Magnetically Deflected Electron Beam Evaporation Source

A technology of electron beam evaporation and magnetic deflection, applied in vacuum evaporation coating, ion implantation coating, metal material coating process, etc., can solve the problems of pollution, temperature rise, poor temperature control ability, etc., to avoid mutual pollution , Improve the service life, the effect of uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

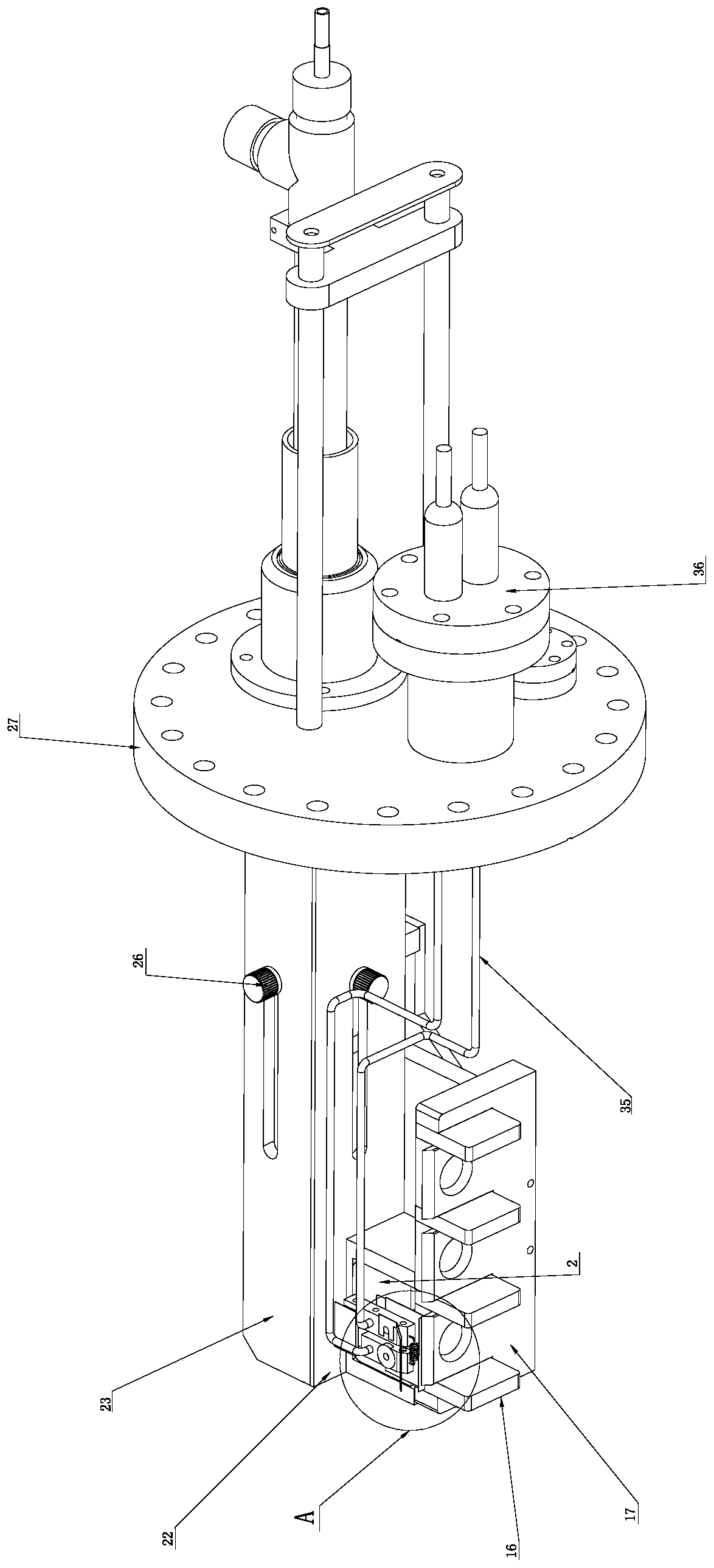

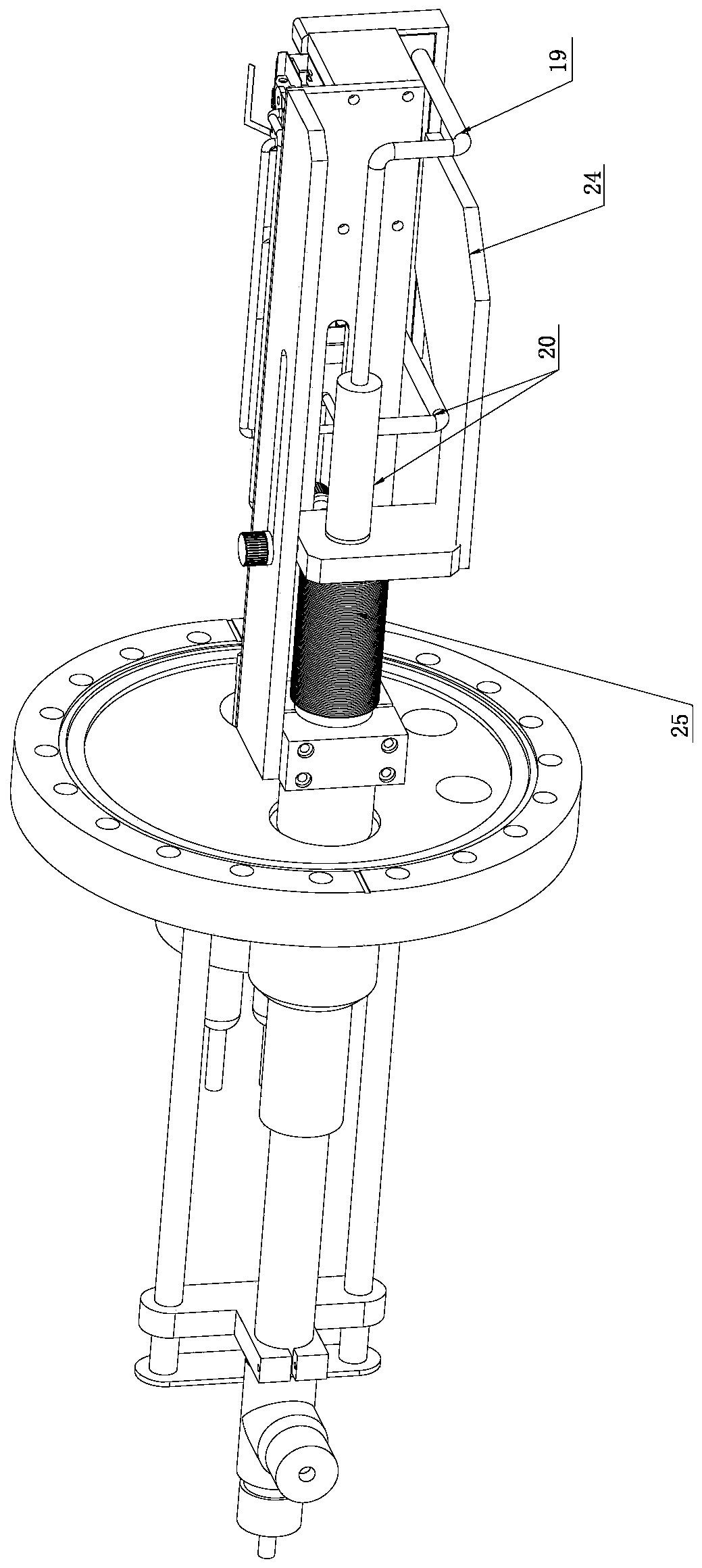

