Patents

Literature

90 results about "Bismuth citrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bismuth citrate - Color additives exempt from certification and permanently listed for COSMETIC use. (None of these colors may be used in products that are for use in the area of the eye, unless otherwise indicated).

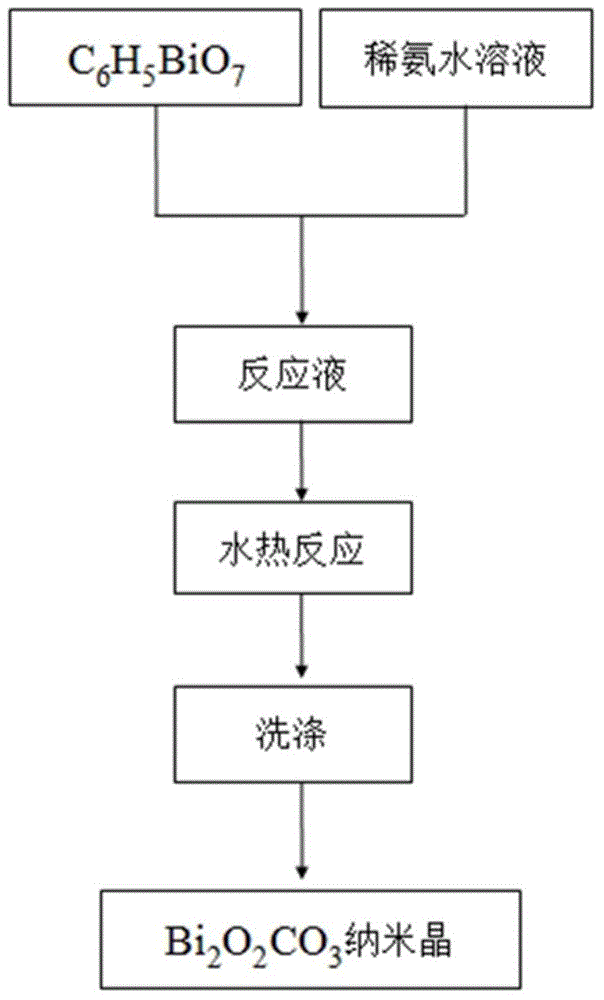

Bismuth subcarbonate photocatalyst and preparation method thereof

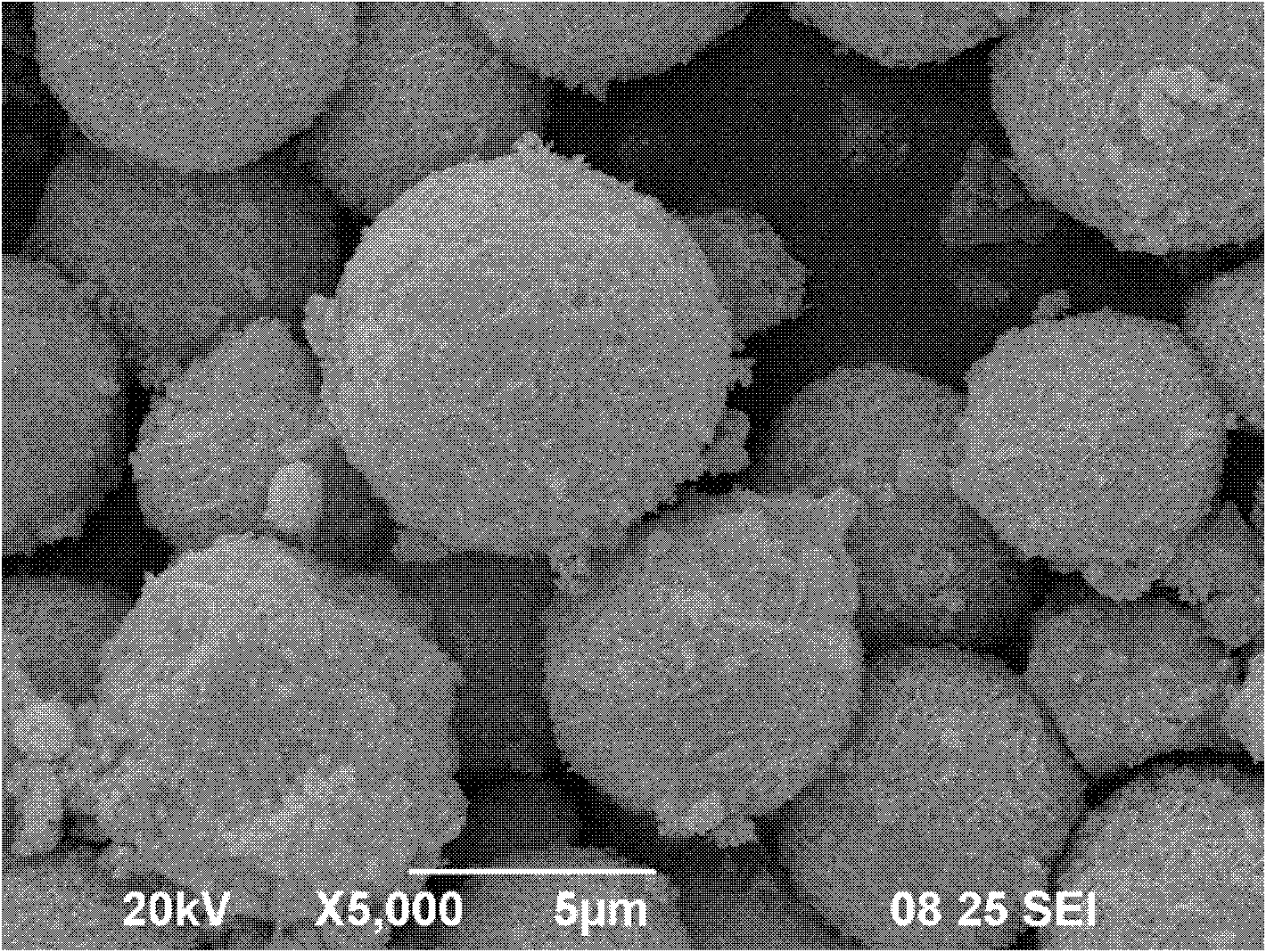

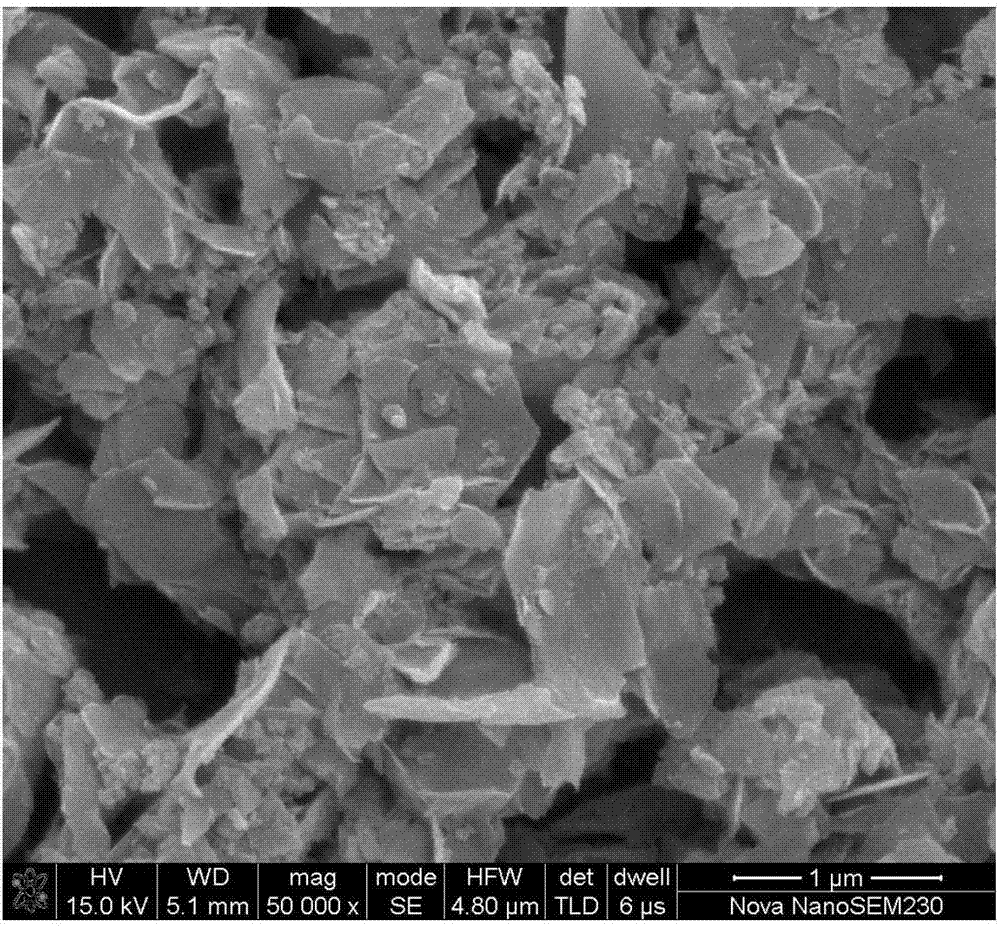

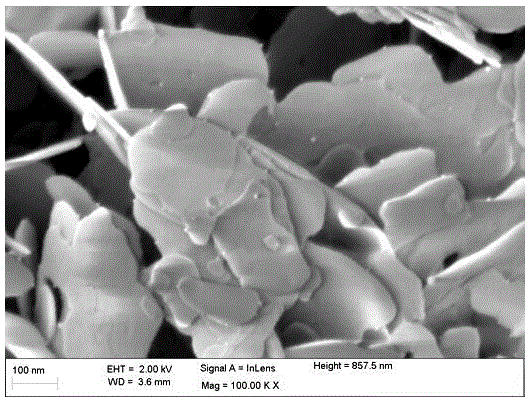

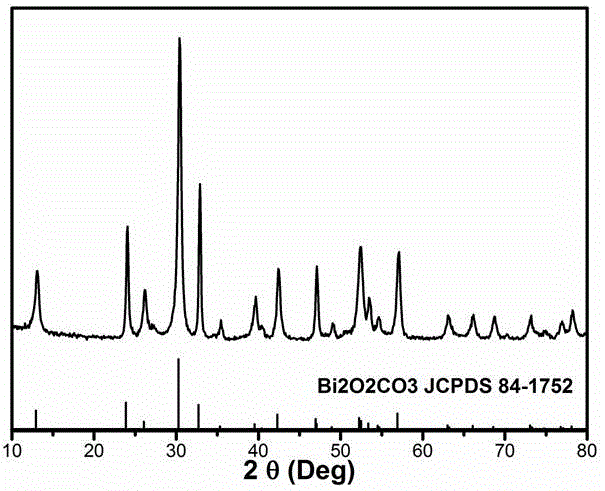

ActiveCN102527420AImprove photocatalytic performanceImprove photocatalytic activityCatalyst activation/preparationMicrosphereAmmonia

The invention provides a bismuth subcarbonate photocatalyst which is a bismuth subcarbonate nanometer sheet or a microsphere formed by the bismuth subcarbonate nanometer sheet. The bismuth subcarbonate photocatalyst provided by the invention is obtained by carrying out hydrothermal reaction on a bismuth source and soluble carbonate in an aqueous solution, wherein the bismuth source is bismuth citrate or bismuth citrate ammonia. The bismuth subcarbonate photocatalyst takes the bismuth citrate or the bismuth citrate ammonia as the bismuth source, and the nanometer sheet shaped bismuth subcarbonate or the microsphere formed by the bismuth subcarbonate nanometer sheet is obtained in a hydrothermal reaction mode. The morphology obtained by the bismuth subcarbonate photocatalyst can accelerate the separation and transmission of the photoproduction electrons and holes of the bismuth subcarbonate photocatalyst so as to inhibit the composition of the electrons and holes and accelerate the diffusion and transfer of reactants and reaction products; reflection is generated between rays and a nanometer layer; and the use ratio of the light source is increased so as to improve the catalytic activity of the bismuth subcarbonate photocatalyst. An experiment result shows that the removal rate on NO by the bismuth subcarbonate photocatalyst provided by the invention is 20-50%.

Owner:铜陵博雅渡业新材料科技有限公司

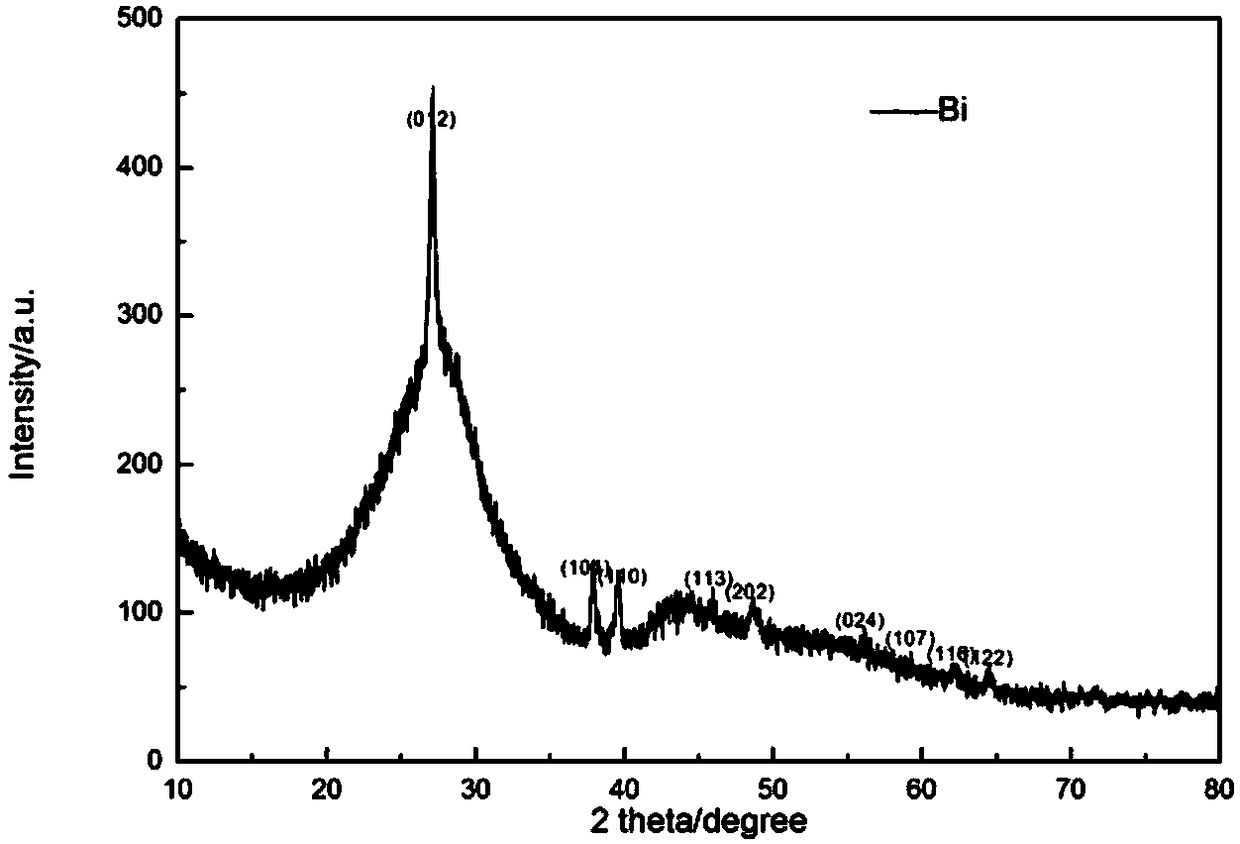

Nanometer bismuth/carbon composite material and preparation method thereof

InactiveCN108134090AAvoid the case of bulky bismuth metalEvenly distributedMaterial nanotechnologyAlkaline accumulatorsCarbon compositesPotassium borohydride

The invention relates to a nanometer composite material, in particular to a nanometer bismuth / carbon composite material and a preparation method thereof. A nanometer bismuth and carbon compound is obtained by taking various carbon materials as a substrate, bismuth nitrate, bismuth chloride, bismuth sulfate, bismuth acetate, bismuth citrate and the like as a bismuth source, water containing an organic complexing agent, ethylene glycol, propylene glycol or other mixture as a solvent and sodium borohydride, potassium borohydride, hydrazine hydrate and the like as a reducing agent and by an absorption-thermal decomposition-reduction method. According to the method, a solution containing bismuth ions is absorbed to a surface of a carbon material, remaining solution is filtered, the bismuth oxide / bismuth and carbon compound is obtained after drying and thermal treatment, and the nanometer bismuth / carbon composite material is finally obtained by reduction reaction. In the composite material obtained by the method, metal bismuth particles are uniformly distributed in surfaces of carbon particles in nanometer size, and a phenomenon that a large amount of bismuth can be agglomerated by a traditional bismuth reduction method is prevented.

Owner:CENT SOUTH UNIV

Method for preparing bismuth-series chemical product

The invention relates to a method for preparing a bismuth-series chemical product, comprising steps as follows: firstly, preparing ordinary-level bismuth oxide by refined bismuth; then preparing a bismuth-series chemical product by the ordinary-level bismuth oxide including steps of refined bismuth pulverization, bismuth low-temperature oxidation, ordinary bismuth oxide chemical conversion, and the like; finally preparing bismuth-series chemical products of bismuth nitrate, bismuth subnitrate, bismuth subcarbonate, bismuthsalicylate, basic bismuth salicylate, bismuth citrate, bismuth trichlor, bismuth oxychloride, electric bismuth oxide or bismuth oxide nanowire, and the like; and recycling chemically-converted mother-liquid. The invention has the advantages of generating no cancerigenic poison gas NOx and waste water, having environment protection, little consumption of chemical reagent, little energy consumption, low cost, simple device and operation, and the like.

