Patents

Literature

46results about How to "Efficient Photocatalytic Degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

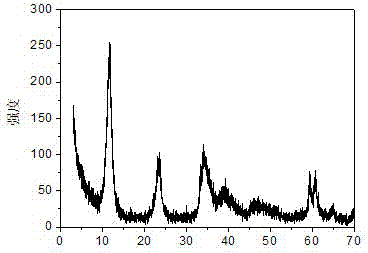

Method for preparing ZnFeCr hydrotalcite photocatalyst

InactiveCN103611543AEfficient Photocatalytic DegradationWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsSlurryZinc nitrate

The invention discloses a method for preparing a ZnFeCr hydrotalcite photocatalyst and relates to preparation methods of catalysts. The method comprises the following preparation steps of (1) preparing a salt solution of ferric nitrate, zinc nitrate and chromic nitrate, wherein the ratio of n(Zn) to n(Fe) to n(Cr) is 1: 1: 1, and the total concentration of metal ions is 1M; (2) preparing a 0.5M solution of sodium hydroxide (NaOH) and sodium carbonate (Na2CO3), wherein the ratio of NaOH to Na2CO3 is 2: 1; (3) simultaneously dropwise adding a metal salt solution and an alkali solution into the salt solution, and controlling the pH value to be 9-10; (4) carrying out hydrothermal crystallization on slurry, obtained after the dropwise adding is ended, for 24 hours at the temperature of 100 DEG C, then, filtrating, washing and drying, thereby obtaining the product. According to the method, the product has good performance in photocatalytic degradation of organic substances; the ZnFeCr hydrotalcite photocatalyst prepared by the method is low in cost, simple and convenient in operation and easy in large-scale production.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

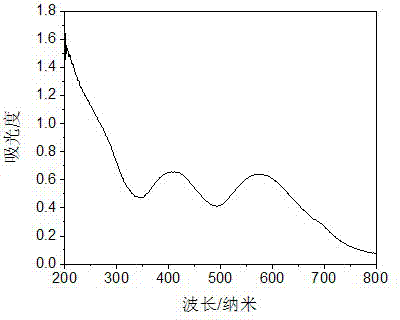

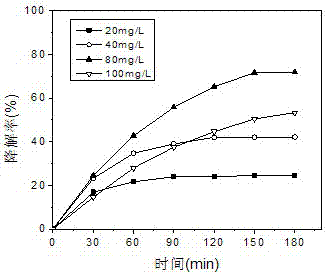

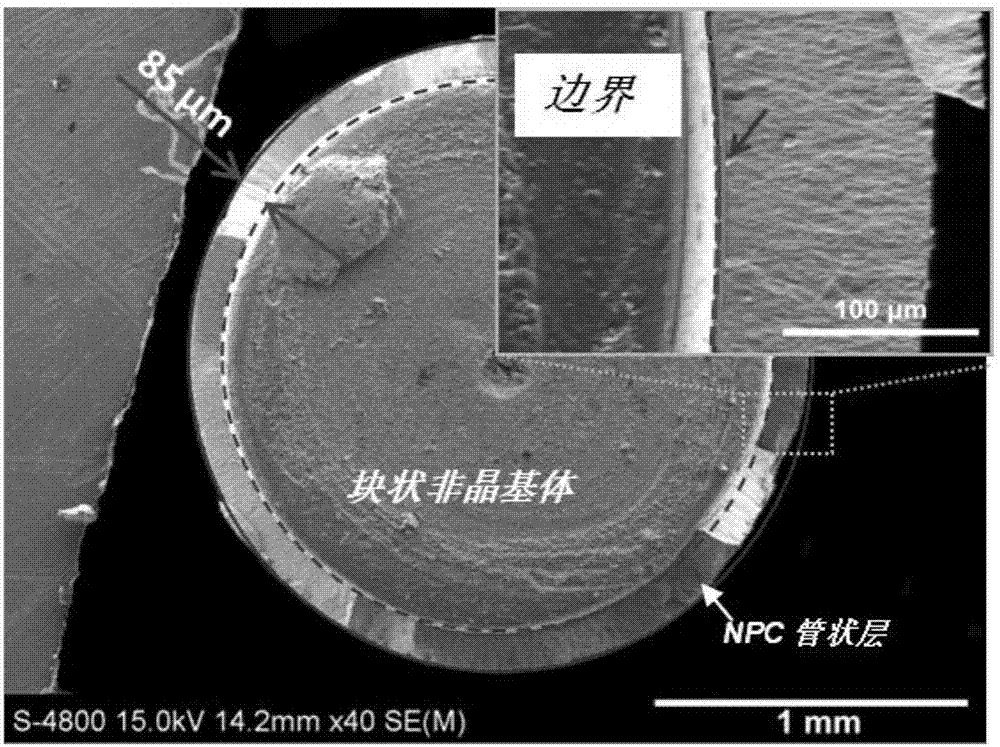

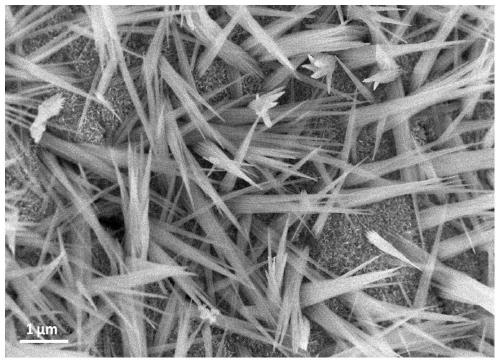

Nano-porous copper loaded ultrafine oxide copper nanowire composite material and preparation method and application thereof

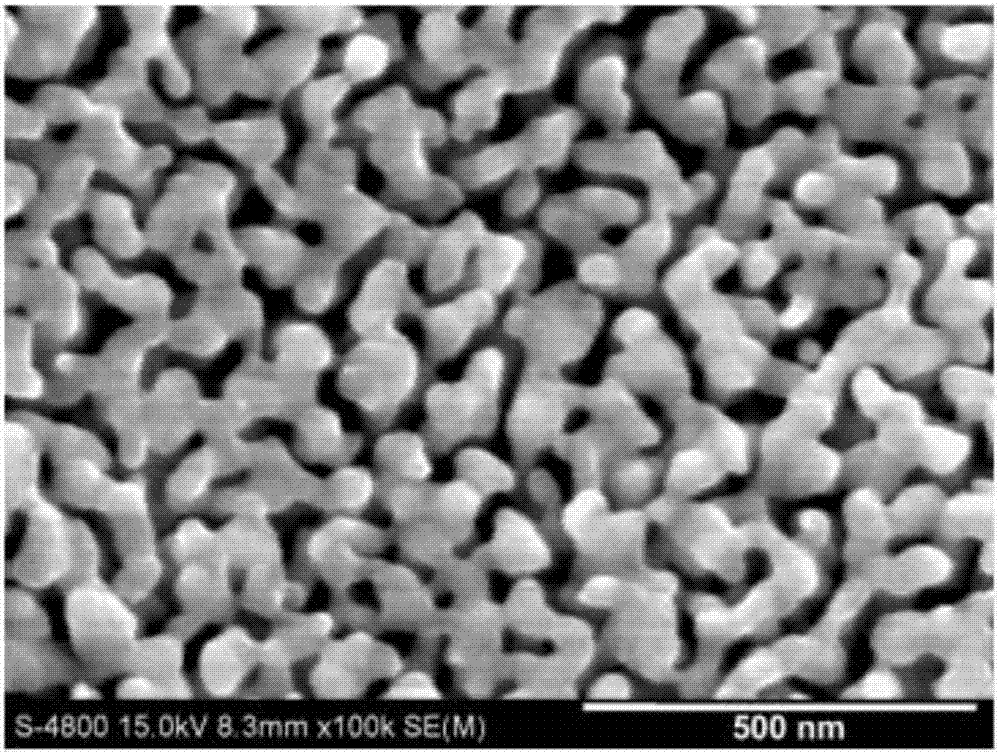

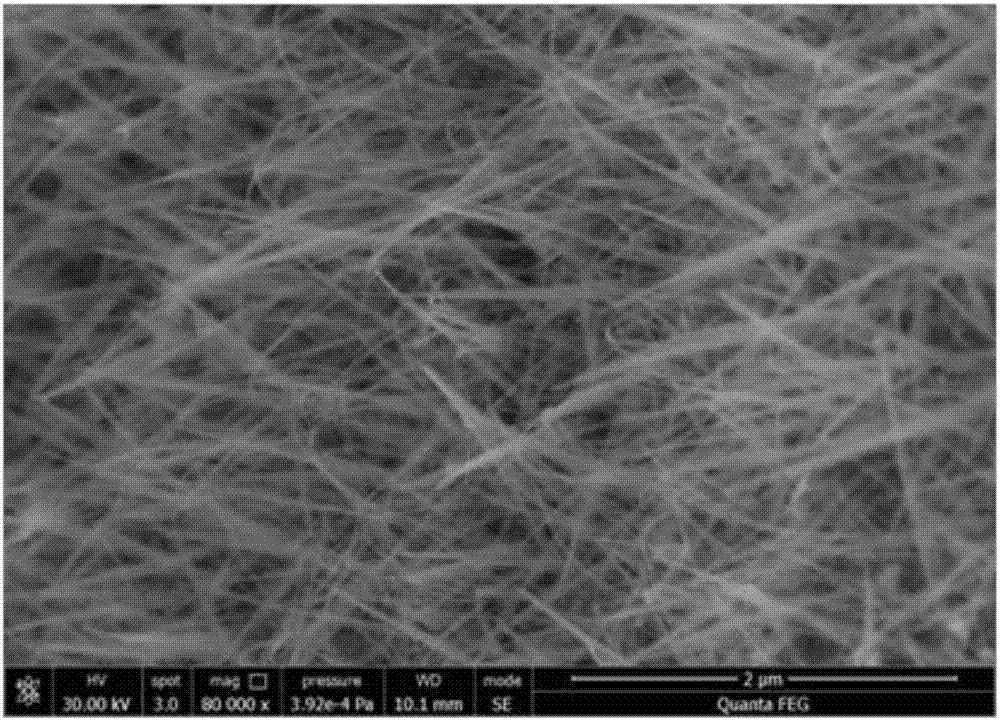

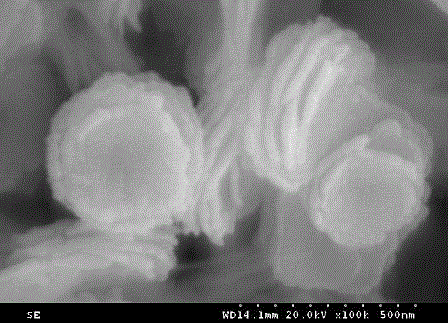

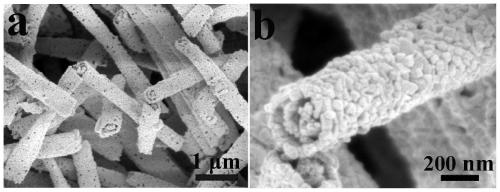

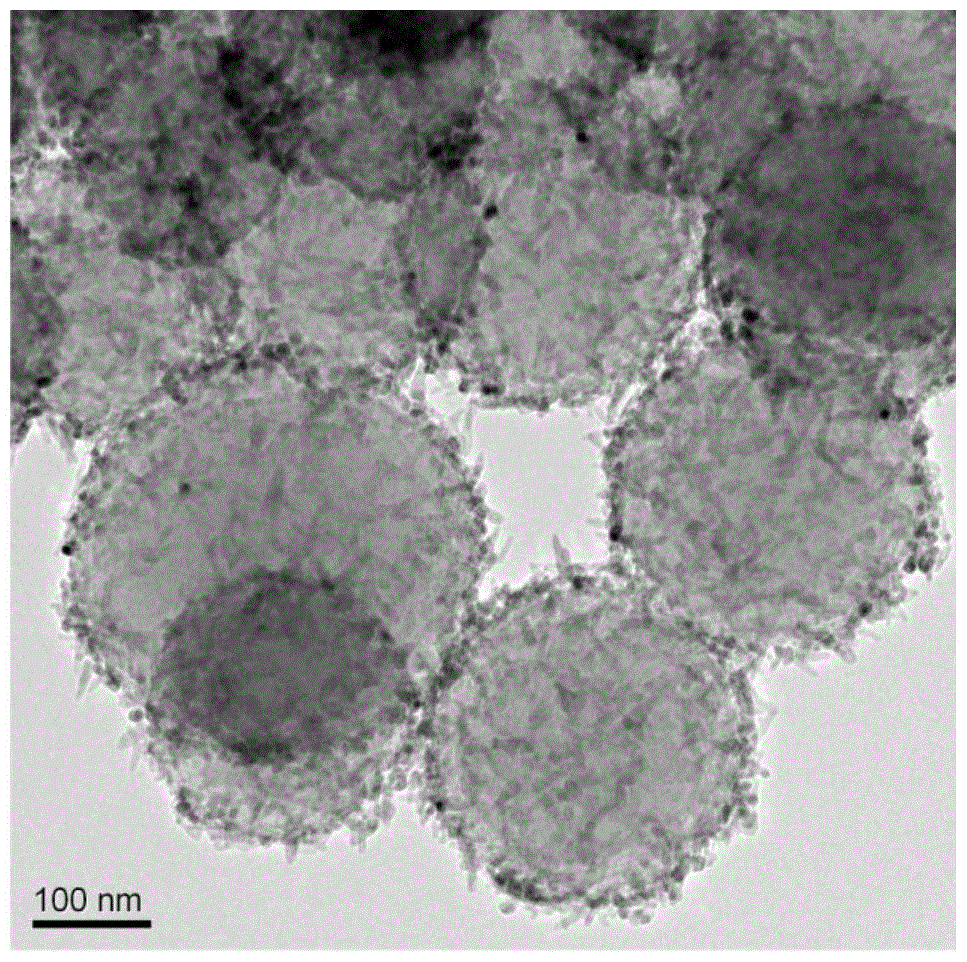

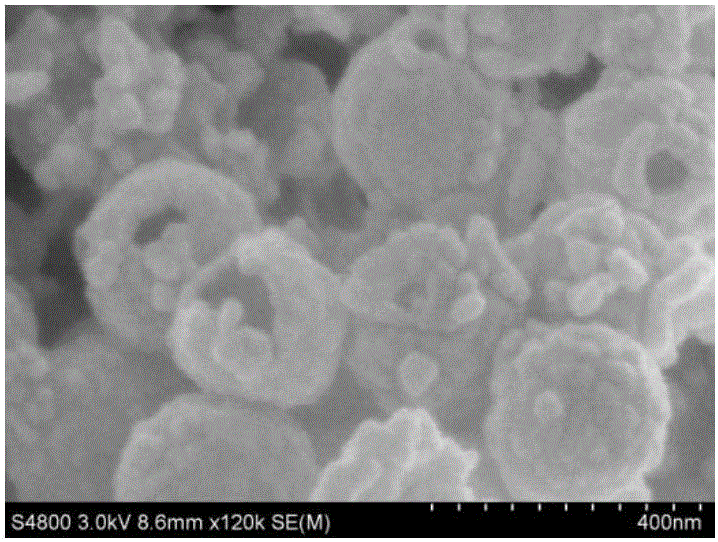

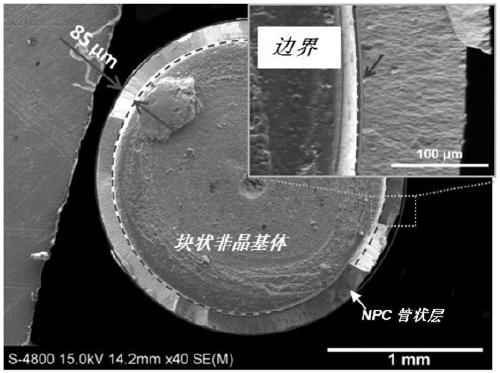

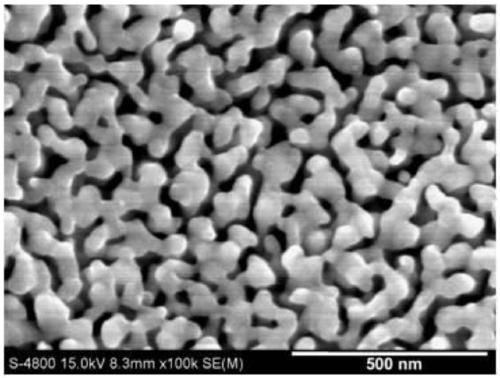

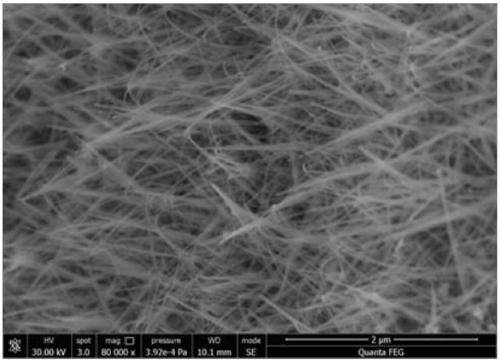

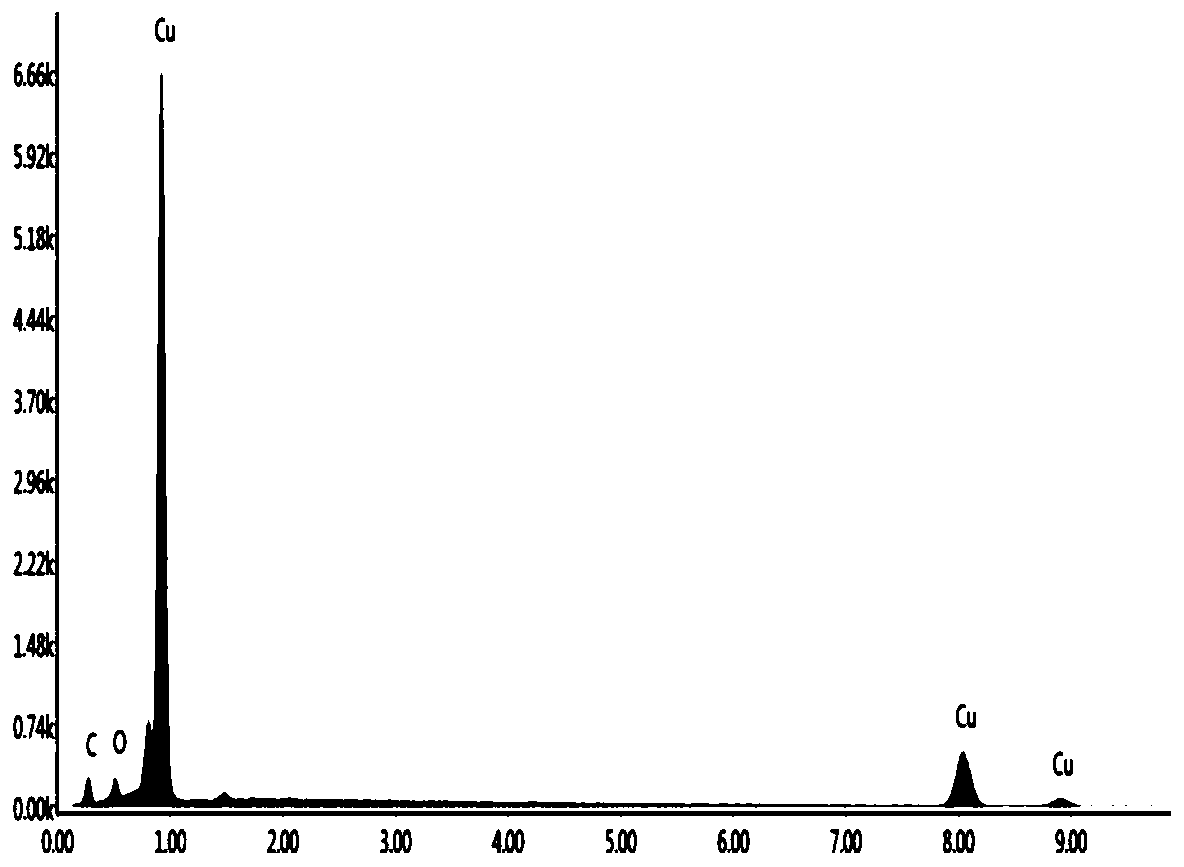

The invention discloses a nano-porous copper loaded ultrafine oxide copper nanowire composite material and a preparation method and application thereof. The material is a rod, and comprises an amorphous basal body, nano-porous copper covering the amorphous basal body, and ultrafine copper oxide nanowires loaded on the surface of the nano-porous copper; the amorphous basal body is CuxZryAlz alloy component, wherein x, y and z are atomic percents; x is not bigger than 50 and not smaller than 45, y is not bigger than 50 and not smaller than 45, z is not bigger than 10 and not smaller than 5; x+y+z is 100; the nano-porous copper has the layer thickness of 85-135 microns, the ligament width of 118-138 nm and the aperture size of 30-100 nm; the nanowires are 4-10 microns long and 5-15 nm wide; and every 20-30 nanowires are clustered as one bundle. The copper oxide nanowires are constructed on the nano-scale basal body for the first time. Nanowire copper oxide is tightly combined with the surface of the nano-porous copper metal, so that the prepared material achieves efficient photocatalytic degradation of organic dye.

