Patents

Literature

48 results about "Natural uranium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural uranium (NU, Uₙₐₜ) refers to uranium with the same isotopic ratio as found in nature. It contains 0.711% uranium-235, 99.284% uranium-238, and a trace of uranium-234 by weight (0.0055%). Approximately 2.2% of its radioactivity comes from uranium-235, 48.6% from uranium-238, and 49.2% from uranium-234.

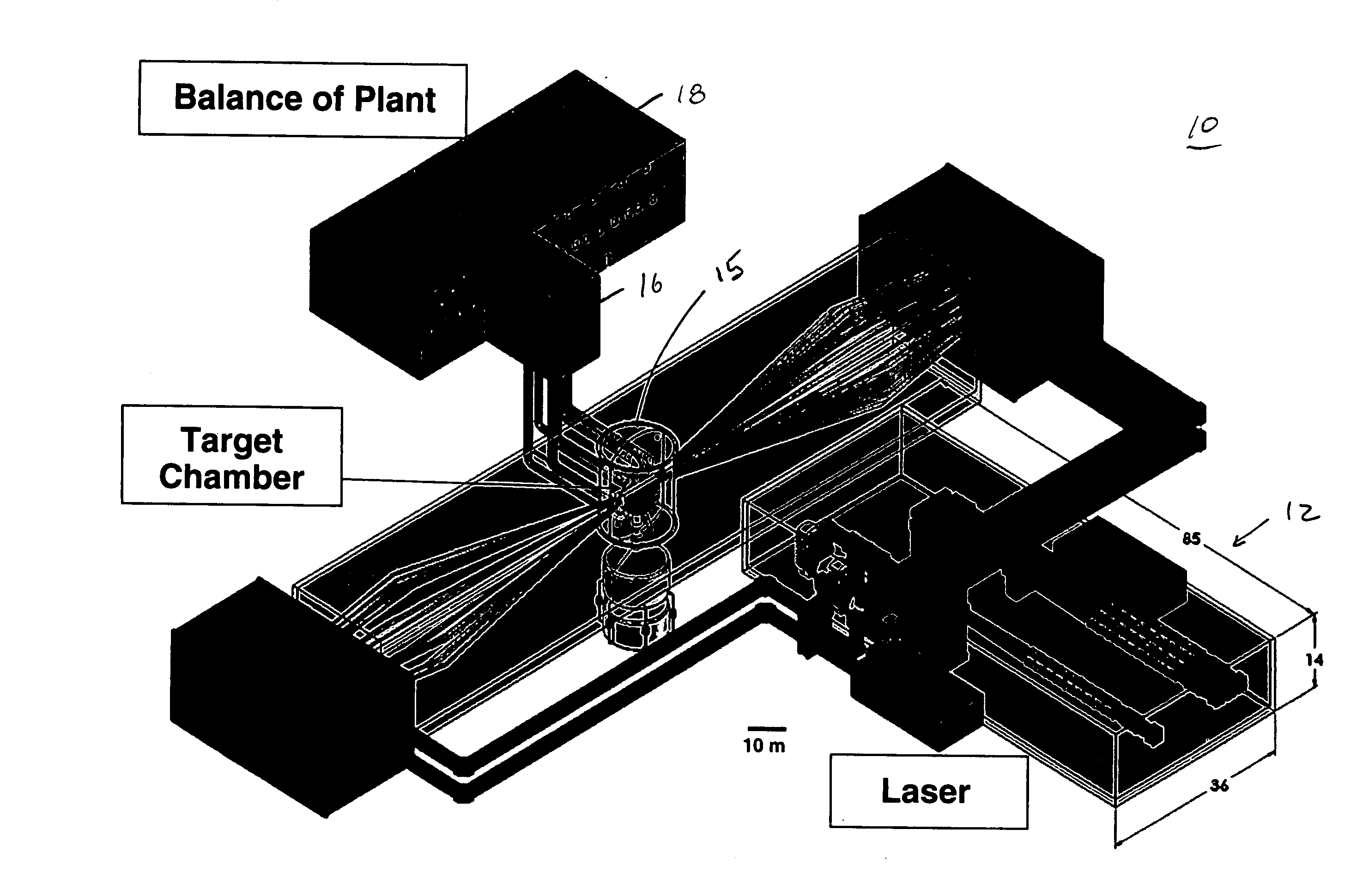

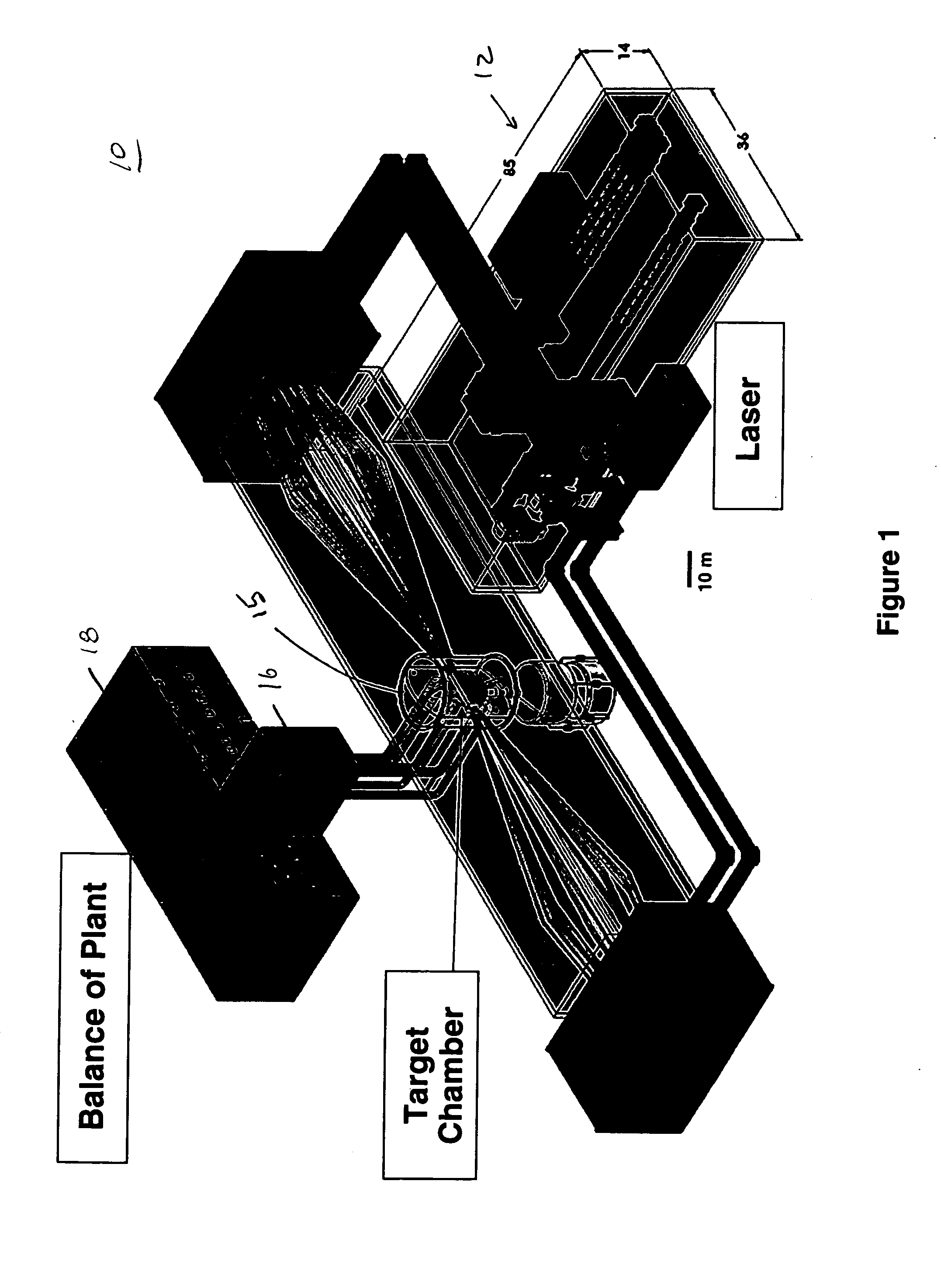

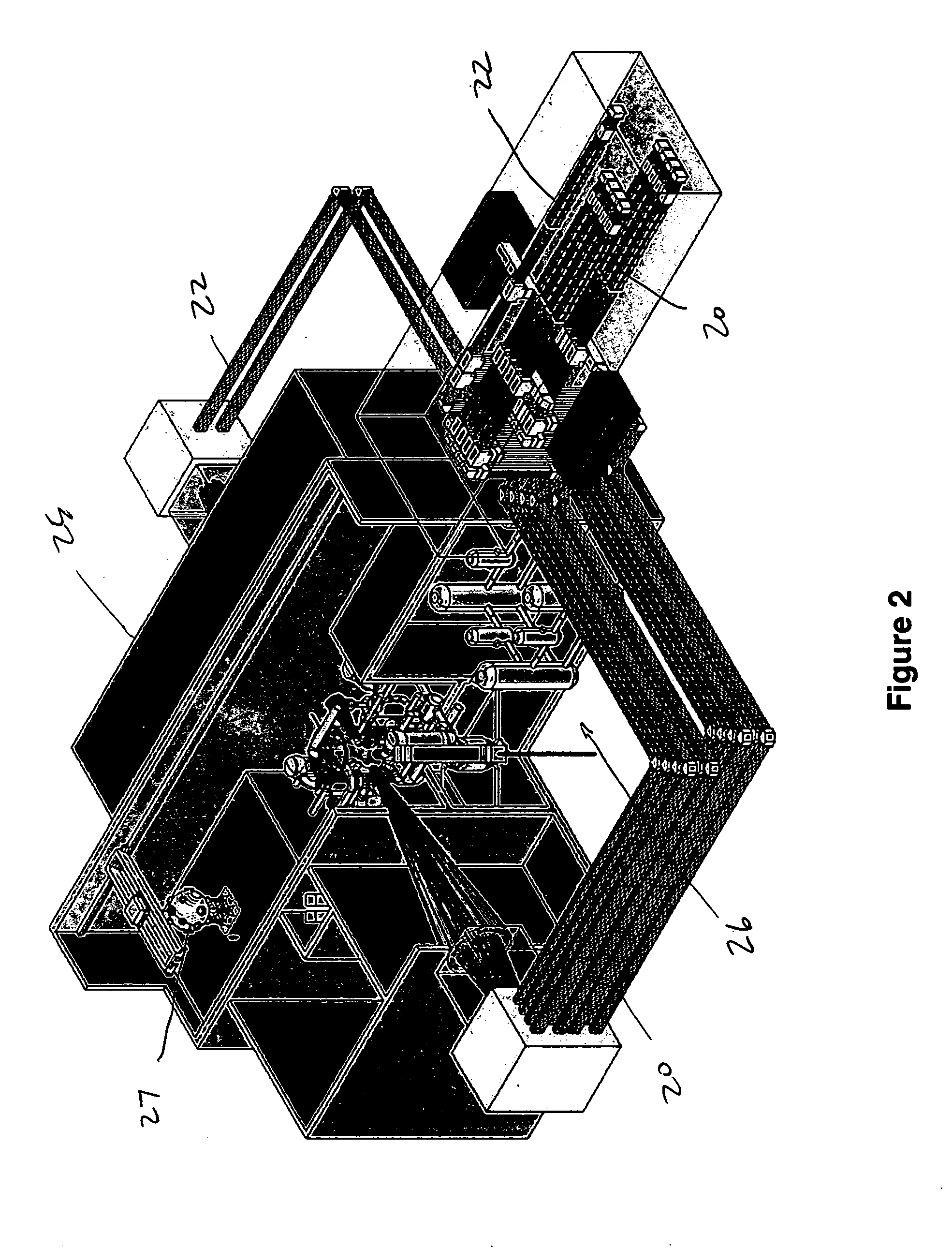

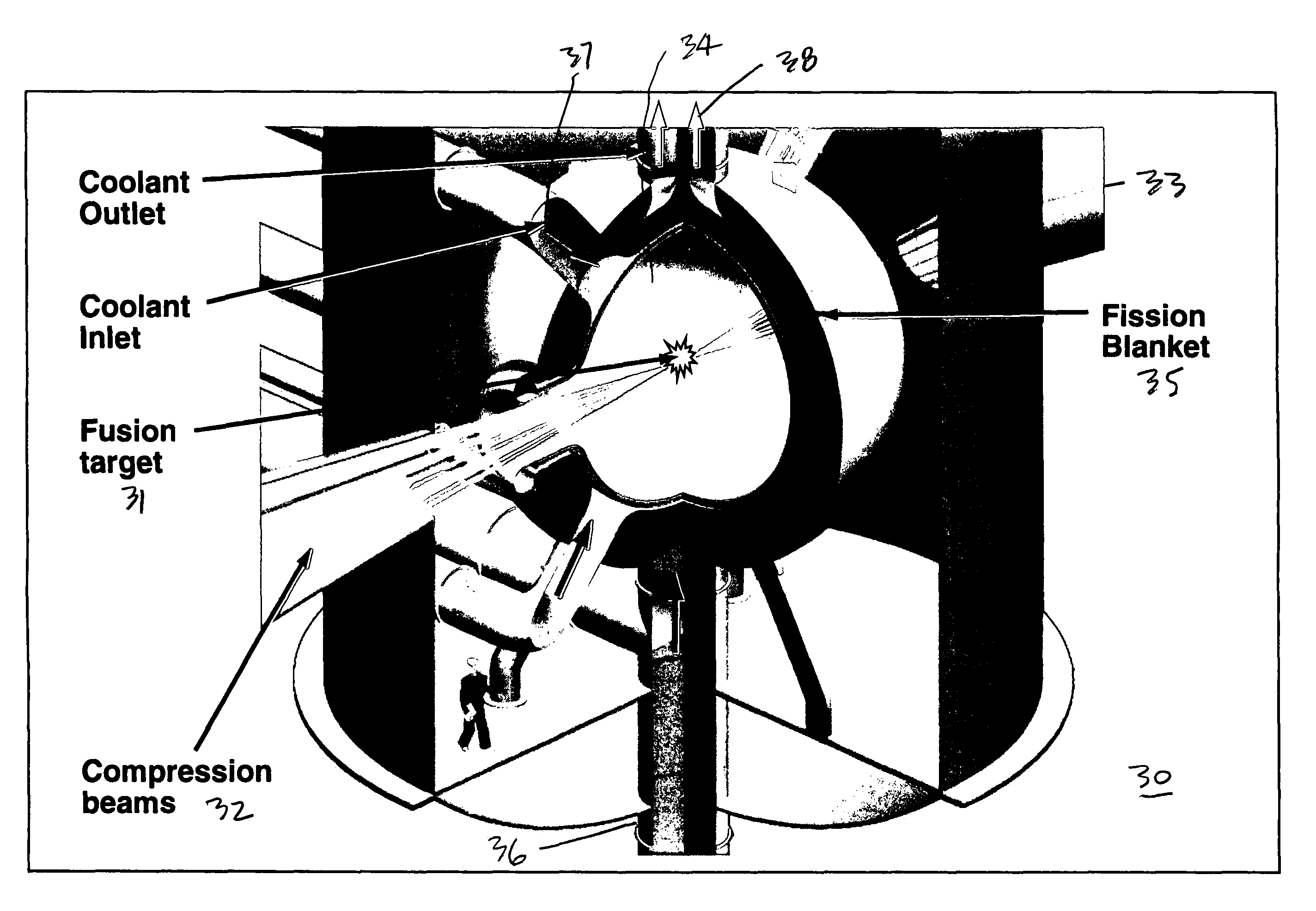

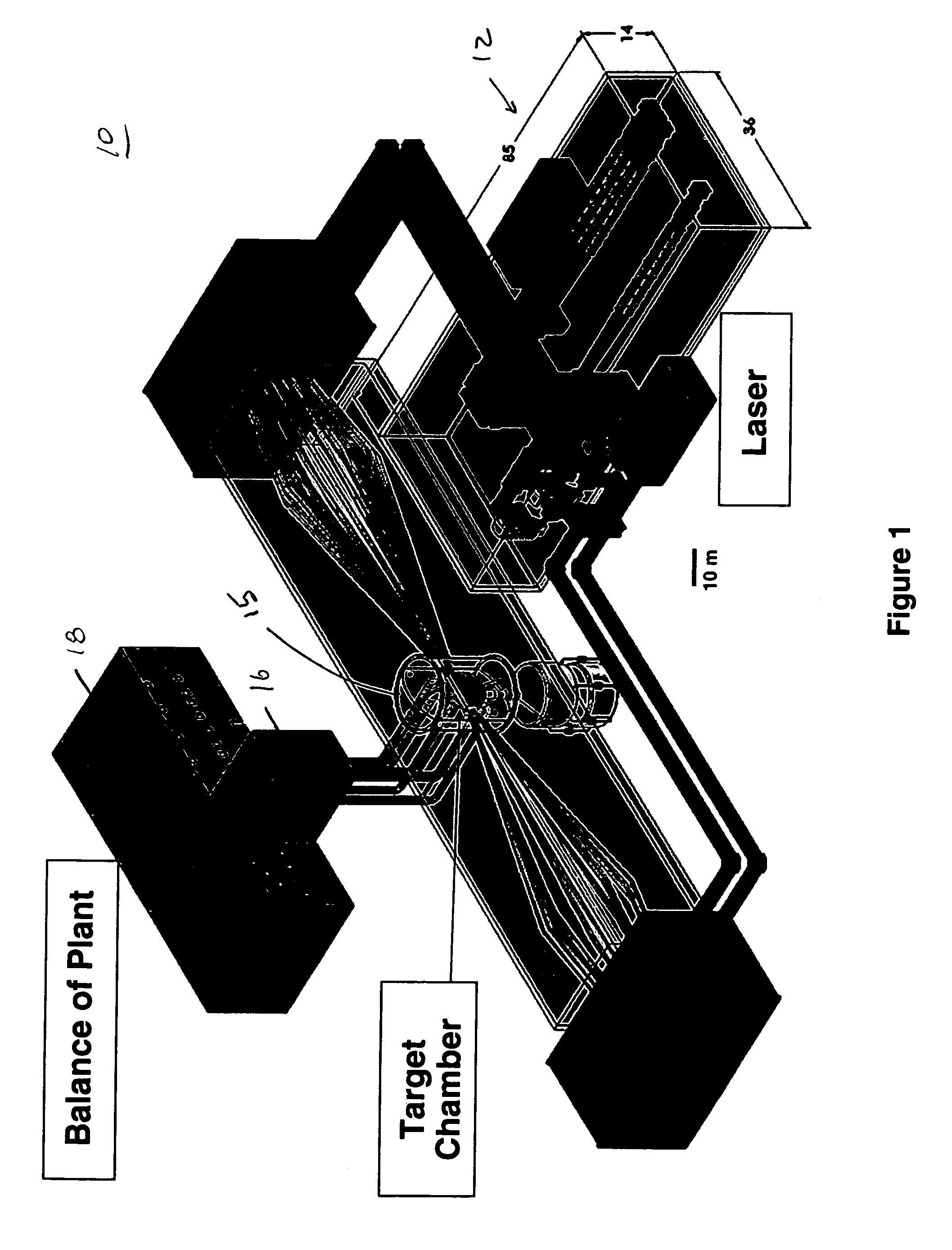

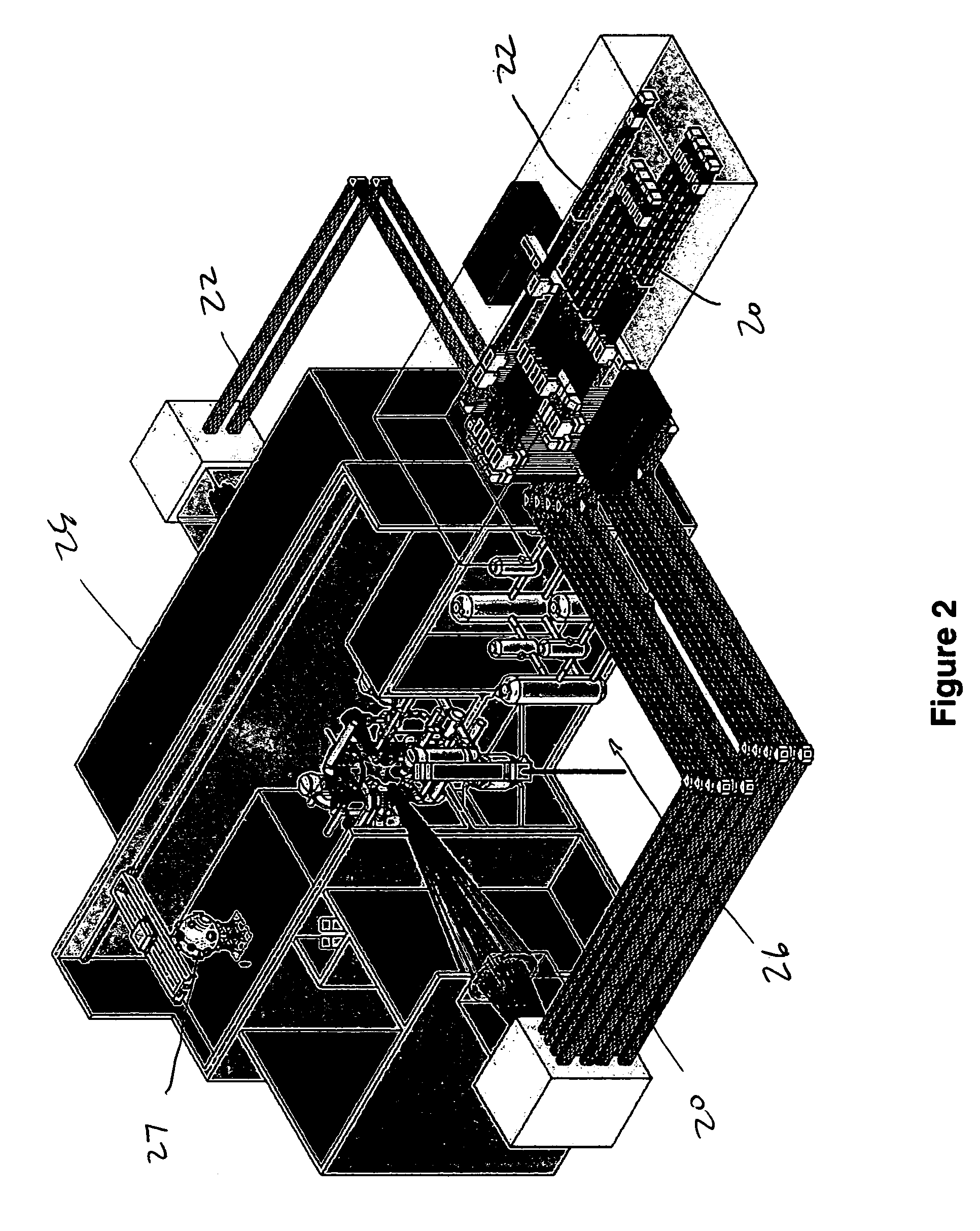

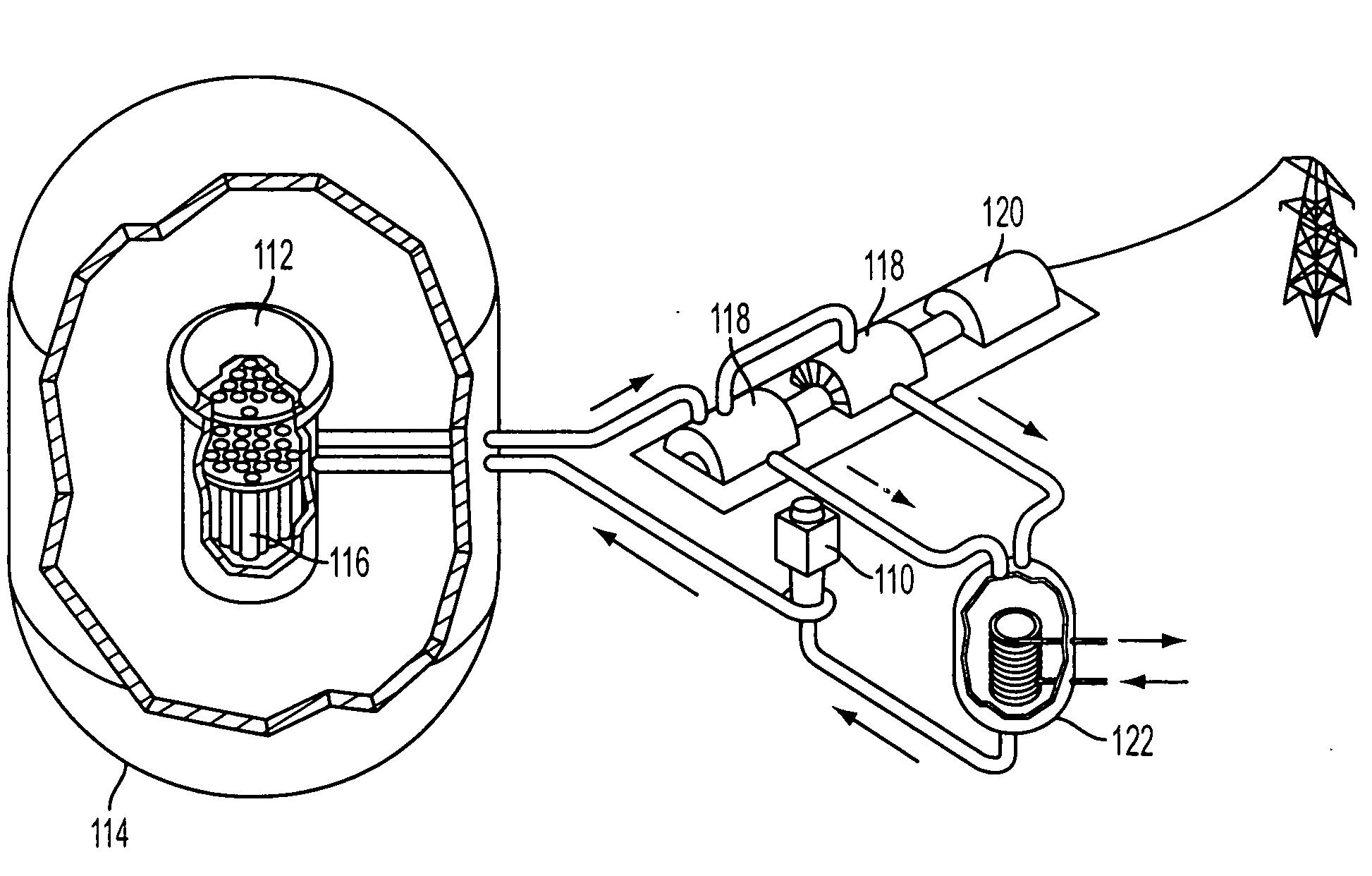

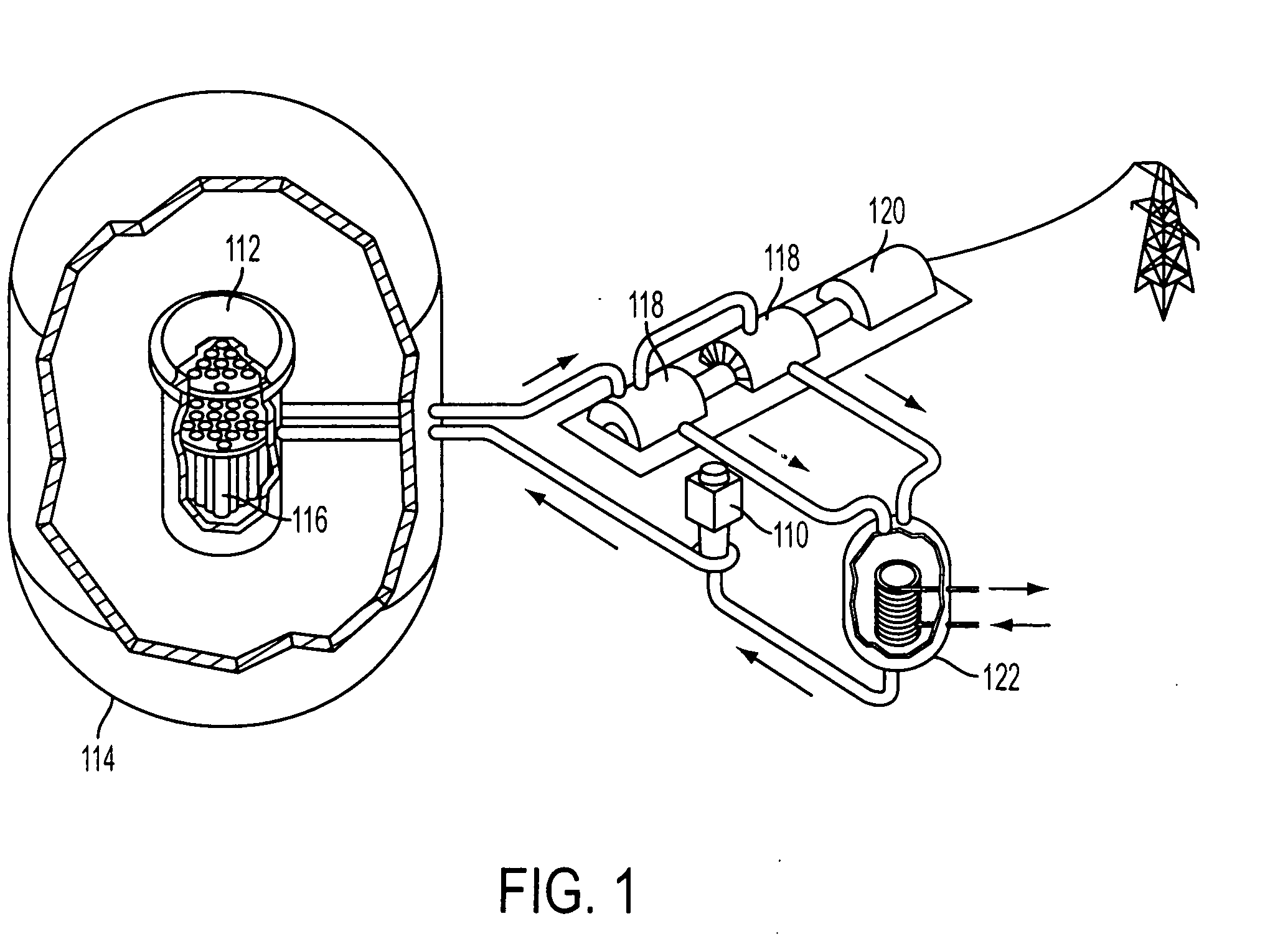

Control of a Laser Inertial Confinement Fusion-Fission Power Plant

ActiveUS20110286563A1Extended service lifeReduce spreadNuclear energy generationWaste based fuelFusion fissionEngineering

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Control of a laser inertial confinement fusion-fission power plant

ActiveUS9171646B2Extended service lifeNuclear energy generationWaste based fuelFusion fissionEngineering

A laser inertial-confinement fusion-fission energy power plant is described. The fusion-fission hybrid system uses inertial confinement fusion to produce neutrons from a fusion reaction of deuterium and tritium. The fusion neutrons drive a sub-critical blanket of fissile or fertile fuel. A coolant circulated through the fuel extracts heat from the fuel that is used to generate electricity. The inertial confinement fusion reaction can be implemented using central hot spot or fast ignition fusion, and direct or indirect drive. The fusion neutrons result in ultra-deep burn-up of the fuel in the fission blanket, thus enabling the burning of nuclear waste. Fuels include depleted uranium, natural uranium, enriched uranium, spent nuclear fuel, thorium, and weapons grade plutonium. LIFE engines can meet worldwide electricity needs in a safe and sustainable manner, while drastically shrinking the highly undesirable stockpiles of depleted uranium, spent nuclear fuel and excess weapons materials.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

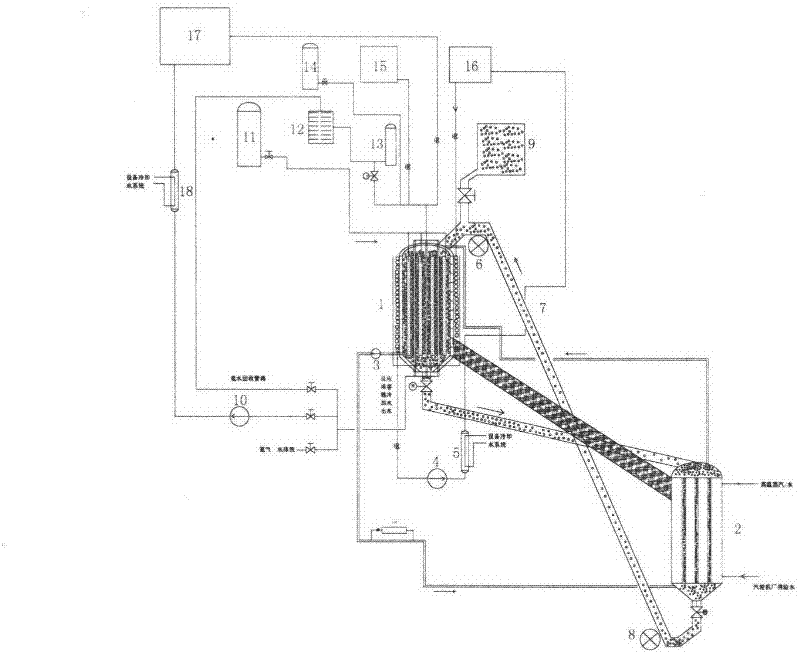

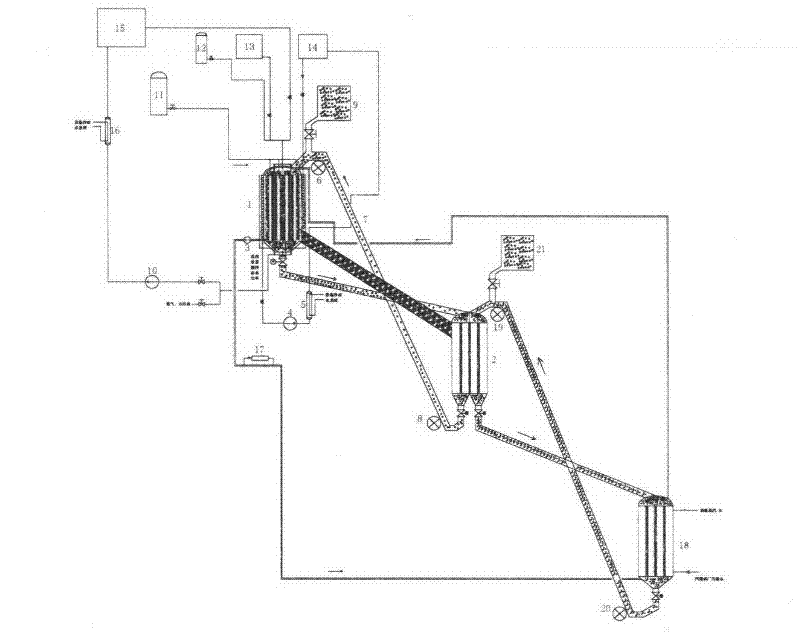

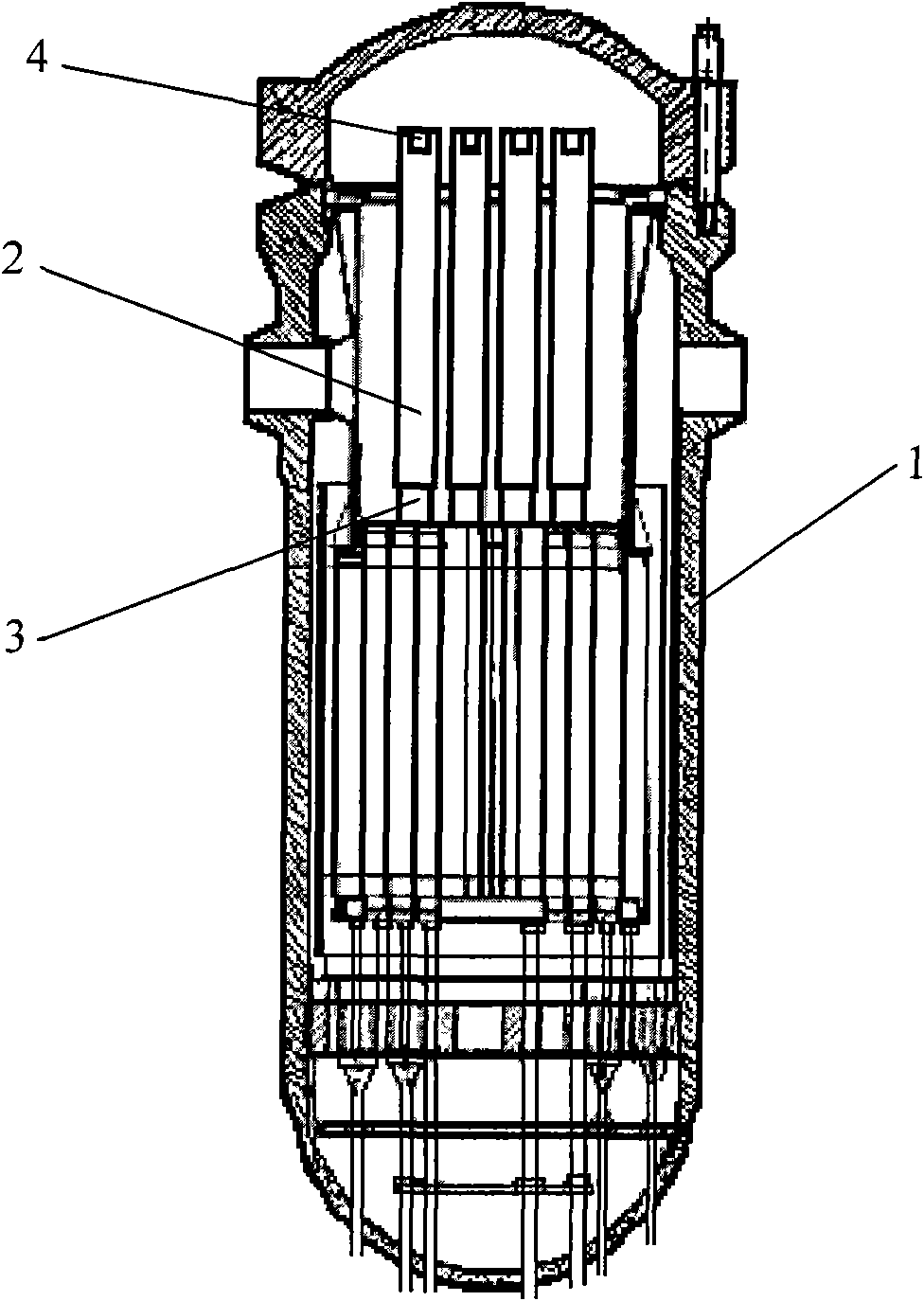

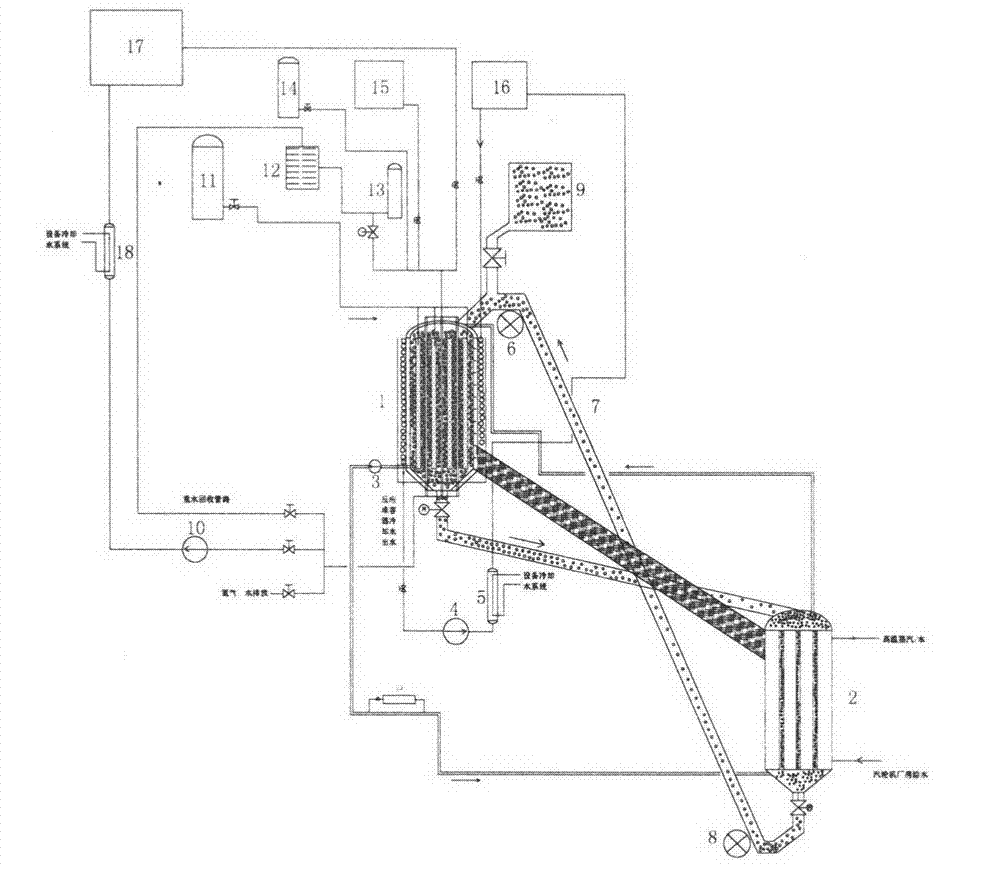

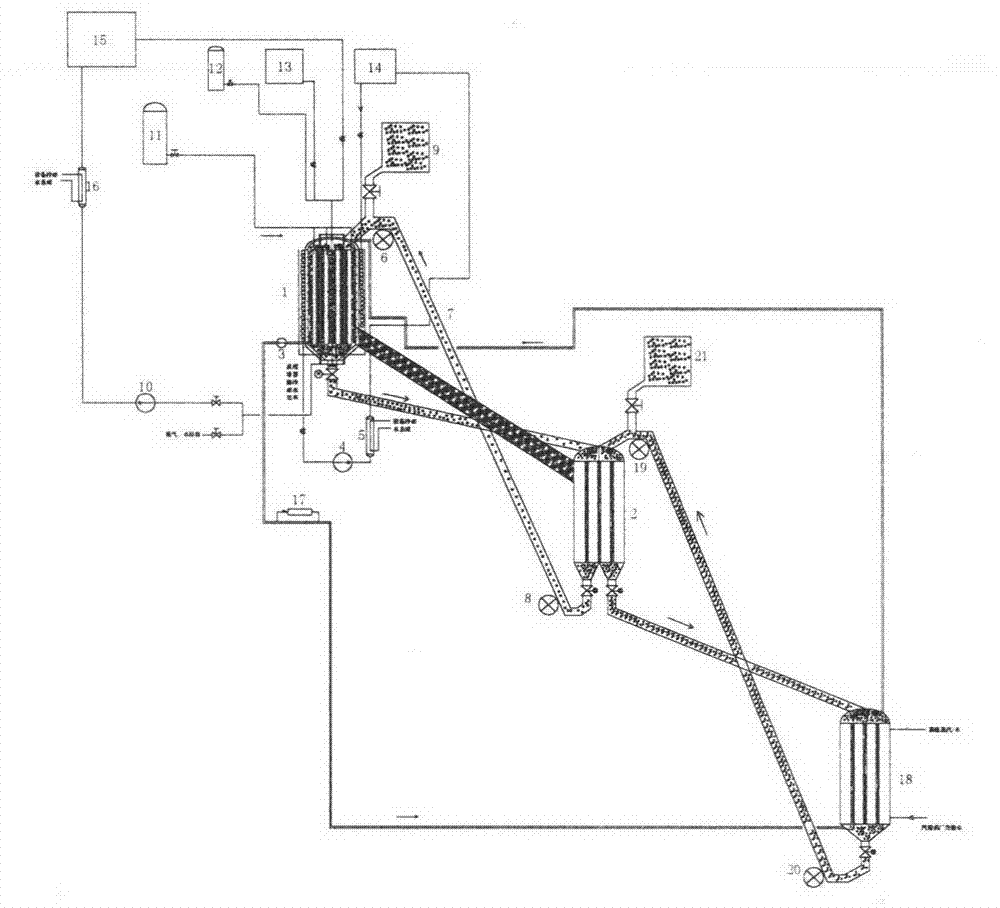

High-temperature supercritical nuclear reactor

InactiveCN102568624AImprove economyTake advantage ofNuclear energy generationCooling arrangementFast-neutron reactorMaterials science

