Composite photocatalysis system, and preparation method and application thereof

A photocatalytic and composite technology, applied in the field of photocatalysis, can solve the problems of green and high-efficiency pollutant degradation system, no formation, long processing time, etc., and achieve the effect of high-efficiency photocatalytic degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

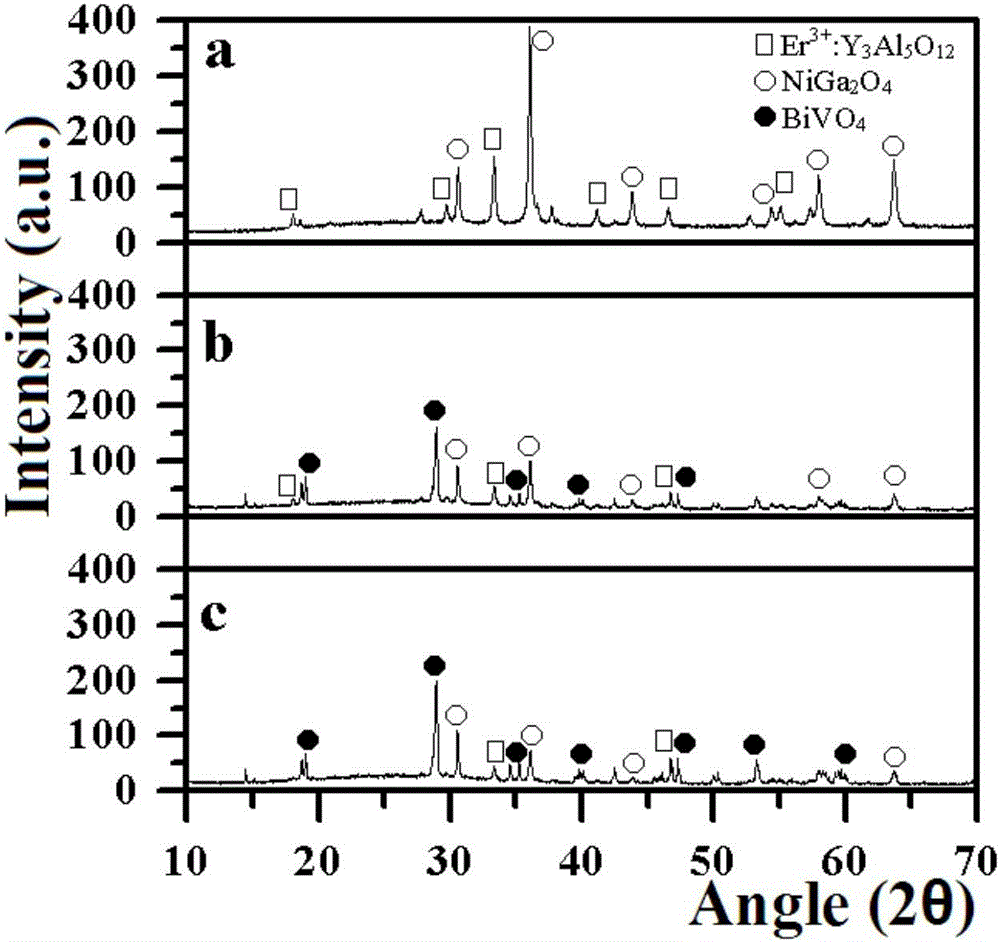

[0021] Example 1 Composite photocatalytic system Er 3+ :Y 3 Al 5 o 12 / (MoS 2 / NiGa 2 o 4 )-(BiVO 4 / PdS)

[0022] The preparation method is as follows:

[0023] 1) Preparation of Er 3+ :Y 3 Al 5 o 12 Nanoparticles: 2.2715 g of Er 2 o 3 and 0.0128g Y 2 o 3 powder, magnetically stirred and heated and kept at 60°C, dissolved in concentrated nitric acid until colorless and transparent, and mixed rare earth oxide solution was obtained. Then 12.6208gAl(NO 3 ) 3 9H 2 O and solid citric acid (the molar ratio of citric acid and rare earth ions is 3:1) were dissolved in double distilled water, and slowly added to the mixed rare earth oxide solution prepared above, and stirred at 50-60 °C until The solution is a viscous foaming gel-like solution. Then place it in an oven at 80° C. for 36 hours to obtain a gel. The obtained gel was first heated to 500 °C and maintained for 50 min in a muffle furnace, and then continued to be heated to 1100 °C for 2.0 h. Finally, the...

