Patents

Literature

323 results about "Bismuth oxychloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bismuth oxychloride is an inorganic compound of bismuth with the formula BiOCl. It is a lustrous white solid used since antiquity, notably in ancient Egypt. Light wave interference from its plate-like structure gives a pearly iridescent light reflectivity similar to nacre. It is also known as pearl white.

Composite with synergistic effect of adsorption and visible light catalytic degradation and preparation method and application thereof

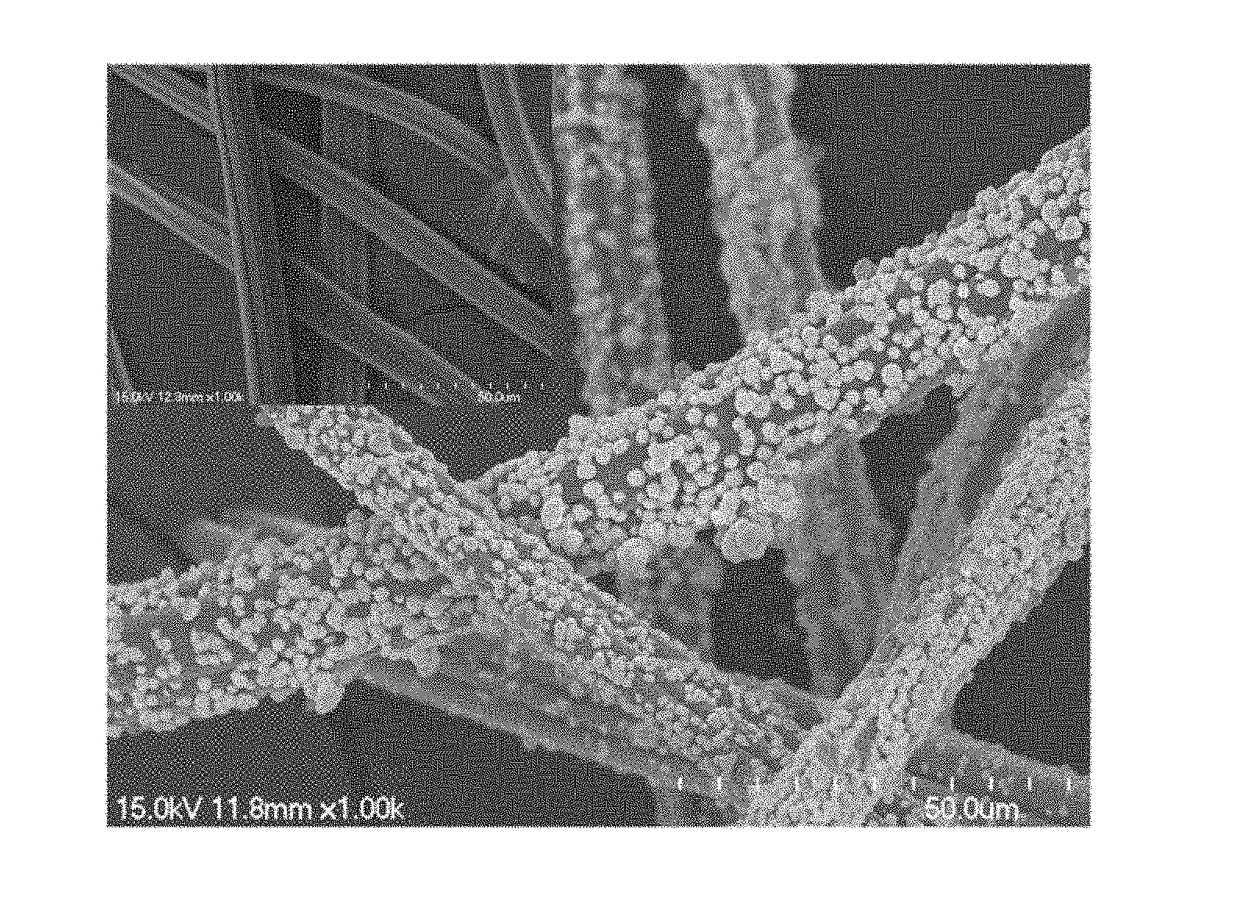

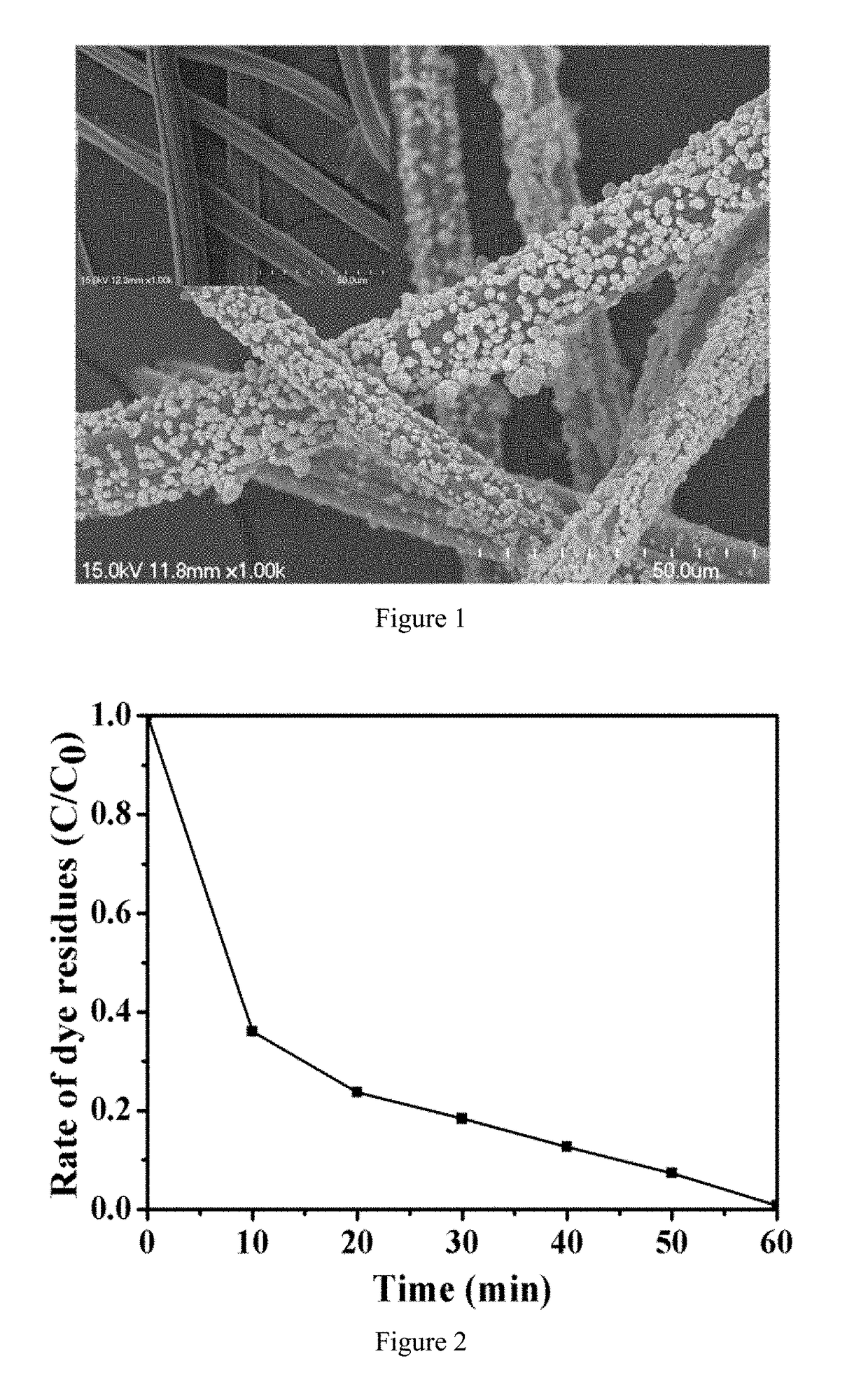

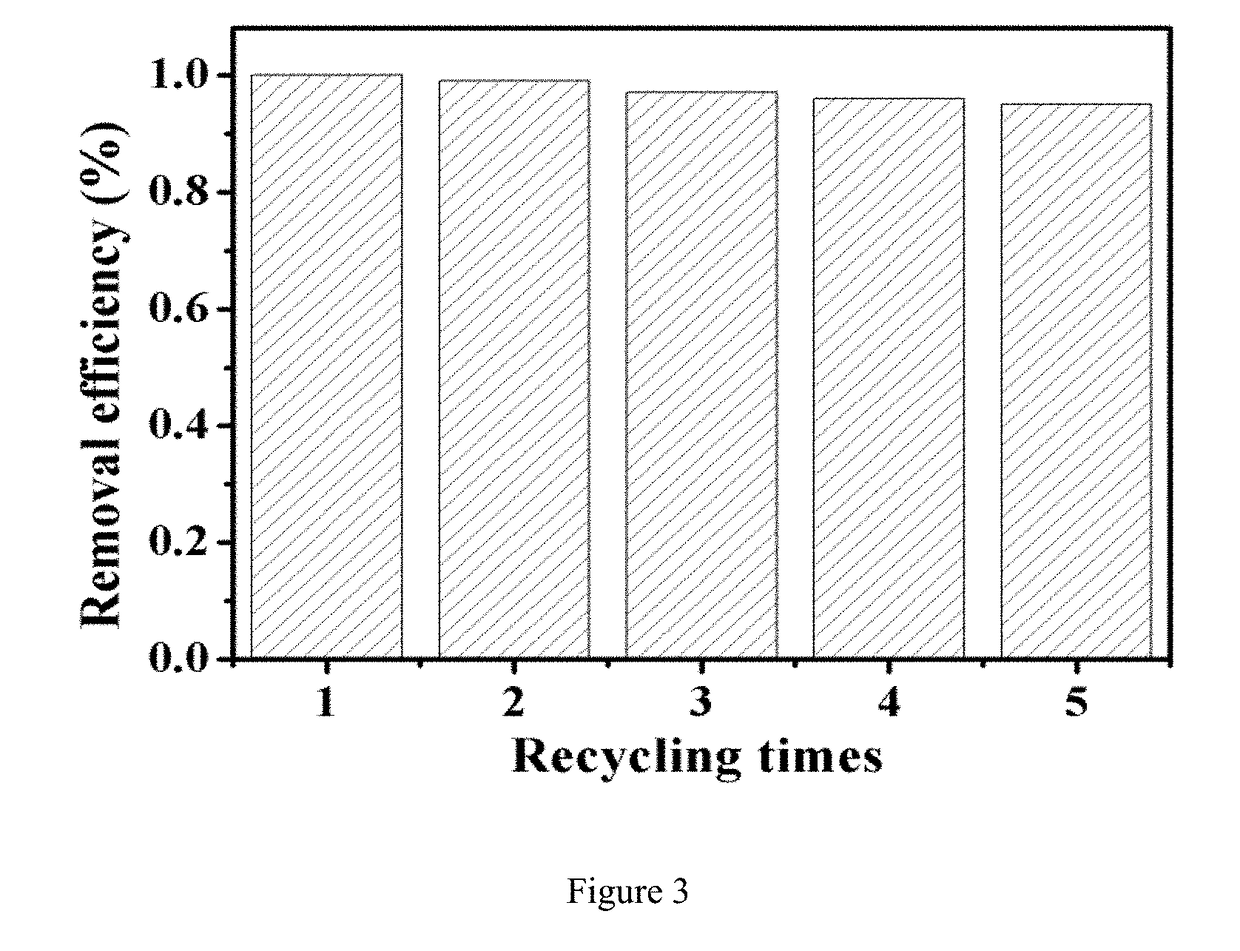

InactiveUS20180008953A1Improve photocatalytic performanceEfficient implementationWater/sewage treatment by irradiationOther chemical processesActivated carbonFiber

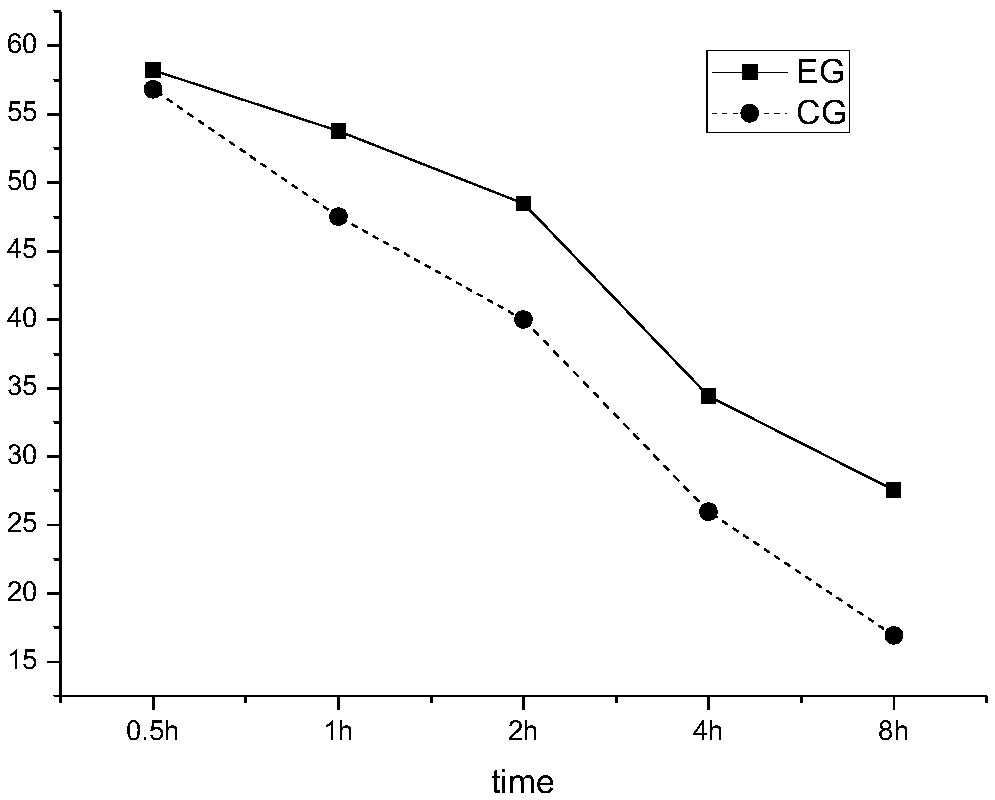

The invention discloses a composite with an adsorption-visible light catalytic degradation synergistic effect and a preparation method and application thereof. The preparation method includes the specific steps that firstly, a bismuth oxyiodide / bismuth oxychloride composite nano-particle loaded activated carbon fiber composite ACF@BiOIxCl1-x is synthesized; then, the fiber surface is grafted with polyethyleneimine, and the end composite PEI-g-ACF@BiOIxCl1-x is obtained. The composite can rapidly adsorb pollutants in water, and meanwhile the pollutants are efficiently degraded with a photocatalyst loaded on the surface of the composite; besides, the purpose of recycling and reusing the photocatalyst is achieved, the comprehensive treatment capability of the composite is improved, the service life of the composite is prolonged, and the use cost is lowered.

Owner:SUZHOU UNIV

Bi/BiOCl (bismuth oxychloride) composite photocatalyst as well as in-situ reduction preparation method and application thereof

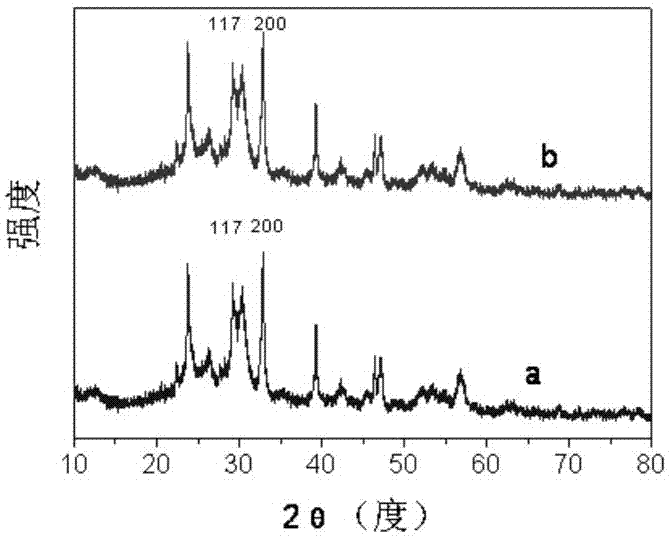

InactiveCN103908973AImprove photocatalytic performanceEfficient degradationWater/sewage treatment by irradiationCatalyst activation/preparationSpectral responseGas phase

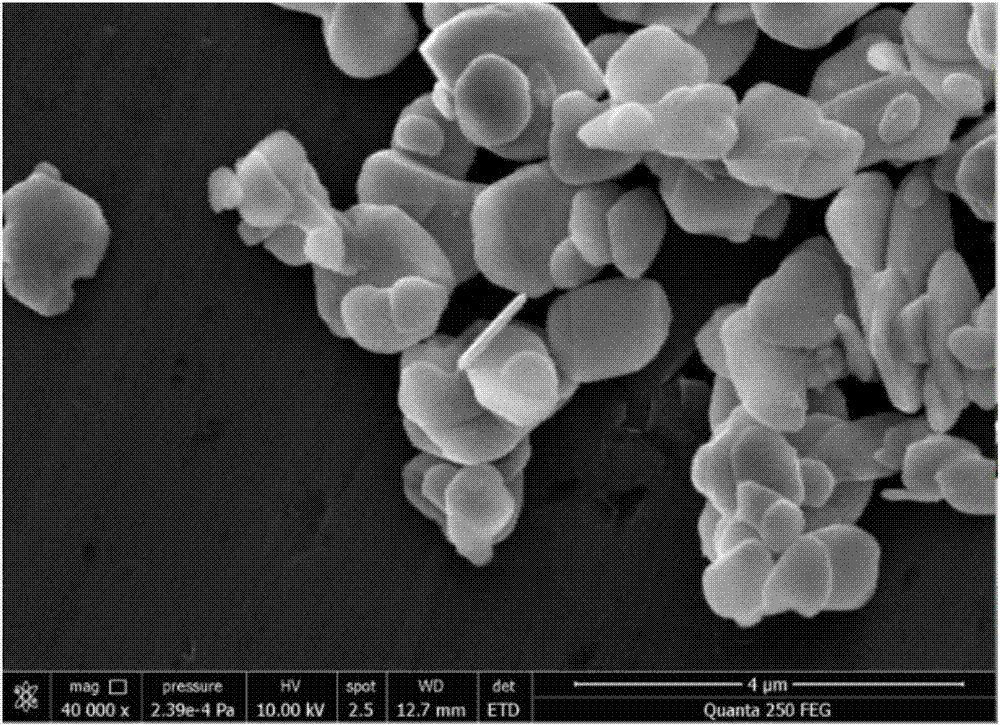

The invention relates to the technical field of nanometer materials and photocatalytic degradation of organic pollutants, and in particular relates to a Bi / BiOCl (bismuth oxychloride) composite photocatalyst as well as an in-situ reduction preparation method and application thereof. Bi nano-particles with particle sizes of 5-20nm are uniformly distributed on a BiOCl nanosheet with 100-600nm or a the surface of a BiOCl microsphere being 1-3 microns to obtain the Bi / BiOCl composite photocatalyst; the Bi / BiOCl composite photocatalyst is prepared by gaseous-phase in-situ reduction or liquid-phase in-situ reduction; as Bi nano-particles are formed on a BiOCl substrate in an in-situ manner, the lattice matching degree of interfaces between the Bi and the BiOCl is high and the charge migration is facilitated; the Bi nano-particles have the good dispersibility, are difficult to cause agglomeration, and have the good size and distribution controllability; the Bi nano-particles can be well combined with the BiOCl and are difficult to drop off, the photo catalytic capability of the BiOCl under the existence of ultraviolet light can be improved, the spectral response range is expanded, and the visible photo catalytic capability can be acquired, and the Bi / BiOCl composite photocatalyst can be effectively applied to photocatalytic degradation of organic pollutants in a water body.

