Graphite-phase carbon nitride photocatalyst modified by basic bismuth carbonate and preparation method of graphite-phase carbon nitride photocatalyst

A graphitic carbon nitride and phase carbon nitride light technology, applied in the field of materials, can solve the problems of unfavorable absorption and utilization, low photocatalytic activity, unsuitable application, etc., and achieves simple and convenient preparation method, high photocatalytic activity, and preparation cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 30 grams of urea (Tianjin Kaitong Chemical Reagent Co., Ltd.) and 10 mg of bismuth citrate (Tianjin Kaima Biochemical Co., Ltd.) were put into an agate mortar, fully stirred, ground, and mixed for 20 minutes, and the above mixture was put into Aluminum oxide porcelain ark, then put the porcelain ark in a muffle furnace for heat treatment, from room temperature to 500 degrees at a rate of 10 degrees per minute, keep it warm for 2 hours, then cool to room temperature with the furnace, and then put agate In a mortar, it is fully ground into a powder of 1-5 microns to obtain a graphite-phase carbon nitride photocatalyst modified by bismuth subcarbonate.

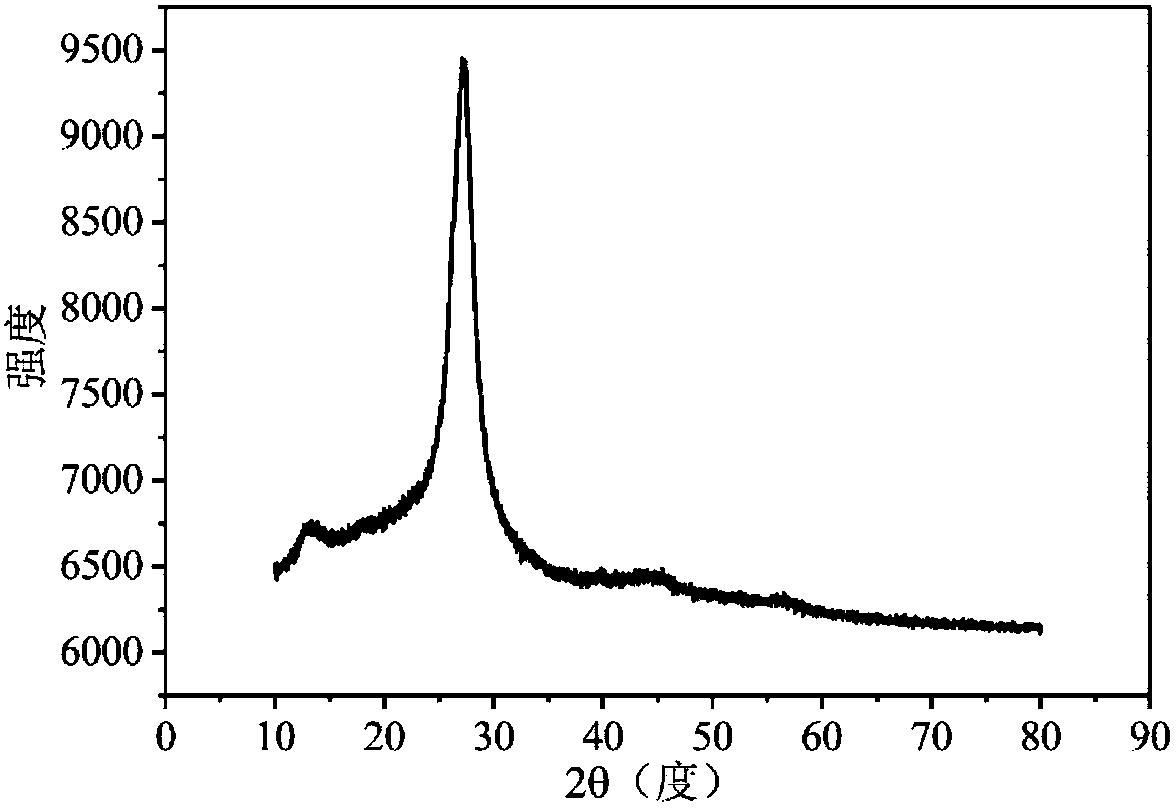

[0019] like figure 1 As shown, the X-ray diffraction pattern of the carbon nitride photocatalyst modified by bismuth subcarbonate is mainly the diffraction peak of carbon nitride.

[0020] like figure 2 As shown, in the transmission electron micrograph of the bismuth subcarbonate-modified carbon nitride photocatalyst, t...

Embodiment 2

[0023] 30 grams of urea (Tianjin Kaitong Chemical Reagent Co., Ltd.) and 5 mg of bismuth citrate (Tianjin Kaima Biochemical Co., Ltd.) were put into an agate mortar, fully stirred, ground, and mixed for 20 minutes, and the above mixture was put into Aluminum oxide porcelain ark, then put the porcelain ark in a muffle furnace for heat treatment, from room temperature to 500 degrees at a rate of 2 degrees per minute, keep it warm for 1 hour, then cool to room temperature with the furnace, and then put agate In a mortar, it is fully ground into a powder of 1-5 microns to obtain a graphite-phase carbon nitride photocatalyst modified by bismuth subcarbonate.