The invention relates to a high-temperature supercritical nuclear reactor. A spherical solid is used as a coolant of the nuclear reactor, which is different from common nuclear reactors that adopt light water, heavy water, gas and liquid sodium. The spherical solid coolant can be graphite spheres coated with silicon carbide, stainless steel spheres, graphite spheres coated with stainless steel and the like. The spherical solid has the characteristic of good rolling ability, so that the spherical solid can roll to a steam generator under the action of gravity after heating in the reactor, and the purpose of transferring heat from the reactor to the steam generator is achieved. The reactor is applicable to both thermal neutron reactor and fast neutron reactor, and natural uranium, low-enriched uranium, plutonium and thorium can be used as nuclear fuel. The temperature of high-temperature steam / water outputted by the steam generator can reach 900 DEG C, the same parameters to a thermal power station can be reached, the requirement of supercritical even ultra-supercritical can be satisfied, and the high-temperature supercritical nuclear reactor has high safety and reliability.

Owner:李正蔚

Natural gamma-ray spectral logging instrument and operating method thereof

ActiveCN104880736AHigh sensitivityReduce volumeX-ray spectral distribution measurementNuclear radiation detectionLow voltagePotassium

The invention discloses a natural gamma-ray spectral logging instrument, which comprises a probe, an operating platform and a winch cable, wherein the probe is connected and communicates with the operating platform through the winch cable, and the probe comprises a detector and an electronics system; the detector comprises a spectrum stabilization device, a detecting element, a photoconductive element, a photomultiplier and a pre-amplification circuit; the electronics system inside the probe comprises an amplifier, a multichannel analyzer, a controller, a memory, a high-voltage power supply and a low-voltage power supply; the detecting element is one of a BGO crystal or a LaBr3 (Ce) crystal; the spectrum stabilization device comprises a shell body and a spectrum stabilization substance arranged in the shell body; and the spectrum stabilization substance is pressed into a pie shape and arranged in the shell body. The natural gamma-ray spectral logging instrument provided by the invention adopts the BGO or LaBr3 (Ce) crystal detector, is high in sensitivity, has good resolution, is internally provided with the natural substance for automatic spectrum stabilization, is convenient to use, and mainly measures gross-count rate caused by natural radioactivity in underground rock and contents and distribution data of natural uranium, thorium and potassium.