Owner:HEBEI UNIV OF TECH

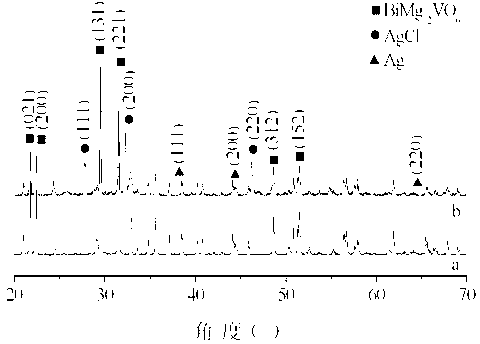

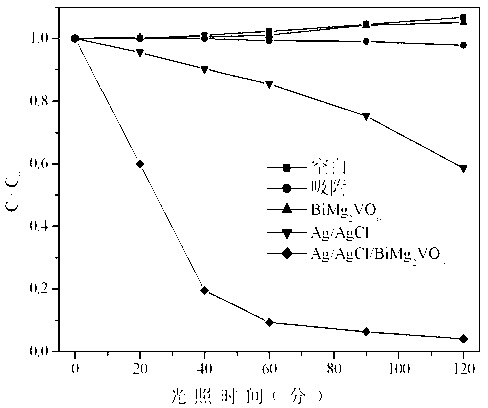

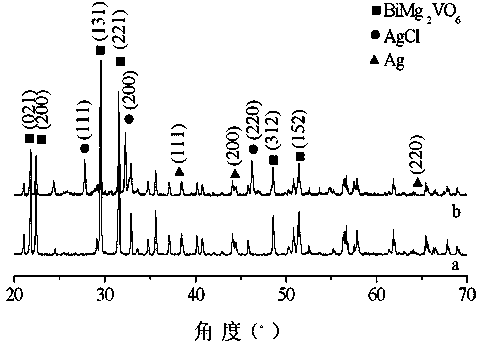

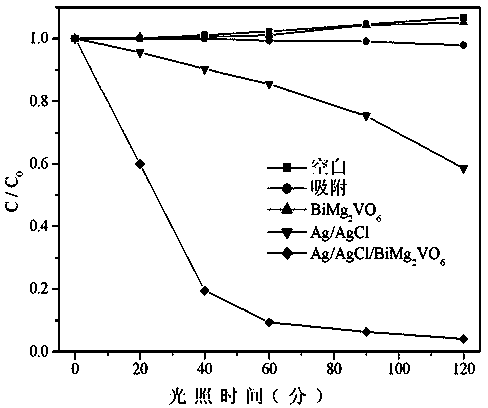

Method for preparing Ag/AgCl/BiMg2VO6 composite photocatalyst

ActiveCN102698777AOvercome temperatureOvercoming activityPhysical/chemical process catalystsAmmonium metavanadateVisible light photocatalytic

The invention provides a method for preparing an Ag / AgCl / BiMg2VO6 composite photocatalyst with a visible light photocatalytic activity. The method is characterized in by comprising the following steps: obtaining a BiMg2VO6 base material from the raw materials: bismuth nitrate pentahydrate, magnesium nitrate hexahydrate, and ammonium metavanadate, by a sol-gel method; adding BiMg2VO6 into deionized water and then ultrasonically treating the mixed solution; then, slowly dropwise adding 0.1 mol / L silver nitrate solution at a proportion of 1 to 3 mmol / g of Ag / BiMg2VO6 and then ultrasonically treating the mixed solution for 10 min, and stirring the mixed solution for 20 min at room temperature in the dark; slowly adding 0.1 mol / L hydrochloric acid solution into the mixed solution at a mole ratio of 1:1 or 1:2 of H ions in the silver nitrate solution to H ions in the hydrochloric acid solution, ultrasonically treating and stirring the mixed solution to generate a AgCl / BiMg2VO6 composite photocatalyst; and optically reducing the AgCl / BiMg2VO6 composite photocatalyst at an ultraviolet lamp of 20 W to obtain the Ag / AgCl / BiMg2VO6 composite photocatalyst. The composite photocatalyst prepared by the method has a high photocatalytic activity in visible light and a simple preparation process.

Owner:WUHAN UNIV OF TECH

Composite photocatalysis system, and preparation method and application thereof

ActiveCN106582722ASolve the disadvantage of not being able to effectively utilize the visible light in sunlightStrong oxidation abilityPhysical/chemical process catalystsWater/sewage treatment by irradiationSystems designClean energy

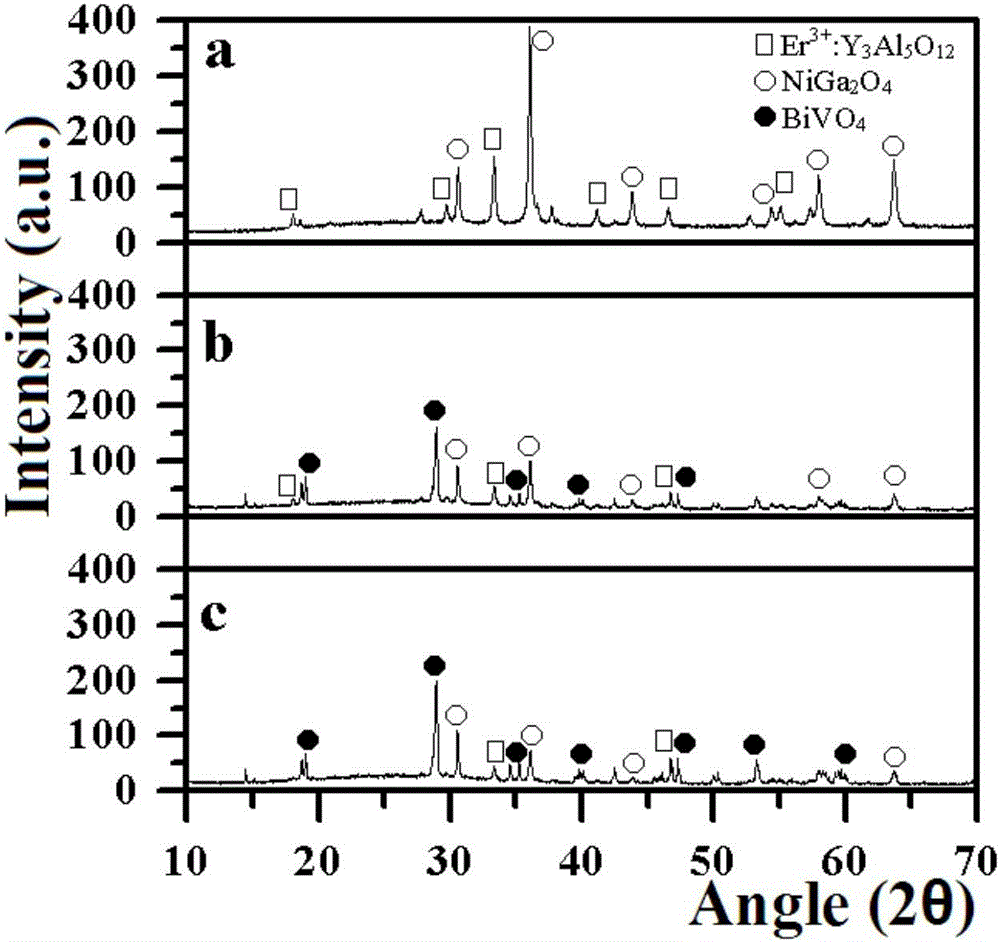

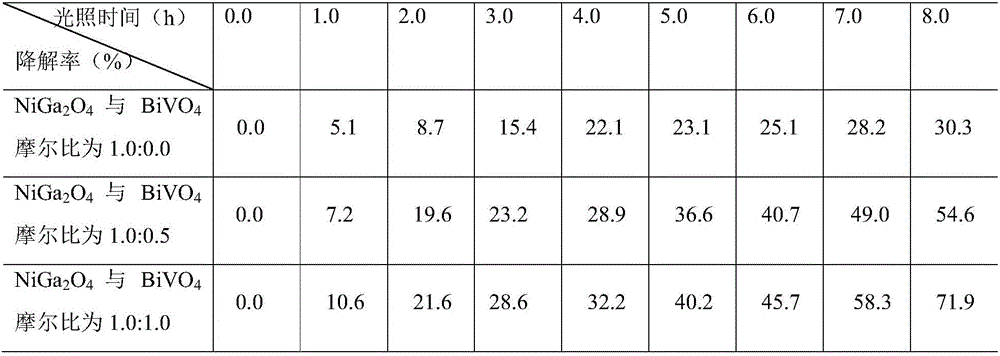

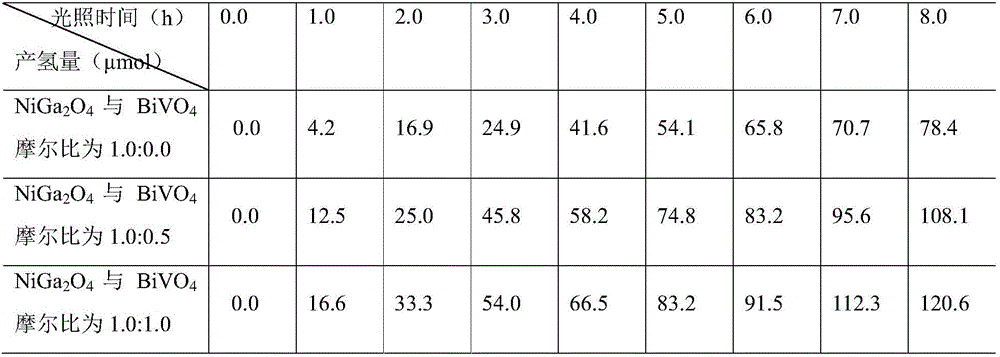

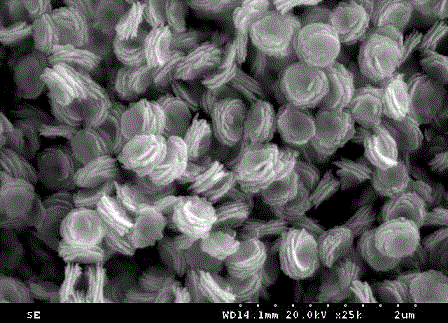

The invention relates to a composite photocatalysis system, and a preparation method and application thereof. The composite photocatalysis system is Er<3+>: YeAl5O12 / (MoS2 / NiGa2O4)-(BiVO4 / PdS). The preparation method comprises the following steps: synthesizing nanometer particles of an up-conversion luminescence agent Er<3+>: YeAl5O12 by using a sol-gel method; then synthesizing NiGa2O4 and BiVO4 by using a hydrothermal method and preparing Er<3+>: YeAl5O12 / NiGa2O4-BiVO4; and loading a conduction band cocatalyst MoS2 and a valence band cocatalyst PdS so as to obtain the composite photocatalysis system. The novel composite photocatalysis system designed in the invention has strong oxidation-reduction performance; and the novel composite photocatalysis system uses pollutants as resources and produces hydrogen energy during removal of pollutants, so the dual purposes of environment treatment and production of clean energy are achieved.

Owner:LIAONING UNIVERSITY

Inside-vehicle efficient VOC purifying spraying agent

InactiveCN106139891AEfficient Photocatalytic DegradationEasy to useDispersed particle separationStyrylacetic acidPhotocatalytic degradation

The invention relates to an inside-vehicle efficient VOC purifying spraying agent, and belongs to the field of air purification. The inside-vehicle efficient VOC purifying spraying agent comprises 2.0-5.0 wt% of a visible light response nanometer photocatalyst, 2.0-8.0 wt% of an organic inclusion agent, 0.5-5.0 wt% of a deodorizing auxiliary agent, 1.0-5.0 wt% of a precipitation sedimentation auxiliary agent, 0.05-1.5 wt% of an antifoaming agent, and 75.0-94.0 wt% of deionized water. According to the present invention, the inside-vehicle efficient VOC purifying spraying agent is green and environmentally friendly, can rapidly remove formaldehyde, acetaldehyde, acrolein, benzene, toluene, xylene, ethylbenzene, styrene, n-butyl acetate, undecane and other common VOC and inside-vehicle odor through the inclusion absorption, chemical bonding, photocatalytic degradation triple path, can be directly sprayed, and can further be used in ultrasonic humidifiers, humidifying purifiers, and other equipment.

Owner:江苏瑞丰科技实业有限公司

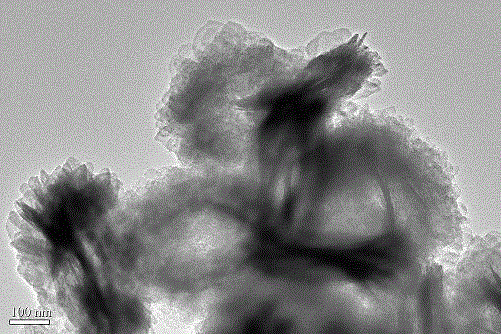

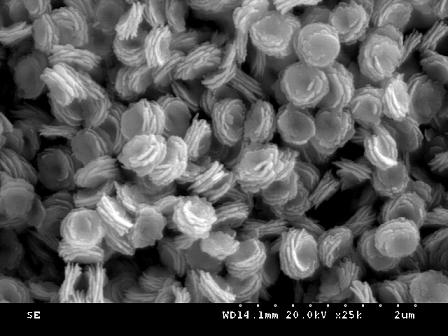

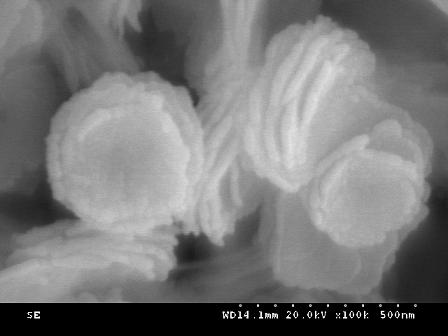

Preparation of hierarchical nanostructure Bi2O3/(BiO)2CO3

ActiveCN106582758AIncrease refractionIncrease profitCatalyst activation/preparationChemical industryNanostructure

The invention relates to a method for synthesizing a Bi2O3 / (BiO)2CO3 composite photocatalytic material and belongs to the technical field of chemical industry. The method comprises the steps of weighing three kinds of chemical reagent raw materials, i.e., Na2CO3, bismuth citrate and NaOH according to a mole ratio, carrying out mixing, stirring the mixture in secondary distilled water for certain time, carrying out treatment by a programmed-heating hydrothermal process, then, carrying out repeated washing separately with deionized water and anhydrous ethanol, and carrying out baking, thereby obtaining the final product, i.e., the Bi2O3 / (BiO)2CO3 composite photocatalytic material. The surface morphology, microscopic structure and photocatalytic activity of the composite photocatalytic material are assayed, and the degradation of a variety of dyes such as rhodamine B under different light sources by the hierarchical garland-shaped Bi2O3 / (BiO)2CO3 composite photocatalytic material is greatly improved. The product is simple and practical in preparation process and stable in performance and has considerable applicability to a variety of dyes.

Owner:QIQIHAR UNIVERSITY

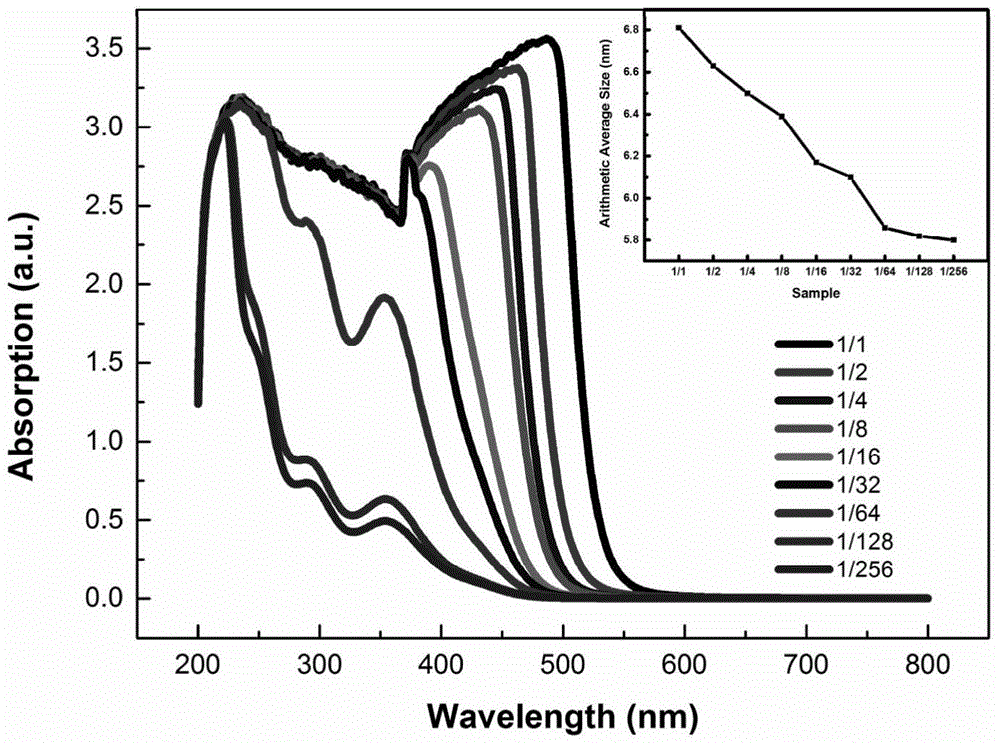

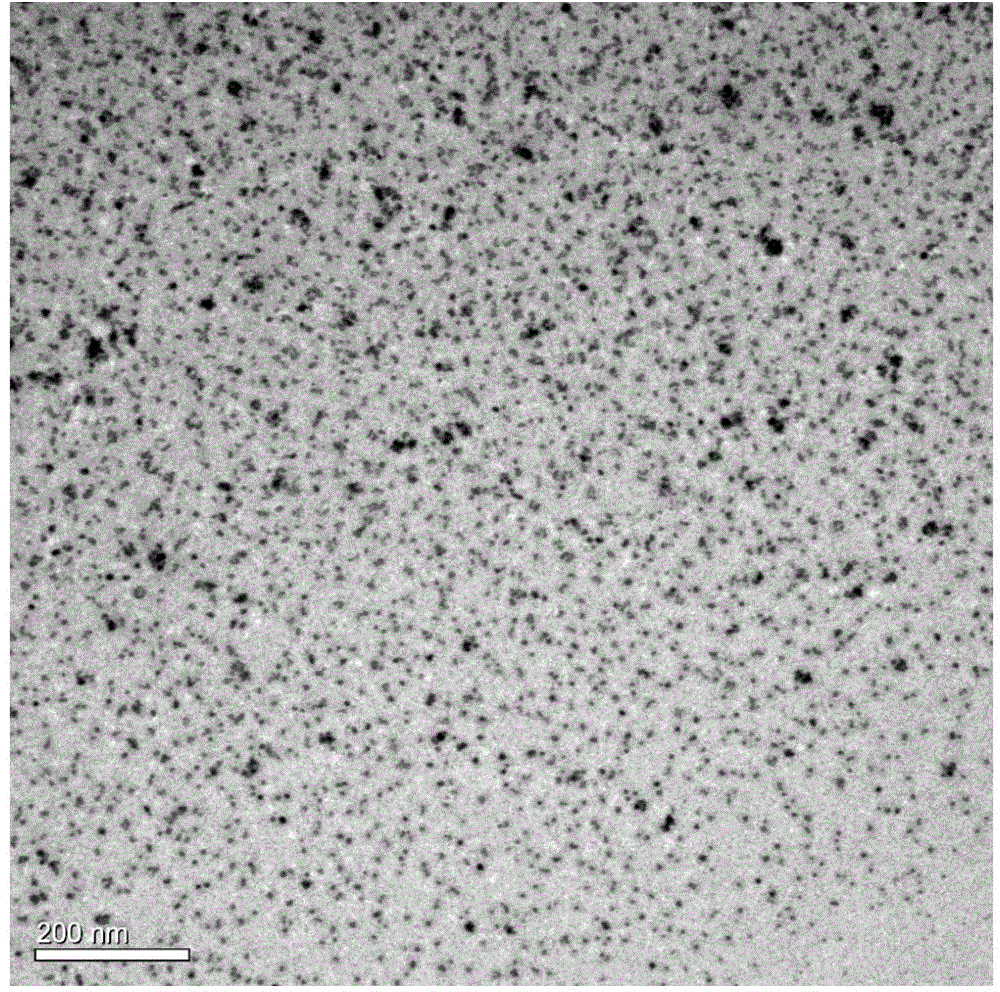

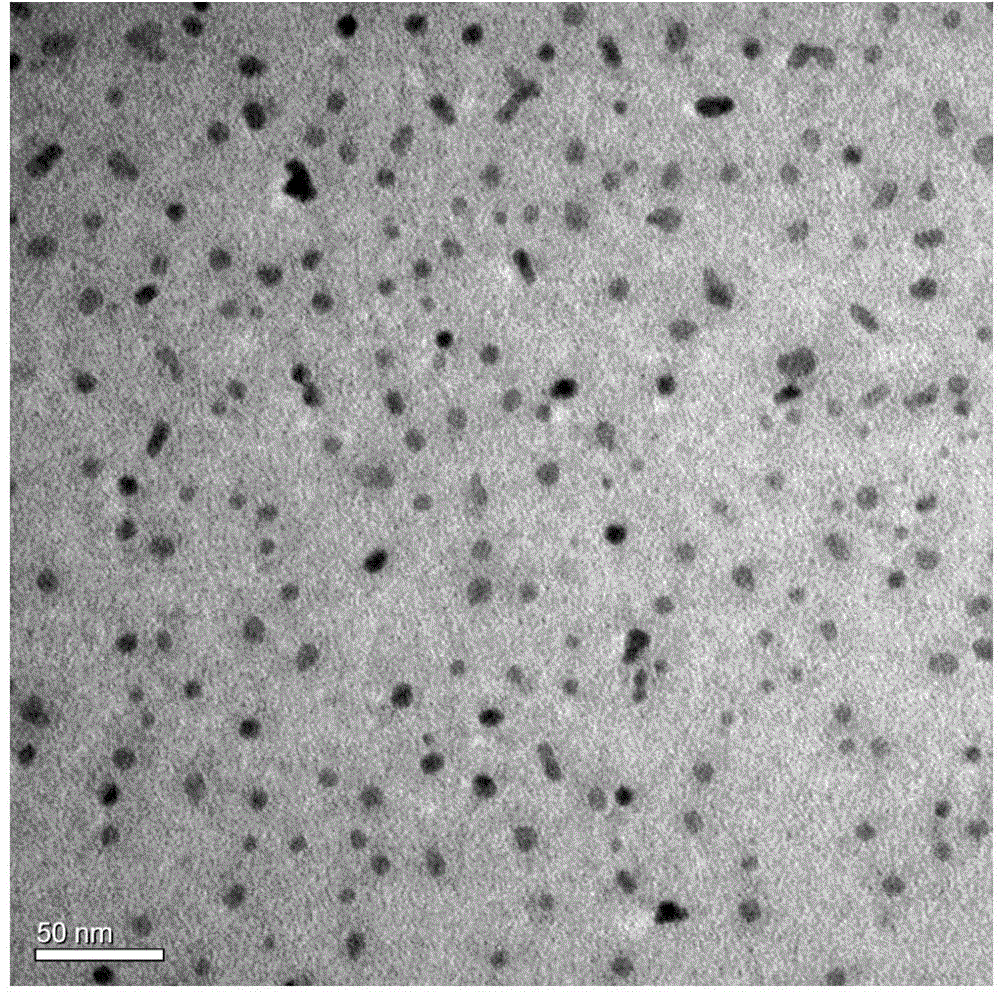

Simple bismuth oxyiodide quantum dot photocatalyst synthesizing method

ActiveCN104817112AReduce sizeUniform particle sizeMaterial nanotechnologyBismuth compoundsOil phasePotassium iodine

