Patents

Literature

45 results about "Bismuth subcarbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

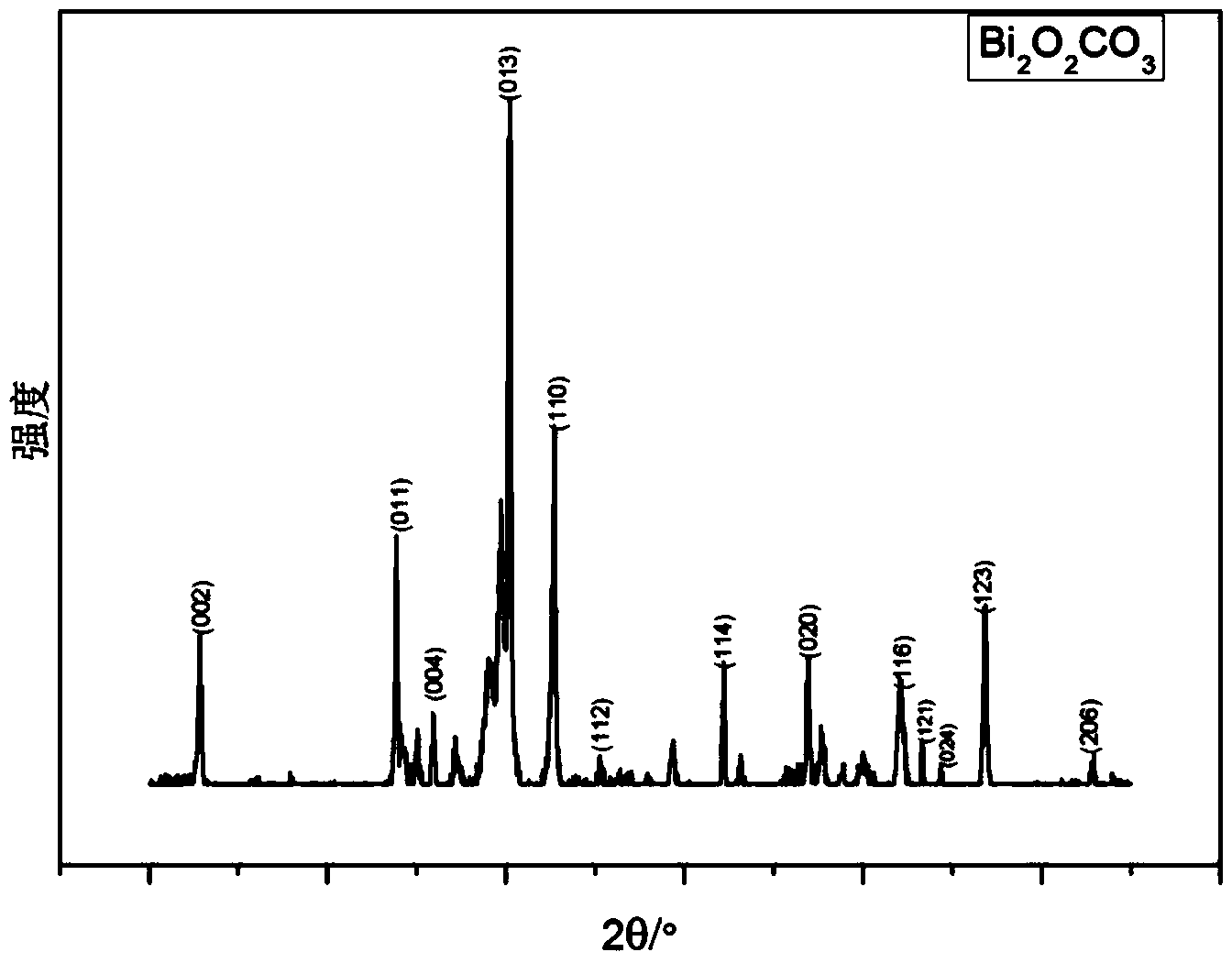

Bismuth subcarbonate (BiO)₂CO₃, sometimes written Bi₂O₂(CO₃) is a chemical compound of bismuth containing both oxide and carbonate anions. Bismuth is in the +3 oxidation state. Bismuth subcarbonate occurs naturally as the mineral bismutite. Its structure consists of Bi-O layers and CO₃ layers and is related to kettnerite, CaBi(CO₃)OF. It is light-sensitive.

Catalyst used for synthesis of vinyl acetate and its prepn. method

ActiveCN1903435AHigh activityReduce consumptionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidActivated carbon

A catalyst for synthesizing vinyl acetate from acetylene and acetic acid is prepared from activated carbon, zinc acetate and alkaline bismuth carbonate in mass ratio of 100: (27-40): 0.026 by excessive solution dipping method.

Owner:CHINA PETROCHEMICAL CORP +2

Catalyst for production of 1,4-butynediol and preparation method of catalyst

ActiveCN102950014AHigh activityHigh selectivityPhysical/chemical process catalystsOrganic compound preparationBASIC CUPRIC CARBONATESlurry reactor

The invention discloses a catalyst for production of 1,4-butynediol and a preparation method of the catalyst, belongs to the field of catalyst research, more particularly relates to a load type catalyst for production of 1,4-butynediol in a slurry reactor and a preparation method of the catalyst. According to the method, nanosilicon dioxide which has a larger external specific surface is used as a carrier, copper and bismuth are attached to the carrier by adopting a settling and depositing method, the active components of the catalyst exist in a form of basic cupric carbonate, and the catalyst comprises the following components in percentage by mass: 20-50 percent of carrier, 35-70 percent of basic cupric carbonate and 2-15 percent of bismuth subcarbonate. The prepared catalyst has the characteristics of good activity and high selectivity and is easy to activate.

Owner:大连瑞克科技股份有限公司

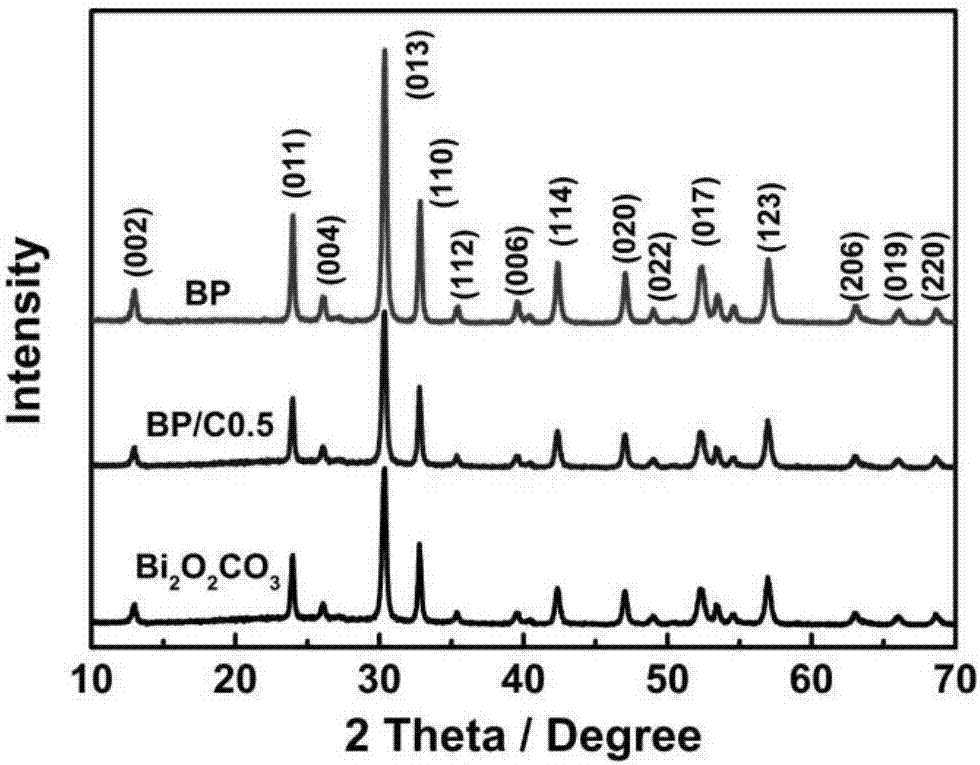

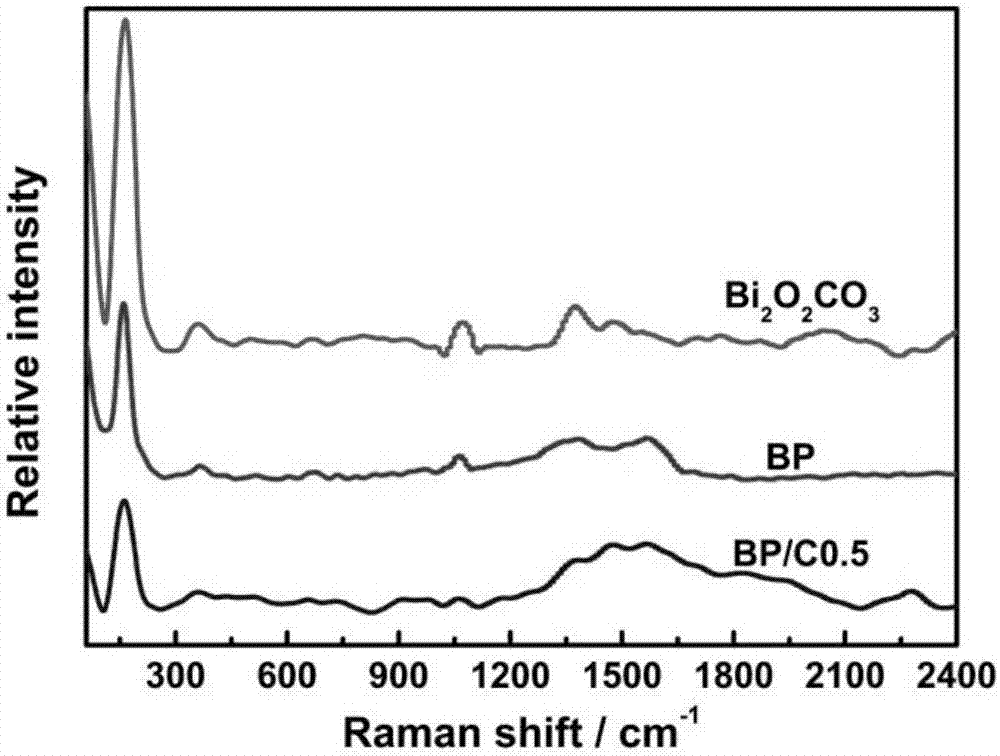

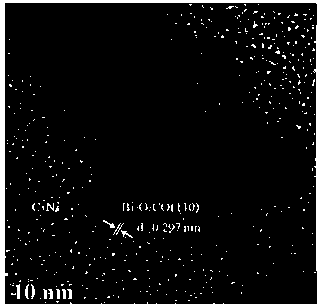

Bismuth subcarbonate photocatalyst and preparation method thereof

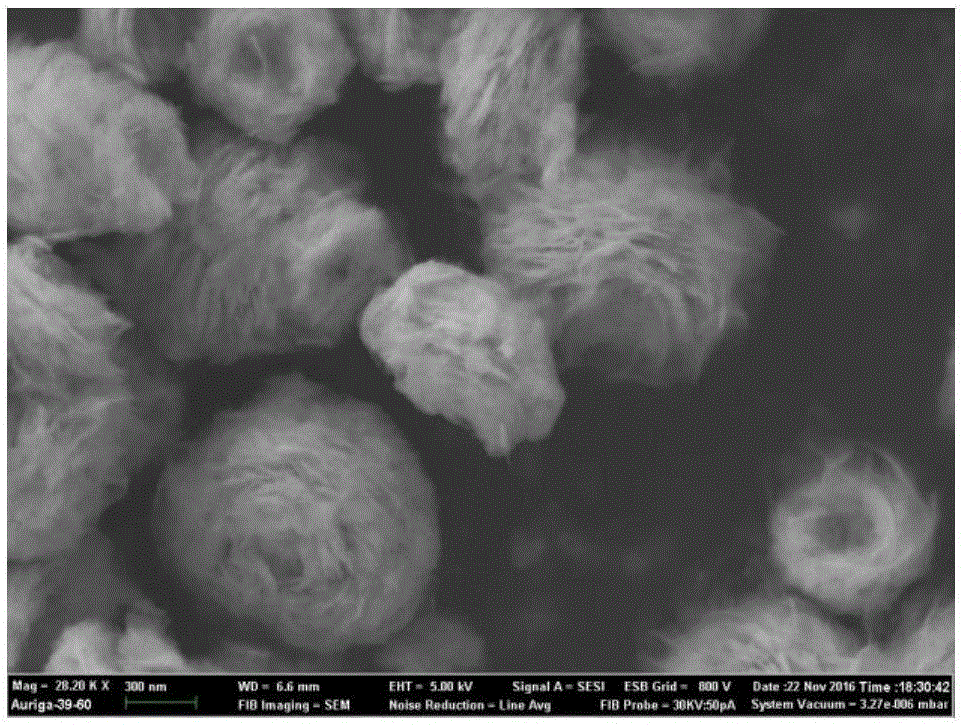

ActiveCN102527420AImprove photocatalytic performanceImprove photocatalytic activityCatalyst activation/preparationMicrosphereAmmonia