Owner:湖南金泰铋业股份有限公司

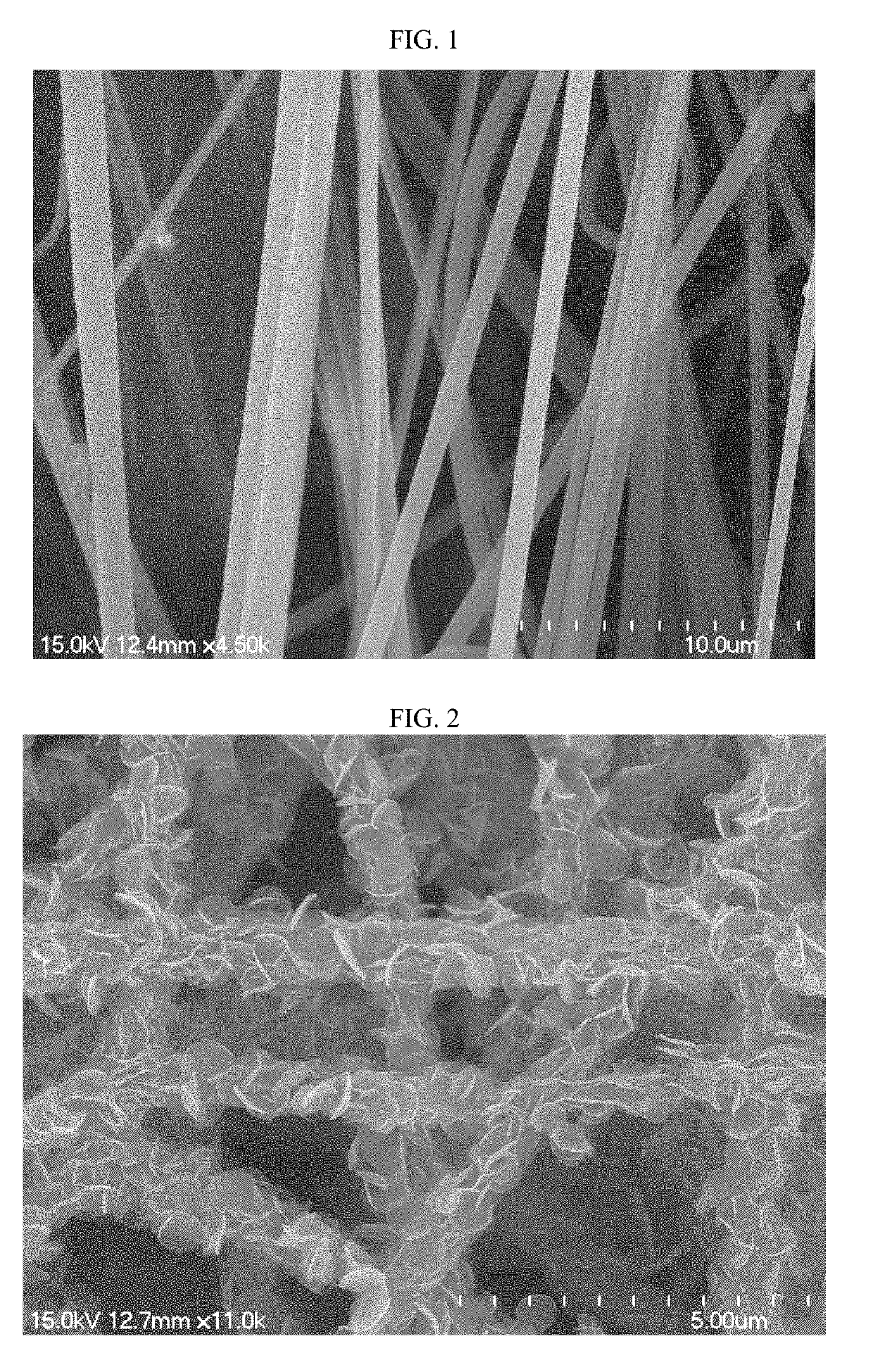

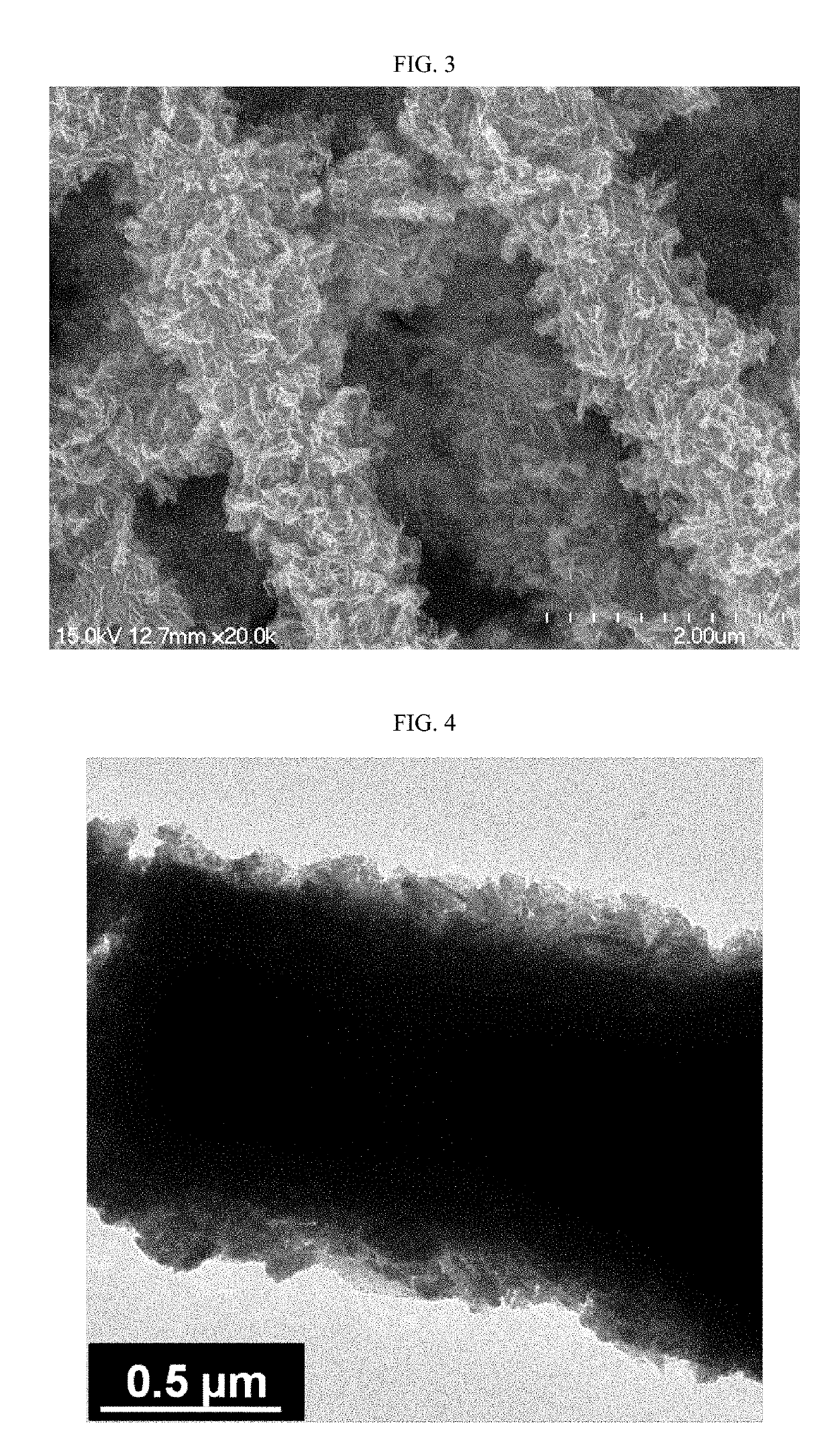

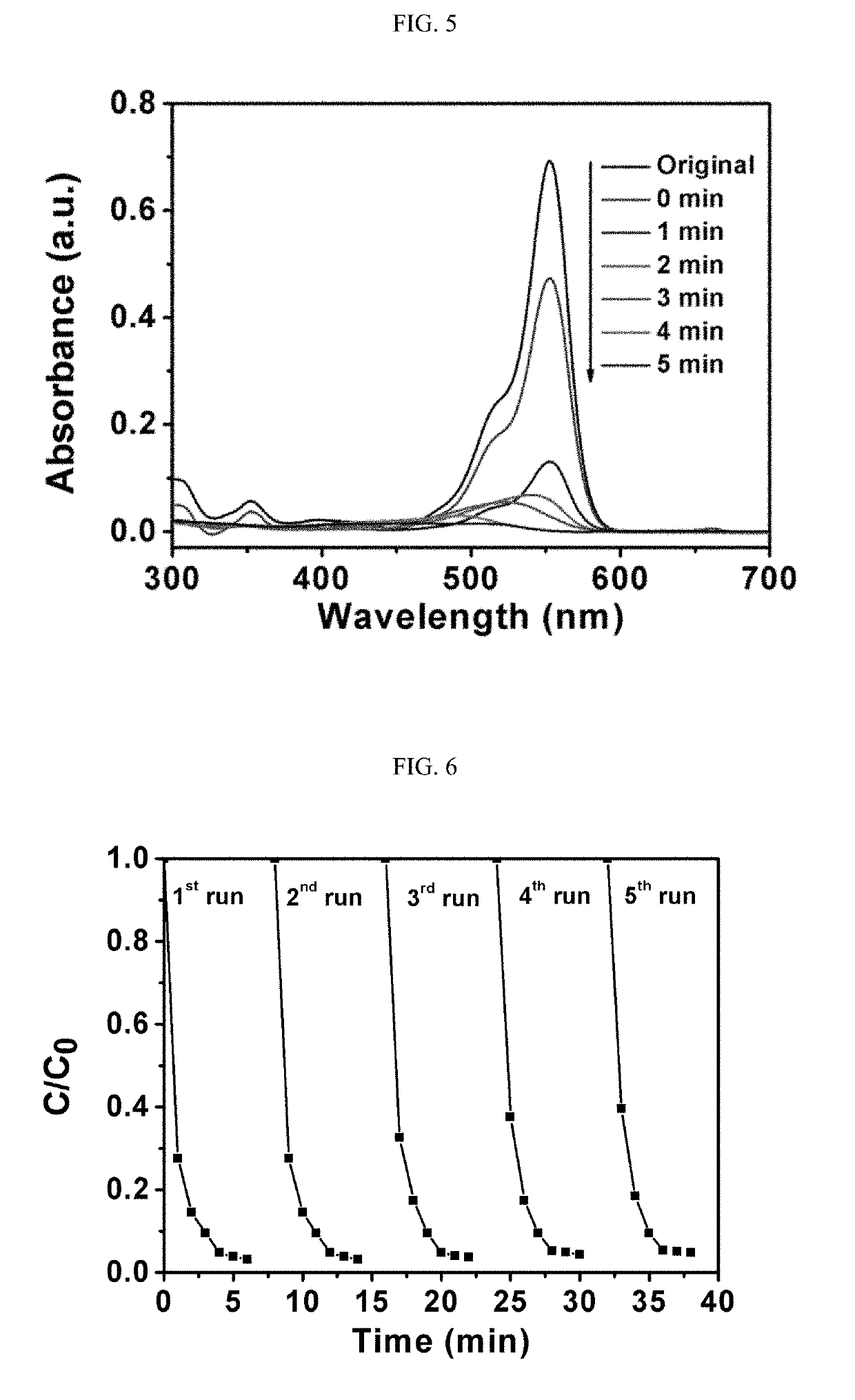

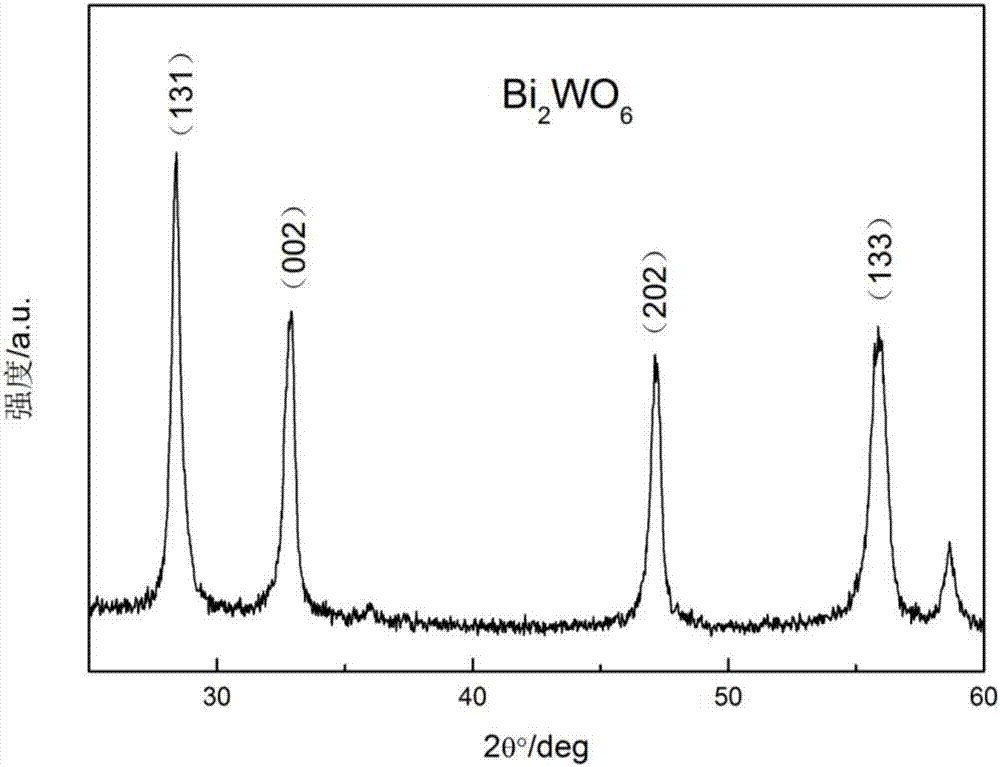

Iodine doped bismuthyl carbonate nanosheet and molybdenum disulfide modified carbon nanofiber composites, preparation method and application thereof

ActiveUS20190127883A1Low costEasy to operateFullerenesArtificial filament washing/dryingFiberSodium iodide

Iodine doped bismuthyl carbonate nanosheet and molybdenum disulfide modified carbon nanofiber composites, preparation method and its application in wastewater treatment are disclosed. Bismuth citrate and sodium carbonate as precursors, sodium carbonate as a precipitating agent, dispersed in a mixed solution of water and ethylene glycol, sodium iodide as a iodine source, nano carbon fiber membrane act as the carrier, to synthesis carbon fiber membrane that modified by iodine-doped Bi2O2CO3 nanosheets; then sodium molybdate and thioacetamide as precursors, dispersed in water to react to obtain iodine doped bismuthyl carbonate nanosheet and molybdenum disulfide modified carbon nanofiber composites. The composite material synthesized through a series of steps exhibit excellent photocatalytic activity for the degradation of Rhodamine B and can be recycled for many times. And this invention has the advantages of simple preparation process, easy recovery and multiple use, etc., and has industrial application prospect in water pollution treatment.

Owner:SUZHOU UNIV

Preparation method of metastable phase bismuth oxide and application thereof in photocatalytic degradation of organic pollutants

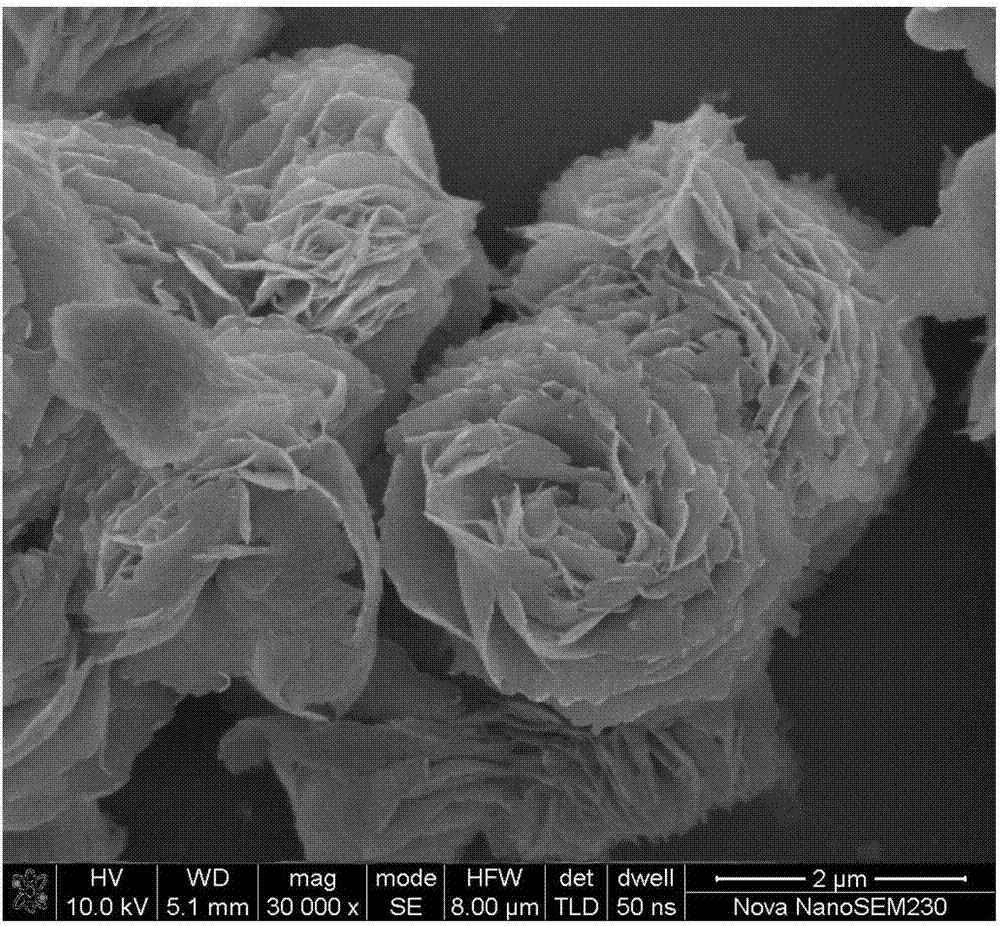

ActiveCN107029770AEasy to separateQuick migrationPhysical/chemical process catalystsWater/sewage treatment by irradiationPhotocatalytic degradationLight response

The invention discloses a preparation method of metastable phase bismuth oxide and application thereof in photocatalytic degradation of organic pollutants. The preparation method comprises the following steps: carrying out hydrothermal reaction on an aqueous solution which contains ammonium bismuth citrate, urea and hexadecyl trimethyl ammonium bromide to obtain bismuthyl carbonate microflowers; and calcining the bismuthyl carbonate microflowers in an air environment to obtain the metastable phase bismuth oxide beta-Bi2O3 / Bi2O2.33@Bi2O2CO3. The preparation method is simple and controllable to operate, and is environmentally friendly. The synthesized metastable phase bismuth oxide has the advantages of visible-light response, large specific surface area, high catalytic activity and the like, has the characteristics of rapidness and high efficiency in a process of visible-light catalytic degradation of the organic pollutants, and can be widely applied to the technical field of treatment of the organic pollutants.