The invention relates to semiconductor nano function material synthesizing methods, particularly to a simple bismuth oxyiodide quantum dot photocatalyst synthesizing method. The simple bismuth oxyiodide quantum dot photocatalyst synthesizing method comprises adjusting the oil-phase and water-phase proportion of microemulsion, adding in bismuth nitrate and potassium iodide under stirring conditions, and performing uniform mixing to obtain controllable bismuth oxyodide quantum dots, wherein the volume ratio of the oil phase and the water phase is 2500-6400:1. The simple bismuth oxyiodide quantum dot photocatalyst synthesizing method is simple and takes only one step; reaction is achieved at room temperature and saves heating processes, thereby being low in energy consumption; short reaction time, uniform quantum dot material granularity and high yield rate can be obtained. The prepared bismuth oxyiodide quantum dots obtain efficient photocatalytic organic pollutant degradation capacity and utilization potential in the fields of environment pollution treatment and the like.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

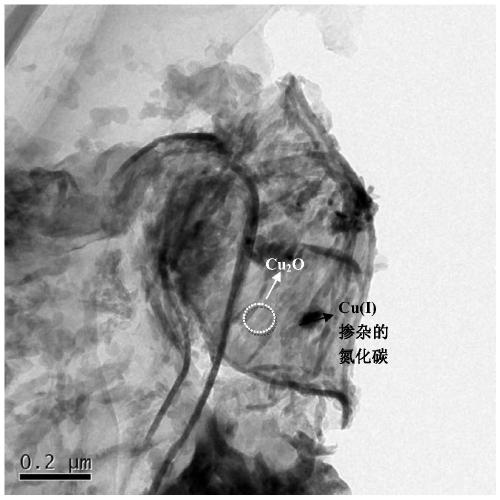

Method for photocatalytic degradation of antibiotics in water body

ActiveCN110217850AEfficient Photocatalytic DegradationImprove photocatalytic degradation efficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationPhotocatalytic degradationIon

The invention relates to a method for photocatalytic degradation of antibiotics in a water body, belonging to the field of photocatalytic treatment of antibiotic wastewater. The method comprises: adding a photocatalyst to a water sample to be treated containing antibiotics; the photocatalyst is a carbon nitride framework material modified by monovalent copper ion; the carbon nitride skeleton has aporous structure. The method is used for high-efficiency photocatalytic degradation of antibiotic in waste water. The waste water treatment method has the advantages of convenient operation, simple equipment and high pollutant removal efficiency, and can be widely used and has high application value.

Owner:HUNAN UNIV

Preparation method of composite p-n type heterojunction photocatalyst and VOCs photocatalytic degradation method

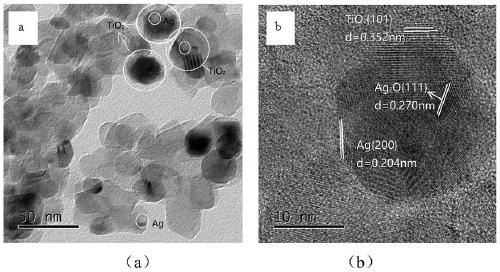

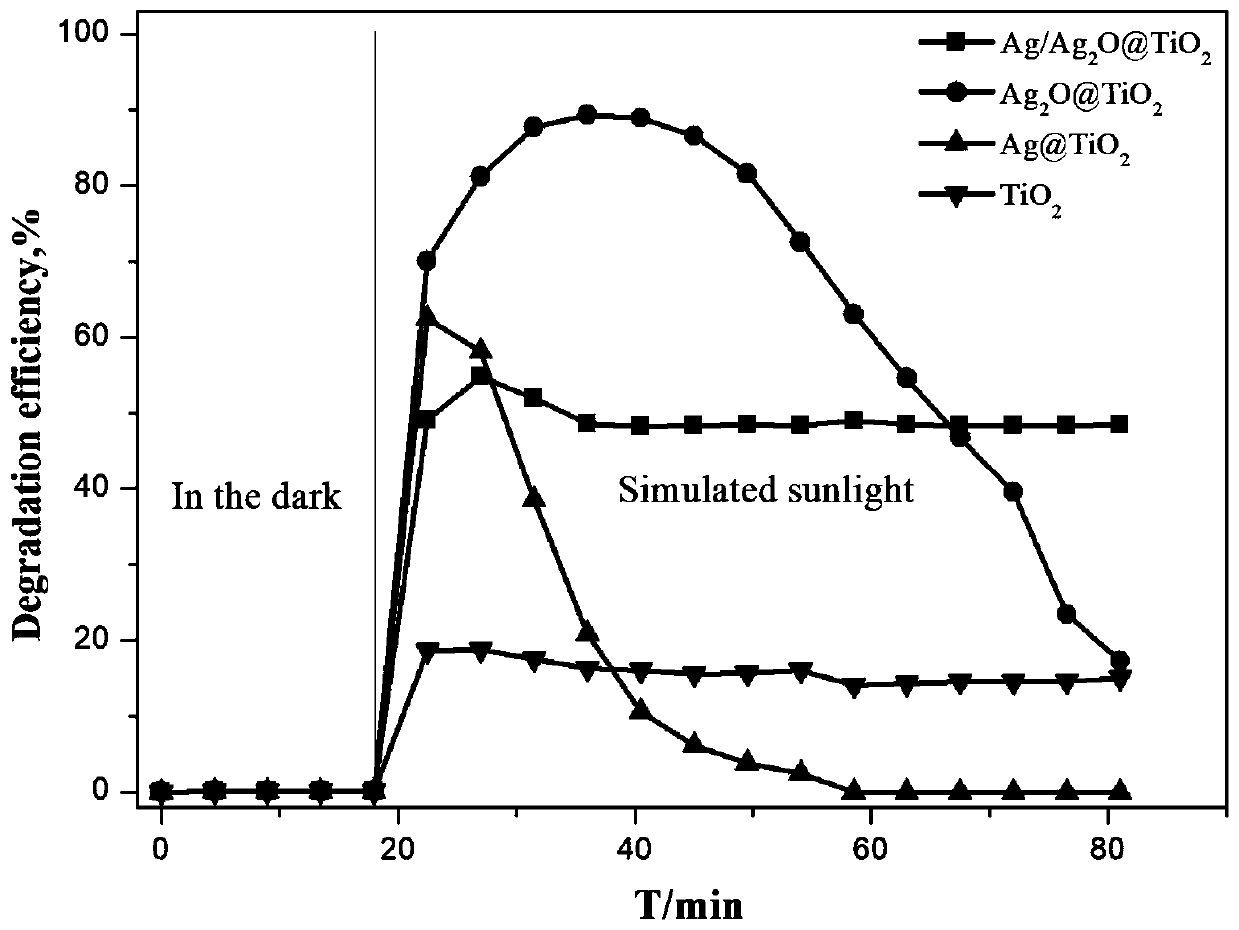

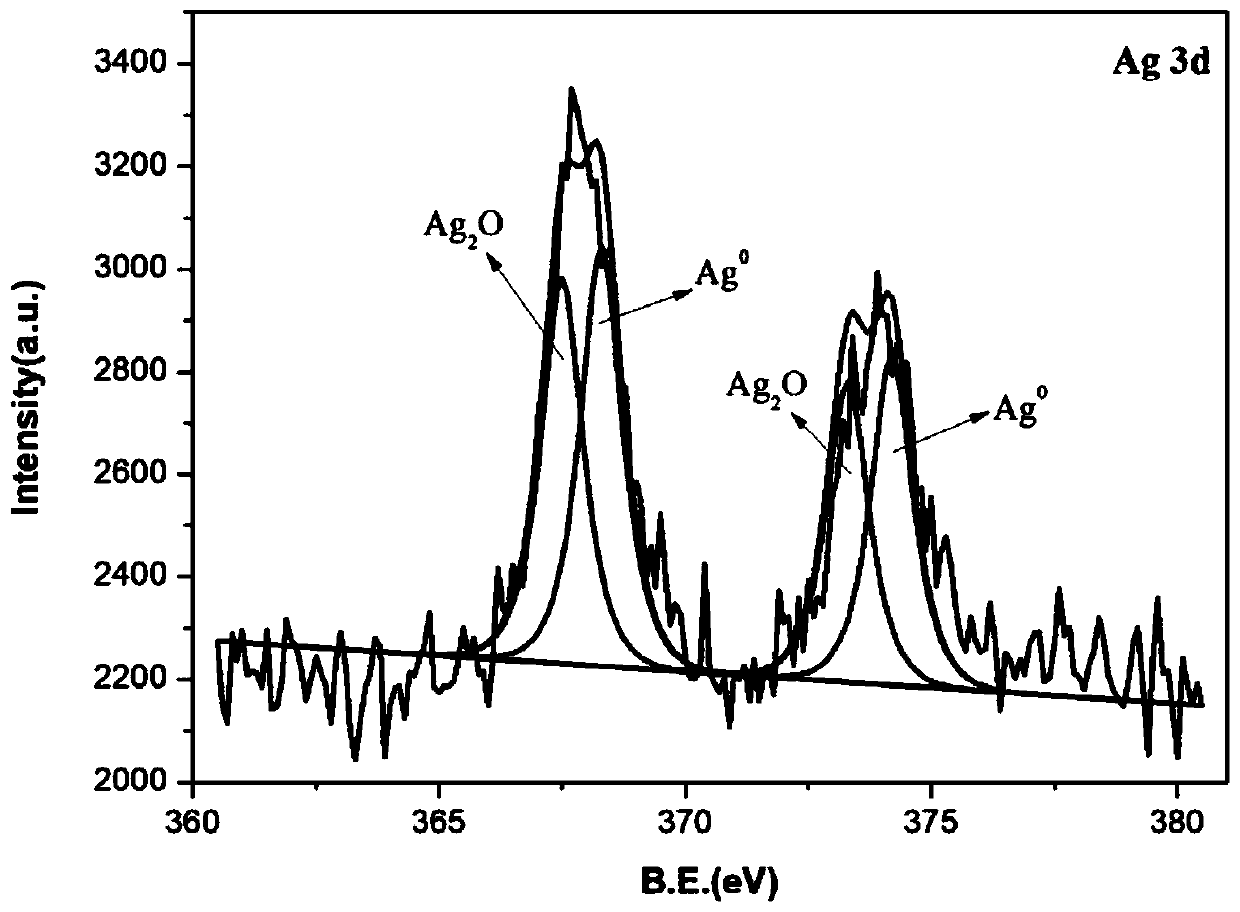

ActiveCN111229217AUniform sizeNot easy to reuniteGas treatmentDispersed particle separationHeterojunctionPtru catalyst

The invention discloses a preparation method of a composite p-n type heterojunction photocatalyst and a VOCs photocatalytic degradation method. The composite p-n type heterojunction photocatalyst is asilver / silver oxide co-doped titanium dioxide composite p-n type heterojunction photocatalyst, is prepared by an in-situ precipitation reduction method, silver series (Ag0 / Ag2O) co-doping is realized, the electron-hole separation efficiency of the catalyst is improved, and the photoresponse range is widened, so that the purpose of efficient and stable photocatalytic degradation of VOCs gas underthe ultraviolet-visible light condition is achieved.

Owner:HUAQIAO UNIVERSITY

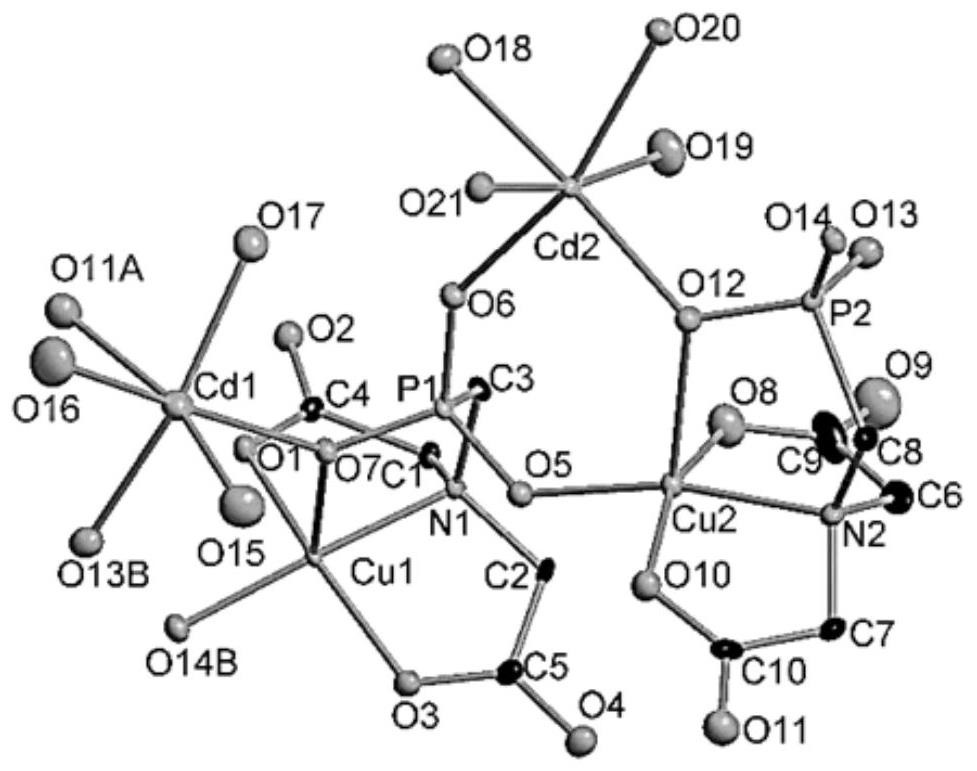

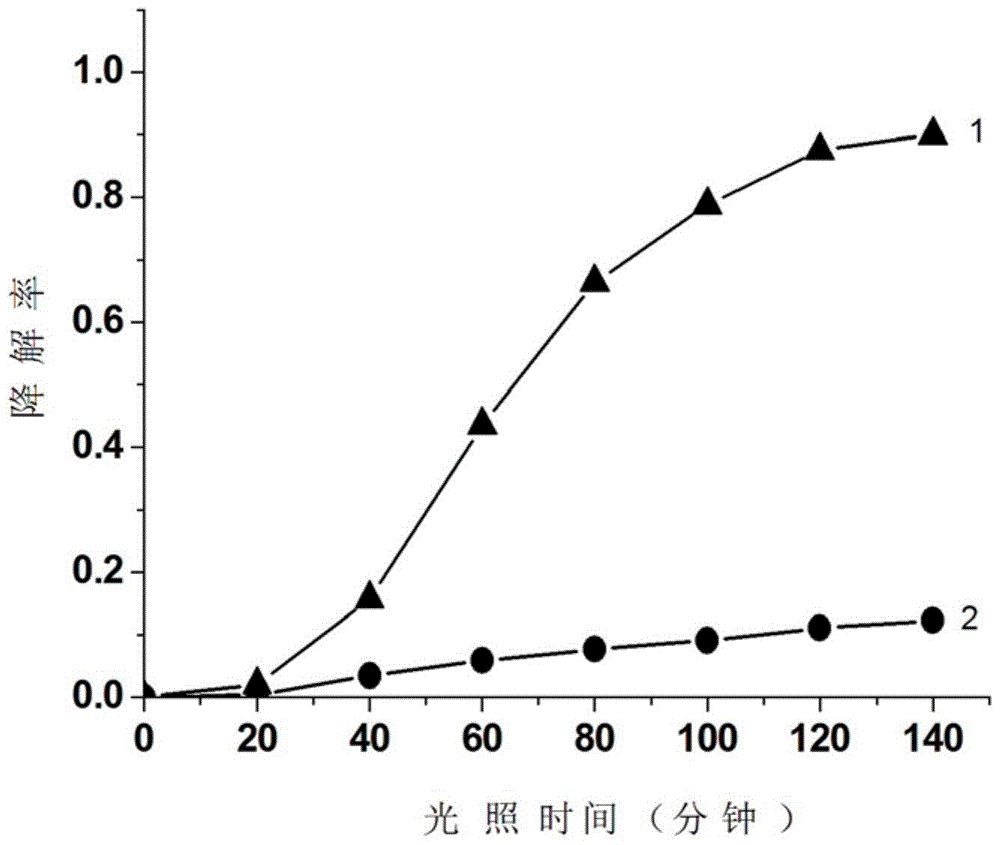

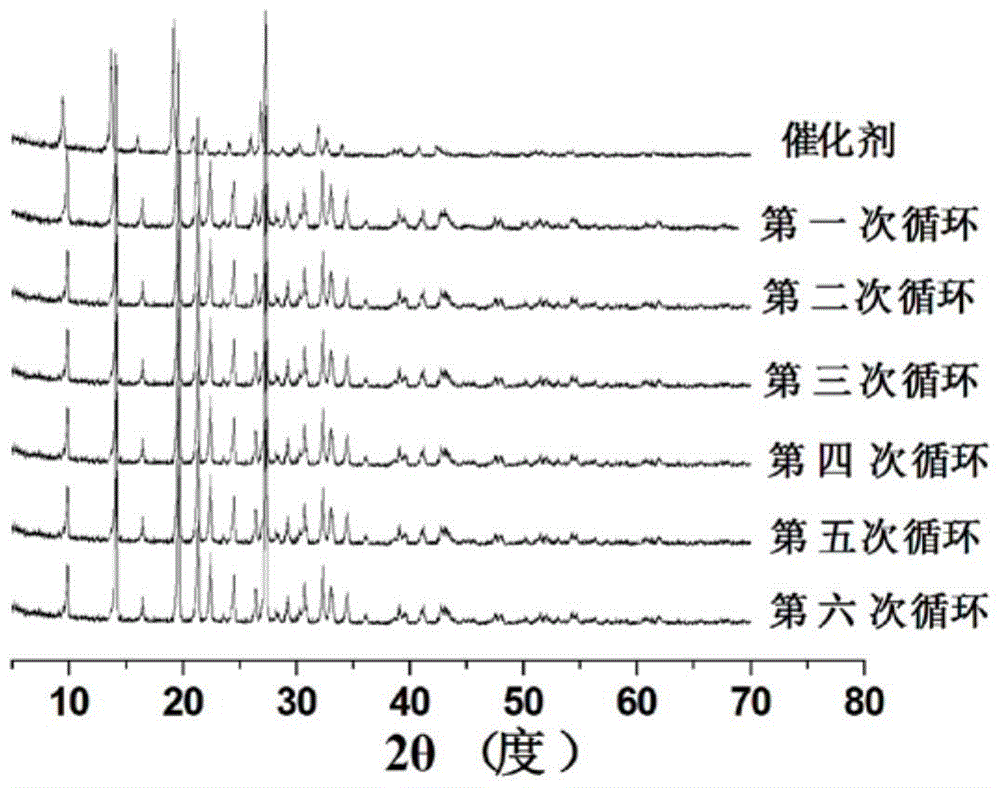

CuCd-MOF/GO-x composite material with visible light catalytic degradation performance and preparation and application thereof

