Tail gas treatment method of hydrofluorination process

A tail gas treatment and chemical process technology, applied in chemical instruments and methods, hydrogen fluoride, separation methods, etc., to achieve the effects of good economy, high safety factor, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

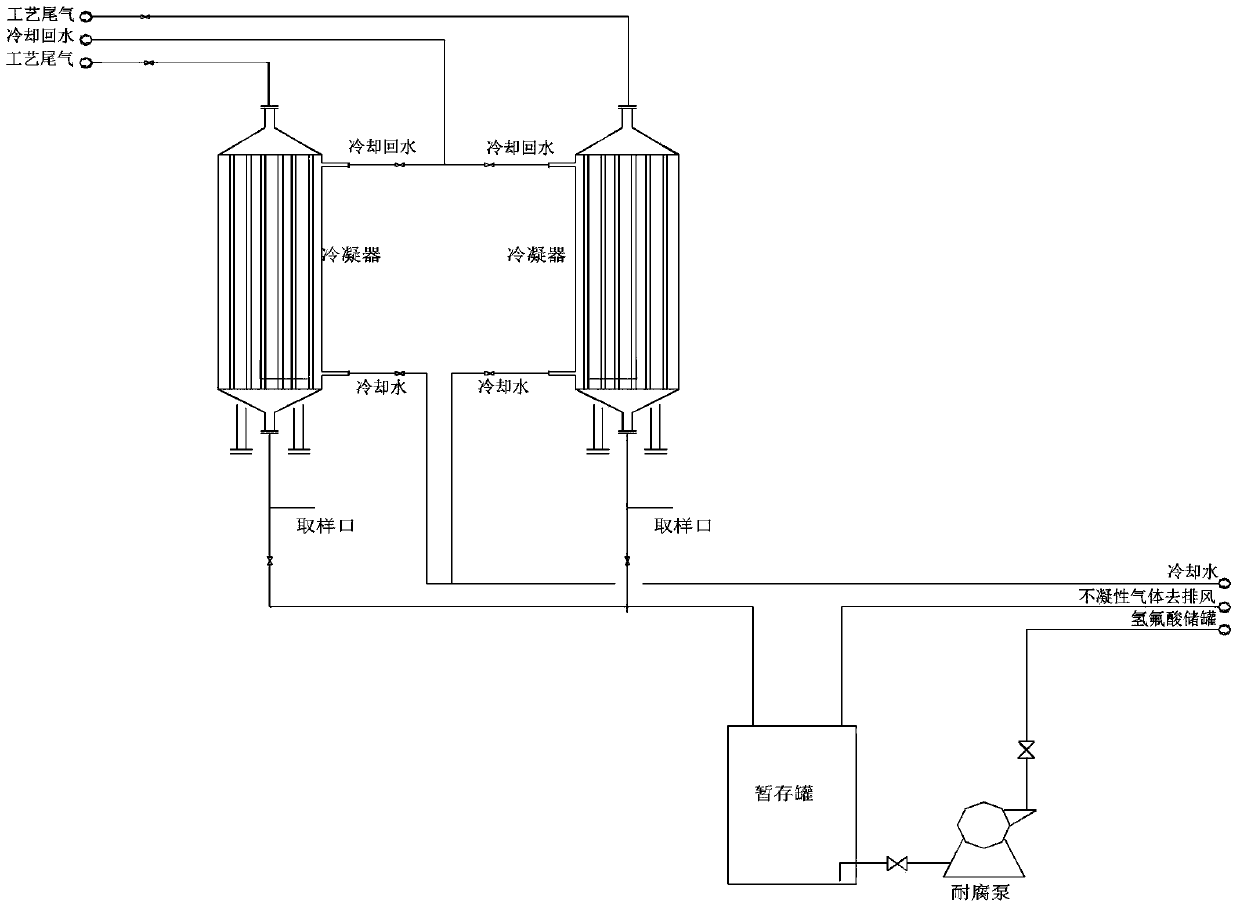

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] Such as figure 1 As shown, the hydrofluorination process tail gas treatment method of the present invention comprises the following steps:

[0026] Step 1: Cool the condenser with cooling water. During the cooling process, control the cooling water inlet temperature to 10-25°C, the outlet temperature to 25-45°C, and the cooling time to 30 minutes; Hydrofluorination process tail gas is condensed;

[0027] Step 2: Take a sample of the condenser liquid once an hour, and analyze the hydrogen fluoride content in the condensate, which should be between 5% and 15%. If it exceeds the limit, you need to make corresponding system adjustments;

[0028] Step 3: If the cooling water outlet temperature is lower than 35°C, it means that the cooling water flow control is appropriate; if the cooling water outlet temperature is greater than 35°C, adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com