Owner:CENT SOUTH UNIV

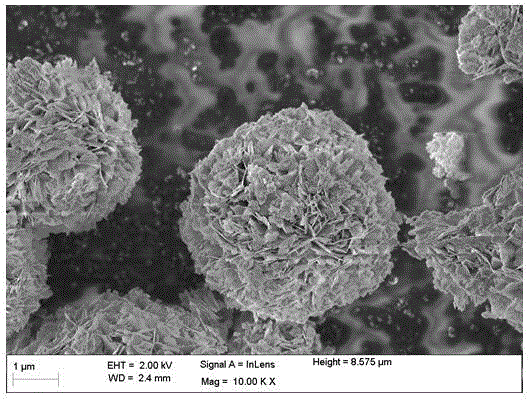

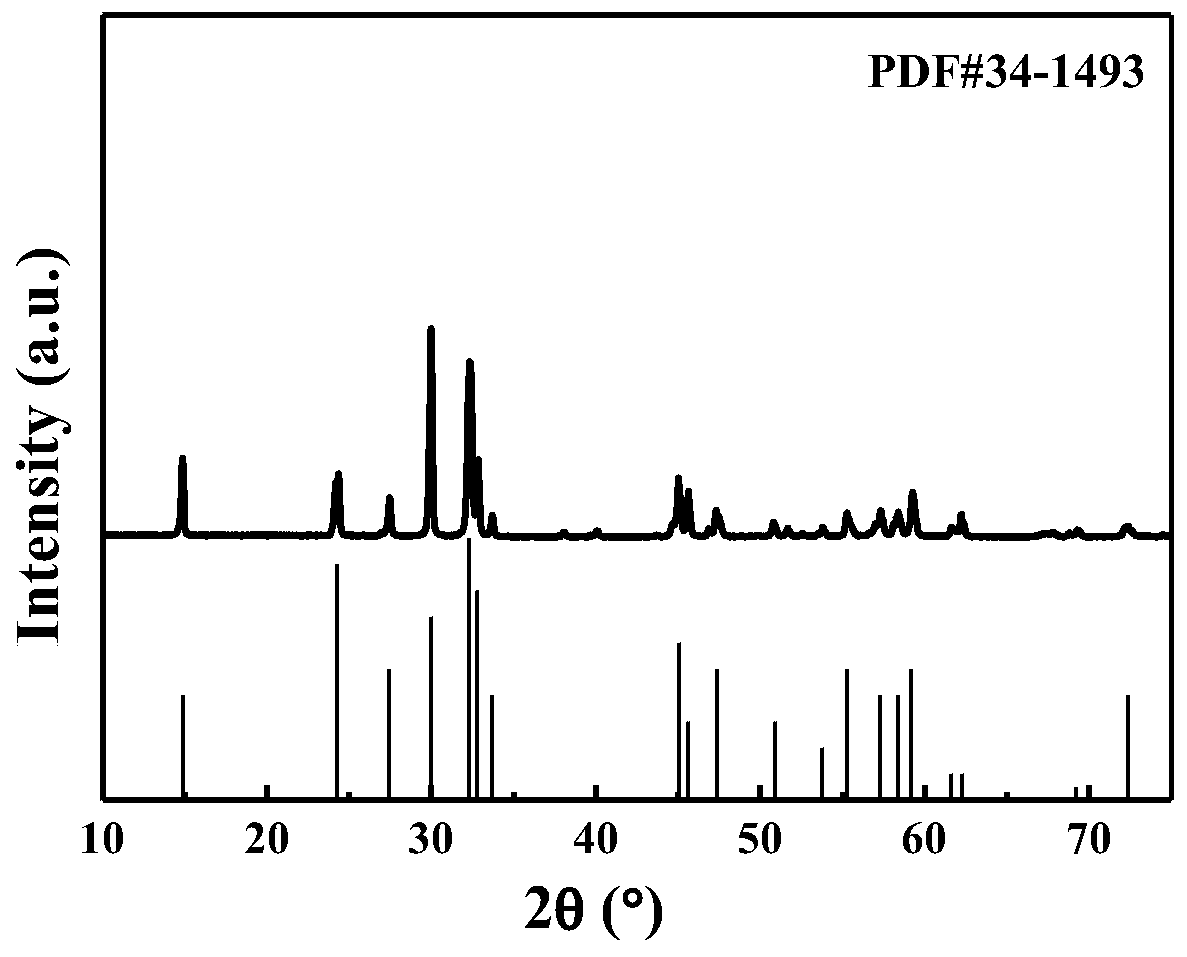

Gold-supported bismuth subcarbonate material for photocatalysis and preparation method

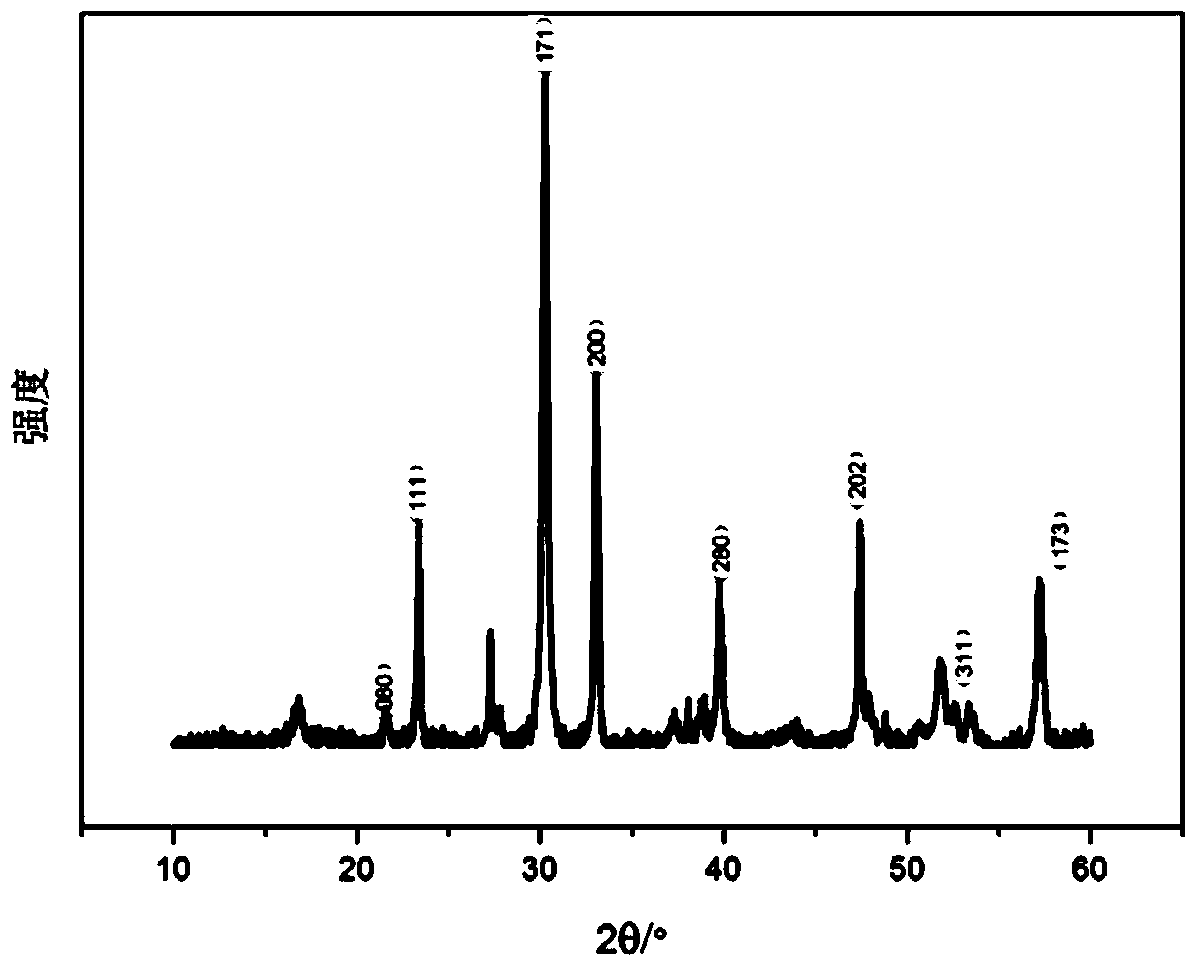

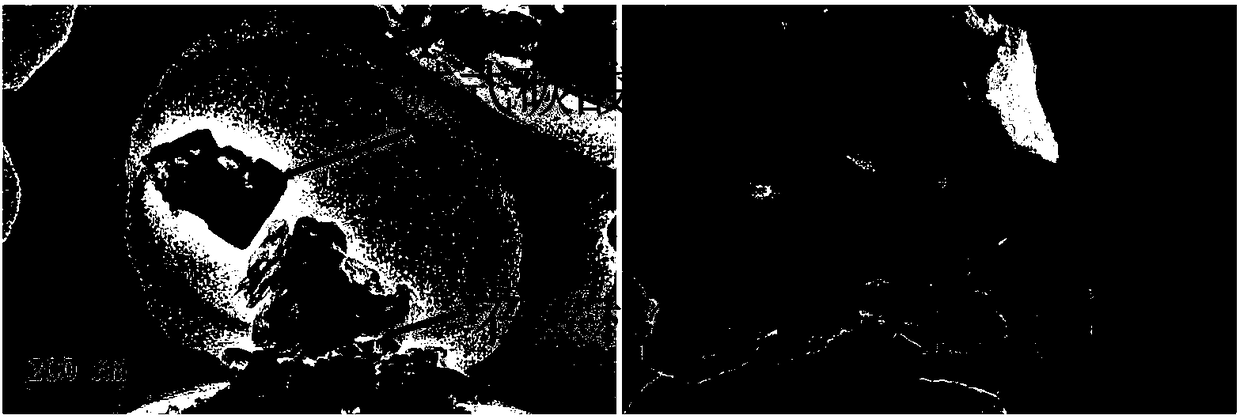

ActiveCN105126888AImprove catalytic performancePhysical/chemical process catalystsWater/sewage treatment by irradiationWater bathsGold particles

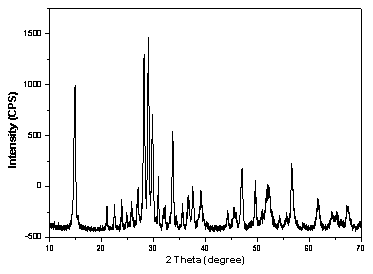

The invention relates to a gold-supported bismuth subcarbonate material for photocatalysis and a preparation method thereof, and belongs to the field of inorganic nano-materials. The preparation method of gold-supported bismuth subcarbonate microspheres comprises the steps that firstly, ammonium bismuth citrate and sodium carbonate are added in water and stirred to obtain an even supernatant solution; secondly, the solution is placed in a hydrothermal reaction kettle for a hydrothermal reaction at 160 DEG C for 24 h; thirdly, precipitate obtained through the reaction is centrifuged, washed and dried to obtain bismuth subcarbonate nanospheres. The gold supporting method comprises the steps that the prepared bismuth subcarbonate reacts with urea, chloroauric acid and water on the water bath condition at 80 DEG C for 4 h, washing and drying are performed after natural cooling is performed, and then the gold-supported bismuth subcarbonate nanospheres are obtained. According to the prepared gold-supported bismuth subcarbonate nanospheres, the physical phase is orthorhombic-phase bismuth subcarbonate of which the JCPDS number is 84-1752, the nanospheres are in the shape of a sphere, the diameter is 2-5 micrometers, and the size of gold particles on the surfaces is 5-10 nm.

Owner:CHONGQING UNIV OF ARTS & SCI

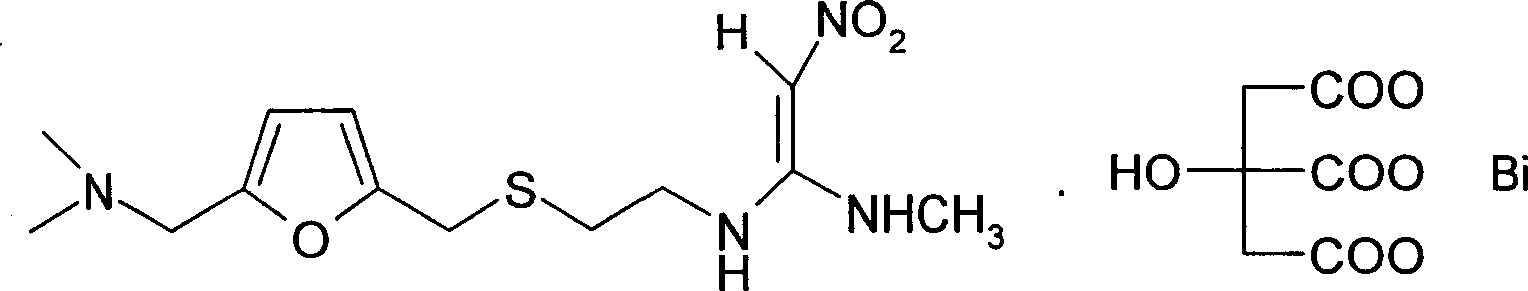

Method of preparing bismuth citrate ranitidine

The present invention discloses a method for preparing ranitidine bismuth citrate. Said method includes the following steps: making bismuth citrate be suspended in water, adding ranitidine and ammonia water to make reaction, the mole ratio of bismuth citrate, ammonia and ranitidine is 1:1-10:0.9, controlling reaction system pH value and making it be 6-12, its reaction temperature is 4-64deg.C, monitoring pH value, after the pH value is reached to neutrality, stopping reaction, filtering reaction solution and spray-drying so as to obtain the invented ranitidine bismuth citrate.

Owner:LIVZON PHARM GRP INC +1

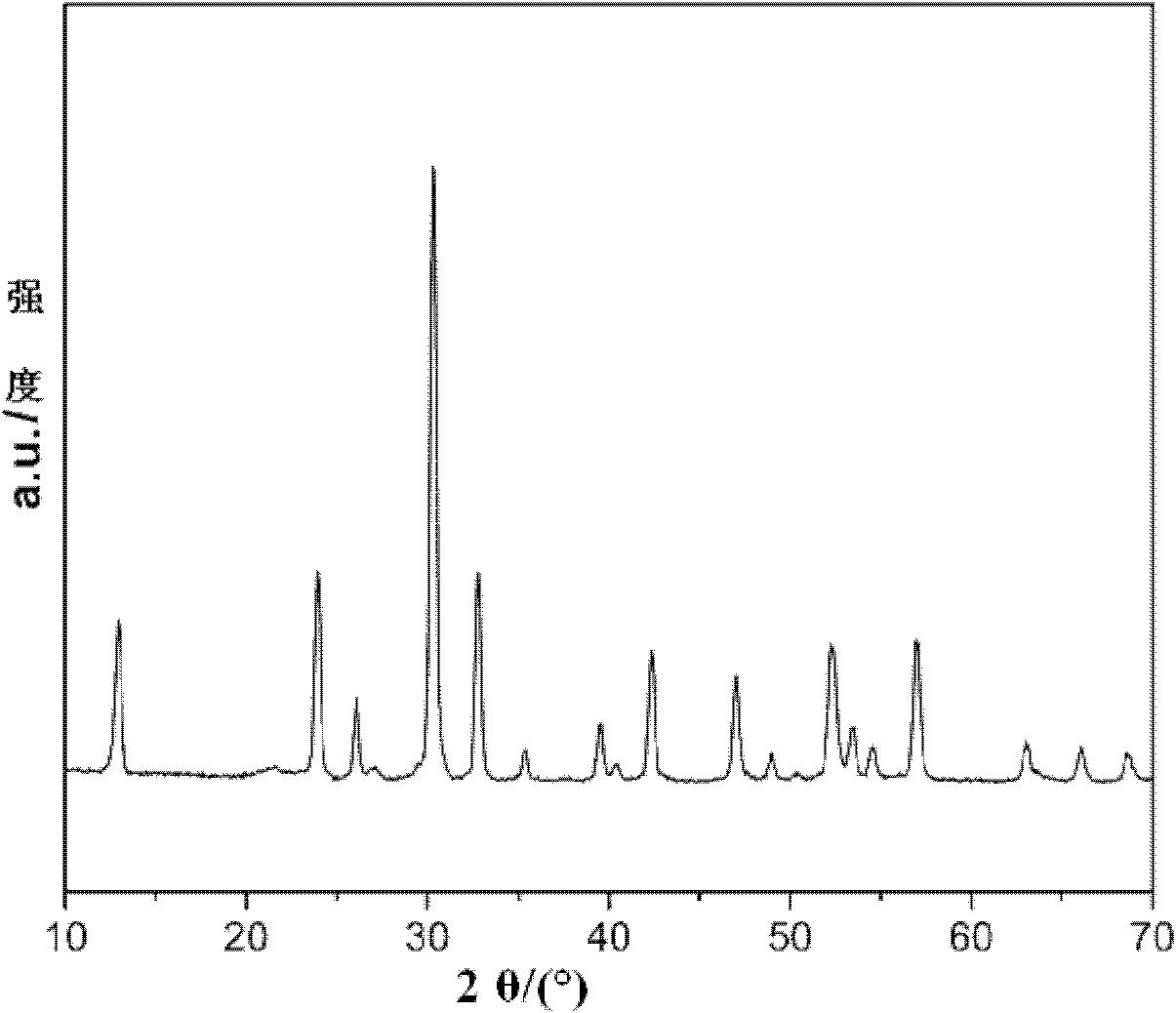

Bismuth series photocatalyst, and preparation method thereof

InactiveCN102600829AShape is easy to controlImprove photocatalytic efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitrogen sourceAqueous solution

The invention provides a bismuth series photocatalyst. The bismuth series photocatalyst has a molecular formula represented by formula (I): Nm[(BiO)2CO3] (1-m) (I), wherein m is ranged in 0.01-5%. According to the invention, a bismuth source and a nitrogen source are used as raw materials, a hydrothermal reaction is carried out on the raw materials in a water solution, and the bismuth series photocatalyst having the molecular formula represented by formula (I) is obtained. The bismuth source is bismuth citrate or bismuth citrate ammonia. In the bismuth series photocatalyst provided by the invention, N element is introduced into the crystal lattice of the (BiO)2CO3 crystal; due to the presence of the N element, the band gap of the bismuth series photocatalyst provided by the invention is reduced to 2.0-2.9eV, and the absorption spectrum is expanded to the visible region from the ultraviolet region, in this way, the bismuth series photocatalyst can be excited by the visible light, and has a high visible light catalytic activity. Furthermore, the preparation method provided by the invention is mild in reaction condition and simple in operation, and the preparation method is suitable for large scale production.

Owner:CHONGQING TECH & BUSINESS UNIV

Process for hydrothermal synthesizing bismuth citrate

InactiveCN1793101AImprove reaction efficiencyAdapt to the needs of industrial productionCarboxylic acid salt preparationChemical synthesisNitrate ion

The invention discloses a method to compounding citron acid bismuth by hydrothermal. It adopts bismuth oxide and citron acid by hydrothermal compounding and filtering and drying to gain citron acid bismuth. The result of the invention has high purity, fully reaction high atom economical efficiency, short reaction time. It has no harmful to environment.

