Bismuth series photocatalyst, and preparation method thereof

A photocatalyst, bismuth-based technology, applied in the field of photocatalysis, can solve problems such as inability to absorb visible light, and achieve the effect of improving photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention provides a kind of preparation method of bismuth series photocatalyst, comprises the following steps:

[0044] Bismuth source and nitrogen source are carried out hydrothermal reaction in aqueous solution, obtain the bismuth series photocatalyst with molecular formula shown in formula (I):

[0045] N m [(BiO) 2 CO 3 ] (1-m) (I);

[0046] Among them, m is 0.01% to 5%;

[0047] The bismuth source is bismuth citrate or bismuth ammonia citrate.

[0048] In the present invention, a bismuth source and a nitrogen source are first dissolved in water to obtain a mixed solution; the bismuth source is bismuth citrate or bismuth ammonium citrate. In the present invention, preferably, the aqueous solution of the nitrogen source is prepared first, and then the bismuth source is added to the aqueous solution of the nitrogen source to obtain a mixed solution. In the present invention, the nitrogen source is preferably ammonia water, ammonium sulfate, ammonium bi...

Embodiment 1

[0066] Dilute 1.6mL of concentrated ammonia water with a mass concentration of 32% to 75mL with deionized water to obtain an aqueous ammonia solution with a mass concentration of 1.5%, add 1.6g of bismuth citrate to it, stir for 30min, and transfer the resulting mixed solution into 100mL of hydrothermal In the kettle, the hydrothermal reaction was carried out at 210°C for 48 hours. After the reaction, the reaction product in the hydrothermal kettle was taken out, the reaction product was centrifuged, filtered, washed with water twice and washed with ethanol twice, and the obtained solid was dried at 80° C. to obtain a bismuth-based photocatalyst.

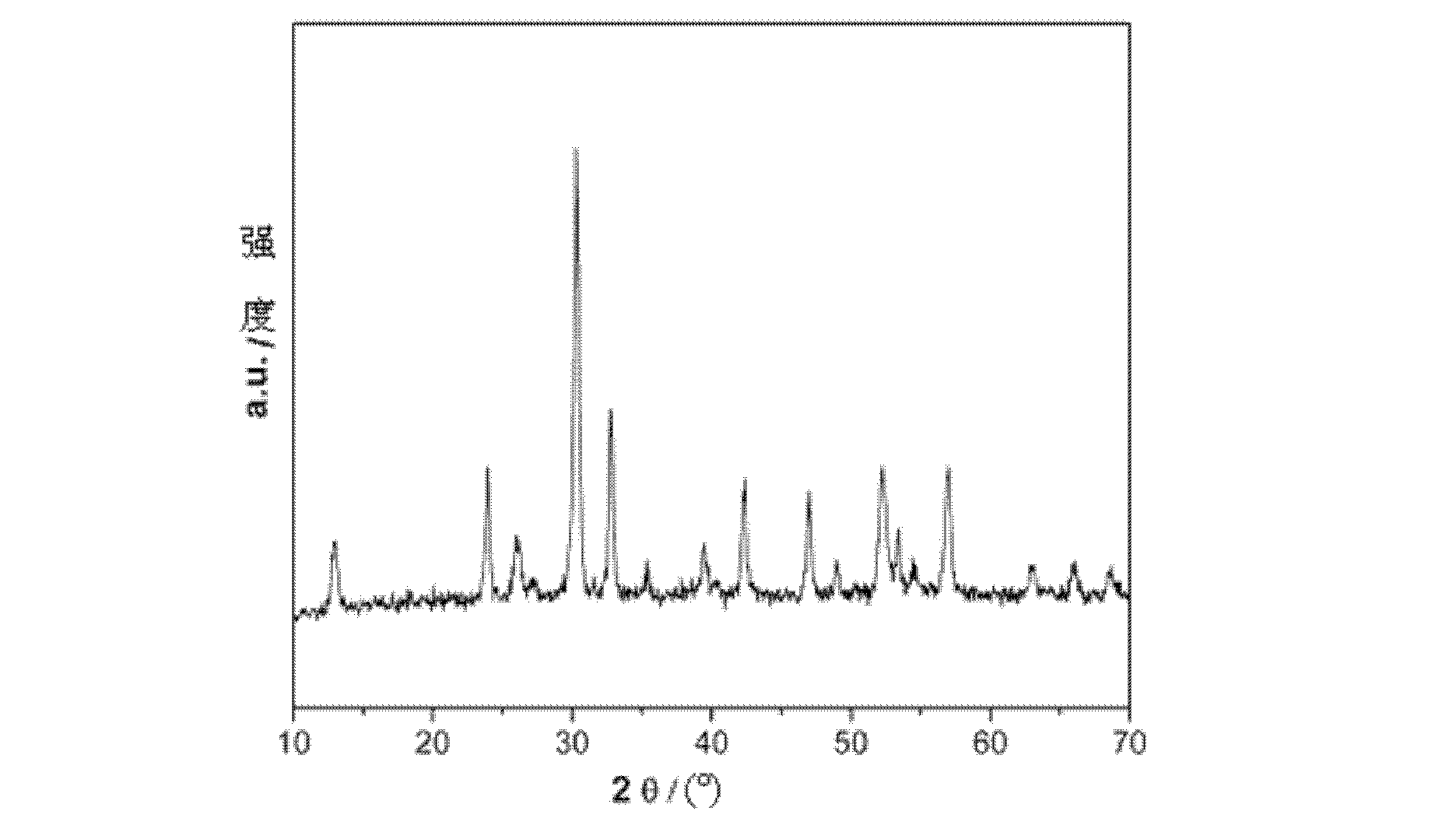

[0067] The present invention carries out XRD analysis to the obtained bismuth photocatalyst, the result is as follows figure 1 as shown, figure 1 For the XRD spectrum of the bismuth photocatalyst prepared in Example 1 of the present invention, by figure 1 It can be seen that the phase of the bismuth photocatalyst obtained in this ...

