Gold-supported bismuth subcarbonate material for photocatalysis and preparation method

A technology of bismuth oxycarbonate and photocatalysis, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of being unable to be used as photocatalytic materials and limited quantum efficiency, and achieve good catalytic effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

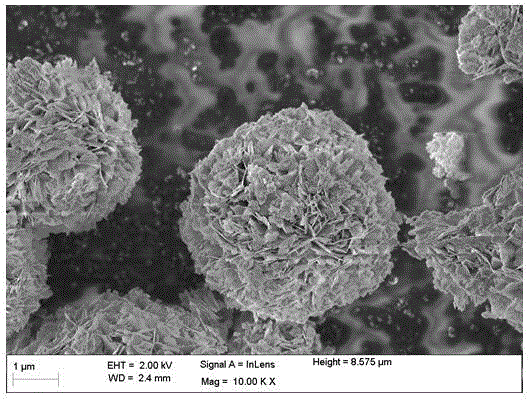

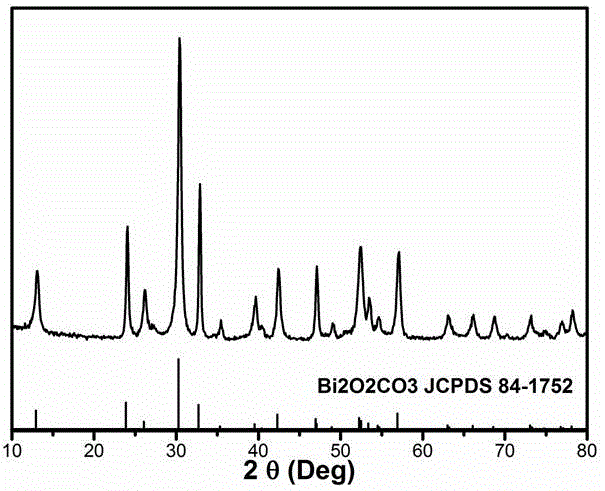

[0019] Weigh 0.46g sodium carbonate [Na 2 CO 3 ], 1.6g ammonium bismuth citrate [C 6 h 13 BiN 2 o 7 ·H 2 O] was added to 70ml of water and stirred at room temperature until the solution was a suspension.

[0020] The above suspension was transferred into a 100ml polytetrafluoroethylene reactor for reaction, reacted at 160°C for 24 hours, cooled naturally, and the obtained precipitate was centrifuged, washed and dried to obtain bismuth oxycarbonate microspheres.

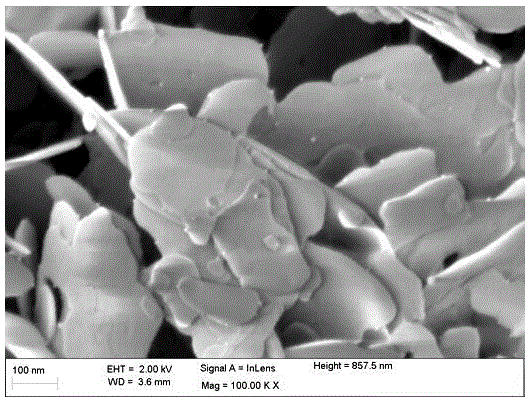

[0021] Weigh 0.5g bismuth oxycarbonate, add 1.26g urea into 50ml water, add 2.6mM chloroauric acid at the same time, put them together into a round bottom flask, stir magnetically, and react at 80°C for 4h under the condition of heating in a water bath.

[0022] After the reaction, cool naturally, centrifuge, wash and dry the precipitate, and finally put the sample into a muffle furnace at 350° C. for 2 hours to obtain gold-supported bismuth oxycarbonate.

[0023] Photocatalytic performance test of materials

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com