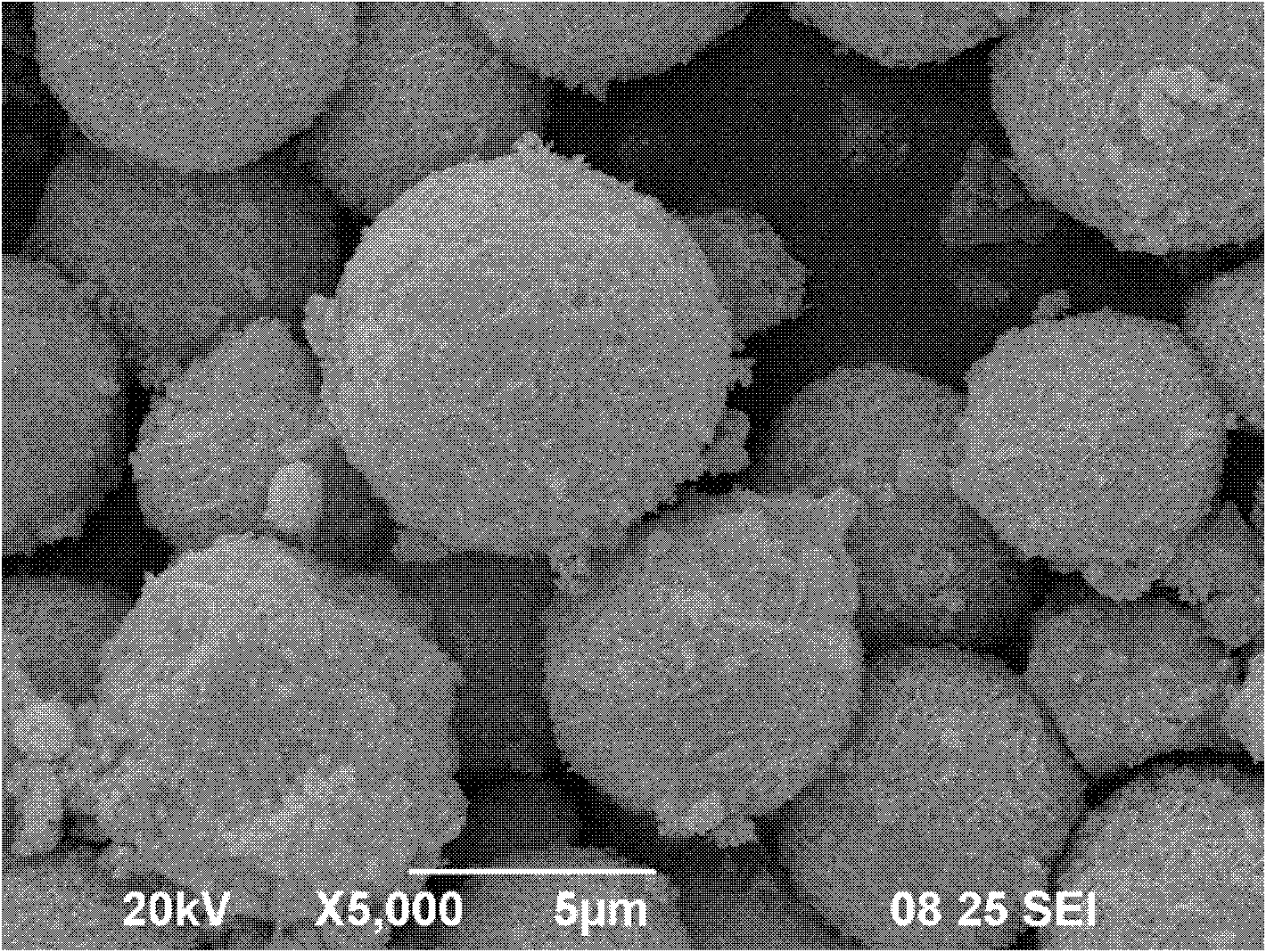

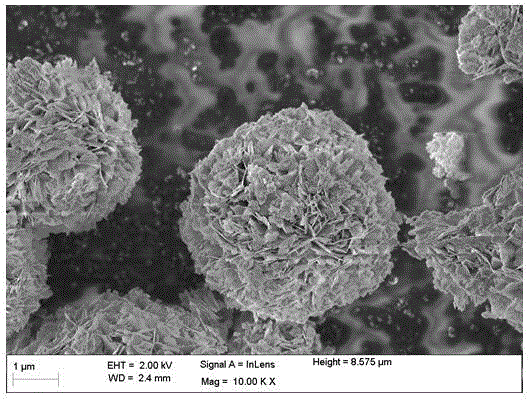

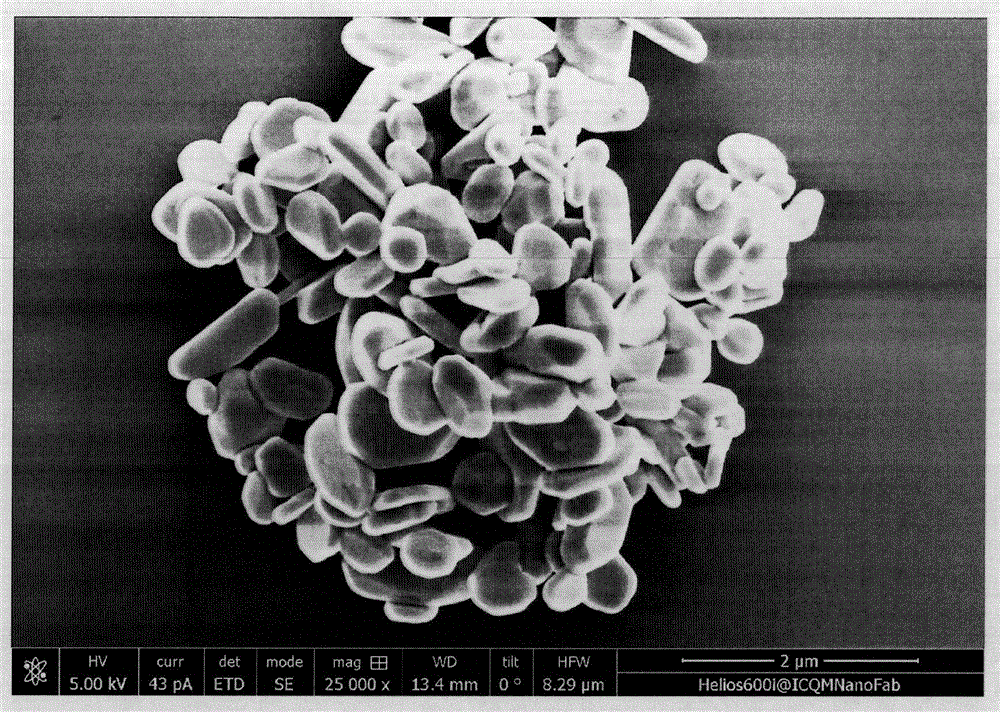

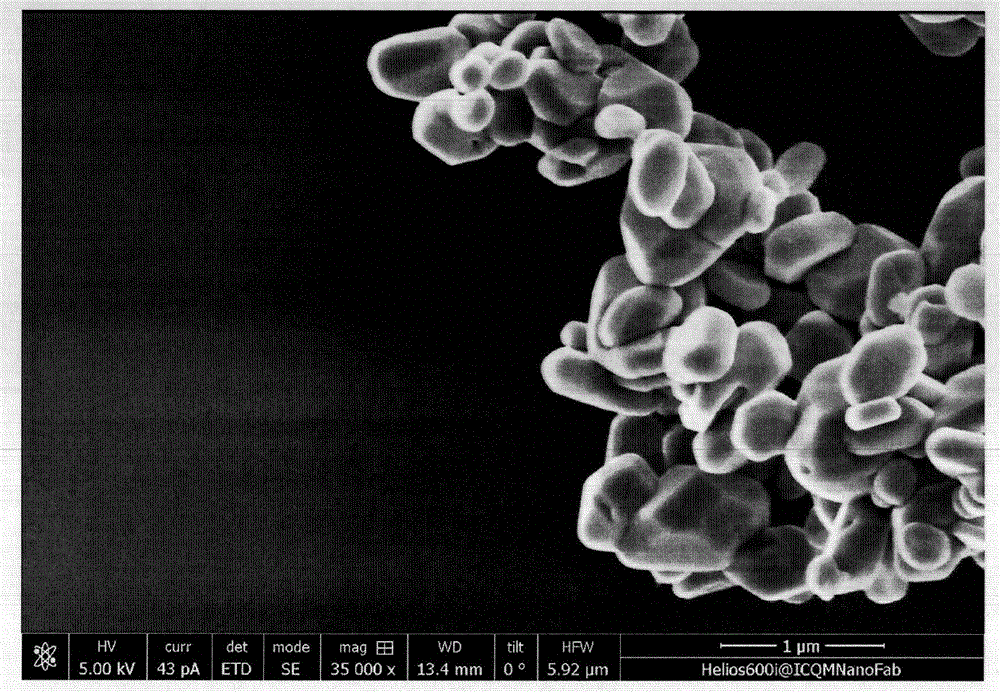

The invention provides a bismuth subcarbonate photocatalyst which is a bismuth subcarbonate nanometer sheet or a microsphere formed by the bismuth subcarbonate nanometer sheet. The bismuth subcarbonate photocatalyst provided by the invention is obtained by carrying out hydrothermal reaction on a bismuth source and soluble carbonate in an aqueous solution, wherein the bismuth source is bismuth citrate or bismuth citrate ammonia. The bismuth subcarbonate photocatalyst takes the bismuth citrate or the bismuth citrate ammonia as the bismuth source, and the nanometer sheet shaped bismuth subcarbonate or the microsphere formed by the bismuth subcarbonate nanometer sheet is obtained in a hydrothermal reaction mode. The morphology obtained by the bismuth subcarbonate photocatalyst can accelerate the separation and transmission of the photoproduction electrons and holes of the bismuth subcarbonate photocatalyst so as to inhibit the composition of the electrons and holes and accelerate the diffusion and transfer of reactants and reaction products; reflection is generated between rays and a nanometer layer; and the use ratio of the light source is increased so as to improve the catalytic activity of the bismuth subcarbonate photocatalyst. An experiment result shows that the removal rate on NO by the bismuth subcarbonate photocatalyst provided by the invention is 20-50%.

Owner:铜陵博雅渡业新材料科技有限公司

Method for preparing bismuth-series chemical product

The invention relates to a method for preparing a bismuth-series chemical product, comprising steps as follows: firstly, preparing ordinary-level bismuth oxide by refined bismuth; then preparing a bismuth-series chemical product by the ordinary-level bismuth oxide including steps of refined bismuth pulverization, bismuth low-temperature oxidation, ordinary bismuth oxide chemical conversion, and the like; finally preparing bismuth-series chemical products of bismuth nitrate, bismuth subnitrate, bismuth subcarbonate, bismuthsalicylate, basic bismuth salicylate, bismuth citrate, bismuth trichlor, bismuth oxychloride, electric bismuth oxide or bismuth oxide nanowire, and the like; and recycling chemically-converted mother-liquid. The invention has the advantages of generating no cancerigenic poison gas NOx and waste water, having environment protection, little consumption of chemical reagent, little energy consumption, low cost, simple device and operation, and the like.

Owner:湖南金泰铋业股份有限公司

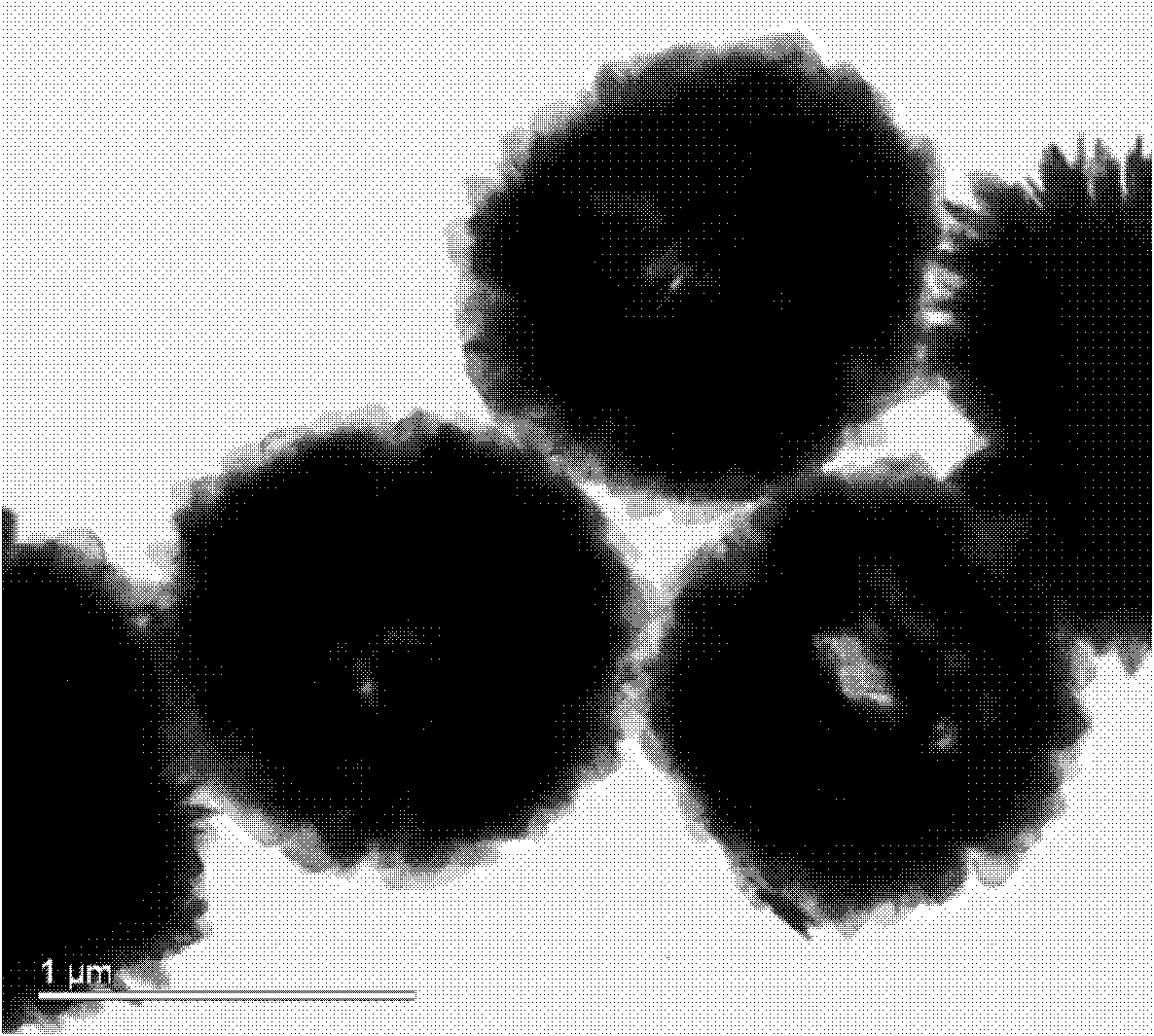

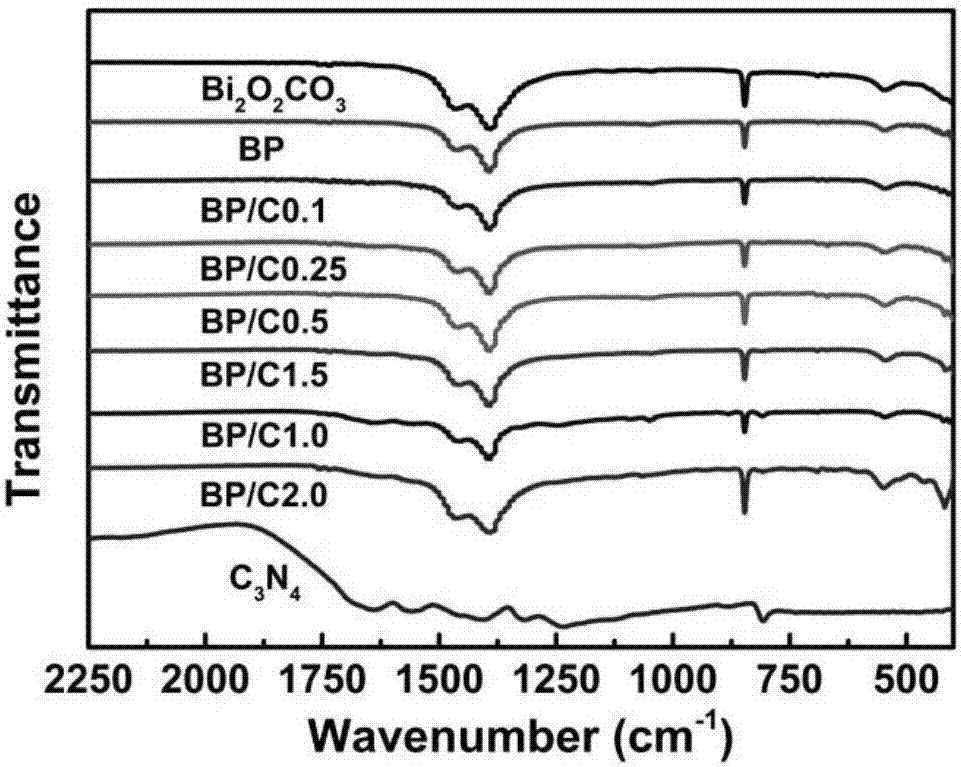

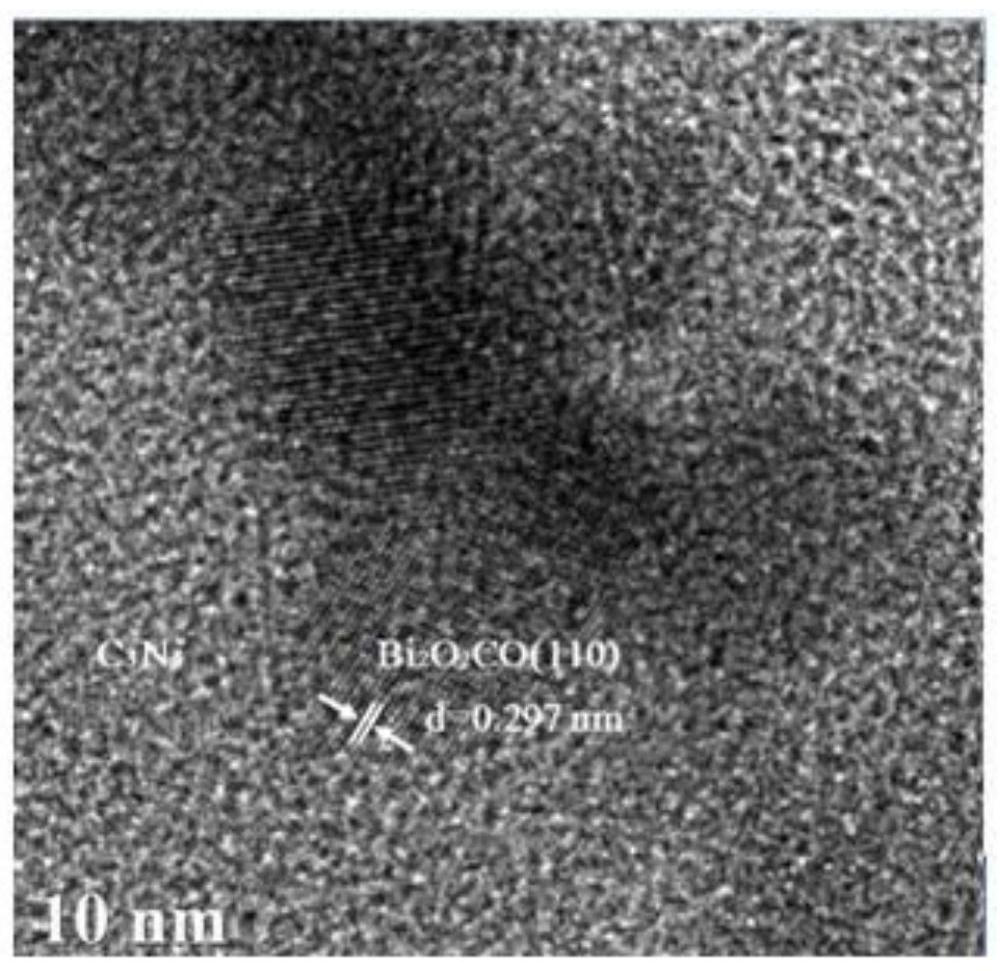

Bi2O2CO3/PPy/g-C3N4 compound photocatalyst and preparation method and application thereof