Embodiment 2

[0070] Dilute 5.3mL of concentrated ammonia water with a mass concentration of 32% to 75mL with deionized water to obtain an aqueous ammonia solution with a mass concentration of 4.53%, add 1.6g of bismuth citrate to it, stir for 30min, and transfer the resulting mixed solution into 100mL of hydrothermal In the kettle, the hydrothermal reaction was carried out at 180°C for 24 hours. After the reaction, the reaction product in the hydrothermal kettle was taken out, the reaction product was centrifuged, filtered, washed with water twice and washed with ethanol twice, and the obtained solid was dried at 80° C. to obtain a bismuth-based photocatalyst.

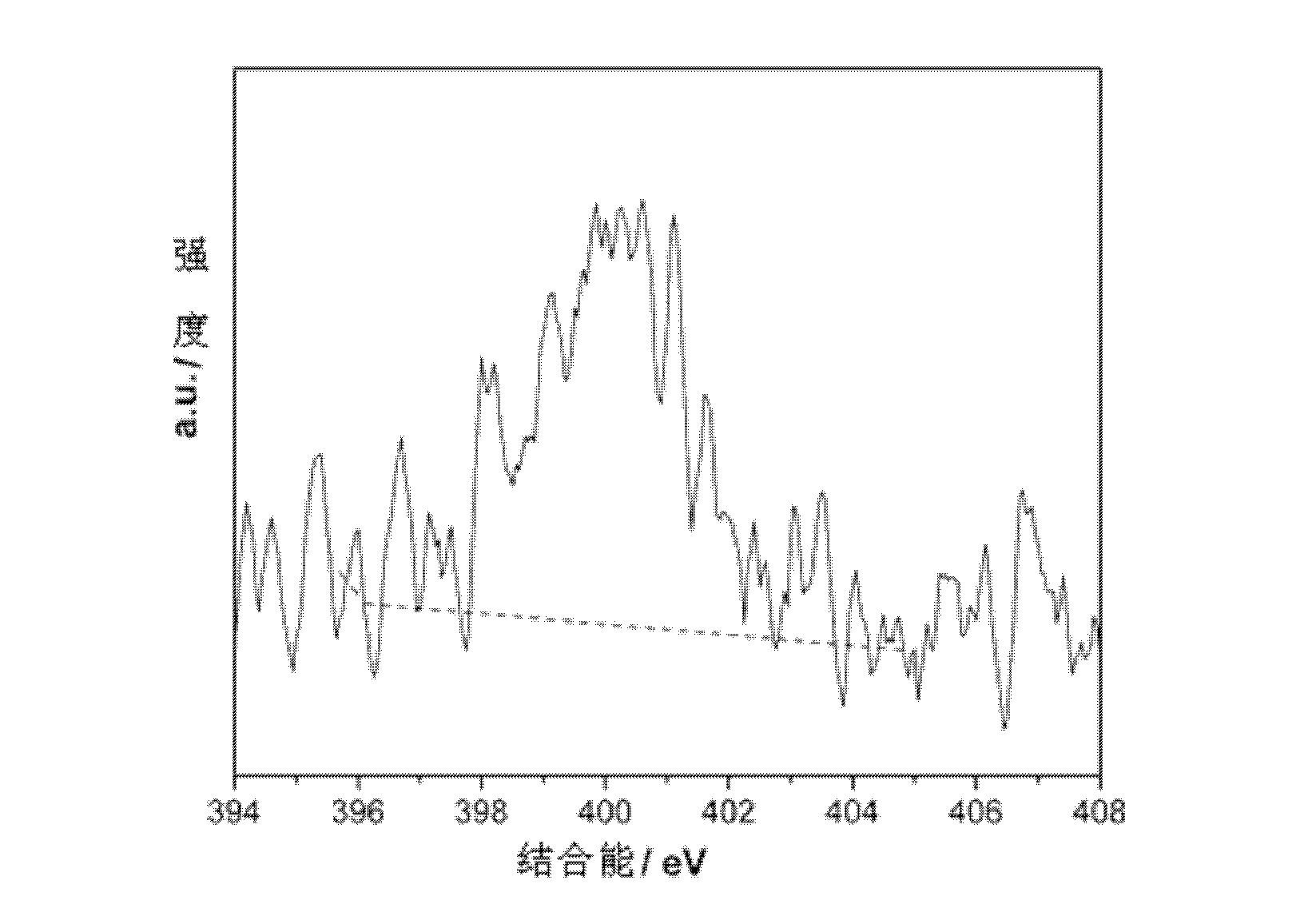

[0071] The present invention carries out XRD analysis to the obtained bismuth-based photocatalyst, and the result shows that the phase of the bismuth-based photocatalyst obtained in the present embodiment is (BiO) 2 CO 3 ; The present invention carries out XPS analysis to the prepared bismuth photocatalyst, the result is as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com