Owner:HEFEI UNIV OF TECH

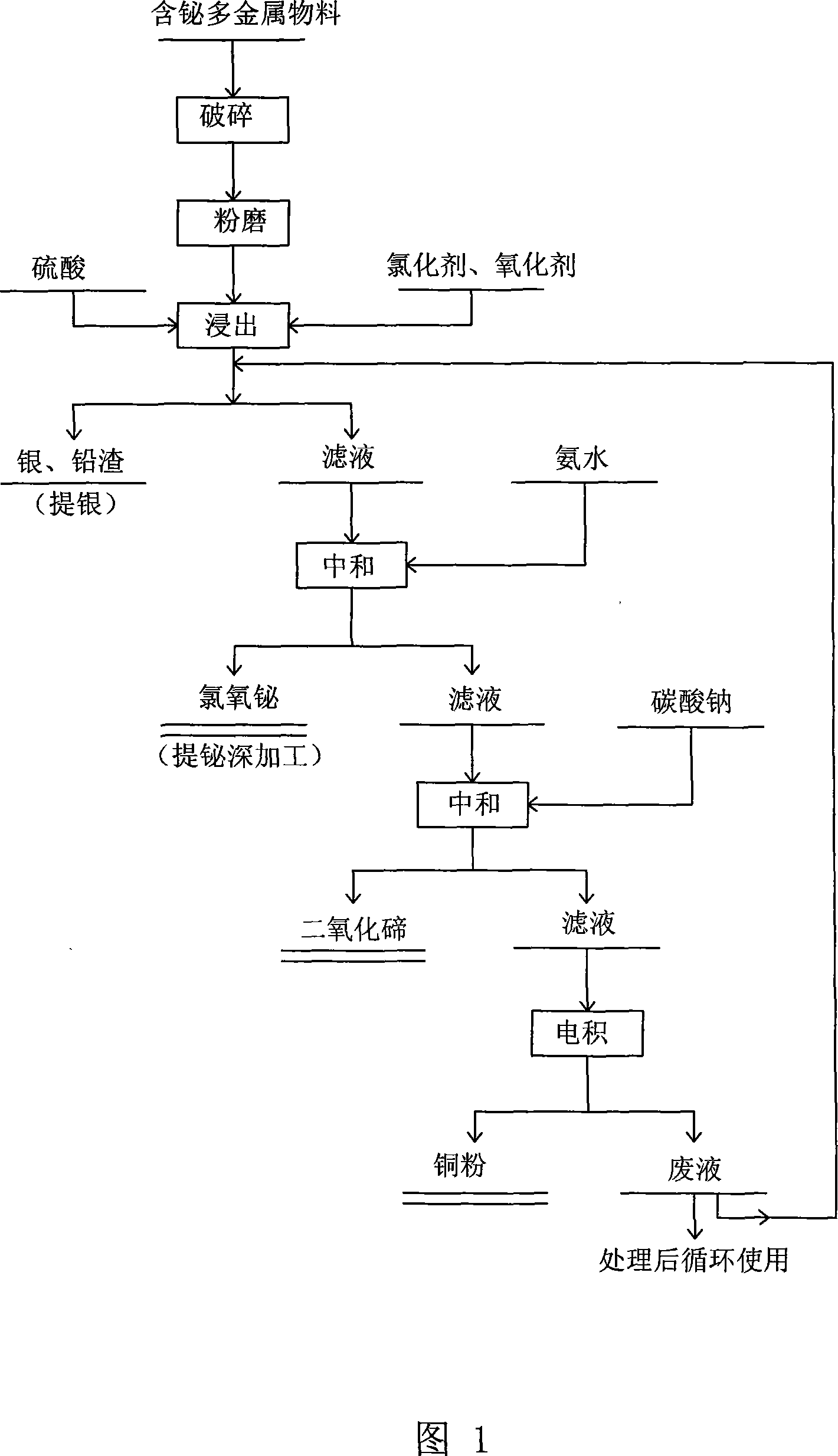

Comprehensive extraction of valent metal from bismuth-containing polymetallic material

InactiveCN101029353AHigh recovery rateImprove product added valuePhotography auxillary processesProcess efficiency improvementSesquioxideTe element

A method for extracting metal from bismuth-contained multi-metal material is carried out by leaching out copper and tellurium from bismuth-contained multi-metal by sulfuric acid, adding into chlorinating agent and oxidant to leach out metal bismuth, extracting silver from leaching-out slag with AgCl, PbSO4 and PbC12, adding ammonia water into leaching-out liquid, adjusting pH value to 1.5 to obtain bismuth oxychloride slag with 70% bismuth content, smelting into coarse bismuth by firing method or machining to obtain high-purity bismuth sesquioxide, adjusting pH value to 4.5 by Na2CO3, depositing tellurium to obtain tellurium dioxide and copper-contained solution, and electrically depositing to obtain copper powder with copper-contained content90%. It adopts wetting and firing metallurgical technology, has higher metal recovery rate and excellent leaching-out separation effect and effluent circulating utilization and no environmental pollution.

Owner:HUNAN JINWANG BISMUTH

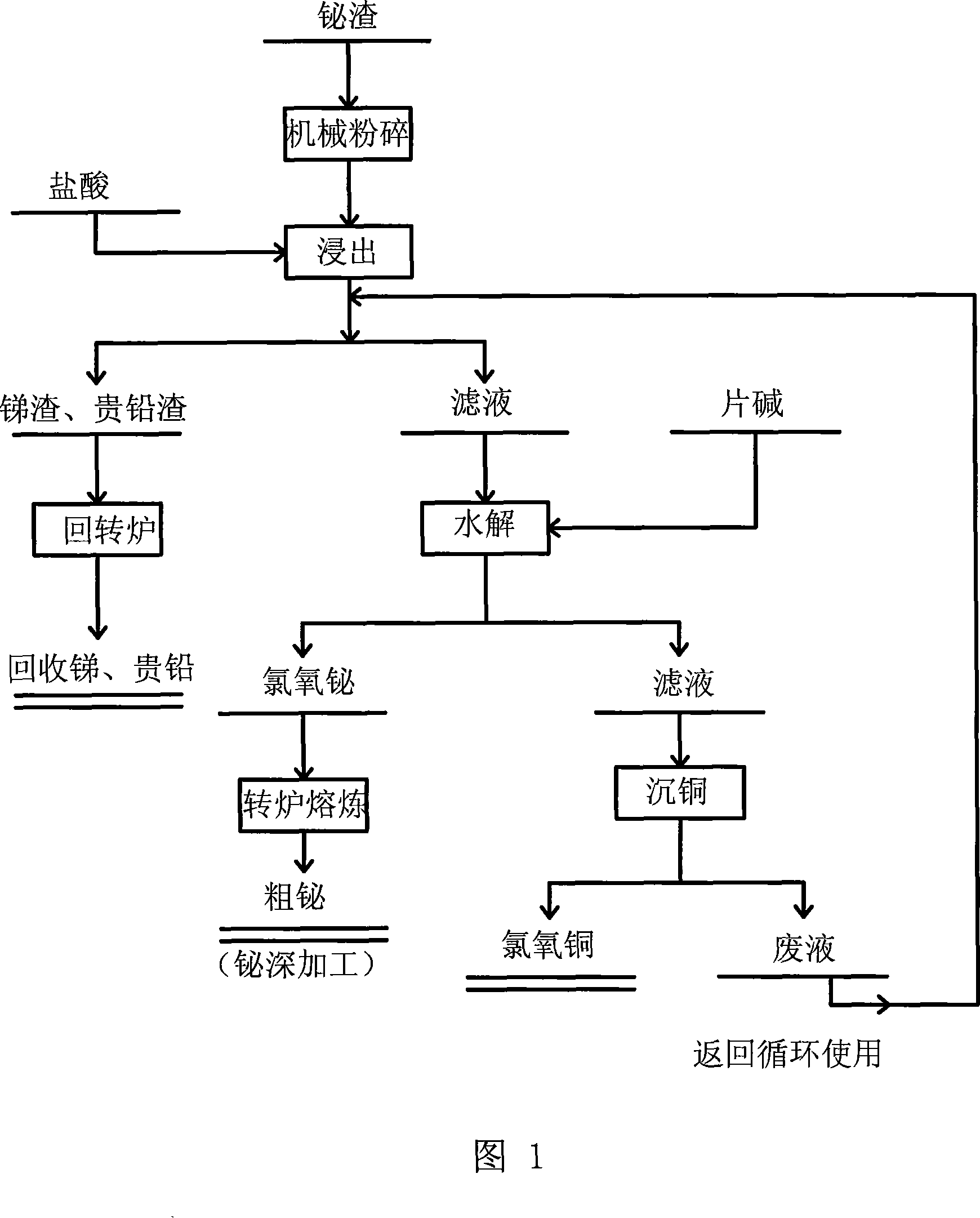

Technique for reclaiming smelting refined bismuth from bismuth slag

InactiveCN101082084AHigh recovery rateAdaptableProcess efficiency improvementPregnant leach solutionSlag

The present invention is process of recovering and smelting bismuth from bismuth slag, and belongs to the field of combined wet and pyrogenic non-ferrous metal smelting technology. The process includes the first wet leaching of bismuth slag with hydrochloric acid, precipitating leaching liquid to obtain bismuth oxychloride, reducing smelting to obtain coarse bismuth product, refining to obtain refined bismuth product, precipitating Cu from the bismuth extracting filtrate, and returning the used liquid to the leaching step. The present invention has high material adaptability, high metal recovering rate and environment friendship.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Preparation method of bismuth oxychloride/graphene composite visible light catalyst

InactiveCN104001495AEfficient degradationWater/sewage treatment by irradiationWater contaminantsWater bathsHydrazine compound

The invention discloses a preparation method of a bismuth oxychloride / graphene composite visible light catalyst. The preparation method comprises the following steps of (1) preparing a silvery white pure bismuth oxychloride photocatalyst; (2) preparing 100 ml of graphene oxide solution with the mass concentration of 10 to 60 mg / l, performing ultrasonic dispersion for 1 h, adding 0.2 g of bismuth oxychloride photocatalyst prepared in the step (1), mixing and adsorbing for 2 hours, then adding hydrazine hydrate, uniformly mixing, and then reducing in a water bath at 80 DEG C until the solution uniformly becomes black; (3) naturally cooling the solution to room temperature after reaction, filtering, washing with water and ethanol respectively for three times, and then drying in a constant-temperature drying box at 60 DEG C for 8 hours, so as to prepare the bismuth oxychloride / graphene composite visible light catalyst. The bismuth oxychloride / graphene composite visible light catalyst prepared with the preparation method responds to sunlight, natural sunlight can be utilized to effectively degrade sulfanilamide waste water, and the bismuth oxychloride / graphene composite visible light catalyst has the advantages of stable performance and no toxicity and has a strong market application prospect.

Owner:HENAN NORMAL UNIV

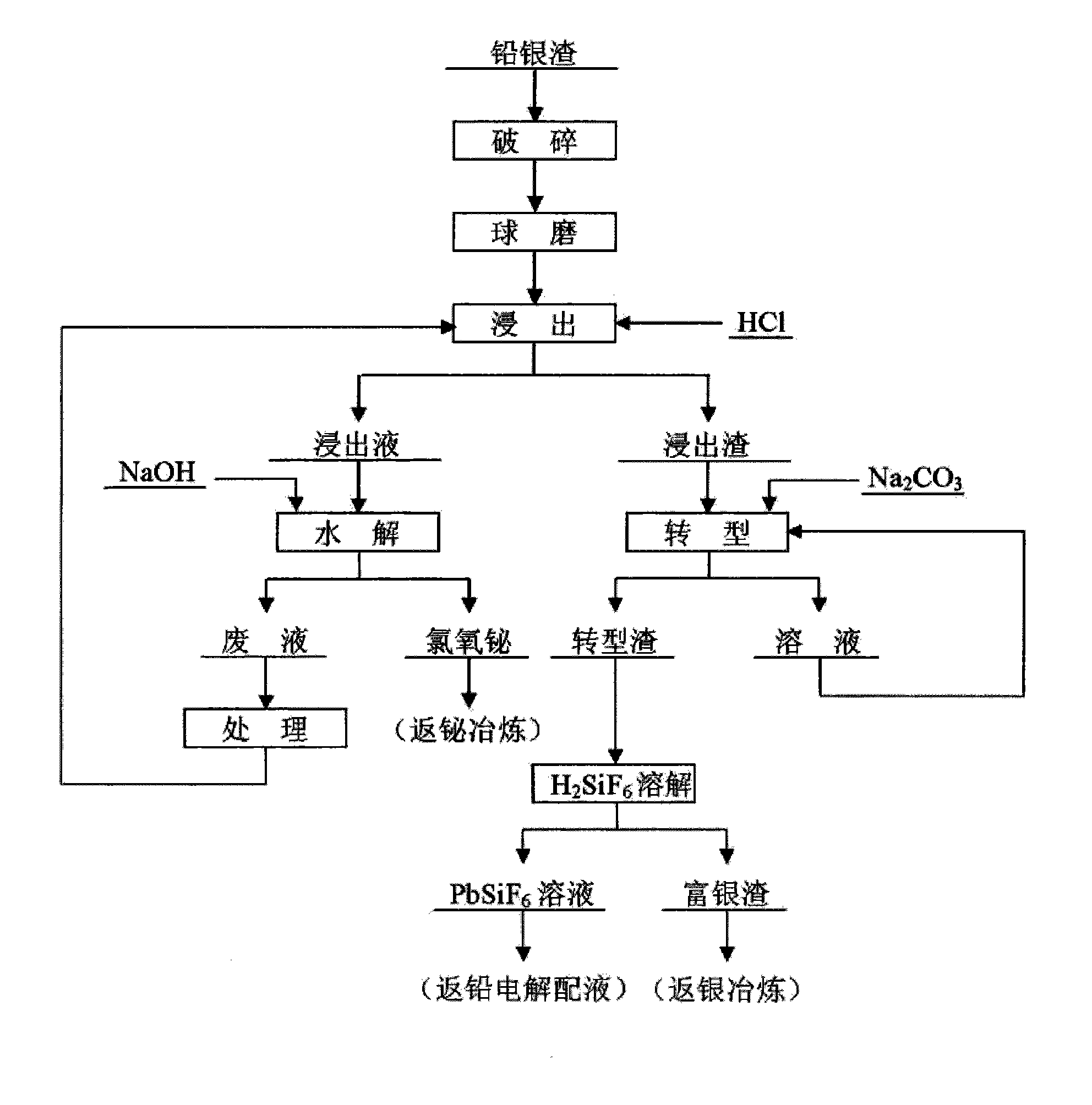

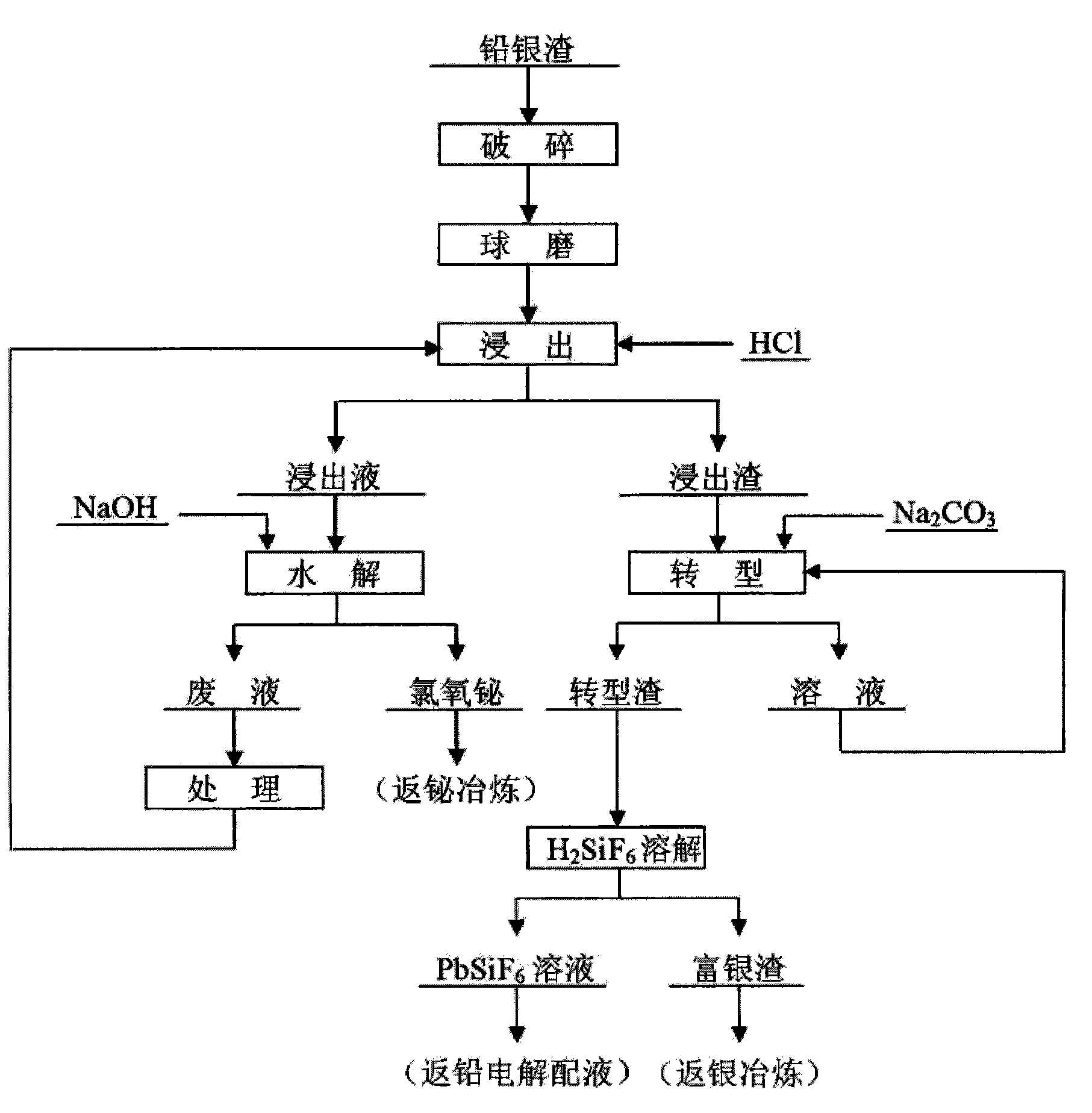

Wet process for lead-silver residues

ActiveCN102031383ANo pollution in the processSimple processProcess efficiency improvementElectrolysisBismuth oxychloride