InactiveCN106984360AImprove photocatalytic activityIncrease profitWater/sewage treatment by irradiationWater treatment compoundsSpectral responsePolypyrrole

The invention belongs to the technical field of photocatalyst materials for degrading wastewater pollutants and discloses a preparation method of a Bi2O2CO3 / PPy / g-C3N4 compound photocatalyst and application of the Bi2O2CO3 / PPy / g-C3N4 compound photocatalyst to Rhodamine B degradation under simulated sunlight. The preparation method includes: mixing a polypyrrole (PPy) doped bismuth subcarbonate (Bi2O2CO3) composite material with graphite-phase carbon nitride (g-C3N4) in an organic solvent according to the proportion, performing heating reflux, washing obtained products for several times, and performing vacuum drying to obtain the Bi2O2CO3 / PPy / g-C3N4 compound photocatalyst material. The preparation method has the advantages that the preparation method is simple and easy to achieve large-scale industrial production, the prepared compound material is stable in property and high in photocatalytic activity, the spectral response range of Bi2O2CO3 is expanded, sunlight utilization rate is increased, and the prepared compound material has a good degrading effect on organic dye Rhodamine B of certain concentration and is applicable to dye wastewater treatment.

Owner:JIANGSU UNIV

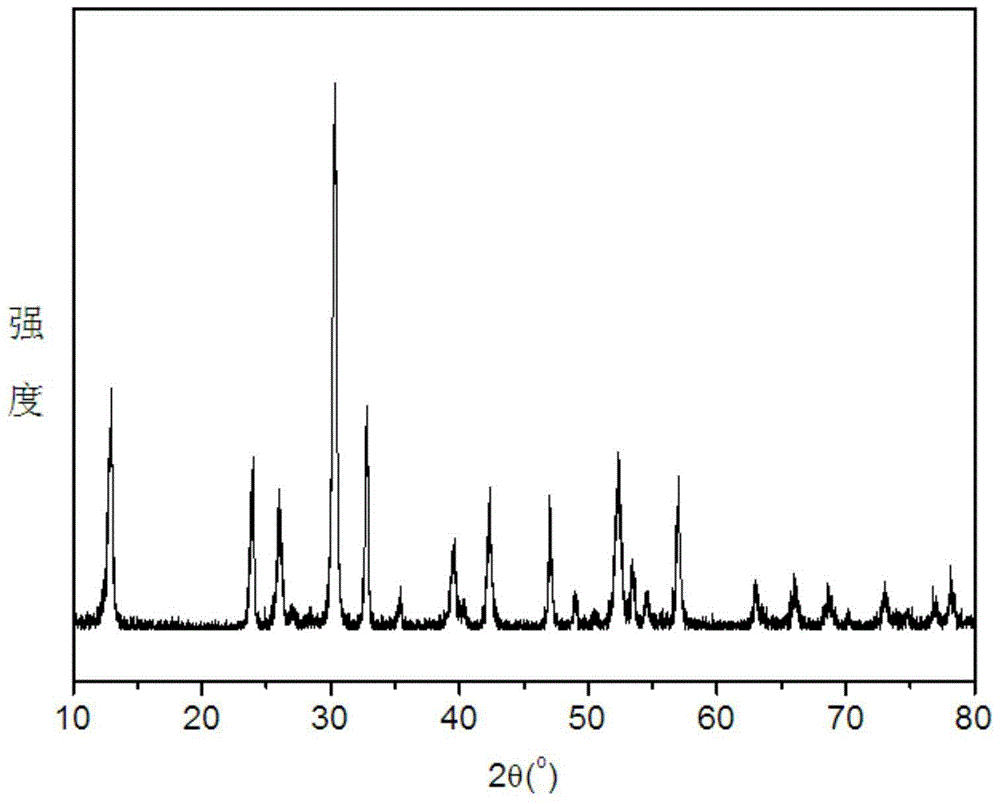

Gold-supported bismuth subcarbonate material for photocatalysis and preparation method

ActiveCN105126888AImprove catalytic performancePhysical/chemical process catalystsWater/sewage treatment by irradiationWater bathsGold particles

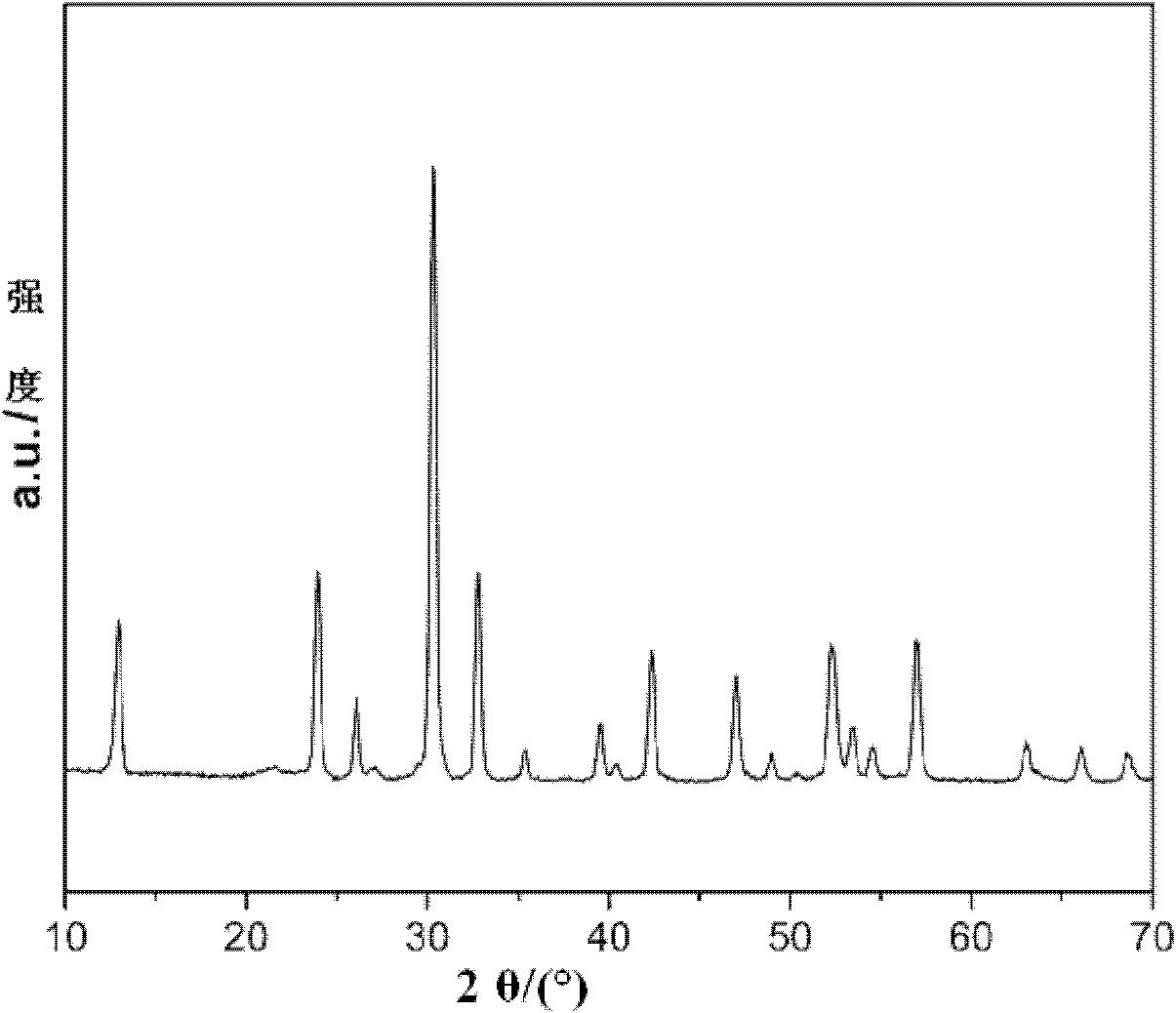

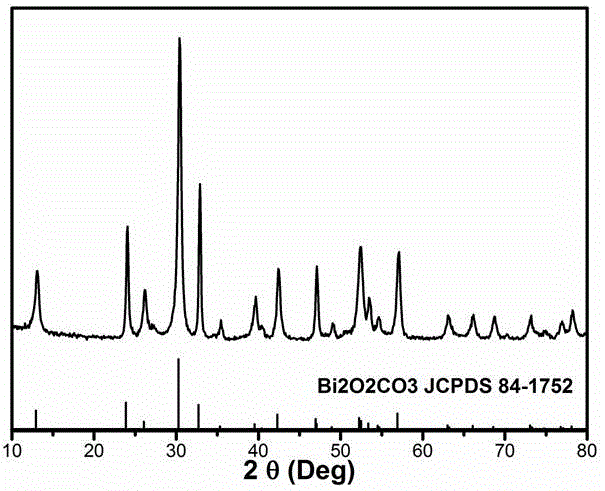

The invention relates to a gold-supported bismuth subcarbonate material for photocatalysis and a preparation method thereof, and belongs to the field of inorganic nano-materials. The preparation method of gold-supported bismuth subcarbonate microspheres comprises the steps that firstly, ammonium bismuth citrate and sodium carbonate are added in water and stirred to obtain an even supernatant solution; secondly, the solution is placed in a hydrothermal reaction kettle for a hydrothermal reaction at 160 DEG C for 24 h; thirdly, precipitate obtained through the reaction is centrifuged, washed and dried to obtain bismuth subcarbonate nanospheres. The gold supporting method comprises the steps that the prepared bismuth subcarbonate reacts with urea, chloroauric acid and water on the water bath condition at 80 DEG C for 4 h, washing and drying are performed after natural cooling is performed, and then the gold-supported bismuth subcarbonate nanospheres are obtained. According to the prepared gold-supported bismuth subcarbonate nanospheres, the physical phase is orthorhombic-phase bismuth subcarbonate of which the JCPDS number is 84-1752, the nanospheres are in the shape of a sphere, the diameter is 2-5 micrometers, and the size of gold particles on the surfaces is 5-10 nm.

