Bi2Ti2O7 ceramic powder and preparation method thereof

A technology of ceramic powder and reaction solution, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., which can solve complex reactions, which are not conducive to ensuring single-phase products, etc. problem, to achieve the effect of simple reaction process, excellent photocatalytic performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

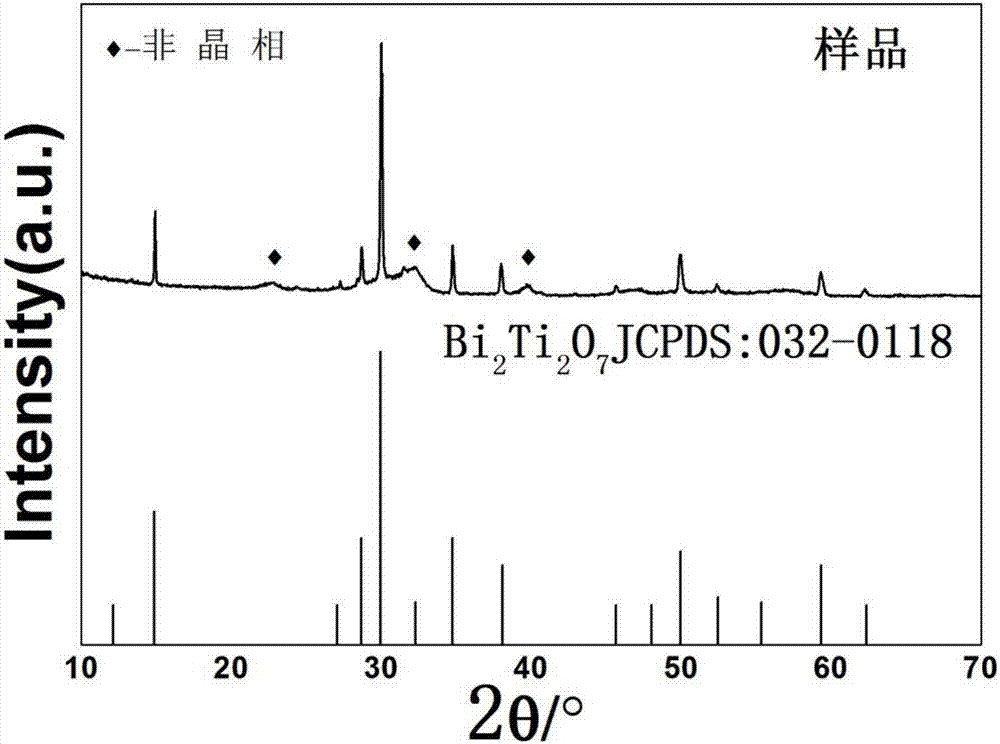

Embodiment 1

[0043] A Bi 2 Ti 2 o 7 Ceramic powder, the specific preparation steps are as follows:

[0044] 1) 0.0010mol bismuth citrate powder (C 6 h 5 BiO 7 ) was dissolved in 5mL ammonia water, fully stirred to obtain colorless and transparent mixed solution I;

[0045] 2) 0.0011mol tetrabutyl titanate (C 16 h 36 o 4 Ti) (bismuth / titanium molar ratio is 1:1.1) was added dropwise to the mixed solution I, and the reaction solution II was obtained after stirring;

[0046] 3) After fully stirring the obtained reaction solution II, pour it into the polytetrafluoroethylene liner, and add ammonia, water, and sodium hydroxide to adjust the filling degree of the polytetrafluoroethylene liner to be 80% (volume) and the pH to be 12 to 13; then placed in a hydrothermal reaction kettle, heated to 220°C for 40 hours in a constant temperature drying oven, and then centrifuged and washed several times until the supernatant was neutral. After drying, the described Bi 2 Ti 2 o 7 Ceramic powd...