The invention discloses a wet process for lead-silver residues, which comprises the following major steps: crushing lead-silver residues, carrying out ball milling, leaching with dilute hydrochloric acid, adding sodium hydroxide to the leached solution to hydrolyze so as to generate bismuth oxychloride as a precipitate, transferring the bismuth oxychloride to a bismuth smelting system, and treating the hydrolysis waste solution for cyclic use; and transforming the leached residues with sodium carbonate, then recycling the mother solution, dissolving the transformed residues in silicofluoric acid, filtering the residues to obtain silver-enriched residues, transferring the silver-enriched residues to a silver smelting system, and using the obtained lead silicofluoride solution for preparing a lead electrolyte. The invention has the advantages of simple flow and no environmental pollution; by preparing lead in lead-silver residues into lead silicofluoride used as the electrolyte, the input amount of yellow lead in the lead electrolysis system is reduced; by dissolving lead in silicofluoric acid, silver-enriched residues with a silver content up to more than 60% can be directly obtained, and the direct silver yield is high; the overall system realizes the cyclic use of the solution, and the comprehensive recycling degree is high; and the treatment time is short, and the comprehensive cost is low.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

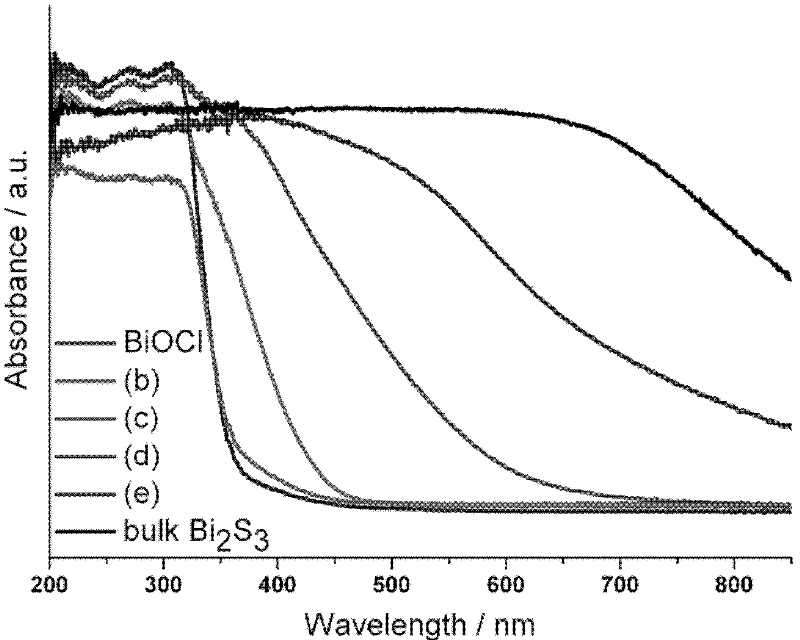

Compound photocatalysis material with bismuth sulfide nano particles/bismuth oxychloride and preparation method thereof

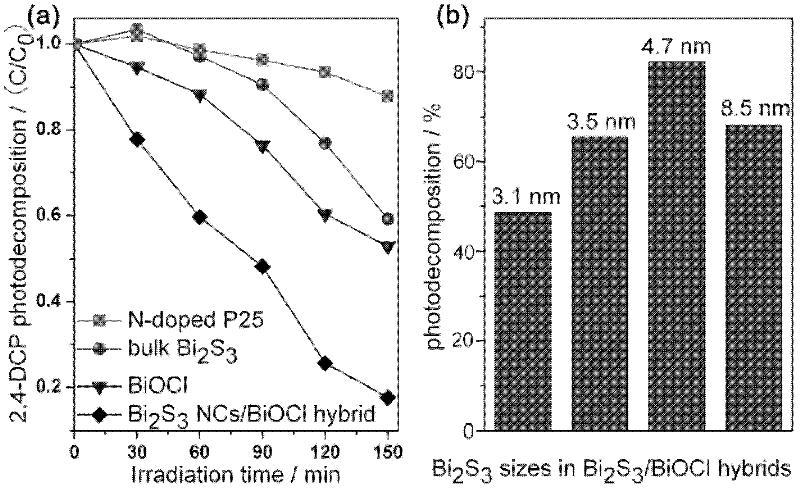

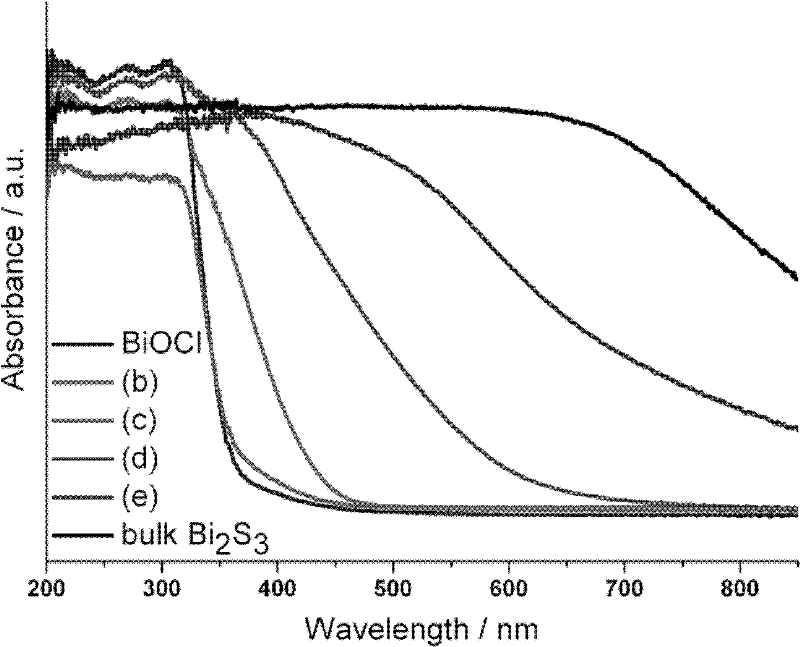

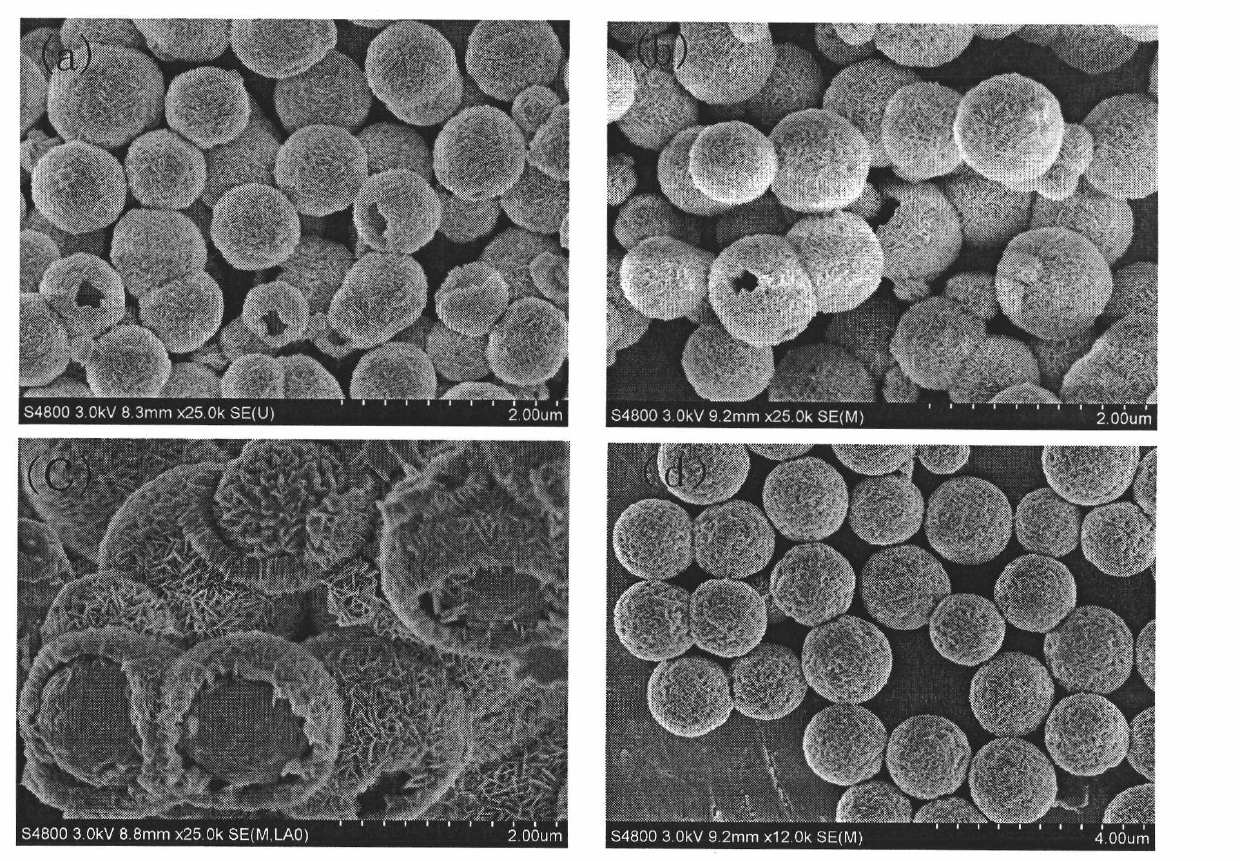

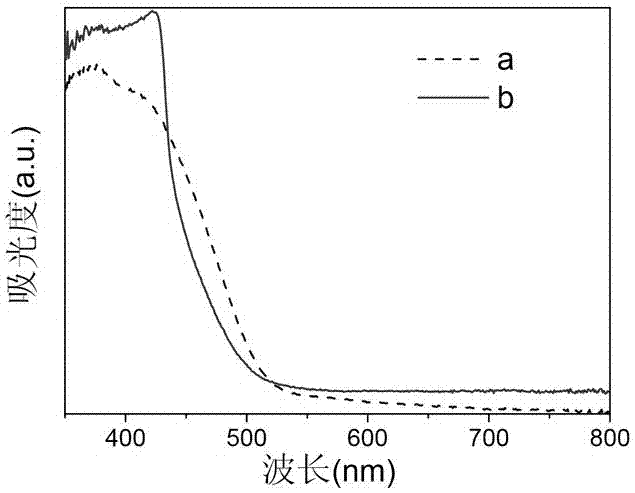

InactiveCN102513134AEfficient light absorptionLight absorption regulationPhysical/chemical process catalystsBismuth sulfideSolvothermal reaction

The invention relates to a compound photocatalysis material with bismuth-sulfide nano particles / bismuth oxychloride and a preparation method thereof. The preparation method comprises the following steps of: firstly, dissolving bismuth nitrate and chlorinated 1-dodecyl-3-methyl glyoxaline into ethylene glycol monomethyl ether respectively, afterwards carrying out a thermal reaction by a solvent soas to prepare bismuth-oxychloride micron balls, then adding the bismuth-oxychloride micron balls into a water solution containing a sulfur source and exchanging parts of ions so as to prepare a compound photocatalysis material containing bismuth-sulfide nano particles and bismuth oxychloride. The method disclosed by the invention can be executed at room temperature and normal pressure, the cost is low, and equipment is simple and is easy to operate; and moreover, the compound photocatalysis material with the bismuth-sulfide nano particles / bismuth oxychloride can be produced at a large scale and has important potential application in the aspect of industrial production. The prepared compound photocatalysis material with the bismuth sulfide / bismuth oxychloride has favorable absorption of visible light, the separation of a photon-generated carrier is obviously improved, and the photocatalysis performance of the material is greatly enhanced.

Owner:SHANDONG UNIV

Method for preparing bismuth-series chemical product

The invention relates to a method for preparing a bismuth-series chemical product, comprising steps as follows: firstly, preparing ordinary-level bismuth oxide by refined bismuth; then preparing a bismuth-series chemical product by the ordinary-level bismuth oxide including steps of refined bismuth pulverization, bismuth low-temperature oxidation, ordinary bismuth oxide chemical conversion, and the like; finally preparing bismuth-series chemical products of bismuth nitrate, bismuth subnitrate, bismuth subcarbonate, bismuthsalicylate, basic bismuth salicylate, bismuth citrate, bismuth trichlor, bismuth oxychloride, electric bismuth oxide or bismuth oxide nanowire, and the like; and recycling chemically-converted mother-liquid. The invention has the advantages of generating no cancerigenic poison gas NOx and waste water, having environment protection, little consumption of chemical reagent, little energy consumption, low cost, simple device and operation, and the like.

Owner:湖南金泰铋业股份有限公司

Preparation method of sheet-like bismuth oxychloride photocatalyst

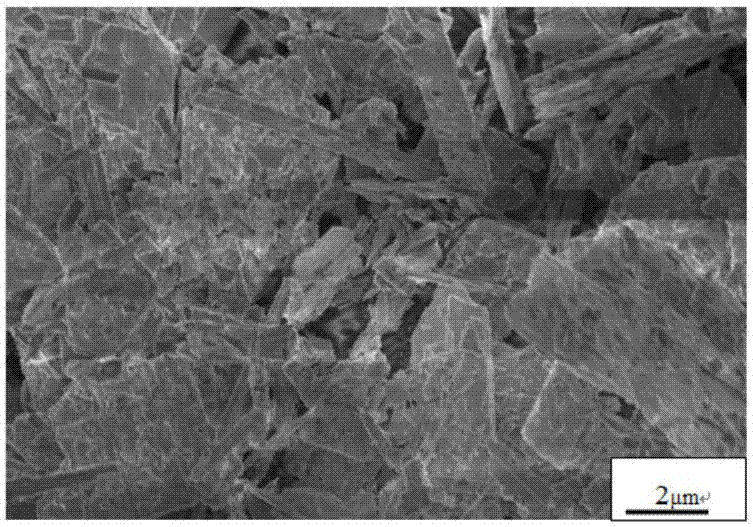

InactiveCN103265076ANovel Crystal MorphologyNovel structureBismuth compoundsTetrafluoroethylenePhysical chemistry

The invention provides a preparation method of a sheet-like bismuth oxychloride photocatalyst. According to the preparation method, the uniformity of bismuth oxychloride is well controlled, the diameter of obtained product sheets is about 800nm, the product sheets are very thin, and the preparation method is simple and feasible and is suitable for industrial production. The preparation method of the bismuth oxychloride specifically comprises the following steps of: (1) adding hexadecyl trimethyl ammonium bromide into distilled water, and stirring until the hexadecyl trimethyl ammonium bromide is dissolved; (2) under the condition of stirring, sequentially adding bismuth nitrate pentahydrate and sodium chloride; (3) stirring for 10 minutes, then pouring the mixture into a tetrafluoroethylene liner, and putting the liner into a 180 DEG C baking oven; and (4) cooling to the room temperature after 24 hours, centrifugally washing, and drying at 60 DEG C, wherein the weight ratio of the distilled water to the hexadecyl trimethyl ammonium bromide is (80-85):(1-5), and the molar ratio of the hexadecyl trimethyl ammonium bromide to the bismuth nitrate pentahydrate to the sodium chloride is (0.5-1.5):(10-20):(5-10).

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Visible-light photocatalytic material and preparation method thereof

InactiveCN102974373AImprove visible light absorptionEasy to separatePhysical/chemical process catalystsWater/sewage treatment by irradiationWater bathsBismuth oxychloride

Owner:SHANDONG UNIV

Preparation method of bismuth oxychloride pearlescent pigment

ActiveCN103303975ARaw materials are cheap and easy to getEasy to operateBismuth compoundsReaction temperatureHydrolysis

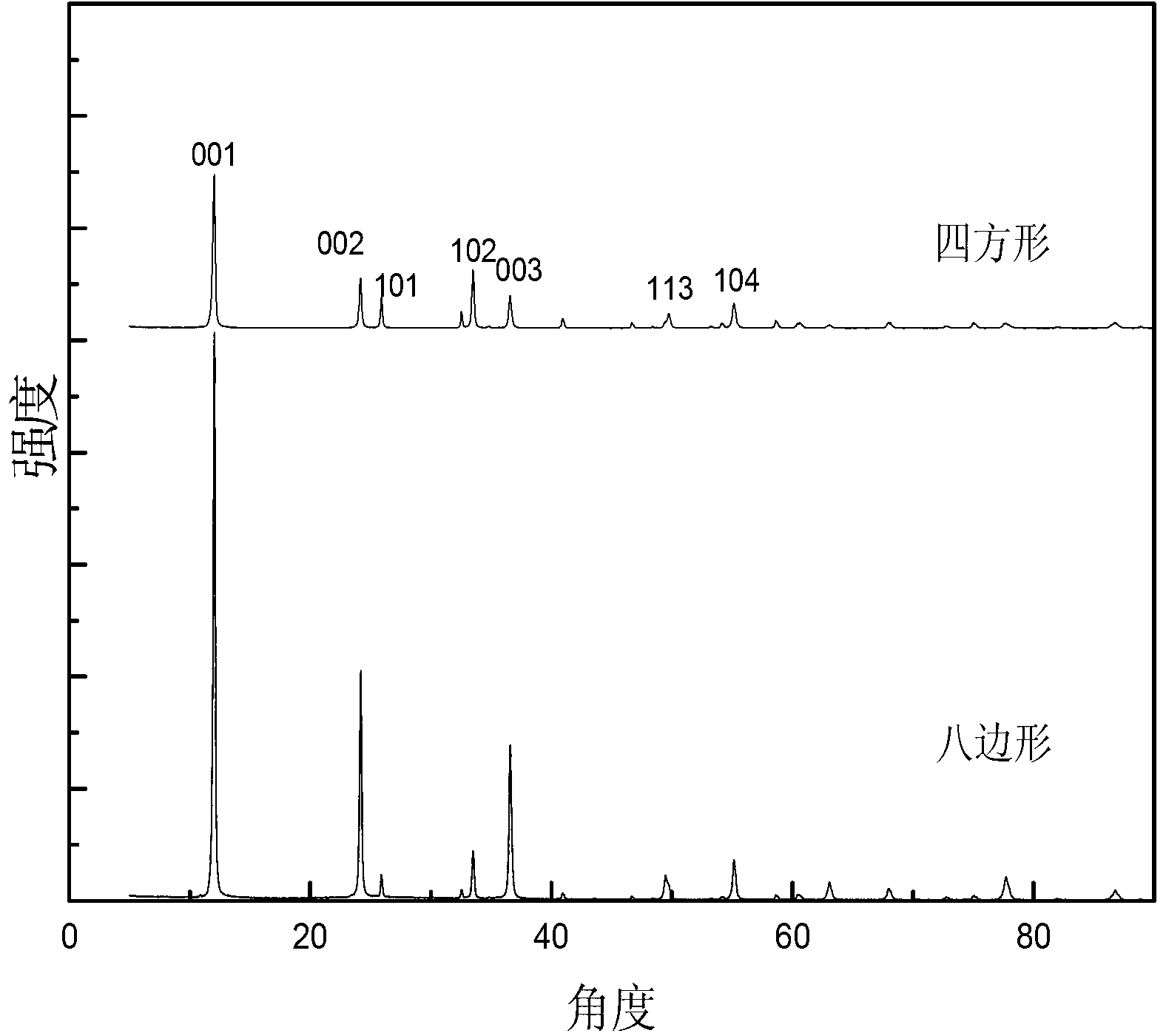

The invention relates to a preparation method of a bismuth oxychloride pearlescent pigment. The method comprises the following steps of: preparing a bismuth salt acidized water solution with a certain concentration by using bismuth salt as raw material, adding water to regulate the PH value of a reaction system, controlling the process parameters such as reaction temperature, reaction time and stirring strength, hydrolyzing the bismuth salt to prepare polygonal (such as quadrilateral or octagonal) laminar pearlescent bismuth oxychloride crystal. The raw material in the preparation method provided by the invention is cheap and easy to obtain, the morphological control can be performed in the bismuth hydrolysis process without adding a surfactant, and the PH value of the reaction system can be controlled without adding alkali liquor; the prepared bismuth oxychloride crystal is uniform in dispersion, good in pearlescent effect, simple in operation process, and good in industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

