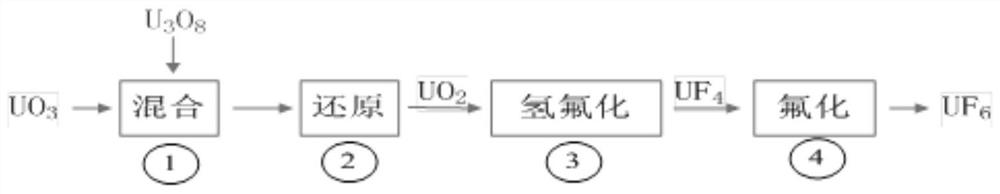

Novel process for preparing UF6 by direct hydrogen reduction dry method of U3O8

A direct and dry technology, applied in the field of natural uranium purification and transformation, can solve the problems of large front-end waste liquid, high system failure rate, long process flow, etc., and achieve the goal of reducing waste treatment volume, shortening process flow, and simplifying process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0020] By researching and conducting U 3 O 8 The hydrogen reduction activity test shows that uranium 88 can be directly reduced by hydrogen to form uranium dioxide. carry out U 3 O 8 Direct hydrogen reduction test, fluidization test and engineering application research, the results show that the U 3 O 8 Material and UO prepared by AUC thermal decomposition reduction, ADU thermal decomposition reduction, UNH denitration reduction 3 mixed (U 3 O 8 with UO 3 The mass mixing ratio can be controlled within the range of 0 to 0.85), and then the reduction fluidized bed hydrogen reduction to prepare UO 2 The feasibility of the process route, on this basis, further verify the denitrification UO 3 Add different proportions of U 3 O 8 UO after hydrogen reduction reaction 2 The influence of product quality on subsequent hydrofluorination and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com