Owner:上海新漫传感科技有限公司

Method and system for subcritical nuclear rubbish treatment and nuclear fuel production based on fissioner neutron breeding

InactiveCN1591700AIncrease productivityImprove processing efficiencyConversion outside reactor/acceleratorsRadioactive decontaminationNatural uraniumBoron carbide

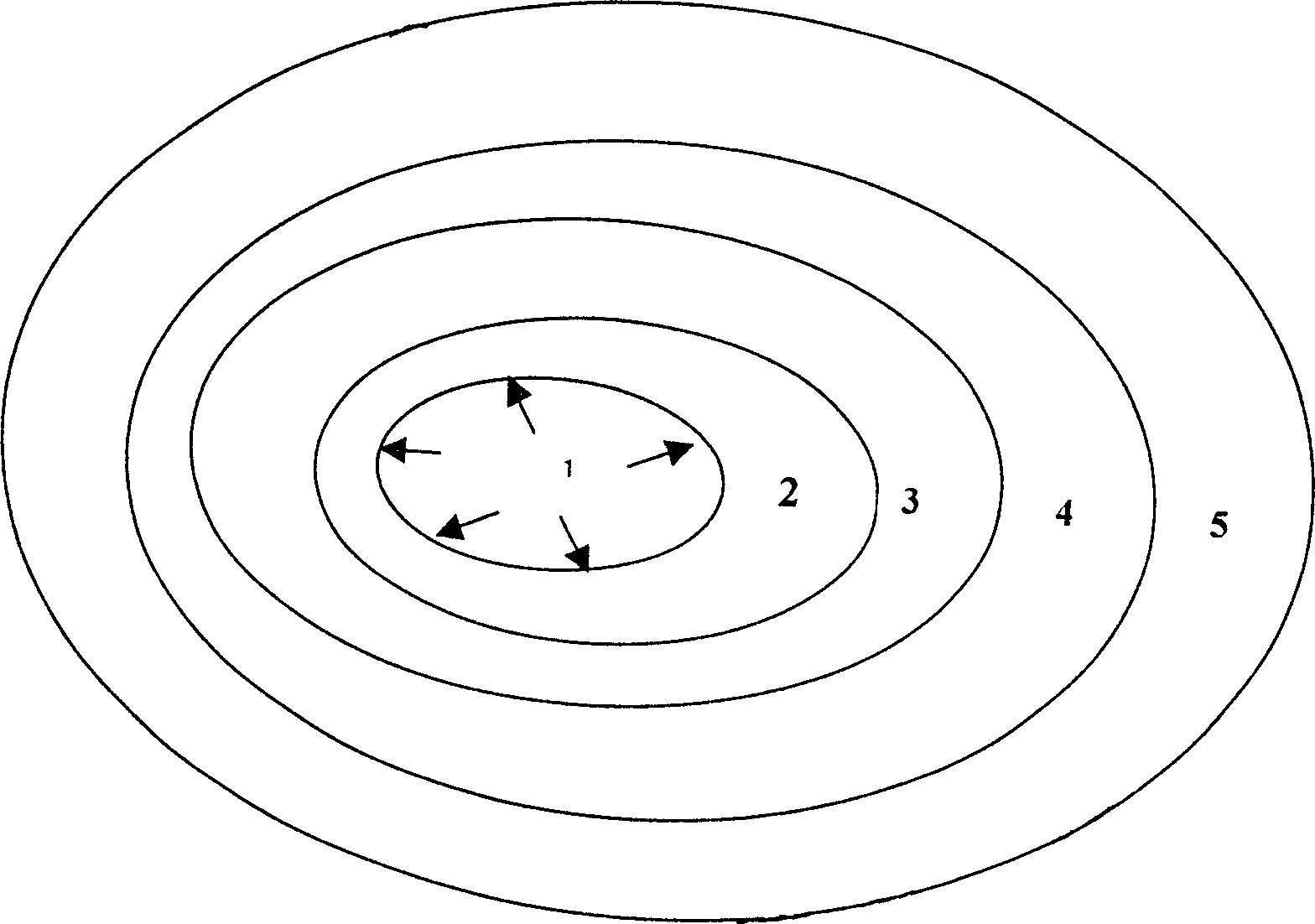

The present invention discloses a method for making subcritical nuclear waste material treatment and nuclear fuel production based on fissionable material neutron proliferation and its system. The exterior of external neutron source generation zone is enclosed successively with actinide elements treating zone, fissionable fuel proliferation zone, fission product treating zone and reflecting and shielding zone, all the zones are separated by means of structure material. The actinide elements treating zone includes actinide elements, fissionable fuel mixture and covering structure material; the fissionable fuel proliferation zone includes natural uranium or thorium or lean uranium and covering structure material; the fission product treating zone includes high radioactive fission product and covering structure material and neutron slowing agent, and the reflecting and shielding zone is formed from graphite, boron carbide, stainless steel and lead, etc.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

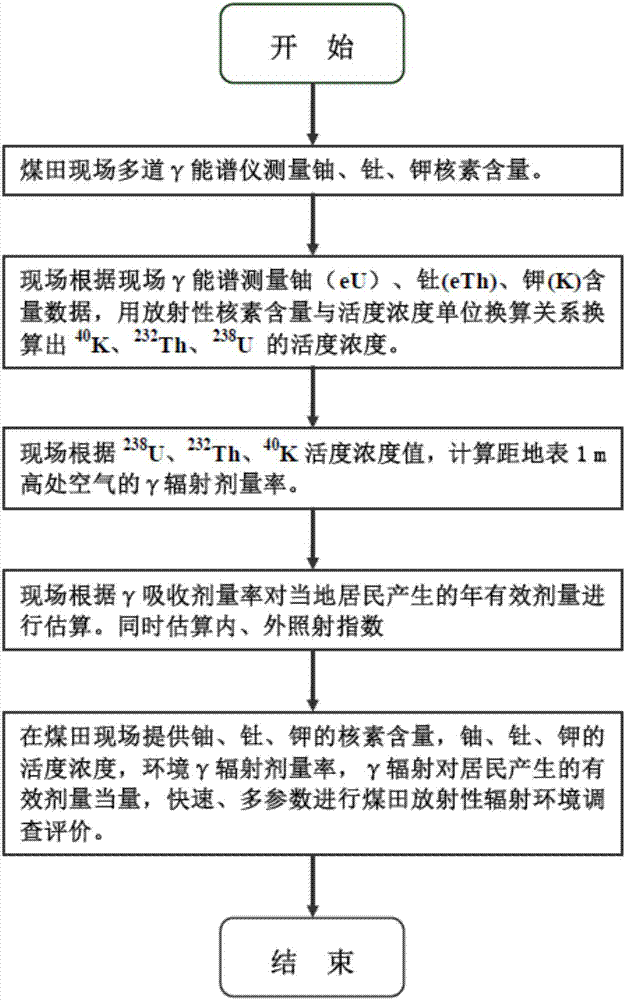

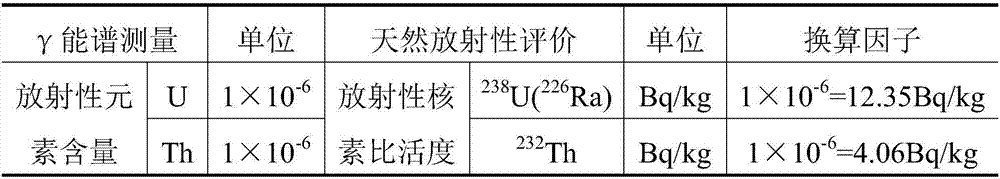

Onsite multi-parameter coal field radioactive radiation environment quick survey and evaluation method

InactiveCN107144868ARapid effective dose equivalentX/gamma/cosmic radiation measurmentUnit Conversion FactorPotassium

The present invention provides a method for quickly investigating and evaluating the radioactive radiation environment of a coalfield with multiple parameters on site, which uses a multi-channel gamma energy spectrometer on the ground or in a well to measure natural uranium, uranium, The nuclide content of thorium and potassium and the total radioactivity of gamma can be used to calculate the activity concentration of uranium, thorium and potassium in the coal field by using the conversion coefficient of the radionuclide content and the activity concentration unit; according to the activity concentration of uranium, thorium and potassium in the coal field On-site calculation of gamma radiation dose rate; on-site estimation of the effective dose equivalent of coal field environment gamma radiation to residents based on gamma radiation dose rate; finally, this technology can replace laboratory analysis and on-site gamma radiation dose rate measurement, and provide uranium, thorium, Nuclide content of potassium, activity concentration of uranium, thorium, and potassium, environmental gamma radiation dose rate, effective dose equivalent of gamma radiation to residents, in order to achieve rapid, economical and multi-parameter completion of coal field radioactive radiation environmental investigation and evaluation.

