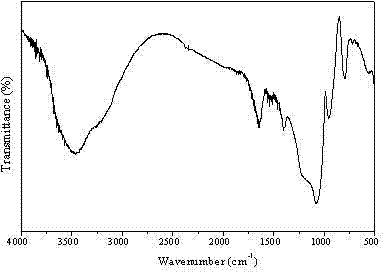

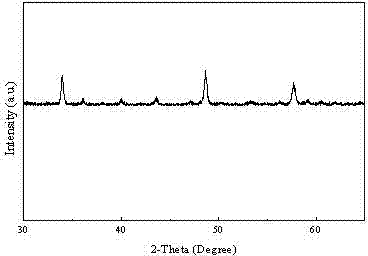

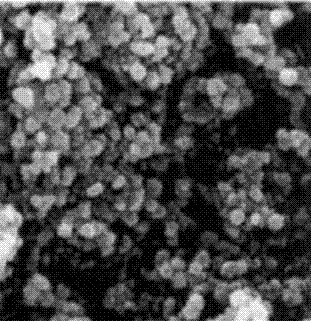

Preparation method of magnetic nano Fe3O4 particles by biological catalysis and application of particles to treatment of uranium-containing wastewater

A magnetic nano, biocatalytic technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve environmental pollution, threats to human living environment, etc., and achieve strong chemical stability , very good adsorption effect, short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The first step, cultivation and domestication of Thiobacillus ferrooxidans

[0034] Measure 20 mL of 745 uranium ore acid pit wastewater into a 250 mL Erlenmeyer flask, add 180 mL of modified 9K medium, and plug it with a sterile cotton plug. Place the Erlenmeyer flask at a temperature of 25 o C. Shaking culture was carried out in a constant temperature incubator with a rotational speed of 100 r / min. When the color of the solution in the Erlenmeyer flask changed from light green to red, take 30 mL of the solution in it to re-cultivate and domesticate twice according to the above method, and then the required Thiobacillus ferrooxidans liquid can be obtained.

[0035] The second step, the preparation of biopolymeric ferric sulfate

[0036] The obtained Thiobacillus ferrooxidans solution was mixed with FeSO 4 ·7H 2 The mass ratio of the O solution is 1.0:2.0, put it into a 250 mL beaker, heat it in a water bath, adjust the pH value of the reaction system to 6.0, and th...

Embodiment 2

[0042] The first step, cultivation and domestication of Thiobacillus ferrooxidans

[0043] Specifically with embodiment 1.

[0044] The second step, the preparation of biopolymeric ferric sulfate

[0045] The obtained Thiobacillus ferrooxidans solution was mixed with FeSO 4 ·7H 2 The mass ratio of the O solution was 1.0:2.0, put it into a 250 mL beaker, heated in a water bath, adjusted the pH value of the reaction system to 7.0, and the reaction temperature was 25 o c. At the same time, control the quality of Thiobacillus ferrooxidans liquid on FeSO 4 Biocatalytic oxidation process to produce Fe 3+ : Fe 2+ A 1:1 solution of biopolymeric ferric sulfate.

[0046] The third step, magnetic nano-Fe 3 o 4 Synthesis of particles

[0047] Put 100 mL of 1.0 mol / L NaOH solution in a 500 mL beaker, put a cup-shaped semi-permeable membrane filled with 200 mL of distilled water into the beaker, and then add biopolymeric ferric sulfate solution dropwise to the semi-permeable membr...

Embodiment 3

[0051] The first step, cultivation and domestication of Thiobacillus ferrooxidans

[0052] Specifically with embodiment 1.

[0053] The second step, the preparation of biopolymeric ferric sulfate

[0054] The obtained Thiobacillus ferrooxidans solution was mixed with FeSO 4 ·7H 2 The mass ratio of the O solution was 1.0:3.0, put it into a 250 mL beaker, heated in a water bath, adjusted the pH value of the reaction system to 7.0, and the reaction temperature was 20 o c. At the same time, control the quality of Thiobacillus ferrooxidans liquid on FeSO 4 Biocatalytic oxidation process to produce Fe 3+ : Fe 2+ A 1:1 solution of biopolymeric ferric sulfate.

[0055] The third step, magnetic nano-Fe 3 o 4 Synthesis of particles

[0056] Put 100 mL of 1.0 mol / L NaOH solution in a 500 mL beaker, put a cup-shaped semi-permeable membrane filled with 200 mL of distilled water into the beaker, and then add biopolymeric ferric sulfate solution dropwise to the semi-permeable membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com