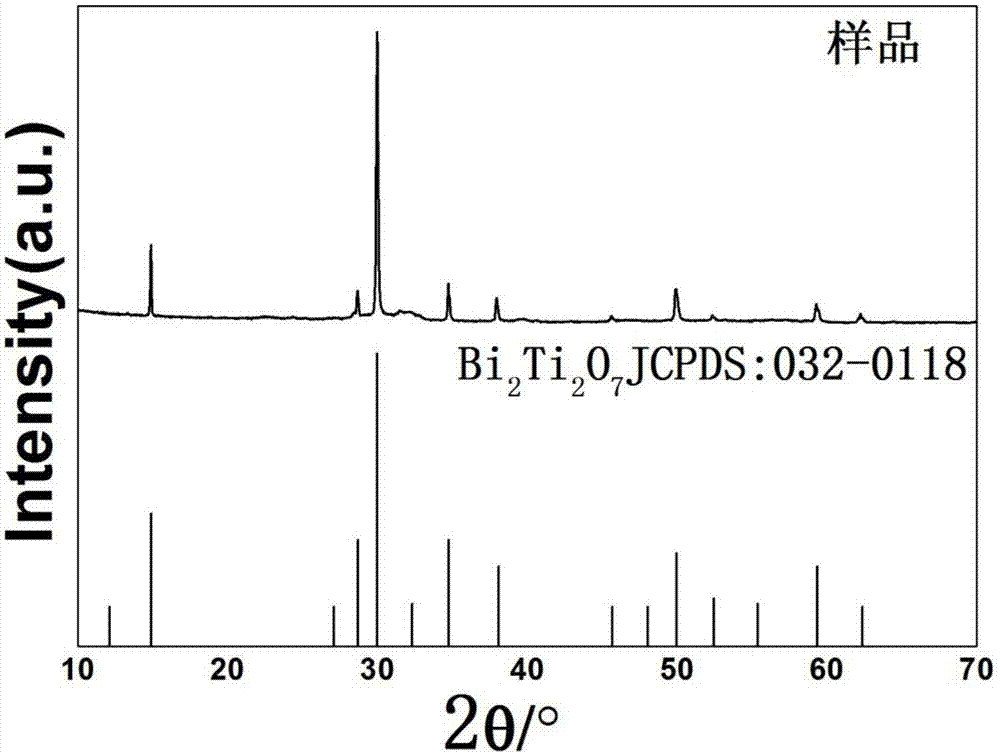

Embodiment 2

[0049] A Bi 2 Ti 2 o 7 Ceramic powder, the specific preparation steps are as follows:

[0050] 1) 0.0010mol bismuth citrate powder (C 6 h 5 BiO 7 ) was dissolved in 5mL ammonia water, fully stirred to obtain colorless and transparent mixed solution I;

[0051] 2) 0.0012mol tetrabutyl titanate (C 16 h 36 o 4 Ti) (bismuth / titanium molar ratio is 1:1.2) is added dropwise in the mixed solution I, and the reaction solution II is obtained after stirring;

[0052] 3) After fully stirring the obtained reaction solution II, pour it into the polytetrafluoroethylene liner, and add ammonia, water, and sodium hydroxide to adjust the filling degree of the polytetrafluoroethylene liner to be 80% (volume) and the pH to be 12 to 13; then placed in a hydrothermal reaction kettle, heated to 220°C for 72 hours in a constant temperature drying oven, and then centrifuged and washed several times until the supernatant was neutral. After drying, the described Bi 2 Ti 2 o 7 Ceramic powder...

Embodiment 3

[0056] A Bi 2 Ti 2 o 7 Ceramic powder, the specific preparation steps are as follows:

[0057] 1) 0.0010mol bismuth citrate powder (C 6 h 5 BiO 7 ) was dissolved in 5mL ammonia water, fully stirred to obtain colorless and transparent mixed solution I;

[0058] 2) 0.0010mol tetrabutyl titanate (C 16 h 36 o 4 Ti) (bismuth / titanium molar ratio is 1:1) was added dropwise into the mixed solution I, and the reaction solution II was obtained after stirring;

[0059] 3) After fully stirring the obtained reaction solution II, pour it into the polytetrafluoroethylene liner, and add ammonia, water, and sodium hydroxide to adjust the filling degree of the polytetrafluoroethylene liner to be 80% (volume) and the pH to be 12 to 13; then placed in a hydrothermal reaction kettle, heated to 220°C for 96 hours in a constant temperature drying oven, and then centrifuged and washed several times until the supernatant was neutral. After drying, the described Bi 2 Ti 2 o 7 Ceramic powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com