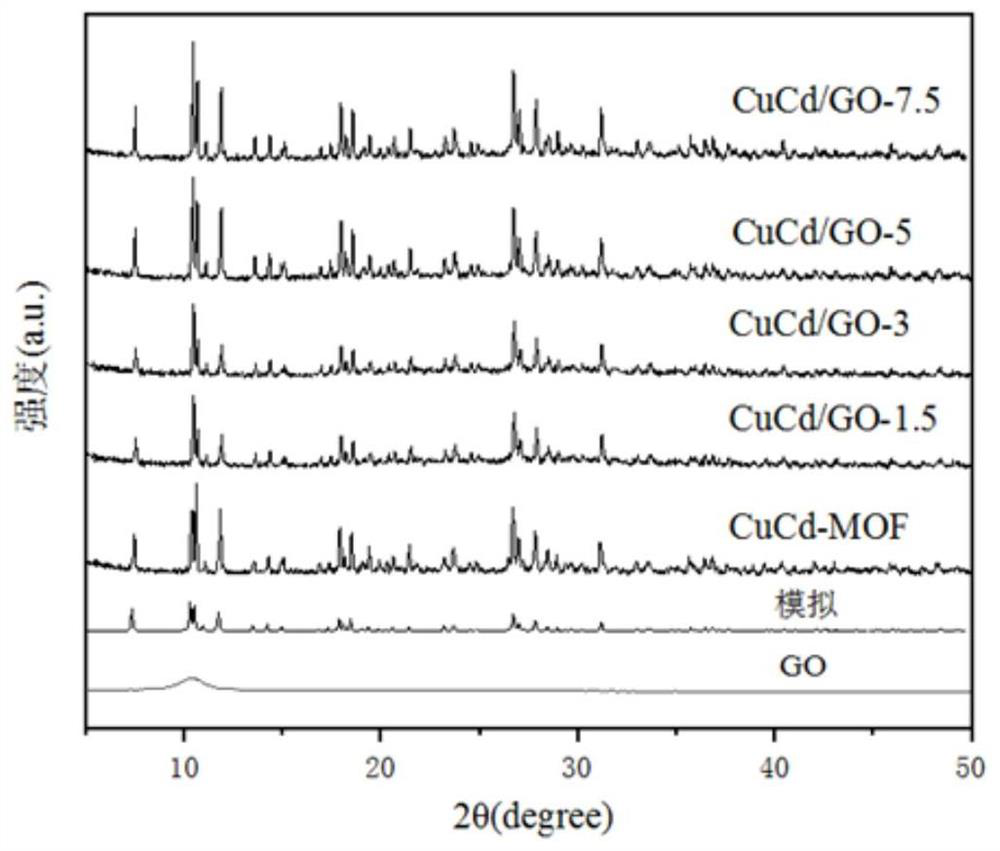

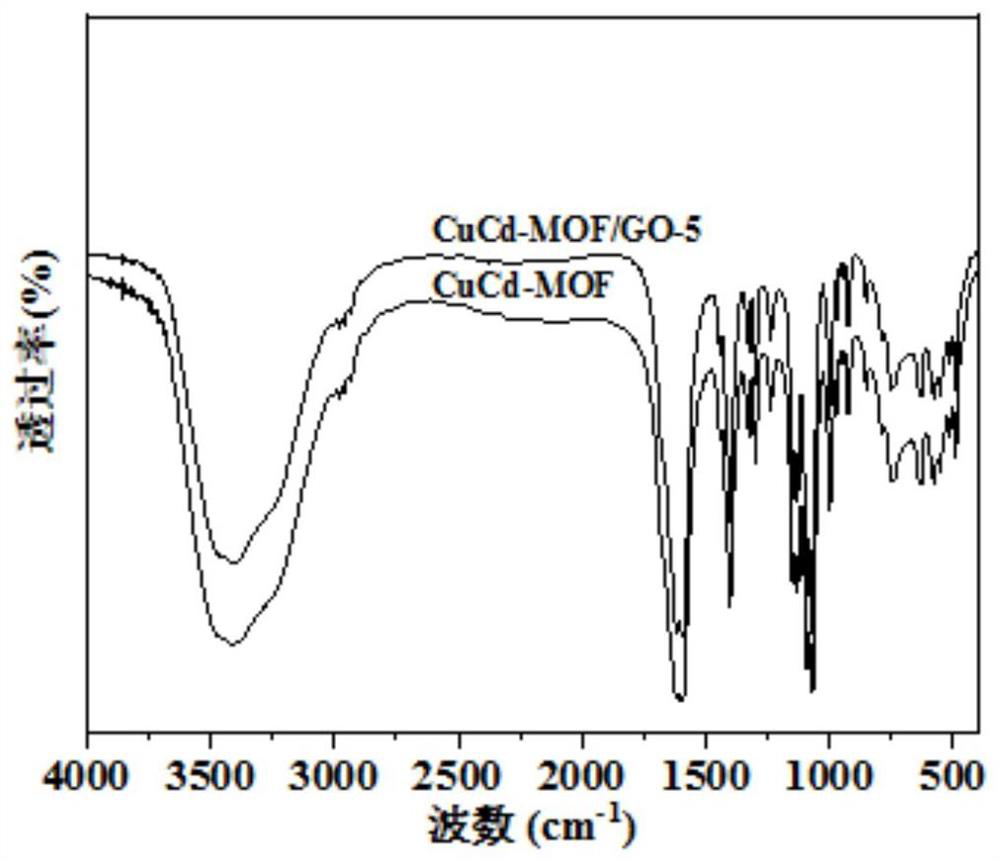

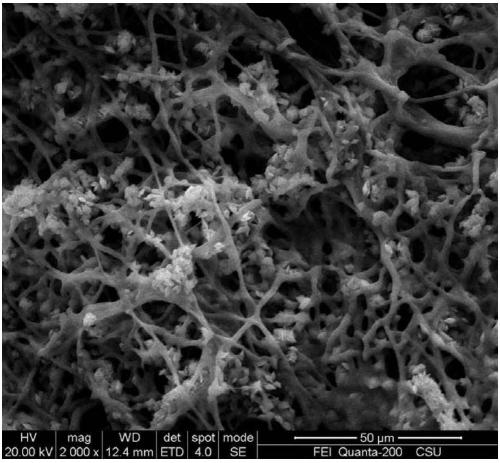

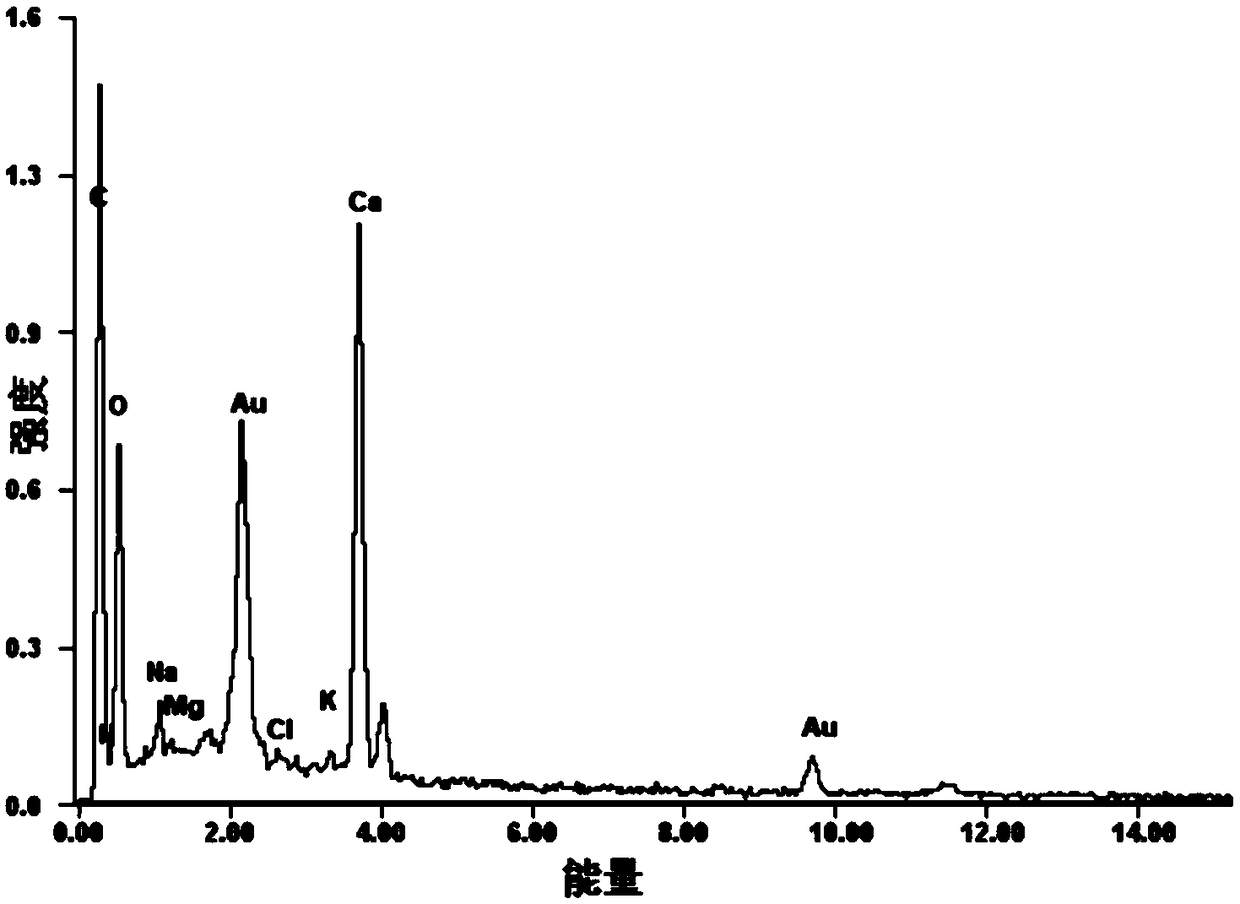

ActiveCN114682304AWith photocatalytic degradation performanceImprove photocatalytic degradation performanceWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsProtonationMetal-organic framework

The invention discloses a CuCd-MOF / GO-x composite material with visible light catalytic degradation performance and preparation and application of the CuCd-MOF / GO-x composite material, the CuCd-MOF / GO-x composite material is formed by combining CuCd-MOF and GO through hydrogen bonds, 0 lt; xlt; 10; the chemical expression of the CuCd-MOF is {[Cu2Cd2 (pmida) 2 (H2O) 7]. 3H2O} n, and the CuCd-MOF is a metal organic framework material which takes H4pmida as a ligand and contains Cu and Cd ions; each asymmetric unit of the CuCd-MOF contains two deprotonated organic ligands pmida4 <->, two copper ions, two cadmium ions, seven coordination water molecules and three crystal lattice water molecules. The composite material has the advantages of simple preparation method and stable structure, can photocatalytically degrade dyes such as MB, CR, MO, RhB and LEV under the irradiation of visible light, can be recycled, and has wide application prospects.

Owner:JIANGSU UNIV OF TECH

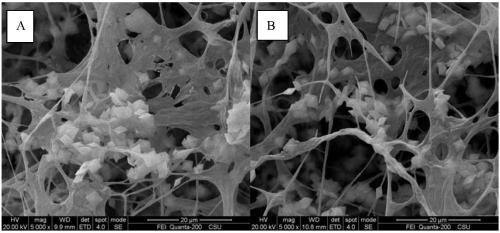

Method for treating landfill leachate with photocatalytic biosorbent

ActiveCN106045058BGood adsorption and degradation effectSimple processPhysical/chemical process catalystsOther chemical processesLitterSorbent

The invention discloses a method for treating landfill leachate with a photocatalytic biological adsorbent, which includes the following steps: mixing the photocatalytic biological adsorbent with the landfill leachate to perform light oscillation adsorption and degradation to complete the treatment of the landfill leachate; photocatalytic biological adsorbent Adsorbents include P. chrysosporium pellets, graphite type C 3 N 4 and calcium alginate, graphite type C 3 N 4 Calcium alginate is used to coat the hyphae of P. chrysosporium cocci. The method of the present invention has the advantages of low cost, simple operation, short cycle, easy separation, etc., and has a good adsorption and degradation effect on organic pollutants in landfill leachate.

Owner:HUNAN UNIV

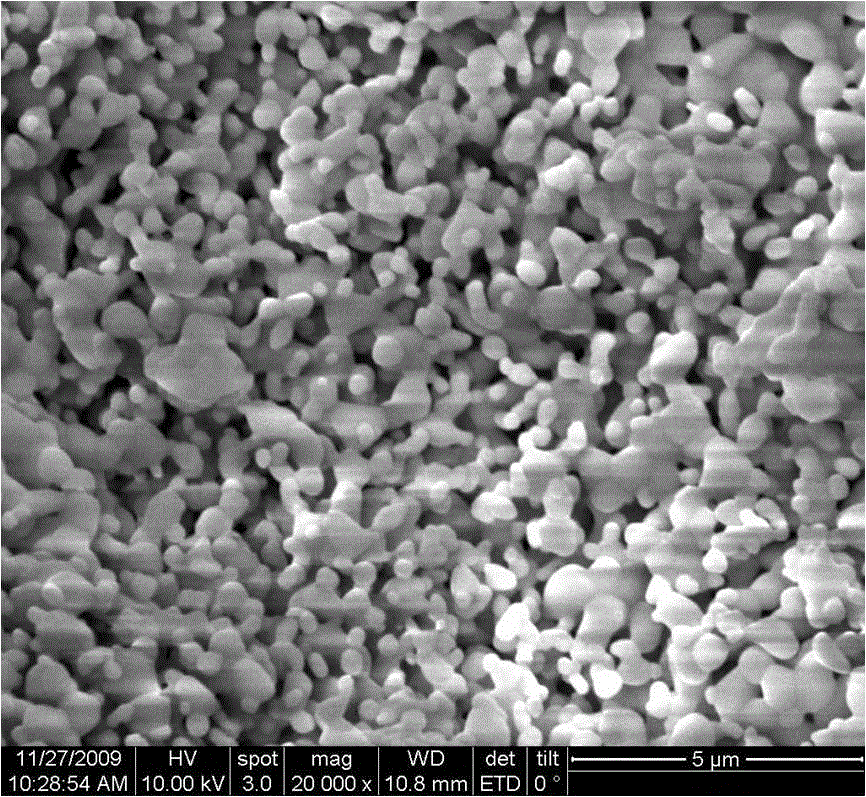

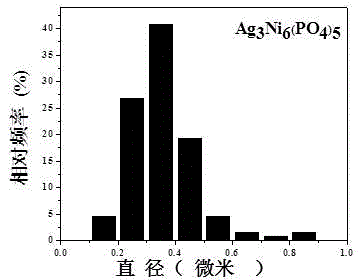

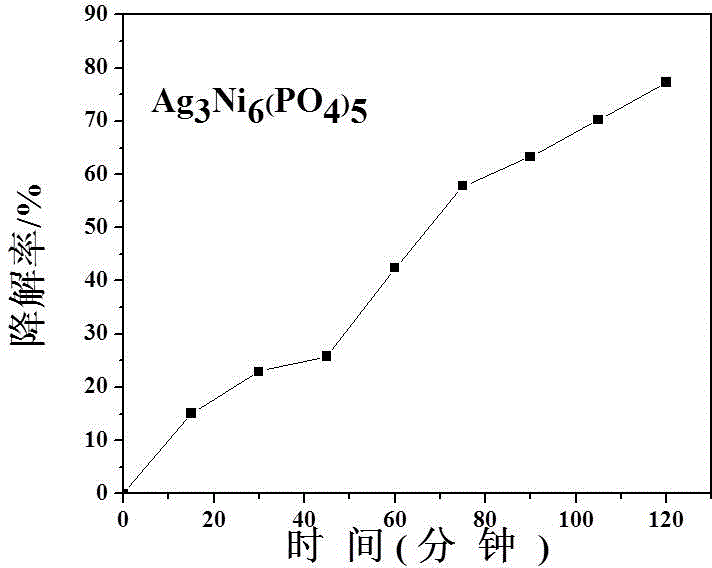

Preparation method and application of catalyst of novel light degradation phosphate organic dye

InactiveCN104549387AEasy to prepareSimple process equipmentPhysical/chemical process catalystsWater/sewage treatment by irradiationChemical solutionPhosphate

The invention relates to a novel phosphate photocatalytic material Ag3Ni6 (PO4)5 and a preparation method thereof, and belongs to the field of novel inorganic photocatalytic materials. The photocatalytic material is prepared by a high-temperature solid-phase method, a chemical solution method, and a co-precipitation method. The technology is simple and easy to operate, and is convenient for industrial production, and the prepared material has uniform particles, good chemical stability, relatively good photocatalytic effects, and good stability, can be used for degrading organic pollutants under the radiation of ultraviolet light and visible light, and is an ideal material for the photocatalyst.