Owner:CHONGQING UNIV OF ARTS & SCI

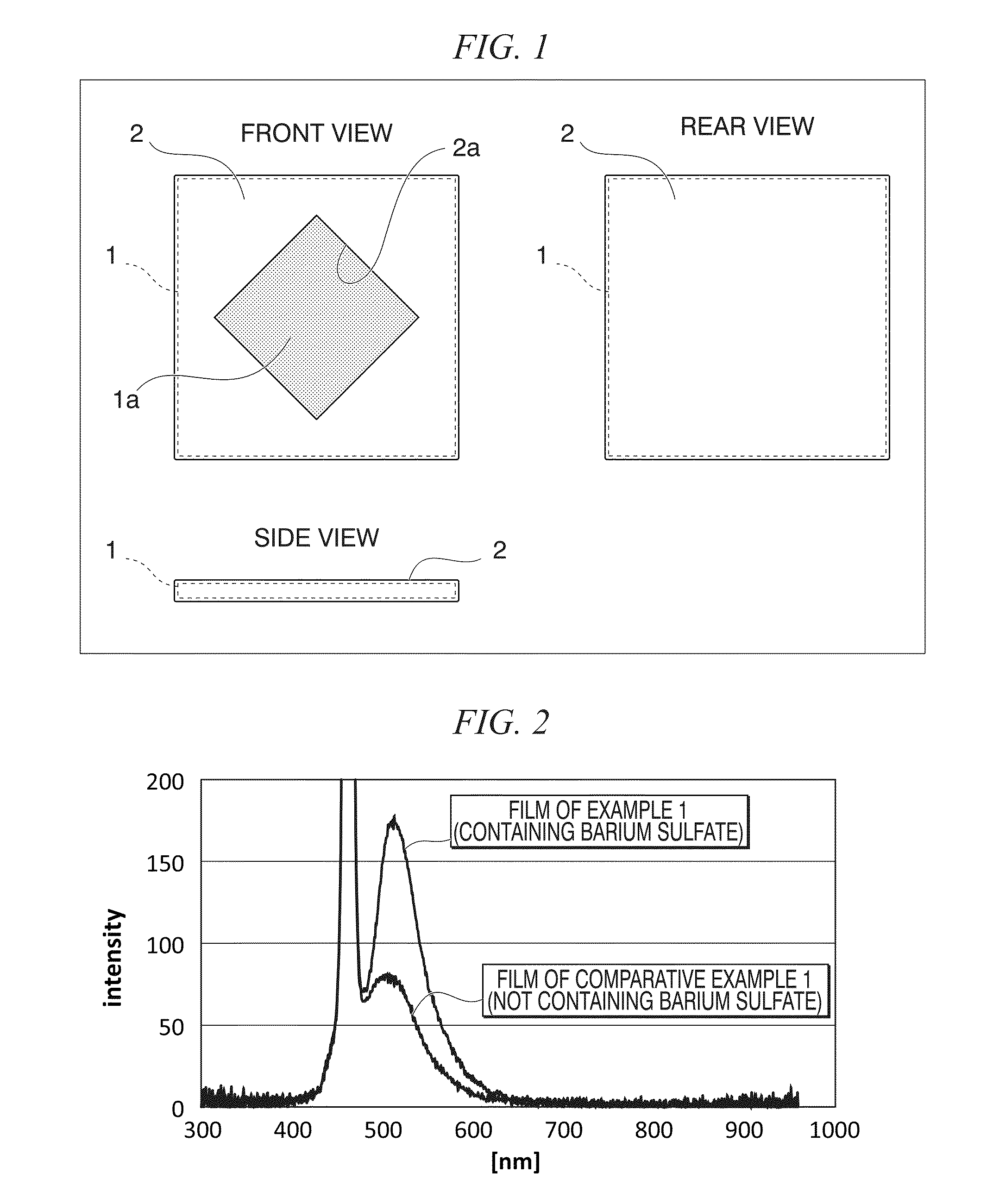

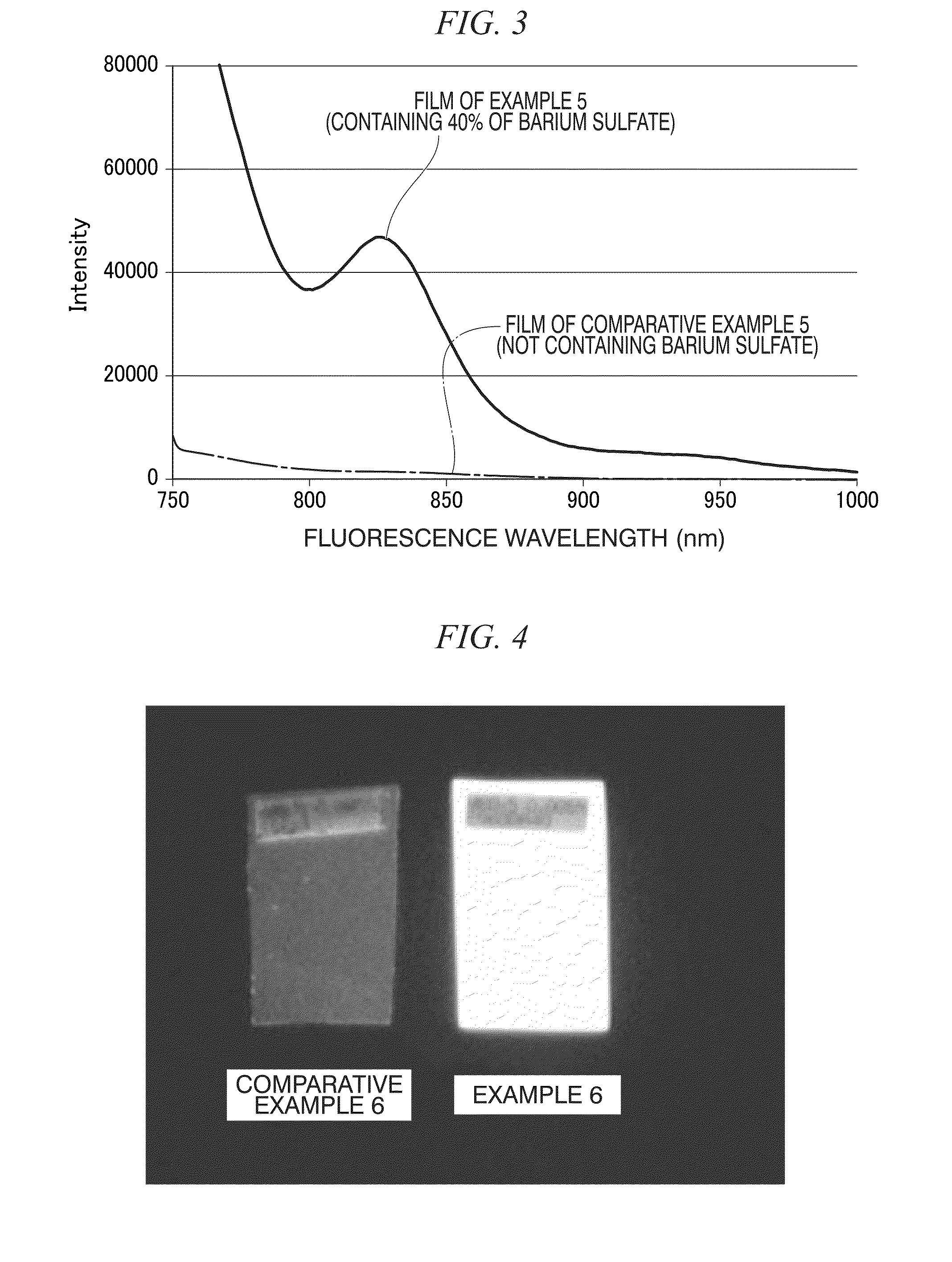

Resin composition and molded article

InactiveUS20160200970A1Opaqueness to radiationHigh emission intensityOther chemical processesPaper-money testing devicesX-rayPt element

An object of the present invention is to provide a resin composition which can be detected both by X-ray radiation and by fluorescence or phosphorescence, and a molded article obtained from the resin composition. The present invention provides a resin composition containing a light-emitting substance and a radiopaque substance; in which the light-emitting substance is a near-infrared fluorescent material or a phosphorescent material. a radiopaque substance of the resin composition is any one of barium sulfate, bismuth oxide, bismuth subcarbonate, calcium carbonate, aluminum hydroxide, tungsten, zinc oxide, zirconium oxide, zirconium, titanium, platinum, bismuth subnitrate, and bismuth. A molded article can be obtained by processing any one of the resin compositions described above.

Owner:DAINIPPON INK & CHEM INC +1

Catalyst for vinyl acetate synthesis and a preparation method thereof

ActiveCN103934030AHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystPorous carbon

The invention relates to a catalyst for vinyl acetate synthesis by use of acetylene method and a preparation method thereof, and mainly solves the problem of low activity of catalysts for vinyl acetate synthesis by use of the acetylene method in the prior art; the catalyst for vinyl acetate synthesis comprises a carrier and active components, the carrier is loaded with the active components, the active components are zinc acetate and bismuth subcarbonate, the catalyst comprises 90-180g / L of the zinc acetate and 0.1-0.3g / L of the bismuth subcarbonate, the carrier of the catalyst is a porous carbon material, the pore volume of the porous carbon material with the pore diameter of 3-10nm accounts for 20%-80% of the total pore volume, and the pore volume of the porous carbon material with the pore diameter of 30-40nm accounts for 10%-60% of the total pore volume; by use of the technical scheme, the problem of low activity of catalysts for vinyl acetate synthesis in the prior art can be well solved, and the catalyst for vinyl acetate synthesis can be used for industrial production of vinyl acetate synthesis by use of the acetylene method.

Owner:CHINA PETROLEUM & CHEM CORP +1

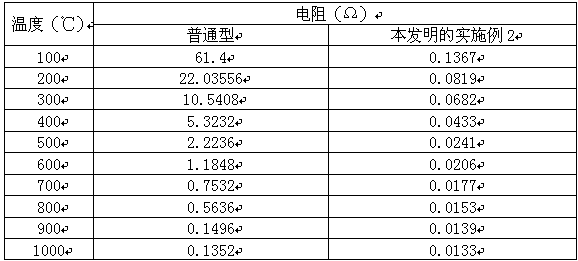

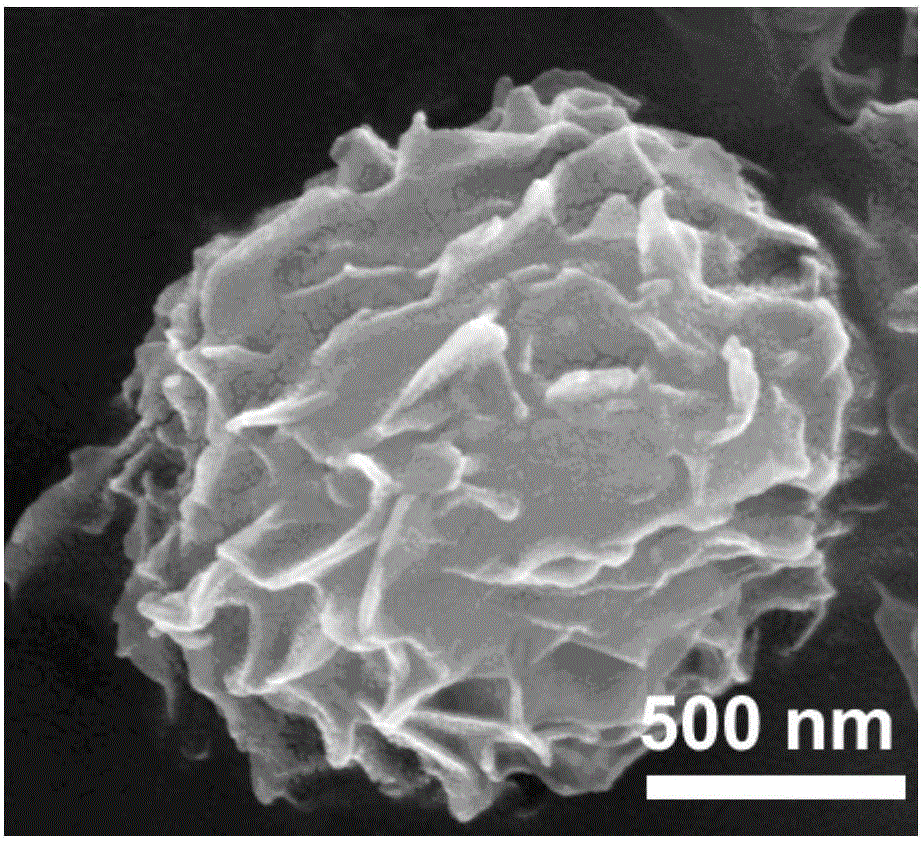

Preparation method of bismuth subcarbonate microflowers and product

The invention discloses a preparation method of bismuth subcarbonate microflowers. The method comprises the steps that tetrabutyl titanate, bismuth nitrate pentahydrate and water are mixed, so as to obtain suspension liquid, and the molar ratio of bismuth nitrate pentahydrate to tetrabutyl titanate is (11 to 13):(8 to 10); KOH is mixed with the suspension liquid, and then ammonium citrate fluid is dropwise added into the suspension liquid, so as to obtain precursor solution; the KOH concentration in the precursor solution is 0.8 to 1.2 mol / L, the bismuth nitrate pentahydrate concentration is 0.2 to 0.4 mol / L and the ammonium citrate concentration is 0.6 to 0.8 mol / L; the precursor solution is subjected to hydrothermal reaction for 18 to 22 h at 190 to 210 DEG C, and the bismuth subcarbonate microflowers are obtained through after treatment. The bismuth subcarbonate microflowers prepared are formed by staggering two-dimensional nano sheets, the average diameter is 5 to 15 micrometers, and the specific surface area is large. Bismuth subcarbonate has obvious degradation effect on toxic organic pollutants, and has a wide application prospect in terms of environmental management.

Owner:ZHEJIANG UNIV

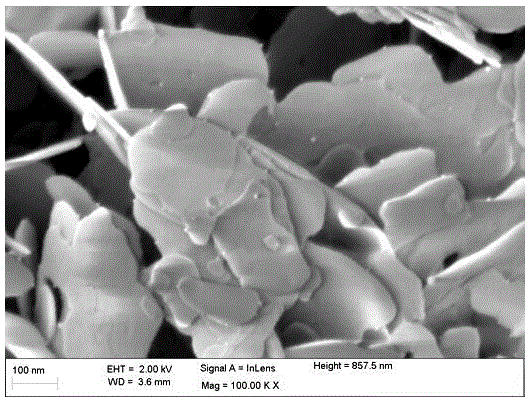

Method used for preparing subsize bismuth subcarbonate via hydrothermal method

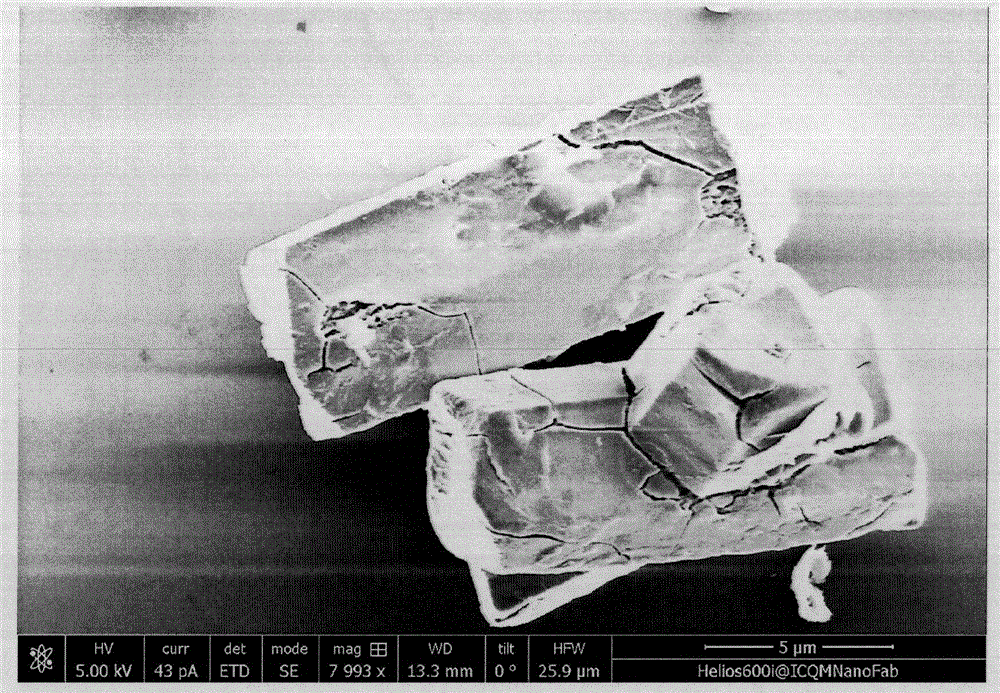

InactiveCN105019012ALow priceAchieve growthPolycrystalline material growthFrom normal temperature solutionsReaction temperatureCarbonate

The invention discloses a method used for preparing subsize bismuth subcarbonate crystal sheets via hydrothermal method. The method comprises following steps: a bismuth salt and a carbonate / bicarbonate are dissolved in water at a certain ratio so as to obtain bismuth subcarbonate crystal nucleus, wherein a template can be added optionally; an obtained mixture is delivered into a hydrothermal reaction vessel, and is reacted for a certain period of time at a certain temperature so as to obtain bismuth subcarbonate crystal sheets; the bismuth subcarbonate crystal sheets are cooled, and are subjected to impurity removing and drying so as to obtain powdery high-purity size-controllable bismuth subcarbonate crystal sheets. The process flow is simple; cost is relatively low; nano-grade and micron-grade bismuth subcarbonate crystals with different size and morphology can be prepared via controlling reaction temperature and time; the method possesses commercial exploitation value; the prepared bismuth subcarbonate can be applied to the field of medicine, or can be taken as a photocatalyst in organic pollutant degradation, and can also be taken as an analysis reagent, a pearlescent plastic additive, a cosmetic adhesive agent, and an enamel fluxing agent.

Owner:燕园众欣纳米科技(北京)有限公司

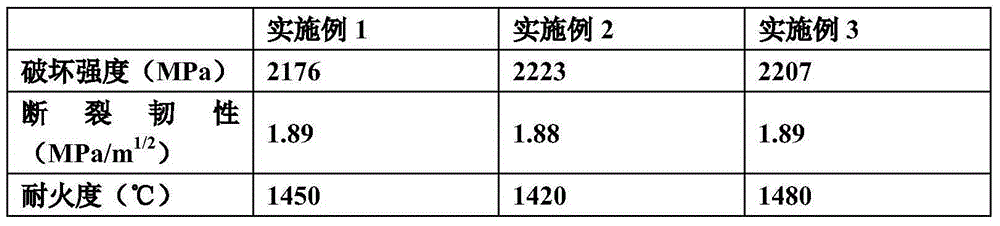

High-performance ceramic and preparation method thereof

The invention discloses high-performance ceramic and a preparation method thereof. The high-performance ceramic is prepared from raw materials in parts by weight as follows: 6-8 parts of zinc oxide, 30-40 parts of high-potassium sand, 3-5 parts of ultrafine molybdenum powder, 1-2 parts of cobalt sulfide, 40-60 parts of hauynite, 1-3 parts of sodium bicarbonate, 3-5 parts of tungsten diselenide, 8-15 parts of Suzhou clay, 0.5-1 part of tartaric acid, 1-2 parts of bismuth subcarbonate, 3-5 parts of tin antimony oxide, 4-6 parts of carboxymethylcellulose, 1-3 parts of nano magnesium titanate, 1-2 parts of polyethylene wax, 6-7 parts of a reinforcing agent and a proper amount of absolute ethyl alcohol. The ceramic is low in production cost, excellent in comprehensive performance, high in strength and good in chemical stability; components such as the hauynite, the ultrafine molybdenum powder and the like are added, so that the ceramic is good in fire resistance and low in thermal expansion rate; components such as the tungsten diselenide, tin antimony oxide, the nano magnesium titanate and the like are added, thus, the strength and the fire resistance of the ceramic are further enhanced, and the ceramic has the reliable safety during usage.