Owner:核工业二一六大队

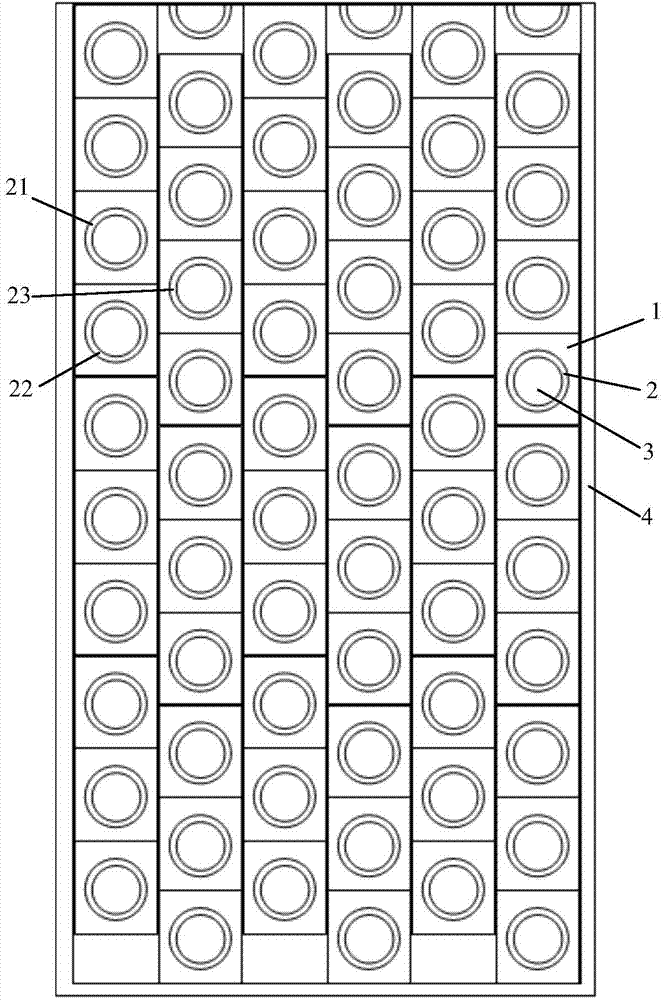

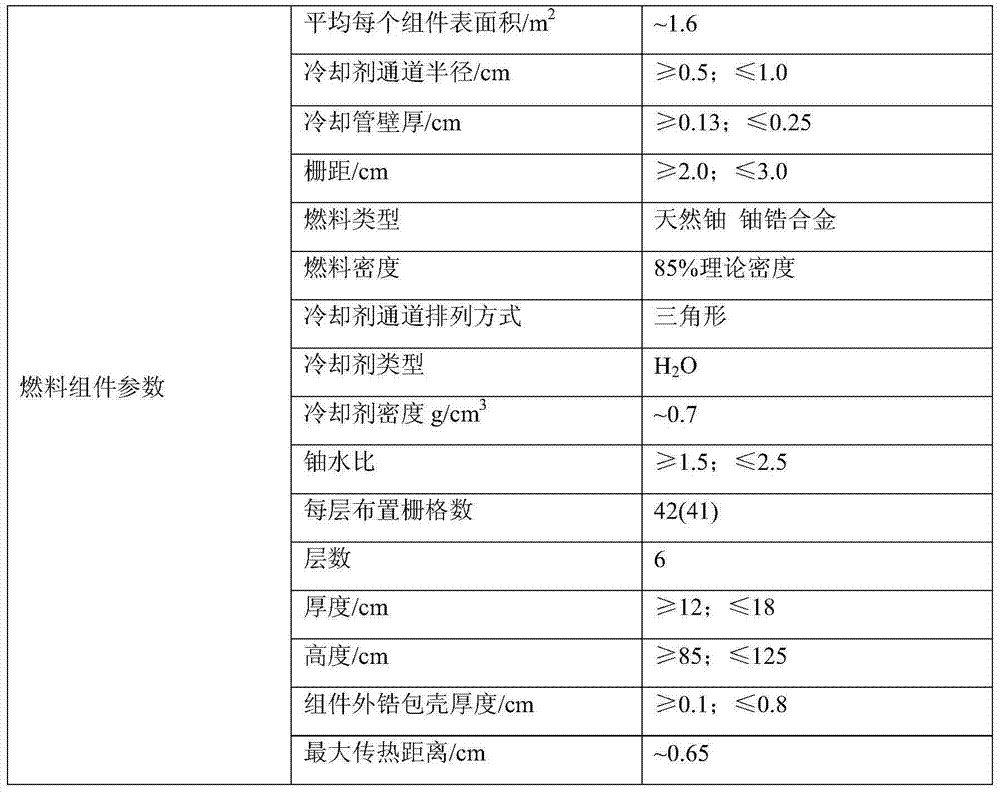

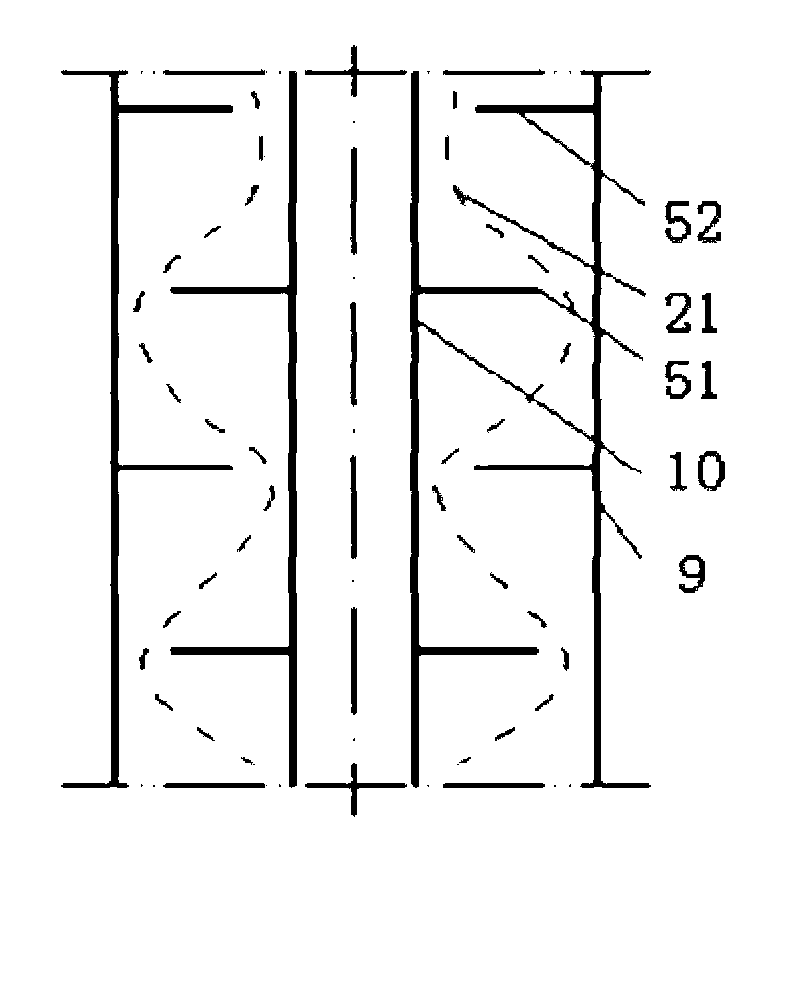

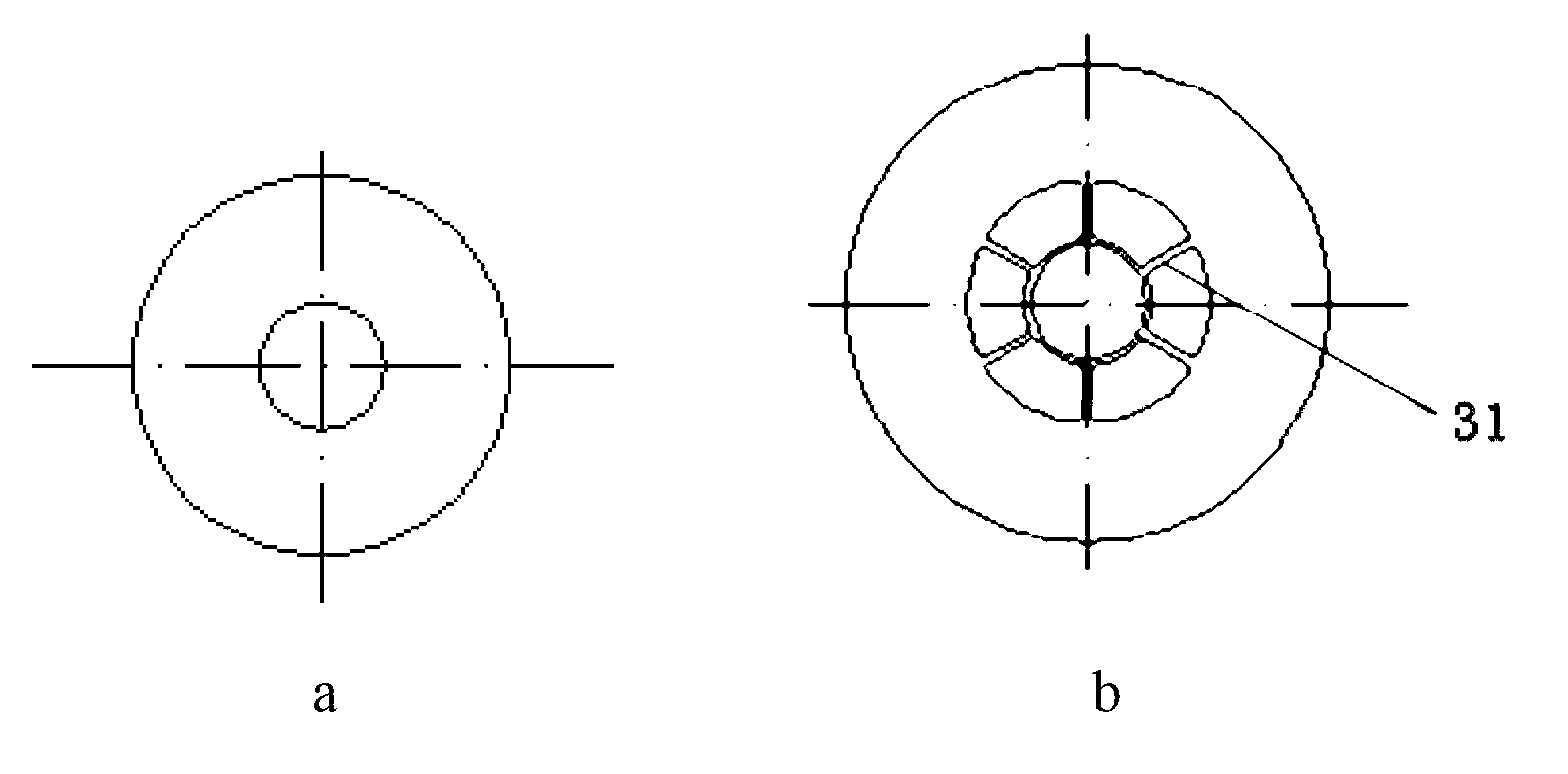

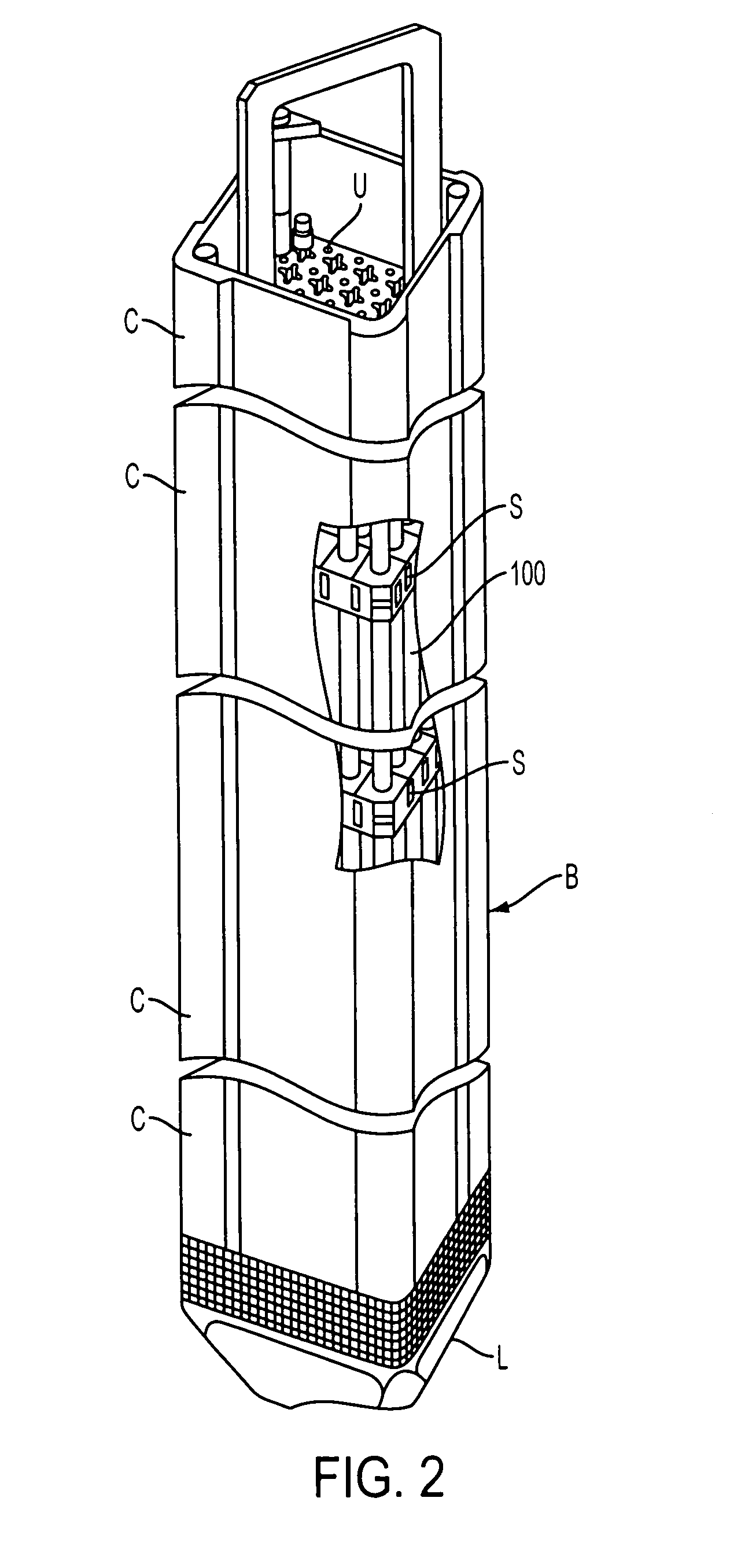

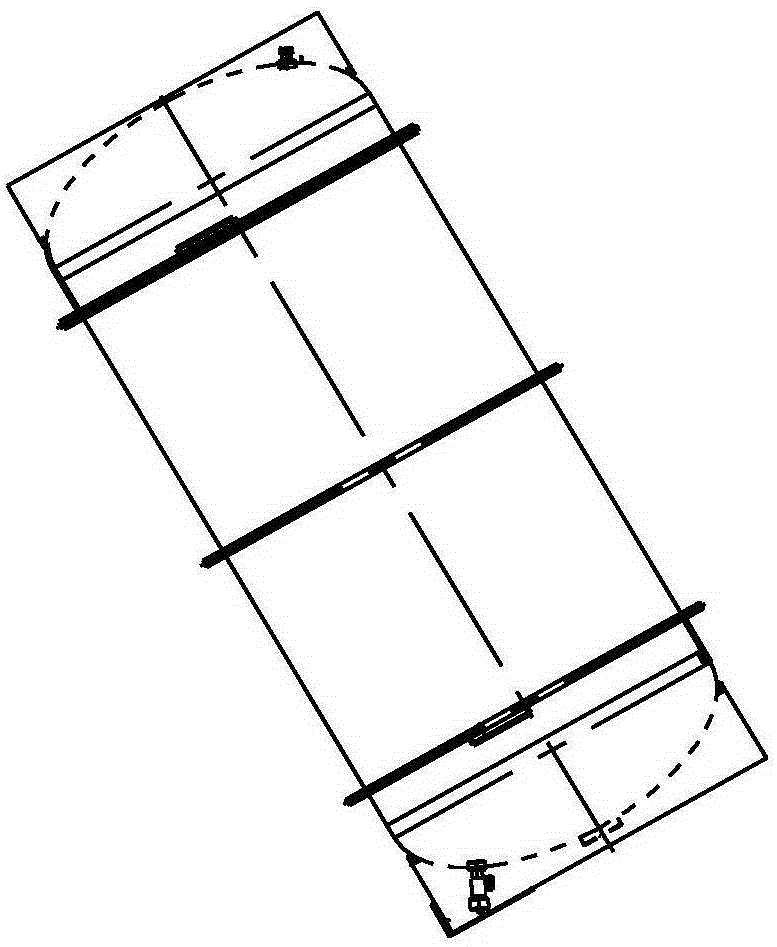

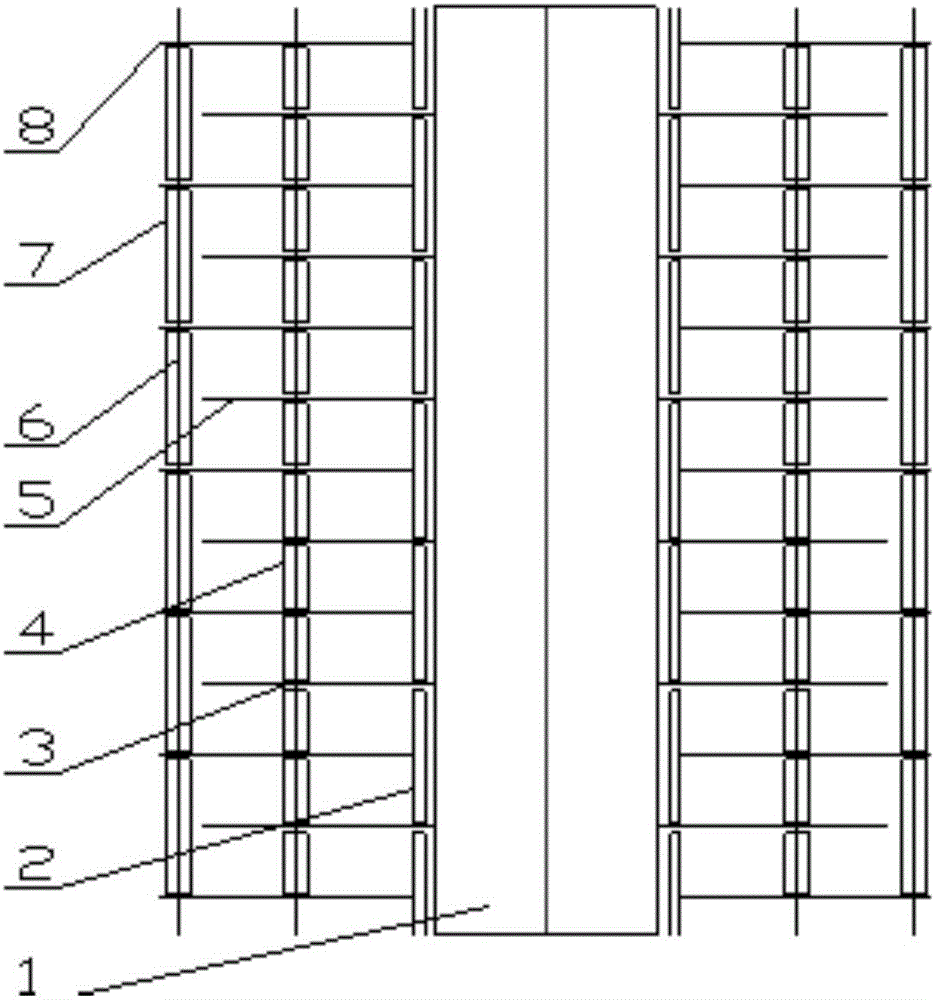

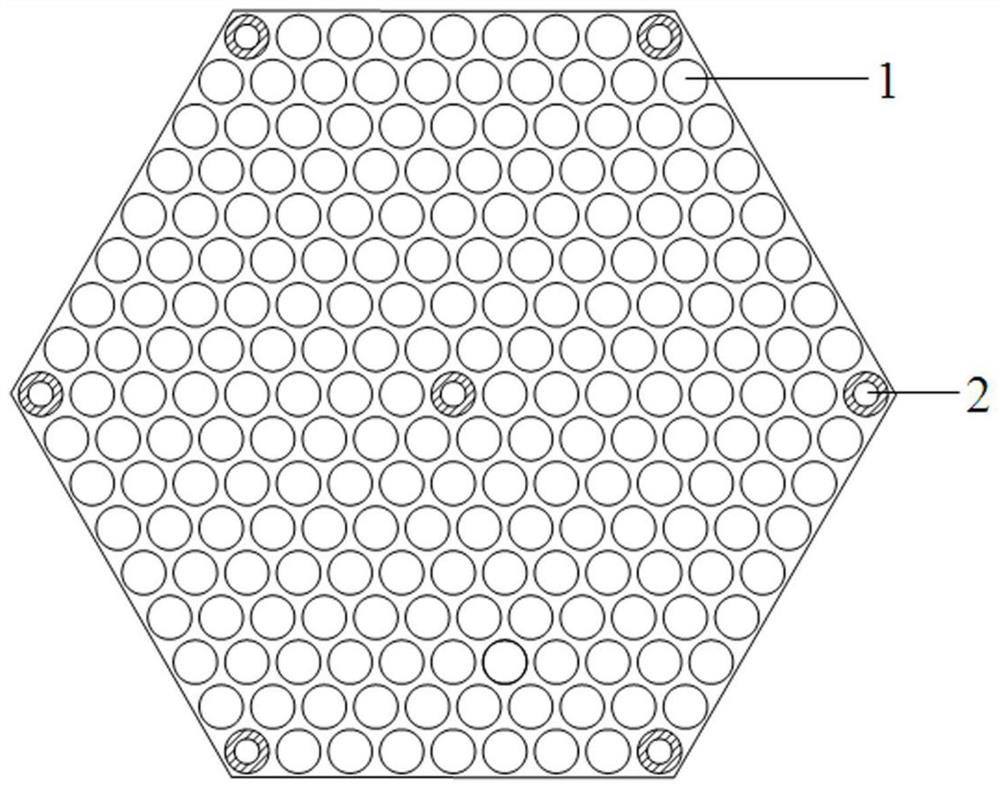

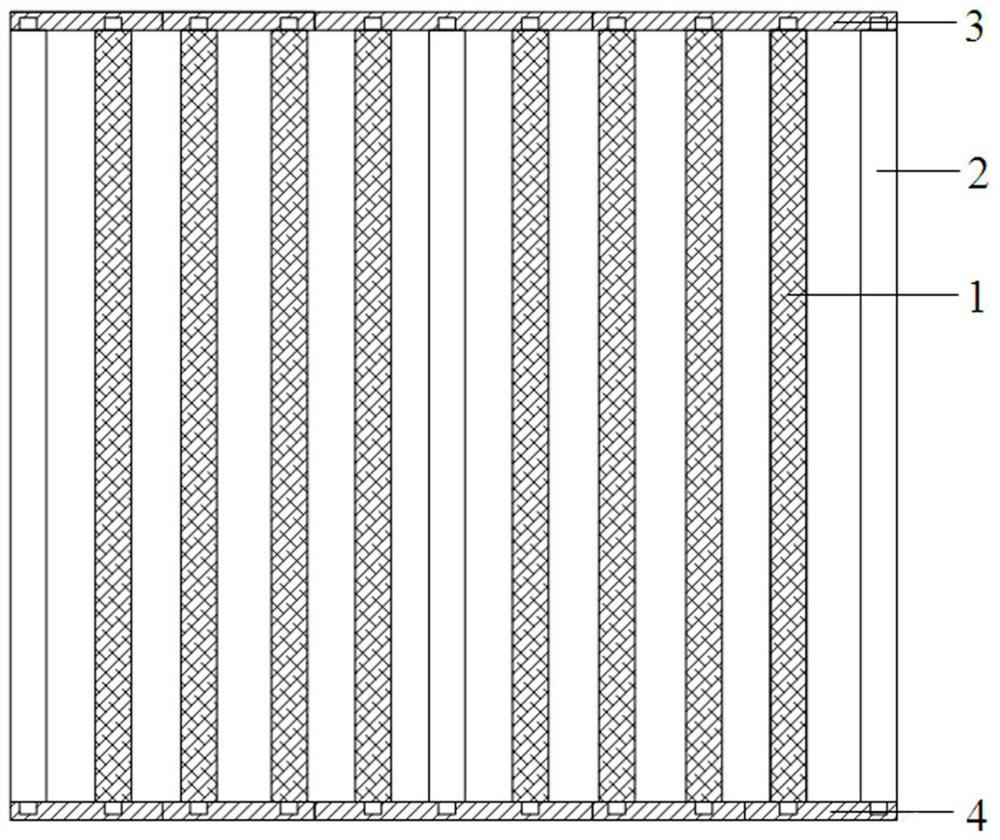

Advanced fusion-fission subcritical energy source reactor core fuel assembly

ActiveCN103578578AEnough energy magnificationGuaranteed cooling effectFuel elementsNuclear energy generationWater volumeNatural uranium

The invention belongs to the design technique of nuclear power and particularly relates to an advanced fusion-fission subcritical energy source reactor core fuel assembly. The fuel assembly comprises multiple layers of structures sequentially arranged along the thickness direction, wherein each layer of structure comprises a plurality of grid units, the grid units are arranged along the height direction and are provided with uranium-zirconium alloy fuels, a cooling tube horizontally penetrates through the uranium-zirconium alloy fuels of each grid unit, the extending direction of the cooling tube is vertical to the thickness direction of the fuel assembly, and flowable cooling agents are filled in the cooling tubes. According to the advanced fusion-fission subcritical energy source reactor core fuel assembly, the natural uranium and zirconium alloys are taken as fission fuels, the cooling tubes are arranged in the fuels in a regular triangle manner, and the cooling of the fuels can be guaranteed due to the arrangement manner of the cooling tubes. The fuel assembly has the advantages that the uranium-water volume ratio is proper, and a reactor core can have an enough energy amplification factor.

Owner:CHINA NUCLEAR POWER ENG CO LTD

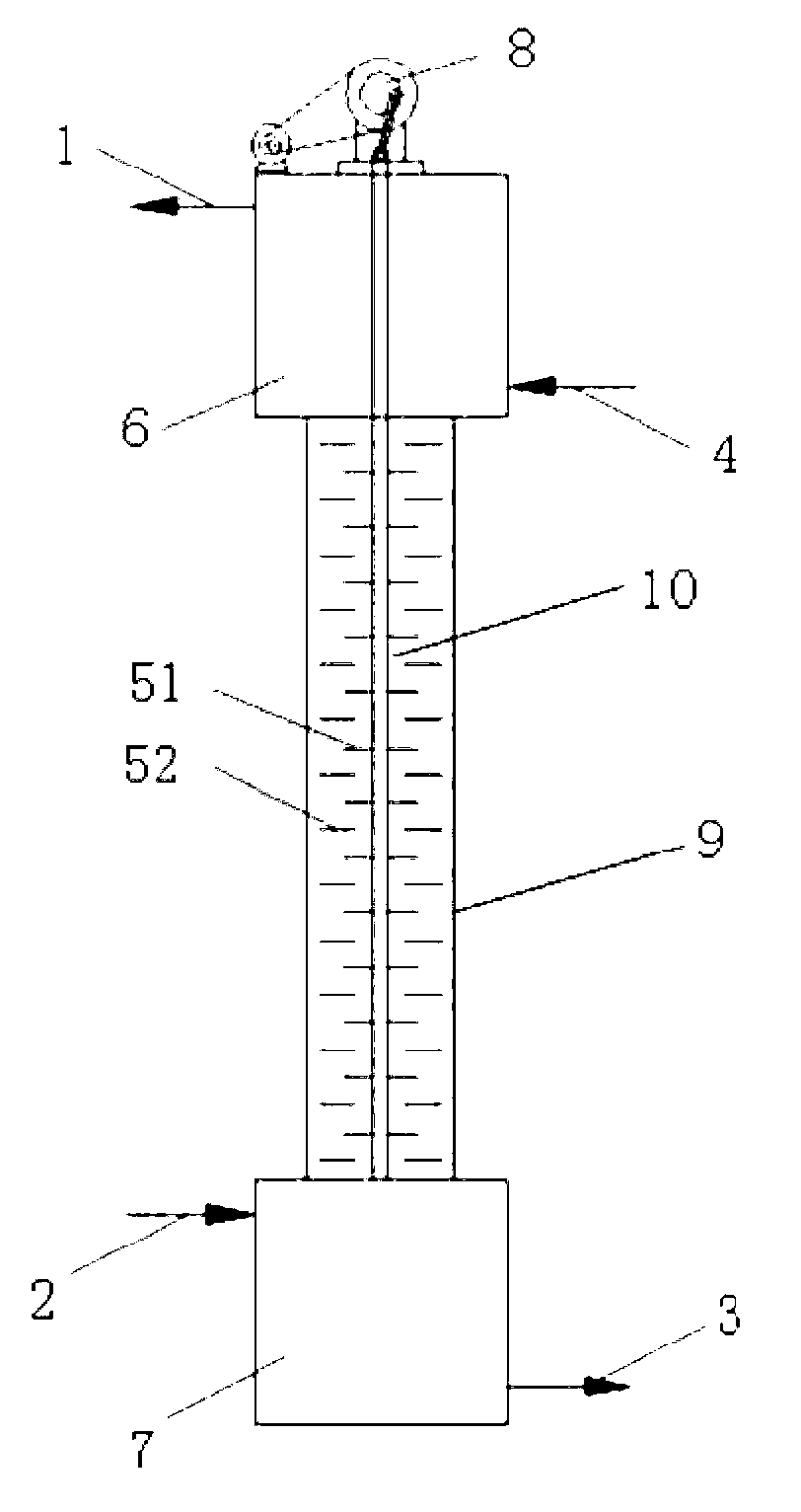

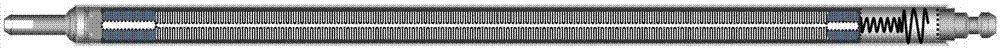

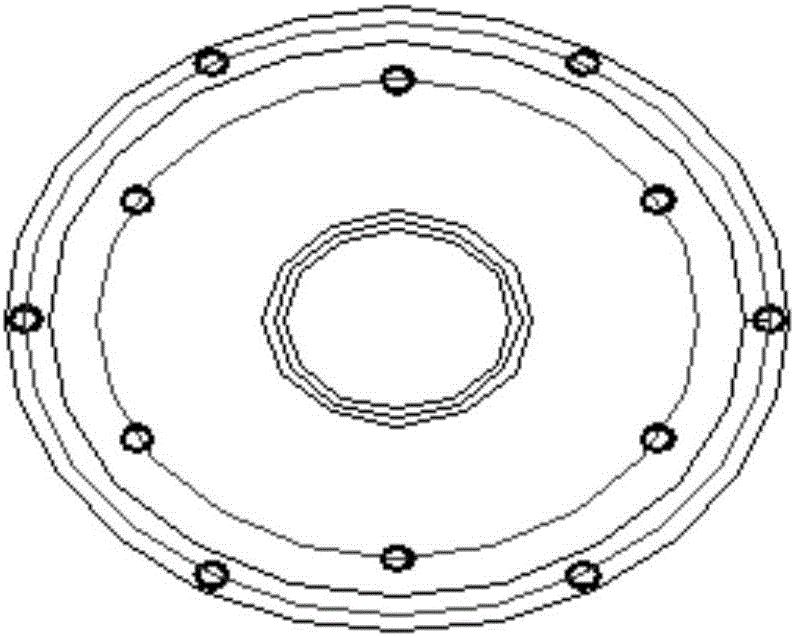

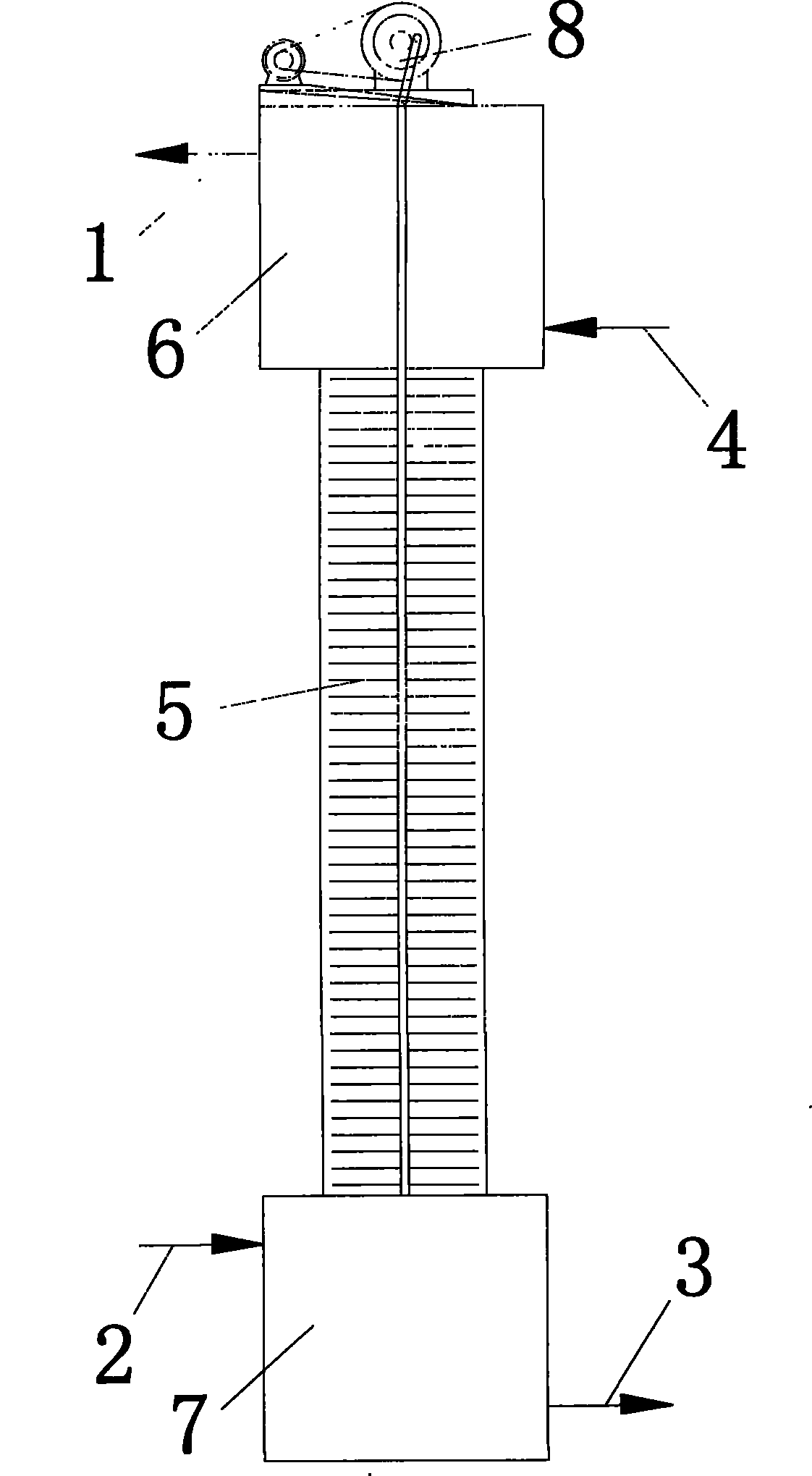

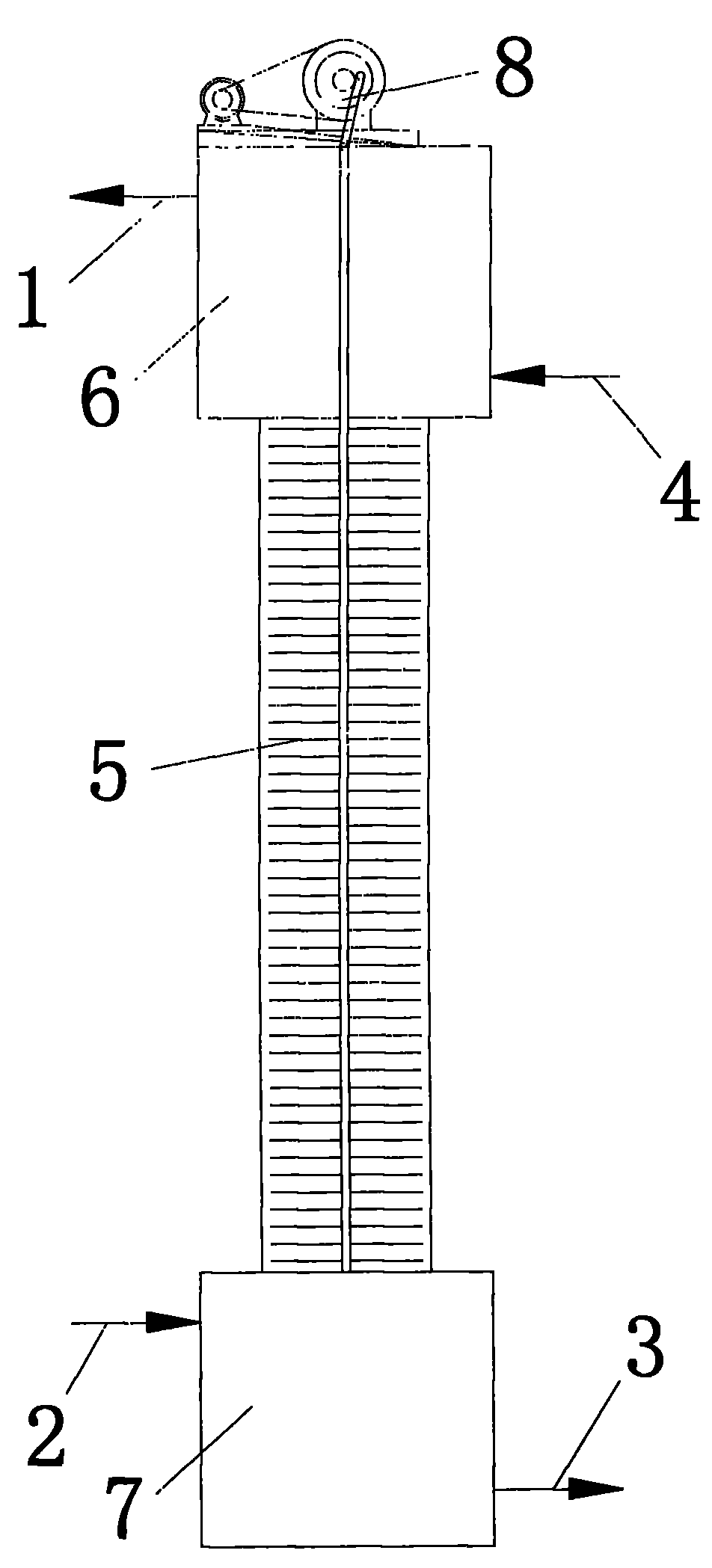

Method for extracting and purifying natural uranium by using vibrating ring-shaped traverse baffle extracting tower

InactiveCN102698467AEasy to handleImprove throughputLiquid solutions solvent extractionNatural uraniumEngineering

The invention discloses a vibrating ring-shaped traverse baffle extracting tower belonging to the field of extraction and a method for extracting and purifying natural uranium by using the extracting tower. The extracting tower comprises a central shaft arranged at the center in a tower body, and an internal ring plate, one pipe spacer, an external ring plate and the other pipe spacer are sleeved on the central shaft one by one at intervals, so that a traverse baffle string can be formed; a motor fixedly arranged on the upper part of the upper expansion end at the upper end of the tower body drives the traverse baffle string to move up and down by a cam; and the upper expansion end and a lower expansion end arranged on the lower part of the tower body are respectively provided with a light / heavy phase inlet and a light / heavy phase outlet. The method for extracting and purifying the natural uranium by the extracting tower comprises the following steps of: charging a material into the tower from the heavy phase inlet of the upper end; and turning on a motor, and charging an extracting agent into the tower from the light phase inlet of the lower end in a flow ratio of organic phase to water phase of 0.5-10, so that the countercurrent extraction of downward water phase and upward organic phase can be formed. The extracting tower disclosed by the invention is simple in structure, large in flux and high in efficiency; and the method disclosed by the invention is environment-friendly and energy-saving, and is low in cost.

Owner:TSINGHUA UNIV

Method for improving energy output of a nuclear reactor, method for determining natural uranium blanket layer for a fuel bundle, and a fuel bundle having a variable blanket layer

In a method for improving the energy generating output of a nuclear reactor containing one or more fuel rods in one or more fuel rod bundles while satisfying a maximum subcritical banked withdrawal position (MSBWP) reactivity limit, enrichments of individual fuel rods in an axial cross-section of a lattice being evaluated at the top of the fuel bundle are ranked, and the fuel pins of the highest ranked rod location in the lattice are replaced with natural uranium pins. A core simulation is then performed to determine whether there is any margin to a MSBWP reactivity limit. For each lower ranked candidate rod position, the pin replacing and core simulation functions are repeated until no rod location violates the MSBWP reactivity limit, so as to achieve a desired lattice design for the top of the fuel bundle.

Owner:GLOBAL NUCLEAR FUEL -- AMERICAS

Follower component driven by driving mechanism in pressure shell and water reactor adopting same

InactiveCN101656112APrevent penetrationReduce cycle costsNuclear energy generationContainmentFuel reprocessingNatural uranium

The invention belongs to the field of nuclear reactor engineering, in particular to a follower component driven by a driving mechanism in a pressure shell and a water reactor adopting the same. The invention realizes the spectral shift control of a reactor and compansates the decrease of reactivity in a burn-up process by a depleted uranium (or thorium) compound follower, and adopts a dense weir and residential uranium compound fuel postprocessed by partially utilizing natural uranium and spent fuel, thereby greatly saving nuclear fuel and decreasing fuel cycle cost. A driving mechanisms driving a great amount of follower components are arranged in the pressure shell, so as to prevent the joint sections of the driving mechanism from penetrating through the upper sealing head of the pressure shell, carry out the spectral shift control under the condition without influencing the reliability of the pressure shell, lower the boron concentration of the water reactor in water in an operation process, avoid the occurrence of the problem of serious corrosion of the joint sections and the upper sealing head of the driving mechanism due to the penetration of boric acid through the upper sealing head of the pressure shell, reduce the possibility of elastic rod accidents and improve the safety.