Owner:EAST CHINA NORMAL UNIV

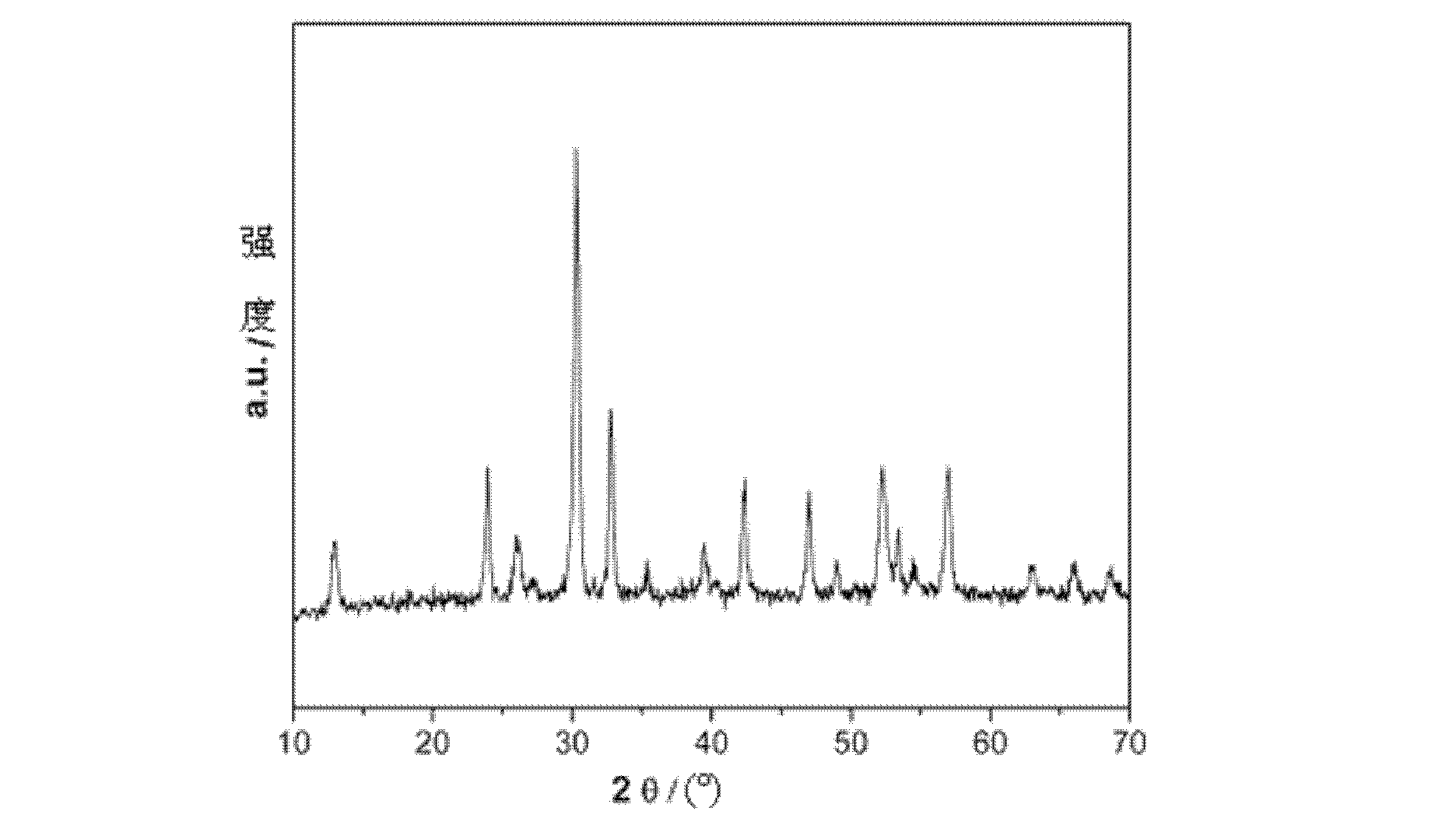

Preparation of hierarchical nanostructure Bi2O3/(BiO)2CO3

ActiveCN106582758AIncrease refractionIncrease profitCatalyst activation/preparationChemical industryNanostructure

The invention relates to a method for synthesizing a Bi2O3 / (BiO)2CO3 composite photocatalytic material and belongs to the technical field of chemical industry. The method comprises the steps of weighing three kinds of chemical reagent raw materials, i.e., Na2CO3, bismuth citrate and NaOH according to a mole ratio, carrying out mixing, stirring the mixture in secondary distilled water for certain time, carrying out treatment by a programmed-heating hydrothermal process, then, carrying out repeated washing separately with deionized water and anhydrous ethanol, and carrying out baking, thereby obtaining the final product, i.e., the Bi2O3 / (BiO)2CO3 composite photocatalytic material. The surface morphology, microscopic structure and photocatalytic activity of the composite photocatalytic material are assayed, and the degradation of a variety of dyes such as rhodamine B under different light sources by the hierarchical garland-shaped Bi2O3 / (BiO)2CO3 composite photocatalytic material is greatly improved. The product is simple and practical in preparation process and stable in performance and has considerable applicability to a variety of dyes.

Owner:QIQIHAR UNIVERSITY

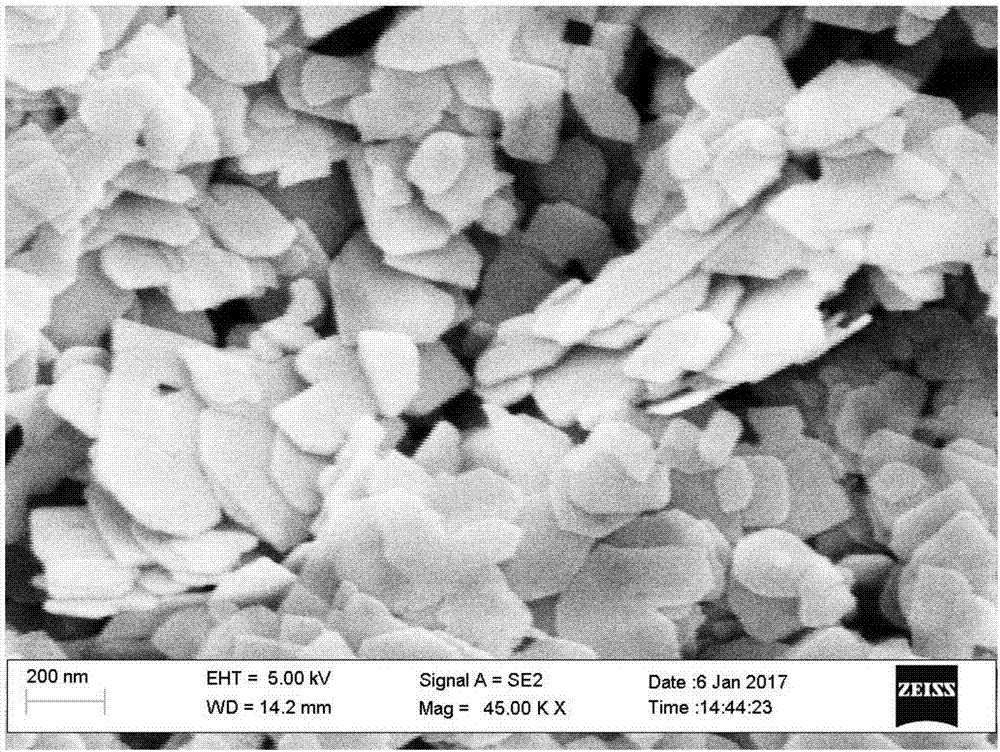

Preparation method for bismuth ferrite Bi2Fe4O9 monocrystal nanosheets

InactiveCN103420427ASimple processEasy to controlNanotechnologyIron compoundsGas detectorPotassium hydroxide

The invention discloses a preparation method for bismuth ferrite Bi2Fe4O9 monocrystal nanosheets. Ferric nitrate and ammonium bismuth citrate are employed as raw materials. Deionized water and nitric acid are added. An appropriate amount of potassium hydroxide is added to promote crystallization. The above mixture is subjected to a hydrothermal reaction at the temperature of 160-230 DEG C to obtain bismuth ferrite Bi2Fe4O9 monocrystal nanosheets. The preparation method is advantaged by simple technological process, easy control, no pollution and low cost, and is easy for large-scale production. The prepared products have stable crystallization quality, and have wide application prospects in fields of semiconductor gas sensors, catalysts and the like.

Owner:ZHEJIANG UNIV

Bismuth-Containing Catalytic System for Polymerising Polymers

InactiveUS20110184119A1Readily dispersiblePigmenting treatmentMaterial nanotechnologyInorganic particleBismuth compound

Bismuth-containing catalytic systems, formed using inorganic particles coated with at least one inorganic or organic bismuth compound that is catalytically active when polymerising polymers, characterised in that the inorganic bismuth compound is selected from the group comprising bismuth oxychloride, bismuth hydroxo-sulphate and bismuth carbonate, and in that the organic bismuth compound is selected from the group comprising bismuth acetate, bismuth benzoate, bismuth citrate, bismuth lactate and bismuth phthalate.

Owner:KRONOS INTERNATIONAL INC

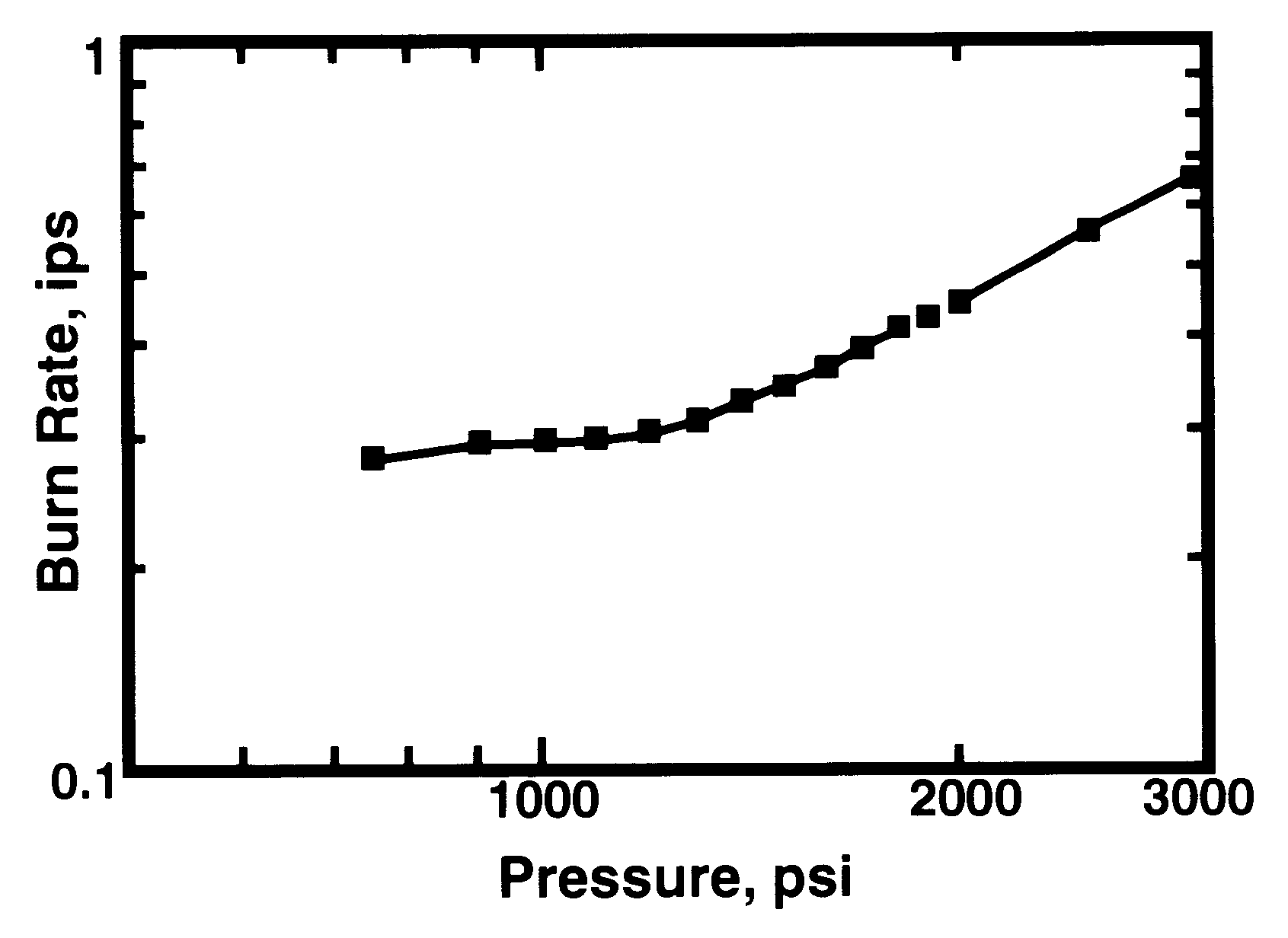

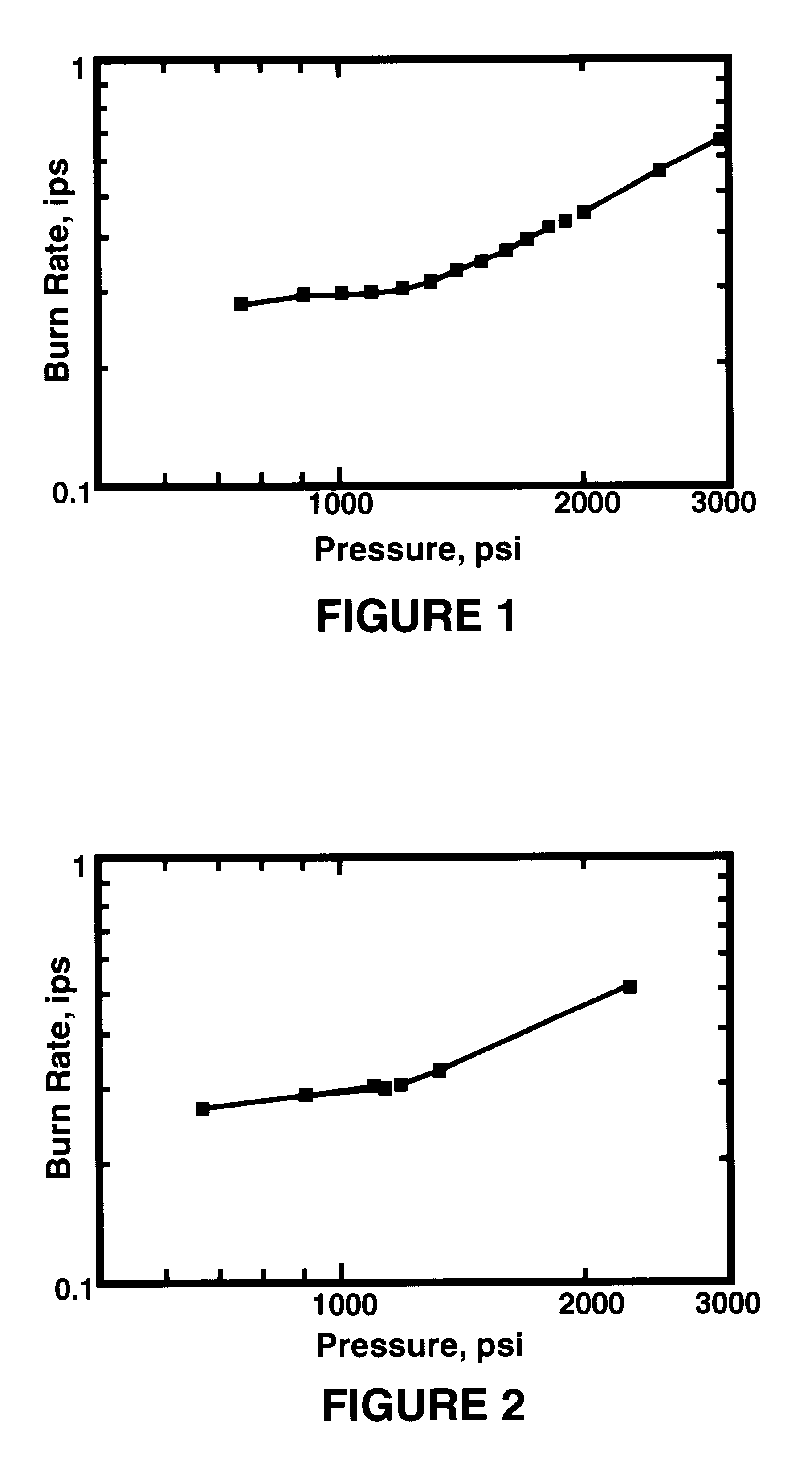

Minimum signature isocyanate cured propellants containing bismuth compounds as ballistic modifiers

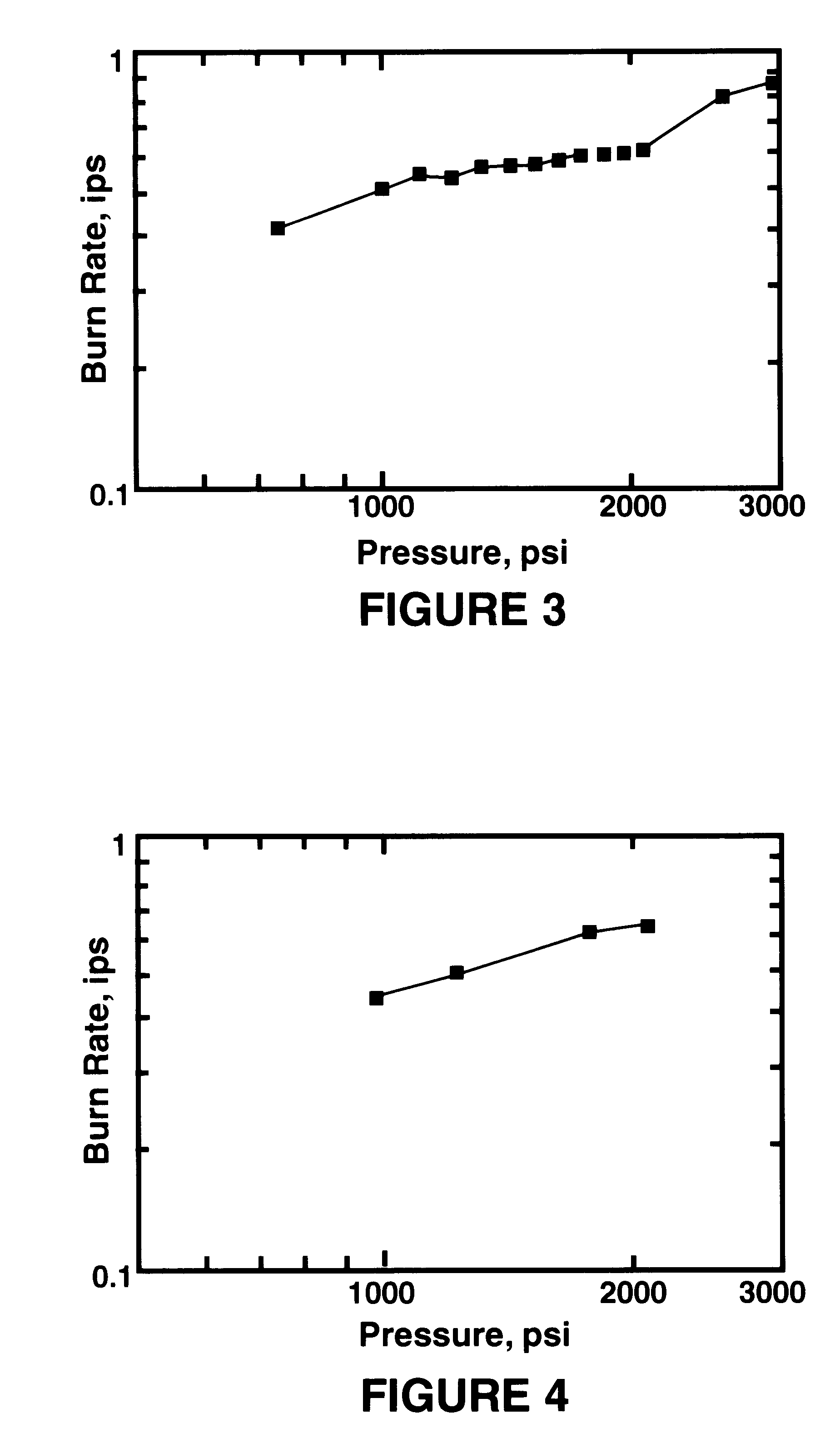

InactiveUS6168677AImprove performanceImprove propertiesNon-explosive/non-thermic compositionsBismuth compoundBismuth salicylate