Owner:FOSHAN LANTU TECH CO LTD

Method for manufacturing low-expansion glass-ceramics by high silicon-iron tailings

A method for manufacturing low-expansion glass-ceramics by high silicon-iron tailings comprises the step of perparing a low-expansion glass-ceramics batch which comprises the following materials in parts by weight: 40-45 parts of 80-mesh high-silicon iron tailings, 50-55 parts of 100-mesh quartz sand, 10-15 parts of 100-mesh alumina, 10-15 parts of lithium carbonate, 3-6 parts of zinc oxide, 3-6 parts of barium selenate, 2-5 parts of rare-earth cerium oxide powder, 1-4 parts of lithium zirconate, 2-5 parts of boron nitride, 3-6 parts of praseodymium chloride, 0.2-0.5 part of beryllia, 0.5-0.9 part of bismuth subcarbonate and 0.1-0.4 part of sodium antimonate. The invention aims to provide the method for manufacturing low-expansion glass-ceramics by high silicon-iron tailings, the method can reduce environmental pollution and lower manufacturing cost, and the obtained glass-ceramics is low in thermal expansion coefficient, high in thermal stability and softening temperature and very good in thermal shock resistance.

Owner:BEIJING QING MAI HUA QING HLDG GRP CO LTD

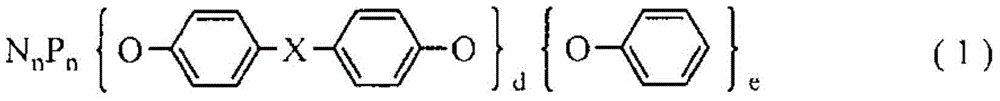

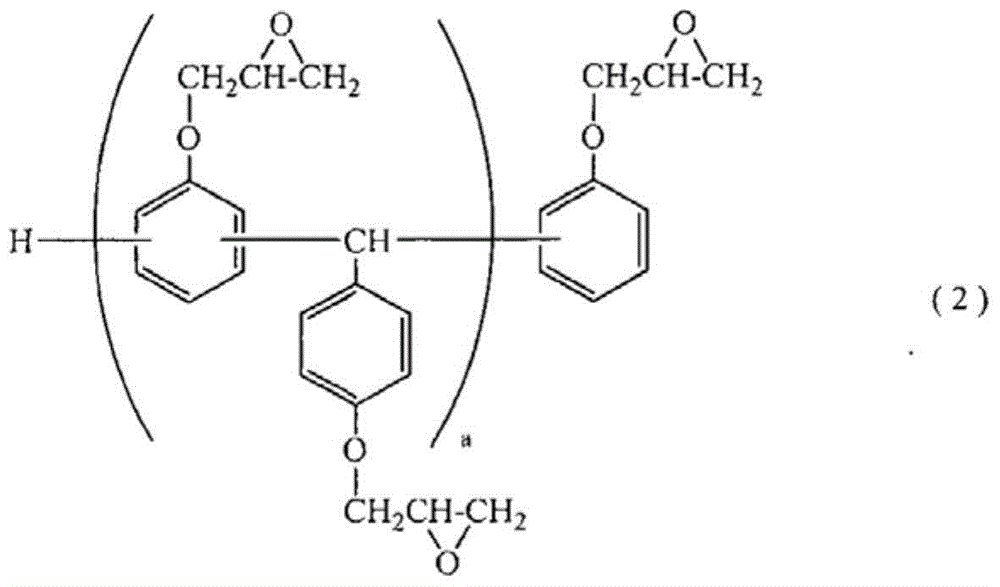

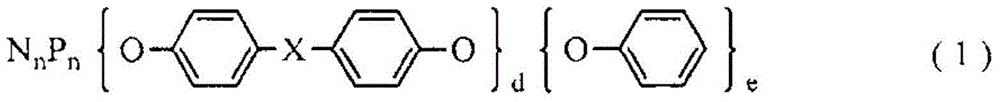

Epoxy resin compound for sealing semiconductor and semiconductor device

ActiveCN104629259AImprove flame retardant performanceExcellent high temperature storage reliabilitySemiconductor/solid-state device detailsSolid-state devicesEpoxyPhosphoric Acid Esters

The invention provides an epoxy resin compound for sealing a semiconductor and a semiconductor device, wherein the plating adhesiveness of CuLF with Ag is excellent even stored for a long time at a high temperature of 175-250 DEG C. Meanwhile, no Cu line, Cu line / AL cushion or broken line exists, and the corrosion reliability is excellent. The epoxy resin compound for sealing the semiconductor is characterized by comprising the following parts as essential ingredients: (A) epoxy resin, (B) curing agent, (C) inorganic filling agent, (D) potassium oxide / bismuth subcarbonate, and (E) phosphazene, wherein the compound does not contain bromide, red phosphorous, phosphoric acid ester and antimony compounds basically.

Owner:SHIN ETSU CHEM IND CO LTD

Environment-friendly compound fertilizer with soil restoration function and preparation method of environment-friendly compound fertilizer

InactiveCN107382526AAchieve fixHigh in nutrientsBio-organic fraction processingAnimal corpse fertilisersStarch xanthateCadmium Cation

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

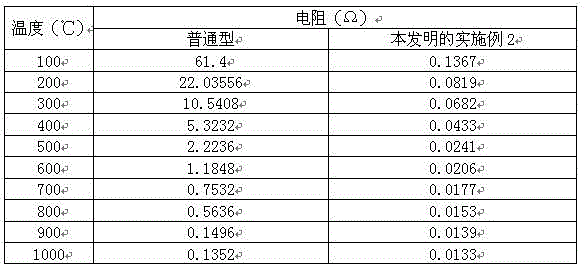

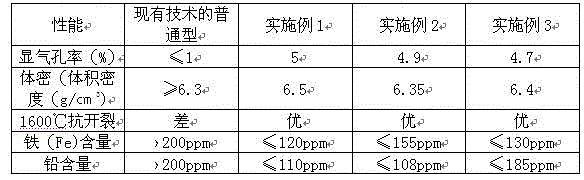

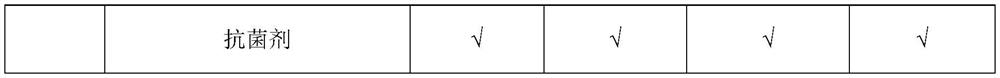

Stannic oxide electrode ceramic material as well as preparation method thereof

The invention relates to a stannic oxide electrode ceramic material as well as a preparation method thereof. The stannic oxide electrode ceramic material comprises the following components in parts by weight: 100 parts of stannic oxide, 0.1-0.3 part of copper oxide as an additive, 0.1-0.5 part of zinc oxide, 1.2-1.5 parts of antimonous oxide, 0.8-1.5 parts of bismuth subcarbonate and 3-5 parts of a sodium silicate aqueous solution. The preparation method comprises the following steps: fully mixing and stirring the raw materials; molding at a high pressure in isostatic pressing; sintering at a high temperature of 1500 DEG C by adding inert gas to prepare a stannic oxide electrode ceramic body with high density (over 6.5); and then machining to prepare a stannic oxide electrode. The stannic oxide electrode is an indispensable electrode material for producing high performance optical glass. The preparation method provided by the invention is simple in process, easy to operate, short in production period, low in production cost, stable and reliable in product quality and suitable for industrial production.

Owner:HUBEI DERUI SITONG TECH

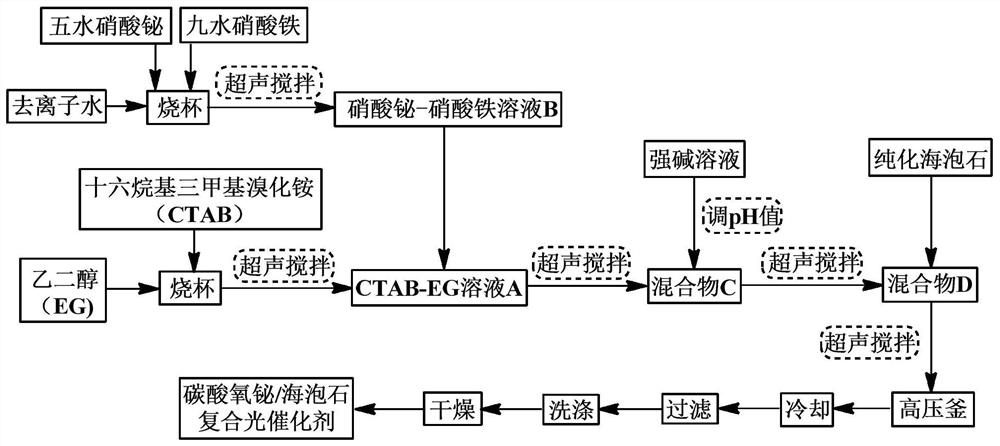

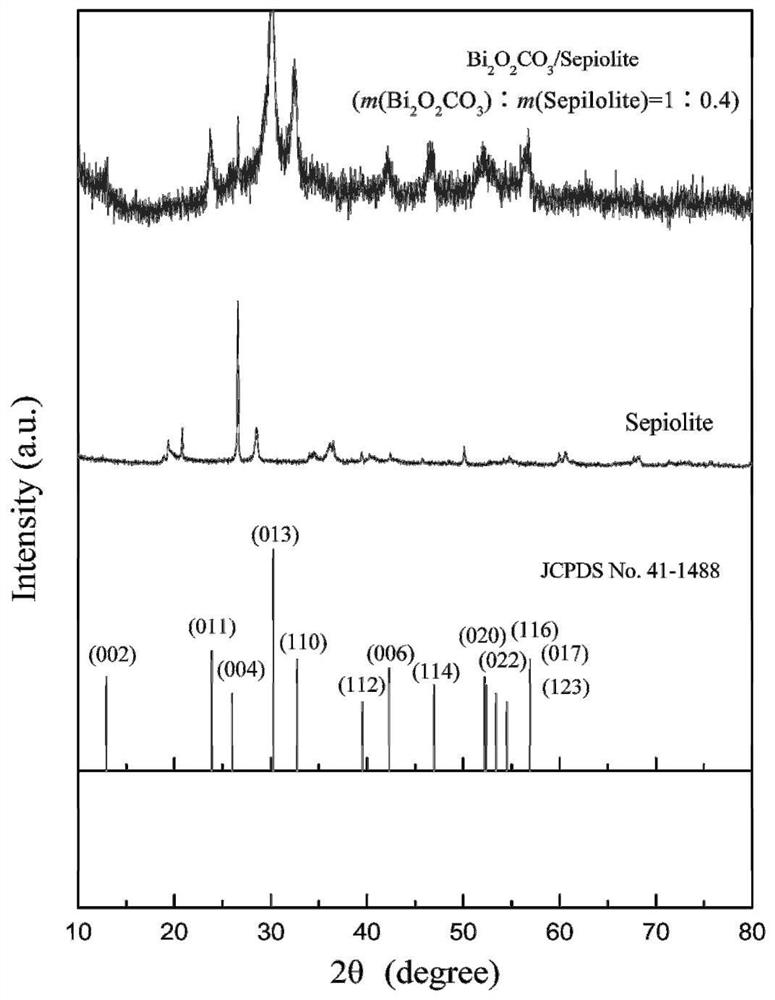

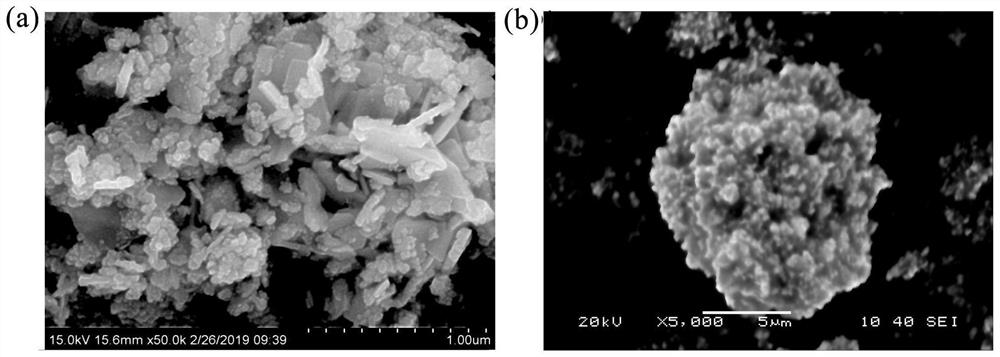

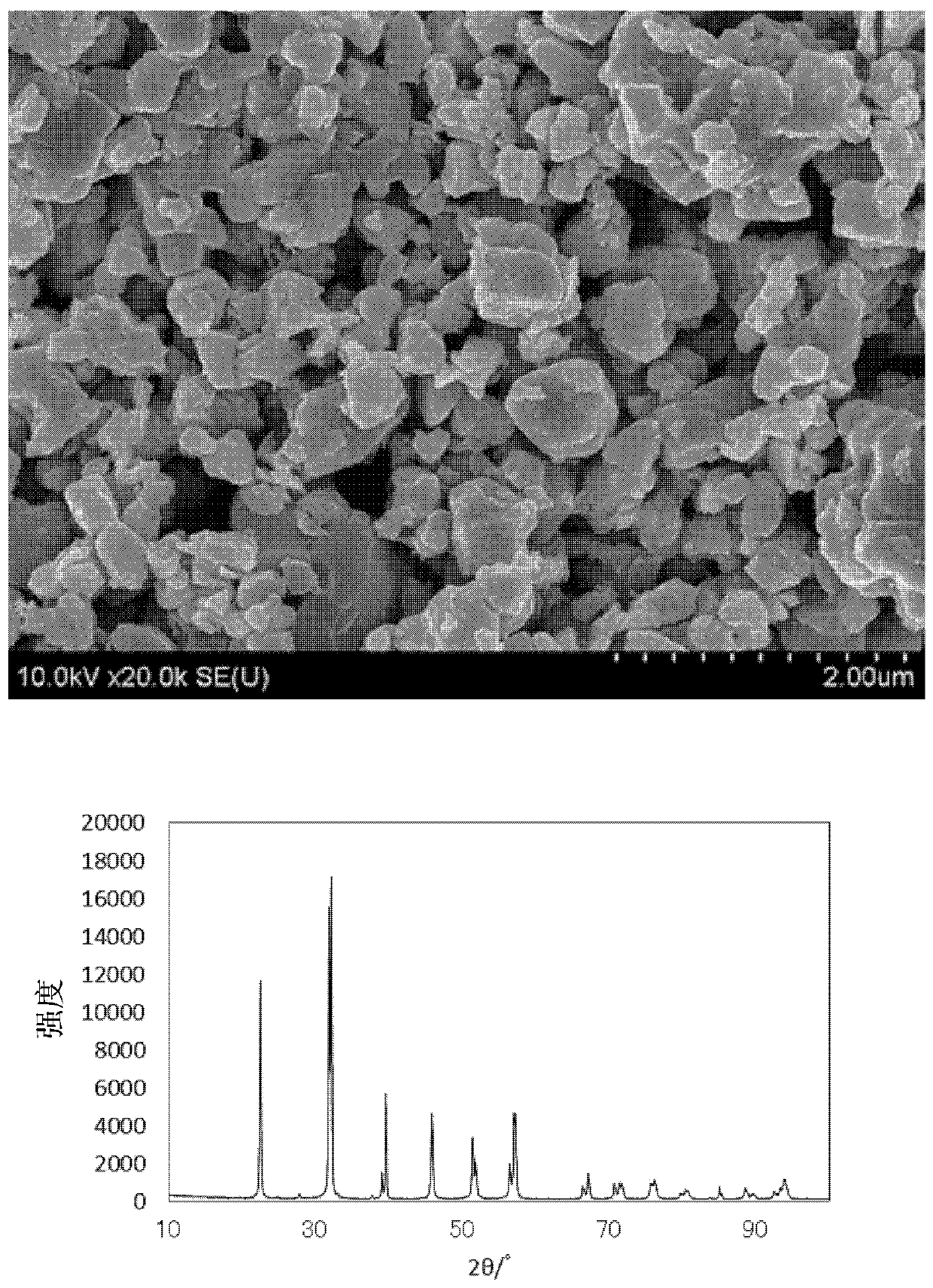

Bismuth subcarbonate/sepiolite composite photocatalyst and preparation method thereof

