Tank type container

A tank container and tank body technology, applied in the directions of packaging, transportation and packaging, containers, etc., can solve the problems of the tank container bottom beam bearing excessive load and reducing the distance, and achieve the effect of improving the stress condition and the use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

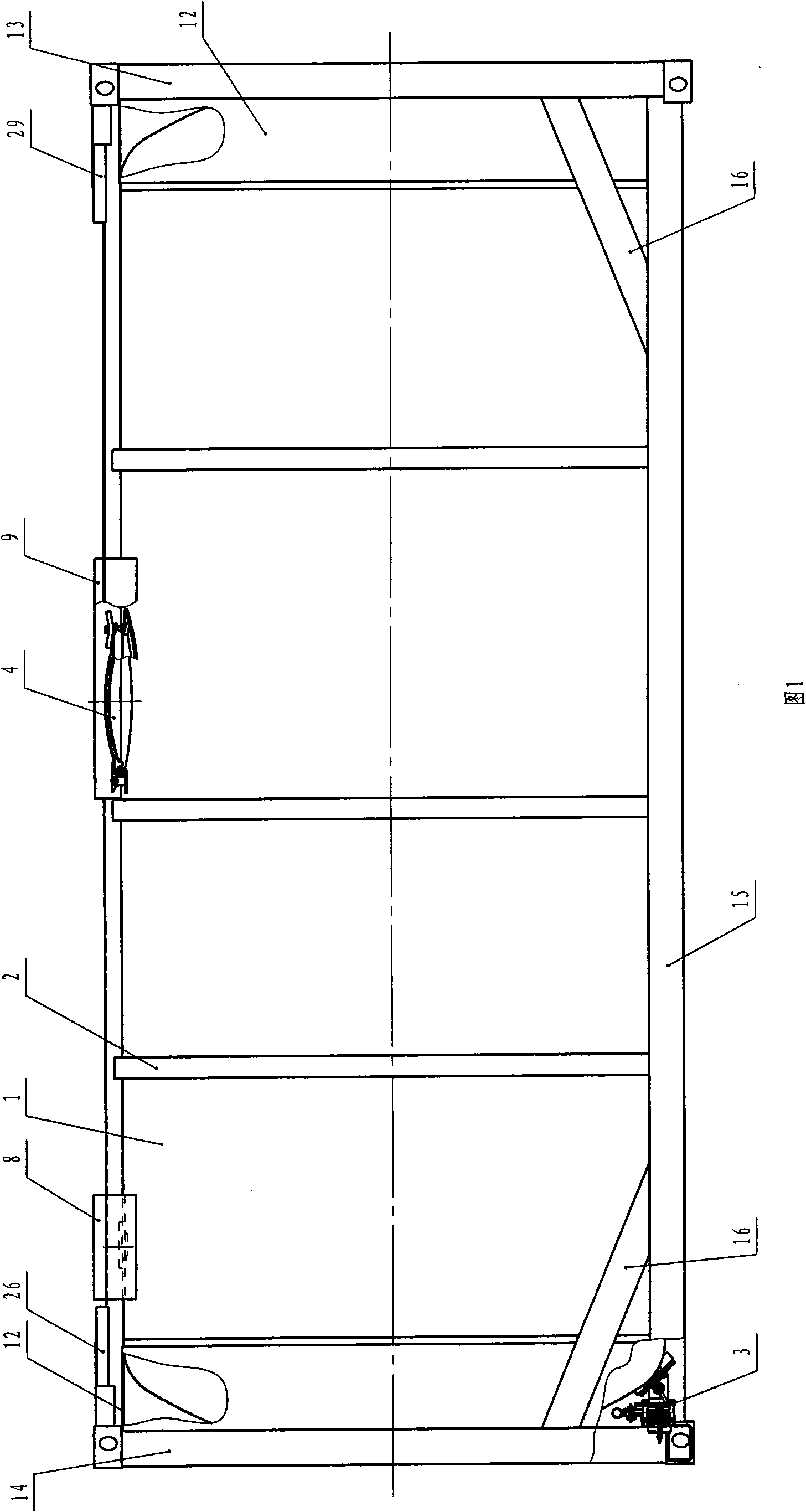

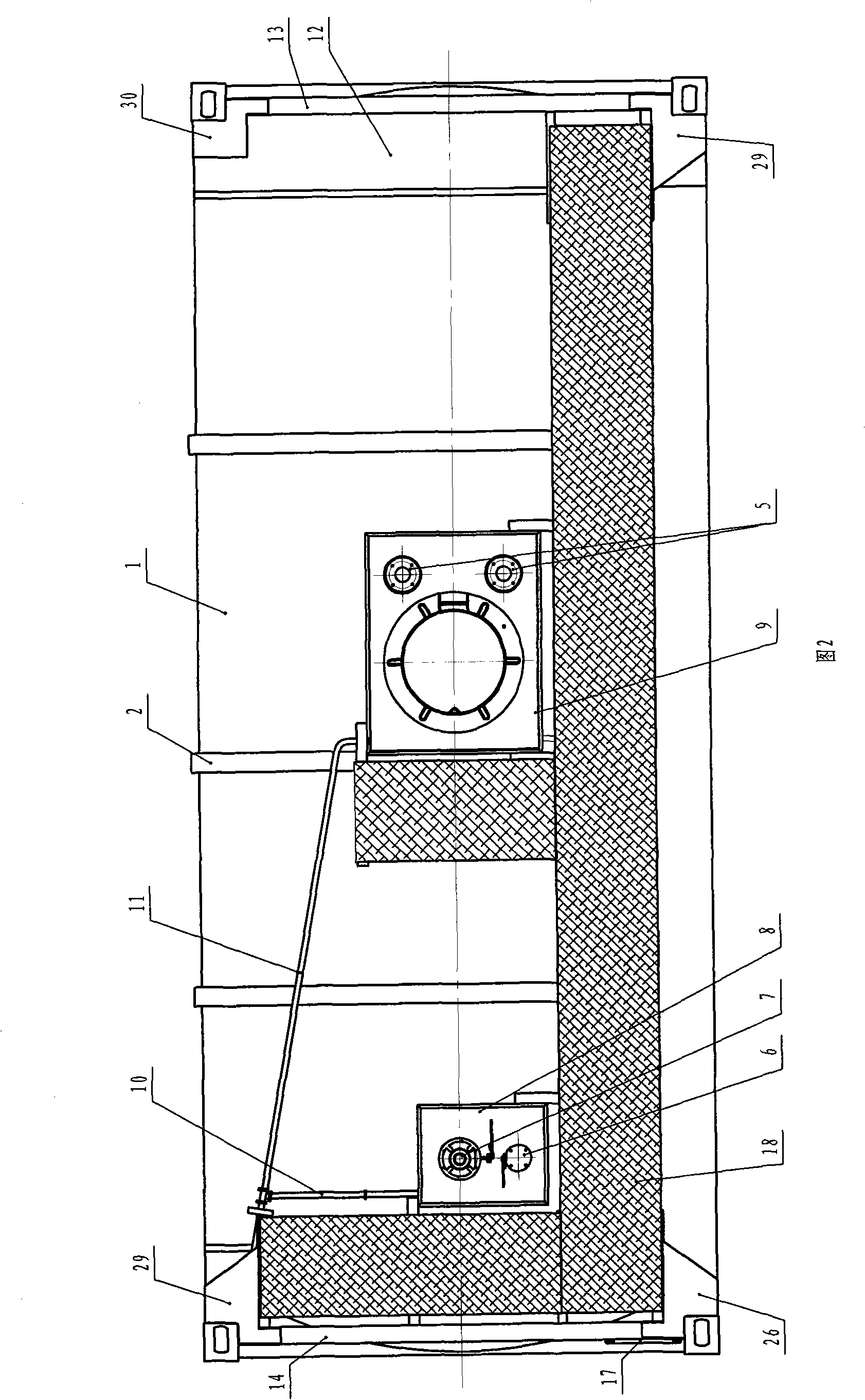

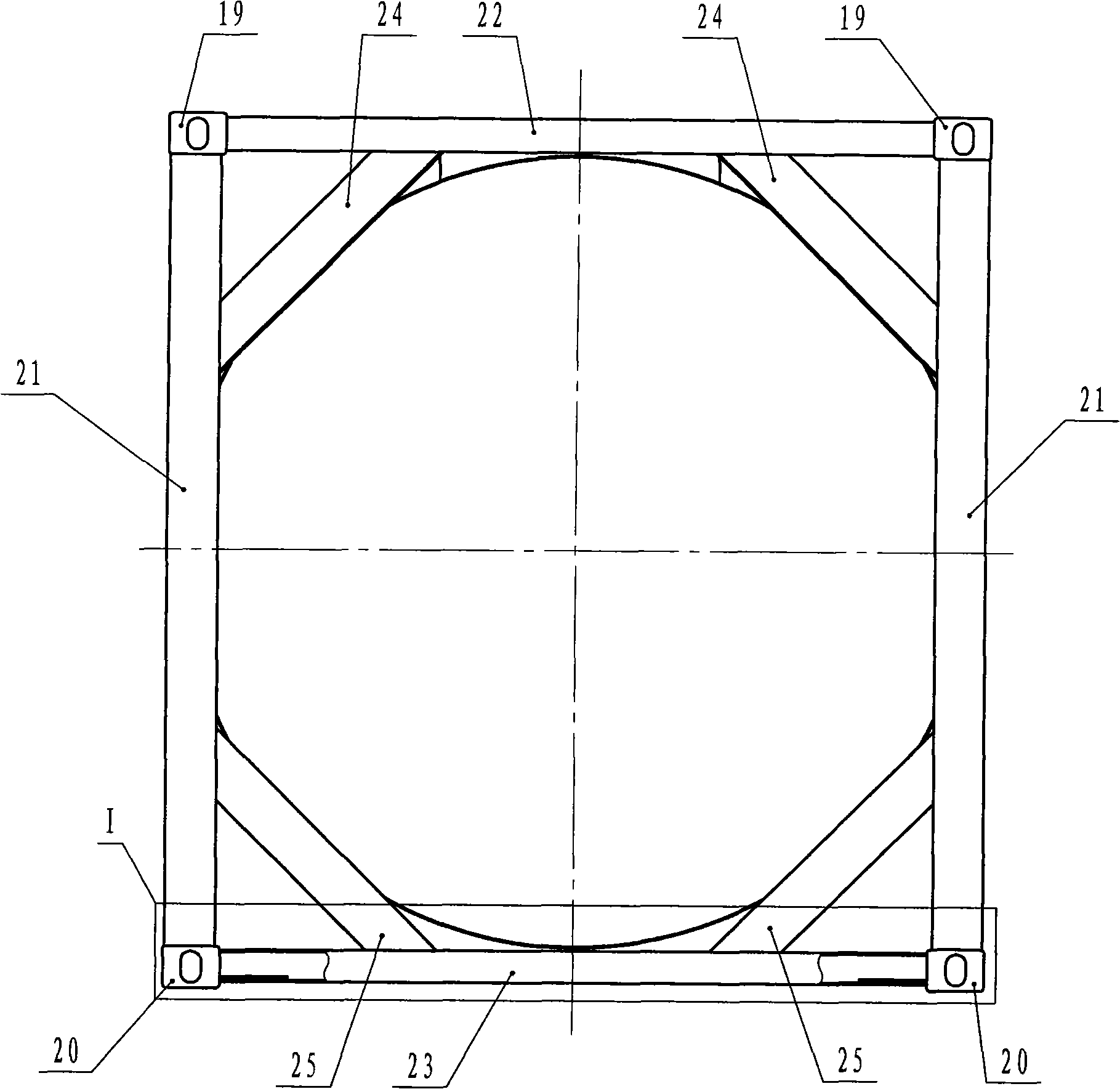

[0030] A tank container (see Figure 1 and Figure 2) has a tank body 1, a reinforcement ring 2 outside the tank body, a bottom discharge valve 3 placed under one end of the tank body, a manhole 4 on the top of the tank body, a safety valve 5, and a gas phase valve 6. Top outlet 7 and