Environmentally friendly high performance minimum signature propellants have been demonstrated for use in next generation tactical missile applications. Bismuth salicylate and bismuth citrate have each been used in propellant formulations and evaluated for processing, ballistic, mechanical, aging and signature properties. These high performance formulations have potential to replace current formulations used in some fielded tactical systems. The propellant binder network is achieved using energetic nitramine polymers where inert polymers have been the polymer of choice for minimum signature propellants. The significance of this has to do with achieving propellant specific impulses greater than 245 seconds without nitroglycerin being used in the formulation. This improves propellant safety properties during the propellant processing and the manufacturing of the final missile configurations. The Army has mandated that the next generation propellant formulations show improvements in safety to the end users. These formulations are environmentally friendly (no-lead) and do not use nitroglycerin to achieve high performance.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Preparation method and product of Bi4Ti3O12 nanosheets

InactiveCN104211117AAvoid introducingAvoid generatingMaterial nanotechnologyBismuth compoundsPotassium hydroxideSingle crystal

The invention discloses a preparation method of Bi4Ti3O12 nanosheets. The preparation method comprises the following steps: by adopting titanium oxyhydroxide precipitate which is prepared by hydrolyzing tetrabutyl titanate by using KOH as a titanium source, sufficiently dispersing the titanium oxyhydroxide precipitate into an ammonium bismuth citrate solution, subsequently adding certain amount of potassium hydroxide as a mineralizer, sufficiently stirring and oscillating, transferring into a reaction kettle, sealing, and performing hydrothermal treatment for 6-48 hours at 150-300 DEG C, thereby finally obtaining the Bi4Ti3O12 single crystal nanosheets of which the thickness is about 100 nanometers and the two-dimensional size is greater than 1 micrometer. The invention provides the method for preparing the Bi4Ti3O12 nanosheets by using a hydrothermal method, ammonium bismuth citrate is adopted as a bismuth source for the first time, no other surface modifier is needed to be added, the Bi4Ti3O12 nanosheets with relatively good dispersity are prepared by precisely regulating and controlling the reaction condition, and the preparation process is simple and controllable.

Owner:ZHEJIANG UNIV

Preparation method of bismuth ferrite BiFeO3 monocrystal micrometer sheet

ActiveCN102877130ASimple processEasy to controlPolycrystalline material growthFrom normal temperature solutionsPotassium hydroxideRaw material

The invention discloses a preparation method of a bismuth ferrite BiFeO3 monocrystal micrometer sheet, which comprises the steps of: with ferric nitrate and ammonium bismuth citrate as raw materials, adding deionized water and adding quantitative potassium hydroxide for promoting crystallization, and carrying out a hydrothermal reaction at a temperature of 160-240 DEG C to prepare the bismuth ferrite BiFeO3 monocrystal micrometer sheet. The preparation method has the advantages of simple process, easy control, no pollution, low cost, and easy mass production. The prepared bismuth ferrite BiFeO3 monocrystal micrometer sheet is stable in crystallization quality, and has a wide potential application prospect in fields such as a transducer, a sensor, a storage and photocatalysis.

Owner:ZHEJIANG UNIV

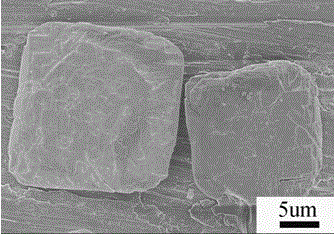

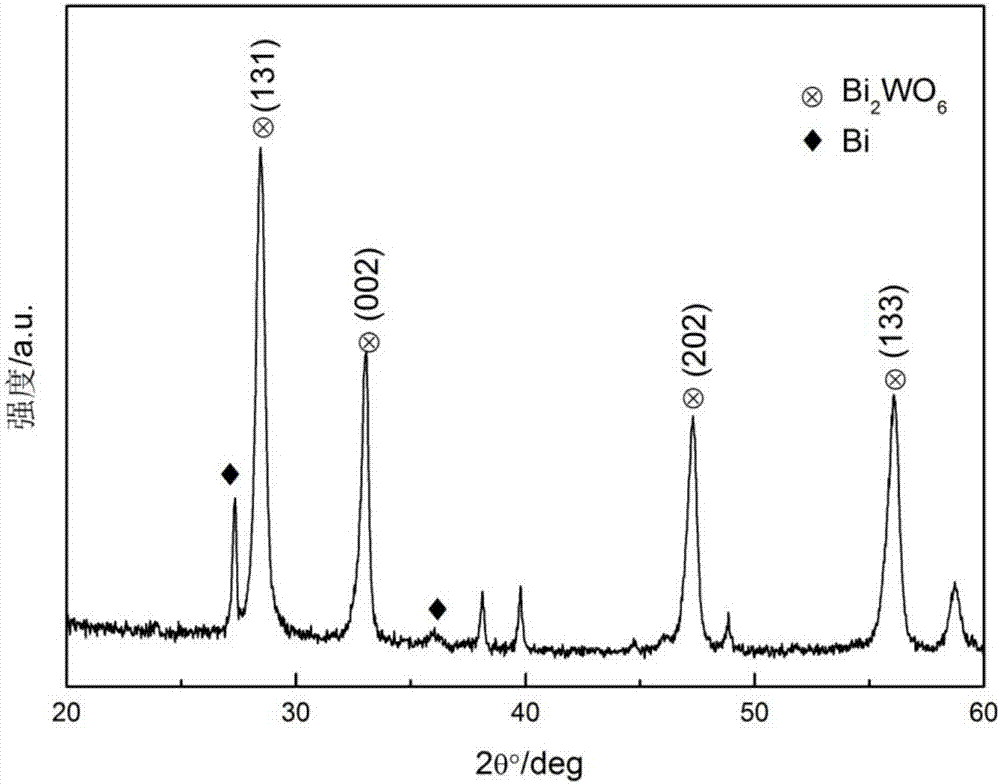

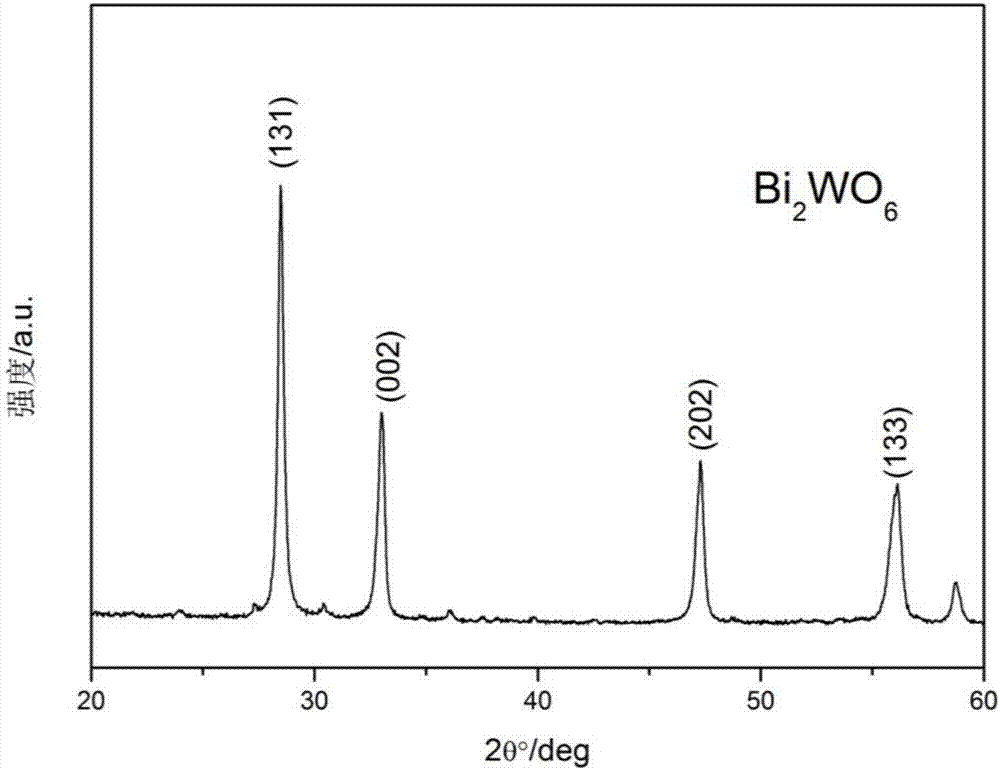

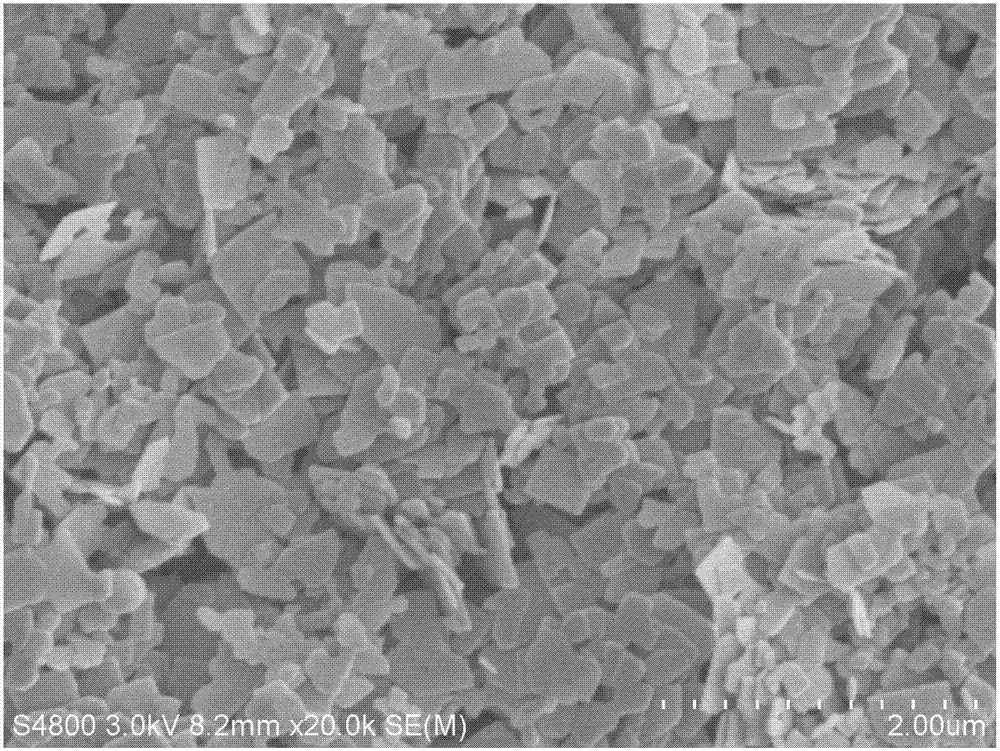

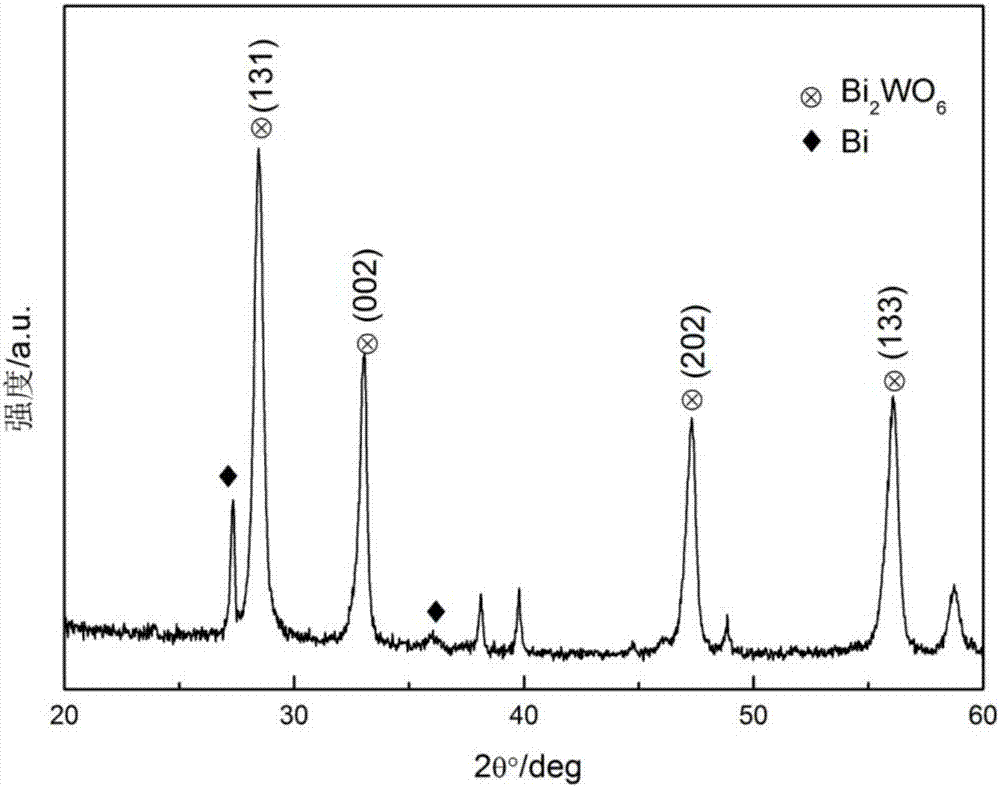

Method for preparing sheet Bi2WO6

InactiveCN107162059ANo pollution in the processSimple processMaterial nanotechnologyTungsten compoundsSodium tungstateSodium hydroxide

The present invention relates to a kind of method for preparing flake Bi2WO6, comprising the following steps: 1) adding bismuth ammonium citrate solution to sodium tungstate solution dropwise; the molar concentration of said bismuth ammonium citrate solution is 0.20~0.60mol / L, The molar concentration of the sodium tungstate solution is 0.10~0.30mol / L; 2) continue to add the sodium hydroxide solution dropwise, carry out the hydrothermal reaction after mixing, filter and wash to obtain the flake Bi2WO6; the mole of the sodium hydroxide solution The concentration is 0.1~2mol / L. The flaky Bi2WO6 prepared by this method has good morphology and uniform size.

Owner:ZHEJIANG UNIV

Method for producing citric acid bismuth, oxalic acid bismuth and bismuth subsalicylate by electrolyzing active metal bismuth

InactiveCN101041617AEliminate emissionsSignificant environmental benefitsPhotography auxillary processesCarboxylic acid salt preparationChemical reactionElectrolysis

The invention discloses a manufacturing method of bismuth citrate, bismuth oxalate and bismuth subsalicylate through electrolyzing and activating metal bismuth, which is characterized by the following: making new hyperfine bismuth with grain size at 20-350nm; reacting the strong hyperfine bismuth and organic acid to produce the product; simplifying the technique; reducing cost; improving impurity effectively without polluting the environment.

Owner:SUZHOU UNIV +1

Preparation method of bismuth citrate

ActiveCN103172510ASimple preparation processEasy to operate and controlCarboxylic acid salt preparationChemical reactionBoiling point

The invention provides a preparation method of bismuth citrate. The preparation method comprises the steps of 1, smashing bismuth oxide into specified average grain diameter; 2, preparing a citric acid aqueous solution with the predetermined concentration and heating to a predetermined temperature lower than the boiling point of water; 3, remaining the initial excess coefficient of citric acid in the citric acid aqueous solution below 1 according to the chemical reaction equation Bi2O3+2C6H8O7=2C6H5BiO7+3H2O and gradually adding the smashed bismuth oxide into the heated citric acid aqueous solution to ensure that the citric acid reacts with the bismuth oxide; 4, as the reaction progresses, gradually adding the citric acid aqueous solution with another concentration to keep the initial liquid-solid ratio; and 5, after the reaction is finished, filtering and drying to obtain the bismuth citrate product. The preparation method of the bismuth citrate, provided by the invention, has the advantages of no special requirements on equipment, easiness in the industrial production, simple process, convenience in operation and control, high yield and little impurity.

