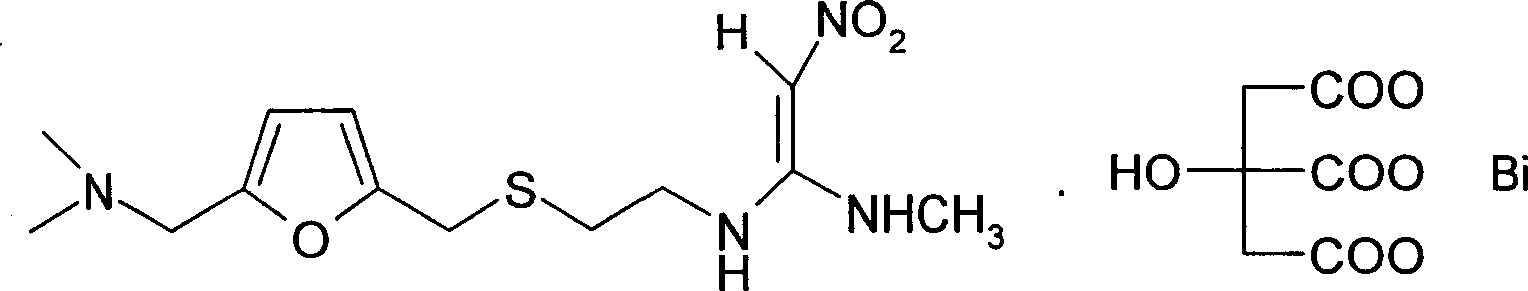

Method of preparing bismuth citrate ranitidine

A technology of bismuth citrate ranitidine and bismuth citrate is applied in directions such as organic chemistry, can solve problems such as low yield, high residual solvent, low production efficiency, etc., and achieves high yield and good product purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1, preparation bismuth citrate ranitidine

[0014] Suspend bismuth citrate (11.2g) in 100ml of water, add 20ml of 1mol / L ammonia water and ranitidine base (8.9g). Ammonia gas emerges, monitor the pH value to neutral, stop the reaction, filter the reaction solution, and spray dry to obtain the product.

[0015] The product purity is 99.4%.

Embodiment 2

[0016] Embodiment 2, preparation bismuth citrate ranitidine

[0017] Suspend bismuth citrate (11.2g) in 100ml of water, add ranitidine base (8.9g) and 14mol / L ammonia water 3ml, at this time the pH of the solution is 12, heat to 64°C for reaction, during the reaction Ammonia gas is constantly coming out, monitor the pH value to neutral, stop the reaction, filter the reaction solution, and spray dry to obtain the product.

[0018] The product purity is 99.2%.

Embodiment 3

[0019] Embodiment 3, preparation bismuth citrate ranitidine

[0020] Suspend bismuth citrate (11.2g) in 100ml of water, add ranitidine base (8.9g) and 5mol / L ammonia water 8ml, at this time the pH of the solution is 11, heat to 60°C for reaction, during the reaction Ammonia gas is constantly coming out, monitor the pH value to neutral, stop the reaction, filter the reaction solution, and spray dry to obtain the product.

[0021] The product purity is 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com