overflow boxes 8 and 9, overflow pipes 10 and 11 for leading the liquid in overflow boxes 8 and 9 to the outside of the tank container respectively at the bottom of overflow boxes 8 and 9. The two ends of the tank body 1 are welded with skirt rings 12, and the skirt rings 12 at both ends are respectively welded to the end frames 13 and 14 at both ends, and the end frames 13 and 14 are respectively connected with the longitudinal bottom beam 15 and the reinforced diagonal brace 16, An escalator 17 is fixedly installed on the end frame 14, and the escalator 17 leads to a walkway plate 18 fixedly installed on the top of the tank container. End frame 13 (see image 3 ) consists of top corner fittings 1...

Embodiment 2

[0032] The difference from Embodiment 1 is that the upper reinforcing braces 24 of the end frame 13 and the end frame 14 are made of angle steel materials, which can be processed by folding profiles or plates.

Embodiment 3

[0034] The difference from Embodiment 1 or 2 is: in order to reduce the processing steps of the walkway slab 18, reduce the number of walkway slab supports, and reduce the cost, the top corner plate 26 and the top corner plate 29 at the place where the walkway slab is installed are provided with a walkway Plate shelving edge 31 (see Fig. 7, Fig. 8, Fig. 9, Fig. 10); the top gusset without walkway board can adopt the same form as top gusset 26 and top gusset 29, also can adopt not to set The top gusset 30 (see Fig. 11 and Fig. 12) of the resting edge of the walkway slab.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com