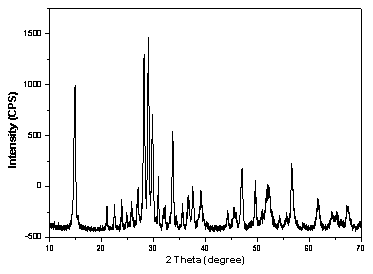

Preparation method for bismuth ferrite Bi2Fe4O9 monocrystal nanosheets

A technology of single-crystal nanometer and bismuth ferrite, which is applied in nanotechnology, chemical instruments and methods, iron compounds, etc., can solve the problems of poor controllability of reaction, low product purity, difficult control of particle size and shape, etc. Low cost, simple process, good feasibility and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] 1) Weigh ferric nitrate and bismuth amine citrate at a molar ratio of 1:1, add deionized water and nitric acid to make the concentration of nitric acid in the system 1.125mol / L, stir well to form a mixture containing bismuth amine citrate and bismuth amine A clear solution of ferric nitrate;

[0021] 2) Under stirring, add an aqueous potassium hydroxide solution to the clarified solution containing bismuth ammonium citrate and ferric nitrate prepared in step 1), to obtain a suspension containing bismuth and iron oxyhydroxide precipitates;

[0022] 3) Transfer the obtained suspension of oxyhydroxide precipitation containing bismuth and iron to the inner tank of the reactor, adjust the volume of the reaction material in the inner tank of the reactor with deionized water to reach 90% of the volume of the inner tank of the reactor, and stir In 10 minutes, in the reaction mass, the molar concentration of ferric nitrate and bismuth amine citrate was 0.05mol / L, and the molar c...

example 2

[0025] 1) Weigh ferric nitrate and bismuth amine citrate at a molar ratio of 1:1, add deionized water and nitric acid to make the concentration of nitric acid in the system 0.75mol / L, stir well to form a mixture containing bismuth amine citrate and bismuth amine A clear solution of ferric nitrate;

[0026] 2) Under stirring, add an aqueous potassium hydroxide solution to the clarified solution containing bismuth ammonium citrate and ferric nitrate prepared in step 1), to obtain a suspension containing bismuth and iron oxyhydroxide precipitates;

[0027] 3) Transfer the obtained suspension of oxyhydroxide precipitation containing bismuth and iron to the inner tank of the reactor, adjust the volume of the reaction material in the inner tank of the reactor with deionized water to reach 90% of the volume of the inner tank of the reactor, and stir In 30 minutes, in the reaction mass, the molar concentration of ferric nitrate and bismuth amine citrate was 0.05mol / L, and the molar co...

example 3

[0030] 1) Weigh ferric nitrate and bismuth amine citrate at a molar ratio of 1:1, add deionized water and nitric acid to make the concentration of nitric acid in the system 1mol / L, stir well, and form a mixture containing bismuth amine citrate and nitric acid clear solution of iron;

[0031] 2) Under stirring, add an aqueous potassium hydroxide solution to the clarified solution containing bismuth ammonium citrate and ferric nitrate prepared in step 1), to obtain a suspension containing bismuth and iron oxyhydroxide precipitates;

[0032] 3) Transfer the obtained suspension of oxyhydroxide precipitation containing bismuth and iron to the inner tank of the reactor, adjust the volume of the reaction material in the inner tank of the reactor with deionized water to 80% of the volume of the inner tank of the reactor, and stir 60 minutes, in the reaction mass, the molar concentration of ferric nitrate and bismuth amine citrate is 0.05mol / L, and the molar concentration of potassium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com