Patents

Literature

331 results about "Copper nanowires" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallic nanowire-graphene bridge structural composite material and preparation method thereof

InactiveCN104934108AImprove technical performance indicatorsMeet industrial application requirementsMaterial nanotechnologyConductive layers on insulating-supportsElectronMultiple layer

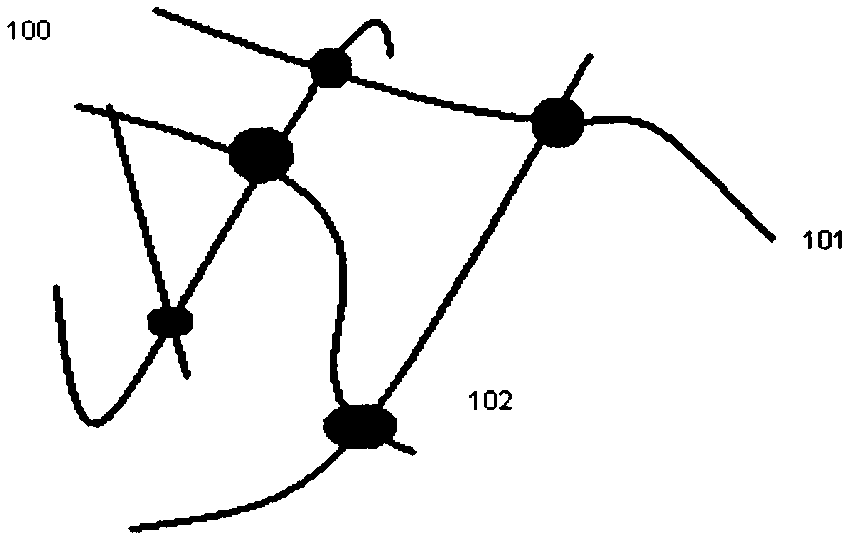

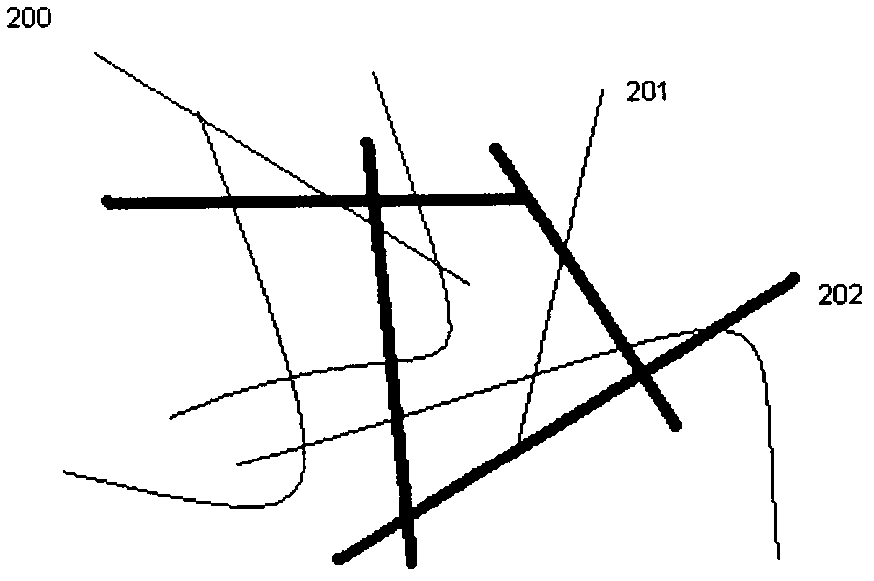

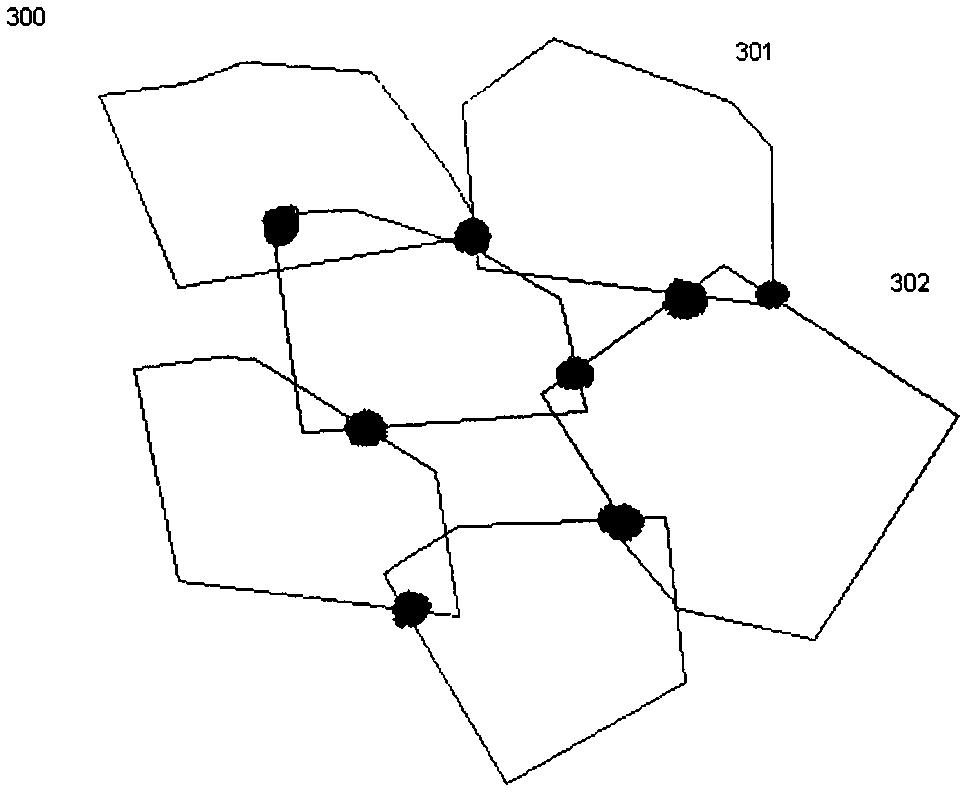

The present invention discloses a metallic nanowire-graphene bridge structural composite material which comprises multiple layers of grapheme and metallic nanowires and is characterized in that the metallic nanowires are arranged at one side or two sides of the surface of a grapheme sheet layer, the metallic nanowires are welded to the metallic nanoparticles at the surface of the grapheme, and a metallic nanowire-graphene bridge structural composite material is formed. According to the composite material, the transmittance is larger than 85% to 92%, the surface resistance is smaller than 1 Omega at the same time, in an optimal embodiment, a transparent conductive film with the transmittance larger than 90% and the surface resistance smaller than 1 Omega is realized, and the current and future industrial application requirements are fully satisfied. Through growing the metallic nanoparticles with proper density at the surface of the single-layer or few-layer grapheme and assembling and welding the metallic nanowires (such as silver nanowires and copper nanowires) on the metallic nanoparticles, grapheme-metallic nanowires are formed and are assembled and processed to form a grapheme-metallic nanowires bridge structure, a transport path is provided for electrons, and thus the surface resistance of a grapheme assembly film is greatly reduced.

Owner:CHONGQING YUANSHI GRAPHENE TECH DEVCO LTD