Owner:SUZHOU DEJIE MEMBRANE MATERIAL SCI & TECH

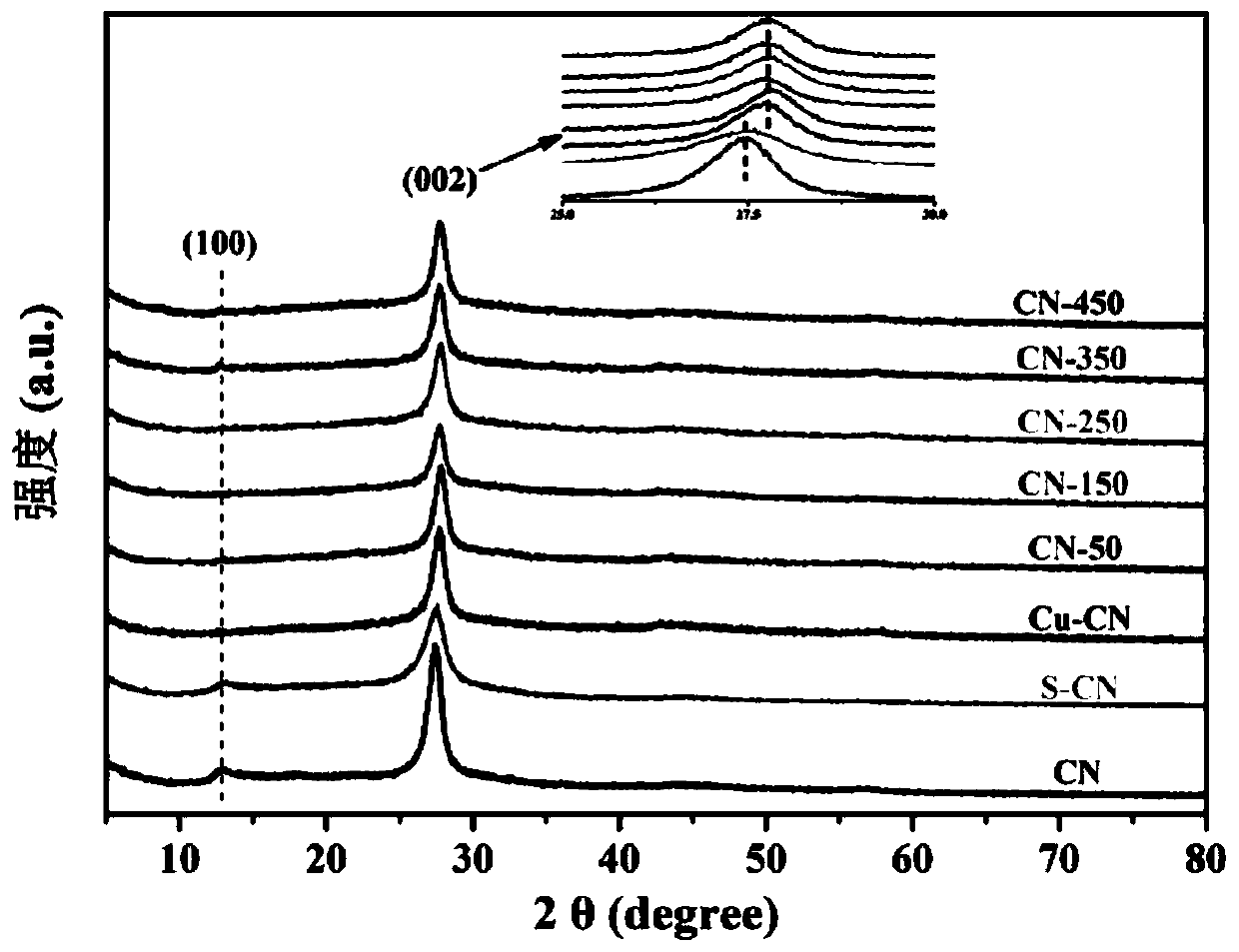

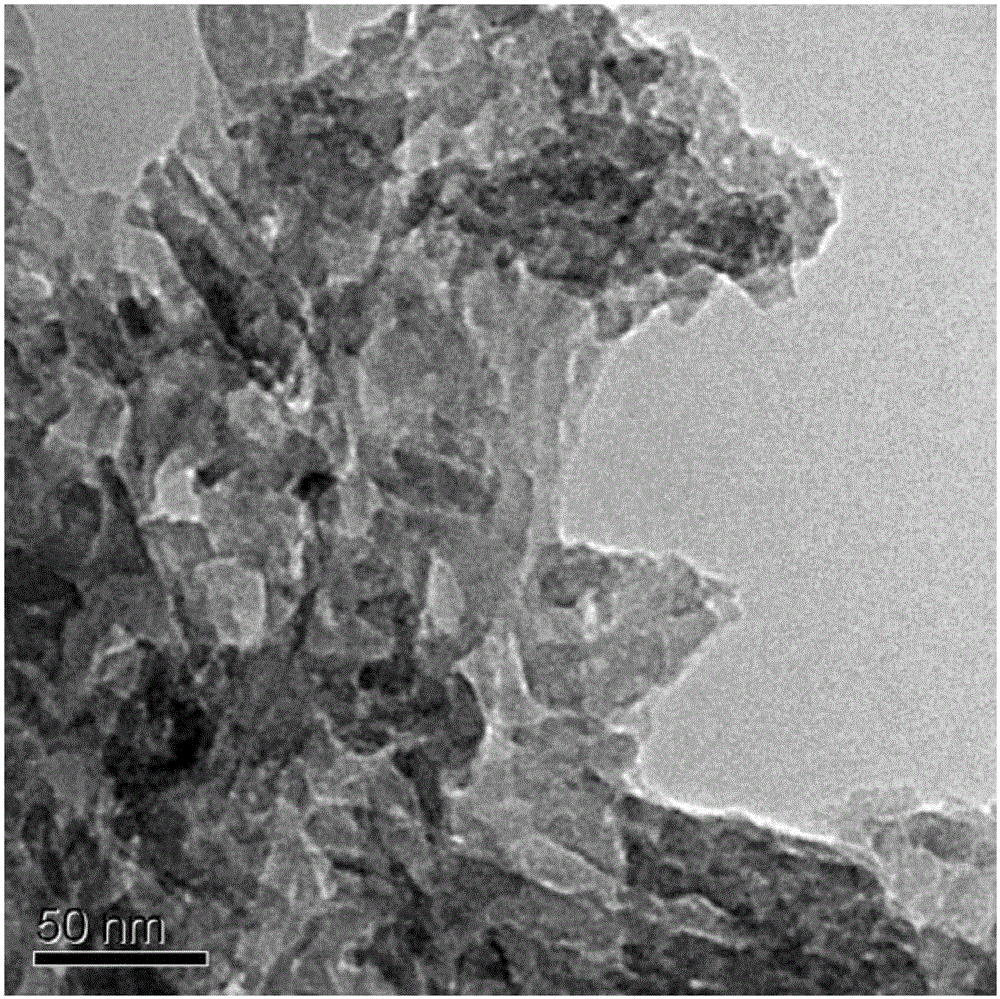

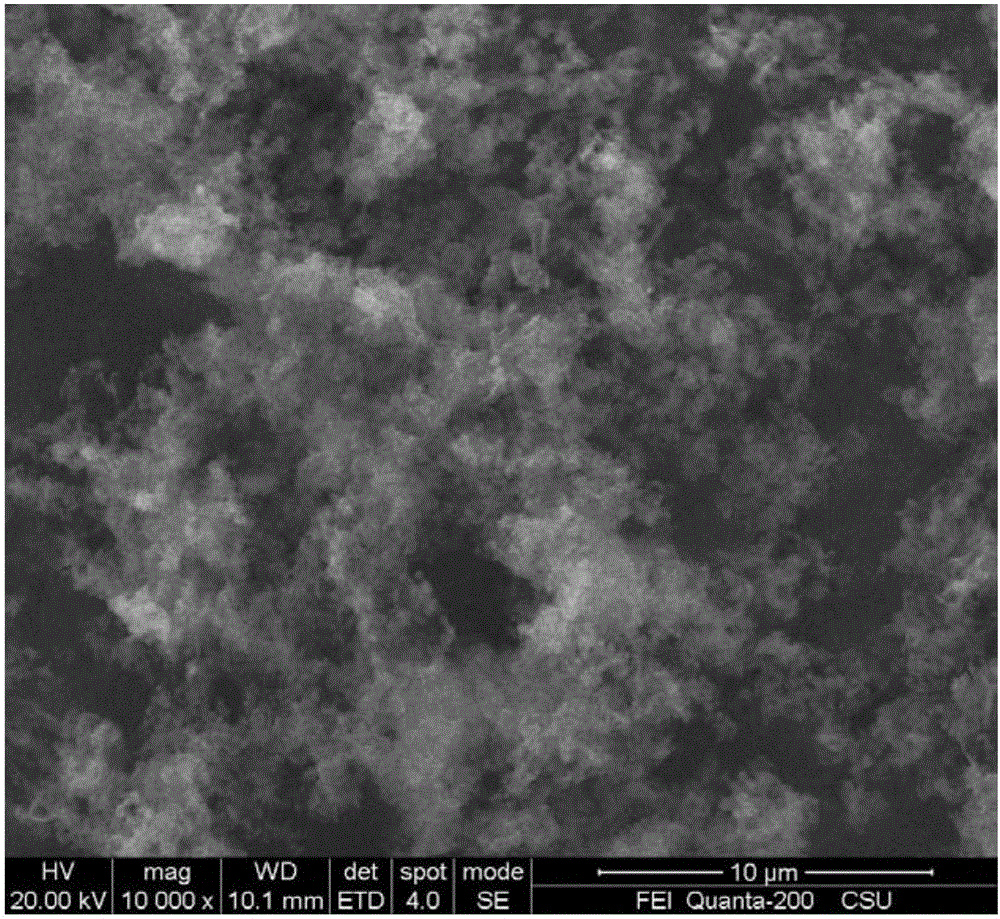

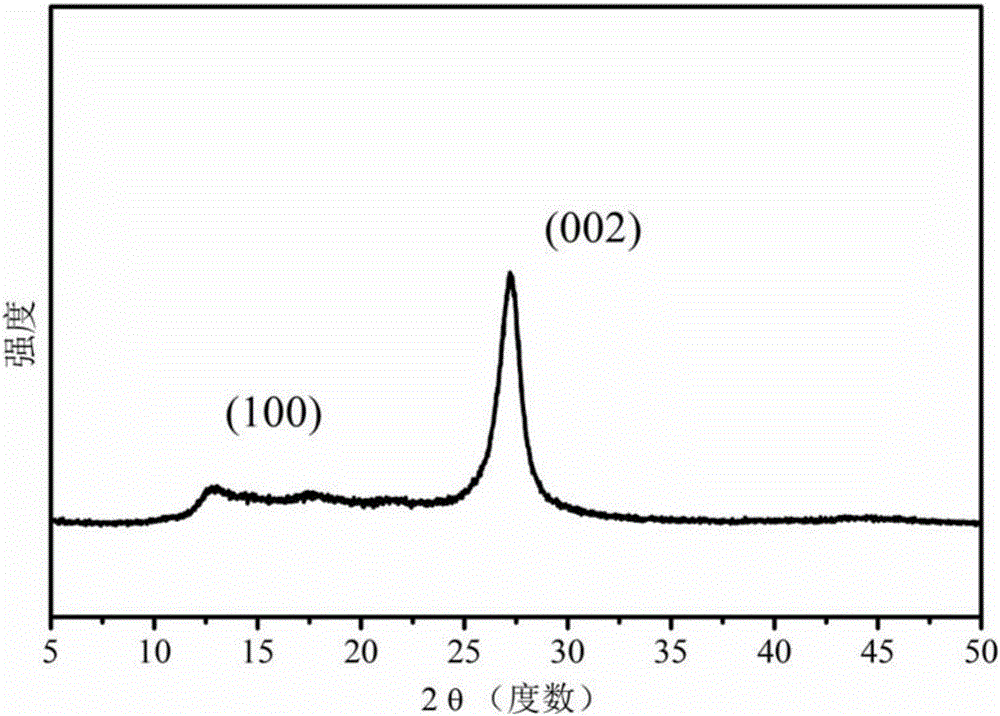

Preparation method of graphite type C3N4 material, graphite type C3N4 material and application of graphite type C3N4 material

InactiveCN106145069ALarge specific surface areaImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationPhotocatalytic degradationPollutant

The invention discloses a preparation method of a graphite type C3N4 material, the graphite type C3N4 material and an application of the graphite type C3N4 material. The preparation method comprises steps of heating calcination and constant-temperature calcination. The preparation method is used for rapidly preparing the graphite type C3N4 material, a small variety of raw materials are required, the cost is low, the process is simple, the production cost is effectively reduced, and accordingly, the preparation method is suitable for industrial large-scale production and has great actual application value. The specific surface area of the graphite type C3N4 material prepared with the method is 30.1 m<2> / g-68.7 m<2> / g, and the graphite type C3N4 material has the advantages of large specific surface area, high photocatalytic activity and the like, can be used for photocatalytic degradation of landfill leachate and can efficiently degrade organic pollutants in the landfill leachate.

Owner:HUNAN UNIV

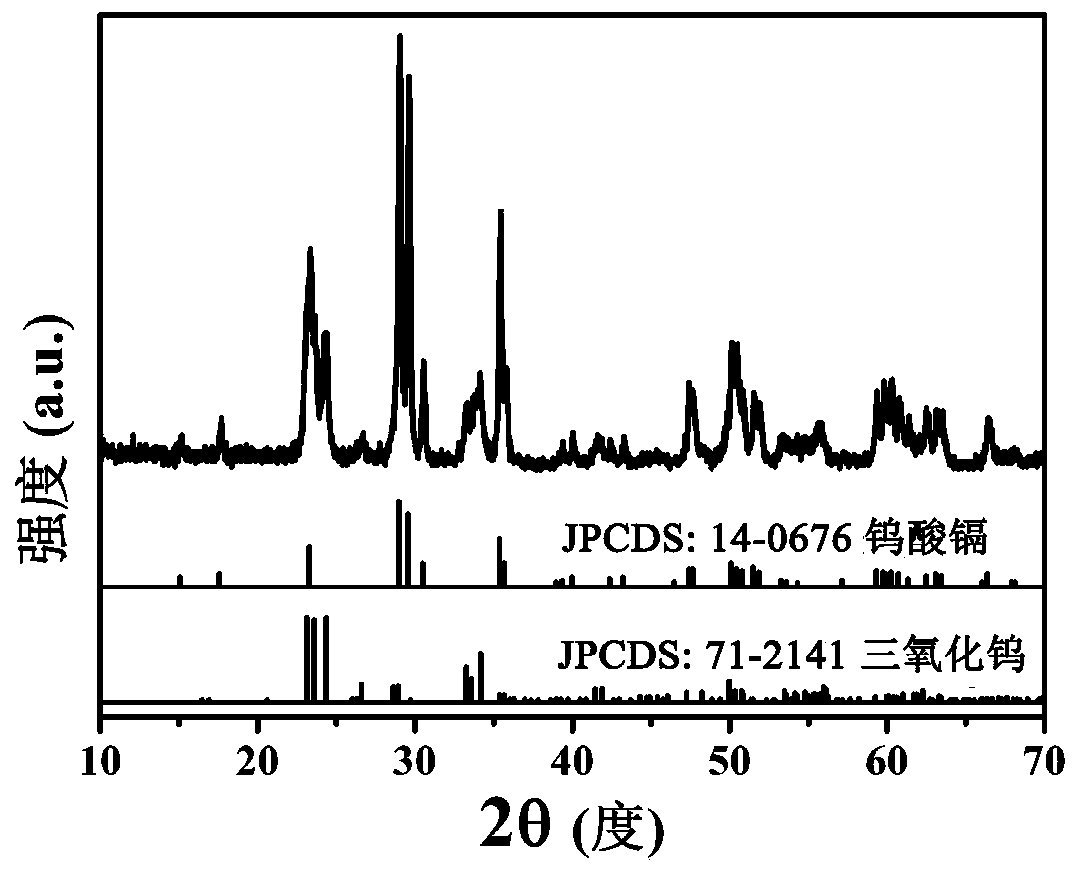

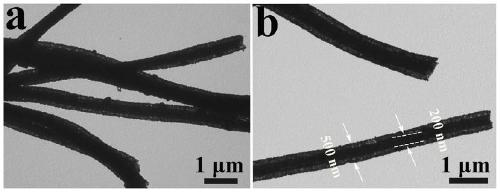

Tungsten trioxide/cadmium tungstate nanofiber photocatalytic material and preparation method and application thereof

ActiveCN110327914AEfficient Photocatalytic DegradationLow costWater/sewage treatment by irradiationWater treatment compoundsFiberN dimethylformamide

The invention relates to a tungsten trioxide / cadmium tungstate nanofiber photocatalytic material and a preparation method and applications thereof. The method comprises the following steps: dissolvingammonium metatungstate and cadmium acetate in a mixed solvent consisting of absolute ethyl alcohol and N,N-dimethylformamide, and adding polyvinylpyrrolidone to obtain spinnable precursor sol; controlling rheological property and spinning process parameters of the spinnable precursor sol to prepare precursor fibers, and calcining the precursor fibers at different temperatures to obtain a tungstentrioxide / cadmium tungstate nanofiber photocatalytic material; finally, producing a nanofiber photocatalytic material with a tube-in-tube structure through a preferable experimental scheme. The photocatalytic material realizes efficient photocatalytic degradation of tetracycline under visible light, and the degradation rate can reach 93.1% within 120 min. The preparation method has the advantagesof simple steps, low cost and recyclability, and greatly reduces the application cost.

Owner:济南蓝海洋环保科技有限公司

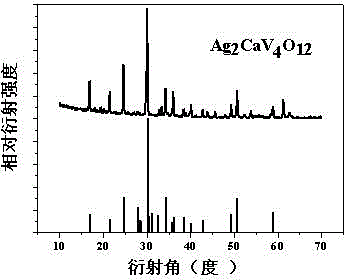

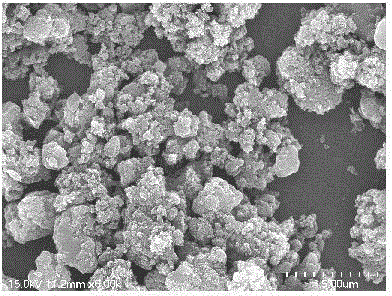

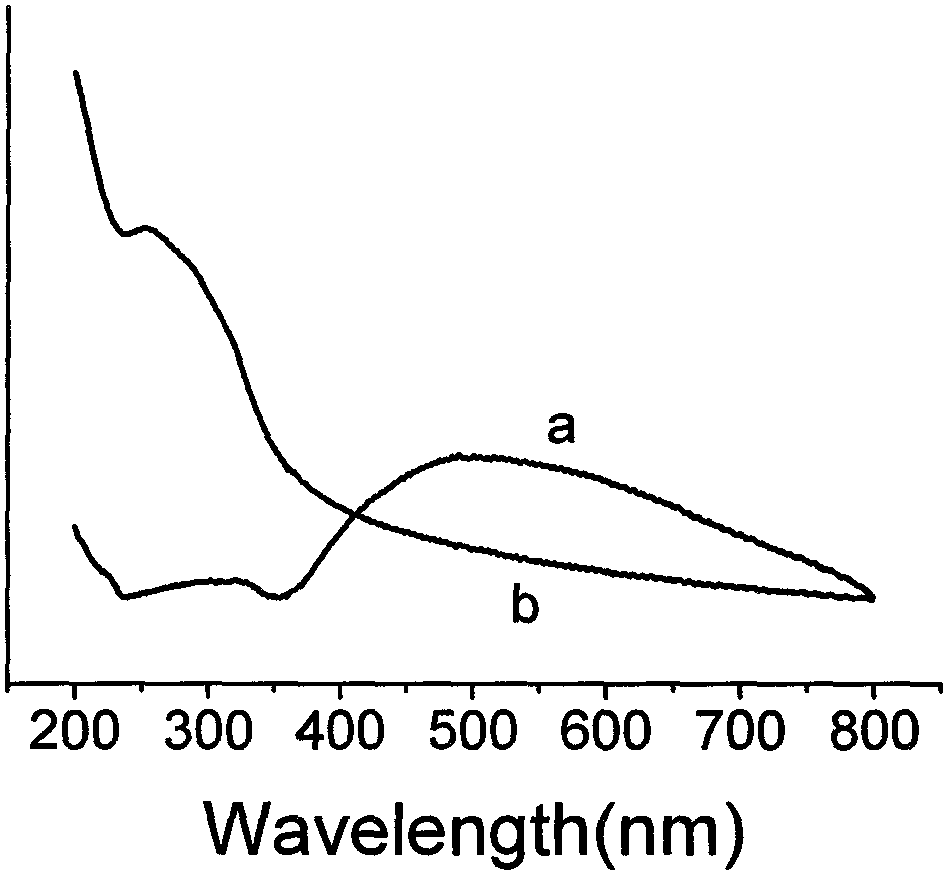

Visible-light-response vanadate photocatalytic material as well as preparation method and application thereof

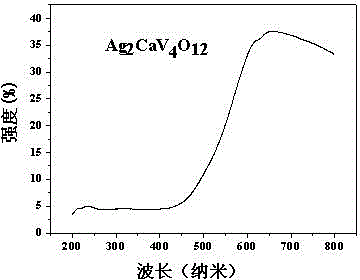

InactiveCN104801302AEfficient Photocatalytic DegradationNo emissionsWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsDispersityChemical solution

The invention discloses a visible-light-response vanadate photocatalytic material as well as a preparation method and application thereof. The chemical formula of the vanadate photocatalytic material is Ag2CaV4O12; the vanadate photocatalytic material can be prepared from a high-temperature solid-phase method, a chemical solution method or a coprecipitation method. The prepared visible-light-response vanadate photocatalytic material is good in dispersity, uniform in particle degree, good in chemical stability, and low in preparation cost and equipment requirements; besides, Ag2CaV4O12 has excellent photocatalytic performance, and can efficiently photoactivate and degrade methylene blue under near ultraviolet radiation, so that the visible-light-response vanadate photocatalytic material has the function of decomposing harmful chemical substances under visible light response; the vanadate photocatalytic material is good in photocatalytic stability, and has favorable application prospect.

Owner:XUZHOU NORMAL UNIVERSITY

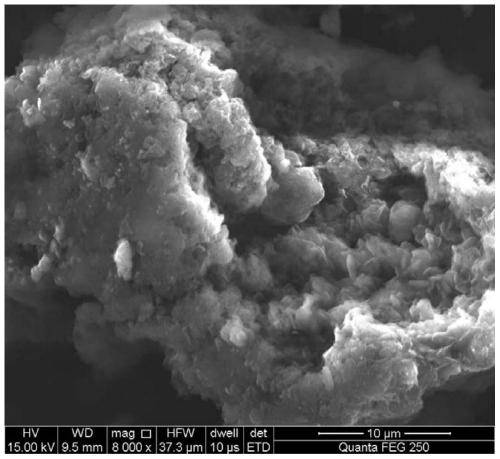

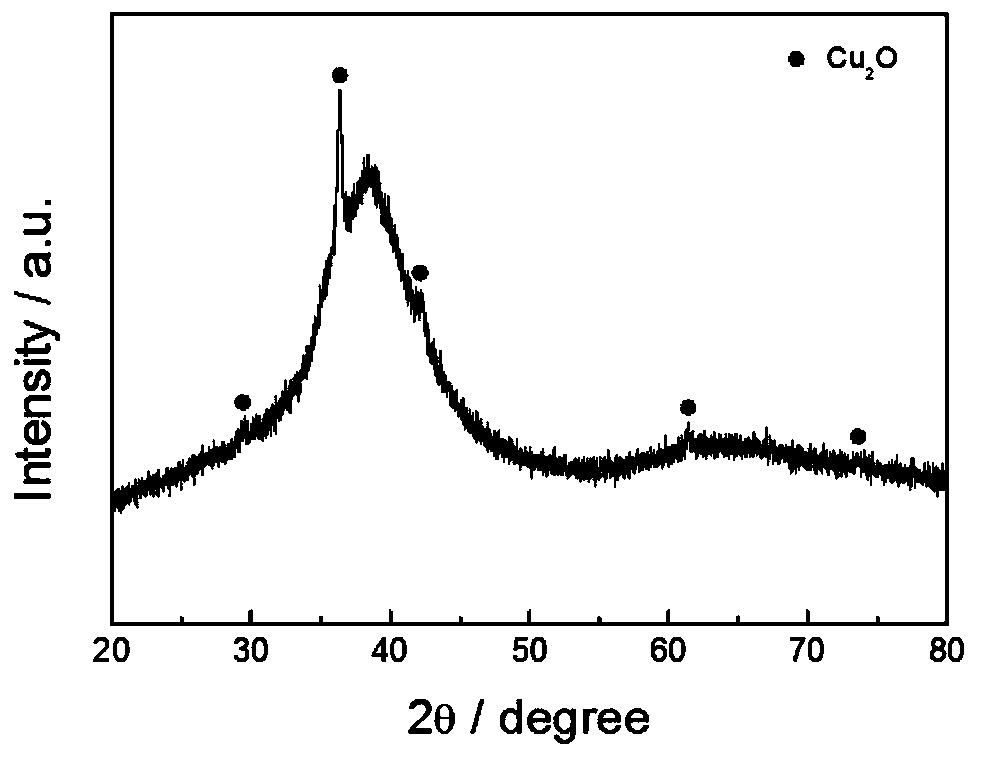

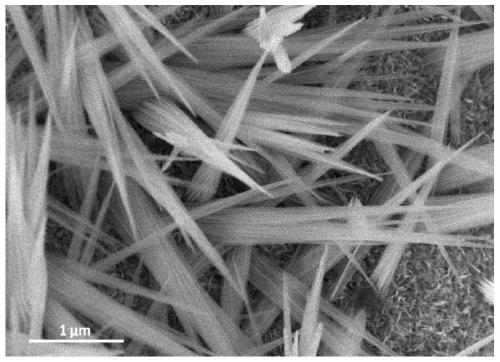

A kind of multi-level porous nanoporous copper-loaded cuprous oxide nanowire composite material and preparation method thereof

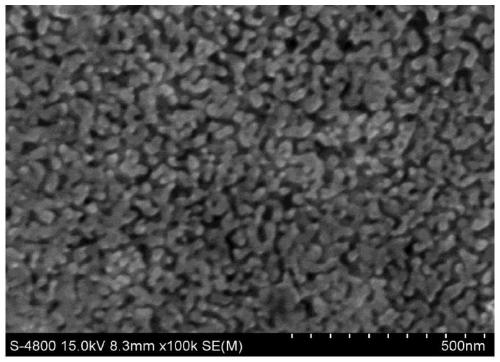

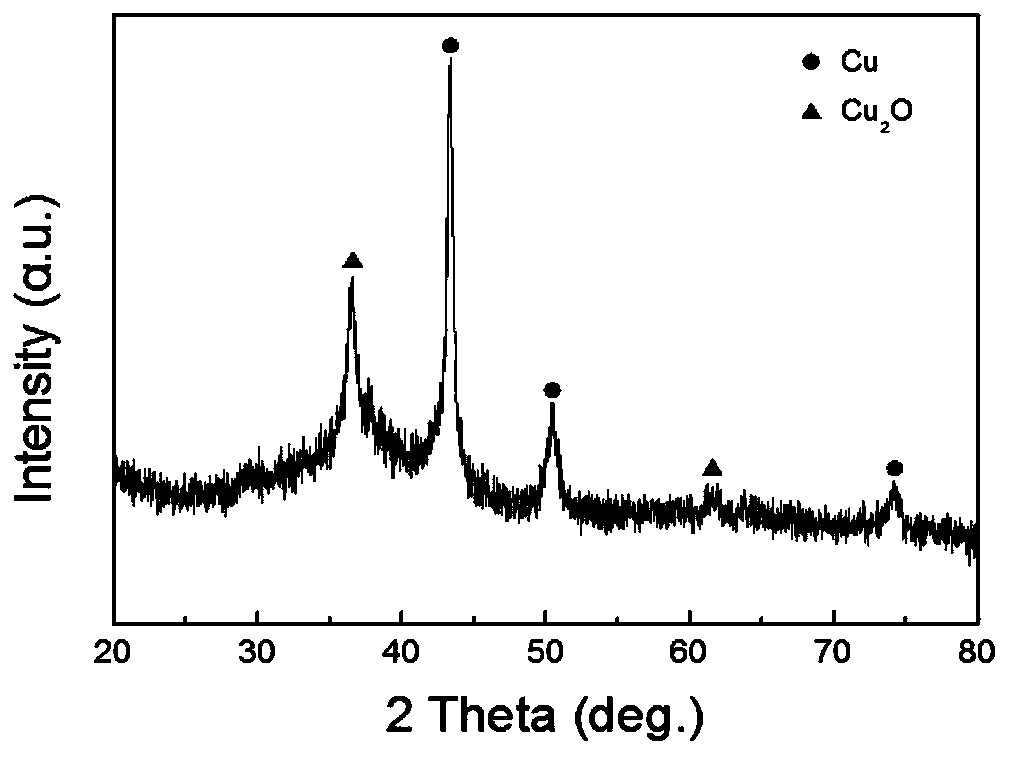

ActiveCN108295854BIntegrityLarge specific surface areaWater/sewage treatment by irradiationWater contaminantsNanoholeMechanical integrity

A hierarchical porous nanoporous copper-loaded cuprous oxide nanowire composite material. The composite material is a thin strip and includes an amorphous matrix, nanoporous copper covering the amorphous matrix, and porous oxide nanowires loaded on the surface of the nanoporous copper. Copper nanowires. Among them, the composite material has 5 layers in cross section, the middle core layer is an amorphous matrix, the surfaces on both sides of the middle core layer are covered with nanoporous copper, and the nanoporous copper surfaces on both sides are loaded with porous cuprous oxide nanowires. Among them, the thickness of the nanoporous copper layer on one side is 6 to 12 μm, the width of the ligament is 20 to 40 nm, the pore size is 15 to 30 nm, the thickness of the nanowire layer on one side is 3 to 12 μm, the length of the nanowire is 5 to 10 μm, and the width is 5 to 10 nm; the nanowires are distributed It has nanopores with a size of 0.5~2nm. The invention has simple process and short preparation cycle; the prepared composite material has good mechanical integrity, can be recycled and reused, and the economic benefits are improved.

