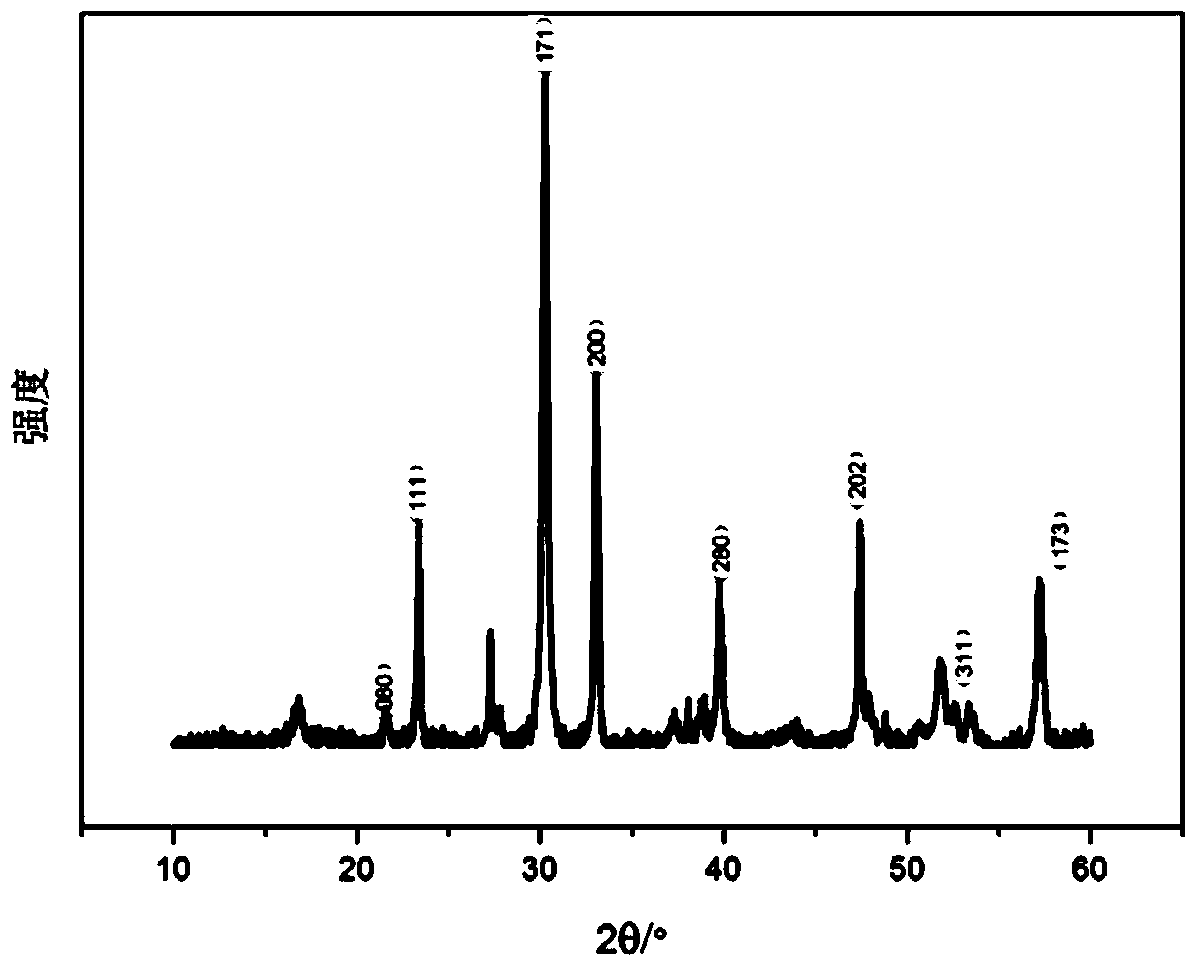

Preparation method and product of Bi4Ti3O12 nanosheets

A nanosheet and precursor solution technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as affecting the purity of the target product, and achieve the effects of easy large-scale production, simple preparation process, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Weighing 6 mmol of tetrabutyl titanate and dissolving it in ethylene glycol methyl ether to finally obtain an ethylene glycol methyl ether solution with a tetrabutyl titanate concentration of 0.4 mol / L. Weigh KOH, dissolve it in deionized water, and control the concentration of KOH to 1mol / L

[0036] 2) Under stirring, add the KOH solution prepared in step 1) dropwise to the tetrabutyl titanate ethylene glycol methyl ether solution prepared in step 1), so that tetrabutyl titanate is hydrolyzed to obtain titanium oxyhydroxide matter precipitation. Thereafter, wash and filter with deionized water more than 3 times.

[0037] 3) Weigh 8mmol of ammonium bismuth citrate, dissolve it in deionized water, and finally obtain an aqueous solution of ammonium bismuth citrate with a concentration of 0.4mol / L;

[0038] 4) Under stirring, disperse the precipitated titanium oxyhydroxide prepared in step 2) in the aqueous solution of ammonium bismuth citrate prepared in step 3), for...