Carbon nano material/metal nano material composite nano ink

InactiveCN102993820AReduce manufacturing costLow costConductive layers on insulating-supportsInksCyclohexanoneKetone

The invention provides a carbon nano material / metal nano material composite nano ink which comprises solvent, an additive, a carbon nano material and a metal nano material. The carbon nano material / metal nano material composite nano ink is characterized in that the solvent can comprise water, alcohol organic solvent (ethanol(alcohol), isopropanol, n-butanol and the like), ester organic solvent (ethyl acetate, butyl acetate, ethylene-propylene acetate and the like), benzene organic solvent (methylbenzene, dimethylbenzene and the like) and ketone organic solvent (cyclohexanone, acetone, methylethylketone, butanone and the like); the additive comprises surfactant, pH value stabilizer, defoaming agent, diluter, reinforcer and the like; the carbon nano material comprises a single-layer carbon nanotube, a double-layer carbon nanotube, a multi-layer carbon nanotube and graphene; the metal (copper, silver, gold, platinum, nickel and the like, also including an alloy nano material, an ITO metal composite nano material and the like) nano material further comprises a metal nanoparticle, a metal nanowire or a metal nanotube; the components of the nano ink must include one carbon nano component and one metal nano component, such as a single-layer carbon nanotube and copper nanowire composite ink, a double-layer carbon nanotube and silver nanowire composite ink, a single-layer carbon nanotube and silver nanoparticle composite ink or any other possible combination; the components can be regulated according to specific applications; and a composite nano conductive film can be formed on different bases through different electronic printing processes. The ink can be used in the printing of a flexible base material and can be conveniently prepared into a flexible conductive film.