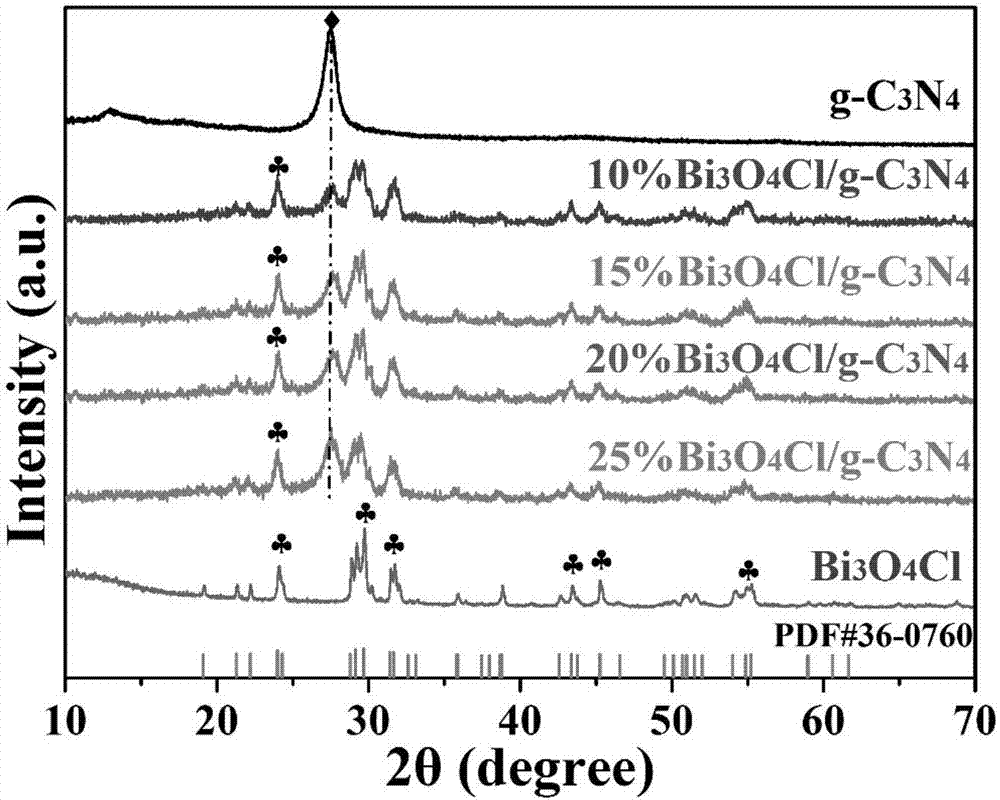

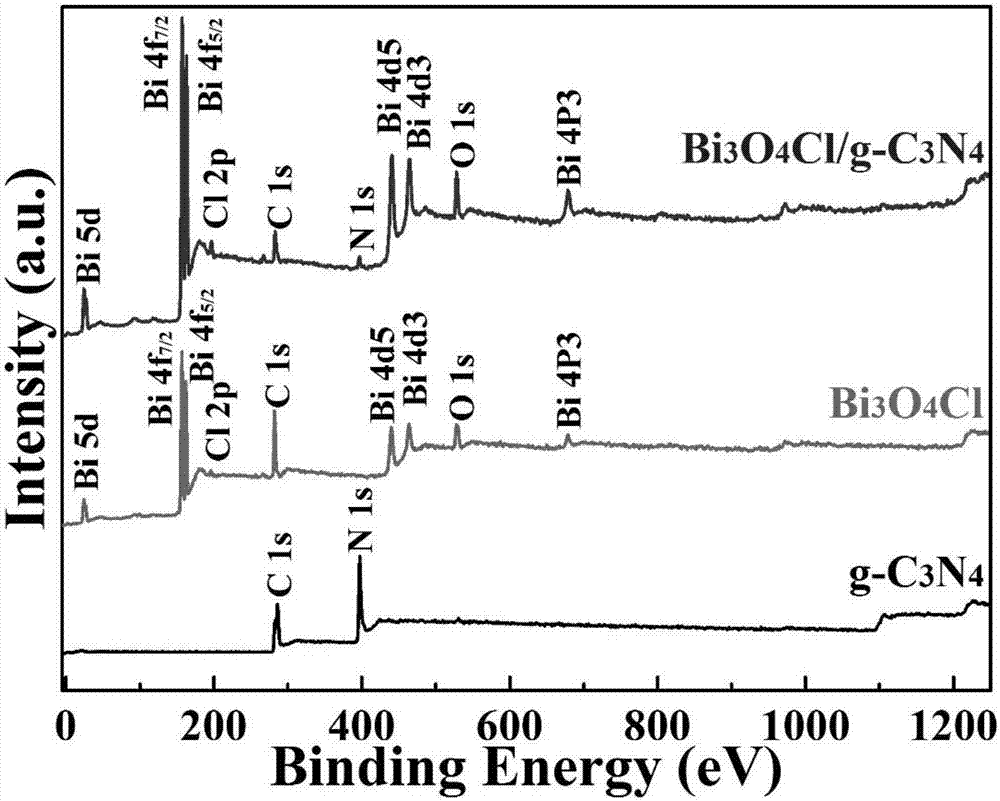

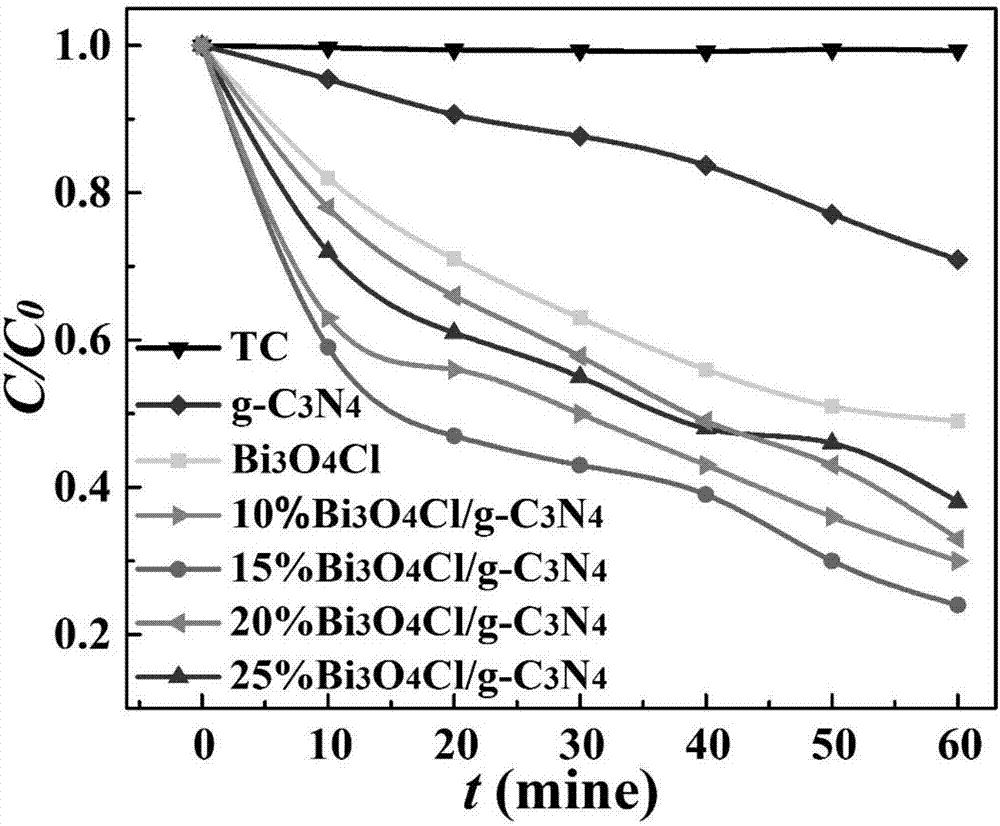

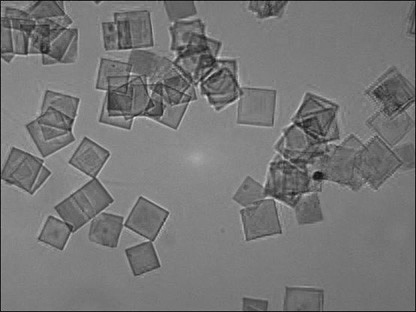

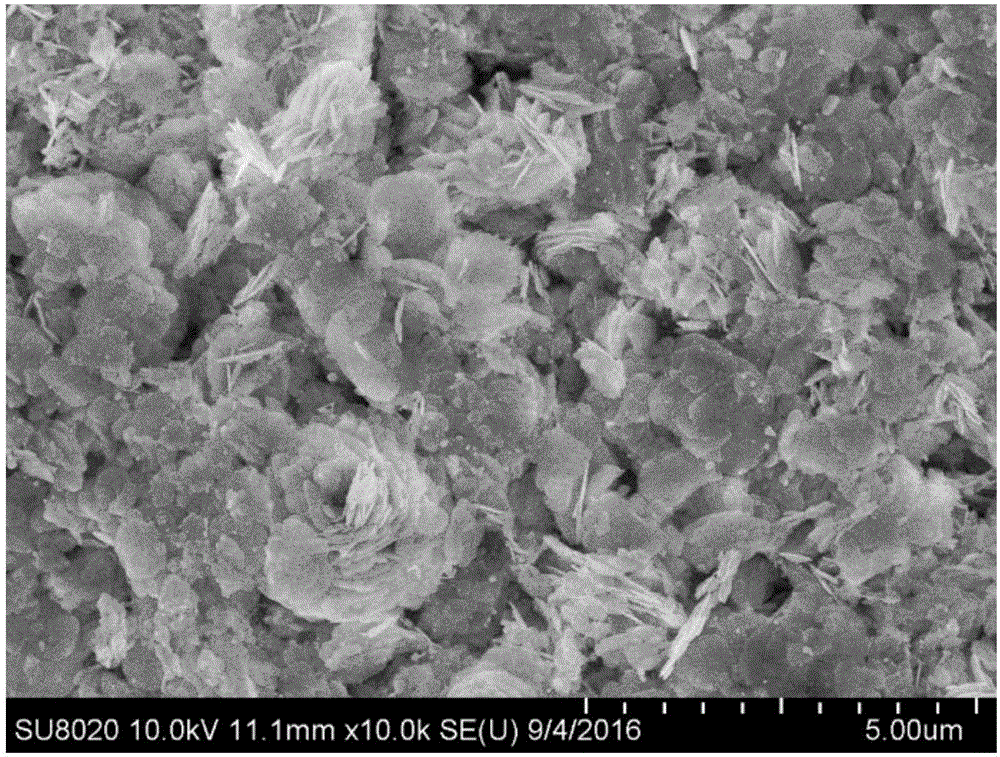

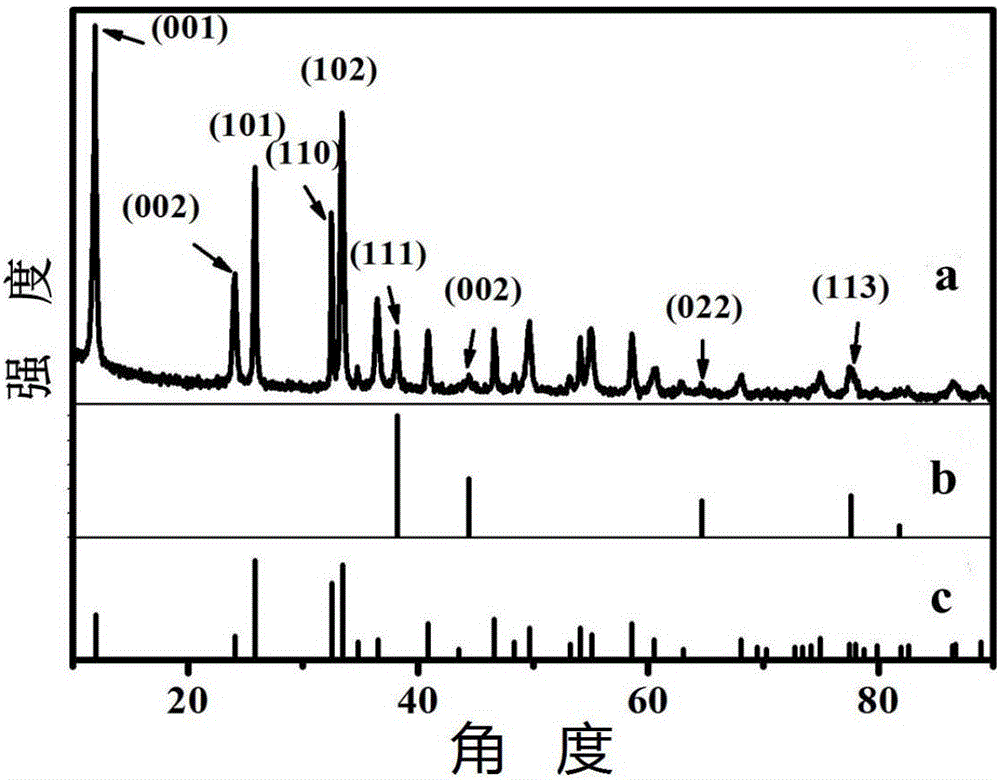

Preparation method and application of visible-light-responsive Bi3O4Cl/g-C3N4 heterojunction material

InactiveCN107262131AMeets friendly requirementsSimple processPhysical/chemical process catalystsWater/sewage treatment by irradiationHeterojunctionSemiconductor materials

The invention discloses a preparation method of a visible-light-responsive Bi3O4Cl / g-C3N4 heterojunction material, and belongs to the technical field of a semiconductor material. The method comprises the following steps: step 1) preparing sheet g-C3N4; step 2) preparing Bi3O4Cl nanosheets; and step 3) taking Bi3O4Cl nanosheets and sheet g-C3N4, fully grinding the obtained product in a mortar, and performing calcination to finally obtain Bi3O4Cl / g-C3N4. According to the preparation method, a bismuth oxychloride (Bi3O4Cl) and carbon nitride (g-C3N4) heterojunction photocatalyst is synthesized through a grinding calcination method. The method is simple in process, low in reaction cost and convenient for massive production, is non-toxic and harmless, and meets the eco-friendly requirement. Another object of the invention is to provide an application of the visible-light-responsive Bi3O4Cl / g-C3N4 heterojunction material. The material is used for degrading tetracycline in visible light and shows excellent photocatalytic activity during tetracycline degradation in visible light.

Owner:HOHAI UNIV

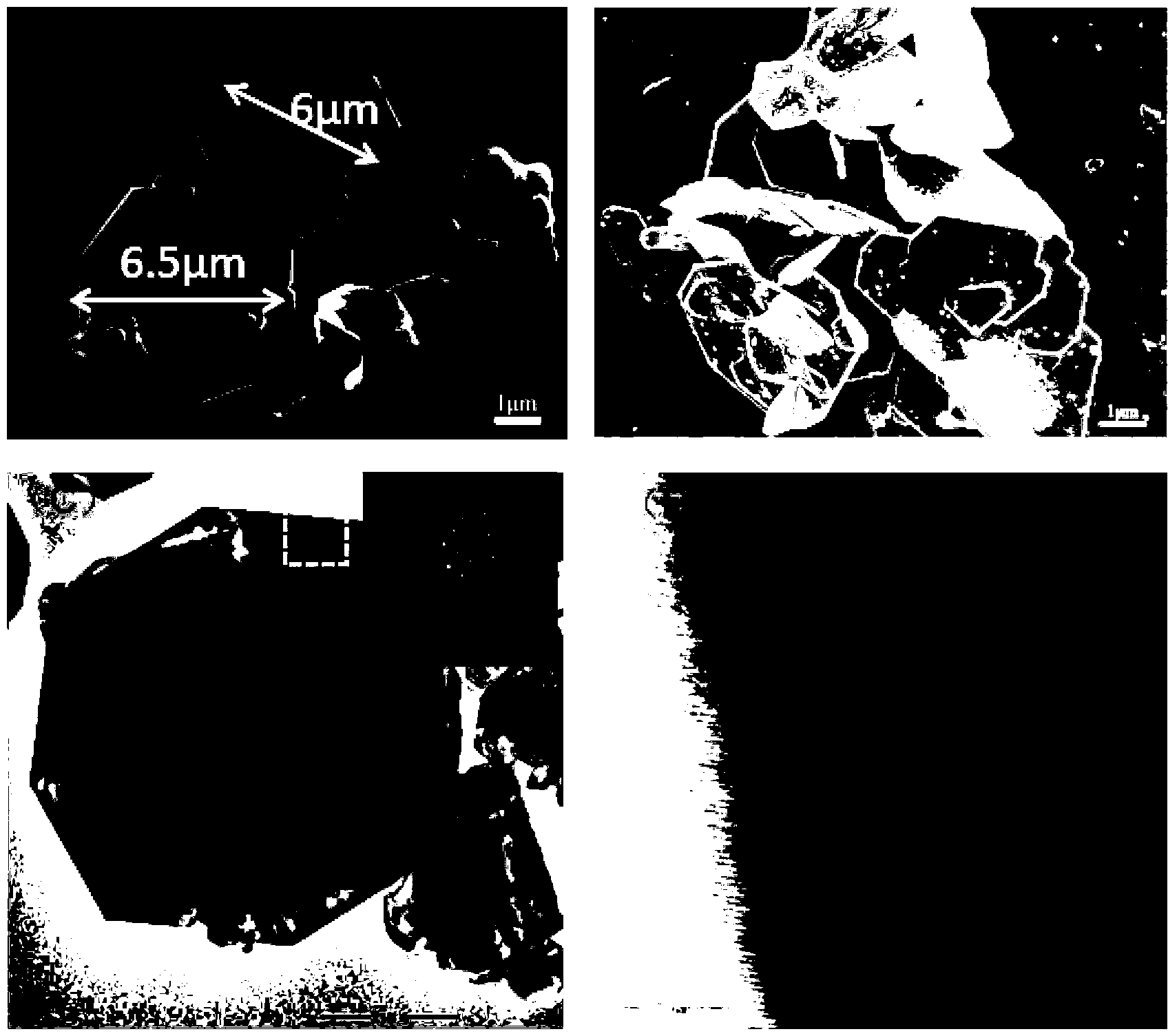

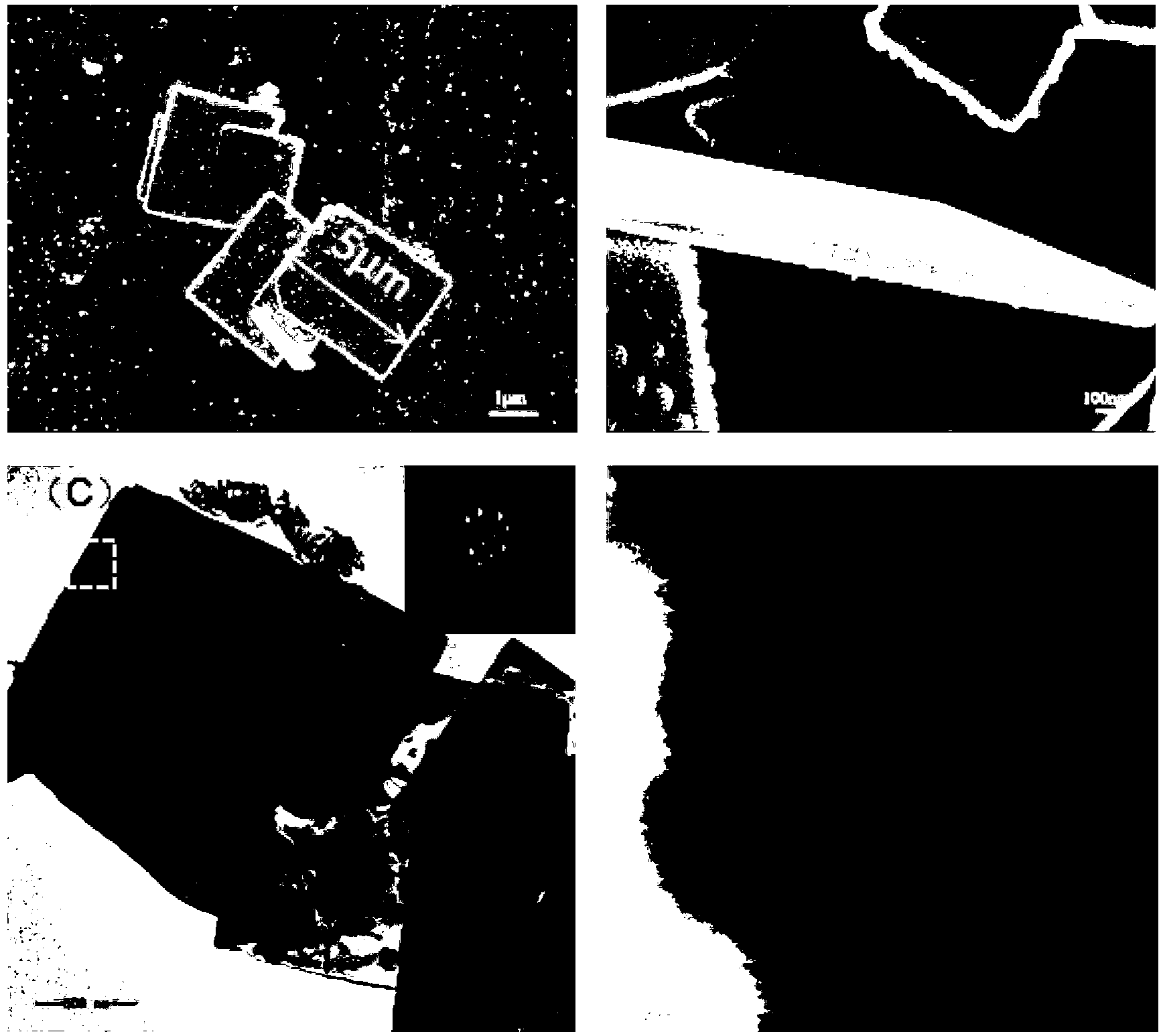

Plate-type bismuth oxychloride crystal with controllable shape and preparation method thereof

