Metal-cooled reactor with mixed loading of multi-type fuel assemblies and management method

A fuel assembly and metal cooling technology, applied in the field of nuclear reactors, can solve the problems of low fuel economy and large loading of enriched uranium fuel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

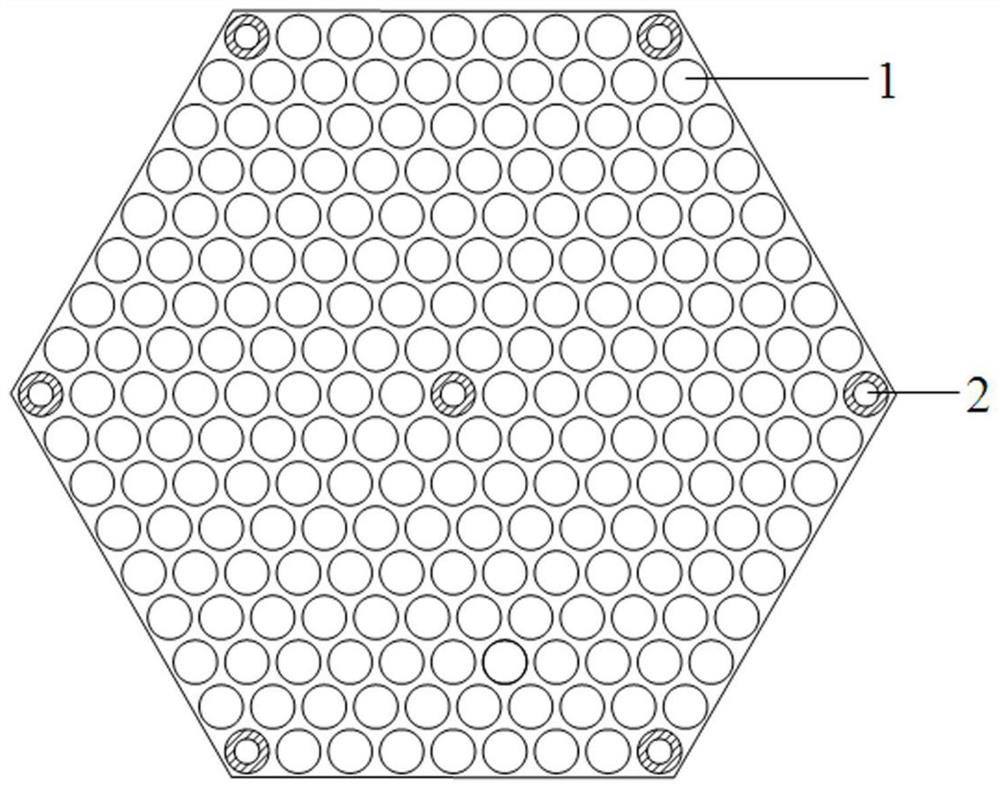

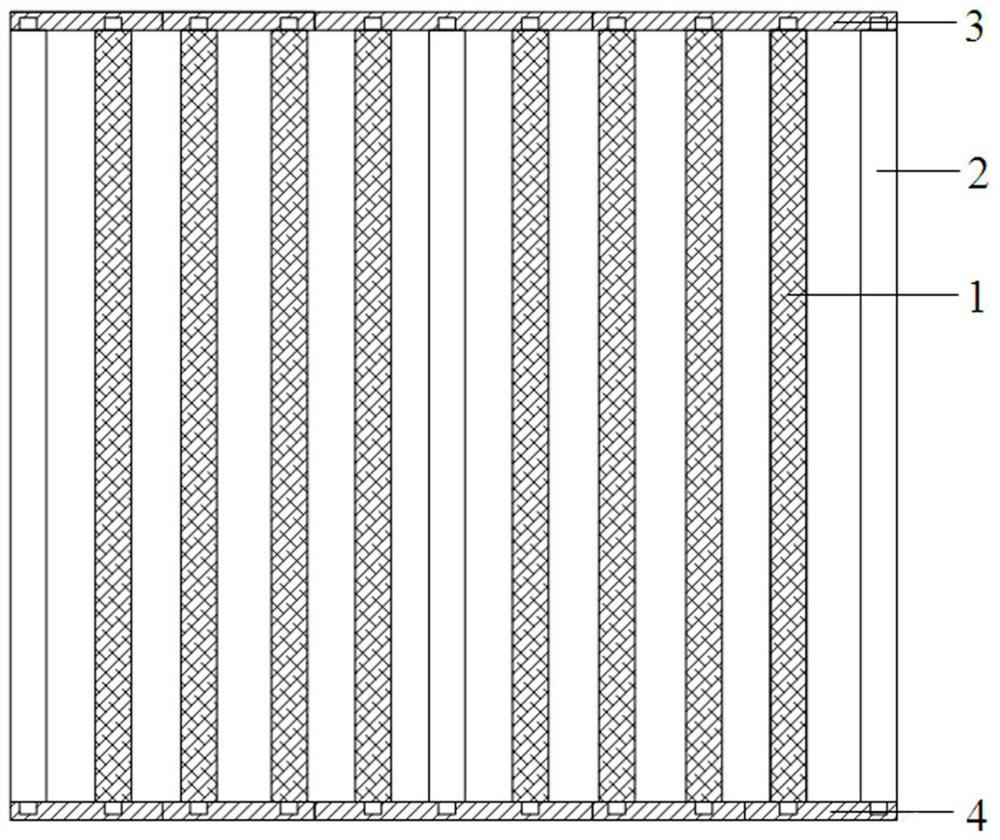

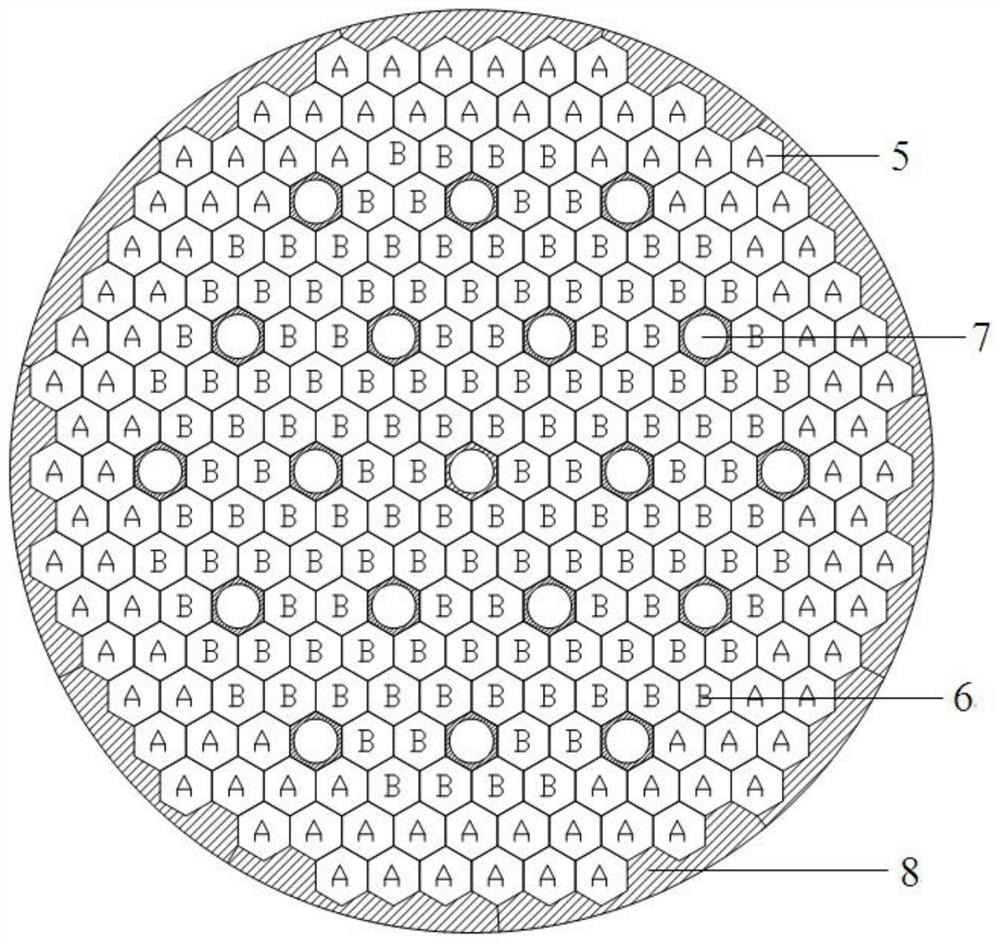

[0032] like Figure 1 to Figure 5 As shown, the multi-type fuel assembly mixed loading metal cooling reactor, the core structure of the reactor is an integral honeycomb regular hexagonal assembly channel, which contains 253 hexagonal channels, including 132 internal fuel assembly channels 6 (B Class A channels), 102 external fuel assembly channels 5 (Class A channels), 19 control rod assembly channels 7, the coolant flow rate of the external fuel assembly channels 5 (Class A channels) is about ), which is relatively low. The control rod assembly channel 7 is in the shape of "outer square inner circle", the inner diameter is 135mm, and the center-to-center distance between adjacent hexagonal channels is 139mm. The inner fuel assembly channel 6, the outer fuel assembly The wall thicknesses of channel 5 and channel 7 of the control rod assembly are both 2.0 mm. The internal fuel assembly passage 6, the external fuel assembly passage 5, and the control rod assembly passage 7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com