Owner:HEBEI UNIV OF TECH

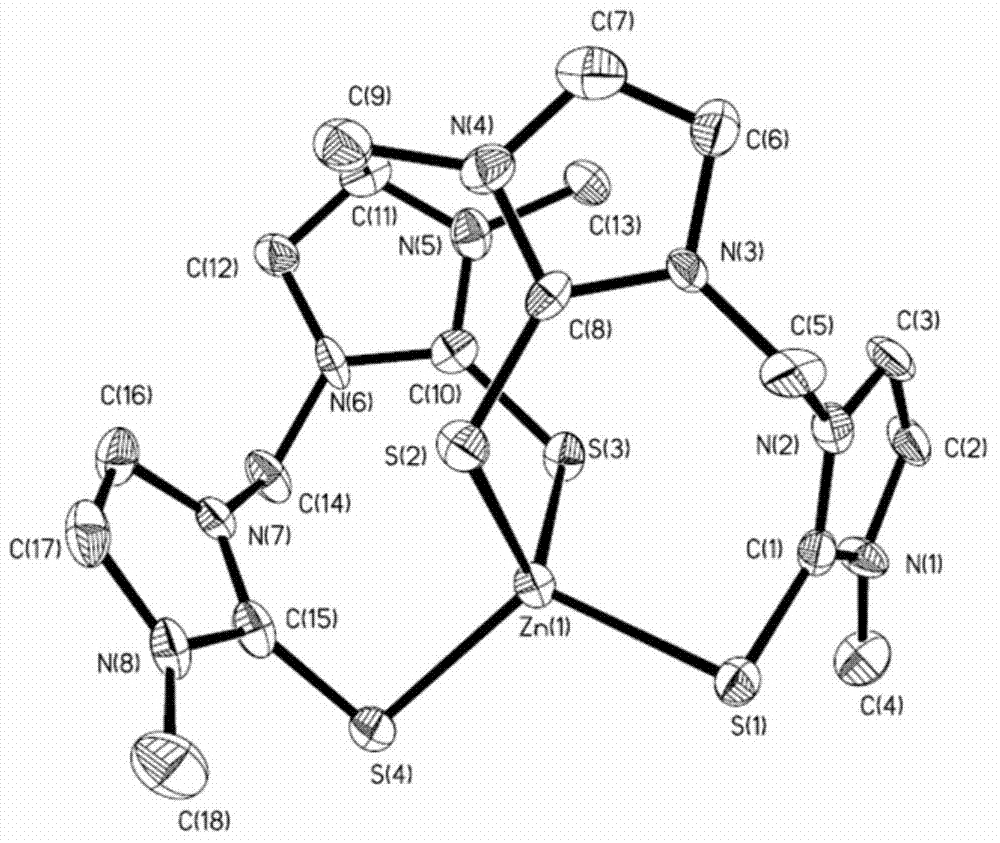

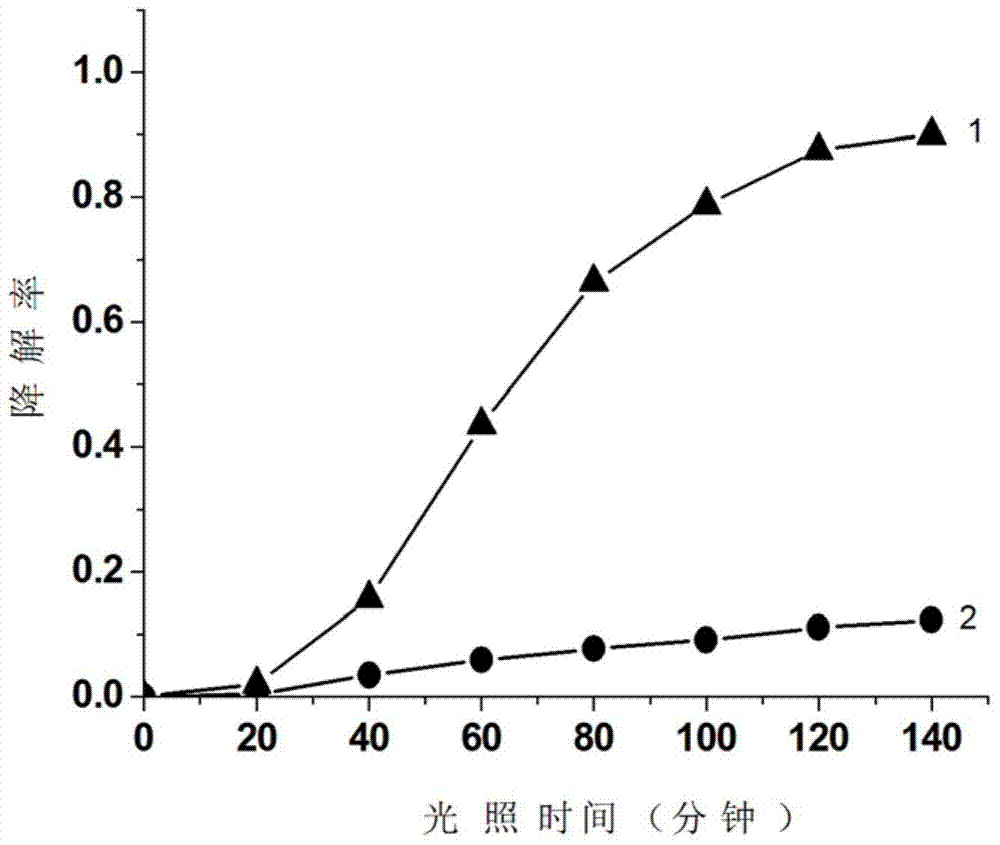

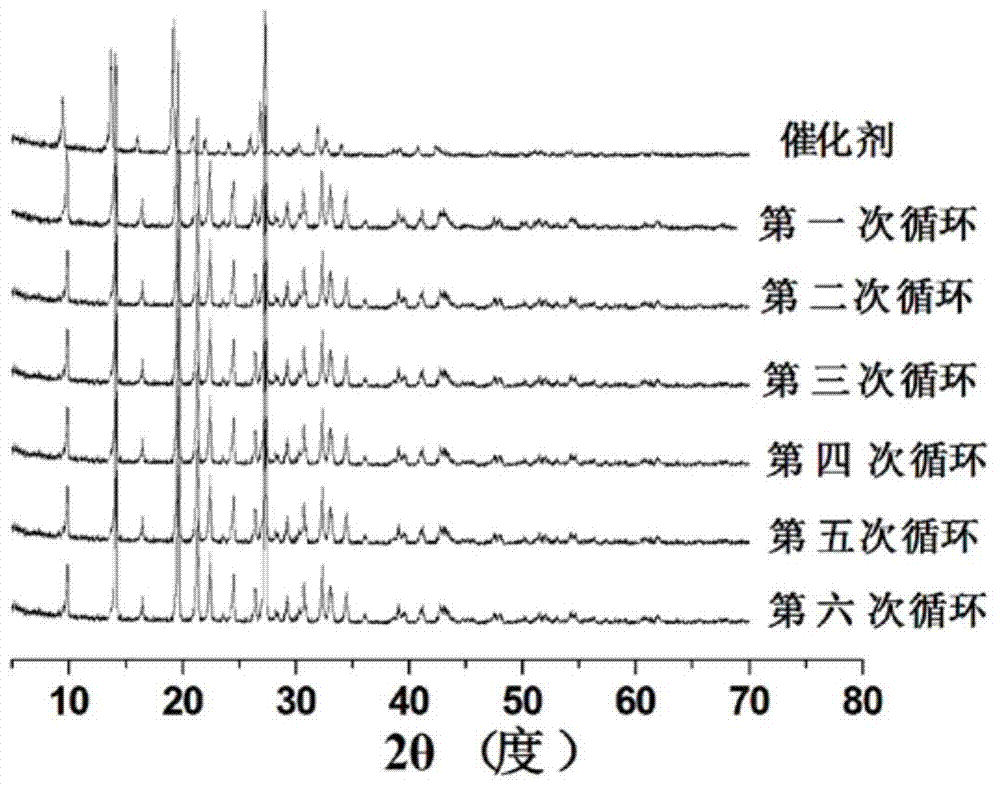

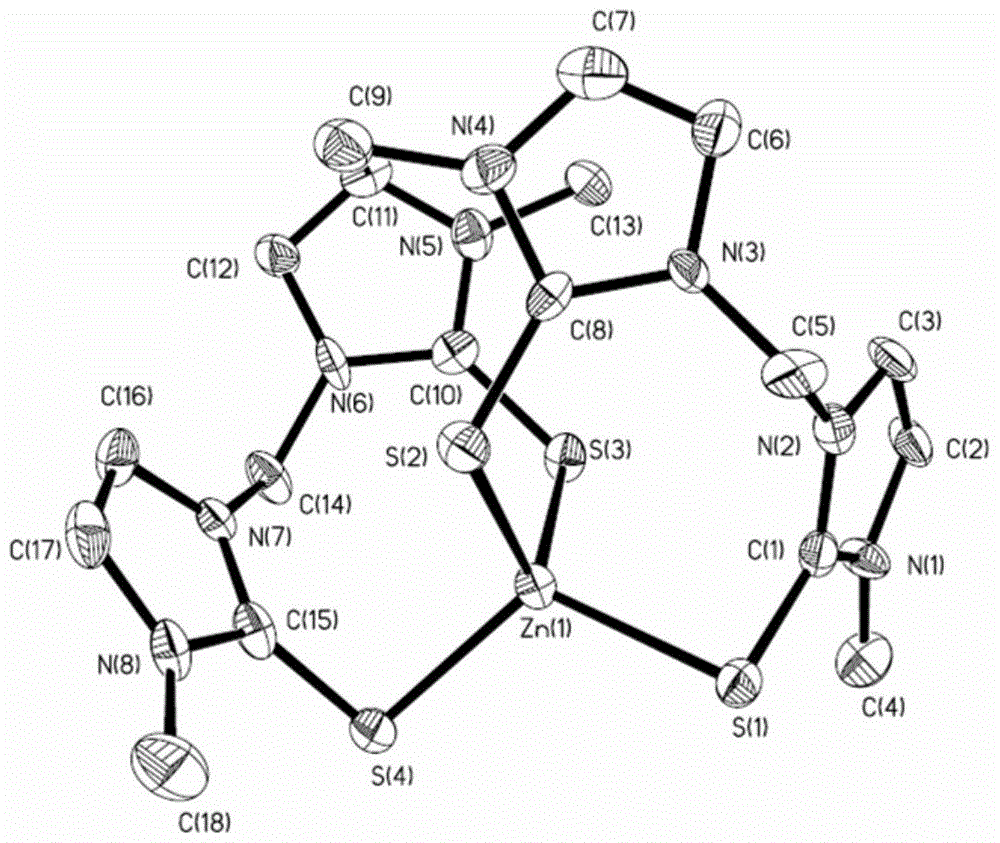

Zinc reagent and preparation method and application thereof

ActiveCN103923111AEfficient Photocatalytic DegradationSimple processWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalysts1-MethylimidazoleSewage

The invention discloses a zinc reagent and a preparation method and application thereof. An efficient zinc reagent catalyst is synthesized by taking 1, 1-bis (1-methylimidazole thione) methane and zinc perchlorate as raw materials. Compared with the prior art, the zinc reagent has the advantages of simple process, simplicity and convenience in operation, low cost and the like, and the zinc reagent can perform photocatalytic degradation on azo type colored compounds efficiently, has good catalytic activity for methyl orange and can be recycled many times. In the aspect of treatment of organic sewage, the zinc reagent has good industrial application prospects.

Owner:ANHUI NORMAL UNIV

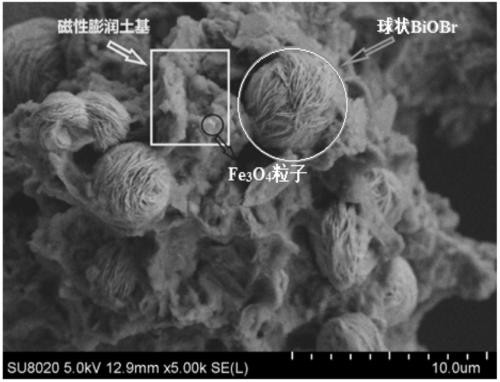

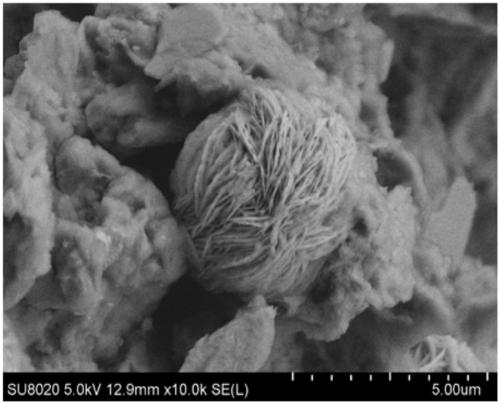

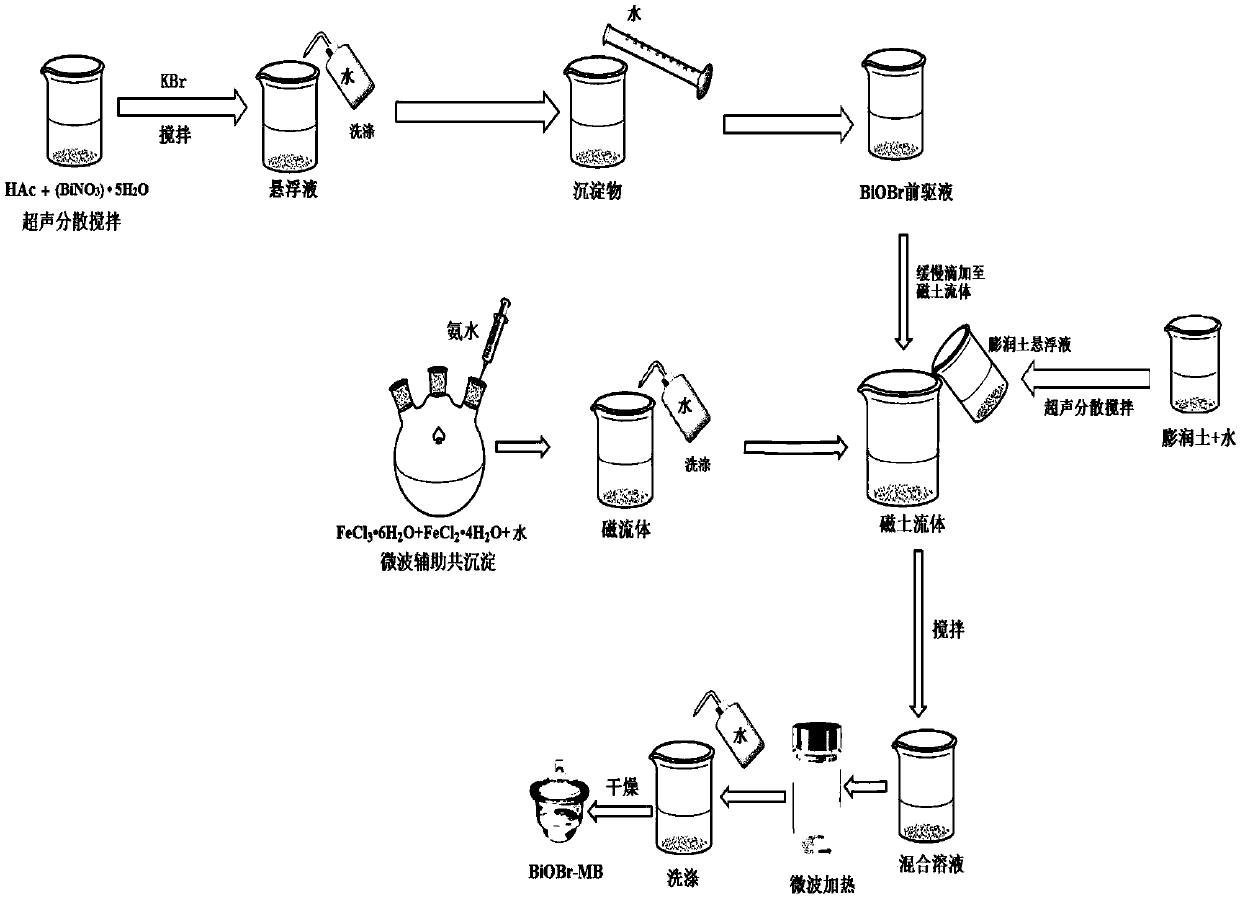

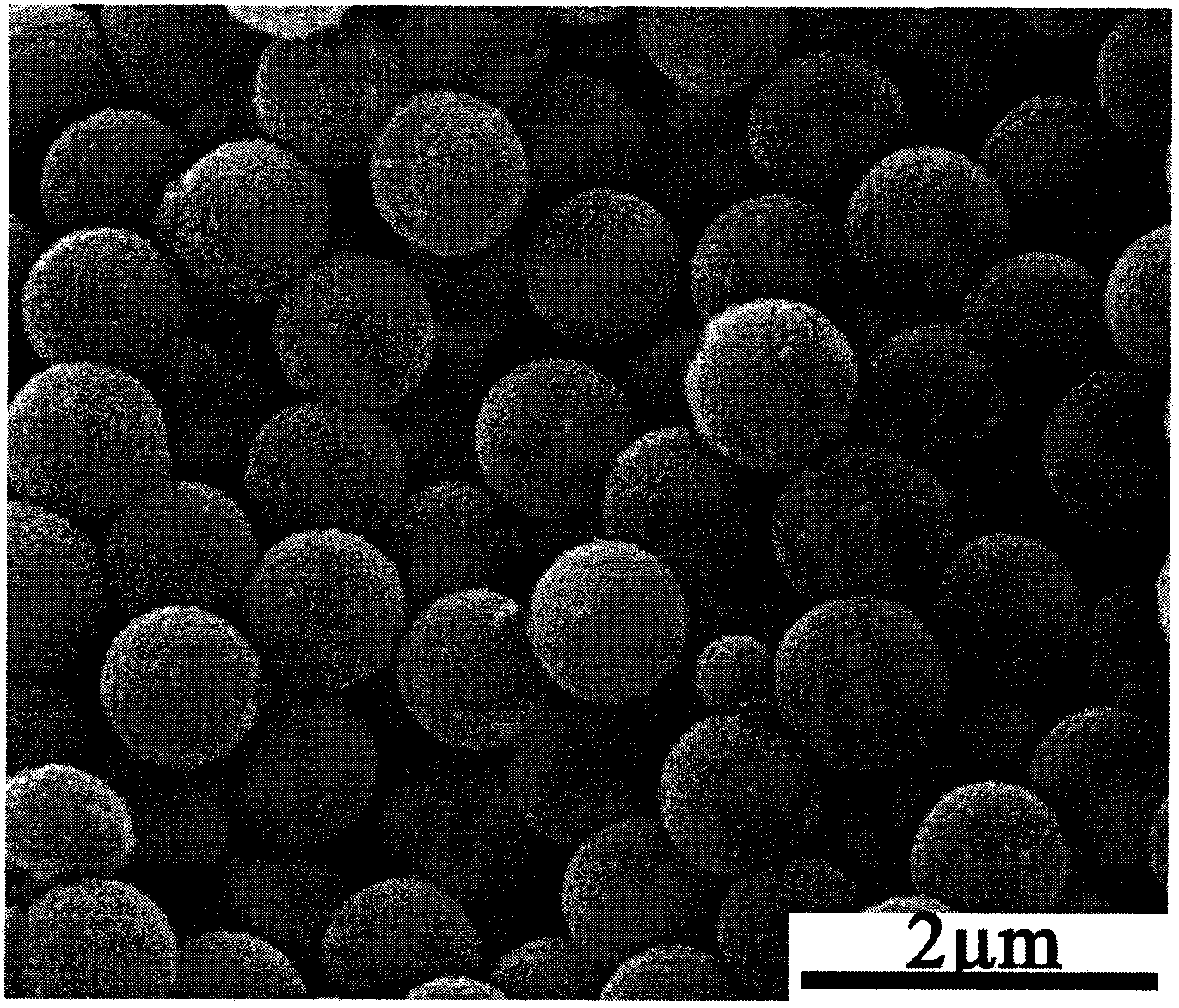

Magnetic bentonite loaded spherical BiOBr, preparation method and application thereof

PendingCN111359639AWide variety of sourcesGood dispersionWater/sewage treatment by irradiationWater treatment compoundsMicrowaveTetracycline

The invention discloses spherical BiOBr loaded by magnetic bentonite, a preparation method and application thereof. The preparation method comprises the following steps: embedding a BiOBr precursor between layers of a magnetic bentonite base and / or depositing the BiOBr precursor on the surface of the magnetic bentonite base, and then realizing in-situ self-assembly under the action of high-temperature pressurization by utilizing a microwave-assisted hydrothermal method to obtain the spherical BiOBr loaded by the magnetic bentonite. According to the invention, the prepared spherical BiOBr loaded by the magnetic bentonite has a large specific surface area and excellent magnetic separation performance while the forbidden band width is narrowed, so that the magnetic bentonite loaded sphericalBiOBr has high visible light absorption capacity, the recombination efficiency of electron hole pairs is reduced, and efficient degradation of tetracycline, ciprofloxacin and other organic solutions is achieved under visible light; and under the action of an external magnetic field, the magnetic bentonite loaded spherical BiOBr can be rapidly recycled, and the magnetic bentonite loaded spherical BiOBr has good repeated utilization rate and stable performance.