ActiveCN101935022AIncrease brightnessIncrease coveragePigment pastesHalogen oxides/oxyacidsBismuth oxychlorideSURFACTANT BLEND

The invention provides a bismuth oxychloride crystal and a preparation method thereof. The bismuth oxychloride crystal is a square and regular octagonal thin-plate bismuth oxychloride crystal with a regular shape. In the preparation process, different selected surfactants are covered on the surface of the bismuth oxychloride seed crystal, so that the bismuth oxychloride crystal can directionally grow in different acidic mediums. The bismuth oxychloride crystal has better brightness, effulgent effect and covering capability, compared with irregular bismuth oxychloride crystal.

Owner:FUJIAN KUNCAI MATERIAL TECH

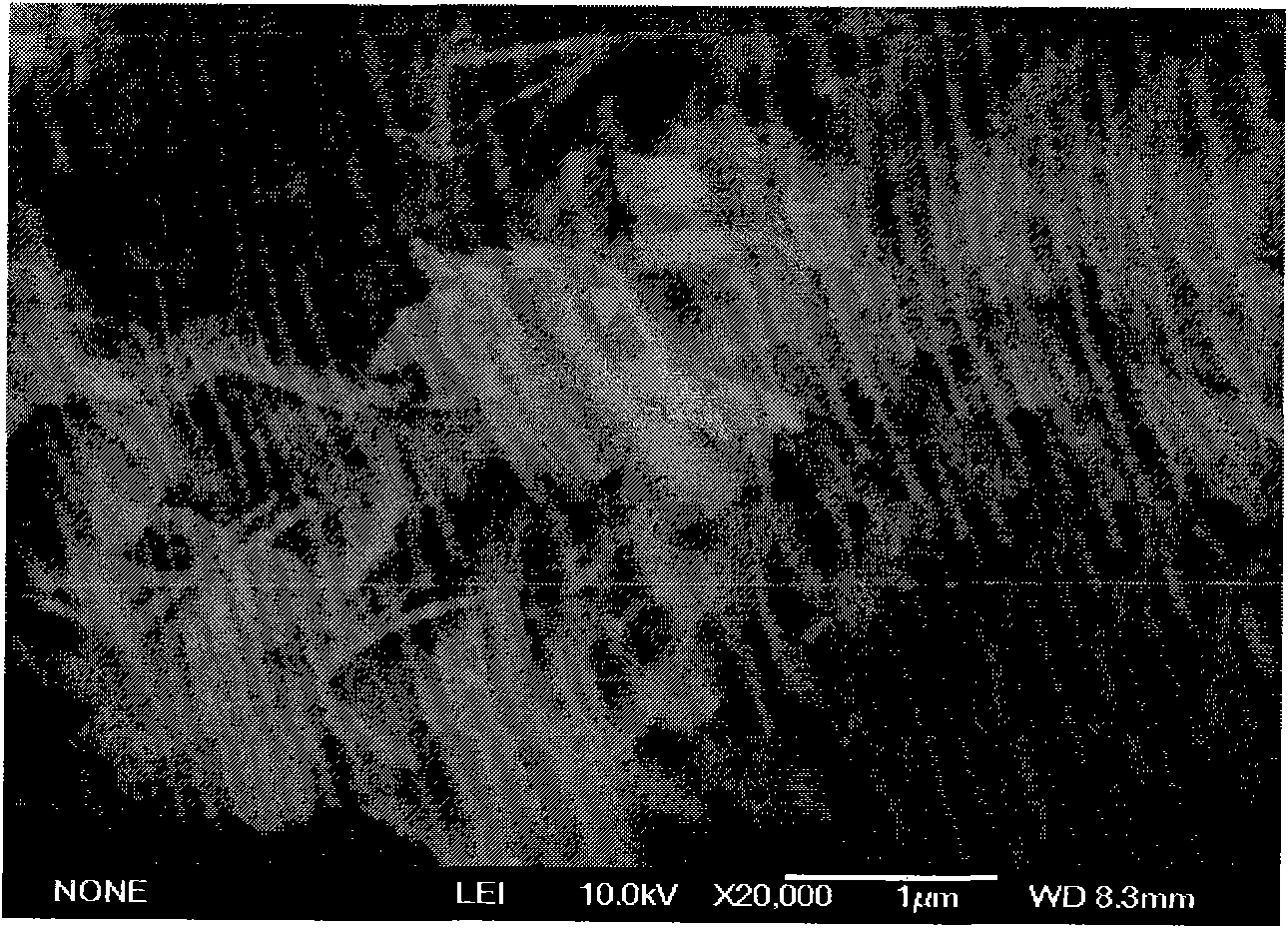

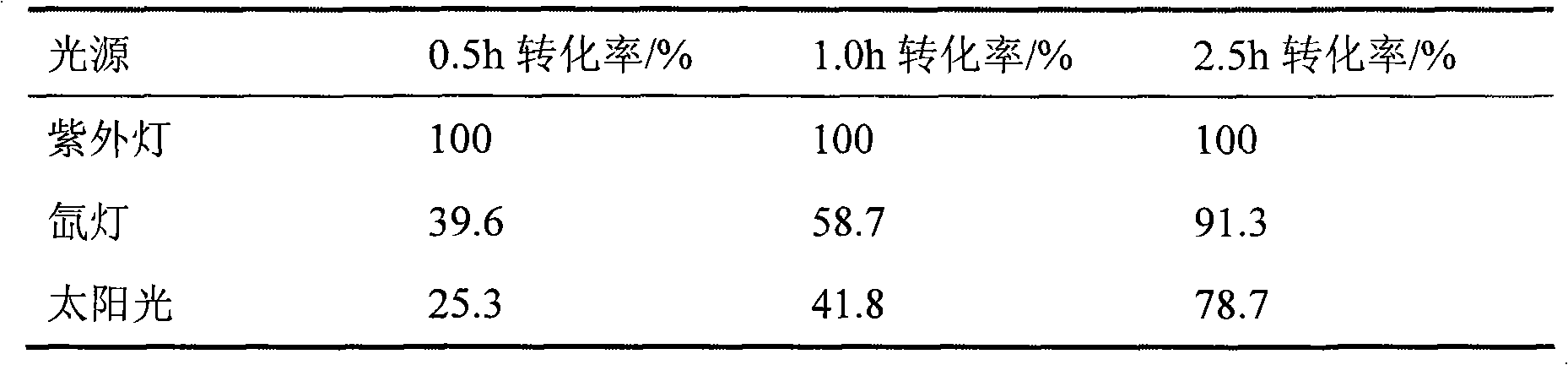

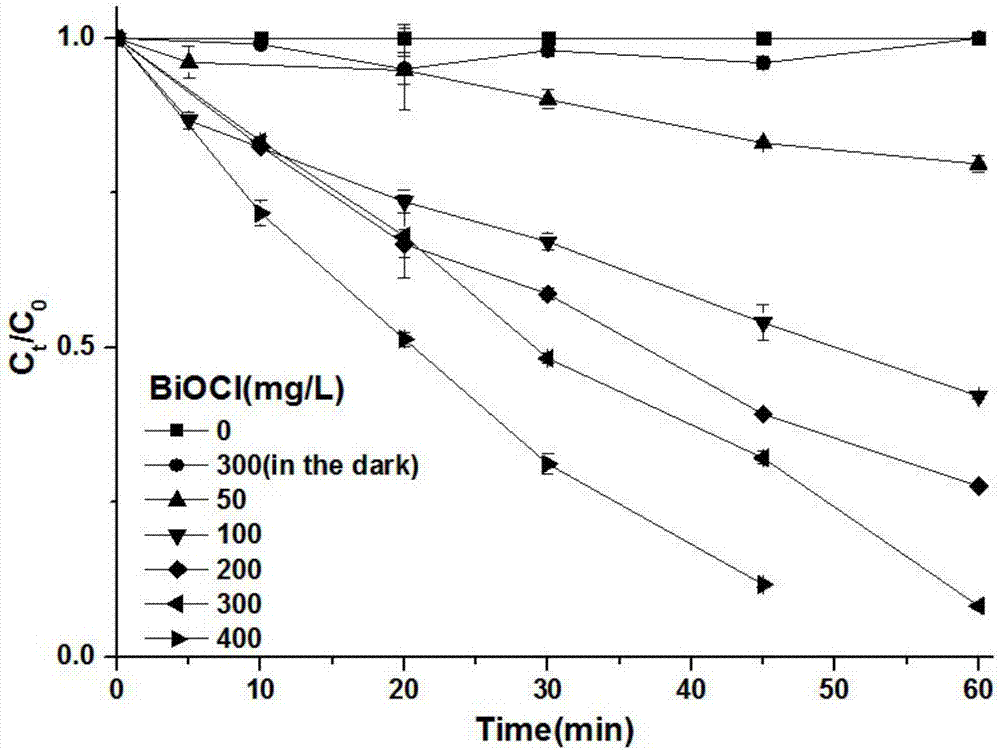

Preparation and application of bismuth oxychloride as photocatalyst

InactiveCN101879455AMild reaction conditionsImplement responsePhysical/chemical process catalystsWater/sewage treatment by irradiationAtmospheric temperatureUltraviolet lights

The invention relates to the preparation and application of a bismuth oxychloride as photocatalyst, which belongs to the technical field of environmental and chemical photocatalytic water treatment. The invention adopts bismuth trichloride as material, diluted hydrochloric acid as hydrolytic agent and sodium carbonate as pH regulator to prepare the bismuth oxychloride photocatalyst under the atmospheric temperature and pressure by simple steps such as hydrolyzation, precipitation, solid-liquid separation and drying. The preparation method has the advantages of atmospheric temperature and pressure, simple, safe and controllable technique, easy industrialization, cheap and easily obtained materials and stable product performance. When the bismuth oxychloride photocatalyst is used for oxidating organic matters in water in a research, a result indicates that the bismuth oxychloride photocatalyst has high photocatalytic activity, and the bismuth oxychloride photocatalyst has the same effect as the commercialized P25 photocatalyst under the irradiation of sunlight and simulated sunlight, and a better photocatalytic effect than the commercialized P25 photocatalyst under the irradiation of ultraviolet light.

Owner:TAIYUAN UNIV OF TECH

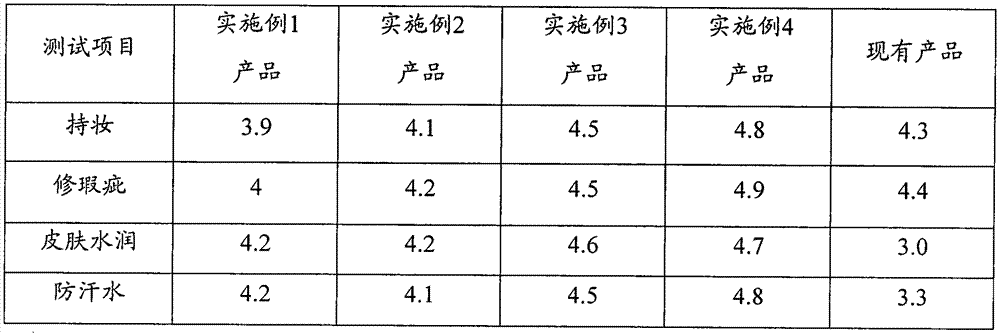

Air cushion BB cream and preparation method thereof

The invention discloses an air cushion BB cream and a preparation method thereof. The air cushion BB cream contains the following components: butanediol, cyclopentasiloxane, glycerol, tridecyl stearate, titanium dioxide, peg-10 polydimethylsiloxane, ethylhexyl Methoxycinnamate, disteardimonium hectorite, polydimethylsiloxane, a sunflower extract, mica, coconut oil, gardenia tahitensis flower, tocopherol, sodium chloride, glucan, folic acid, bacillus acidi lactic or a soybean fermentation product extract, phenoxyethanol, hydrogenated polydecene, a dunaliella salina extract, ethylhexylglycerin, bismuth oxychloride, iron oxide yellow, a Glycyrrhiza glabra extract and water. The preparation method comprises the steps of stirring until a mixture is dissolved every time one component is added, and then adding the next component. The air cushion BB cream disclosed by the invention can ensure that the skin is moisturized, exquisite, tender and smooth, has invisible pores and is uniform in skin color; and the air cushion BB cream has multiple effects of repairing flaws, preventing sweat, keeping the makeup well and the like.

Owner:广州悦瑞生物科技有限公司

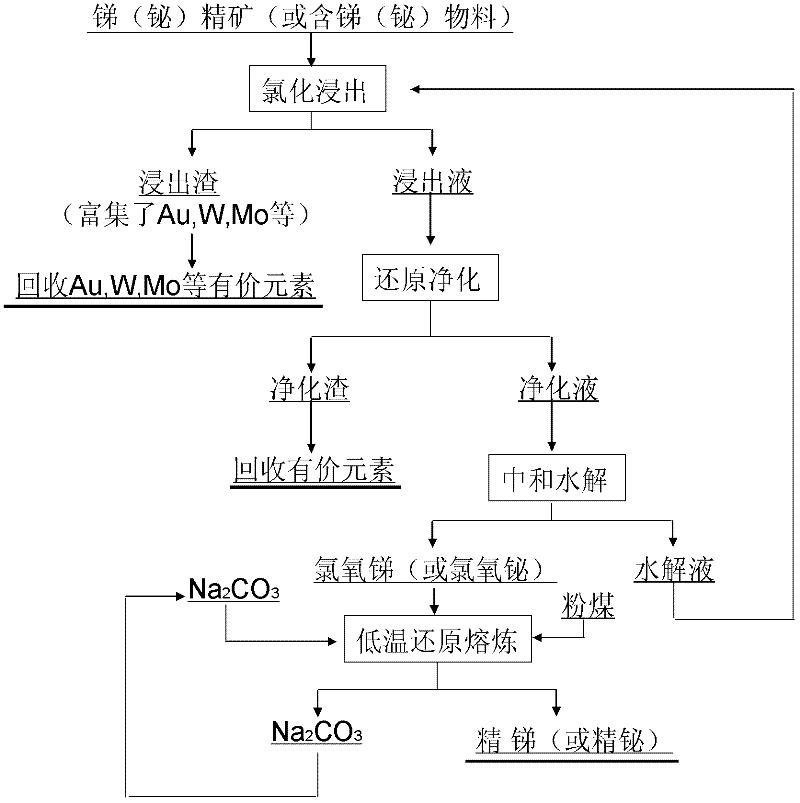

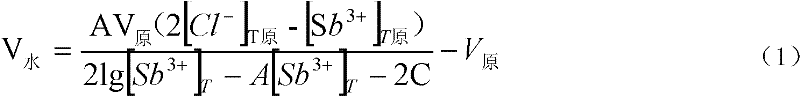

Wet process-pyrogenic process joint smelting process for antimony or bismuth

The invention discloses a wet process-pyrogenic process joint smelting process for antimony or bismuth. First, antimony is leached out from a material containing antimony (or bismuth), then reduction and purification are conducted on leaching liquid, then hydrolysis is conducted on the purified liquid to obtain antimony oxychloride (or bismuth oxychloride), and finally refined antimony (or refined bismuth) is obtained through inertia reduction smelting in a Na2CO3 system with the obtained antimony oxychloride (or bismuth oxychloride) serving as a raw material. The method solves the problems in the existing high temperature smelting of antimony (or bismuth) that pollution of low concentration SO2 and heavy metal powder is severe, energy consumption is big, efficiency is low, precious and rare metal is dispersed and the like. Simultaneously, Na2CO3 is not consumed during reduction smelting and can be used as an inertia fusing agent to return to smelting again, therefore energy consumption and reagent consumption are greatly reduced, and defects that a large amount of arsenic sludge hard to process is produced in the existing smelting process and the like are avoided. The wet process-pyrogenic process joint smelting process has the prominent advantages of being small in environment pressure, strong in raw material adaptability, high in metal (enrichment rate) recovery rate, small in energy consumption and low in cost.

Owner:YIYANG SHENGLI CHEM IND

Method for removing chlorine in manganese electrolyte or zinc electrolyte

InactiveCN102839283ASimple processEasy to operatePhotography auxillary processesProcess efficiency improvementElectrolysisDechlorinator

The invention relates to a method for removing chlorine in manganese electrolyte or zinc electrolyte. The method comprises the steps of: adding a certain quantity of bismuth (III)-containing antichlor into chloridion-containing manganese electrolyte or chloridion-containing zinc electrolyte by means of continuous stirring; adjusting the pH value of the solution at 1.0-5.0, so that the trivalent bismuth ions are hydrolyzed to generate insoluble bismuth oxychloride precipitate on the premise of chloridion; filtering, wherein the filter liquor is used for the follow-up electrolysis production technology; and regenerating filter residue bismuth oxychloride precipitate by an alkaline solution to generate bismuth hydroxide for recycling, and timely adding a small quantity of antichlor in the process of recycling to compensate the loss in the process of regeneration.