Owner:昆明先导新材料科技有限责任公司

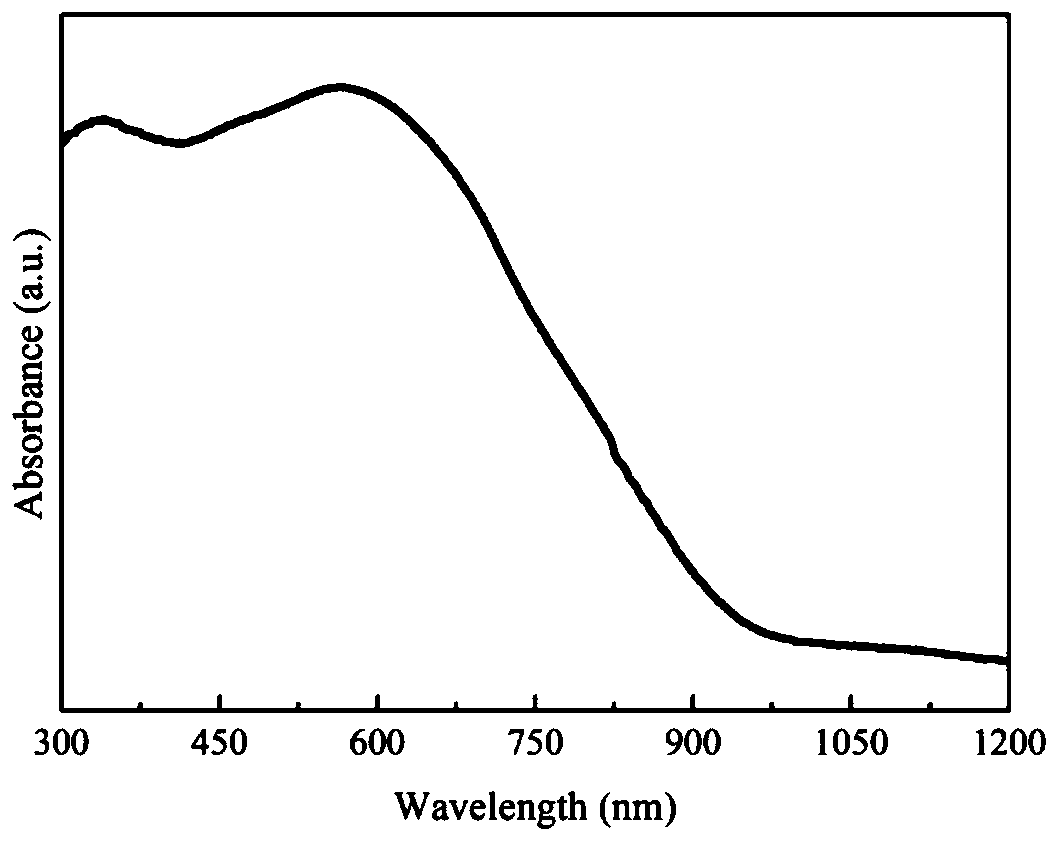

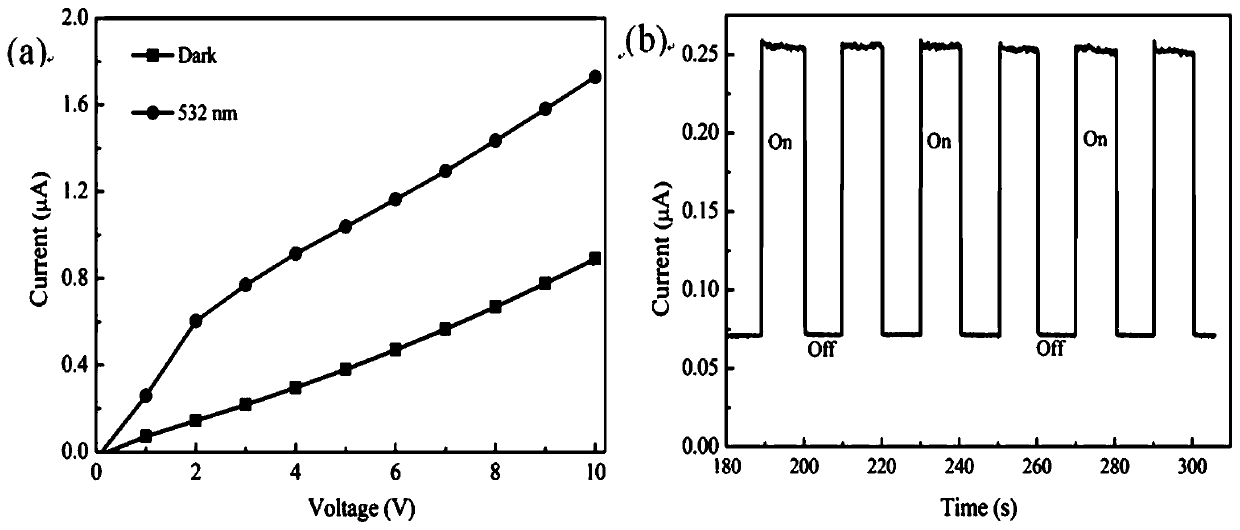

Preparation method of bismuth oxygen sulfur two-dimensional material and photoelectric detector

ActiveCN109888031AGood photodetection performanceFinal product manufactureSemiconductor/solid-state device manufacturingThioureaPotassium hydroxide

The invention provides a preparation method of a bismuth oxygen sulfur two-dimensional material and a photoelectric detector. The preparation method comprises the steps of 1, dispersing thiourea in deionized water, and adding ammonium bismuth citrate after the thiourea is completely dissolved by magnetic stirring; 2, adding potassium hydroxide after uniform stirring of a solution in the step 1, and performing stirring for 1-3 hours under a room temperature, wherein the concentration is 0.2-4.0mol / L; 3, transferring the stirred mixed solution to a polyphenylene reaction kettle resistant to hightemperature, and performing heat preservation for 3-48 hours under 25-220 DEG C; and 4, alternatively washing the product with two solvents comprising the deionized water or absolute ethyl alcohol, and performing alternative washing for 2-6 times so as to prepare a Bi2O2S two-dimensional material. The preparation method has the beneficial effects that the prepared Bi2O2S two-dimensional materialhas favorable photoelectric property, and the fabricated photoelectric detector has the characteristics of relatively high light dark current ratio, favorable cycle stability and the like.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Preparation method of bismuth sulfide nanoparticle and graphene composite material

InactiveCN112209437ANo pollution in the processPromote generationGrapheneBismuth compoundsBismuth sulfideReducing agent

A preparation method of a well-dispersed bismuth sulfide nanoparticle and graphene composite material comprises the following steps: dissolving graphene oxide, bismuth ammonium citrate and thioacetamide in water to prepare a mixed solution, conducting heating in a constant-temperature oil bath in an oil bath pan, so as to combine bismuth ions, sulfur ions and graphene oxide to form a graphene oxide and bismuth sulfide intermediate product, and synthesizing the bismuth sulfide and graphene composite material under the action of a reducing agent hydrazine hydrate. The bismuth sulfide nanoparticles on the graphene are uniform in particle size, the size is about 25 nm, the growth density and the particle size of the bismuth sulfide nanoparticles can be regulated and controlled by controlling the reactant concentration and the reaction time, and the experiment process is simple and effective. The invention not only provides an experimental thought for synthesizing the semiconductor nano composite material of the base graphene, but also can be widely applied to the fields of photoelectrons, catalysis, electrode materials and the like.

Owner:NANKAI UNIV

Bi2Ti2O7 ceramic powder and preparation method thereof

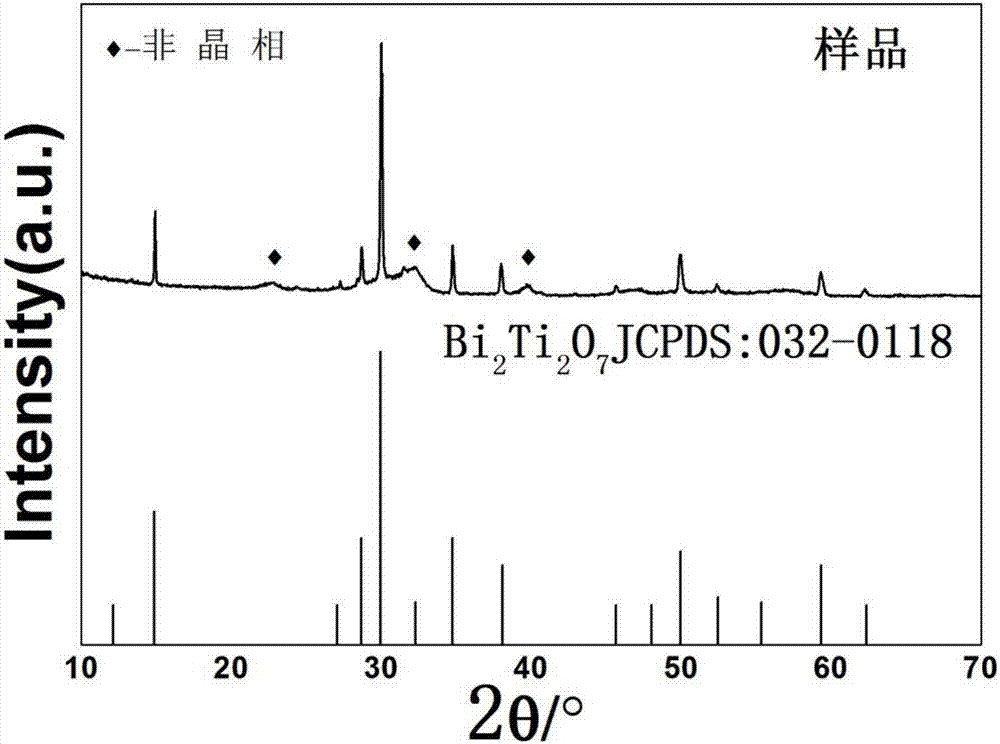

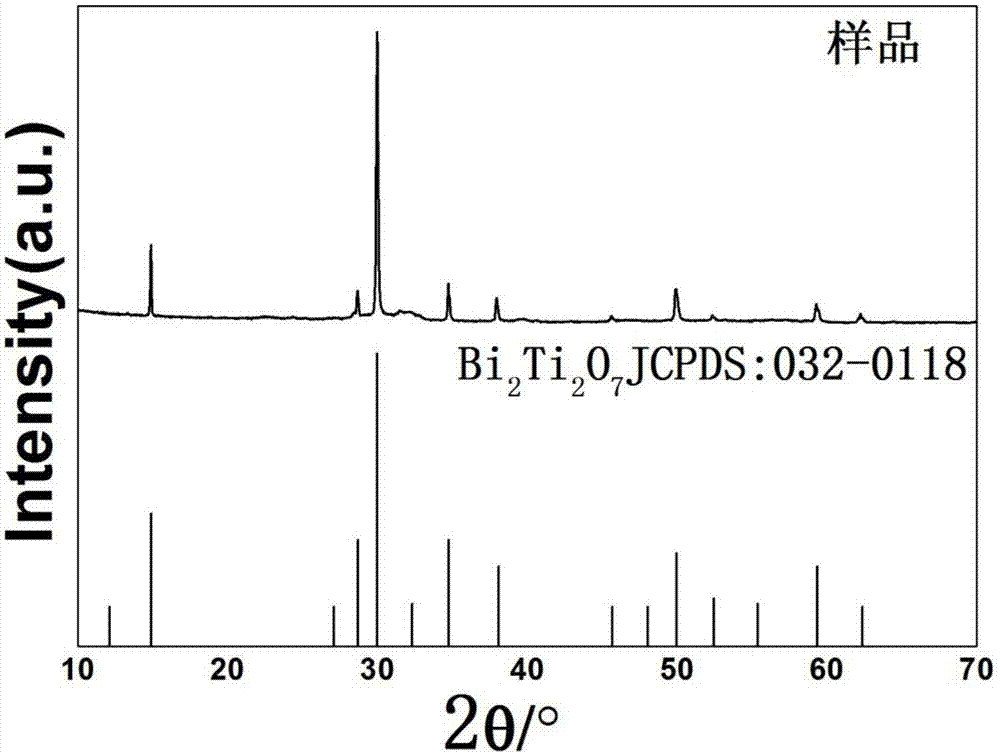

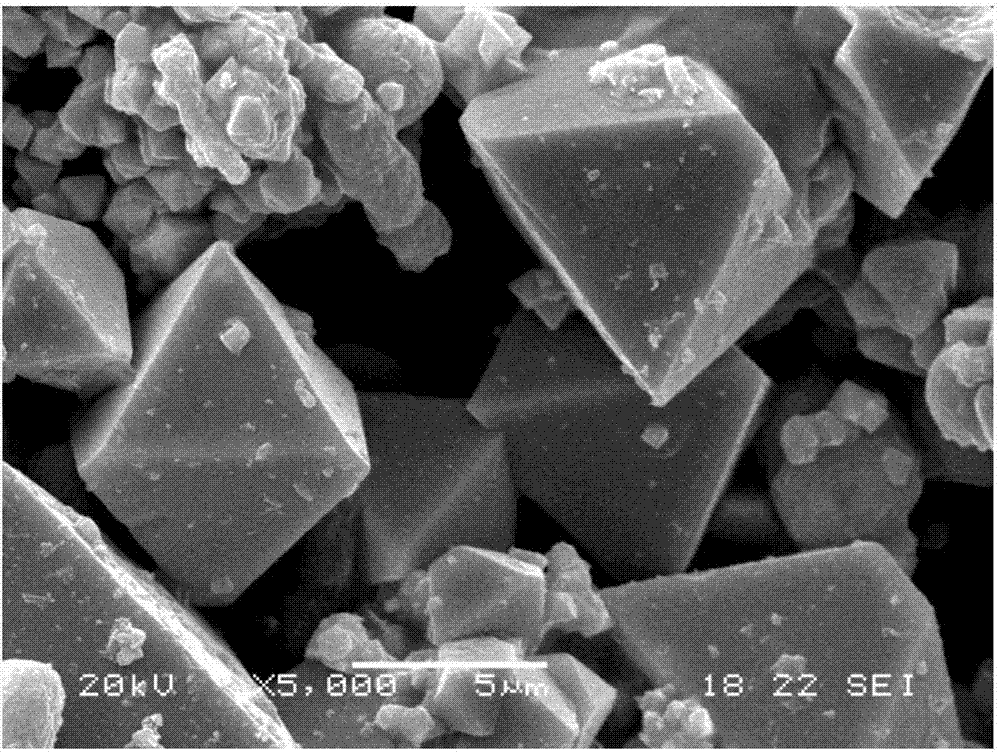

ActiveCN107381635ALower requirementImprove responseBismuth compoundsMetal/metal-oxides/metal-hydroxide catalystsRepeatabilityAmmonia

The invention discloses Bi2Ti2O7 ceramic powder and a preparation method thereof. The preparation method comprises the following steps: 1) dissolving bismuth citrate into a proper amount of ammonia water, and sufficiently stirring to obtain a colorless mixed solution; then dropwise adding tetrabutyl titanate into the mixed solution in an inert environment, so as to obtain a reaction solution; carrying out hydrothermal reaction on the reaction solution to prepare the Bi2Ti2O7 powder in one step. The product prepared by the preparation method has high purity, and a crystal shape is octahedral; the product can have excellent photocatalytic performance; the preparation method has the advantages of simplicity, moderate reaction conditions, low cost and good repeatability; requirements on synthesis equipment are low, so that the preparation method is suitable for being popularized and applied.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method of bismuth citrate

ActiveCN103864605AQuick responseReduce consumptionOrganic compound preparationCarboxylic acid salt preparationReaction speedTreatment costs

The embodiment of the invention discloses a preparation method of bismuth citrate. The method comprises the following steps: A, adding a bismuth nitrate solution into a citrate solution; B, reacting for 1 to 6 hours in a heat preservation manner at 60 DEG C to 80 DEG C; and C, washing and drying so as to prepare the bismuth citrate. The bismuth citrate is synthesized by one step by taking the bismuth nitrate solution and the citrate solution as raw materials, so that the process is simple and short in time; the reaction speed of the citrate solution is rapid, so that the yield of the bismuth citrate is high and the quality of the bismuth citrate is good; the consumption of the raw materials is decreased, so that the treatment cost of waste liquids is reduced; the reaction is thoroughly carried out, so that the obtained bismuth citrate is good; the difficult problem caused by the existing technology is avoided well.

Owner:FIRST RARE MATERIALS CO LTD

Preparation method of ranitidine bismuth citrate

ActiveCN103896888AReduce trace impuritiesReduce the generation of maximum simplexCarboxylic acid salt preparationActivated carbonAlcohol

The invention discloses a preparation method of ranitidine bismuth citrate. The preparation method concretely comprises the following steps: (1) reacting ranitidine with bismuth citrate at the temperature of 90-95DEG C to obtain a solution containing ranitidine bismuth citrate; (2) cooling the solution containing ranitidine bismuth citrate to 50-60DEG C, adding activated carbon, preserving heat and decoloring for 20-30min; (3) carrying out suction filtration, adding the filtrate into homemade absolute ethyl alcohol and stirring and crystallizing, carrying out suction filtration, and drying a filter cake to obtain ranitidine bismuth citrate. The homemade absolute ethyl alcohol is obtained by adding sodium salt into the commercially available industrial-grade absolute ethyl alcohol, and stirring and filtering. According to the method, the trace impurities in the absolute ethyl alcohol can be greatly decreased, and further the maximum individual impurity in the ranitidine bismuth citrate can be reduced, the content of the maximum individual impurity can be reduced to less than 0.5%, and minimally to less than 0.3%, and the quality of products can be greatly improved.

Owner:CHANGZHOU LANLING PHARMA

Method for preparing bismuth-series chemical product

The invention relates to a method for preparing a bismuth-series chemical product, comprising steps as follows: firstly, preparing ordinary-level bismuth oxide by refined bismuth; then preparing a bismuth-series chemical product by the ordinary-level bismuth oxide including steps of refined bismuth pulverization, bismuth low-temperature oxidation, ordinary bismuth oxide chemical conversion, and the like; finally preparing bismuth-series chemical products of bismuth nitrate, bismuth subnitrate, bismuth subcarbonate, bismuthsalicylate, basic bismuth salicylate, bismuth citrate, bismuth trichlor, bismuth oxychloride, electric bismuth oxide or bismuth oxide nanowire, and the like; and recycling chemically-converted mother-liquid. The invention has the advantages of generating no cancerigenic poison gas NOx and waste water, having environment protection, little consumption of chemical reagent, little energy consumption, low cost, simple device and operation, and the like.