Owner:张育曼 +2

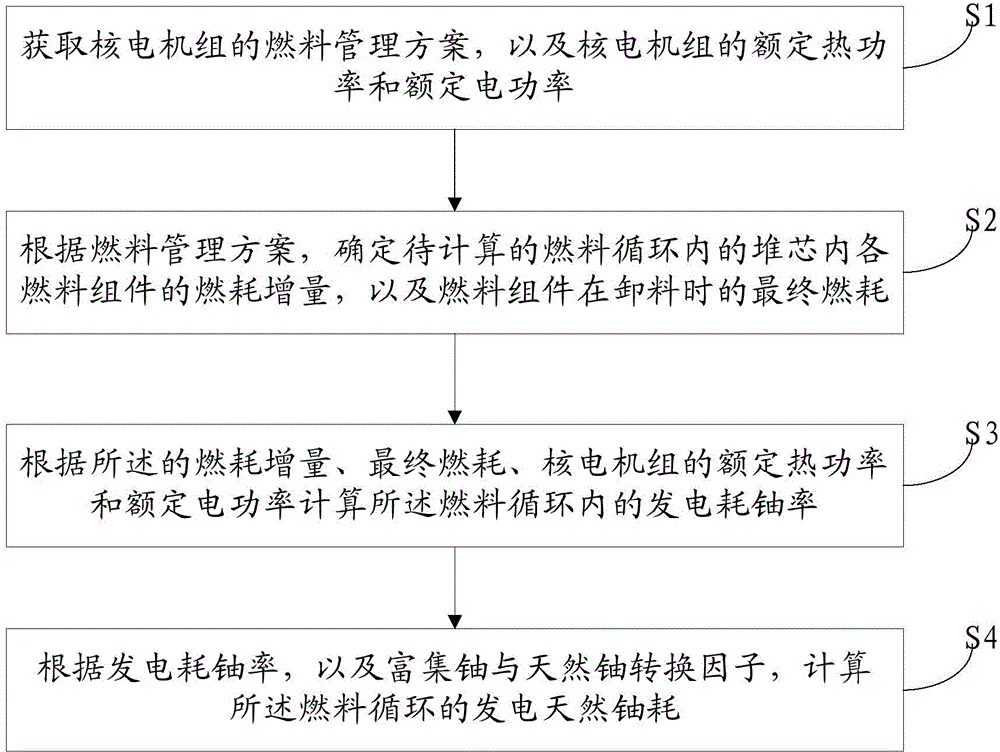

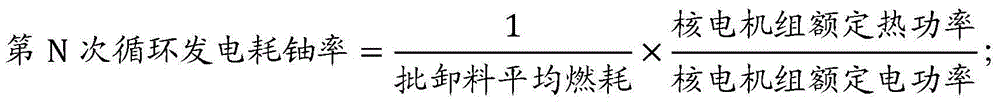

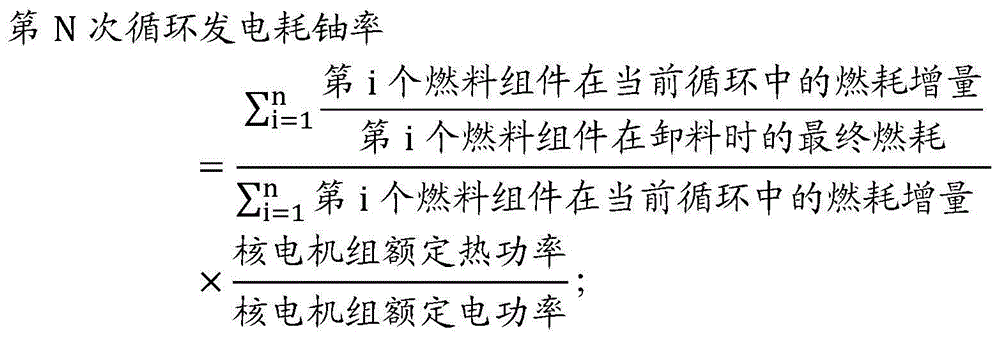

Method for calculating uranium consumption rate of nuclear power unit

ActiveCN104680316AHigh precisionIncrease credibilityResourcesInformation technology support systemHypothesisNatural uranium

The invention discloses a method for calculating the uranium consumption rate of a nuclear power unit. The method comprises the following steps: firstly, acquiring a fuel management scheme of the nuclear power unit, and the rated heat power and the rated electric power of the nuclear power unit, confirming combustion consumption gain to be calculated, of different fuel components inside a reactor core in fuel circulation according to the fuel management scheme, and the final combustion consumption of the fuel components when being unloaded, and finally calculating the power generation uranium consumption rate in the fuel circulation according to the combustion consumption gain, the final combustion consumption and the rated heat power and the rated electric power of the nuclear power unit. According to the power generation uranium consumption calculation method disclosed by the invention, the power generation uranium consumption rate and the power generation natural uranium consumption can be rapidly, easily and conveniently calculated by calculating the reactor core combustion consumption history and the initial enrichment degree of the fuel components in circulation according to the reactor core fuel management scheme and the main parameters of the nuclear power unit, a great amount of hypothesis items of a conventional calculation method are abandoned, input data are reduced, and the precision and the reliability of calculation are improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

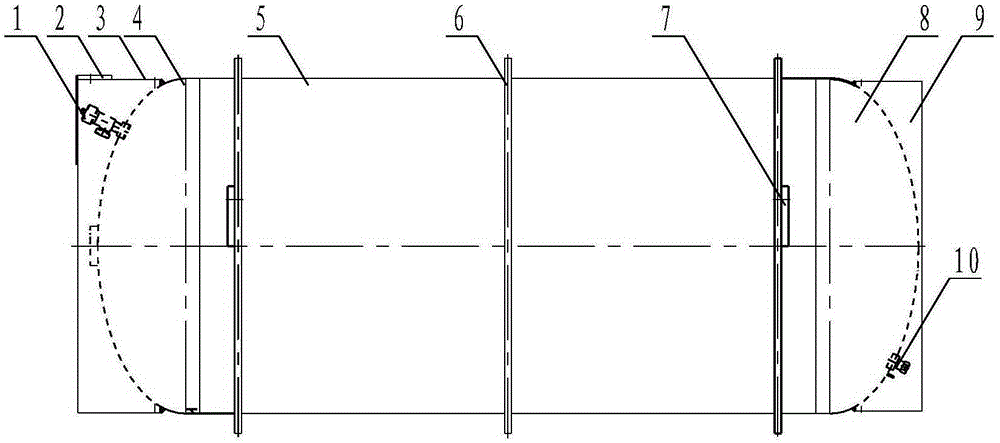

Container for natural uranium hexafluoride transportation

InactiveCN106429048AMeet performance test requirementsLarge containersRigid containersFree fallingNatural uranium

The invention relates to the technical field of nuclear fuel transportation systems, and in particular, discloses a container for natural uranium hexafluoride transportation. The container for natural uranium hexafluoride transportation comprises a cylinder, a left seal and a right seal, wherein two ends of the cylindrical cylinder are fixedly sealed through the left seal and the right seal with standard elliptic structures; a thick wall skirt base is arranged on the left seal; a valve is arranged on the left seal; a thin wall skirt base is arranged on the right seal; and a plug is arranged on the right seal. The container for natural uranium hexafluoride transportation can satisfy the performance test requirements after free fall in the radioactive substance safe transportation management regulation.

Owner:CNNC SEVENTH RES & DESIGN INST CO LTD

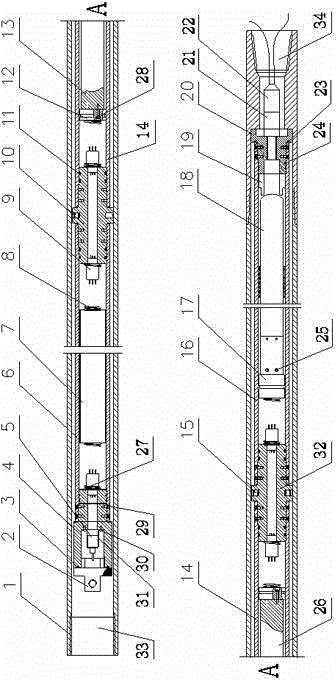

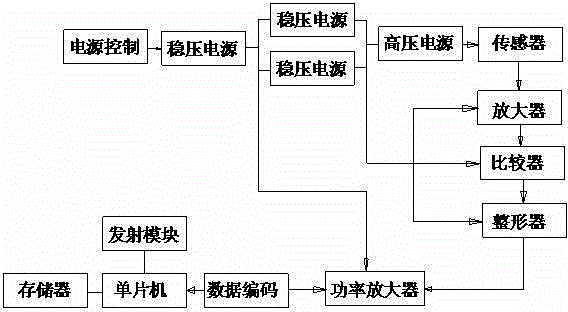

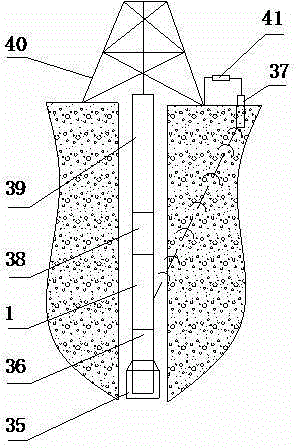

While-drilling natural gamma uranium measuring instrument based on rock core drilling

InactiveCN104373119AEffective explorationBorehole/well accessoriesMicrocontrollerSignal processing circuits

The invention relates to equipment capable of detecting a uranium ore in real time in a coring drilling process. A while-drilling gamma uranium measuring instrument based on rock core drilling is characterized by comprising an outer pipe, an inner pipe, a battery component, a fastening pressure spring and a sensor, wherein the outer pipe is a non-magnetic drill rod; the inner pipe is positioned in the outer pipe, and comprises a power supply switch fixing piece, a battery bin compression-resisting cylinder, a first compression-resisting cylinder connecting head, a circuit board bin compression-resisting cylinder, a second compression-resisting cylinder connecting head, a sensor bin compression-resisting cylinder and a plug screw; the battery component supplies power to a signal processing circuit and the sensor; the sensor is positioned in the sensor bin compression-resisting cylinder, and is connected with a sensor signal input end of the signal processing circuit; the signal processing circuit comprises a single-chip microcomputer; and the single-chip microcomputer is connected with a storer through an interface circuit. The instrument can perform the uranium ore exploration for a stratum difficult to obtain a rock core, through measuring natural gamma strength of the stratum, and measures the natural gamma strength while drilling in the coring drilling process to judge if the drilled stratum is the uranium ore.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

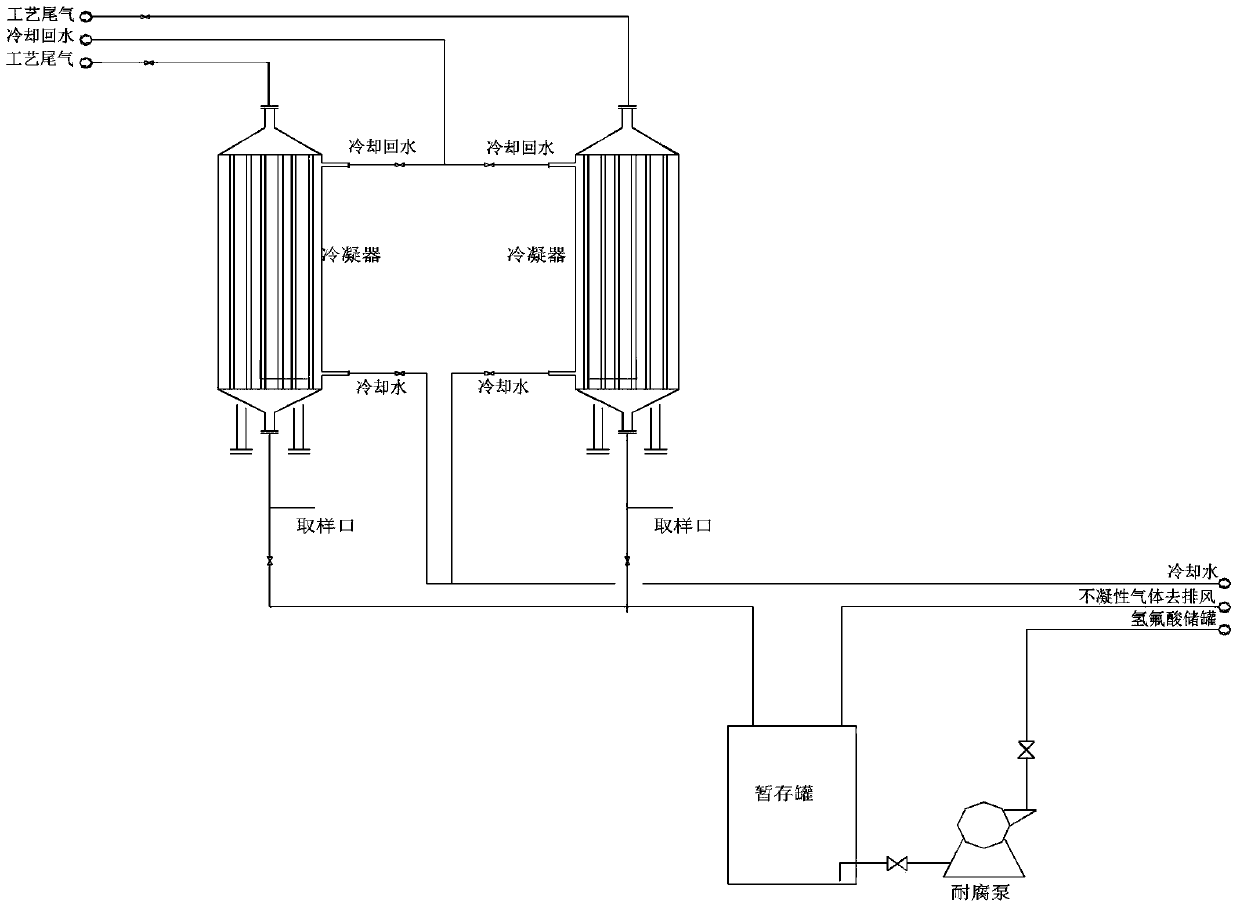

Natural uranium hexafluoride gas-phase transfer system and natural uranium hexafluoride gas-phase transfer method

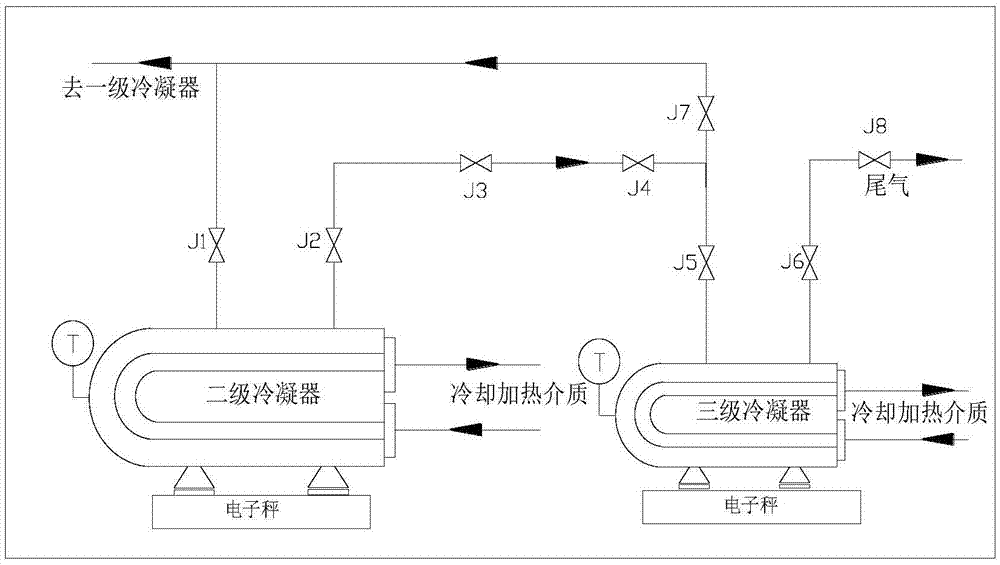

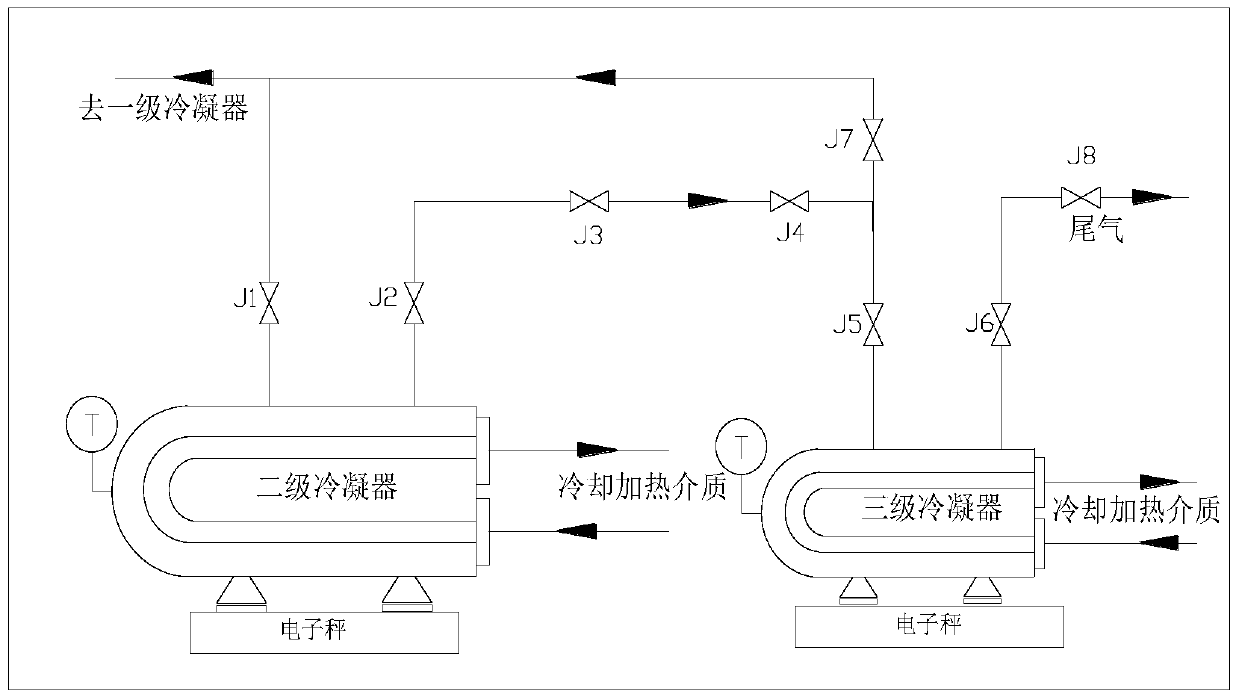

ActiveCN106924989AImprove direct yieldAchieve purificationSolidificationLiquefactionNatural uraniumTransfer system

The invention belongs to the technical field of natural uranium hexafluoride gas-phase transfer, in particular to a natural uranium hexafluoride gas-phase transfer system and a natural uranium hexafluoride gas-phase transfer method. A secondary condenser and a tertiary condenser are arranged above two electronic scales respectively, and ethylene glycol and steam serve as a cold medium and a heat medium respectively. The secondary condenser is provided with two outlets, one of the outlets is connected to an inlet of a primary condenser through a valve J1, and the other outlet is connected to an inlet of the tertiary condenser through a valve J2, a valve J3, a valve J4 and a valve J5. The tertiary condenser is provided with two outlets, one of the outlets is connected to the inlet of the primary condenser through the valve J5 and a valve J7, and the other outlet is connected to an external tail gas treatment process system through a valve J6 and a valve J8. By the system and the method, assistance in pressure-relieved purification and gas-phase transfer of UF6 products in a cold trap can be realized, purity of the natural UF6 products is improved, the metal direct recovery rate is increased, and safety risks in a transfer process are reduced.