Owner:杨阳

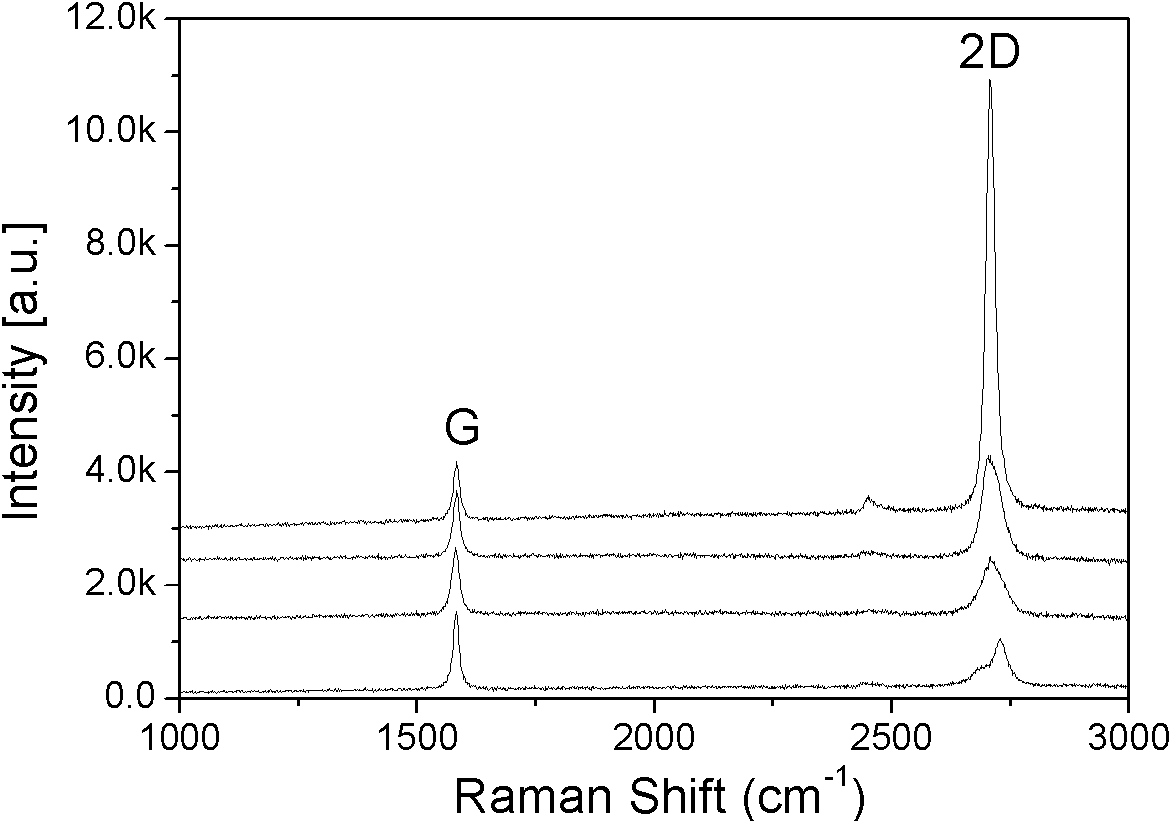

Graphene/copper nanowire composite electric-conducting material and preparation method thereof

ActiveCN102176338AImprove fill factorSimple processMetal/alloy conductorsCarbon-silicon compound conductorsDiameter ratioConductive materials

