Process for comprehensively recovering rare and precious metals including gold, silver, platinum and palladium from gold-bearing wastes

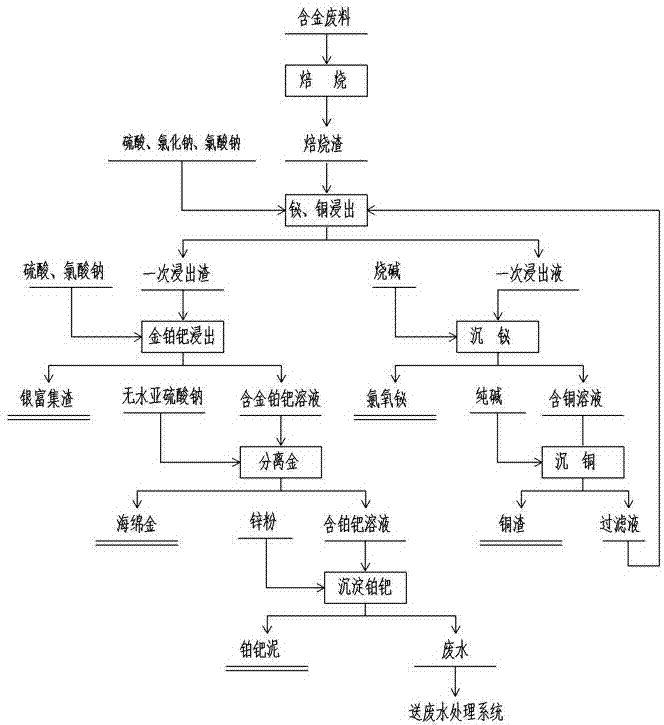

A technology of rare precious metals and scraps, which is applied in the field of comprehensive recovery of gold, silver, platinum, palladium and rare precious metals, can solve problems such as low labor productivity, slow capital turnover, and large environmental pollution, and achieve low environmental pollution, simple process, and high direct recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0017] Take 10kg of anode slime, which contains 7.43% bismuth, 9.06% copper, 203.52g / t gold, 1.53% silver, 23.05 g / t platinum and 99.63 g / t palladium.

[0018] (1) Roasting: Roast the anode slime in a horse-boiling furnace at 580°C for 4.5 hours, and then take out the anode slime (9.18kg).

[0019] (2) Bismuth and copper leaching: Add 27kg of water, 4.59kg of sulfuric acid, 1.84kg of sodium chloride, and 0.46kg of sodium chlorate to the roasted anode slime, and leaching at 85°C for 3 hours. After filtration, 27.83 L of copper-bismuth solution and 6.37 kg of filter residue were obtained.

[0020] (3) Recovery of bismuth and copper: Use 2.61kg of caustic soda to adjust the pH of the copper-containing and bismuth-containing solution produced in step (2) to 2.5, and obtain 1.15kg of bismuth oxychloride (62.32% bismuth-containing) and 22.83% copper-containing solution by filtration. L, use 1.68kg of soda ash to adjust the pH of the copper-containing solution to 5.0, filter to obta...

Embodiment approach 2

[0025] Take 5kg of electroplating sludge, which contains 118.63g / t gold, 2.43% silver, 85.68 g / t platinum and 77.32 g / t palladium.

[0026] (1) Roasting: Roast the gold-containing waste in a horse-boiling furnace at 550°C for 4.5 hours, and then take out the gold-containing waste (4.02kg).

[0027] (2) Gold, platinum, and palladium leaching: add 14kg of water, 2.41kg of sulfuric acid, and 1.21kg of sodium chlorate to the filter residue produced in step (1), leaching at 85°C for 5 hours and then adding 14L of water Filtration obtained 13.66 L of gold-containing platinum-palladium solution, which contained 0.021 g / L of gold, 0.015 g / L of platinum, 0.014 g / L of palladium and 1.69 kg of silver-enriched slag (containing 7.18% silver). The silver recovery rate is 99.87%.

[0028] (3) Separation of gold from the gold-containing platinum-palladium solution: add 0.3 kg of soda ash and 2.3 g of anhydrous sodium sulfite to the gold-containing platinum-palladium solution produced by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com