Owner:THE 404 CO LTD CHINA NAT NUCLEAR

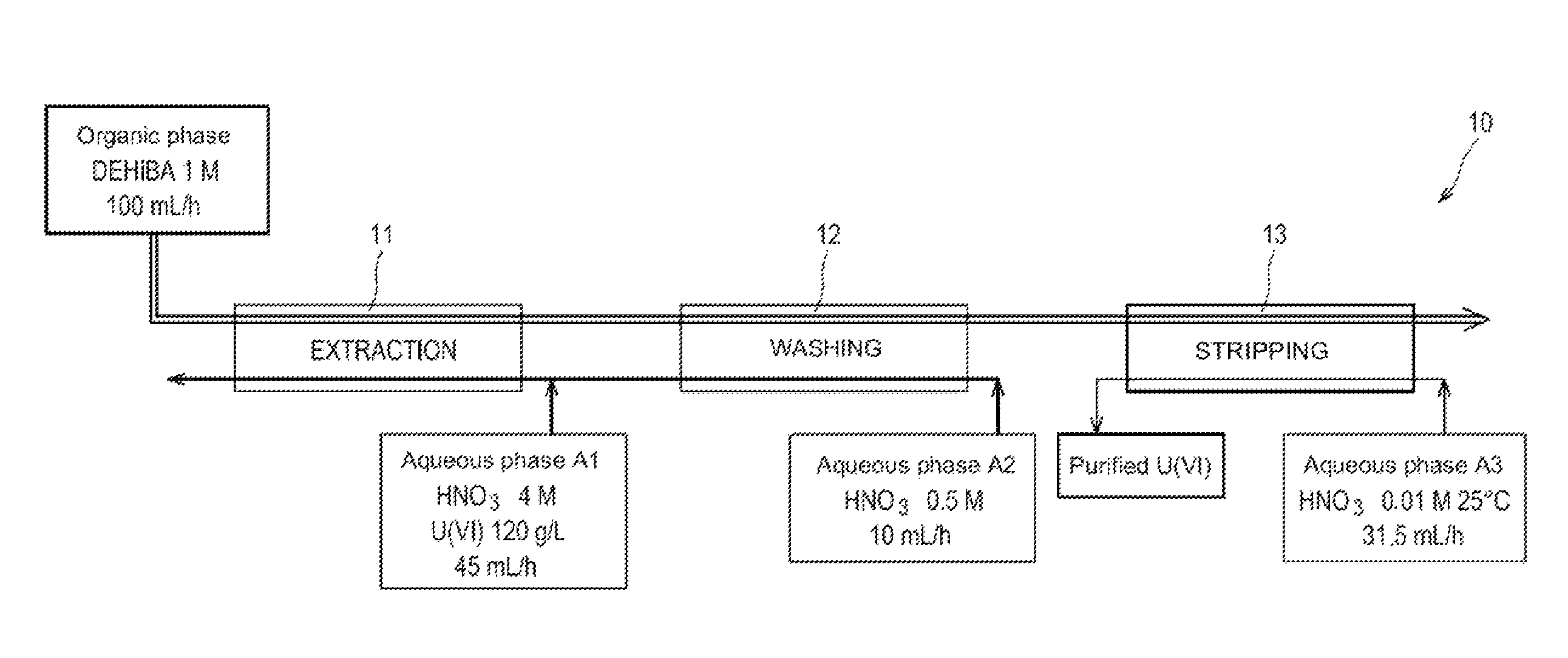

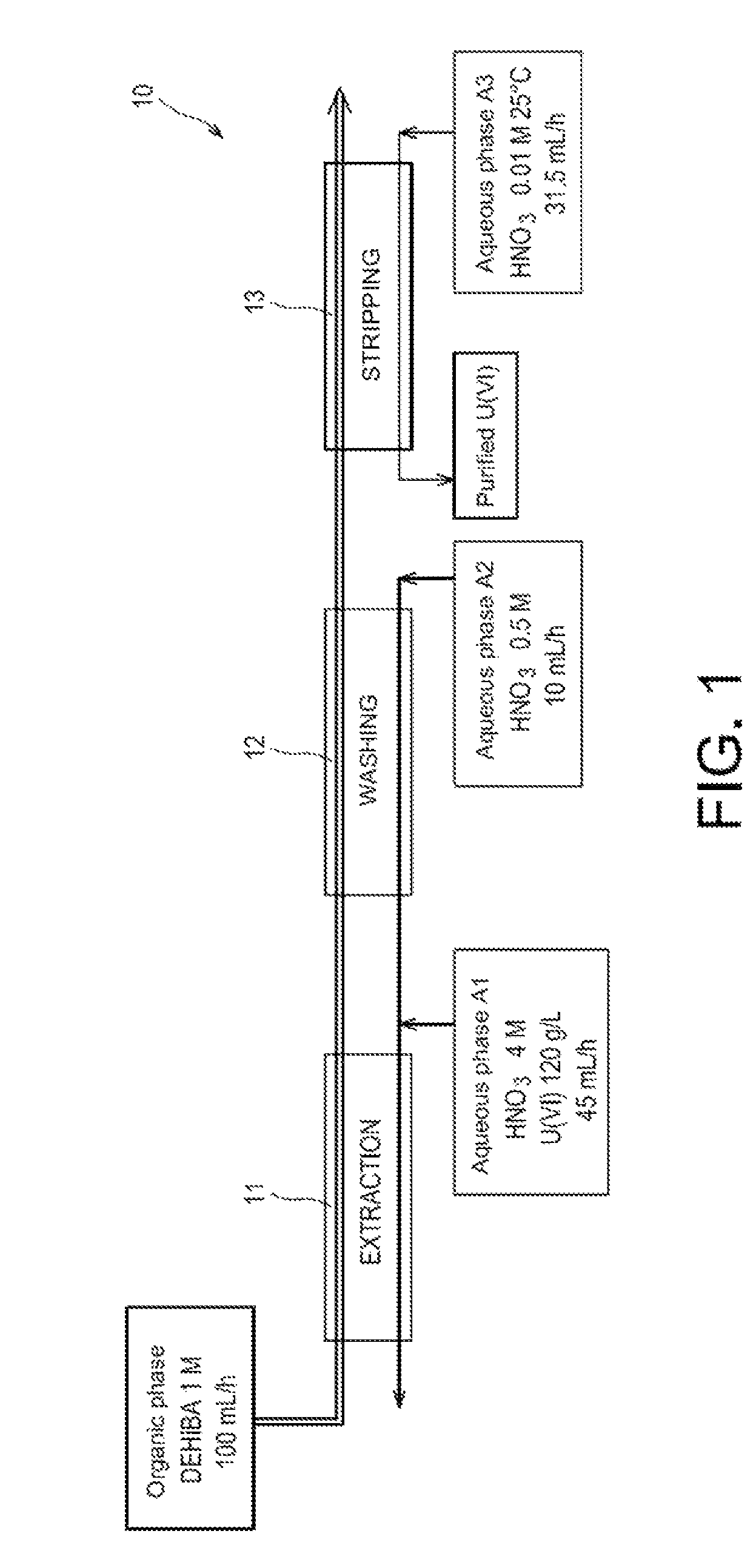

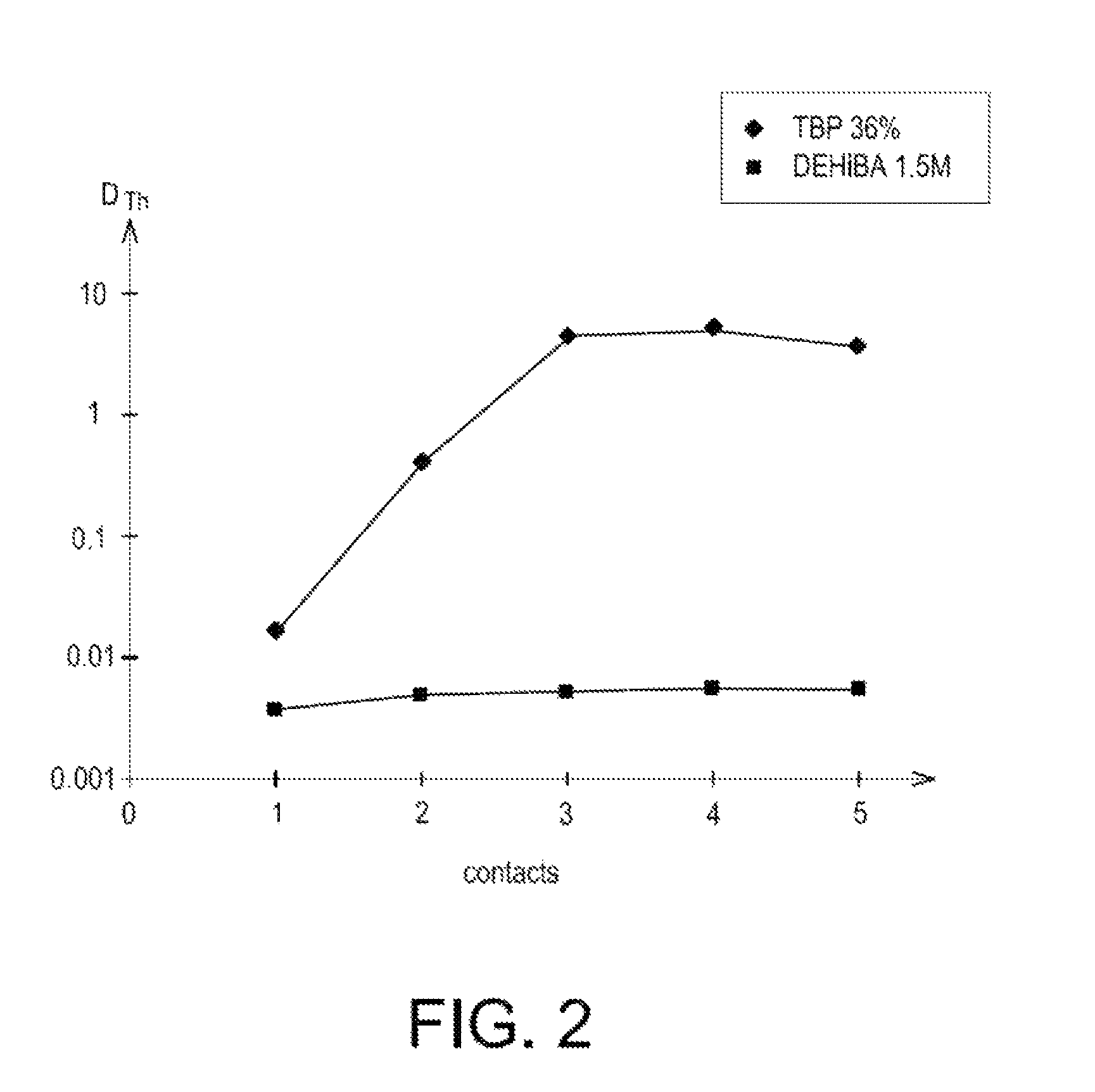

Method for purifying the uranium from a natural uranium concentrate

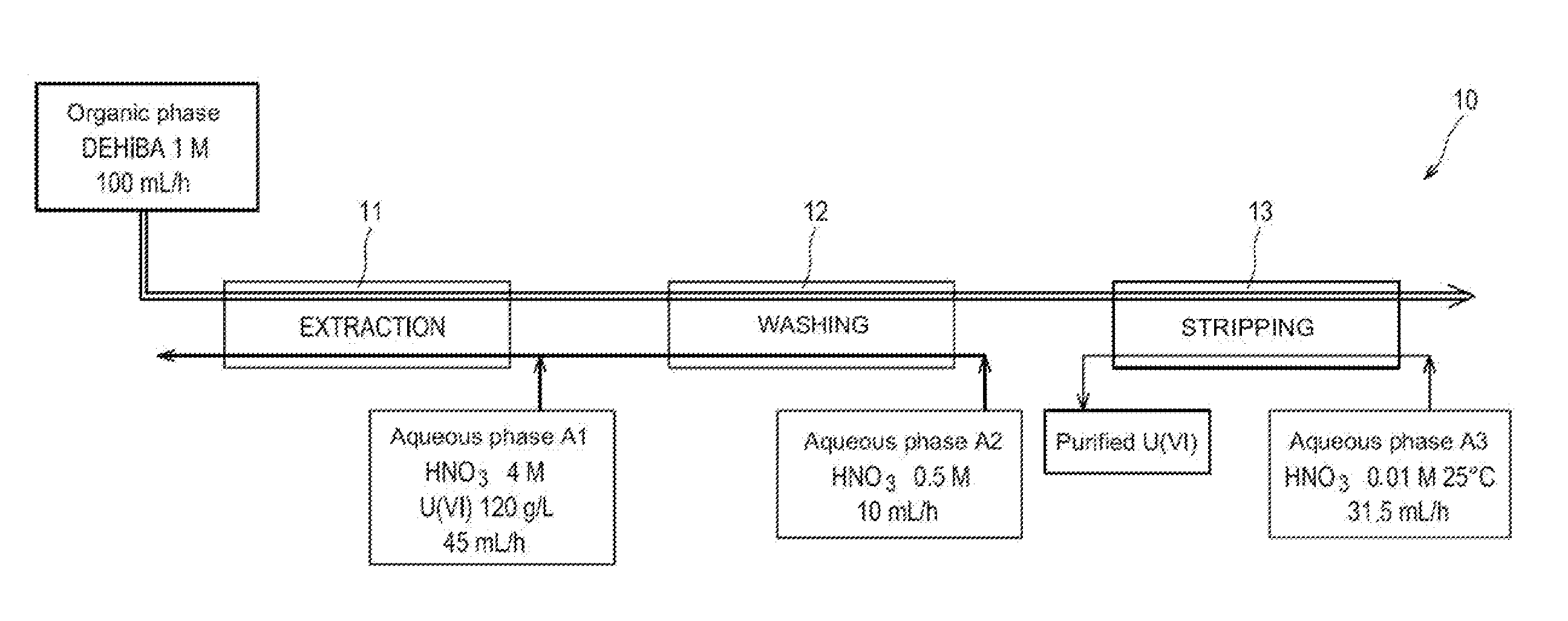

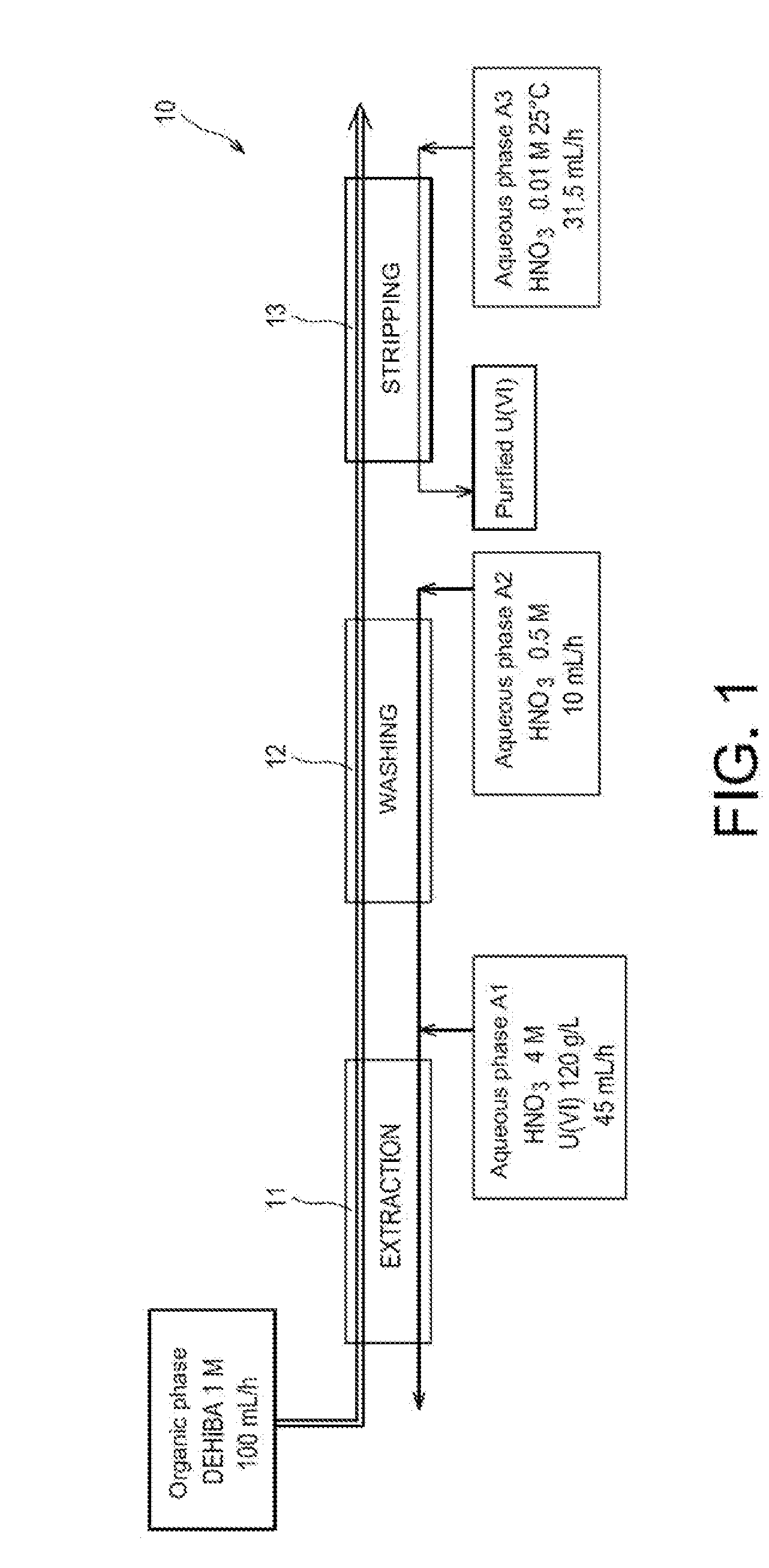

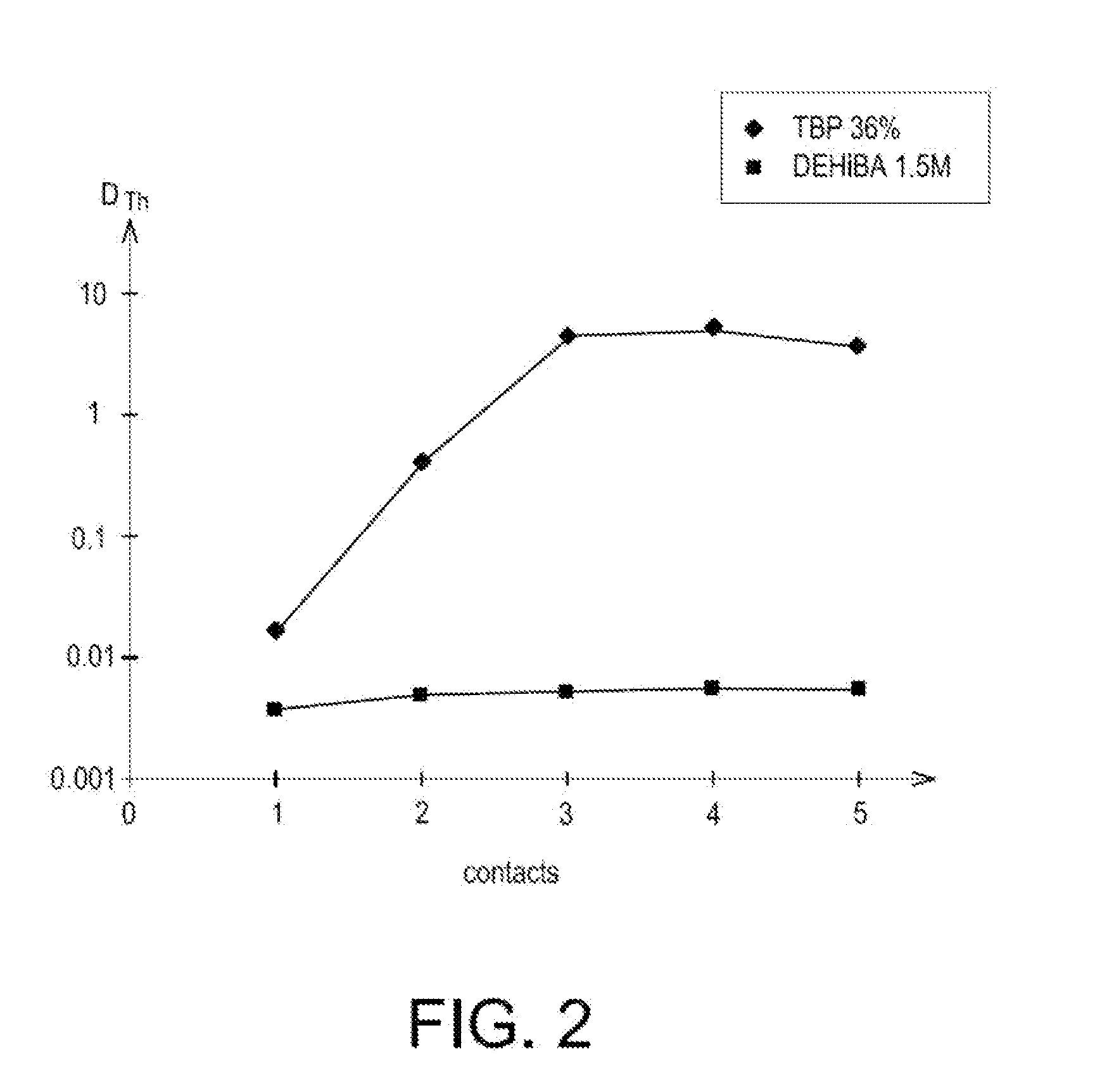

ActiveUS20120247276A1Simplification of exploitationEasy to processNuclear energy generationNuclear elementsNatural uraniumDiluent

A method with which uranium from a natural uranium concentrate may be purified, includinga) extracting the uranium present as uranyl nitrate in an aqueous phase A1 resulting from the dissolution of the natural uranium concentrate in nitric acid, by means of an organic phase which contains an extractant in an organic diluent;b) washing the organic phase obtained at the end of step a), with an aqueous phase A2; andc) stripping the uranyl nitrate of the organic phase obtained at the end of step b), by circulating this organic phase in an apparatus, as a counter current against an aqueous phase A3.The extractant is an N,N-dialkylamide and the ratio between the flow rate at which the organic phase obtained at the end of step b) and the aqueous phase A3 circulate in the apparatus where step c) occurs, is greater than 1.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Method for purifying the uranium from a natural uranium concentrate

ActiveUS8795611B2Simplification of exploitationEasy to processNuclear fuel reprocessingSolvent extractionNatural uraniumDiluent

A method with which uranium from a natural uranium concentrate may be purified, includinga) extracting the uranium present as uranyl nitrate in an aqueous phase A1 resulting from the dissolution of the natural uranium concentrate in nitric acid, by means of an organic phase which contains an extractant in an organic diluent;b) washing the organic phase obtained at the end of step a), with an aqueous phase A2; andc) stripping the uranyl nitrate of the organic phase obtained at the end of step b), by circulating this organic phase in an apparatus, as a counter current against an aqueous phase A3.The extractant is an N,N-dialkylamide and the ratio between the flow rate at which the organic phase obtained at the end of step b) and the aqueous phase A3 circulate in the apparatus where step c) occurs, is greater than 1.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

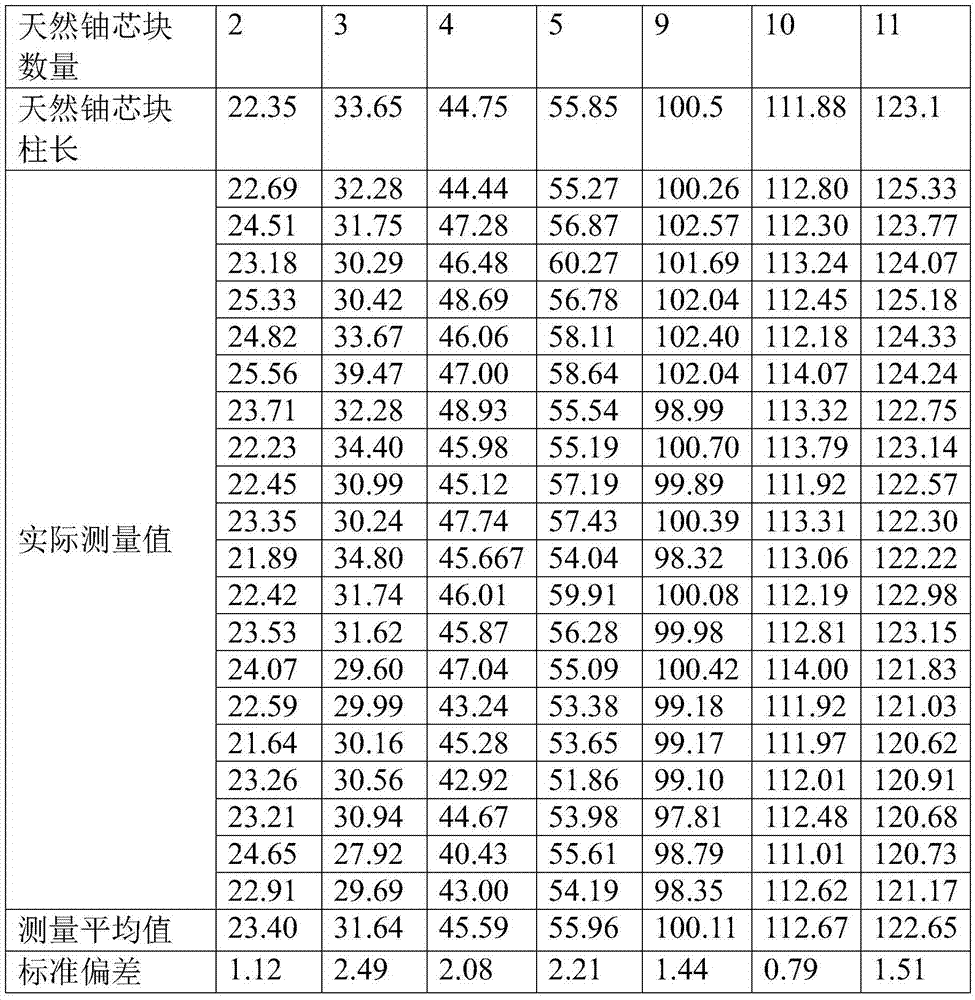

Method for measuring lengths of multiple kinds of enriched uranium pellet columns in nuclear rods

ActiveCN106935292ARealize measurementMeet the measurement requirementsNuclear energy generationNuclear monitoringNatural uraniumEngineering

The invention belongs to the technical field of fuel assemblies and particularly relates to a method for measuring lengths of multiple kinds of enriched uranium pellet columns in nuclear rods. The method includes the specific steps of manufacturing a standard rod, determining a gamma count value, performing data fitting and detecting actually. The method solves the technical problem that an existing measurement method fails to measure the lengths of the natural uranium pellet columns, is capable of measuring the lengths of the natural uranium pellet columns through a gamma-ray energy spectrum measurement method, solves the problem that a gamma absorption method fails to measure and meets the requirements on measuring the lengths of the natural uranium pellet columns in the TVS-2M fuel rods.

Owner:CNNC JIANZHONG NUCLEAR FUEL

High-temperature supercritical nuclear reactor

InactiveCN102568624BImprove economyTake advantage ofNuclear energy generationCooling arrangementFast-neutron reactorMaterials science

The invention relates to a high-temperature supercritical nuclear reactor. A spherical solid is used as a coolant of the nuclear reactor, which is different from common nuclear reactors that adopt light water, heavy water, gas and liquid sodium. The spherical solid coolant can be graphite spheres coated with silicon carbide, stainless steel spheres, graphite spheres coated with stainless steel and the like. The spherical solid has the characteristic of good rolling ability, so that the spherical solid can roll to a steam generator under the action of gravity after heating in the reactor, and the purpose of transferring heat from the reactor to the steam generator is achieved. The reactor is applicable to both thermal neutron reactor and fast neutron reactor, and natural uranium, low-enriched uranium, plutonium and thorium can be used as nuclear fuel. The temperature of high-temperature steam / water outputted by the steam generator can reach 900 DEG C, the same parameters to a thermal power station can be reached, the requirement of supercritical even ultra-supercritical can be satisfied, and the high-temperature supercritical nuclear reactor has high safety and reliability.