Owner:湖南金泰铋业股份有限公司

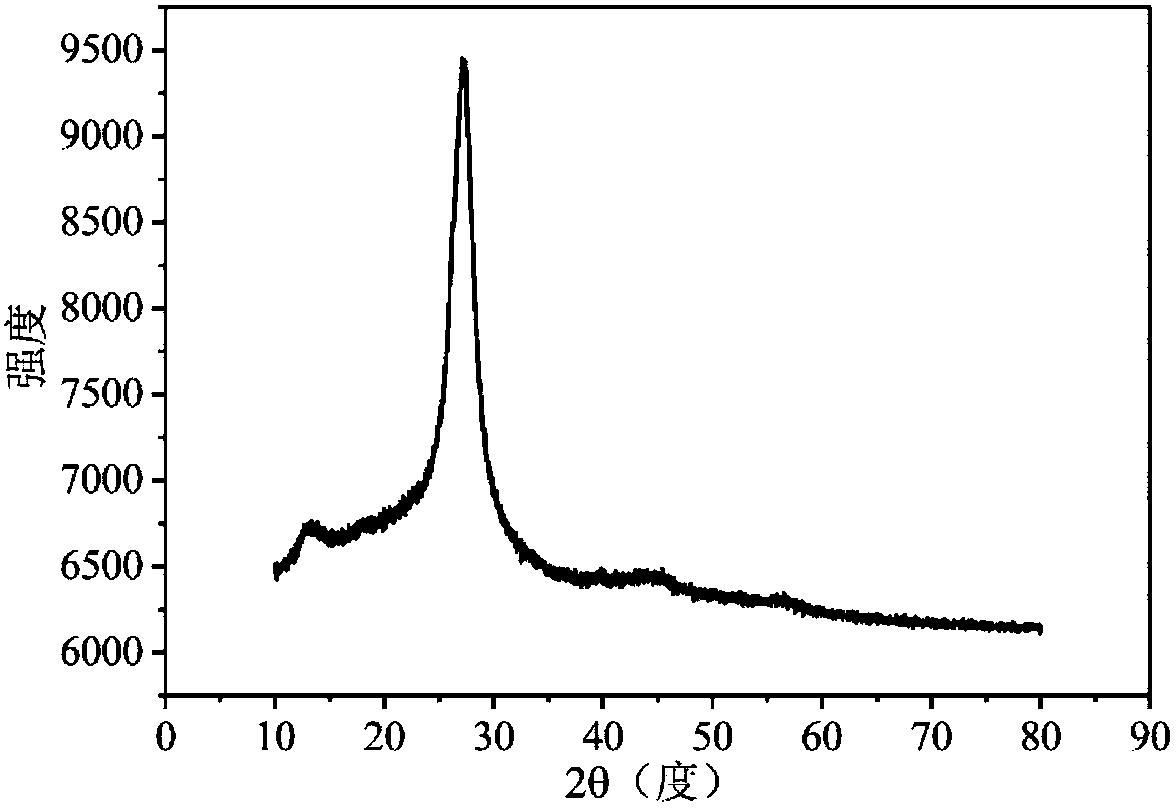

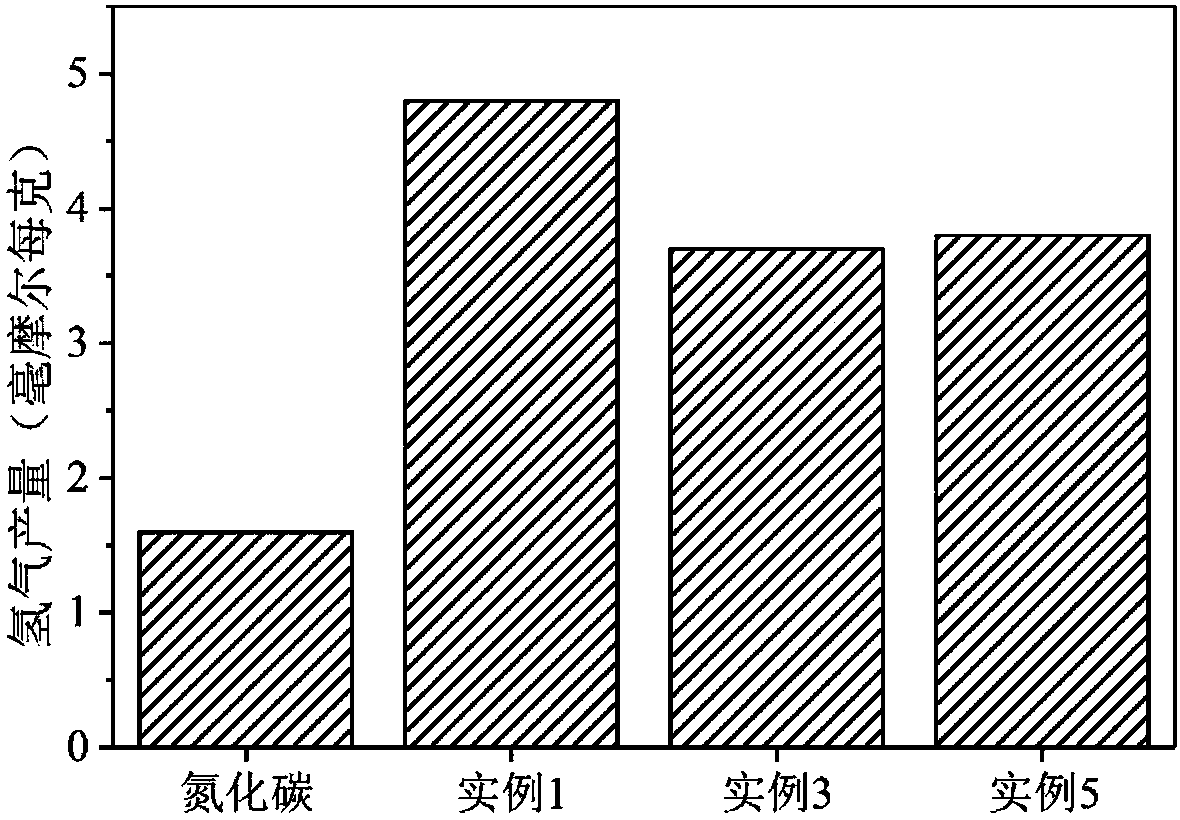

Graphite-phase carbon nitride photocatalyst modified by basic bismuth carbonate and preparation method of graphite-phase carbon nitride photocatalyst

ActiveCN108339561AEasy to prepareReduce manufacturing costPhysical/chemical process catalystsThermal insulationMuffle furnace

Provided is a graphite-phase carbon nitride photocatalyst modified by basic bismuth carbonate. The graphite-phase carbon nitride photocatalyst comprises the chemical components of: in percent by mass,0.1-1.5% of basic bismuth carbonate and the balance graphite-phase carbon nitride, and the preparation method of the graphite-phase carbon nitride photocatalyst modified by the basic bismuth carbonate mainly comprises the steps of: adding 5-20 mg of bismuth citrate into every 30 g of urea, putting the urea and bismuth citrate into an agate mortar, performing full stirring, grinding and mixing for20 minutes, placing the obtained mixture in an alumina porcelain ark, then placing the porcelain ark in a muffle furnace for heat treatment, raising the temperature from a room temperature to 450-600DEG C at a heating rate of 2-30 DEG C per minute, performing thermal insulation for 1-2 hours, cooling to room temperature with the furnace, placing the obtained mixture in the agate mortar again, and grinding the mixture thoroughly into powder of 1-5 mum so as to obtain the graphite-phase carbon nitride photocatalyst modified by the basic bismuth carbonate. The graphite-phase carbon nitride photocatalyst has a preparation method with simple and easy operation, easily available raw materials, stable physical and chemical properties, environmental friendliness and high photocatalytic activity,and is beneficial to practical application and industrial production.

Owner:YANSHAN UNIV

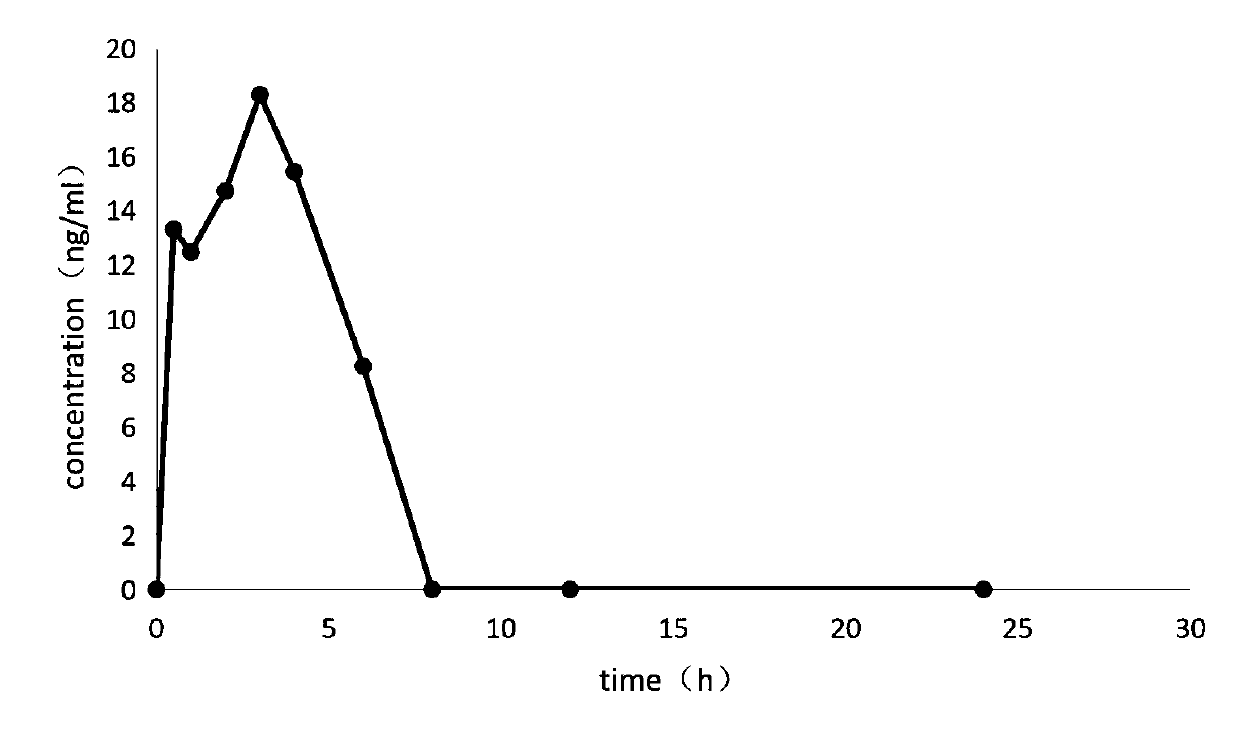

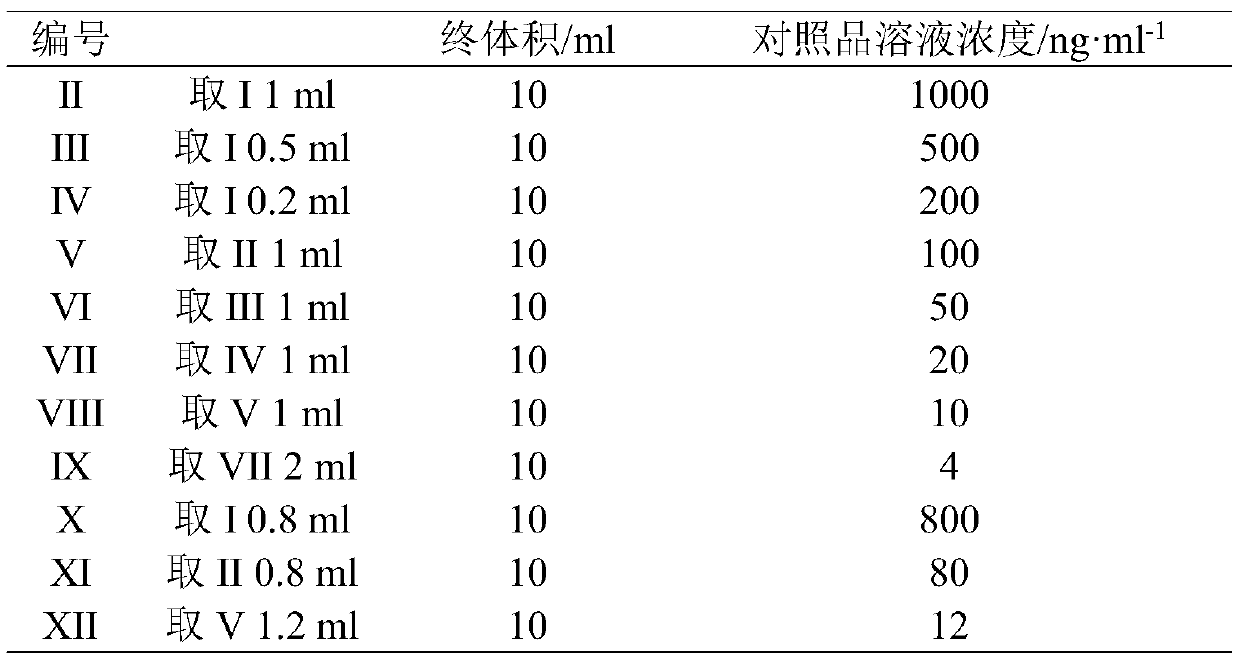

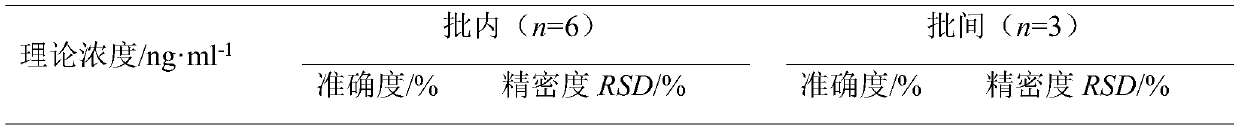

Method for quantitatively detecting concentration of bismuth in serum by inductively coupled plasma mass spectrometry

PendingCN111562303AMeet detectionHigh sensitivityComponent separationMaterial analysis by electric/magnetic meansRadio frequencyPhysics

The invention discloses a method for quantitatively detecting the concentration of bismuth in serum by inductively coupled plasma mass spectrometry. The method comprises the steps of firstly, nitrifying a beagle serum sample by adopting nitric acid, and detecting the content of bismuth in beagle serum by taking rhodium as an internal standard and adopting an inductively coupled plasma mass spectrometry (ICP-MS) method. The mass spectrometry detection parameters are as follows: the radio frequency power is 1550W; the pump speed is 40r.min<-1>; the temperature of an atomizing chamber is 2.7 DEGC; the sampling depth is 5mm; the cooling air flow velocity is 14L.Min<-1>; the auxiliary air flow velocity is 0.8L.min<-1>; and the atomized air flow velocity is 1.1L.min<-1>. According to the method, the linear relation of folic acid at 0.2-50ng / ml is good. The recovery rate of the method ranges from 101.1% to 103.4%; the accuracy in batches and the accuracy between batches are 91.9%-101.4%, andthe precision in batches and the precision between batches are 3.2%-10.5%. The method is low in limit of quantitation, short in analysis time and good in reproducibility, can meet the detection requirements of the concentration of bismuth in beagle serum, and can be used for pharmacokinetic research of colloidal bismuth citrate capsules.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

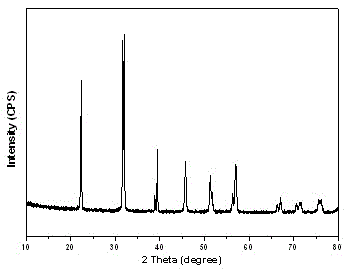

Method for preparing Bi2WO6 nano-sheets

InactiveCN107200355ANo pollution in the processSimple processNanotechnologyTungsten compoundsSodium tungstate dihydrateAmmonium

The invention relates to a method for preparing Bi2WO6 nano-sheets. The method comprises the following steps: 1) dropwise adding an ammonium bismuth citrate solution into a sodium tungstate solution, wherein the mol concentration of the ammonium bismuth citrate solution is 0.2mol / L to 0.6mol / L, and the mol concentration of the sodium tungstate solution is 0.1mol / L to 0.3mol / L; 2) continually dropwise adding an NaOH solution and a PVA solution; after mixing, carrying out hydrothermal reaction; filtering and washing to obtain the Bi2WO6 nano-sheets, wherein the mol concentration of the NaOH solution is 0.1mol / L to 3mol / L, and the mol concentration of the PVA solution is 0.01mol / L to 0.1mol / L. The Bi2WO6 nano-sheets prepared by the method have a good appearance and a uniform size.

