Bismuth citrate synthesizing method

A bismuth citrate and synthesis method technology, applied in the direction of carboxylate preparation, etc., can solve the problems of environmental hazards, increased labor load, unfavorable large-scale production, etc., and achieve the effect of complete reaction, mild process conditions, and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

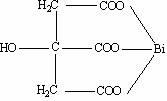

Image

Examples

Embodiment 1

[0014] A kind of bismuth citrate synthesis method, it comprises the following steps:

[0015] Dissolve 672.5g of citric acid completely in 324g of water at a temperature of 45°C, then add 466g of bismuth oxide, heat up to 80°C after mixing, and react at normal pressure for 20 hours (tested with ammonia water with a mass concentration of 25-28%, no precipitation ), the reaction product was filtered, washed with water, and dried to obtain 789.6 g of white powdery solid, namely bismuth citrate, with a yield of 99.2%.

Embodiment 2

[0017] Dissolve 730.1g of citric acid completely in 342g of water at a temperature of 46°C, then add 466g of bismuth oxide, heat up to 83°C after mixing, and react at normal pressure for 22 hours (tested with ammonia water with a mass concentration of 25-28%, no precipitation ), the reaction product was filtered, washed with water, and dried to obtain 791.2 g of white powdery solid, namely bismuth citrate, with a yield of 99.4%.

Embodiment 3

[0019] Dissolve 768.6g of citric acid completely in 360g of water at 48°C, then add 466g of bismuth oxide, mix well, heat up to 85°C, and react at normal pressure for 24 hours (tested with ammonia water with a mass concentration of 25-28%, no precipitation ), the reaction product was filtered, washed with water, and dried to obtain 790.4 g of white powdery solid, namely bismuth citrate, with a yield of 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com