Owner:李正蔚

Method for applying uranium recycled from pressurized water reactor to heavy water reactor

ActiveCN105825904AAvoid the effects of high radioactivityCost-effective useNuclear energy generationReactors manufactureProduction lineNatural uranium

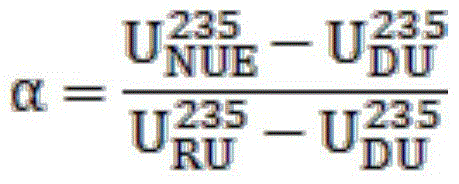

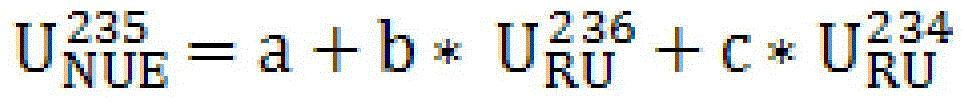

The invention provides a method for applying uranium recycled from a pressurized water reactor to a heavy water reactor. The method replaces natural uranium with natural uranium equivalent to produce a fuel for the heavy water reactor on a heavy water reactor fuel production line. The natural uranium equivalent is prepared through the following steps: (1) measuring the metal uranium content, uranium isotope composition and / or uranium isotope distribution of recycled uranium and depleted uranium by using a mass spectrometer; (2) according to the uranium isotope composition of the recycled uranium and depleted uranium, calculating the mixing ratios alpha and 1-alpha of the recycled uranium and depleted uranium and target value of natural uranium equivalent according to a formula or mixing computation procedure so as to achieve the effect equivalent to the effect of natural uranium; 3) accurately measuring the recycled uranium and depleted uranium and then carrying out physical mixing so as to form natural uranium equivalent; (4) carrying out sampling analysis on the natural uranium equivalent formed through mixing; and (5) replacing natural uranium with the natural uranium equivalent to produce the fuel for the heavy water reactor. The method provided by the invention avoids the influence of high radioactivity of the recycled uranium, realizes economic high-efficiency utilization of the recycled uranium and reduces cost of the fuel of the heavy water reactor.

Owner:THIRD QINSHAN NUCLEAR POWER

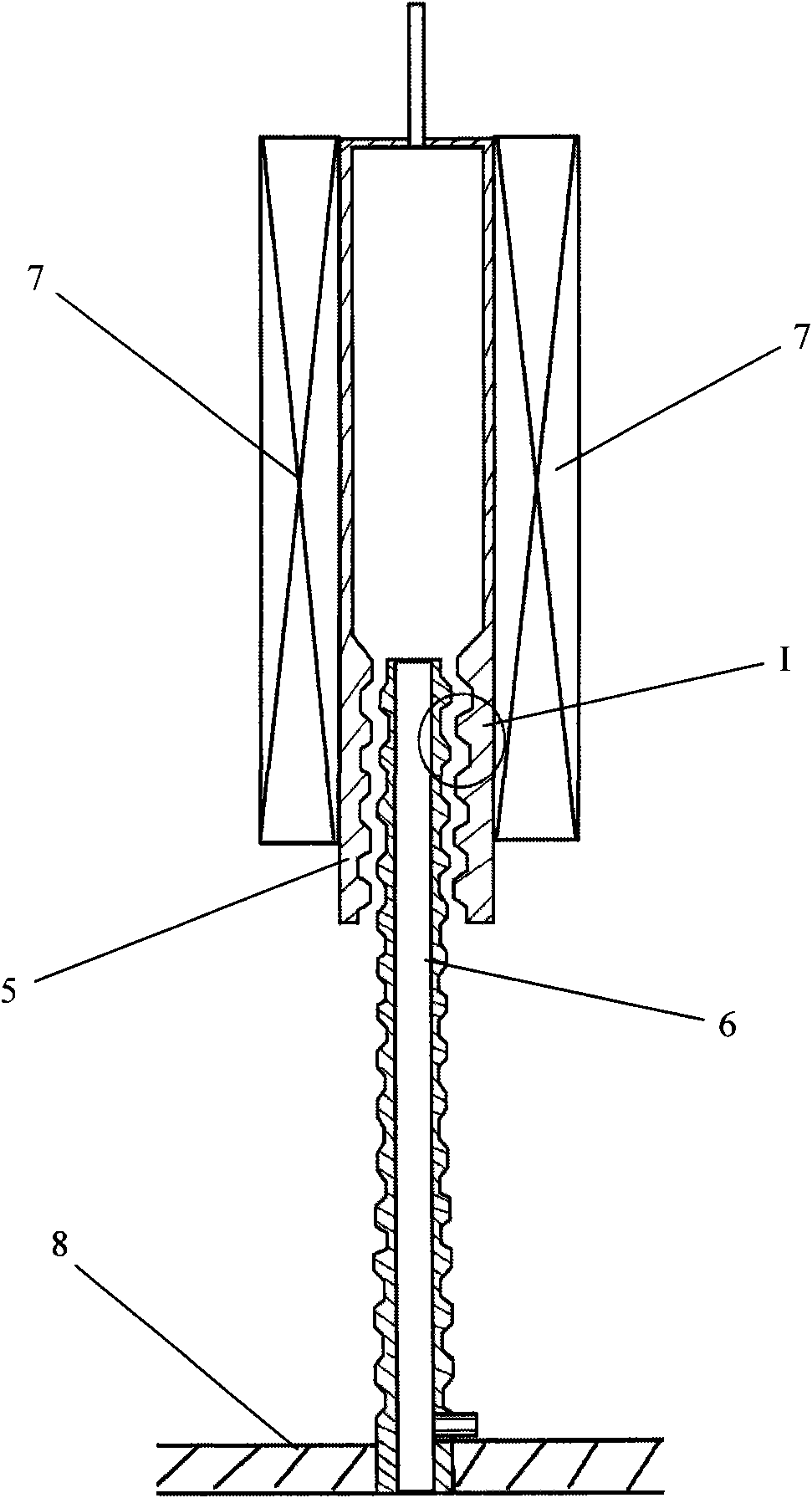

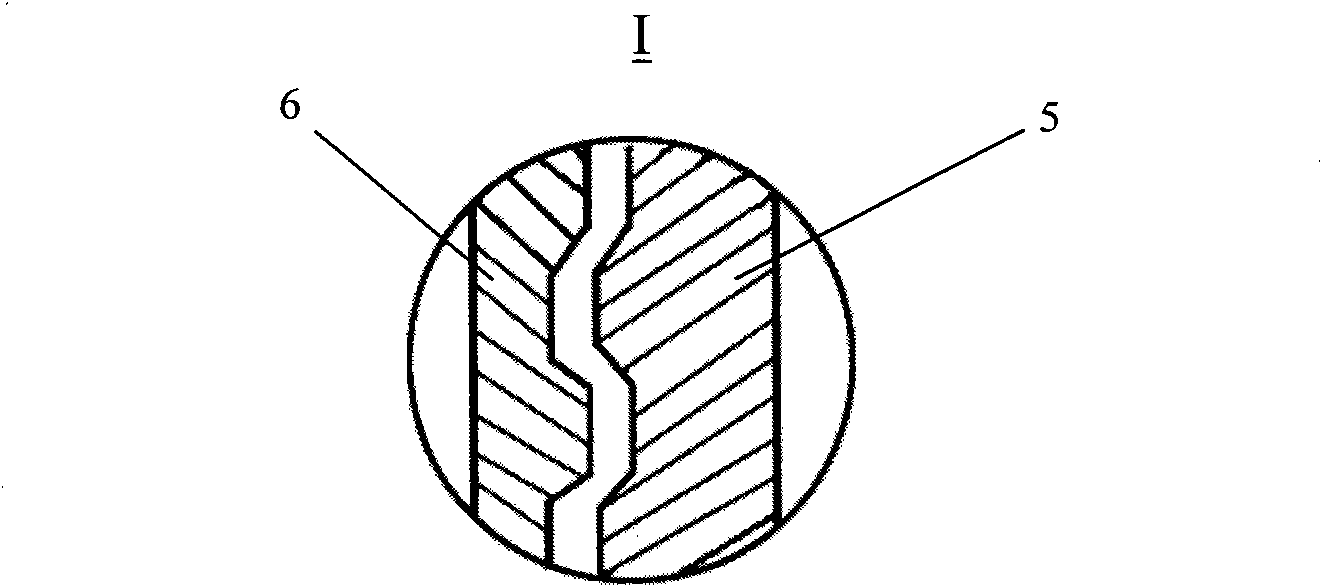

Fixing method of pulse baffle column plate string

ActiveCN106582064AEasy to moveEasy to fixLiquid solutions solvent extractionNatural uraniumEngineering

The invention belongs to the technical field of a nuclear fuel circulating natural uranium purification process and particularly relates to a fixing method of a pulse baffle column plate string. Meanwhile, fixation between baffles is enhanced through adopting a self-gravity effect of the baffles. Compared with other fixing methods including traditional welding and the like, an active fixing method is adopted, so that the linearity and concentricity between a central column and the plate string are effectively reduced. A distance sink tube guarantees that the distance between the baffles is strictly equal, so that the whole fixation of each baffle is facilitated and an easy-to-move part is not adopted; and fluid can conveniently and regularly flow in a baffle pulse column, and the stability and the two-phase mass transferring effect are enhanced.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

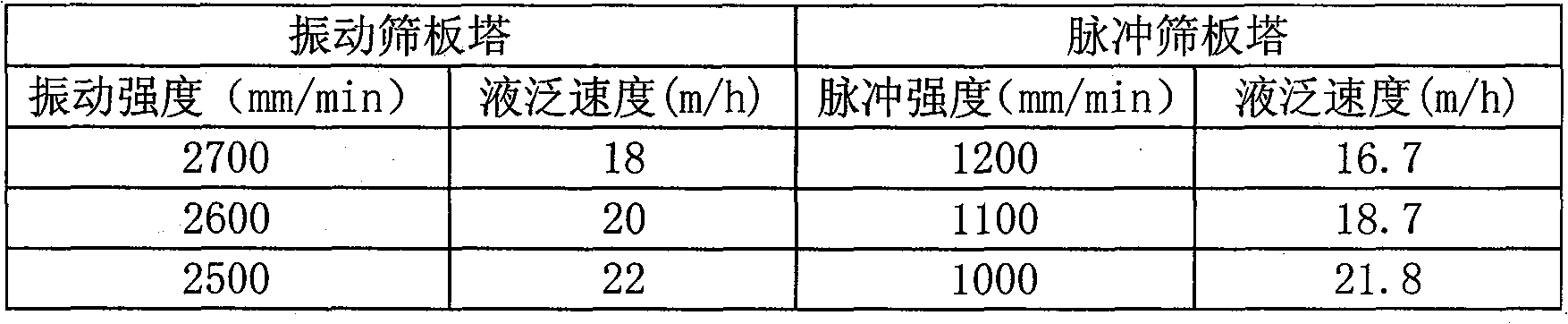

Method for extracting and purifying normal uranium with vibrating screen plate column

InactiveCN101269838BSimple structureGuaranteed uptimeUranium dioxideNatural uraniumPhysical chemistry

The invention relates to a method using a reciprocating sieve plate column to extract and purify native uranium, and the method belongs to the field of extraction. When a pulsed sieve-plate column carries out the extraction and the purification of the native uranium, the energy dissipation is big, the impulse action for feed liquid is not easy to be uniform, and the input and the operation of energy are more difficult. The method has the steps that: when the top interface operation is made and the continuous water phase is adopted, materials are charged towards the reciprocating sieve plate column from an inlet of a water phase, and when a column body which contains a sieve plate series, the water phase stops feeding; a driving device is started, and the vibration frequency is regulated to 80 to 240 per minute according to an organic phase; the flow ratio of the water phase ranges from 1.5 to 3, and an extracting agent is charged towards the column from an inlet of the organic phase; when an interface is established, the rafinate is discharged form an outlet of the water phase through a lower bellend; after the extracting agent of the organic phase begins to pass through an upper bellend to overflow from an outlet of the organic phase, the feeding and the discharging holes of the organic phase and the water phase are respectively provided with the extracting agent and materials to pass in and out according to the flow ratio, and the sieve plate series vibrates. The method has the advantages of simple equipment, stable operation, large flooding loading and low energy consumption.

Owner:TSINGHUA UNIV +1

Gas phase transfer method of natural uranium hexafluoride

ActiveCN106924989BGuarantee product qualityImprove direct yieldSolidificationLiquefactionNatural uraniumTransfer system

The invention belongs to the technical field of natural uranium hexafluoride gas-phase transfer, in particular to a natural uranium hexafluoride gas-phase transfer system and a natural uranium hexafluoride gas-phase transfer method. A secondary condenser and a tertiary condenser are arranged above two electronic scales respectively, and ethylene glycol and steam serve as a cold medium and a heat medium respectively. The secondary condenser is provided with two outlets, one of the outlets is connected to an inlet of a primary condenser through a valve J1, and the other outlet is connected to an inlet of the tertiary condenser through a valve J2, a valve J3, a valve J4 and a valve J5. The tertiary condenser is provided with two outlets, one of the outlets is connected to the inlet of the primary condenser through the valve J5 and a valve J7, and the other outlet is connected to an external tail gas treatment process system through a valve J6 and a valve J8. By the system and the method, assistance in pressure-relieved purification and gas-phase transfer of UF6 products in a cold trap can be realized, purity of the natural UF6 products is improved, the metal direct recovery rate is increased, and safety risks in a transfer process are reduced.

Owner:THE 404 CO LTD CHINA NAT NUCLEAR

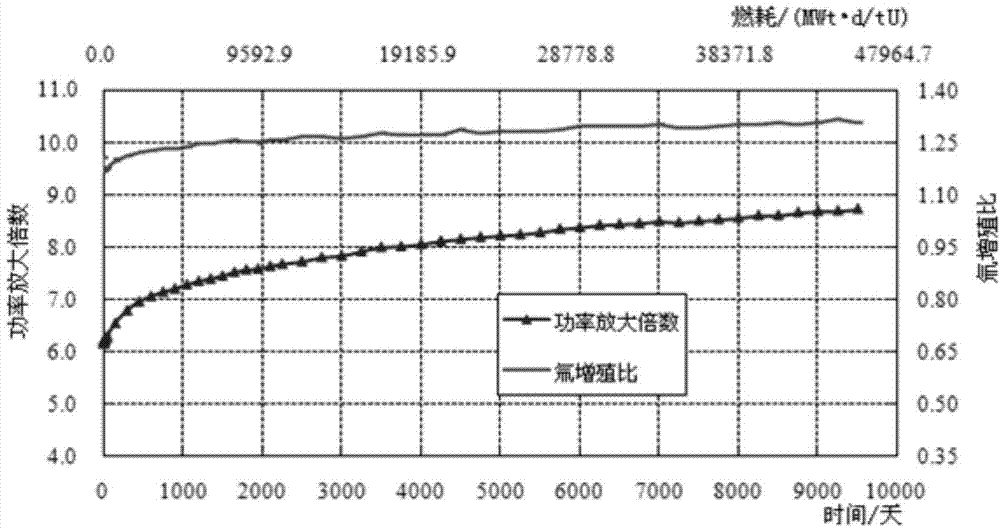

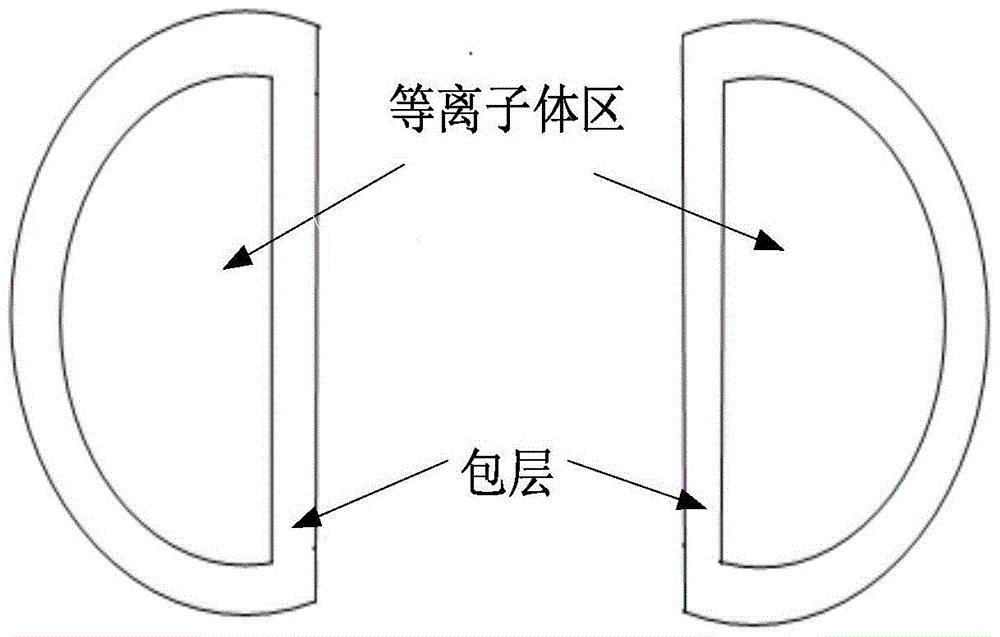

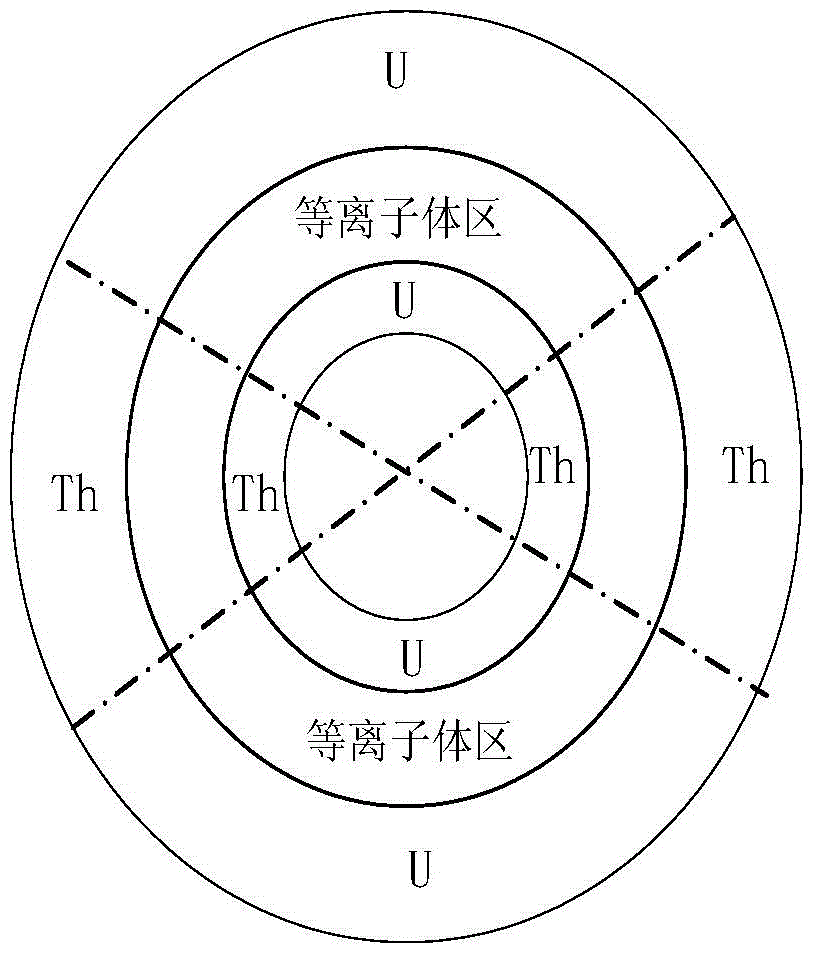

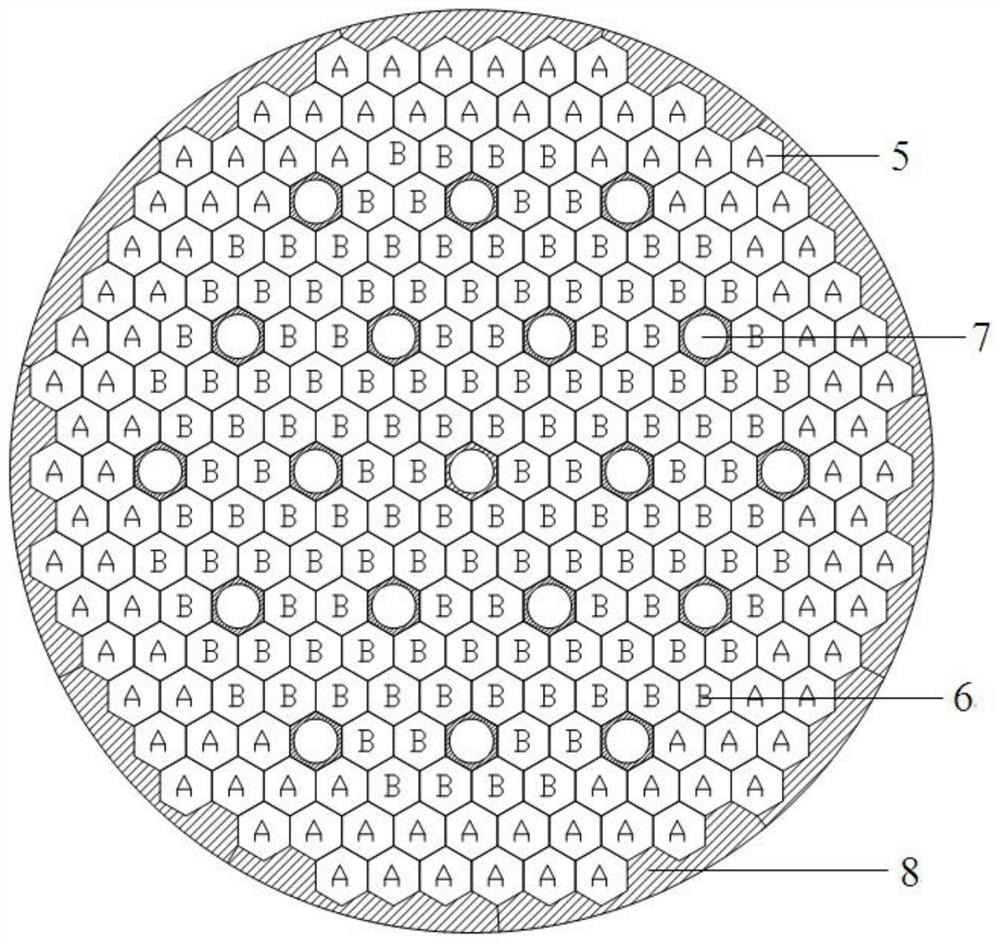

Hybrid reactor system and operation method using cross arrangement of water-cooled thorium-uranium fuel modules

ActiveCN103886918BWide range of optional volume fractionSolve the narrow operating spaceNuclear energy generationThermonuclear fusion reactorHybrid systemNatural uranium

The invention belongs to the field of fusion and fission hybrid energy reactors and cladding design, and particularly relates to a hybrid reactor system arranged by means of water-cooling thorium fuel modules and water-cooling uranium fuel modules in a staggered mode and an operating method. Natural thorium fuel reaction modules and natural uranium fuel reaction modules are annularly and alternately arranged in an optimized mode, a seed-cladding strategy is made full use of to improve overall neutron economy of the system, the aim of making the best of thorium fuel under high-energy magnification is achieved, namely good neutron performance of the water-cooling natural uranium modules is used for compensating for defects of natural thorium neutron multiplication and energy amplification, achievement of energy amplification and neutron multiplication of the system mainly depends on natural uranium, and redundant neutrons generated from the natural uranium are used for driving natural thorium to operate and multiplying 233U. When 233U in the natural thorium is accumulated to a certain quantity, the natural uranium can be extracted step by step and replaced by new natural thorium, a hybrid reactor can be filled with thorium fuel ultimately, and cycle operations of thorium and uranium are achieved.