[0024] Photocatalytic water splitting hydrogen production performance test of bismuth subcarbonate modified graphite phase carbon nitride photocatalyst: 300 watt xenon lamp as light source, 50 mg carbon nitride photocatalyst, 8 milliliters of triethanolamine, 4 milliliters of chloroplatinic acid (1 mg per milliliter), 68 mill...

Embodiment 3

[0026] 30 grams of urea (Tianjin Kaitong Chemical Reagent Co., Ltd.) and 20 mg of bismuth citrate (Tianjin Kaima Biochemical Co., Ltd.) were put into an agate mortar, fully stirred, ground, and mixed for 20 minutes, and the above mixture was put into In the alumina porcelain ark, the porcelain ark is then placed in a muffle furnace for heat treatment, and the temperature is raised from room temperature to 500 degrees at a rate of 30 degrees per minute, kept for 2 hours, then cooled to room temperature with the furnace, and then placed in agate In a mortar, it is fully ground into a powder of 1-5 microns to obtain a graphite-phase carbon nitride photocatalyst modified by bismuth subcarbonate.

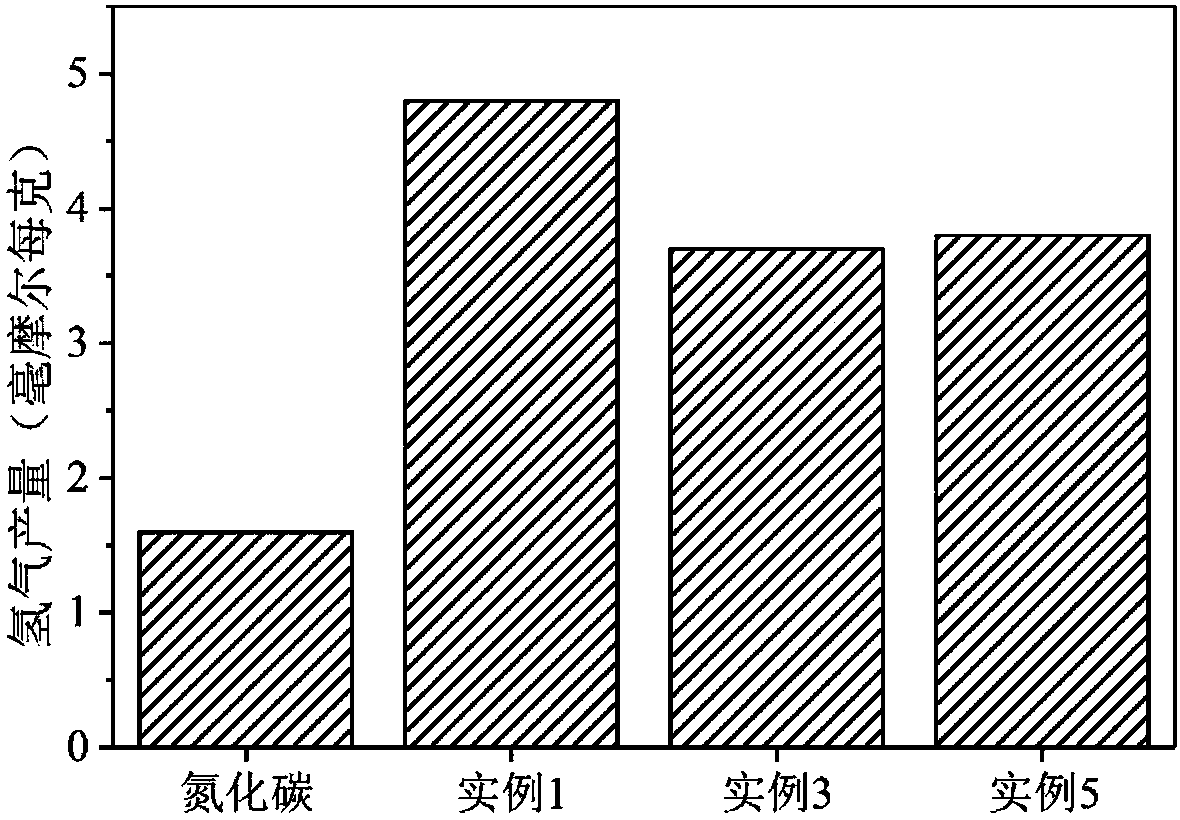

[0027] like image 3 As shown, the photocatalytic hydrogen production performance test of the graphitic carbon nitride photocatalyst modified by bismuth subcarbonate: 300 watt xenon lamp as light source, 50 mg carbon nitride photocatalyst, 8 ml triethanolamine, 4 ml chloroplatinic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com