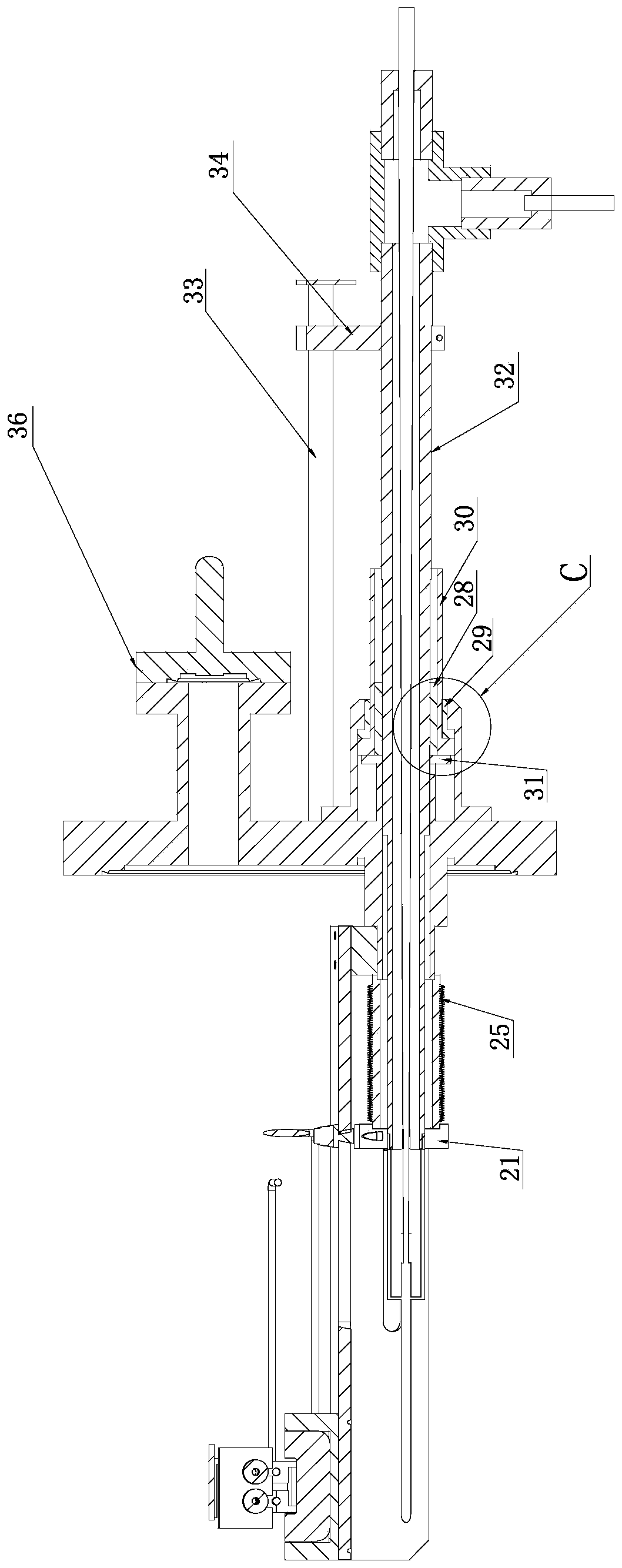

[0040] Such as Figure 1 to Figure 10 A magnetic deflection electron beam evaporation source shown includes: an electron beam generating mechanism, a magnetic deflection assembly, a water-cooled crucible mechanism, a linear transposition mechanism and a working circuit;

[0041] The electron beam generating mechanism includes: filament 8, filament seat A12, filament seat B11, ceramic sheet 10, ceramic seat 9, ceramic seat sleeve 15, support block 13, ceramic column 14, ceramic column protective cover 7, cathode shielding Cover 3, magnet cover 1;

[0042] The filament is fixed on the filament holder A12 and the filament holder B11 by means of screw connection, the filament itself has a certain resistance and generates heat and emits thermal electrons under the condition of negative high voltage and current; the two ceramic sheets 10 are connected by screws fixed in the upper and lower positioning holes of the filament holder A12, the two ceramic holders 9 are located directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com