Owner:ZHEJIANG UNIV

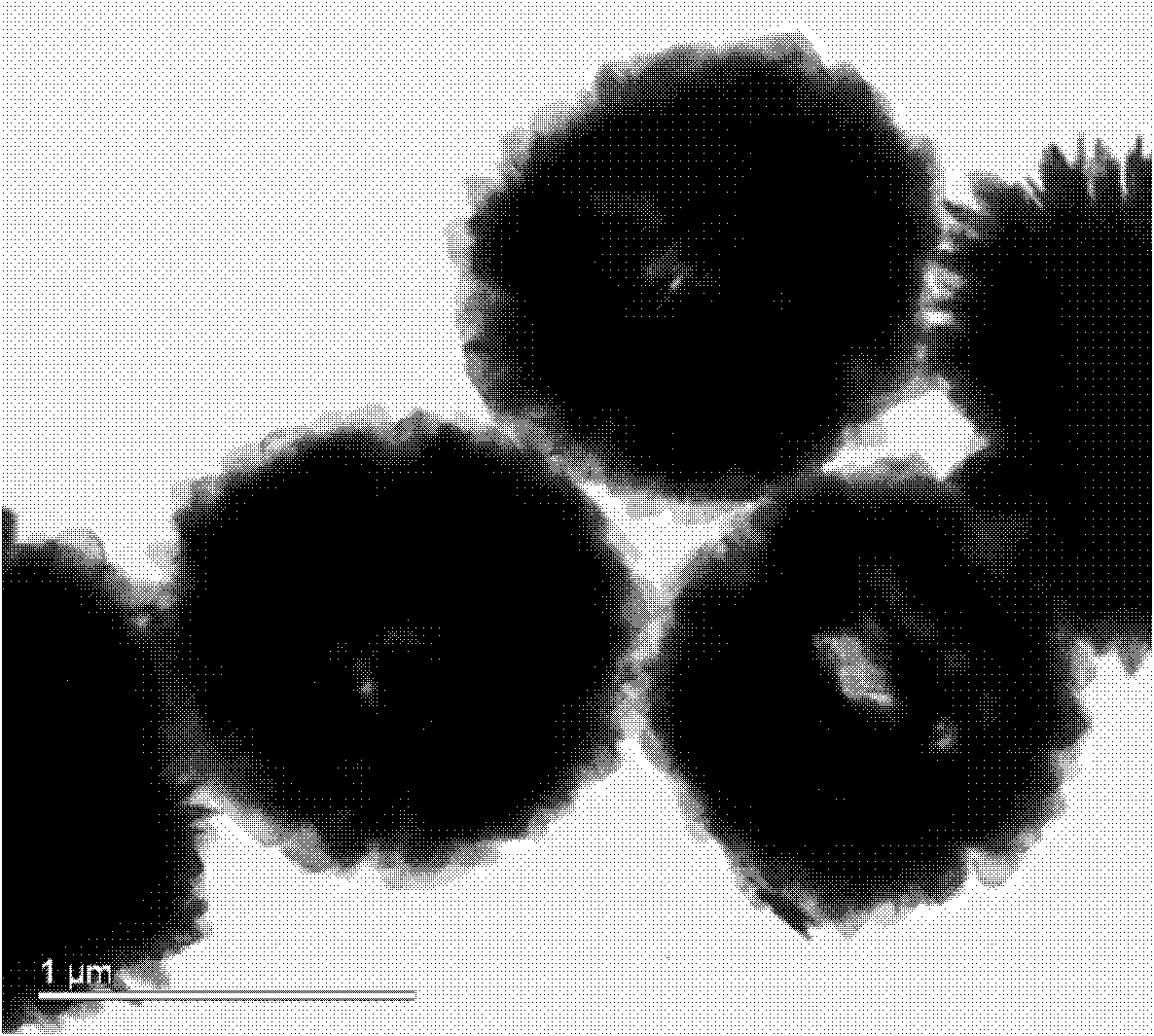

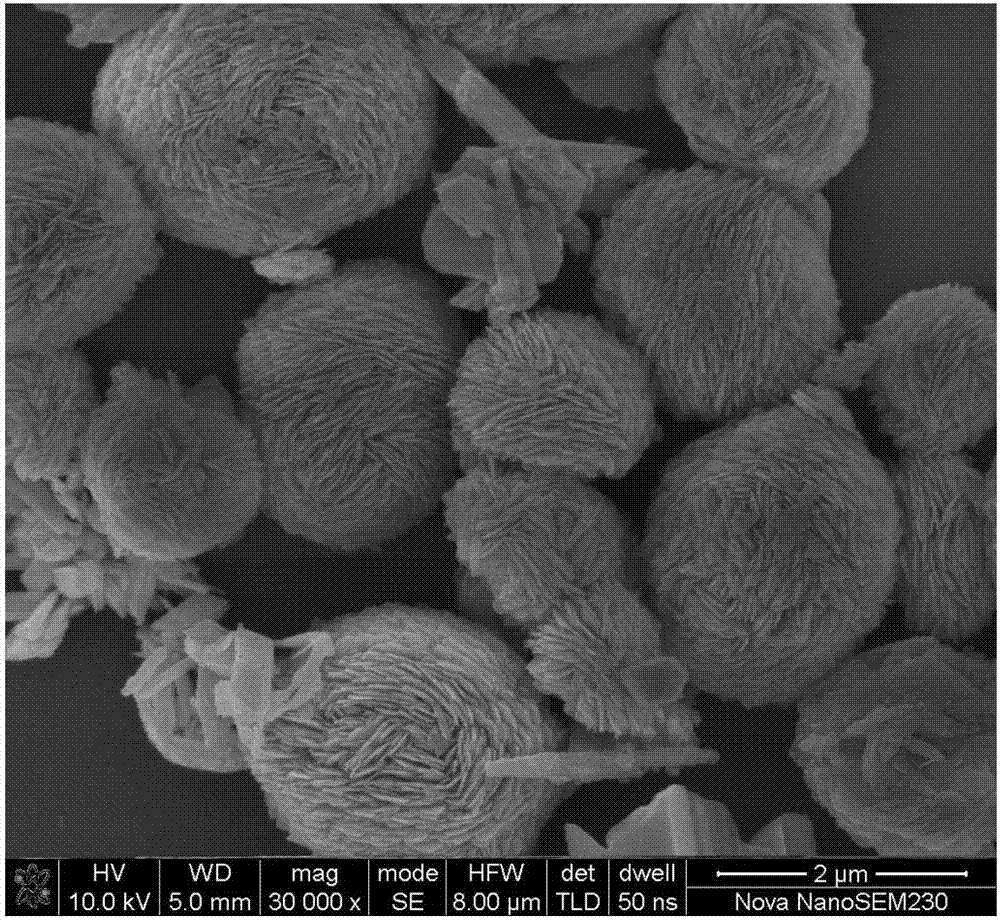

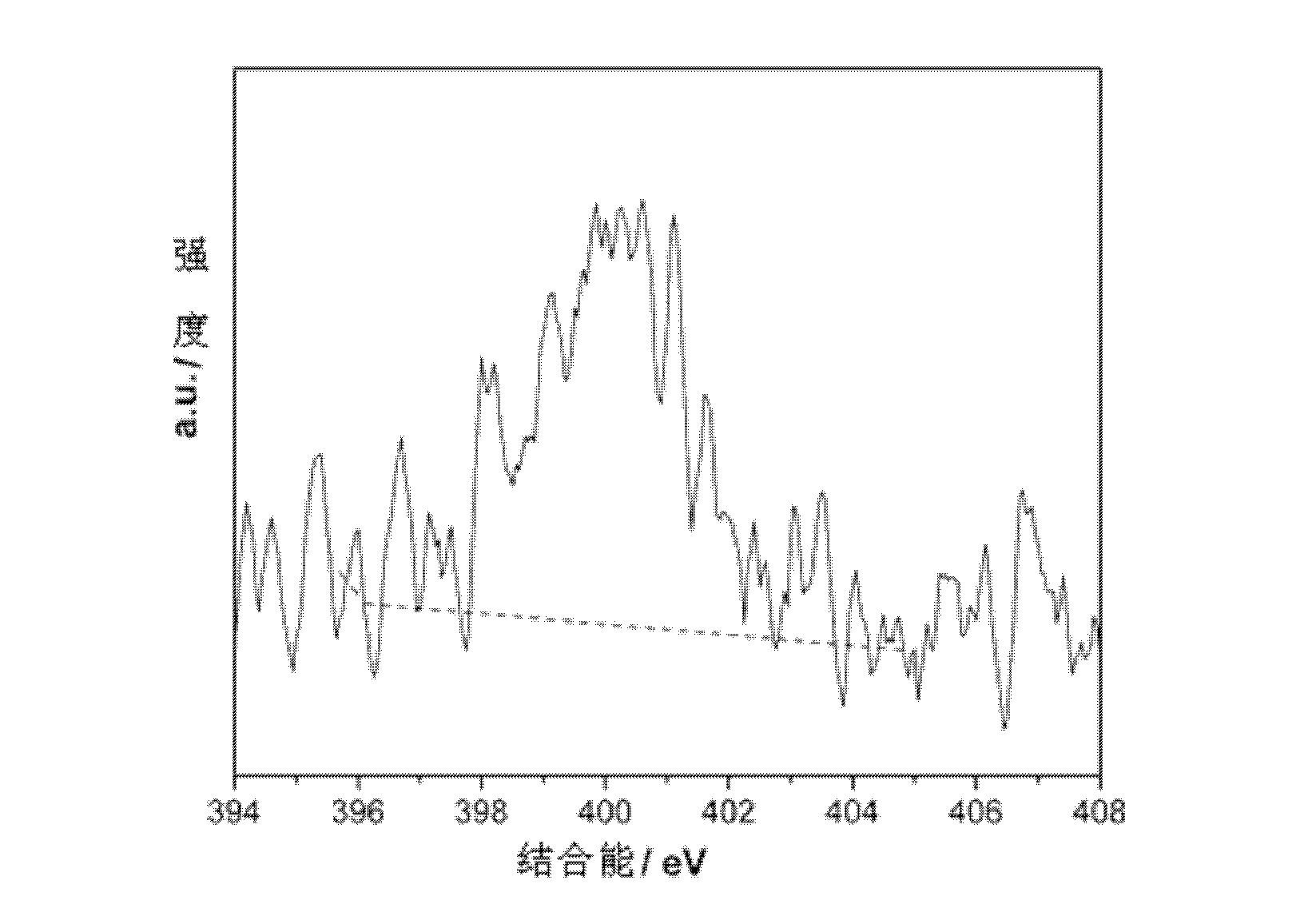

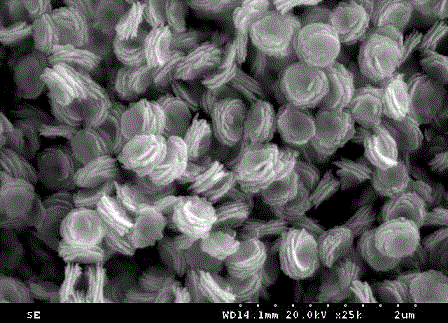

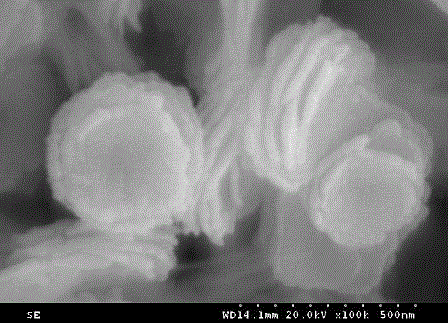

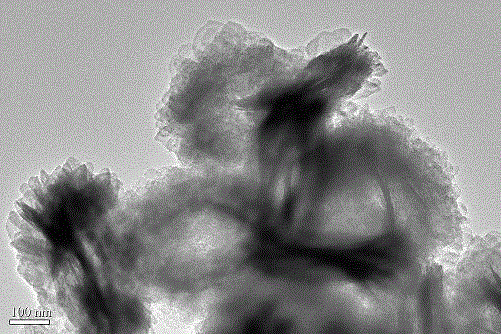

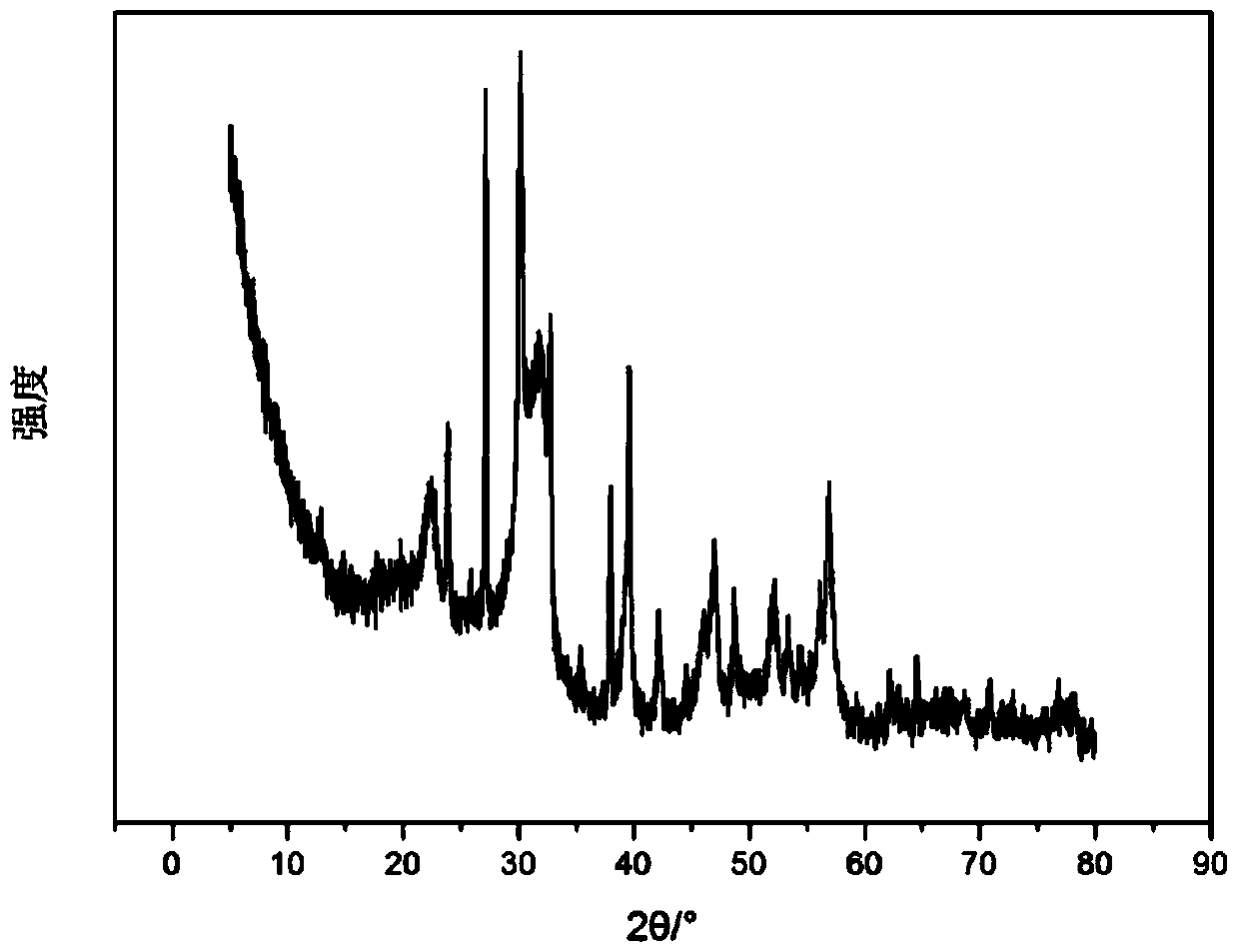

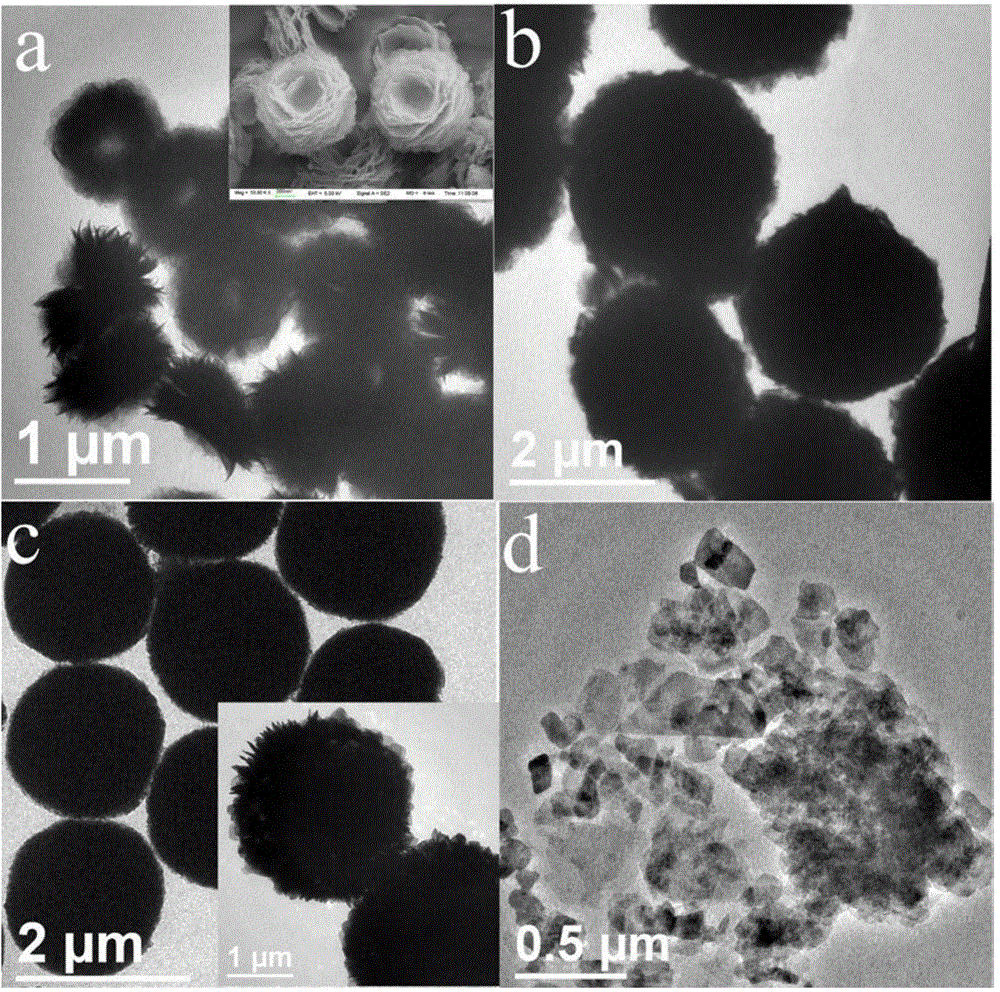

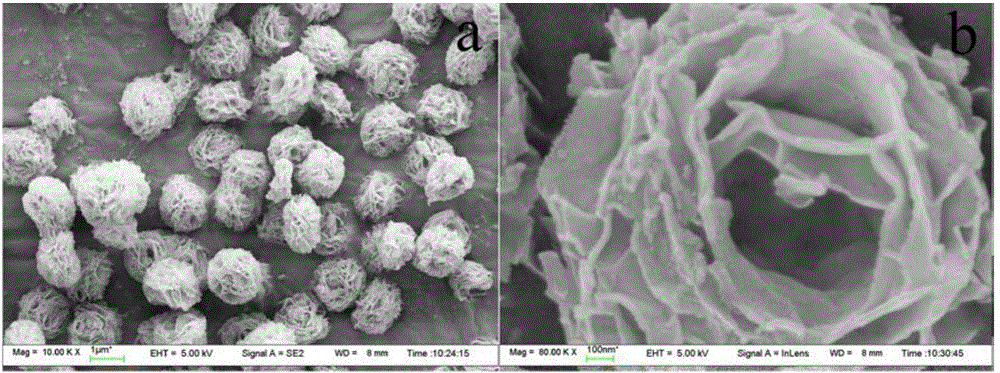

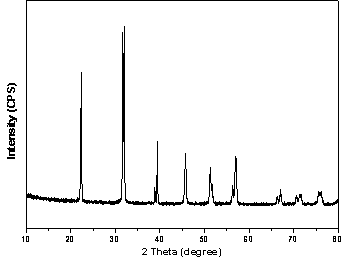

Bi2O2CO3 nanocrystal with unique morphology, and preparation method thereof

InactiveCN105523584ASimple methodNo pollution in the processMaterial nanotechnologyPhysical/chemical process catalystsSolventAmmonia

The invention discloses a Bi2O2CO3 nanocrystal with a unique morphology, and a preparation method thereof. According to the invention, bismuth citrate (C6H5BiO7) is adopted as a raw material; a dilute ammonia water solution is adopted as a solvent; and the hemispherical-structured Bi2O2CO3 nanocrystal composed of wound nano-sheets with curl edges is prepared with a hydrothermal method. The preparation method of the Bi2O2CO3 nanocrystal comprises the following steps: C6H5BiO7 is dissolved in the dilute ammonia water solution; the solution is subjected to a reaction in a reaction kettle; when the reaction is finished, washing is carried out, such that the hemispherical Bi2O2CO3 nanocrystal is obtained. The Bi2O2CO3 nanocrystal obtained through the reaction has a unique morphology and high specific surface area. With the Bi2O2CO3 nanocrystal, material performance can be effectively improved. In a photocatalysis performance test, the product obtained with the method shows good RhB catalytic degradation activity, which shows that the product has good application prospect in the respect of pollutant photocatalytic degradation.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of bismuth ferrite BiFeO3 monocrystal micrometer sheet

ActiveCN102877130BSimple processEasy to controlPolycrystalline material growthFrom normal temperature solutionsPotassium hydroxideRaw material

Owner:ZHEJIANG UNIV

Bismuth citrate synthesizing method

Owner:SHANGHAI MODERN HASEN SHANGQIU PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com