Natural uranium hexafluoride gas-phase transfer system and natural uranium hexafluoride gas-phase transfer method

A gas-phase transfer and uranium hexafluoride technology, which is applied in the field of natural uranium hexafluoride gas-phase transfer, can solve the problems such as the lack of application of purification and transfer, and achieves easy realization of control conditions, improves direct yield, and reduces the risk of liquid-phase transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

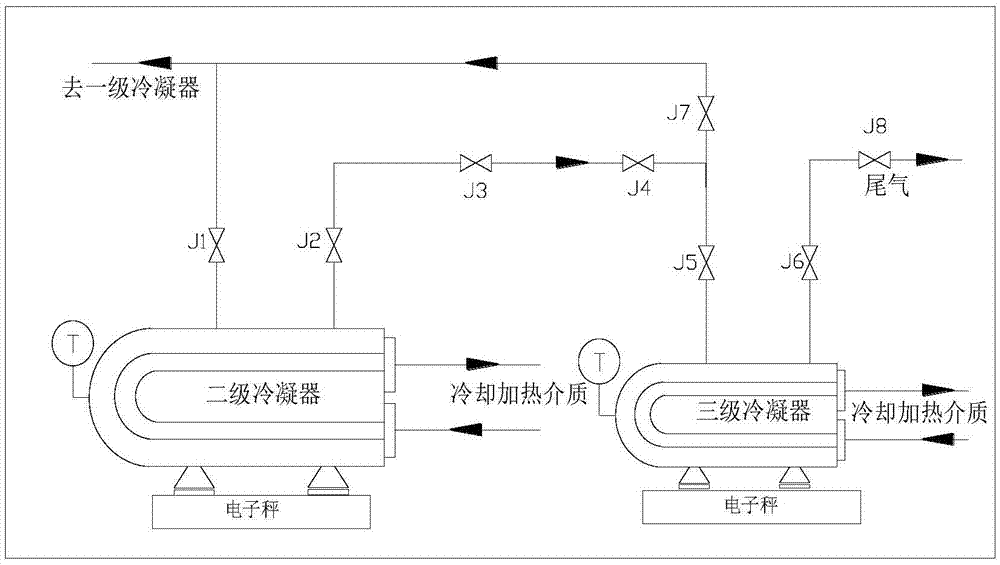

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] At 101.325kPa, UF 6 When heated to 56.4°C, it can be directly sublimated without melting. Therefore, as long as the temperature of the auxiliary cold trap is controlled above the sublimation point, UF can be realized. 6 gas phase transfer. In addition, in the fluorine gas produced by medium-temperature electrolysis, the content of hydrogen fluoride is generally 4% to 10%. 6 There is a large difference between the sublimation point (56.4 ℃), therefore, the temperature of the auxiliary cold trap is controlled at the boiling point of hydrogen fluoride and UF 6 between the sublimation points, can effectively UF 6 Hydrogen fluoride in the removal. at UF 6 During the preparation process, most of the non-volatile metal fluoride impurities enter the slag tank collector with the fluoride slag, but some of them enter the cold trap with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com