ActiveCN112774706AEffective control of formation speedControl formation speedPhysical/chemical process catalystsWater/sewage treatment by irradiationMeth-Photocatalytic degradation

The invention relates to a bismuth subcarbonate / sepiolite composite photocatalyst and a preparation method thereof. The preparation method comprises the following steps: dissolving cetyltrimethylammonium bromide (CTAB) in ethylene glycol (EG) to prepare a CTAB-EG solution serving as a template agent and a reducing agent, adding a bismuth nitrate-ferric nitrate solution, adjusting the pH value of the mixed solution by using a strong alkali solution, adding purified sepiolite, fully conducting mixing, transferring the treated system into a polytetrafluoroethylene autoclave, and carrying out hydrothermal reaction to generate the porous bismuth subcarbonate / sepiolite composite photocatalyst with controllable morphology. EG or CTAB is oxidized and decomposed under a hydrothermal condition to generate carbonate, and bismuth subcarbonate is loaded and grown on sepiolite under the combined action of the surface activity and template action of CTAB and the interfacial effect of sepiolite, so that the structure and morphology of the bismuth subcarbonate can be effectively controlled, the recombination rate of an energy band gap and a photon-generated carrier is reduced, and the absorption and utilization rate of visible light and the adsorption performance on organic matters are improved, so that the photocatalytic degradation performance and the mineralization capability are improved.

Owner:HUNAN UNIV OF SCI & TECH

Porous silicon carbide ceramic and low-temperature preparation method

ActiveCN111548186AHigh porosityImprove bending strengthCeramicwareCarbide siliconAmmonium perchlorate

The invention relates to the technical field of ceramic materials, and discloses a porous silicon carbide ceramic, which comprises the following raw materials: a main material, a dispersant, a binderand deionized water. The main material comprises the following components in parts by weight: 80-90 parts of silicon carbide, 1-5 parts of a sintering aid, 4-10 parts of a pore-forming agent and 5-10parts of an additive; wherein the sintering aid is potassium oxide, the pore-forming agent is a mixture of ammonium perchlorate and bismuth subcarbonate, and the additive is a mixture of calcium oxideand titanium dioxide. The porous silicon carbide ceramic provided by the invention not only has lower sintering temperature, but also has higher porosity and better bending strength, so that the preparation of the porous silicon carbide ceramic with excellent performance is realized, and the energy consumption is reduced.

Owner:宁波欧翔精细陶瓷技术有限公司

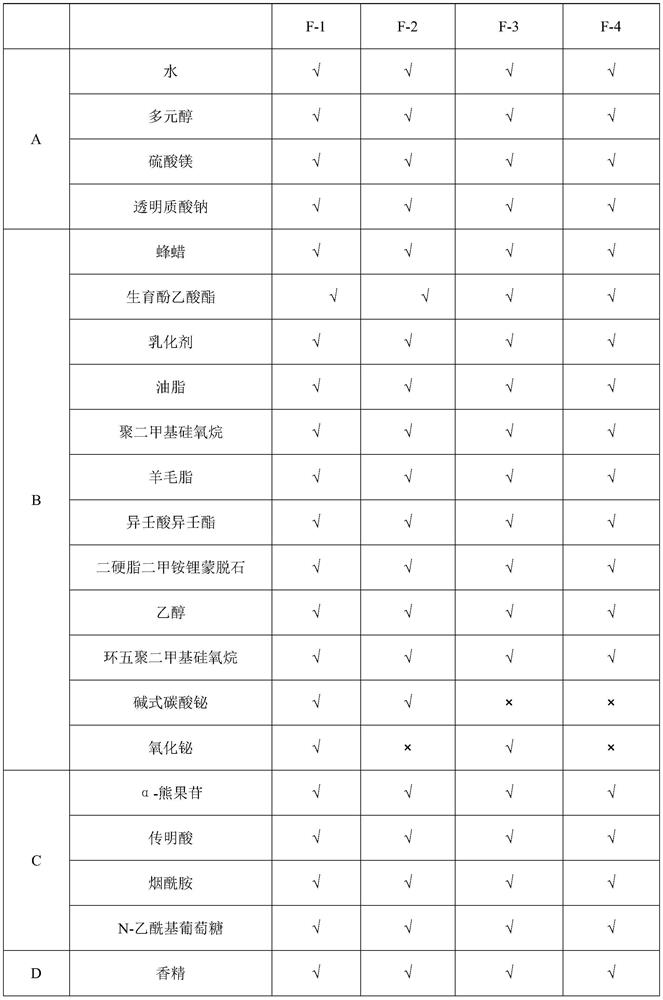

Whitening cream with self-protection function and preparation method thereof

PendingCN113768810AImprove protectionProtect against blue light radiationCosmetic preparationsToilet preparationsDimethyl siloxaneAntibacterial agent

The invention discloses whitening cream with the self-protection function and a preparation method thereof. The whitening cream comprises the following components in percentage by weight of 0.5-1% of bismuth subcarbonate, 0.5-1% of bismuth oxide, 1.5-2% of alpha-arbutin, 1-1.5% of nicotinamide, 2-2.8% of tranexamic acid, 1-5% of N-acetylglucose, 1.6-2.5% of beewax, 1.3-1.8% of a thickening agent, 7-15% of polyhydric alcohol, 0.2-0.5% of an antibacterial agent, 0.1-0.15% of essence, 0.2-0.5% of tocopheryl acetate, 2-2.7% of an emulsifier, grease, 2-3% of polydimethylsiloxane, 4-6% of cyclopentasiloxane, 0.03-0.08% of sodium hyaluronate, 0.7-1% of magnesium sulfate, 0.8-1.3% of wool fat, 0.3-0.7% of disteardimonium hectorite, 0.5-1% of ethanol, 3-4% of isononyl isononanoate, and the balance of deionized water. The bismuth subcarbonate and the bismuth oxide used in the invention can resist visible light with different wavelengths, have a good protection effect on the whitening raw material, and can effectively form a film on the skin surface to effectively resist blue light radiation caused by electronic products and the like to the skin.

Owner:陕西恒远生物科技有限公司

A kind of tin dioxide electrode ceramic material and preparation method thereof

The invention relates to a stannic oxide electrode ceramic material as well as a preparation method thereof. The stannic oxide electrode ceramic material comprises the following components in parts by weight: 100 parts of stannic oxide, 0.1-0.3 part of copper oxide as an additive, 0.1-0.5 part of zinc oxide, 1.2-1.5 parts of antimonous oxide, 0.8-1.5 parts of bismuth subcarbonate and 3-5 parts of a sodium silicate aqueous solution. The preparation method comprises the following steps: fully mixing and stirring the raw materials; molding at a high pressure in isostatic pressing; sintering at a high temperature of 1500 DEG C by adding inert gas to prepare a stannic oxide electrode ceramic body with high density (over 6.5); and then machining to prepare a stannic oxide electrode. The stannic oxide electrode is an indispensable electrode material for producing high performance optical glass. The preparation method provided by the invention is simple in process, easy to operate, short in production period, low in production cost, stable and reliable in product quality and suitable for industrial production.

Owner:HUBEI DERUI SITONG TECH

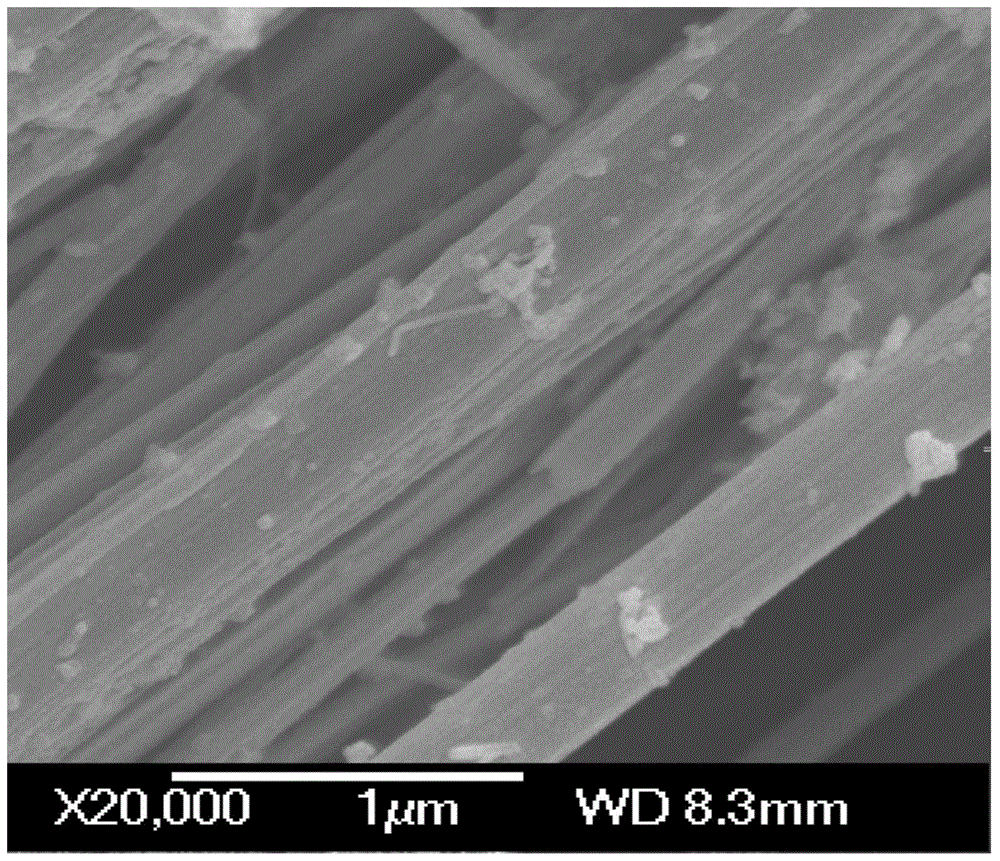

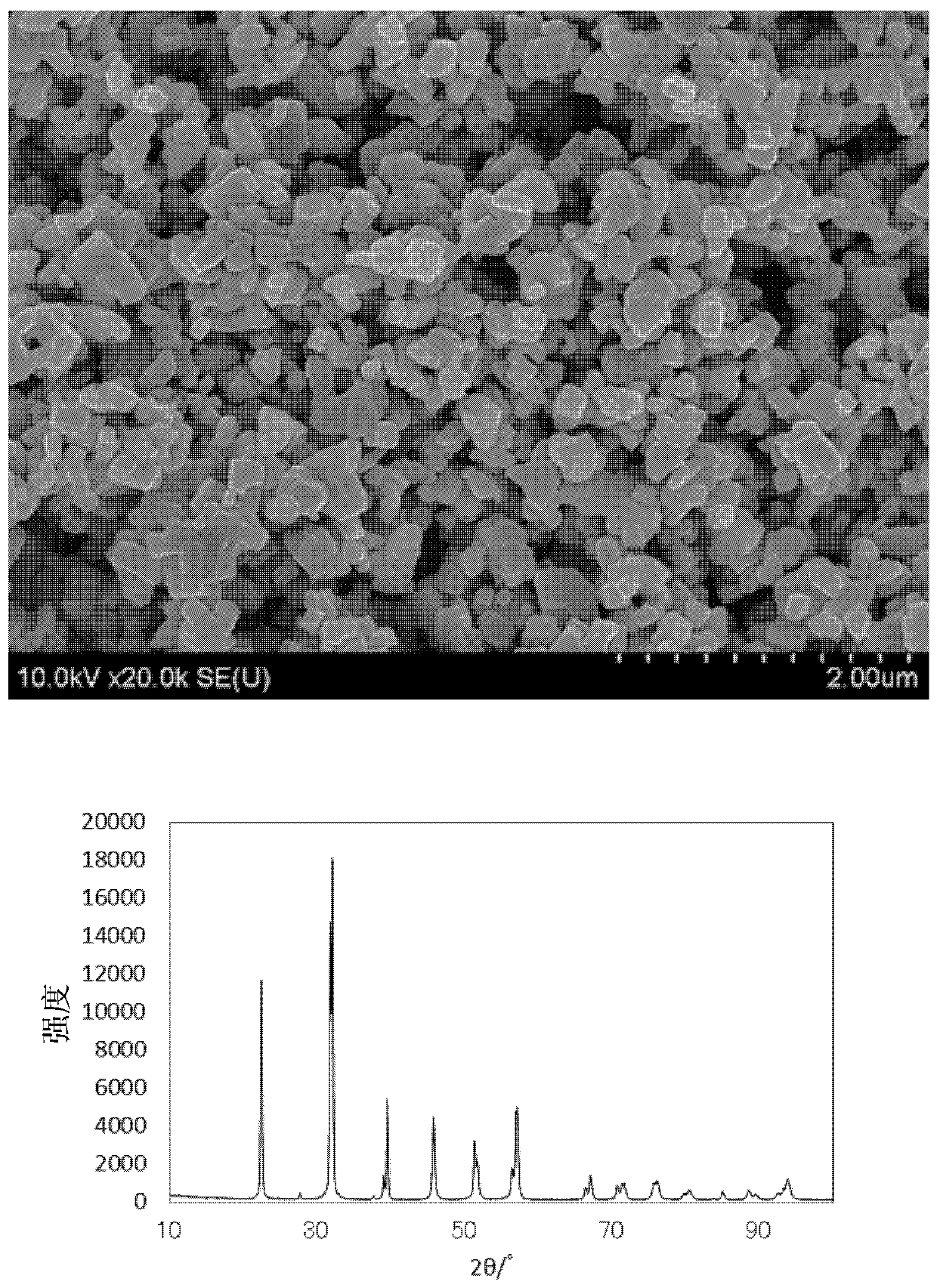

Nickel manganese double-metal hydroxide composite material, photocatalyst and electrode material

ActiveCN106847526AImprove electrochemical performanceImprove photocatalytic performancePhysical/chemical process catalystsHybrid capacitor electrodesManganeseRedox

The invention provides a nickel manganese double-metal hydroxide composite material. The nickel manganese double-metal hydroxide composite material comprises bismuth subcarbonate and nickel manganese double-metal hydroxide loaded on the surface of bismuth subcarbonate. Compared with the prior art, the nickel manganese double-metal hydroxide composite material adopts bismuth subcarbonate as a carrier, the surface of bismuth subcarbonate is loaded with nickel manganese double-metal hydroxide, and bismuth subcarbonate is adopted as a substrate for nickel manganese double-metal hydroxide to grow, and can guide and control the shape and structure of nickel manganese double-metal hydroxide; moreover, tight connection of bismuth subcarbonate and nickel manganese double-metal hydroxide can more fully and more quickly provide an ion channel for an redox reaction; under the joint action of bismuth subcarbonate and nickel manganese double-metal hydroxide, the obtained composite material can simultaneously have good electrochemical performance and photocatalytic performance. The invention further provides an electrode material and a photocatalyst.

