Method for extracting and purifying natural uranium by using vibrating ring-shaped traverse baffle extracting tower

A vibrating ring and baffle technology, which is applied in the field of extraction, can solve the problems of energy input and operation difficulties, uneven material-liquid pulse action, large energy consumption, etc., and achieve stable and reliable operation, low noise, and energy saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

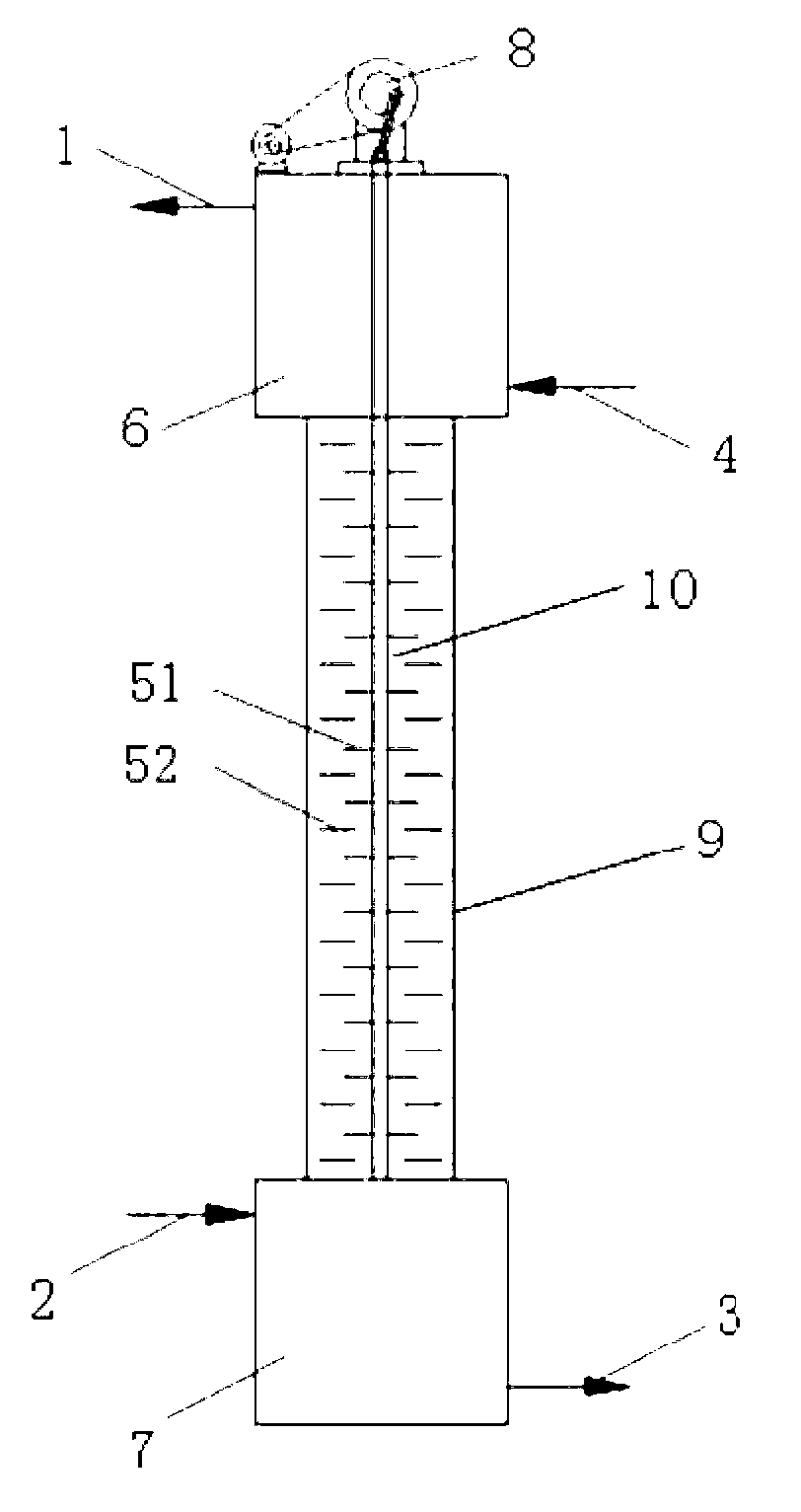

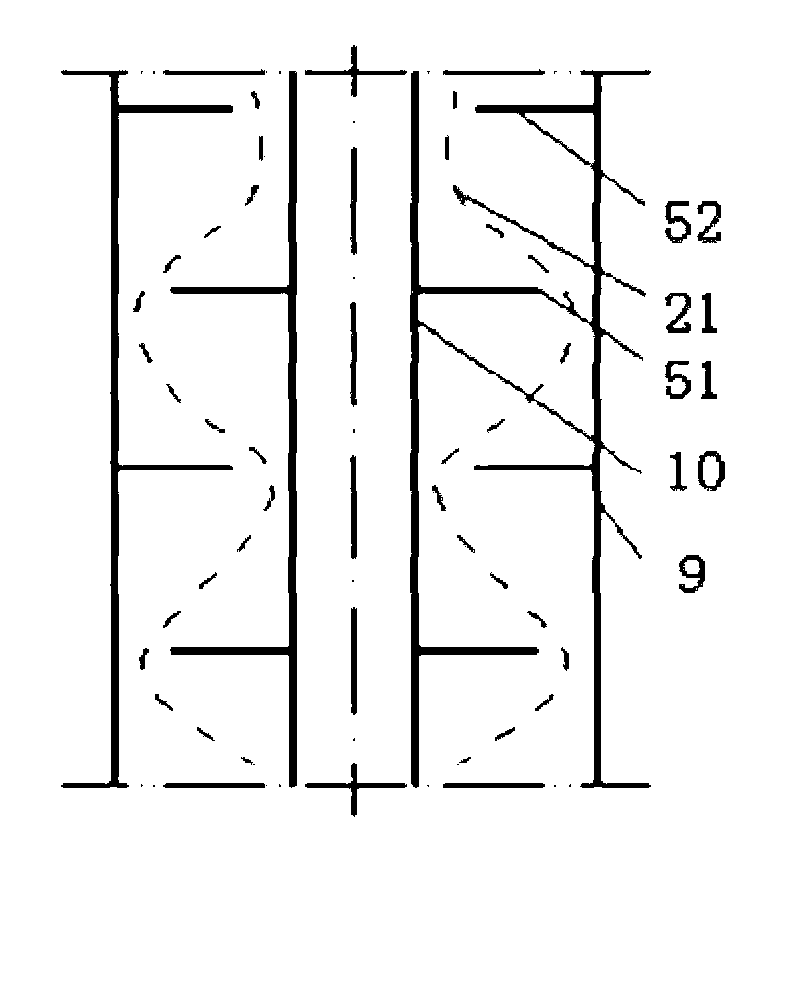

[0029] system such as figure 1 As shown, when the upper interface is used and the water phase is continuous, firstly, the water phase inlet 4 is used to fill the tower, and after the tower body containing the baffle plate string is filled with materials, the water phase stops feeding; turn on the motor 8. The frequency is adjusted to 80 / min. According to the organic phase:water phase flow ratio (i.e. volume ratio) of 1.5, the extraction agent is fed into the tower from the organic phase inlet 2, and the raffinate is discharged from the water phase outlet 3 after the interface is established. Water phase; after the organic phase begins to overflow from the organic phase outlet 1, the complete extraction process begins (the inlet and outlet of the organic phase and the water phase have extraction agent and material in and out according to the flow ratio, and the baffle plate string vibration). Under the action of the vibration of the baffle plate series, the aqueous phase and t...

Embodiment 2

[0031] The operation steps are the same as in Example 1, except that the frequency is 240 / min; the flow ratio of organic phase:water phase is 3, and the organic phase is prepared from TBP and sulfonated kerosene at a ratio of 3.6:6.4.

Embodiment 3

[0033] The operation steps are the same as in Example 1, except that the frequency is 160 / min; the flow ratio of organic phase:water phase is 2, and the organic phase is prepared by TBP and sulfonated kerosene in a ratio of 3:7.

[0034] Compared with the tower diameter and tower height of the vibrating annular baffle extraction tower with the same tower diameter and tower height, the vibration intensity of the vibrating annular baffle extraction tower for achieving the same purity effect The wider the parameter range, the greater the flooding velocity. Vibration intensity is used as a parameter to measure the energy input, and the wide range of parameters indicates that the equipment has great flexibility. The flooding speed is a parameter to measure the processing capacity of the equipment. The greater the flooding speed, the greater the processing capacity of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com