Preparation of hierarchical nanostructure Bi2O3/(BiO)2CO3

A hierarchical and composite photocatalytic technology, applied in the direction of catalyst activation/preparation, chemical/physical process, physical/chemical process catalyst, etc., can solve the problems of wide band gap and low light utilization rate, achieve stable performance and simple reaction method , Increase the effect of light utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

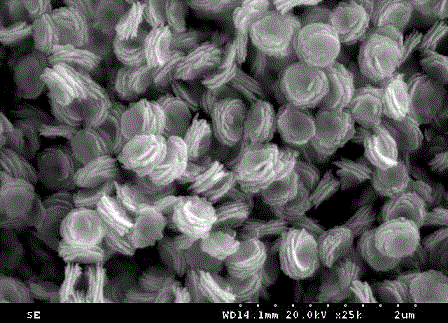

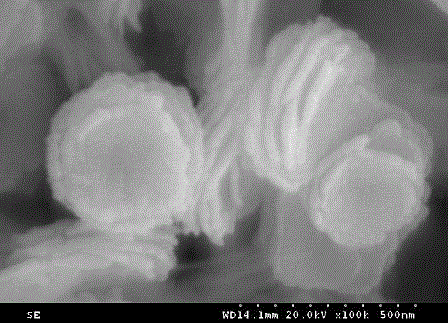

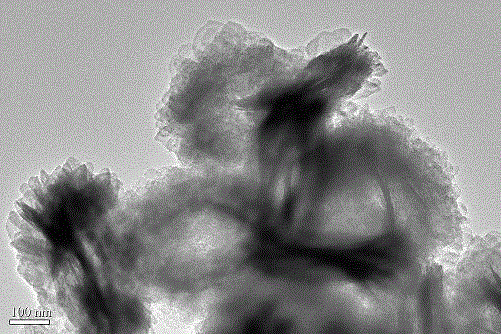

[0017] 2323 The temperature-programmed hydrothermal synthesis method of composite photocatalytic materials, weighing 99.8% anhydrous sodium carbonate purchased from Tianjin Kaitong Chemical Reagent Co., Ltd. Bismuth citrate, with a mass of 1.6±0.010 g, was purchased from Tianjin Kaitong Chemical Reagent Co., Ltd. 96.0% NaOH, with a mass of 0.2±0.010 g. Measure 60 mL of double distilled water, add 0.46±0.001 g Na 2 CO 3 , to fully dissolve it. Then add 1.6±0.010 g of bismuth citrate and stir for 30 min. After the solution is clarified, add a quantitative NaOH (0.2±0.010 g NaOH, 5 mL deionized water) solution drop by drop, and continue stirring for 0.5 h. The above mixed solution was transferred to a polytetrafluoroethylene reactor, the temperature was programmed to rise at 2 °C / min to 160 °C, and kept under water heat for 24 h. Then, the resulting product was washed three times with deionized water and ethanol. Filter the sediment and put it in a drying box, set the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com