Owner:GUANGXI UNIV

Method for preparing Ag/AgCl/BiMg2VO6 composite photocatalyst

ActiveCN102698777BHigh crystallinitySimple processPhysical/chemical process catalystsRoom temperatureAmmonium metavanadate

The invention provides a method for preparing an Ag / AgCl / BiMg2VO6 composite photocatalyst with a visible light photocatalytic activity. The method is characterized in by comprising the following steps: obtaining a BiMg2VO6 base material from the raw materials: bismuth nitrate pentahydrate, magnesium nitrate hexahydrate, and ammonium metavanadate, by a sol-gel method; adding BiMg2VO6 into deionized water and then ultrasonically treating the mixed solution; then, slowly dropwise adding 0.1 mol / L silver nitrate solution at a proportion of 1 to 3 mmol / g of Ag / BiMg2VO6 and then ultrasonically treating the mixed solution for 10 min, and stirring the mixed solution for 20 min at room temperature in the dark; slowly adding 0.1 mol / L hydrochloric acid solution into the mixed solution at a mole ratio of 1:1 or 1:2 of H ions in the silver nitrate solution to H ions in the hydrochloric acid solution, ultrasonically treating and stirring the mixed solution to generate a AgCl / BiMg2VO6 composite photocatalyst; and optically reducing the AgCl / BiMg2VO6 composite photocatalyst at an ultraviolet lamp of 20 W to obtain the Ag / AgCl / BiMg2VO6 composite photocatalyst. The composite photocatalyst prepared by the method has a high photocatalytic activity in visible light and a simple preparation process.

Owner:WUHAN UNIV OF TECH

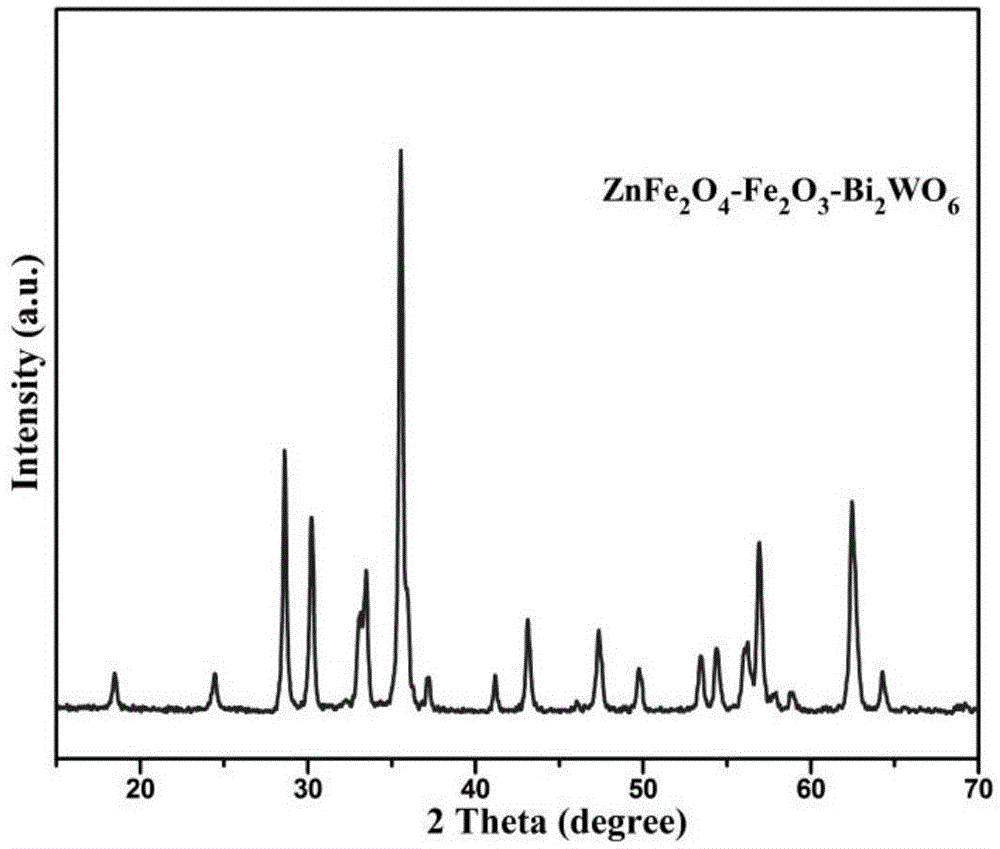

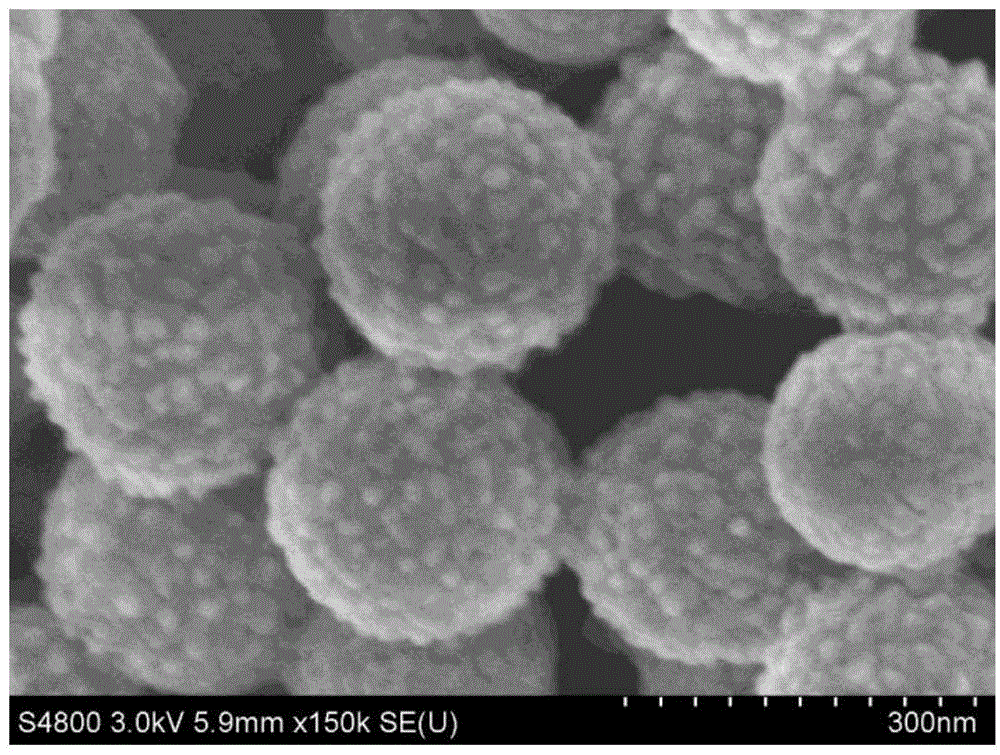

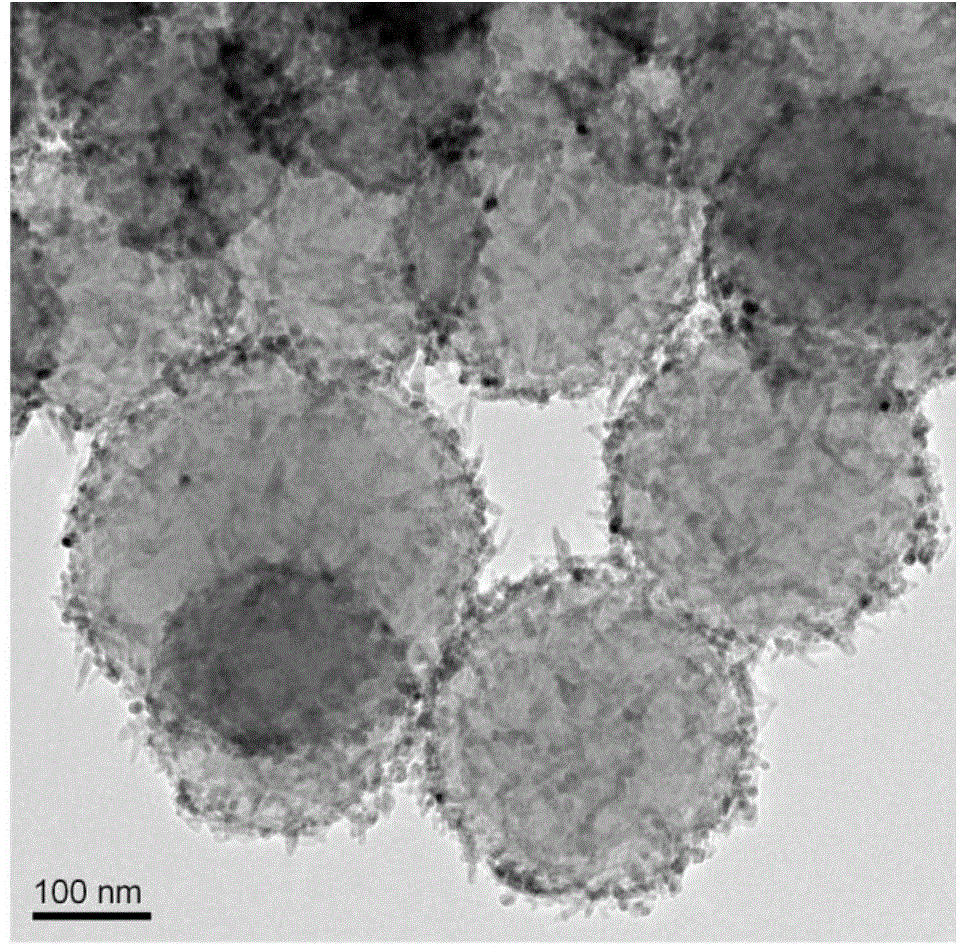

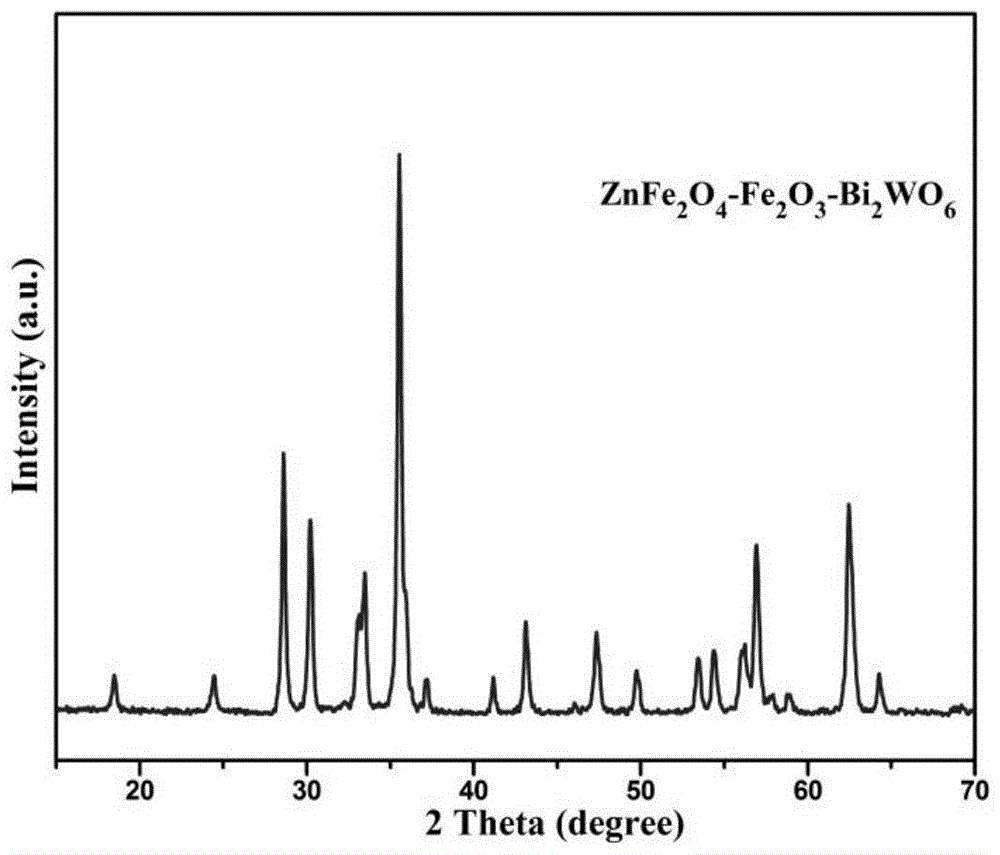

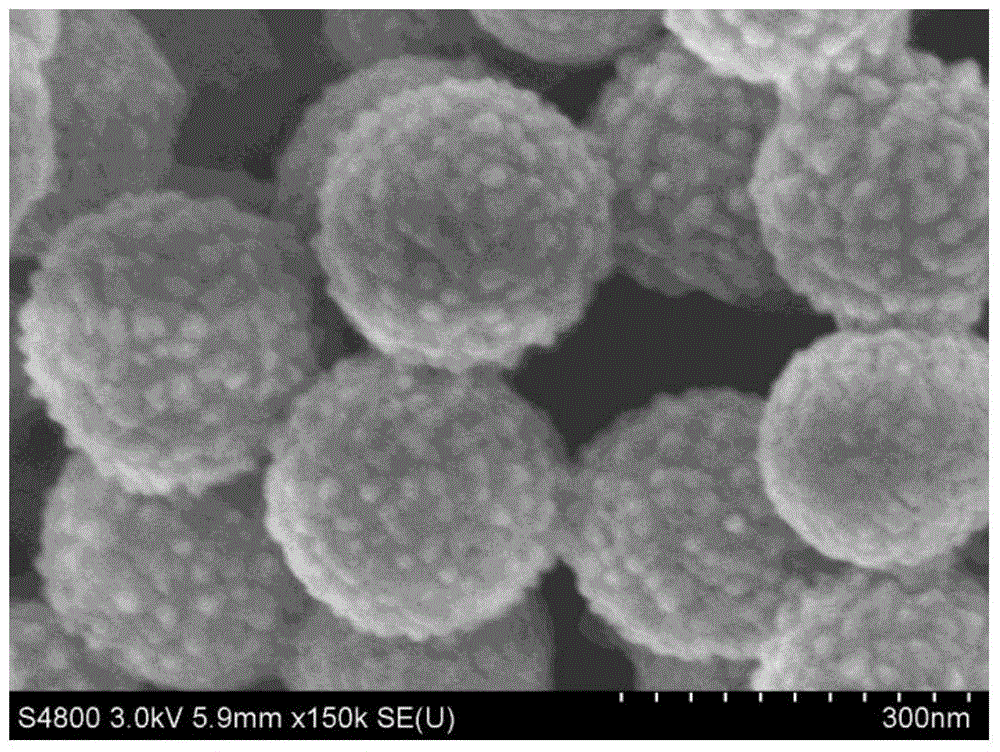

Bismuth-tungstate-modified magnetic-separation hollow composite photocatalyst and preparation method thereof

ActiveCN104128191AEfficient separationEfficient Photocatalytic DegradationMetal/metal-oxides/metal-hydroxide catalystsIron saltsTungstate

The invention discloses a bismuth-tungstate-modified magnetic-separation hollow composite photocatalyst which is obtained by composing ZnFe2O4, Fe2O3 and Bi2WO6. A particle size of hollow micro-spheres is 50-1000nm, and a hollow housing thickness is 1-100nm. The invention also discloses a preparation method of the photocatalyst. The method comprises the following steps: phenolic resin micro-spheres are prepared through a hydrothermal reaction; the micro-spheres are soaked in a mixed solution of iron salt and zinc salt, and ultrasonic processing, aging, and calcining are carried out, such that C@ZnFe2O4-Fe2O3 micro-spheres are obtained; the C@ZnFe2O4-Fe2O3 micro-spheres are soaked in a mixed ethylene glycol solution of Bi(NO3)3 and Na2WO4, and ultrasonic processing, aging, and calcining are carried out, such that the photocatalyst is obtained. With the photocatalyst provided by the invention, toxic and harmful substances can be highly efficiently photo-catalytically degraded under sunlight and ultraviolet light. A degradation rate is close to 100%. Also, ZnFe2O4 has magnetism, and is easy to separate and recover. The preparation method of the photocatalyst is simple.

Owner:陕西万华环境工程有限公司

A kind of zinc reagent and its preparation method, application

ActiveCN103923111BEfficient Photocatalytic DegradationSimple processWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalysts1-MethylimidazoleSewage

The invention discloses a zinc reagent and a preparation method and application thereof. An efficient zinc reagent catalyst is synthesized by taking 1, 1-bis (1-methylimidazole thione) methane and zinc perchlorate as raw materials. Compared with the prior art, the zinc reagent has the advantages of simple process, simplicity and convenience in operation, low cost and the like, and the zinc reagent can perform photocatalytic degradation on azo type colored compounds efficiently, has good catalytic activity for methyl orange and can be recycled many times. In the aspect of treatment of organic sewage, the zinc reagent has good industrial application prospects.

Owner:ANHUI NORMAL UNIV

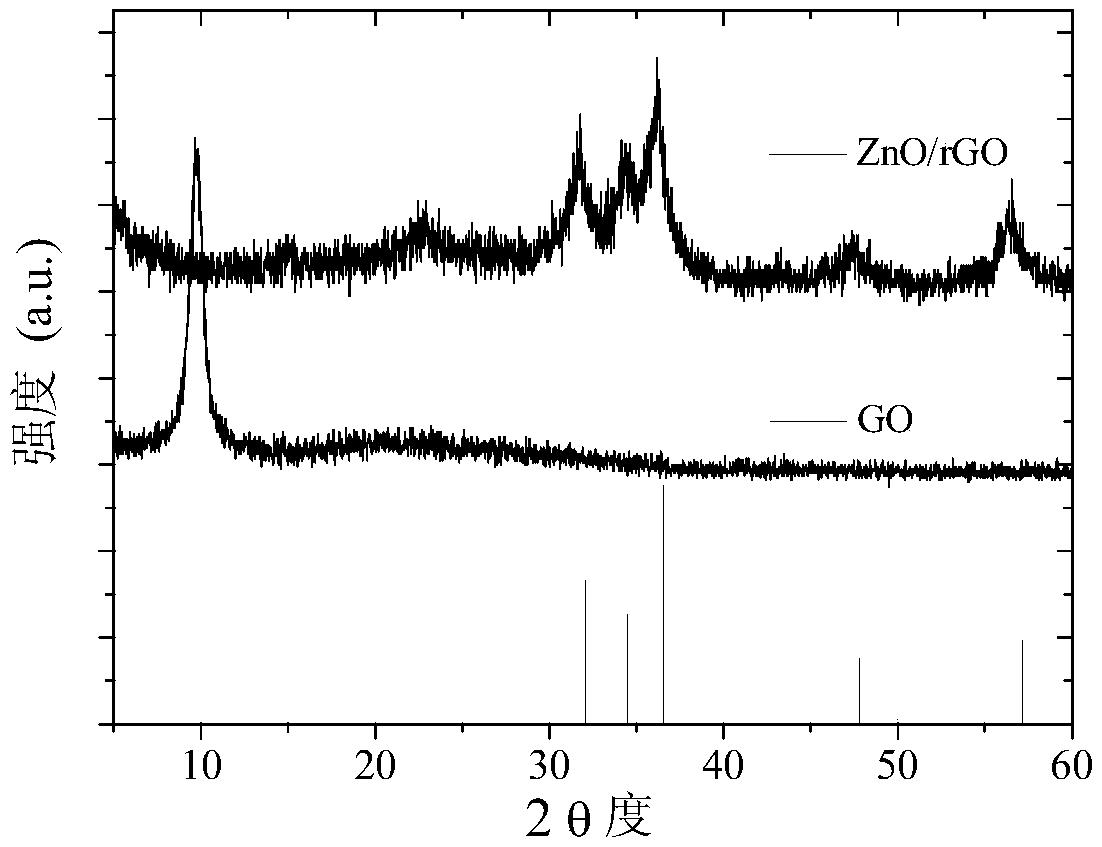

Method of preparing zinc oxide-reduced graphene oxide composite material

ActiveCN109926039AGood dispersionShort formation timeWater/sewage treatment by irradiationWater contaminantsPhotoinitiatorIndustrial waste

The present invention provides a method of preparing a zinc oxide-reduced graphene oxide composite material. The method comprises: 1) providing a mixture containing graphene oxide, at least a zinc source, at least a weak base and at least a photoinitiator; and 2) irradiating the mixture obtained in the step 1) with ultraviolet light to obtain a zinc oxide-reduced graphene oxide composite material.The invention further relates to a zinc oxide-reduced graphene oxide composite material obtained by the method, and uses in degradation of organic pollutants, purification of air, treatment of industrial waste gases and degradation of plastics.