Owner:JISHOU UNIVERSITY

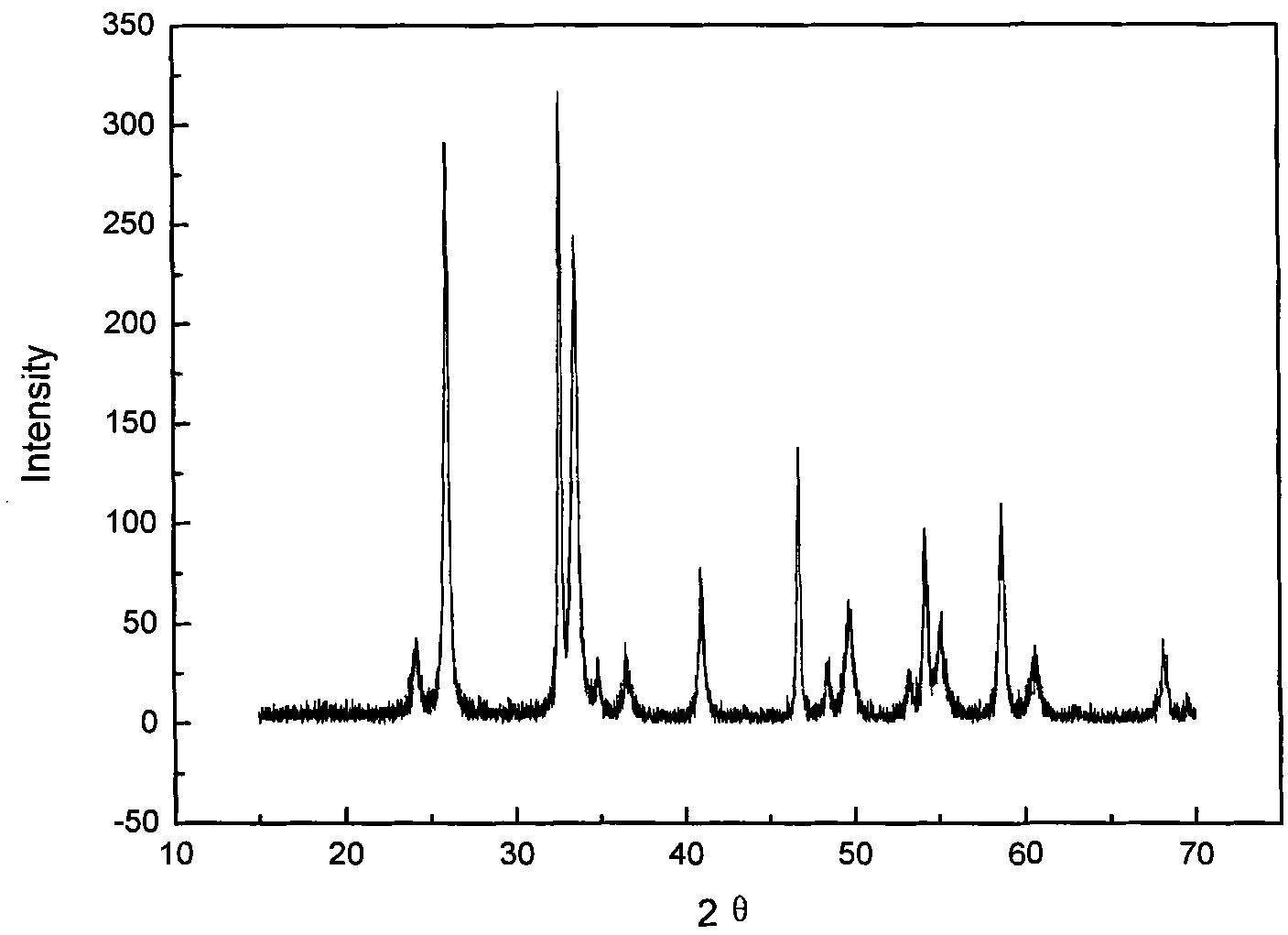

Preparation method and application of high-efficiency ultraviolet visible full-spectrum photocatalytic material

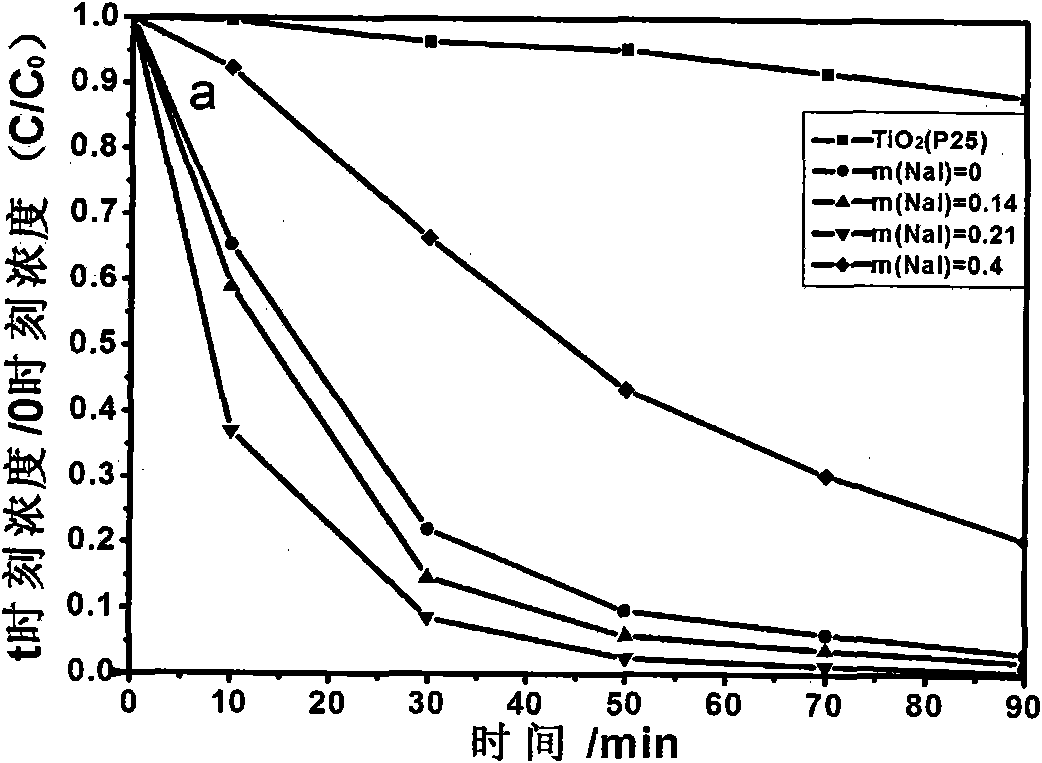

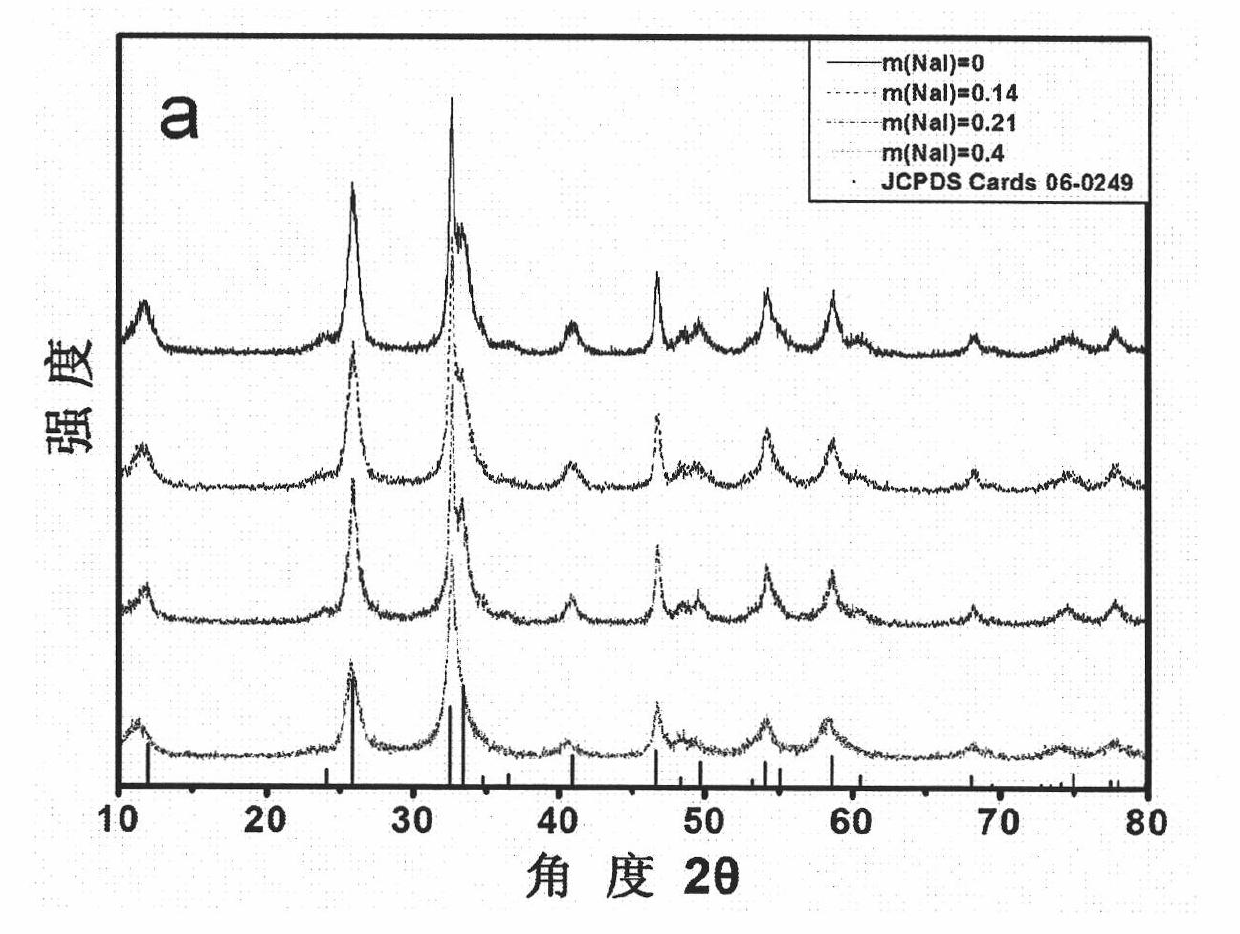

InactiveCN101947463AHigh catalytic efficiencyImprove photocatalytic degradation performancePhysical/chemical process catalystsCatalytic decompositionUltraviolet

The invention discloses a preparation method and application of a high-efficiency ultraviolet visible full-spectrum photocatalytic material and relates to a preparation method of a nano material which is doped with bromine and / or iodine and uses bismuth oxychloride as the matrix. The invention prepares the novel core-shell structured high-efficiency ultraviolet visible full-spectrum halogen-doped bismuth oxychloride photocatalytic material for the first time. The technical scheme is characterized in that the photocatalytic material has extremely high catalytic efficiency under the irradiation of a filament lamp, an iodine tungsten lamp, a daylight lamp and sunlight; the photocatalytic material has a wide catalytic degradation range and can carry out high-efficiency visible light catalytic decomposition on researched organic pollutants such as rhodamine B, methylene blue, methyl orange, 2,4,6-trichlorophenol, formaldehyde and the like; the degradation efficiency of the catalyst on the typical organic pollutant rhodamine B is up to 91% after the irradiation of sunlight for 10 minutes; the catalyst can be directly added to the paint to perform photo-absorption or degradation on formaldehyde and other harmful gases generated by interior finish and furniture; and the preparation method has the advantages of simple and convenient operation, energy saving and environment friendliness, thereby being applicable to large-scale industrial production.

Owner:SHANGHAI NORMAL UNIVERSITY

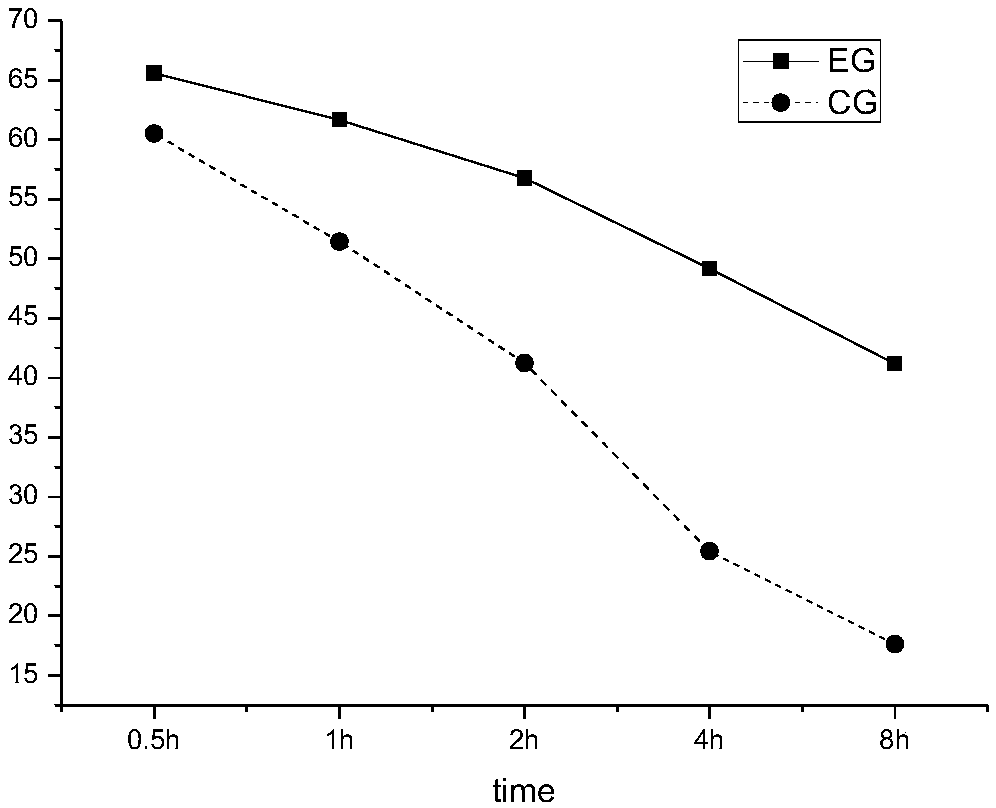

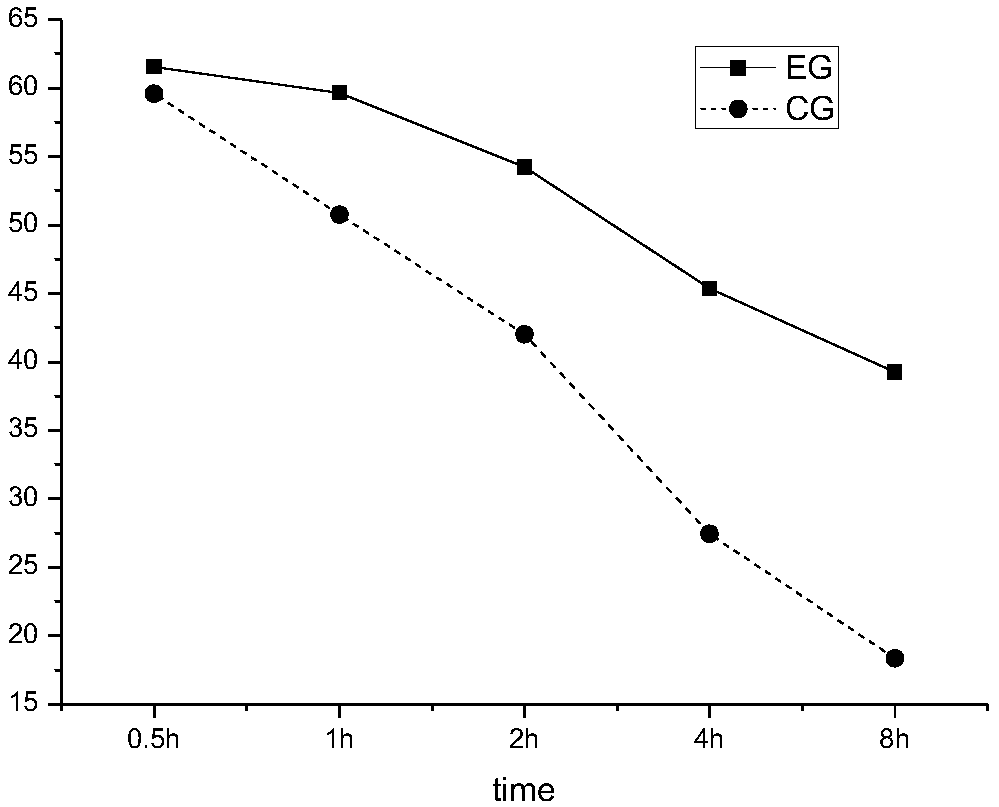

Photocatalyst-supported hydrogel as well as preparation method and application thereof

ActiveCN107051586APromote degradationEasy to prepareWater/sewage treatment by irradiationWater treatment compoundsSynthesis methodsConductive materials

The invention discloses photocatalyst-supported hydrogel as well as a preparation method and an application thereof and belongs to the field of environment function materials and catalysis. The photocatalyst-supported hydrogel comprises a conventional hydrogel composite conductive material and a photocatalysis material, wherein conventional hydrogel comprises acyclic acid / acrylamide hydrogel and can also be hydrogel formed through polymerization of other monomers. The conductive material comprises graphite, graphene and the like, and a photocatalyst can comprise bismuth oxychloride, titanium dioxide and the like. Bismuth oxychloride is immobilized, and the photocatalysis properties of bismuth oxychloride and electrical stimulation responsiveness of the hydrogel are combined. The conductive material in the compound hydrogel can transfer photo-induced electrons produced by bismuth oxychloride under illumination, the mass transfer rate between a catalyst and a pollutant cannot be affected, and the photocatalysis performance of bismuth oxychloride is improved. The synthesis method is simple and efficient, can realize industrial production and can be used for degrading atenolol, other medicines, personal care products and other organic pollutants in water.