Owner:TSINGHUA UNIV

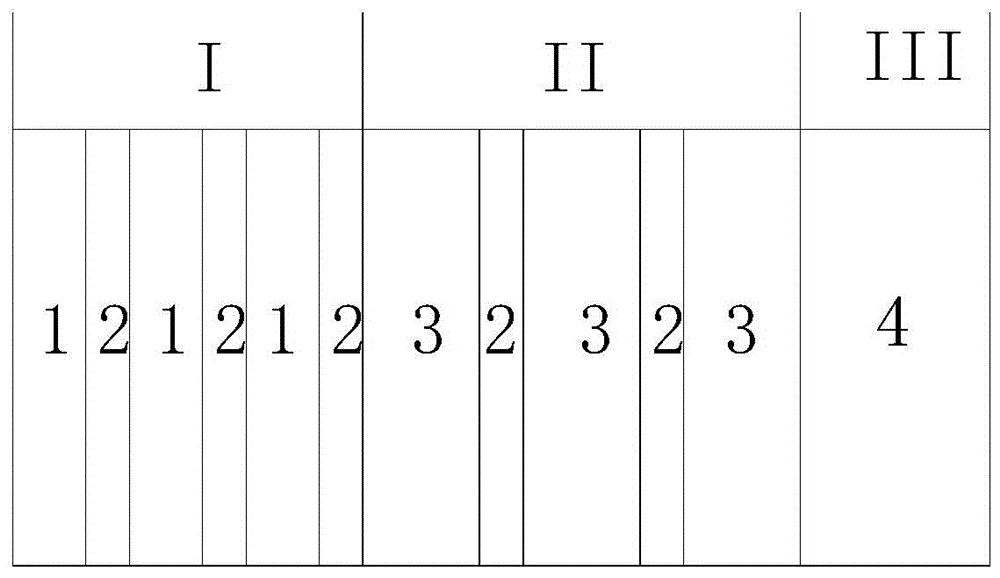

Metal-cooled reactor with mixed loading of multi-type fuel assemblies and management method

ActiveCN110853775BIncrease profitImprove economyNuclear energy generationReactor fuel susbtancesNatural uraniumEngineering

The invention discloses a multi-type fuel assembly mixed-loaded metal cooling reactor and a management method. The core structure of the reactor is an integral honeycomb-shaped regular hexagonal assembly channel, and the channel includes an internal fuel assembly channel, an external fuel assembly channel, and a control system. The rod assembly passage, the internal fuel assembly passage, the external fuel assembly passage, and the control rod assembly passage are provided with multiple cartridges of fuel assemblies in the axial direction, the external fuel assembly passage is arranged on the periphery of the internal fuel assembly passage, and the control rod assembly The channel is arranged crosswise with the internal fuel assembly channel, and the upper and lower ends of the internal fuel assembly channel are arranged with low-cost natural uranium fuel assemblies, and the middle is arranged with enriched uranium fuel assemblies. The invention solves the problems of large loading capacity, high enrichment degree and low utilization rate of the existing metal-cooled reactor core fuel.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

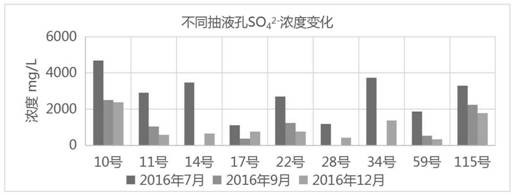

Method for replacing and repairing underground water of in-situ leaching uranium mining base by adopting sewage pumping and clean water injection

The invention provides a method for replacing and repairing underground water of an in-situ leaching uranium mining base by adopting sewage pumping and clean water injection, and belongs to the technical field of underground water treatment. The method comprises the following steps that clean water is injected into surrounding liquid injection holes while underground water is pumped out of liquid pumping holes of the in-situ leaching uranium mining base; and according to the method, the underground water is repaired by adopting a pollution-pumping, clean-water-injection and replacement repair technology, a specific liquid pumping hole is selected to pump out polluted water, and a liquid injection hole is selected to inject clean water to replace the polluted water with the clean water, so that the radionuclide natural uranium, radium-226 and non-radioactive pollutant concentration of the underground water of the in-situ leaching well site reach a repair target value.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

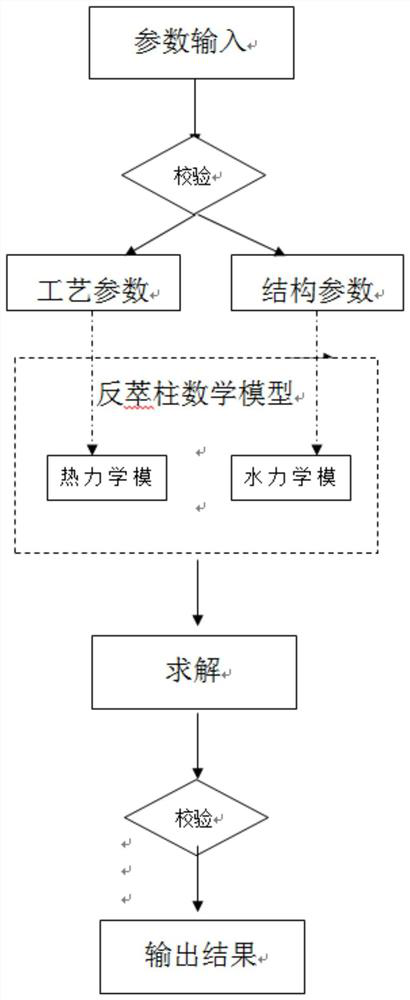

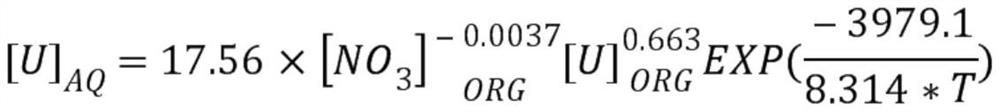

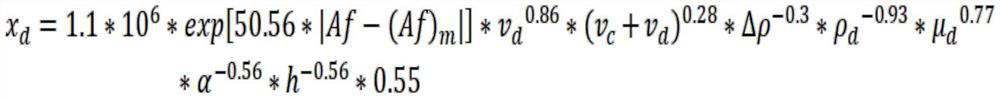

Modeling method of large industrial sieve plate uranyl nitrate reverse extraction column

PendingCN114649059AImprove accuracyHigh precisionChemical processes analysis/designComputational theoretical chemistryNatural uraniumPhysical chemistry

The invention belongs to the technical field of uranium purification and conversion, and particularly relates to a modeling method of a large industrial sieve plate uranyl nitrate reverse extraction column. Inputting parameters of the pulse sieve plate reverse extraction column, wherein the parameters comprise process operation parameters and structure parameters; the method comprises the following steps: establishing a thermodynamic model of a uranyl nitrate reverse extraction process, establishing a pulsed sieve plate reverse extraction column hydraulic model, combining the thermodynamic model of the uranyl nitrate reverse extraction process with the pulsed sieve plate reverse extraction column hydraulic model, and solving by utilizing a Junge-Kutta method; calculating uranyl nitrate concentration results at water phase and organic phase outlets of the pulsed sieve plate reverse extraction column under the precondition of introducing technological operation parameters and structural parameters of the pulsed sieve plate reverse extraction column; and the calculation result is verified, the final calculation result is obtained for the output meeting the requirement, and the calculation is carried out again for the return which does not meet the requirement. The method is suitable for simulation of the pulsed sieve plate reverse extraction column in the natural uranium reverse extraction process, the method is high in accuracy, and simulation data is within the error range of 8% of actual data.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

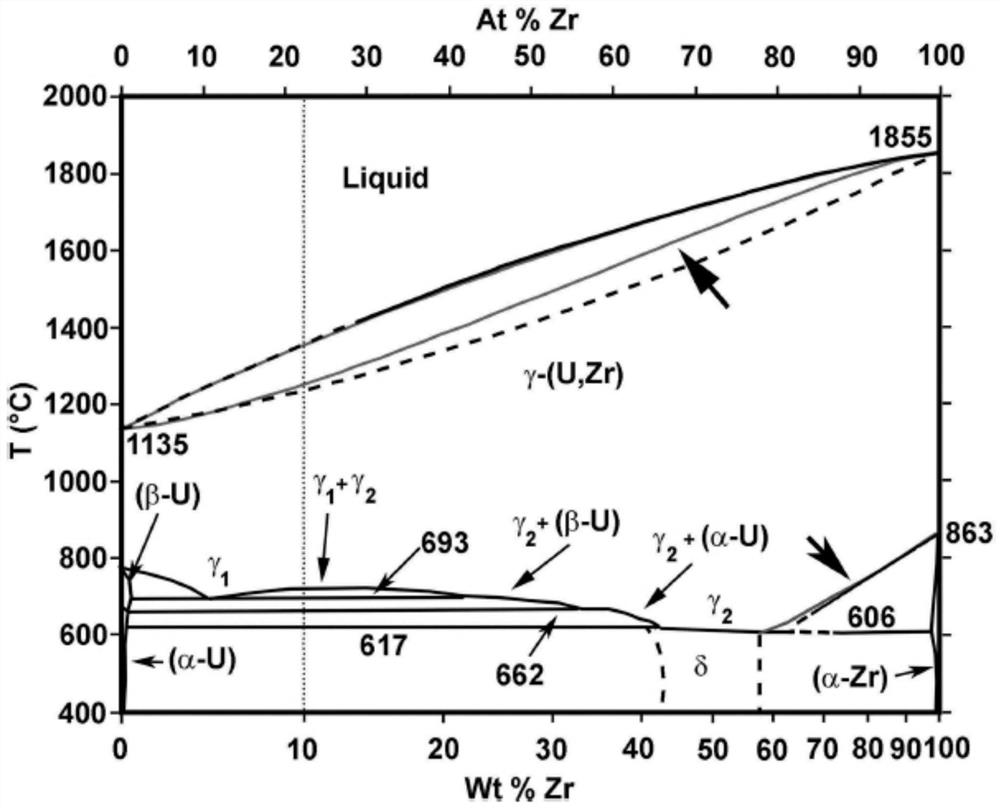

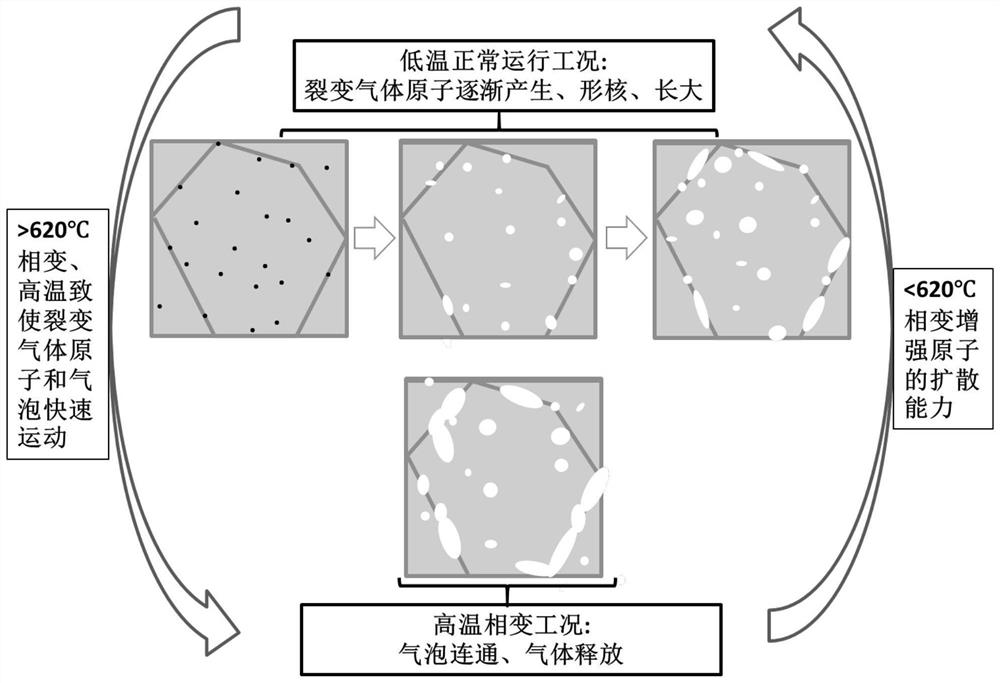

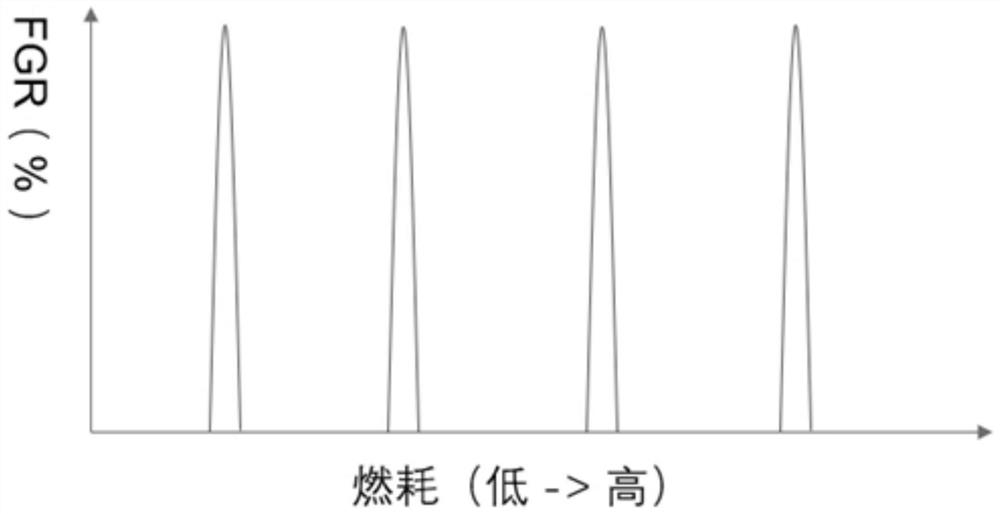

High-burnup fast neutron reactor metal fuel

ActiveCN113270209AIncrease fuel consumptionIncrease profitNuclear energy generationFast fission reactorsNatural uraniumNuclear power

The invention discloses a high-burnup fast neutron reactor metal fuel, a reactor core is loaded with a metal fuel, and the metal fuel adopts a natural uranium U-50Zr alloy. Phase change is achieved by manually controlling the temperature, fuel consumption is improved, and the service life of fuel is prolonged; the burnup of fuel is increased, the utilization rate of uranium is increased, and the pressure for treating nuclear waste is reduced; the service life of the fuel is prolonged, the nuclear power cost is reduced, and the nuclear energy economy is improved; and timely release of fission gas and periodic elimination of fuel defects are effectively carried out, core-cladding mechanical interaction caused by swelling is reduced, and safety is improved.

Owner:XI AN JIAOTONG UNIV

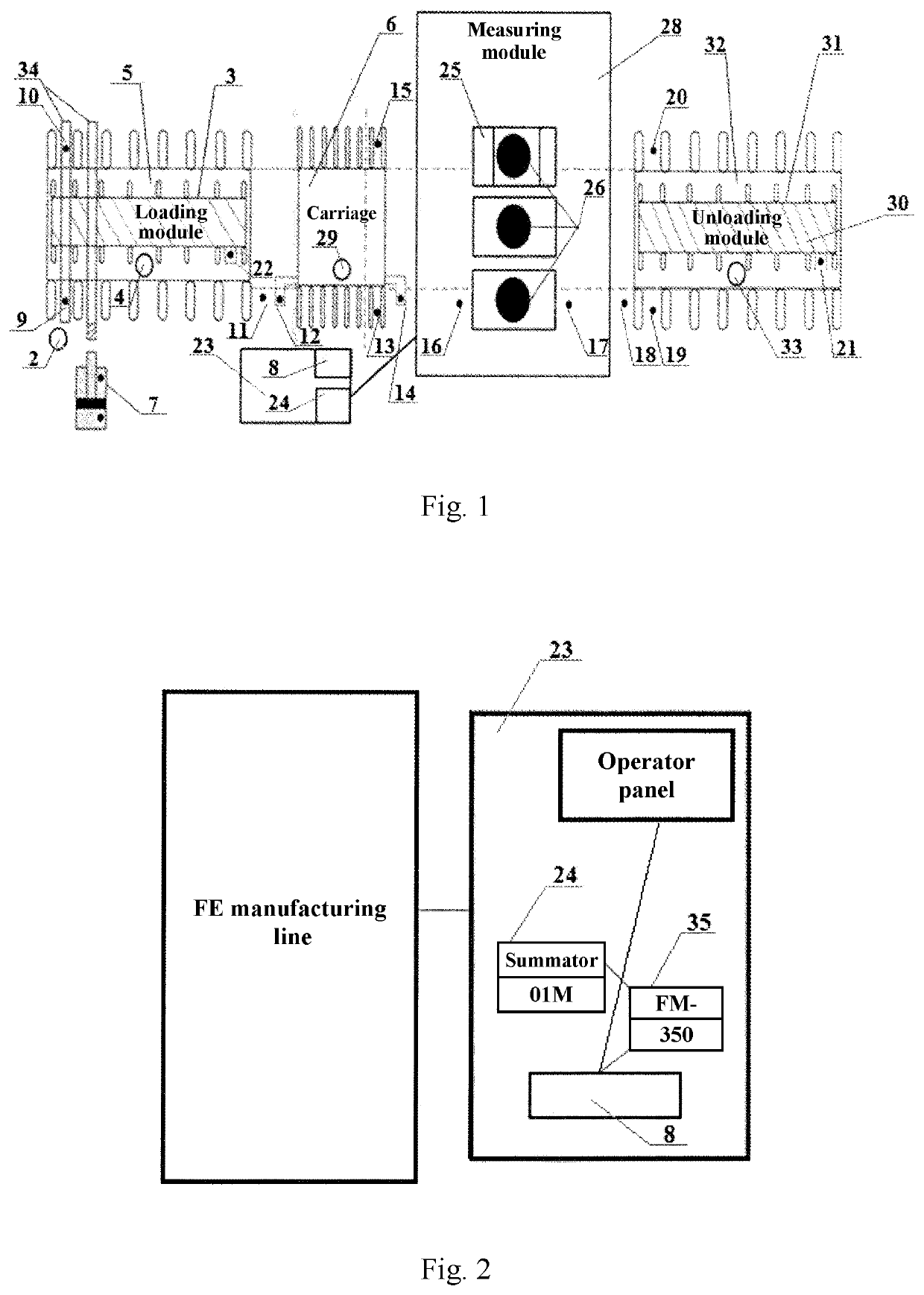

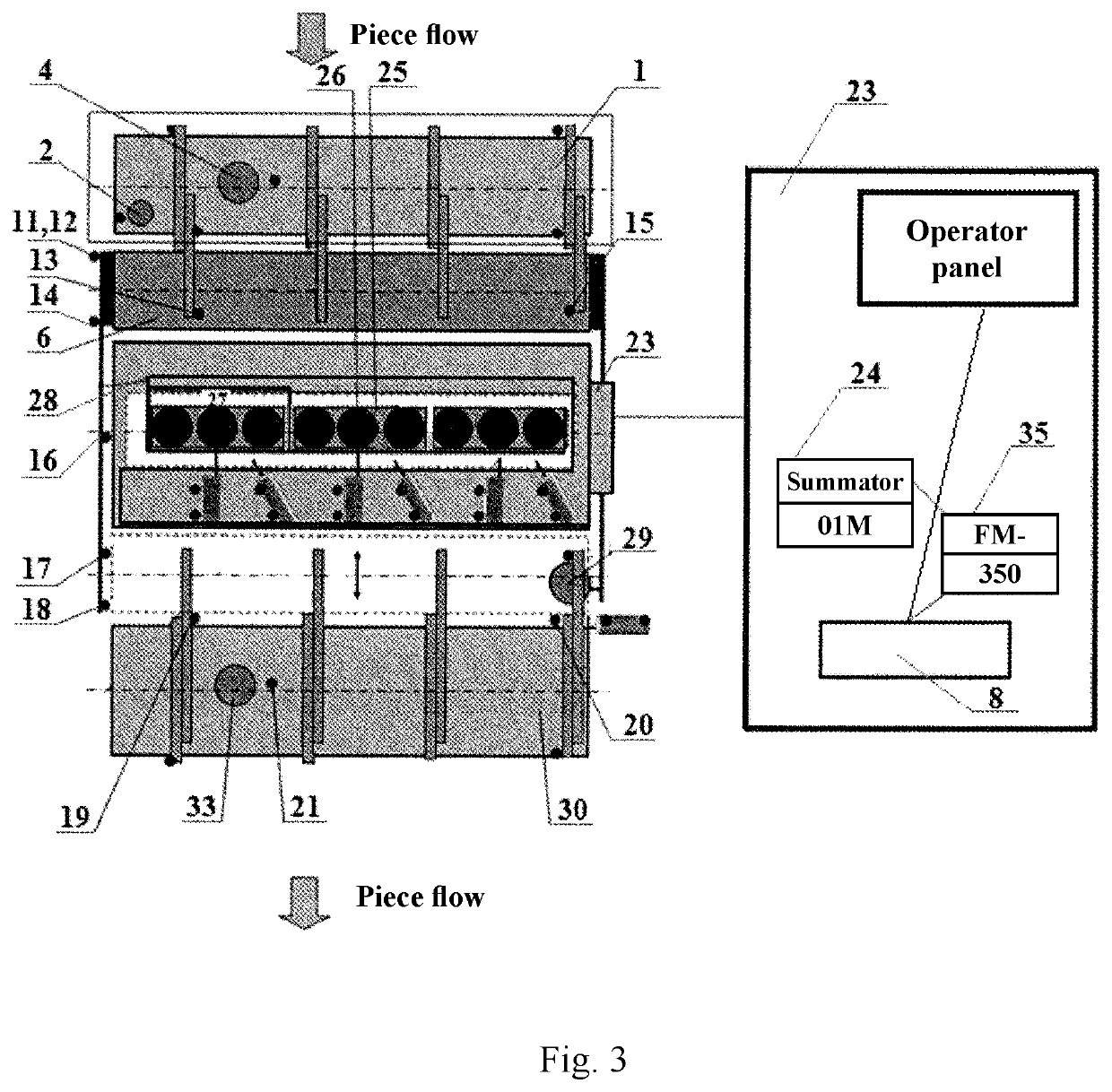

Alpha-Contamination Tester of Fuel Elements

InactiveUS20220013244A1Improve efficiencyImprove performanceNuclear energy generationReactors manufactureNatural uraniumTester device

Tester for monitoring alpha contamination of fuel elements containing tandem loading module and unloading module of fuel elements, each having a fixed frame with cradles, position indicators of fuel elements, measurement module located between the loading module and unloading module, which includes the detection units of alpha radiation from the surface of fuel elements, pneumatic cylinders with position indicators of the rods for samples forwarding with the source of alpha radiation. The loading module is supplied with a movable automated carriage with cradles for forwarding fuel elements to the measurement module and then to the unloading module, besides the loading and unloading modules are provided with movable racks for placing the fuel elements on the cradles of the modules and carriage, and the samples with natural uranium isotopes are used as the source of alpha radiation for setup of the measurement module.

Tail gas treatment method of hydrofluorination process

ActiveCN106925071BSimple structureEasy to operateDispersed particle separationHydrogen fluorideLiquid ChangeHydrofluoric acid

The invention belongs to the technical field of treating tail gas from the process of generating uranium tetrafluoride from natural uranium dioxide through hydrofluorination, and particularly relates to a hydrofluorination process tail gas treatment method. Cooling water is introduced to internally cool a condenser, and after being cooled, the condenser is switched into a production system and used for condensing hydrofluorination process tail gas; condenser liquid is sampled once at the interval of one hour to analyze the content of hydrogen fluoride in condensate until the content is kept at 5-15%; when the cooling water outlet temperature is higher than 35 DEG C, the flow of cooling water is adjusted to increase by 5 m<3> / h for each 5 DEG C increase in temperature will raise, and the adjustment is the same as that of 5DEG C temperature raise if the temperature is raised less than 5 DEG C; an inlet and outlet valve, located above the condenser, of a temporary storage tank is switched on to receive hydrofluoric acid; the acidity of non-condensable gas is analyzed, and the acidity value should be smaller than 2%; the process tail gas flow change is observed all the time; the liquid change of hydrofluoric acid in the temporary storage tank is monitored, when the volume reaches 70%, a shield pump is started to pump hydrofluoric acid into a hydrofluoric acid storage tank to recover and treat hydrofluoric acid. System tail gas can be completely treated by means of the hydrofluorination process tail gas treatment method, and the influence on the environment can be ignored.

Owner:THE 404 CO LTD CHINA NAT NUCLEAR

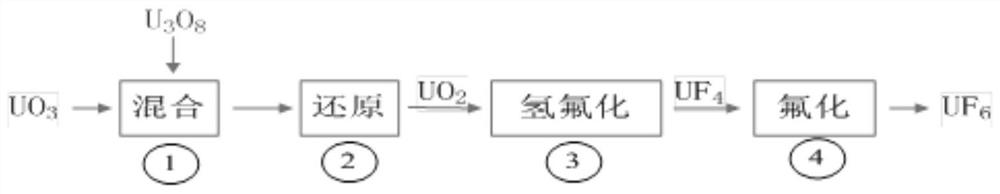

Novel process for preparing UF6 by direct hydrogen reduction dry method of U3O8

PendingCN114644360AReduce processingImprove securityUranium fluoridesHydrogen fluorideNatural uranium

The invention belongs to the technical field of purification and conversion of natural uranium, and particularly relates to a novel process for preparing UF6 through a U3O8 direct hydrogen reduction dry method. The method comprises the following steps: adding a U3O8 raw material and a denitration UO3 material, mixing, carrying out a reduction reaction in a reduction fluidized bed after mixing to prepare a UO2 material, carrying out a countercurrent fluidization reaction on anhydrous hydrogen fluoride and UO2 produced by reduction in the fluidized bed to prepare a UF4 product, and carrying out a fluorination reaction on uranium tetrafluoride and fluorine gas produced by hydrofluorination in a vertical fluorination reactor. And the UF6 product meeting the requirements is prepared. The uranium conversion production cost is reduced, waste liquid discharge is reduced, and a new thought is provided for preparation of uranium hexafluoride in the future.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com