Owner:CHONGQING UNIV

A kind of preparation method of bismuth oxycarbonate nanobelt

The invention provides a preparation method of a bismuth subcarbonate nanoribbon. The method comprises the steps that Bi(NO3)3.5H2O serves as the raw material and is added to a mixed solution of ethanolamine and water, and magnetic stirring and ultrasonic treatment are conducted; obtained white suspension is transferred to a hydrothermal reaction kettle for a reaction, after the reaction is completed, cooling is conducted, white precipitate in the reaction kettle is taken out, washed and dried, and the bismuth subcarbonate nanoribbon is obtained. The method has the advantages that devices are simple, the temperature ranging from 120 DEG C to 140 DEG C is low, and environmental protection is achieved due to the fact that the synthesis reaction is conducted in a sealed system; a chemical reagent capable of being decomposed to generate CO2 does not need to be introduced to serve as the raw material, powder is synthesized in one time through a solvent-thermal method, high-temperature calcination is not needed, synthesized powder is high in purity, high in crystallinity and regular in morphology, and the preparation method is simple in technology, high in efficiency, low in energy consumption, low in cost and environmentally friendly.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

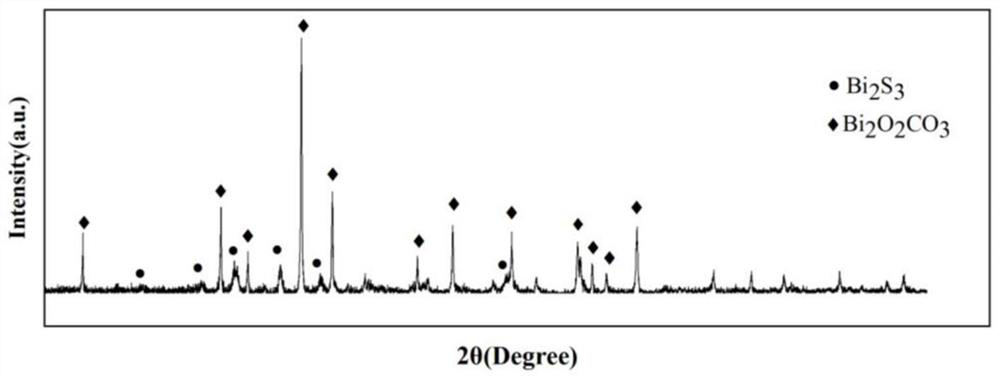

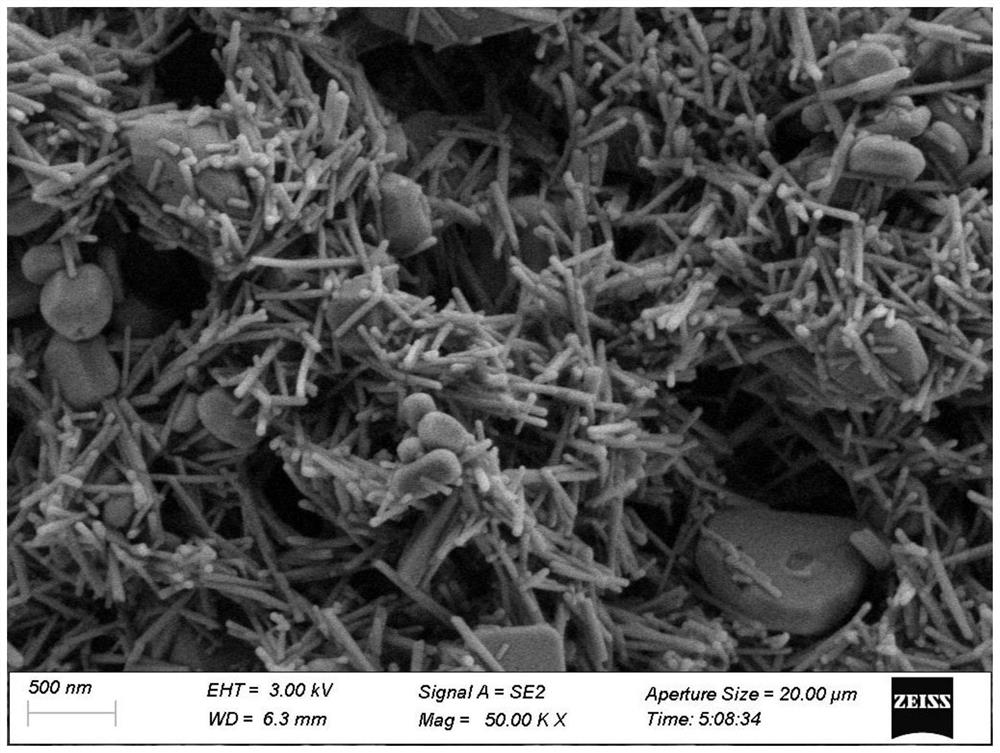

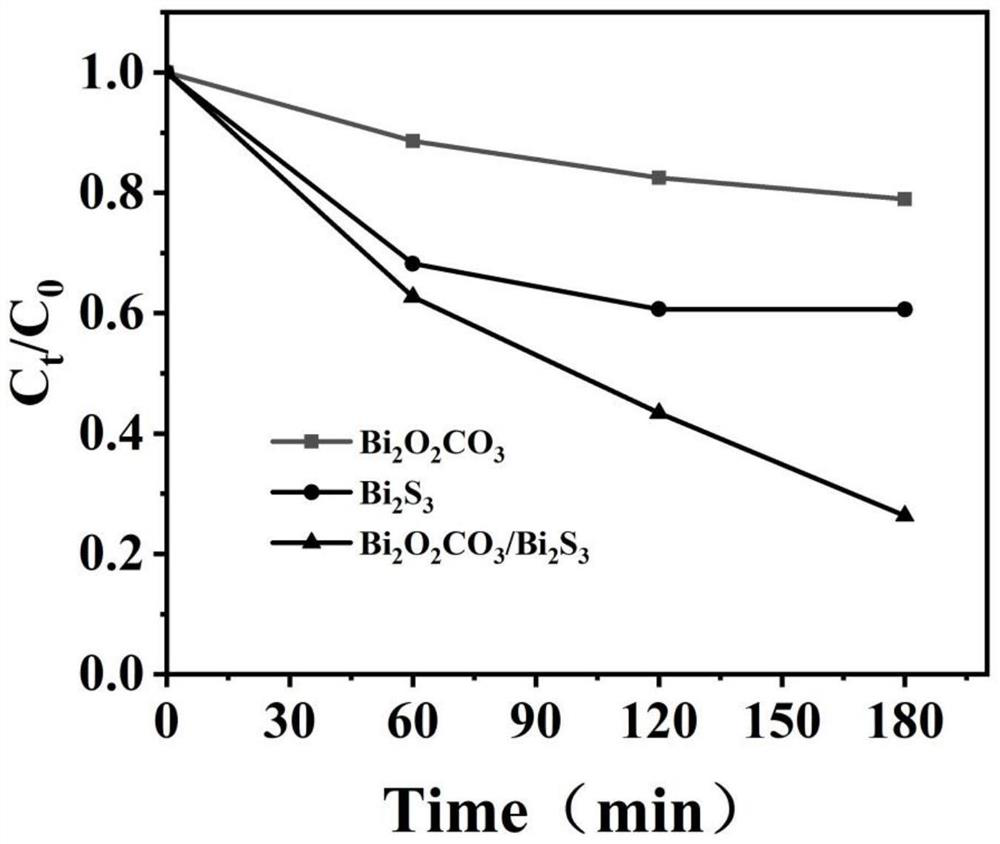

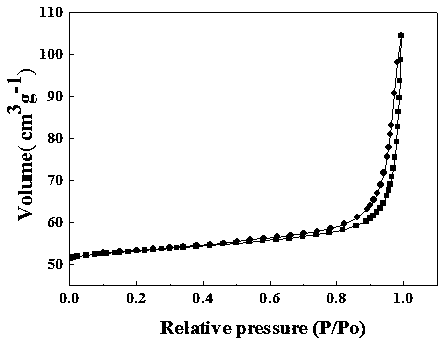

Preparation method of bismuth subcarbonate-bismuth sulfide heterostructure photocatalytic material

PendingCN114210353ASimple processLow costPhysical/chemical process catalystsWater/sewage treatment by irradiationBismuth sulfideAlcohol

The invention discloses a preparation method of a bismuth subcarbonate-bismuth sulfide heterostructure photocatalytic material, which comprises the following steps: (1) adding urea into deionized water, stirring and dissolving, then adding Bi (NO3) 3.5 H2O, continuously stirring, and then adding sodium sulfide to obtain a mixed solution; and (2) stirring the mixed solution, then carrying out a closed reaction, after the reaction is completed, naturally cooling to room temperature, and carrying out centrifugation, water washing, alcohol washing and drying at room temperature on a product to obtain the bismuth subcarbonate-bismuth sulfide heterostructure photocatalytic material. The preparation method can effectively solve the problem of insufficient response to ultraviolet light when bismuthyl carbonate is used as a photocatalytic material, and compared with other bismuthyl carbonate-bismuth sulfide heterojunctions, the preparation method is simple, the cost is low, and large-scale production is easy.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

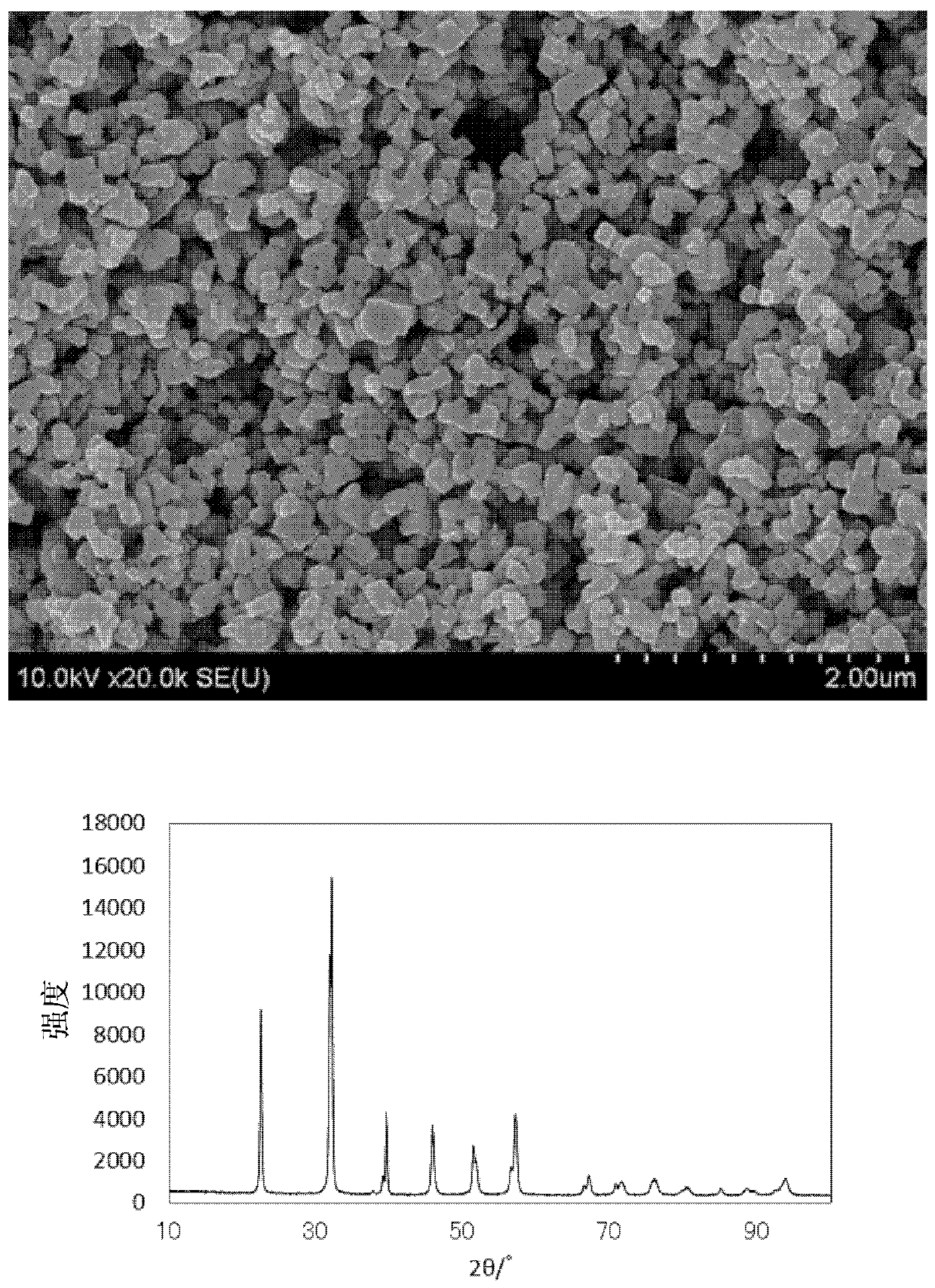

Photocatalyst for treating dye in high-salt wastewater and preparation method thereof

ActiveCN107684926BLarge apertureLarger than surfacePhysical/chemical process catalystsWater/sewage treatment by irradiationPtru catalystOrganic solvent

The invention discloses a photocatalyst for treating dyes in high-salt wastewater and a preparation method thereof, and belongs to the field of photocatalysis. The photocatalyst of the present invention uses porous graphite phase carbonized nitrogen nanosheets as a carrier, and the porous graphite phase carbonized nitrogen nanosheets carrier is loaded with bismuth oxycarbonate nanoparticles. The catalyst obtained by the invention can catalytically treat dyes in high-salt wastewater under visible light, and has the advantages of response under visible light, low cost and high degradation rate. In the preparation process of the catalyst, graphite phase carbonized nitrogen after hydrothermal treatment is used, directly ground and roasted with bismuth nitrate, so that bismuth oxycarbonate particles can be generated in situ on the surface of the carbonized nitrogen carrier, and the strong interaction between the two is used to improve the optical efficiency. Catalytic reaction stability of the catalyst. In addition, no organic solvent is introduced during the preparation process, which is environmentally friendly, has a simple process, and is conducive to industrial production.

Owner:BINZHOU UNIV

Method for producing bismuth iron oxide

The present invention is an industrially advantageous method for producing a bismuth iron oxide which is represented by BiFeO3 and which has a low amount of impurities. The method for producing the bismuth iron oxide is characterized by comprising: a wet pulverization step for obtaining pulverized and mixed raw material powder by wet-pulverizing and mixing, in the presence of a medium and an aqueous dispersion medium, bismuth subcarbonate powder and iron compound powder; and a firing step for obtaining a bismuth iron oxide represented by BiFeO3 by firing, as a raw material to be fired, the pulverized and mixed raw material powder at 450-700 DEG C.

Owner:NIPPON CHECMICAL IND CO LTD

Medicine for treating gastropathy

InactiveCN101773631ATo achieve the purpose of treating both the symptoms and the root causesDigestive systemMammal material medical ingredientsSodium bicarbonateHealed ulcer

The invention relates to a medicine for treating gastropathy, which is characterized in that the medicine contains the following components in parts by weight: 10.5-33.7 parts of elecampane, 10.5-33.7 parts of chicken gizzard membrane, 10.5-33.7 parts of Fructus piperis Longi, 10.5-33.7 parts of Fructus evodiae, 10.5-33.7 parts of lesser galangal, 7.0-22.5 parts of cassia bark, 25-80 parts of bismuth subcarbonate, 15.2-48.5 parts of sodium bicarbonate and 180.5-400.3 parts of starch. Elecampane, chicken gizzard membrane, Fructus piperis Longi, Fructus evodiae, lesser galangal and cassia bark are taken according to the parts by weight and are crushed into fine powder, and then bismuth subcarbonate, sodium bicarbonate and starch are added according to the parts by weight and are evenly mixed to obtain. The medicine can obviously and rapidly relieve epigastric pain, can gradually heal ulcers and causes no relapse after the medicine is stopped being taken. The medicine has good effect on especially ulcers and stomachache caused by deficient cold of spleen and stomach, and the effectiveness reaches 84 percent.