Embodiment 2

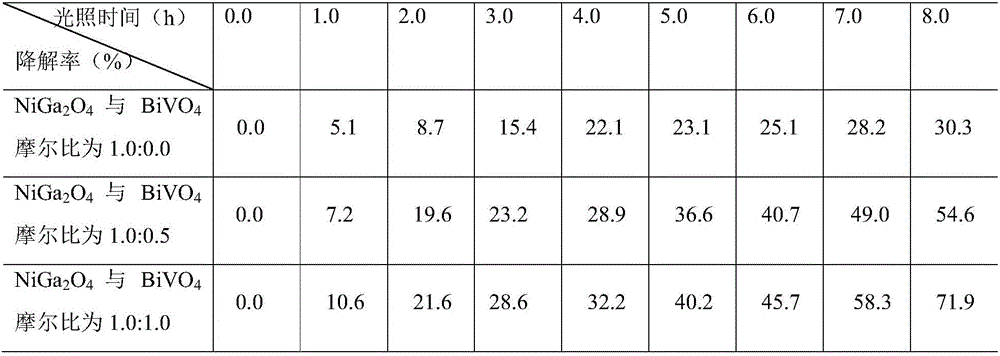

[0031] Example 2 Photocatalytic degradation of dye-orange G by composite photocatalytic system

[0032] Method: Measure 25mL of 10mg / L Orange G solution in a 100mL Erlenmeyer flask, add 25mg of different NiGa prepared in Example 1 2 o 4 and BiVO 4 Composite photocatalytic system with molar ratio Er 3+ :Y 3 Al 5 o 12 / (MoS 2 / NiGa 2 o 4 )-(BiVO 4 / PdS), irradiated under visible light (300W) for 8.0h. Filter and measure its UV spectrum at 200-800nm. The absorbance at 475nm was used to calculate the degradation rate of Orange G, and the results are shown in Table 1.

[0033] Degradation rate (%) = (C 0 –C) / C 0 ×100%

[0034] Among them, C 0 : the concentration of the stock solution; C: the concentration of the sample

[0035] Table 1 Visible light photocatalytic degradation of orange G by different composite photocatalytic systems

[0036]

[0037] As shown in Table 1, with the prolongation of the light time, the degradation rate of orange G by the three catal...

Embodiment 3

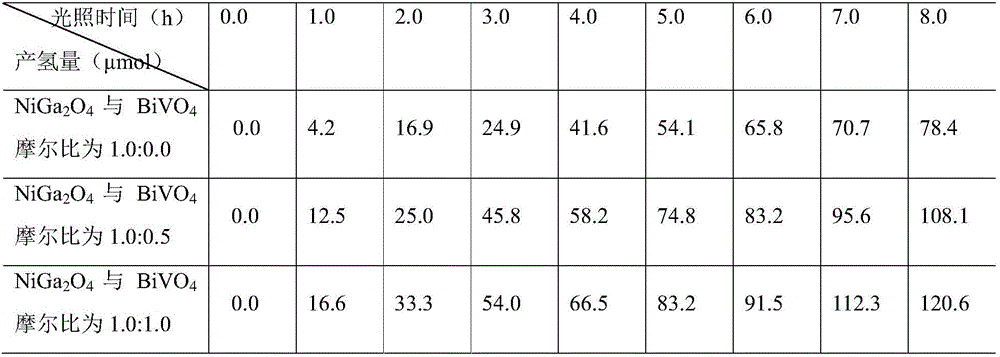

[0038] Example 3 Composite photocatalytic system uses dye-orange G as a sacrificial agent to photocatalyze hydrogen production

[0039] Method: Measure 500mL of 50mg / L orange G solution in the photocatalytic hydrogen production reactor, add 200mg of different NiGa prepared in Example 1 2 o 4 and BiVO 4 Composite photocatalytic system with molar ratio Er 3+ :Y 3 Al 5 o 12 / (MoS 2 / NiGa 2 o 4 )-(BiVO 4 / PdS), irradiated under visible light (300W) for 8.0h. Gas chromatography was used to measure the amount of hydrogen generated during the reaction. The results are shown in Table 2.

[0040] Table 2 Visible light photocatalytic hydrogen production of different composite photocatalytic systems

[0041]

[0042] As shown in Table 2, with the prolongation of the light time, the hydrogen production of the three catalysts and the BiVO 4 The amount of hydrogen in the catalytic system increases, and the hydrogen production also shows an increasing trend. in NiGa 2 o 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com