A kind of multi-level porous nanoporous copper-loaded cuprous oxide nanowire composite material and preparation method thereof

A technology of nanoporous copper and composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

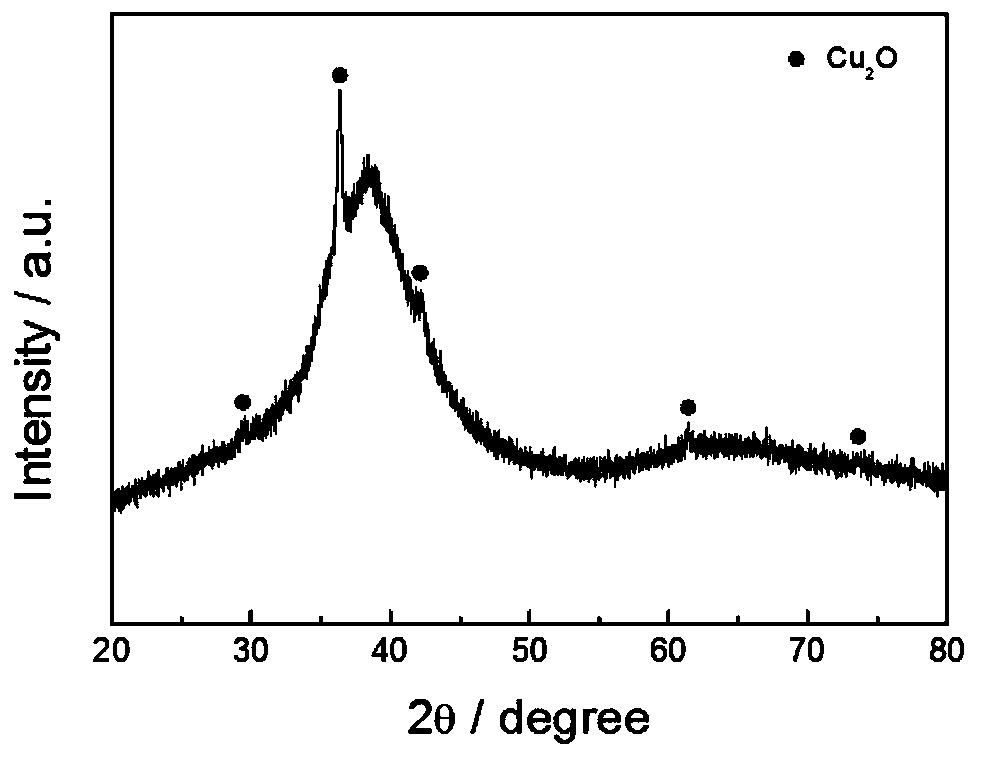

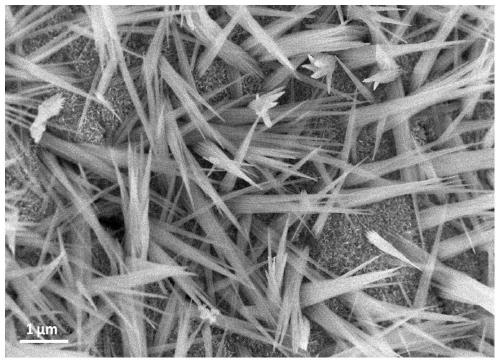

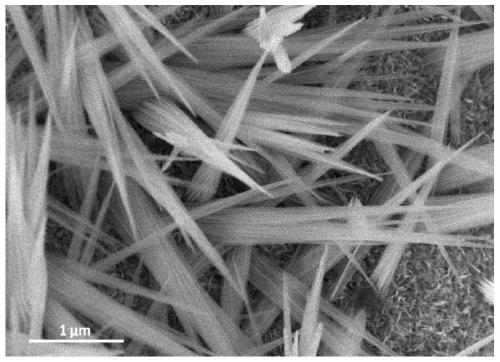

Image

Examples

Embodiment 1

[0035] Select alloy composition Cu 50 Zr 20 Ti 25 Al 5, according to the atomic percentages of each element in the target alloy: Cu is 50at.%, Zr is 20at.%, Ti is 25at.%, Al is 5at.%, and the high-purity copper sheet (7.525g ), zirconium grain (4.321g), titanium grain (2.835g) and aluminum sheet (0.32g) obtain master alloy raw material 15g; Master alloy raw material is placed in vacuum arc melting furnace (put into 99.9wt% pure titanium before smelting granules as oxygen-scavenging material), and repeated melting 4 times under the protection of high-purity argon (to ensure the uniformity of the alloy), each time about 40s. Cool down to room temperature with the furnace to get Cu 50 Zr 20 Ti 25 Al 5 alloy ingot.

[0036] Take 3-4g of the polished and cleaned alloy ingot and place it in a quartz test tube, put the quartz test tube into the induction coil of the vacuum belt throwing machine and fix it in the induction coil, carry out induction melting under the protection...

Embodiment 2

[0043] Select alloy composition Cu 50 Zr 20 Ti 25 Al 5 , according to the atomic percentages of each element in the target alloy: Cu is 50at.%, Zr is 20at.%, Ti is 25at.%, Al is 5at.%, and the high-purity copper sheet (7.525g ), zirconium grain (4.321g), titanium grain (2.835g) and aluminum sheet (0.32g) obtain master alloy raw material 15g; Master alloy raw material is placed in vacuum arc melting furnace (put into 99.9wt% pure titanium before smelting granules as oxygen-scavenging material), and repeated melting 4 times under the protection of high-purity argon (to ensure the uniformity of the alloy), each time about 40s. Cool down to room temperature with the furnace to get Cu 50 Zr 20 Ti 25 Al 5 alloy ingot.

[0044] Take 3-4g of the polished and cleaned alloy ingot and place it in a quartz test tube, put the quartz test tube into the induction coil of the vacuum belt throwing machine and fix it in the induction coil, carry out induction melting under the protectio...

Embodiment 3

[0051] Select alloy composition Cu 50 Zr 20 Ti 25 Al 5 , according to the atomic percentages of each element in the target alloy: Cu is 50at.%, Zr is 20at.%, Ti is 25at.%, Al is 5at.%, and the high-purity copper sheet (7.525g ), zirconium grain (4.321g), titanium grain (2.835g) and aluminum sheet (0.32g) obtain master alloy raw material 15g; Master alloy raw material is placed in vacuum arc melting furnace (put into 99.9wt% pure titanium before smelting granules as oxygen-scavenging material), and repeated melting 4 times under the protection of high-purity argon (to ensure the uniformity of the alloy), each time about 40s. Cool down to room temperature with the furnace to get Cu 50 Zr 20 Ti 25 Al 5 alloy ingot.

[0052] Take 3-4g of the polished and cleaned alloy ingot and place it in a quartz test tube, put the quartz test tube into the induction coil of the vacuum belt throwing machine and fix it in the induction coil, carry out induction melting under the protectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com