Owner:QINGHAI YIXIN PHARMA

Subcutaneous positioning liquid

The invention provides subcutaneous positioning liquid, which is mainly prepared by the following raw materials in parts by weight: 18-42 parts of chromophore, 12-25 parts of bioactive glass, 5-8 parts of alcohol, 5-8 parts of glycerol, 4-10 parts of polyamide resin, 1-5 parts of polyvinyl alcohol, 1-5 parts of bismuth subcarbonate, 0.5-2 parts of isoindolinone, 0.3-0.5 part of methylcellulose, 0.1-0.8 part of sodium carboxymethyl starch and 22-75 parts of a diluent. The subcutaneous positioning liquid provided by the invention is easy to color, intensive in color and capable of avoiding easygeneration of color spots; appearance of the subcutaneous positioning liquid is not affected; the subcutaneous positioning liquid, instead of fading within a short time, automatically and gradually fading after 3-6 months; and the subcutaneous positioning liquid is low in cost and is convenient and rapid to prepare.

Owner:蔡志春

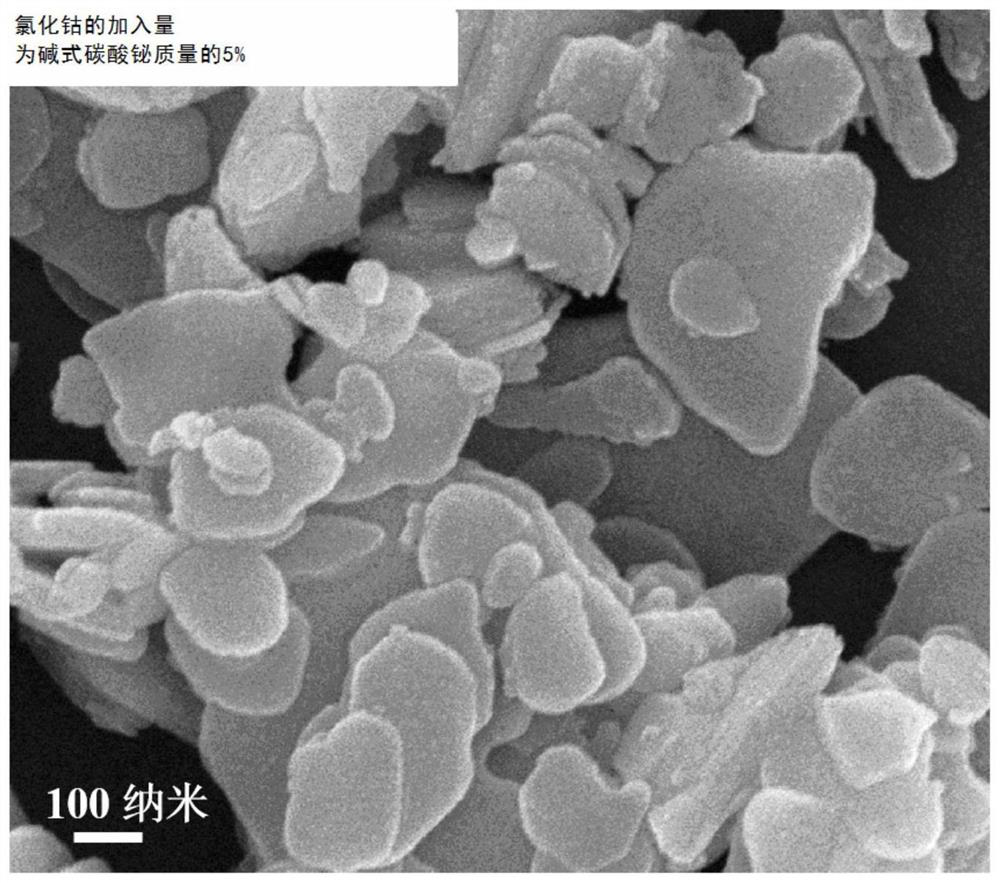

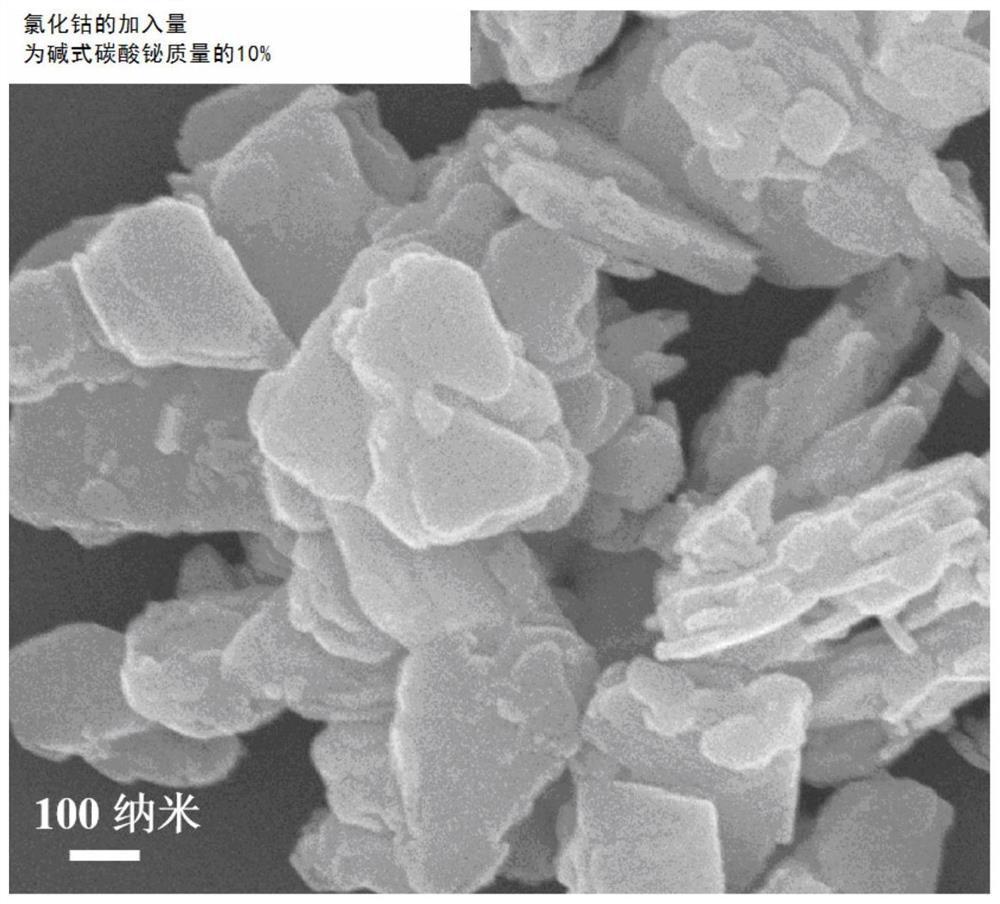

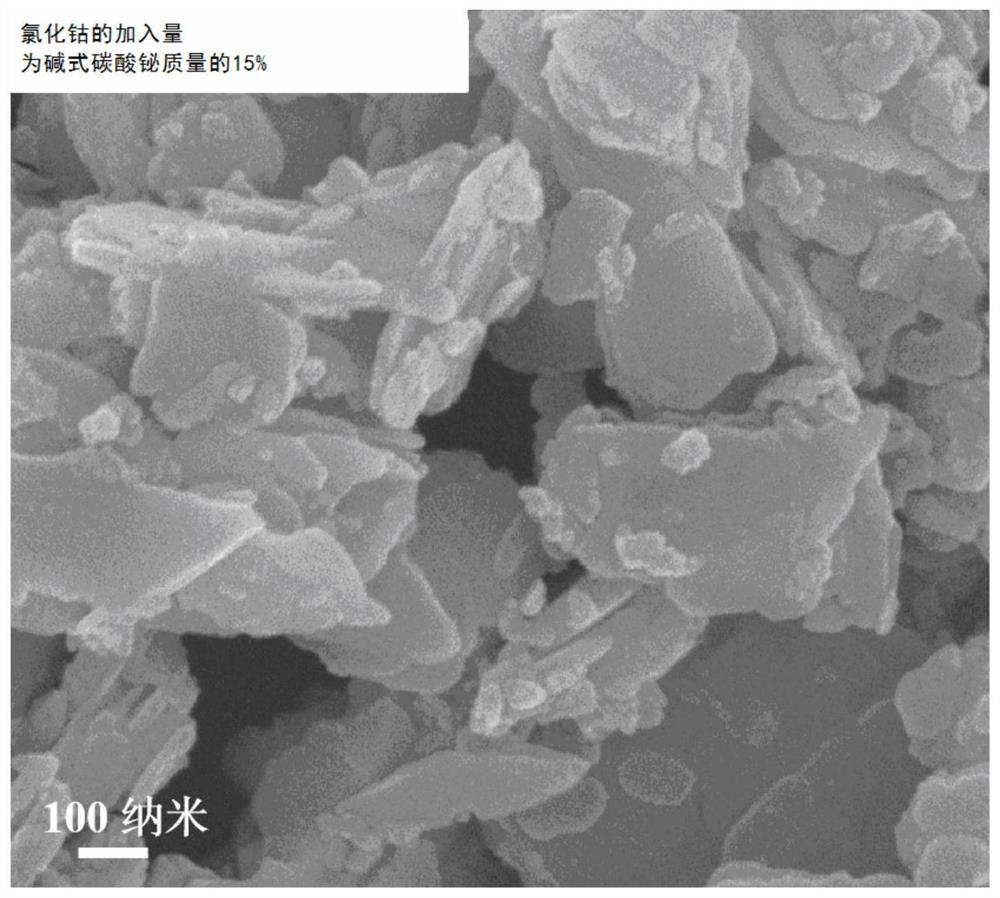

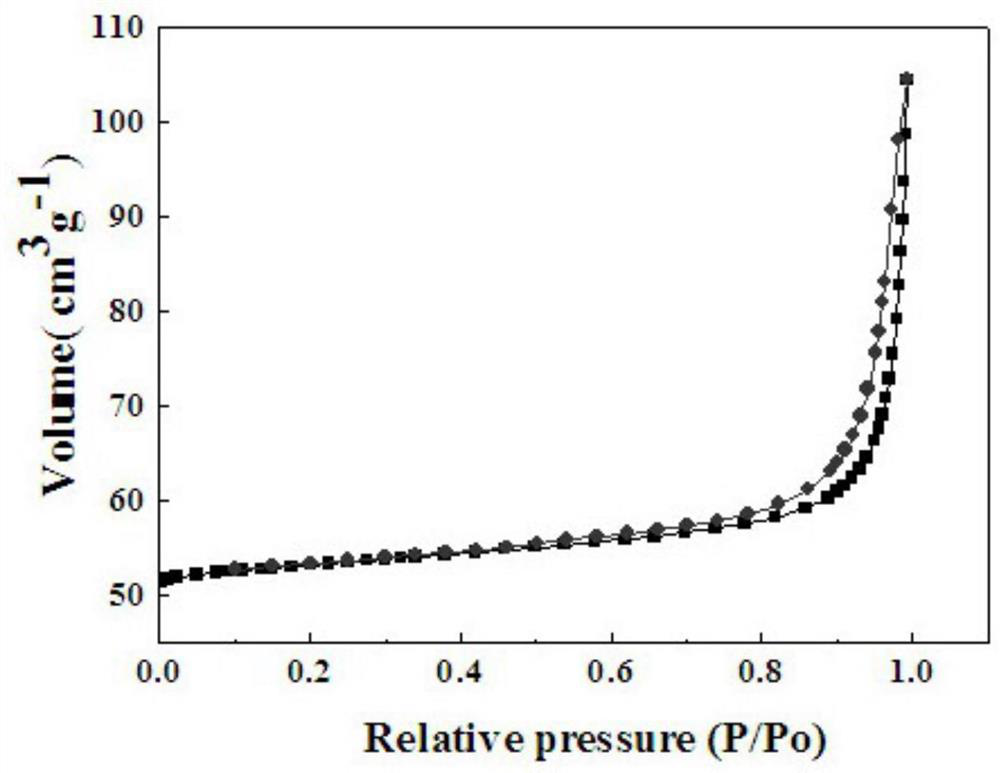

A kind of cobalt oxide-doped bismuth subcarbonate/bismuth oxychloride photocatalyst and preparation method thereof

ActiveCN106824213BBroaden the response rangePromote absorptionWater/sewage treatment by irradiationWater contaminantsPtru catalystCatalytic decomposition

Owner:SHANGHAI UNIV

Method for producing low-expansion glass-ceramics from high-silicon iron tailings

InactiveCN105481255BImprove high temperature resistanceHigh mechanical strengthThermal dilatationFerrosilicon

Owner:BEIJING QING MAI HUA QING HLDG GRP CO LTD

Powder explosion suppressant for suppressing titanium powder explosion and preparation method of powder explosion suppressant

The invention relates to a powder explosion suppressant for suppressing titanium powder explosion and a preparation method of the powder explosion suppressant, and belongs to the technical field of explosion suppressants. The powder explosion suppressant for suppressing titanium powder explosion is composed of a plurality of powder materials, and the powder explosion suppressant comprises the following components in percentage by weight: 13.2%-26.5% of ammonium dihydrogen phosphate, 17.4%-30.9% of sodium pyrophosphate decahydrate, 15.3%-28.2% of bismuth subcarbonate, 10.6%-23.7% of stannous chloride, 3.9%-8.6% of sodium methyl silicate and 5.8%-10.2% of sodium hexametaphosphate. According to the powder explosion suppressant for inhibiting the titanium powder explosion, all the components are matched according to a special proportion, so that the powder explosion suppressant has a very good synergistic explosion suppression effect, and the powder explosion suppressant for suppressing the titanium powder explosion further has the advantages of being good in explosion suppression performance, small in dosage, easy to prepare and the like; The powder explosion suppressant for suppressing the explosion of the titanium powder is particularly suitable for an explosive region of the titanium powder, and the explosion risk is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

Photocatalyst for treating dye in high-salinity wastewater, and preparation method thereof

InactiveCN111659447AImprove adsorption capacityPromote enrichmentPhysical/chemical process catalystsWater/sewage treatment by irradiationPtru catalystOrganosolv

The invention discloses a photocatalyst for treating dye in high-salinity wastewater, and a preparation method thereof, and belongs to the field of photocatalysis. The photocatalyst disclosed by the invention takes a porous graphite phase nitrogen carbide nanosheet as a carrier, and bismuth subcarbonate nanoparticles are loaded on the porous graphite phase nitrogen carbide nanosheet carrier. The obtained catalyst can catalyze and treat the dye in high-salinity wastewater under visible light, and has the advantages of response under visible light, low cost and high degradation rate. In the preparation process of the catalyst, graphite-phase nitrogen carbide subjected to hydrothermal treatment and bismuth nitrate are directly ground and roasted to make bismuth oxycarbonate particles generated on the surface of the nitrogen carbide carrier in situ, and the catalytic reaction stability of the photocatalyst is improved by utilizing the strong interaction force of the graphite-phase nitrogencarbide and the bismuth nitrate. In addition, no organic solvent is introduced in the preparation process, so environmental protection is achieved, the process is simple, and industrial production isfacilitated.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com