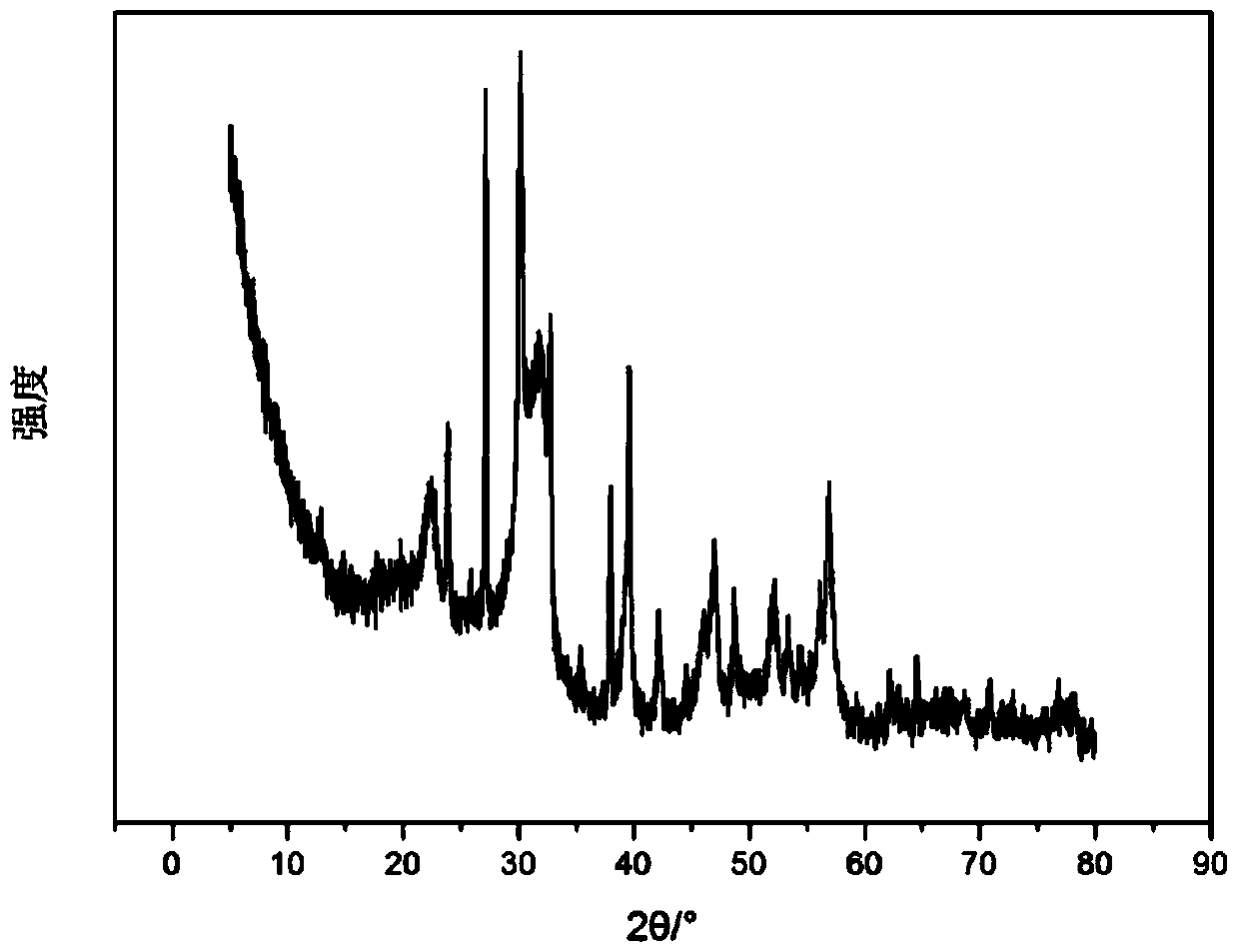

Embodiment 2

[0045] 1) Weighing 6 mmol of tetrabutyl titanate and dissolving it in ethylene glycol methyl ether to finally obtain an ethylene glycol methyl ether solution with a tetrabutyl titanate concentration of 0.5 mol / L. Weigh KOH, dissolve it in deionized water, and control the concentration of KOH to 2mol / L.

[0046] 2) Under stirring, add the KOH solution prepared in step 1) dropwise to the tetrabutyl titanate ethylene glycol methyl ether solution prepared in step 1), so that tetrabutyl titanate is hydrolyzed to obtain titanium oxyhydroxide matter precipitation. Thereafter, wash and filter with deionized water more than 3 times.

[0047] 3) Take 8mmol of ammonium bismuth citrate, dissolve it in deionized water, and finally obtain an aqueous solution of ammonium bismuth citrate with a concentration of 0.5mol / L;

[0048] 4) Under stirring, disperse the precipitated titanium oxyhydroxide prepared in step 2) in the aqueous solution of ammonium bismuth citrate prepared in step 3), for...

Embodiment 3

[0053] 1) Weigh 6 mmol of tetrabutyl titanate, dissolve it in ethylene glycol methyl ether, and finally obtain an ethylene glycol methyl ether solution with a tetrabutyl titanate concentration of 0.7 mol / L. Weigh KOH, dissolve it in deionized water, and control the concentration of KOH to be 3mol / L

[0054] 2) Under stirring, add the KOH solution prepared in step 1) dropwise to the tetrabutyl titanate ethylene glycol methyl ether solution prepared in step 1), so that tetrabutyl titanate is hydrolyzed to obtain titanium oxyhydroxide matter precipitation. Thereafter, wash and filter with deionized water more than 3 times.

[0055] 3) Weigh 8mmol of ammonium bismuth citrate, dissolve it in deionized water, and finally obtain an aqueous solution of ammonium bismuth citrate with a concentration of 0.7mol / L;

[0056] 4) Under stirring, disperse the precipitated titanium oxyhydroxide prepared in step 2) in the aqueous solution of ammonium bismuth citrate prepared in step 3), formin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com