Owner:NANJING UNIV

Light-sensation bright white tone-up cream and preparation method thereof

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +1

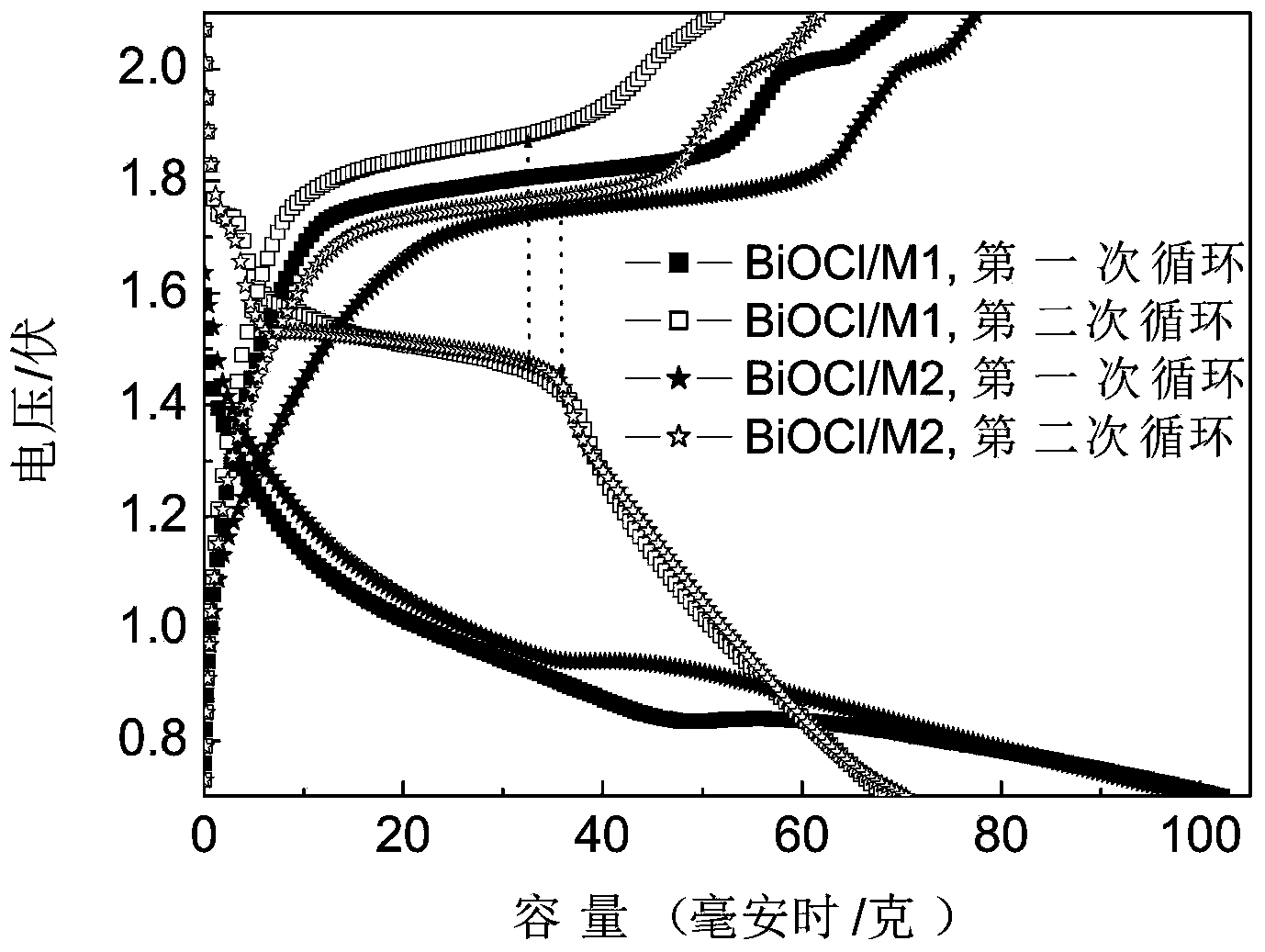

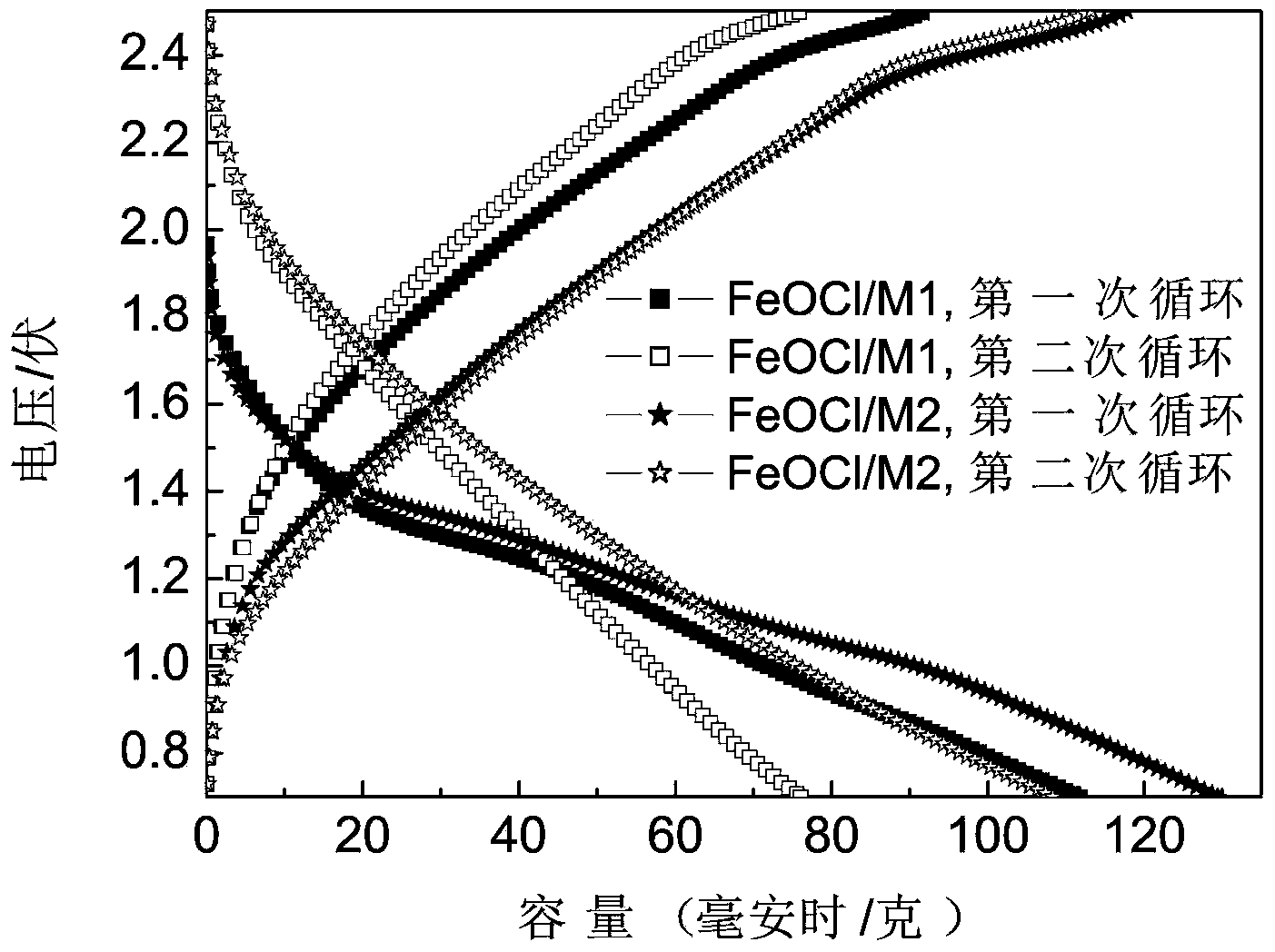

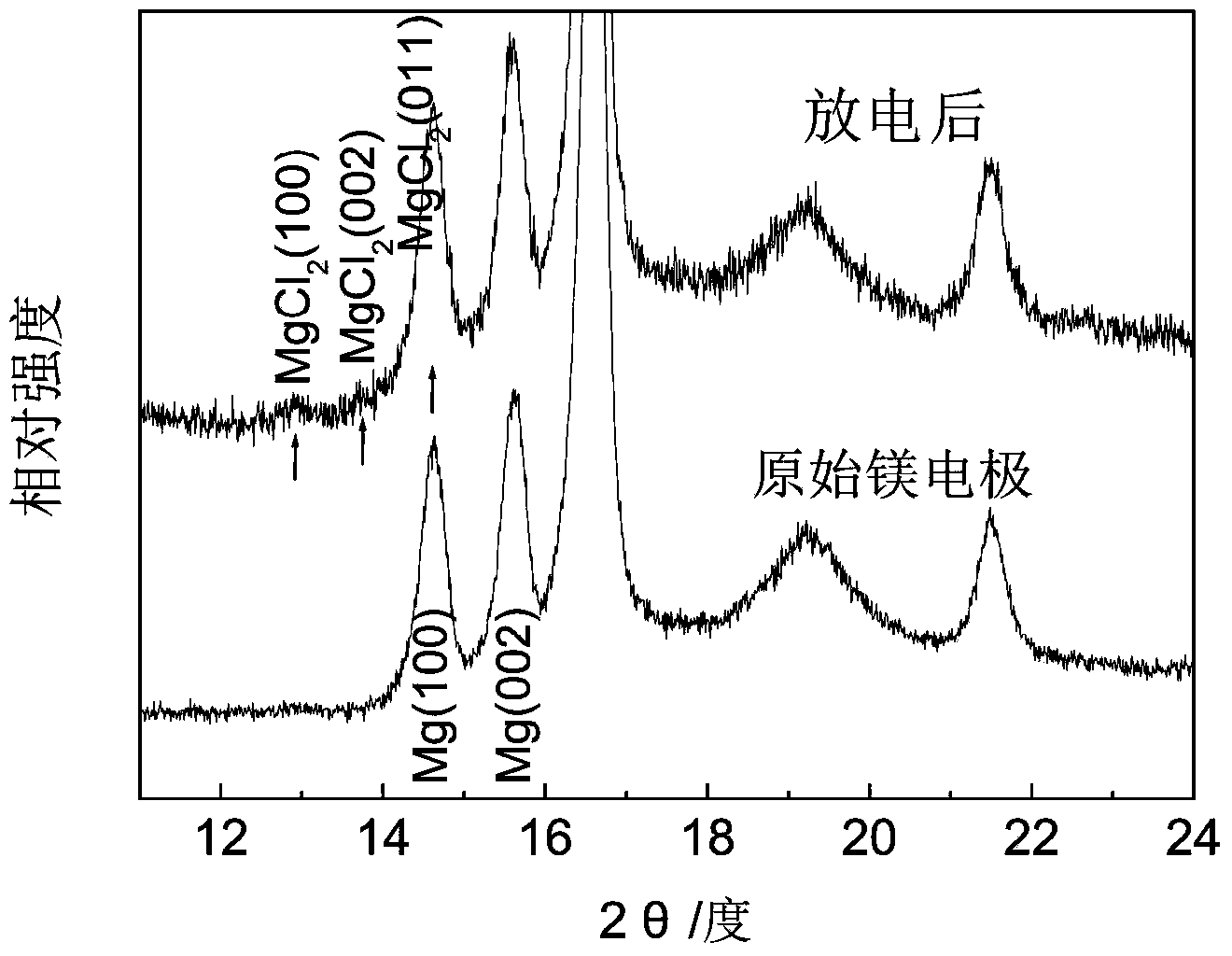

Chloride ion battery

The invention provides a chloride ion battery. A magnesium-carbon (Mg / C) composite material which is low in price, large in storage capacity and capable of realizing multi-electron reaction is used as a cathode material and includes an Mg / C material which is prepared by ball milling magnesium powder and carbon powder and an Mg / C material which is prepared by thermally decomposing MgH2 / C material. A composite material of one out of bismuth oxychloride (BiOCl) and chloride ferric oxide (FeOCl) or dichloro vanadium oxide (VOCl2) and carbon is used as an anode material; a mixed ion solution of N-methyl-N-butyl piperidine bi(trifluoromethyl sulfonyl) imine (PP14TFSI) and N-methyl-N-butyl piperidine chloride (PP14Cl) is used as electrolyte. A novel chloride ion battery electrode system adopting the magnesium as the negative electrode is established.

Owner:NANJING UNIV OF TECH

Prussian blue pearlescent pigment and preparation method thereof

The invention relates to a novel pearlescent pigment having high color depth and brightness. The novel pearlescent pigment is made of substances which are prepared by coating transparent or translucent inorganic flaky materials (including natural mica, synthetic mica, glass sheet, silicon oxide, aluminum oxide, iron oxide and bismuth oxychloride crystals) with Prussian blue (Fe4[Fe(CN)6]3) and coating these flaky materials with metal or metal oxide, wherein the particle diameter of the inorganic flaky materials is 5-1000 micrometers, and the thickness is 0.1-5 micrometers; and the thickness of the coated Prussian blue film is 1-100 nanometers. The pearlescent pigment prepared from Prussian blue is widely used in the industries of paint, cosmetics, ink, plastics, leather and the like.

Owner:FUJIAN KUNCAI MATERIAL TECH

Method for preparing bismuth oxychloride by solid-phase reaction at room temperature

The invention provides a method for preparing bismuth oxychloride by solid-phase reaction at room temperature. The method is characterized in that oxygen-containing bismuth salt and sodium chloride are taken as raw materials, and comprises the following steps: mixing and grinding or carrying out ball-milling on the oxygen-containing bismuth salt and the sodium chloride, removing soluble by-products by rinsing, and drying to obtain the bismuth oxychloride. The method has the advantages of simple process, high efficiency and low cost, and is easy to amplify; especially, in the whole preparation method, acid and alkali as well as organic additives are not used, and heating is not required; and the method has the advantages of energy conservation and environmental friendliness. The bismuth oxychloride prepared by the method has wide market prospects in the fields, such as coatings, inorganic pigment, high-quality cosmetics, pearly jewelries and the like.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

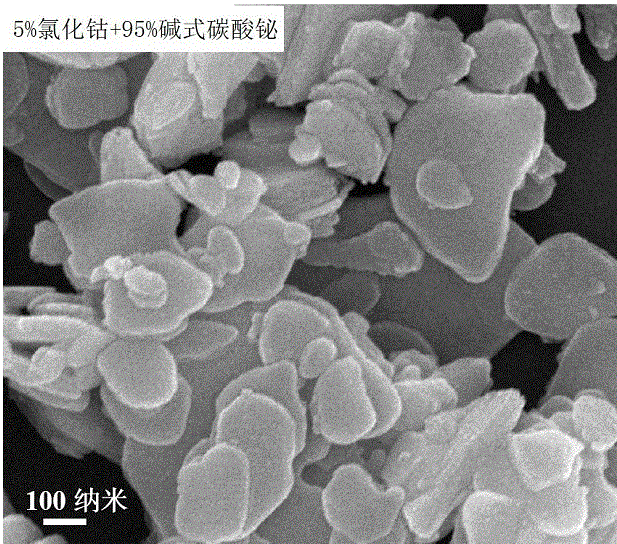

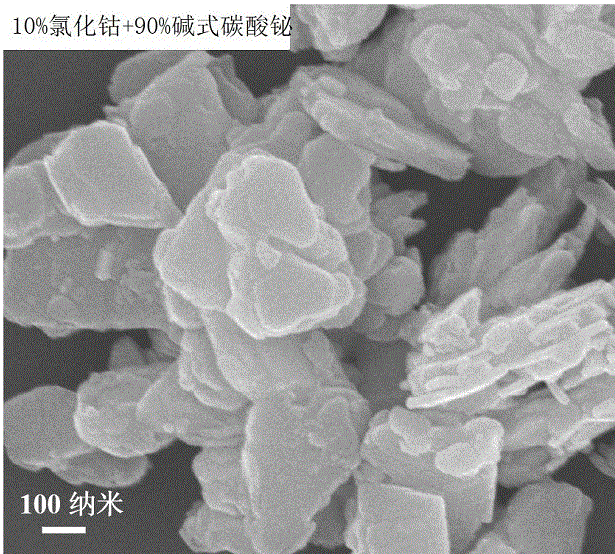

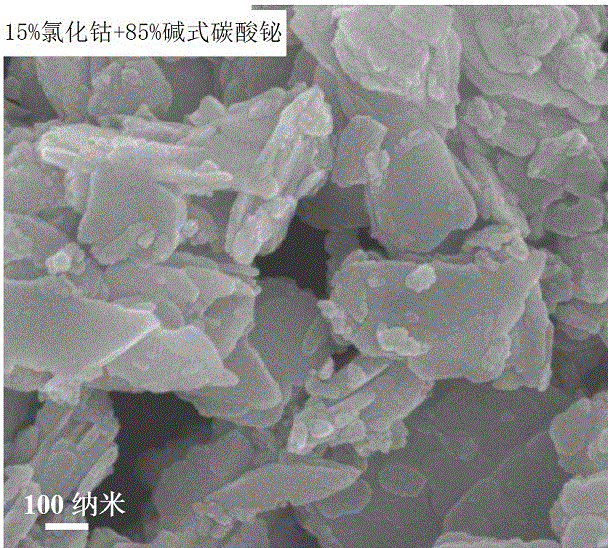

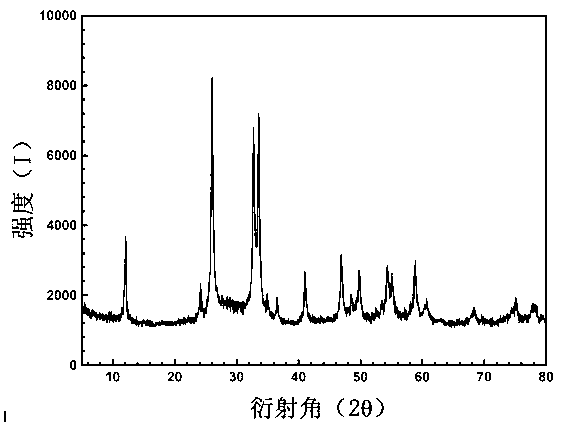

Cobalt oxide doped basic bismuth carbonate/bismuth oxychloride photocatalyst and preparation method thereof

ActiveCN106824213ABroaden the response rangePromote absorptionWater/sewage treatment by irradiationWater contaminantsHydrogenBismuth oxychloride

The present invention discloses a cobalt oxide doped basic bismuth carbonate / bismuth oxychloride photocatalyst, which comprises, by weight, 55-90% of basic bismuth carbonate (Bi2O2CO3) and 10-45% of bismuth oxychloride (BiOCl). The preparation method comprises: (1) adding Bi2O2CO3 to a BiOCl aqueous solution, and carrying out ultrasonic dispersion for 30 min, wherein the mass of the cobalt chloride is 5-30% of the mass of the basic bismuth carbonate; and (2) carrying out heating stirring on the ultrasonic dispersion mixing solution obtained in the step at a temperature of 100 DEG C until the water is completely evaporated, grinding into powder, heating to a temperature of 350 DEG C at a rate of 5 DEG C / min, and calcining for 3 h to obtain the basic bismuth carbonate / bismuth oxychloride photocatalyst. According to the present invention, the method is simple and rapid, can improve the catalytic efficiency of the catalyst, and is suitable for industrial production, and the obtained basic bismuth carbonate / bismuth oxychloride photocatalyst can be widely used in the fields of organic pollutant degradation, photocatalytic decomposition water-to-hydrogen, and the like.