Owner:ZHENRUN ENVIRONMENTAL SCI & TECH CO LTD

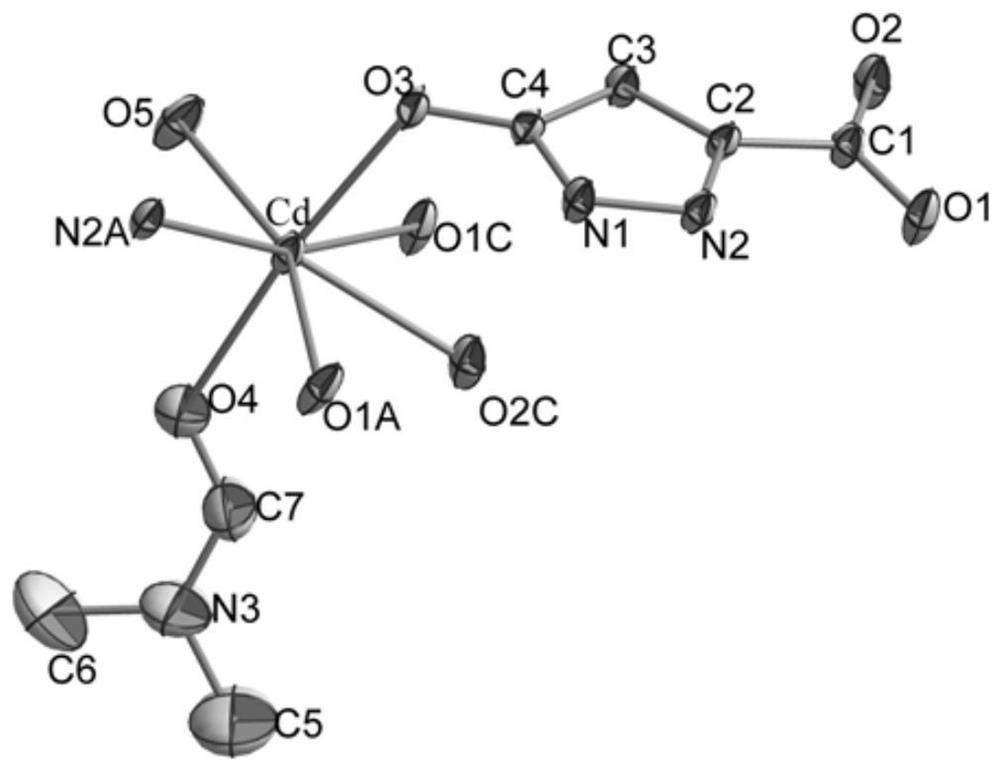

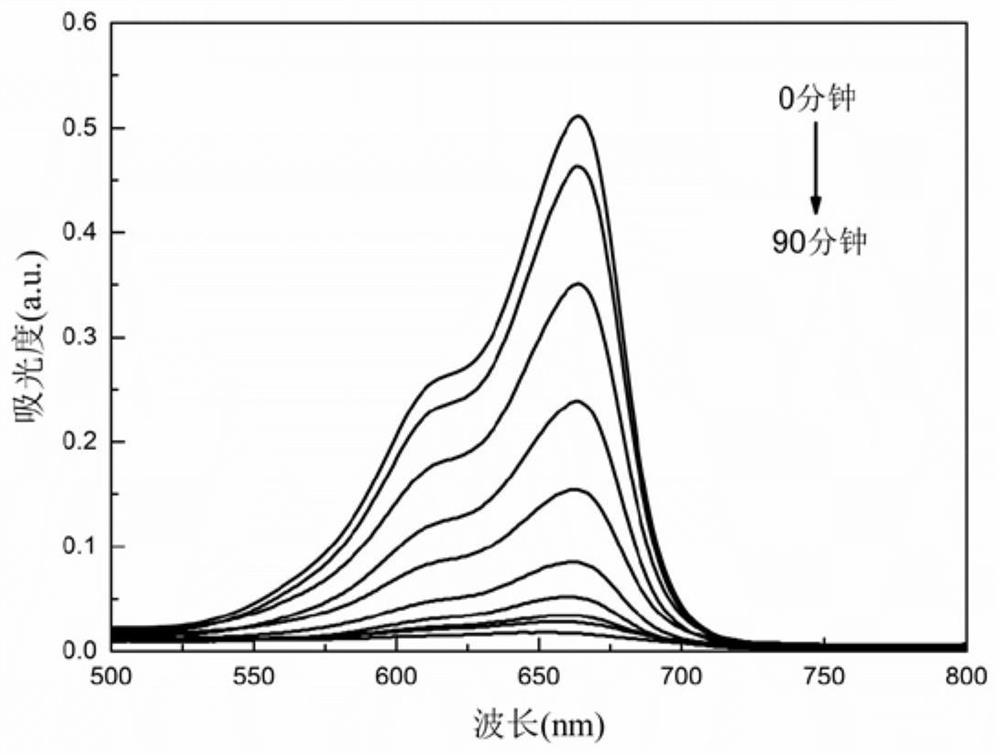

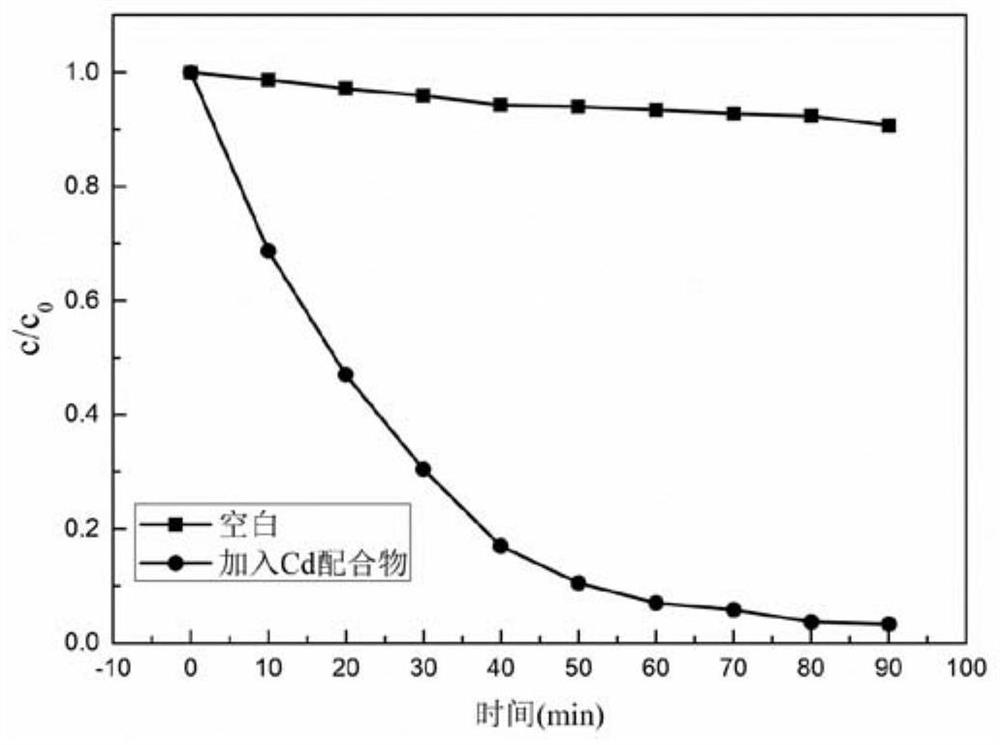

Cadmium Hydroxypyrazolecarboxylate Coordination Polymer for Catalytic Degradation of Organic Dyes by Visible Light and Its Preparation and Application

ActiveCN111518282BThe synthesis method is simpleEasy to operateWater/sewage treatment by irradiationWater treatment compoundsOrganic dyeMethyl blue

The invention discloses a cadmium coordination polymer of hydroxypyrazole carboxylate for visible light catalytic degradation of organic dyes and its preparation and application. The chemical expression of the cadmium coordination polymer is [Cd(hpcH)(H 2 O)(DMF)] n , where hpcH 3 is a 5-hydroxypyrazole-3-carboxylic acid containing 1 metal Cd per asymmetric unit 2+ ion, a deprotonated organic ligand (hpcH 2‑ ), a coordinated water molecule and a coordinated DMF molecule, Cd 2+ The ions are linked by 5-hydroxypyrazole-3-carboxylic acid ligands to form a two-dimensional layered structure. The synthesis method of the cadmium coordination polymer is simple and the yield is high; it has stable photocatalytic dye degradation performance at room temperature, can efficiently photocatalyze the degradation of methylene blue (MB) azo dye, and has a high recycling rate; at the same time, the The structure of the polymer is stable, insoluble in water and common organic solvents, which can avoid secondary pollution problems.

Owner:南通市隆润化工有限公司

Bismuth tungstate modified magnetic separation hollow composite photocatalyst and preparation method thereof

ActiveCN104128191BEfficient separationEfficient Photocatalytic DegradationMetal/metal-oxides/metal-hydroxide catalystsSolar lightMicrosphere

The invention discloses a bismuth tungstate modified magnetic separation hollow composite photocatalyst, which is composed of ZnFe 2 o 4 , Fe 2 o 3 and Bi 2 WO 6 Composite; the particle size of the hollow microspheres is 50-1000nm, and the thickness of the hollow shell is 1-100nm. The invention also discloses its preparation method: preparing phenolic resin microspheres by hydrothermal reaction; adding them into the mixed solution of iron salt and zinc salt for ultrasonication, aging and calcining to obtain C@ZnFe 2 o 4 ‑Fe 2 o 3 microspheres; the C@ZnFe 2 o 4 ‑Fe 2 o 3 Microspheres soaked in Bi(NO 3 ) 3 and Na 2 WO 4 It can be obtained by ultrasonication, aging and calcination in mixed ethylene glycol solution. The photocatalyst of the present invention can efficiently photocatalyze and degrade toxic and harmful substances under sunlight and ultraviolet light, and the degradation rate is close to 100%, and ZnFe 2 o 4 It has magnetism, is easy to separate and recover, and has a simple preparation method.

Owner:陕西万华环境工程有限公司

A silver phosphate modified magnetic separation hollow composite photocatalyst and its preparation method

ActiveCN104148098BEfficient separationEfficient Photocatalytic DegradationPhysical/chemical process catalystsHeterojunctionMicrosphere

The invention discloses a silver phosphate modified magnetic separation hollow composite photocatalyst, which is composed of ZnFe 2 o 4 , ZnO and Ag 3 PO 4 Composite; the particle size of the hollow microsphere is 50-1000nm, and the thickness of the hollow shell is 1-100nm. The invention also discloses its preparation method: mixing zinc salt and iron salt solution into phenolic resin microspheres, ultrasonic aging, drying, calcining, and then adding AgNO 3 Ethanol solution and Na 3 PO 4 Ethanol solution, stirring, and drying. The present invention consists of ZnFe 2 o 4 , ZnO and Ag 3 PO 4 It forms a heterojunction with a waterfall structure, which promotes the effective separation of photogenerated electrons and holes, thereby improving its photocatalytic activity; ZnFe 2 o 4 It has magnetism, is easy to separate and recover, and has a simple preparation method.

Owner:SHAANXI UNIV OF SCI & TECH

A nanoporous copper-loaded ultrafine copper oxide nanowire composite material and its preparation method and application

The invention discloses a nano-porous copper loaded ultrafine oxide copper nanowire composite material and a preparation method and application thereof. The material is a rod, and comprises an amorphous basal body, nano-porous copper covering the amorphous basal body, and ultrafine copper oxide nanowires loaded on the surface of the nano-porous copper; the amorphous basal body is CuxZryAlz alloy component, wherein x, y and z are atomic percents; x is not bigger than 50 and not smaller than 45, y is not bigger than 50 and not smaller than 45, z is not bigger than 10 and not smaller than 5; x+y+z is 100; the nano-porous copper has the layer thickness of 85-135 microns, the ligament width of 118-138 nm and the aperture size of 30-100 nm; the nanowires are 4-10 microns long and 5-15 nm wide; and every 20-30 nanowires are clustered as one bundle. The copper oxide nanowires are constructed on the nano-scale basal body for the first time. Nanowire copper oxide is tightly combined with the surface of the nano-porous copper metal, so that the prepared material achieves efficient photocatalytic degradation of organic dye.

Owner:HEBEI UNIV OF TECH

A nanoporous copper-loaded porous cuprous oxide nanosheet composite material and preparation method thereof

ActiveCN108193255BLarge specific surface areaMany reactive sitesMaterial nanotechnologyAnodisationMechanical integrityEconomic benefits

Owner:HEBEI UNIV OF TECH

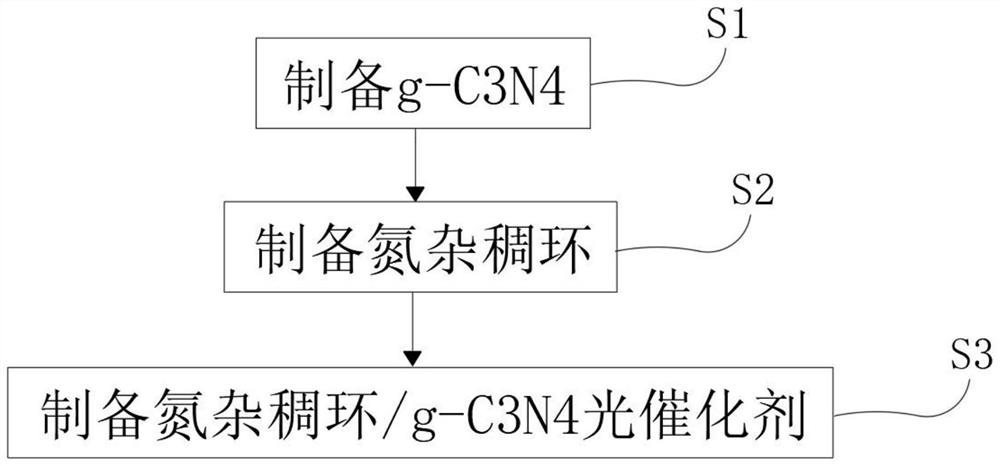

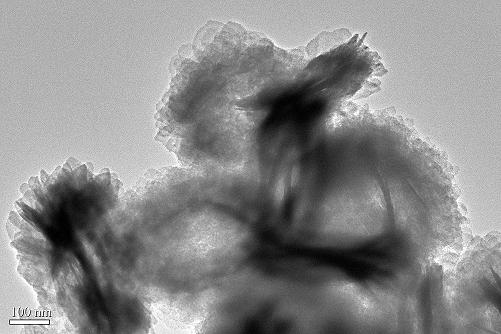

Preparation method and application of aza fused ring g-C3N4 composite material

PendingCN114768869AEfficient Photocatalytic DegradationImprove degradation efficiencyGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsPhotocatalytic degradationTube furnace

The invention provides a preparation method and application of an aza-fused ring g-C3N4 composite material, and relates to the technical field of material chemistry, the preparation method of the aza-fused ring g-C3N4 composite material comprises the following steps: S1, preparing g-C3N4: directly pyrolyzing 20g of melamine in a tubular furnace under a nitrogen protection atmosphere to prepare g-C3N4, and preserving for later use; s2, preparing the aza-condensed ring, adding 1g to 3g of cyclohexanehexone octahydrate and 1g to 4g of 1, 2, 4, 5-phenylenetetramine tetrahydrochloride into a round-bottom flask in a nitrogen atmosphere, and then adding a mixed solution of 0.5 mL to 5mL of H2SO4 and 100 mL to 150mL of deoxidized N-methyl pyrrolidone; the photocatalyst is prepared by compounding aza fused rings and g-C3N4, the preparation method comprises the following steps: uniformly mixing g-C3N4 and aza fused rings, and carrying out a hydrothermal reaction to obtain the photocatalyst, and the photocatalyst has excellent formaldehyde photocatalytic degradation capability, is high in degradation efficiency, is environment-friendly, is relatively high in practicability, and is suitable for industrial production. And the progress is obvious.

Owner:深圳市绿蔓科技有限公司

Hierarchical nanostructure bi 2 o 3 /(bio) 2 co 3 preparation of

ActiveCN106582758BIncrease refractionIncrease profitCatalyst activation/preparationChemical industryEngineering

The present invention relates to a Bi 2 o 3 / (BiO) 2 CO 3 The invention relates to a synthesis method of a composite photocatalytic material, which belongs to the technical field of chemical industry. Using Na 2 CO 3 , bismuth citrate, and NaOH three kinds of chemical reagent raw materials are weighed according to the molar ratio, mixed into double distilled water and stirred for a certain period of time. After drying to obtain the final product Bi 2 o 3 / (BiO) 2 CO 3 Composite photocatalytic materials. Its surface morphology, microstructure, and photocatalytic activity were measured, and the hierarchical rosette Bi 2 o 3 / (BiO) 2 CO 3 The composite photocatalytic material has a great improvement in the degradation of rhodamine B and other dyes under different light sources. The production process of this product is simple and practical, the product performance is stable, and it has considerable applicability to various dyes.

Owner:QIQIHAR UNIVERSITY

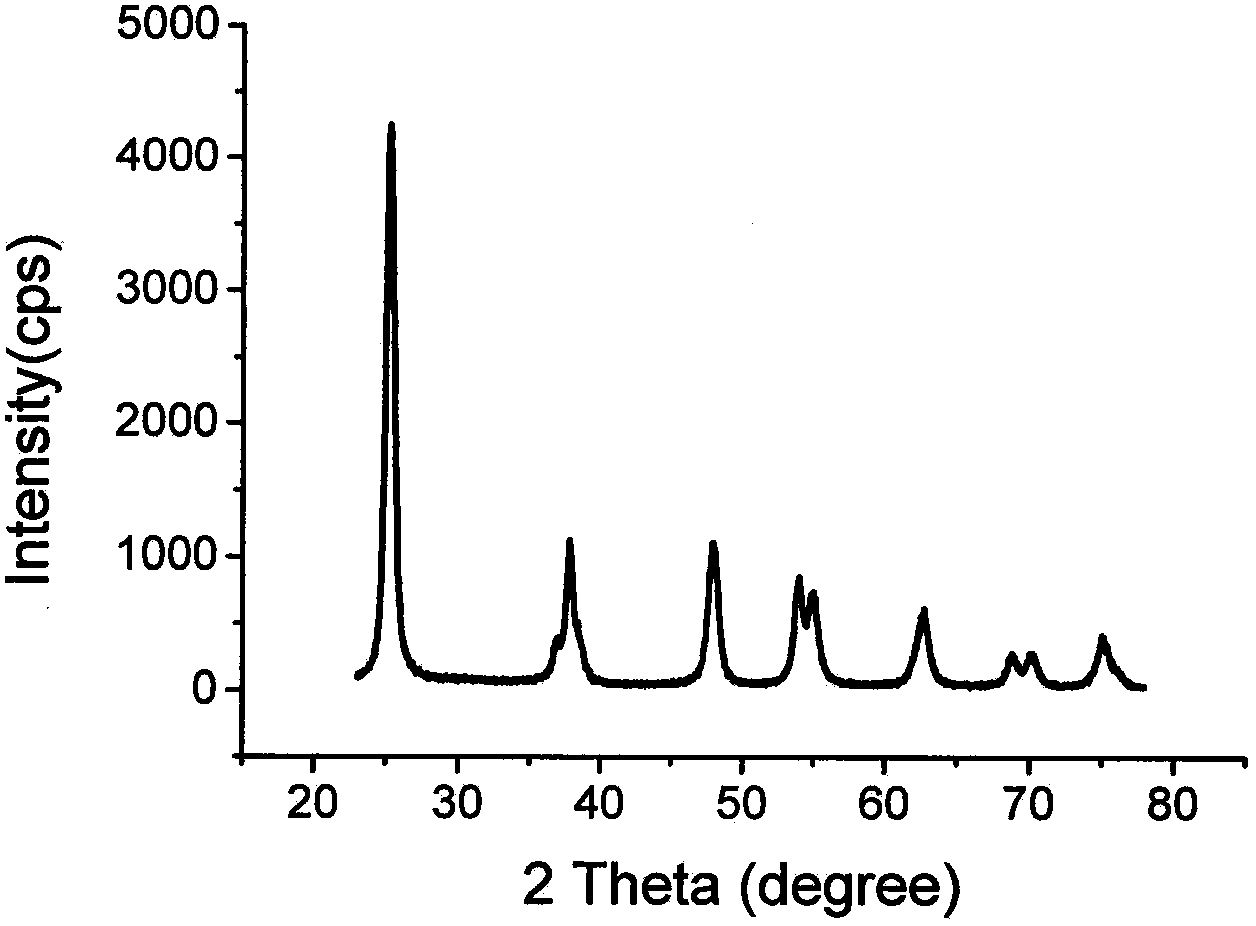

Imprinting-doped mesoporous TiO2 microspheres and preparation method and application thereof

InactiveCN102658210BEfficient and selective photocatalytic degradationDegradation rate increasedWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsAbsorption capacityMicrosphere

Owner:YUNNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com