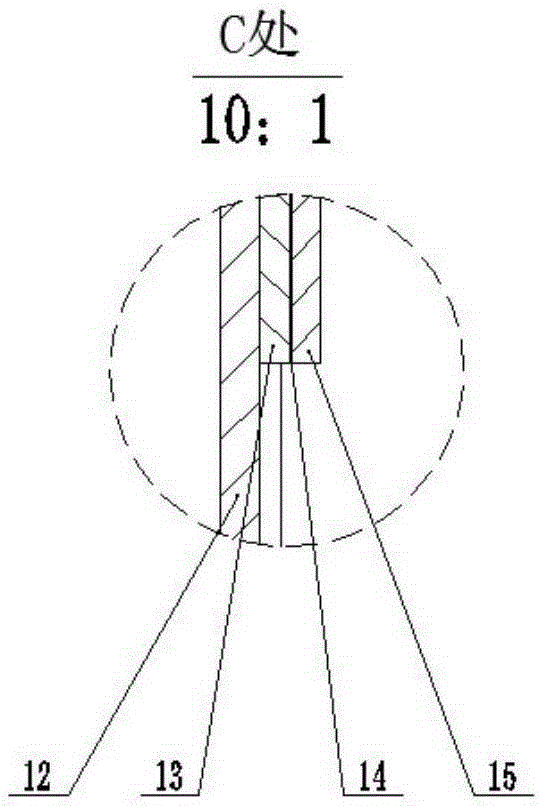

[0032] Such as Figure 1-7 Shown: an X-ray source, the filament 19 releases thermal electrons after being energized, and the thermal electrons are accelerated to a high energy of up to 15keV and then bombard the anode target. Based on the principle of photoelectric effect and electron energy level transition outside the nucleus, the anode target emits emit X-rays of a certain wavelength.

[0033] Since the present invention is a dual-anode X-ray source, two tungsten wires are also designed. For different X-ray requirements, select the corresponding tungsten wire to emit thermal electrons.

[0034] The anode targets of the present invention are selected from Mg a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com