Owner:SHANGHAI UNIV

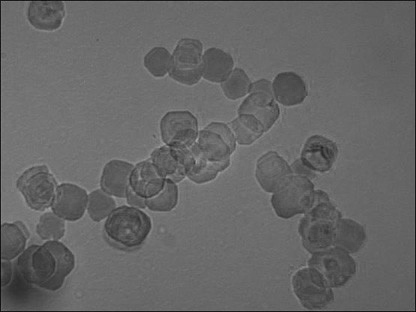

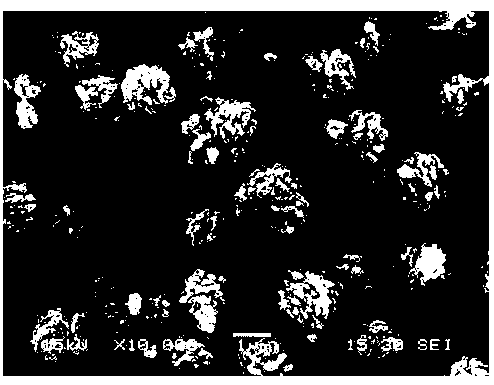

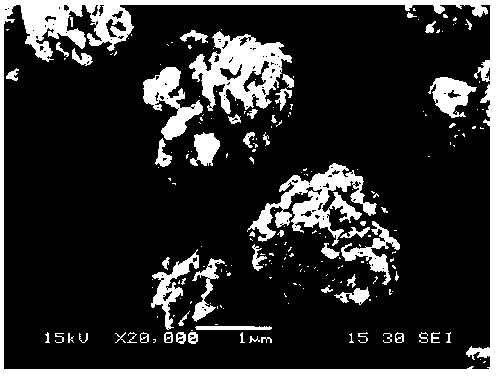

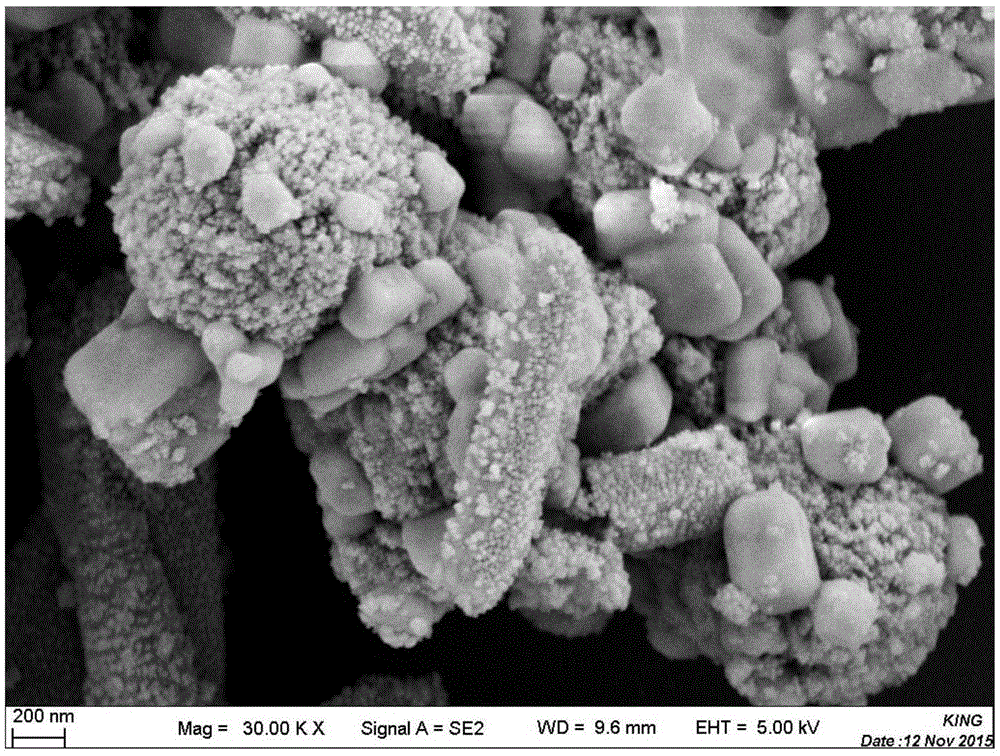

Bismuth oxychloride powder and preparation method thereof

InactiveCN103101974ASimple processWide adjustable range of parametersNanotechnologyBismuth compoundsMicrometerCompound (substance)

The invention relates to a bismuth oxychloride powder and its preparation method. A single bismuth oxychloride nanocrystal grain is irregular in shape, and has a size of 50-150 nanometers; and a plurality of nanocrystal grains aggregate into clusters with a size of 0.8-2 micrometers. The preparation method specifically consists of: adding a bismuth salt solution acidified by nitric acid into an ammonium chloride solution of certain concentration, conducting rapid stirring to form a uniform suspension liquid, and using ammonia water to adjust the pH to neutrality, then subjecting the suspension liquid to a one-step hydrothermal treatment, thus obtaining the bismuth oxychloride powder. The preparation method has the advantages of simple process, wide parameter adjustable range, strong repeatability as well as low cost, thus being a preparation method with business prospects. The prepared bismuth oxychloride powder can be widely applied in daily use chemicals, environmental protection, plastics, paint, electronics and other industries and fields.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

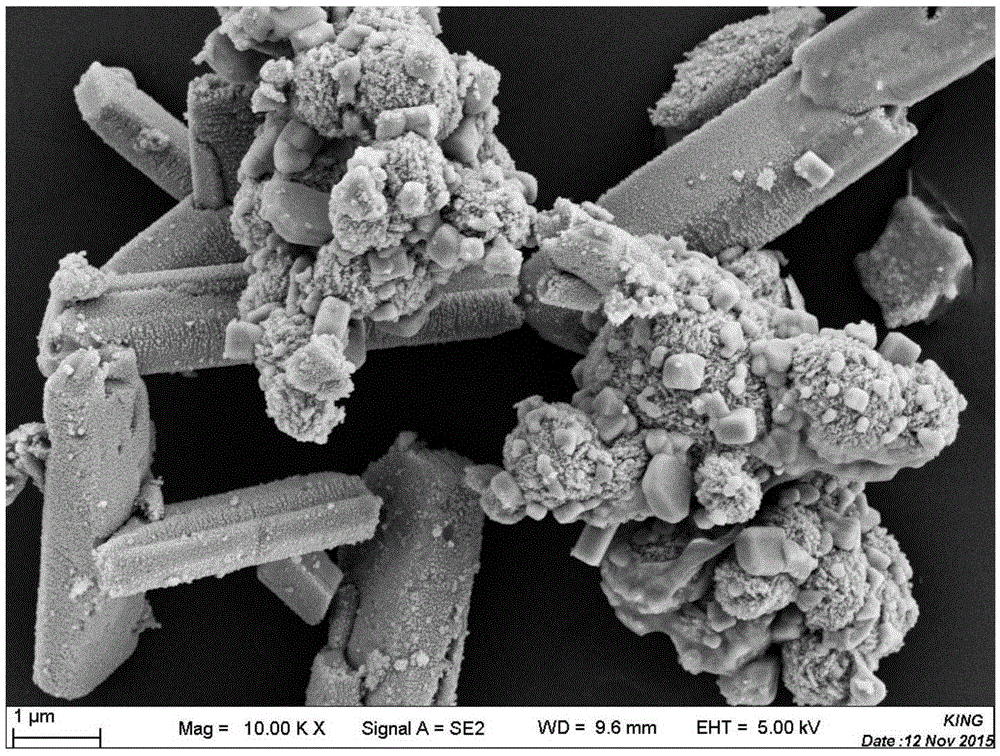

Gold-bismuth oxychloride nano composite material and preparation method thereof

InactiveCN106563472AStructural parameters are controllableProne to extensive degradationMaterial nanotechnologyPhysical/chemical process catalystsNanoparticleChloride

The invention discloses a gold-bismuth oxychloride nano composite material and a preparation method thereof. The composite material is composed of bismuth oxychloride and gold nanoparticles, wherein bismuth oxychloride has a shape of nanosheets or microflowers; the sheet length of the bismuth oxychloride nanosheets is 200-2000 nm, the sheet width is 200-2000 nm, and the thickness is 10-25 nm; the diameter of the bismuth oxychloride microflowers is 2-6 [mu]m and is composed of the bismuth oxychloride nanosheets; the gold nanoparticles are supported on the bismuth oxychloride nanosheets, and have the particle diameter of 10-30 nm. The method comprises the steps of firstly placing a gold target in a precursor solution prepared from bismuth nitrate and chloride under stirring, irradiating the gold target by using laser, and then carrying out solid-liquid separation, washing and drying treatment of the obtained mixed colloidal solution, to prepare the target product. The composite material has high visible light photocatalytic efficiency and can be easily widely applied in degradation of organic pollutants under visible light irradiation.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

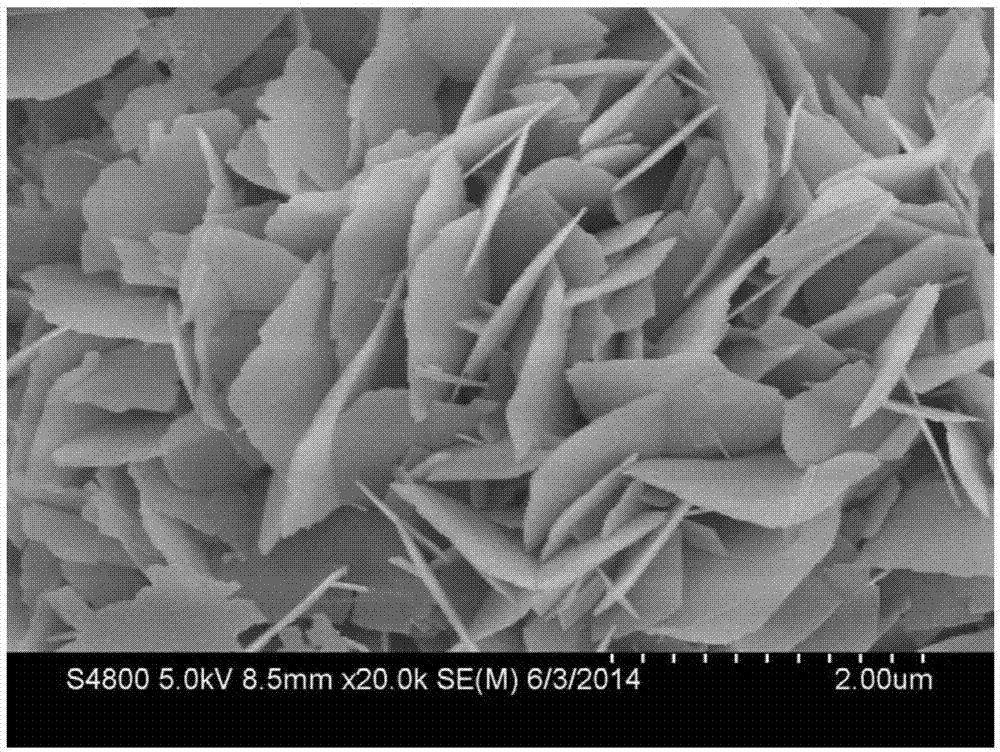

Preparation method and application of layered bismuth oxychloride visible-light photocatalyst

ActiveCN107497456AImprove controllabilityEase of large-scale synthesisWater/sewage treatment by irradiationWater treatment compoundsControllabilitySodium hydroxide

The invention discloses a preparation method and an application of a layered bismuth oxychloride visible-light photocatalyst. The preparation method includes the steps of: dissolving bismuth nitrate and polyvinylpyrrolidone in ethylene glycol to form an A phase; dissolving ammonium chloride and sodium hydroxide in water to form a B phase; mixing the A phase and the B phase, performing a hydrothermal reaction to the mixed solution, and filtering, washing and drying the reaction product to obtain the layered bismuth oxychloride visible-light photocatalyst, molecular formula of the bismuth oxychloride being Bi12O17Cl2. The catalyst has good controllability and is easy to synthesize in large scale, and can be used for high-effectively degrading organic pollutants in wastewater.

Owner:HUNAN UNIV

Method for synthesizing flaky pearlized bismuth oxychloride

ActiveCN101804965ASolve processing problemsSimple processHalogen oxides/oxyacidsState of artEcological environment

The invention relates to a method for synthesizing flaky pearlized bismuth oxychloride, which belongs to the technical field of inorganic material preparation. The method comprises the following steps: 1) preparing a bismuth chloride solution; 2) preparing acidified pure water; 3) dropwisely adding the bismuth chloride solution to hydrolyze and synthetize the flaky pearlized bismuth oxychloride; and 4) processing into finished flaky pearlized bismuth oxychloride. The method has the advantages of easy amplification, convenient regulation and control, and strong controllability. The product obtained by using the method has the advantages of uniform dispersibility, good glossiness and stable property, and has broad market prospects in the fields of inorganic pigments, pearlized buttons, pearlized decorations and the like. The invention solves the problem of difficulty in waste water treatment after production in the prior art, and protects the ecological environment.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

Preparation method for visible-light-driven photocatalyst compositing bismuth oxychloride/silver carbonate

InactiveCN105289680ANo pollution in the processHigh catalytic efficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationEnvironmental resistanceSilver carbonate

The invention relates to a preparation method for a visible-light-driven photocatalyst compositing bismuth oxychloride / silver carbonate. The preparation method comprises the following steps: preparing bismuth oxychloride; adding bismuth oxychloride into distilled water, performing ultrasonic stirring, adding silver nitrate, performing stirring, adding a sodium bicarbonate solution dropwise, performing stirring, performing centrifugation, washing the product by ethanol and water in turn, and drying the product. The preparation method is simple, and the preparation condition is easy to control. Moreover, the prepared visible-light-driven photocatalyst compositing bismuth oxychloride / silver carbonate is a green catalyst with high performance, is pollution-free, has high catalytic efficiency, and has a certain application value.

Owner:CHANGZHOU UNIV

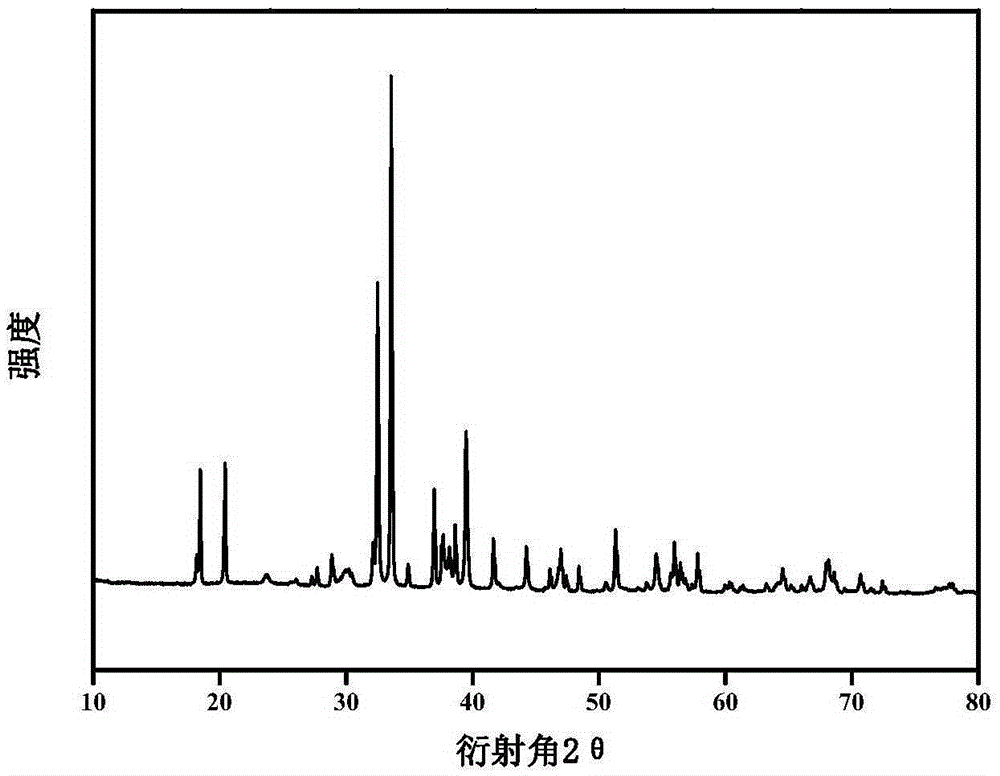

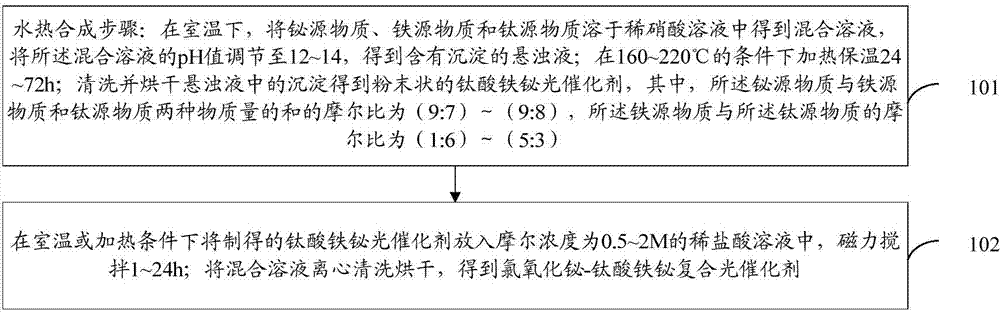

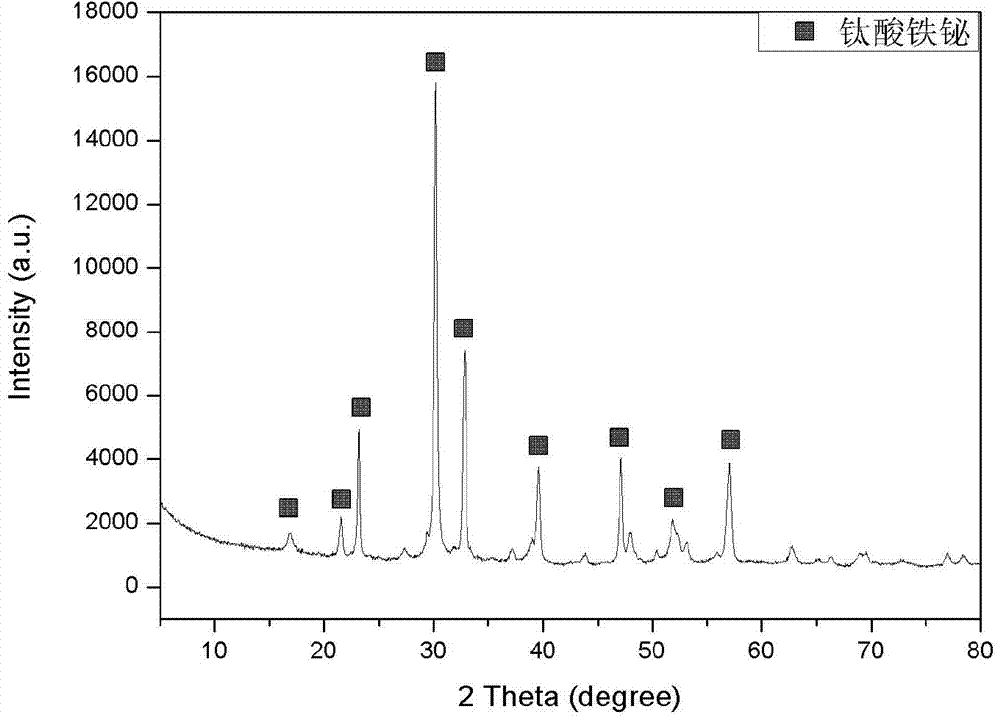

Bismuth oxychloride-iron bismuth titanate composite photocatalyst and preparation method thereof

InactiveCN104511293APromote crystallizationNo pollution in the processPhysical/chemical process catalystsCentrifugationRoom temperature

The invention provides a bismuth oxychloride-iron bismuth titanate composite photocatalyst and a preparation method thereof. The method comprises the steps: a hydrothermal synthesis step comprising at room temperature, dissolving a bismuth source substance, an iron source substance and a titanium source substance in a dilute nitric acid solution to obtain a mixed solution, adjusting the pH value of the mixed solution to 12-14 to obtain a precipitate-containing suspension, under a condition of the temperature of 160-220 DEG C, heating and carrying out heat preservation for 24-72 h, and cleaning and drying the precipitate in the suspension to obtain a powdery iron bismuth titanate photocatalyst; and a hydrochloric acid treatment step comprising under a condition of room temperature or heating, putting the prepared iron bismuth titanate photocatalyst into a dilute hydrochloric acid solution with the molar concentration of 0.5-2 M, carrying out magnetic stirring for 1-24 h, and carrying out centrifugation cleaning and drying on the mixed solution, to obtain the bismuth oxychloride-iron bismuth titanate composite photocatalyst.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com