Preparation method of bismuth subcarbonate microflowers and product

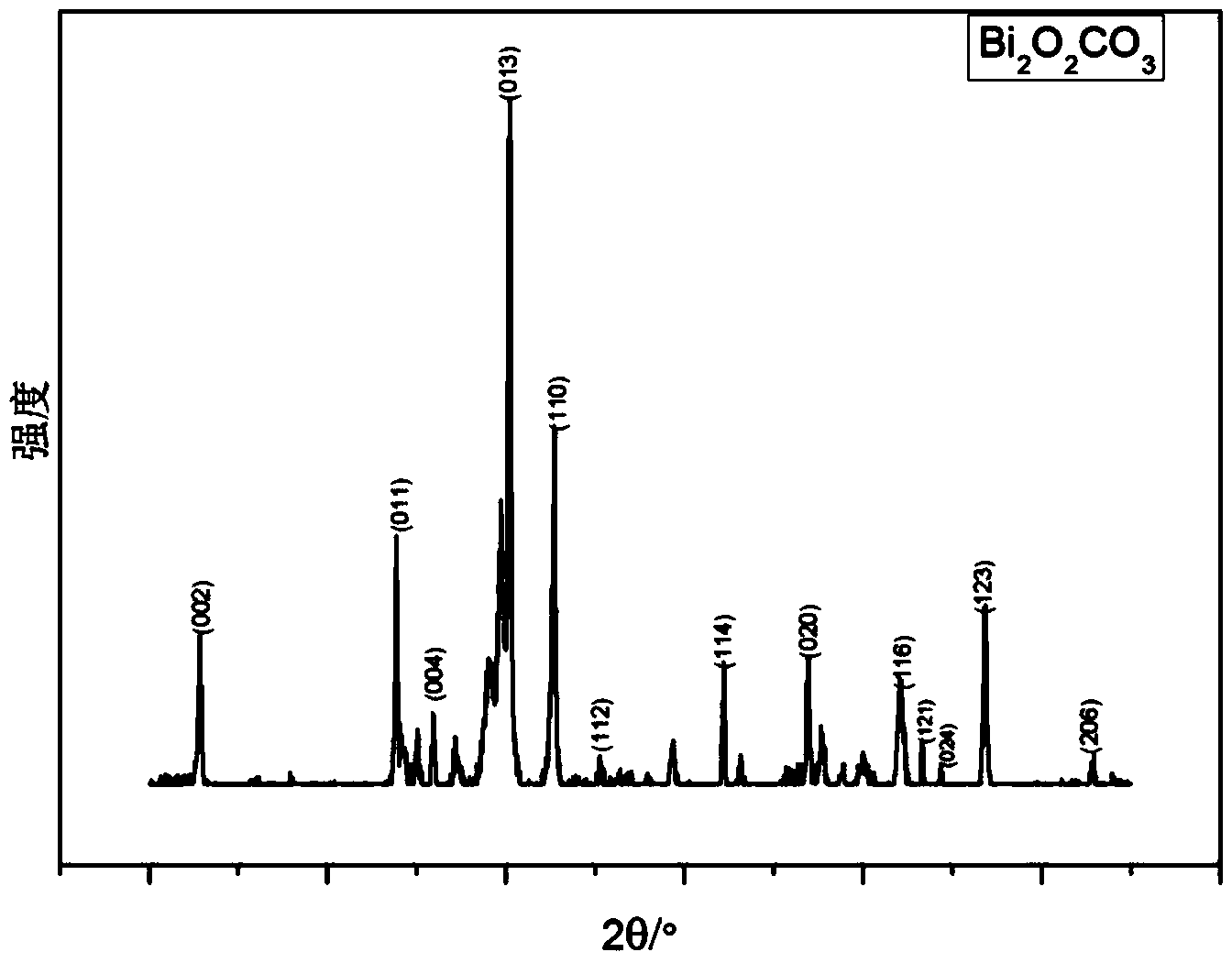

A technology of bismuth oxycarbonate and micro-flowers, which is applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., can solve the problems of poor controllability of morphology, disordered flower-like structure, and low crystallinity of bismuth oxycarbonate micro-flowers. , to achieve the effect of easy control, simple preparation process and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Weigh 8 mmol of tetrabutyl titanate, add it dropwise into deionized water, and control the concentration of tetrabutyl titanate to 1.0 mol / L.

[0027] 2) Weigh 11 mmol of bismuth nitrate pentahydrate, add it into the suspension prepared in step 1), and stir thoroughly.

[0028] 3) Weigh 0.04 mol of potassium hydroxide, add to the suspension solution prepared in step 2), and stir for at least 30 minutes.

[0029] 4) Weigh 28 mmol of ammonium citrate, dissolve it in deionized water, and control the concentration of ammonium citrate to 2.8 mol / L.

[0030] 5) Add the solution prepared in step 4) dropwise to the suspension prepared in step 3) under stirring state, and disperse through sufficient stirring and ultrasonic vibration.

[0031] 6) Add the suspension prepared in step 5) into the liner of the reaction kettle. Use deionized water to adjust its volume to account for 4 / 5 of the inner tank volume of the reactor to obtain a suspension of the reaction precursor. At ...

Embodiment 2

[0034] 1) Weigh 10 mmol of tetrabutyl titanate, add it dropwise to deionized water, and control the concentration of tetrabutyl titanate to 1.0 mol / L.

[0035] 2) Weigh 13 mmol of bismuth nitrate pentahydrate, add it into the suspension prepared in step 1), and stir thoroughly.

[0036] 3) Weigh 0.04 mol of potassium hydroxide, add to the suspension solution prepared in step 2), and stir for at least 30 minutes.

[0037] 4) Weigh 28 mmol of ammonium citrate, dissolve it in deionized water, and control the concentration of ammonium citrate to 2.8 mol / L.

[0038] 5) Add the solution prepared in step 4) dropwise to the suspension prepared in step 3) under stirring state, and disperse through sufficient stirring and ultrasonic vibration.

[0039] 6) Add the suspension prepared in step 5) into the liner of the reaction kettle. Use deionized water to adjust its volume to account for 4 / 5 of the inner tank volume of the reactor to obtain a suspension of the reaction precursor. At t...

Embodiment 3

[0042] 1) Weigh 9 mmol of tetrabutyl titanate, add it dropwise into deionized water, and control the concentration of tetrabutyl titanate to 1.0 mol / L.

[0043] 2) Weigh 12 mmol of bismuth nitrate pentahydrate, add it into the suspension prepared in step 1), and stir thoroughly.

[0044] 3) Weigh 0.04 mol of potassium hydroxide, add to the suspension solution prepared in step 2), and stir for at least 30 minutes.

[0045] 4) Weigh 29 mmol of ammonium citrate, dissolve it in deionized water, and control the concentration of ammonium citrate to 2.9 mol / L.

[0046] 5) Add the solution prepared in step 4) dropwise to the suspension prepared in step 3) under stirring state, and disperse through sufficient stirring and ultrasonic vibration.

[0047] 6) Add the suspension prepared in step 5) into the liner of the reaction kettle. Use deionized water to adjust its volume to account for 4 / 5 of the inner tank volume of the reactor to obtain a suspension of the reaction precursor. At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com