The invention provides a composite electric-conducting material, in particular a graphene / copper nanowire composite electric-conducting material which comprises graphene, copper nanowires and a bonding agent, wherein the weight of the copper nanowires accounts for 1-99% of the weight of the graphene, and the weight of the bonding agent accounts for 1-50% of the total weight of the graphene / copper nanowires; the graphene is divided into 1-20 layers and has the area of 1-2500 mum<2>; and the length / diameter ratio of the copper nanowires is 10-10000. The invention further provides a preparation method of the composite electric-conducting material and a back electrode containing the composite electric-conducting material. The composite electric-conducting material provided by the invention has the advantages of low cost and excellent electric performance and can be produced in a large scale.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

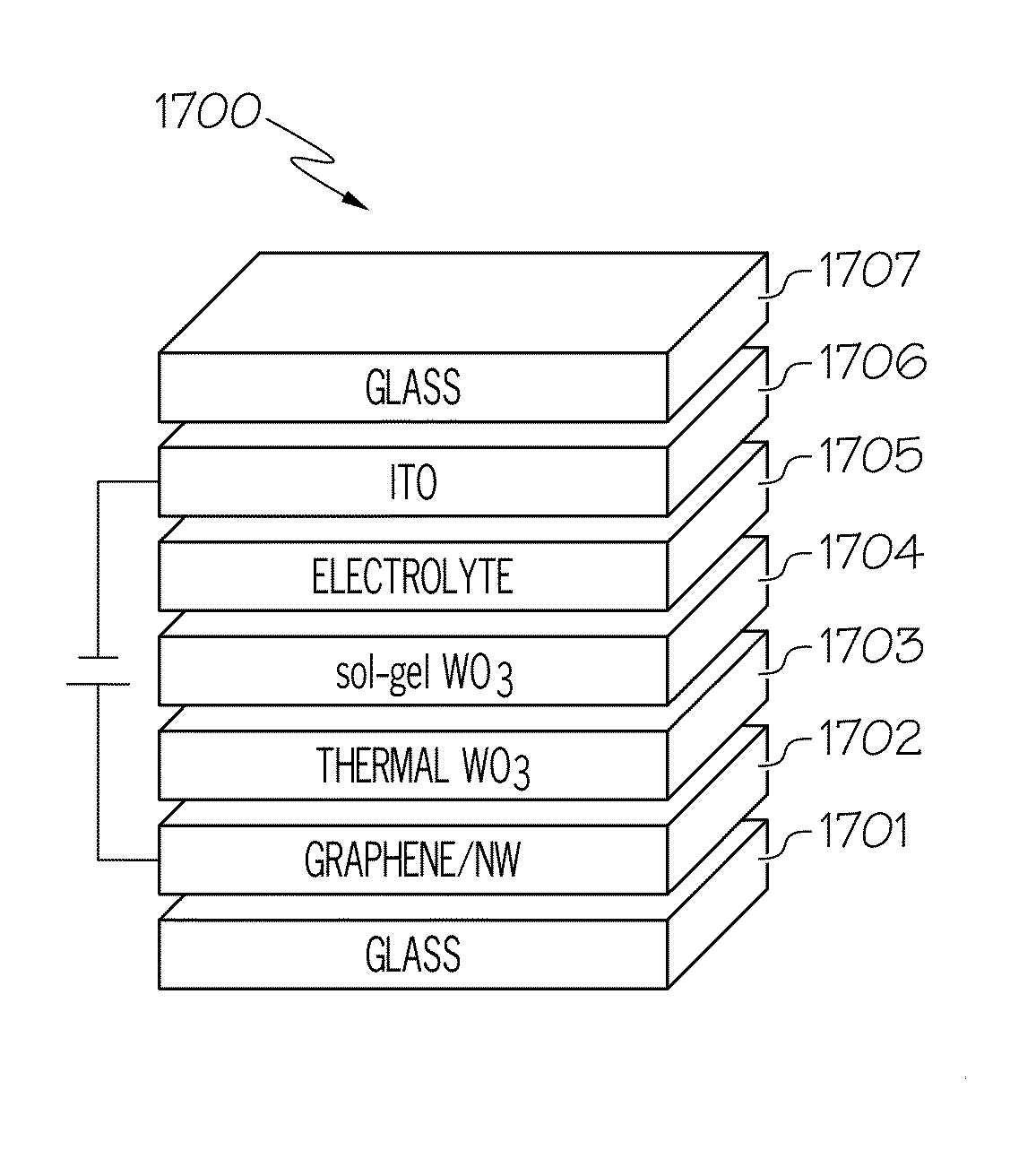

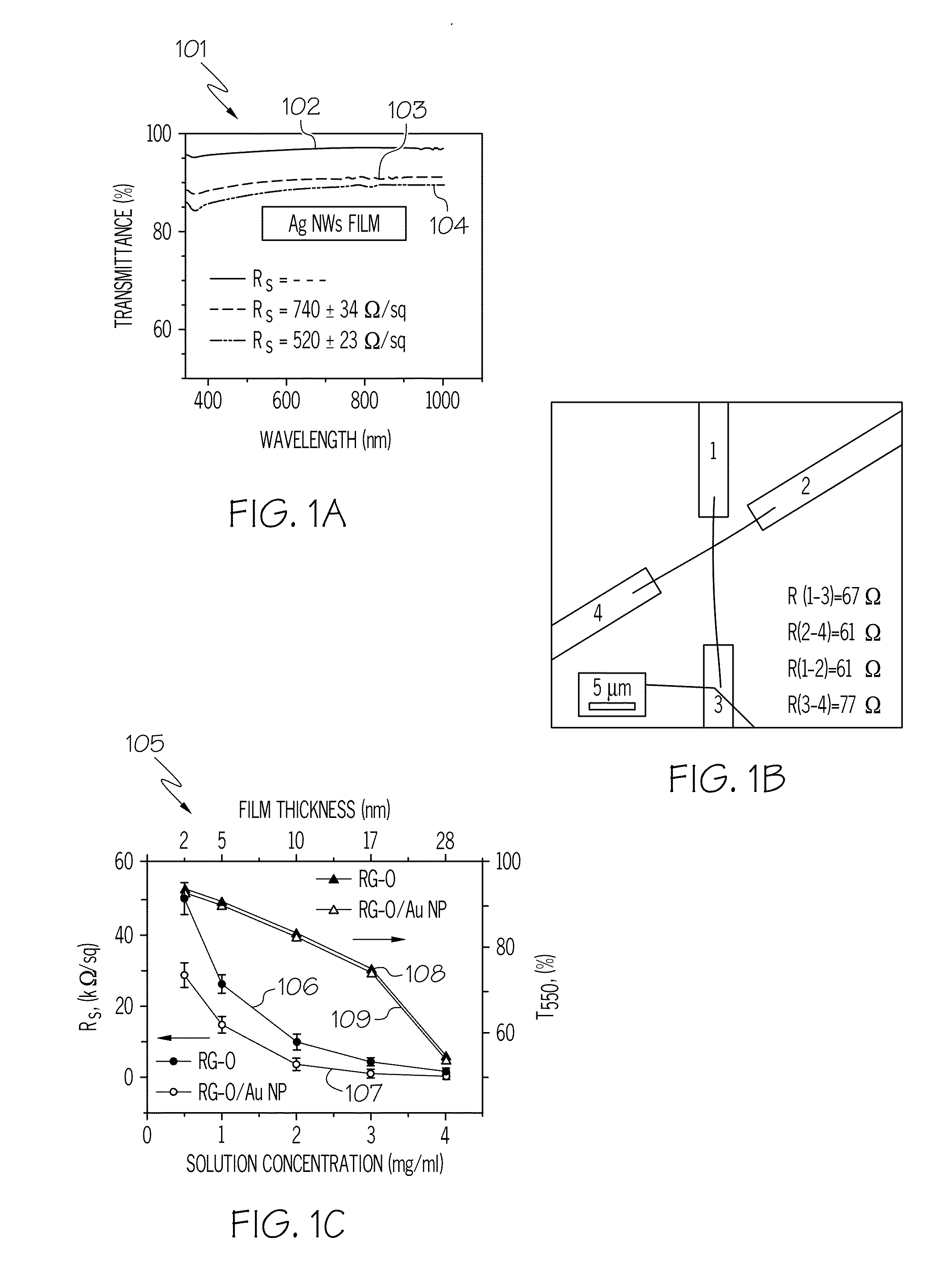

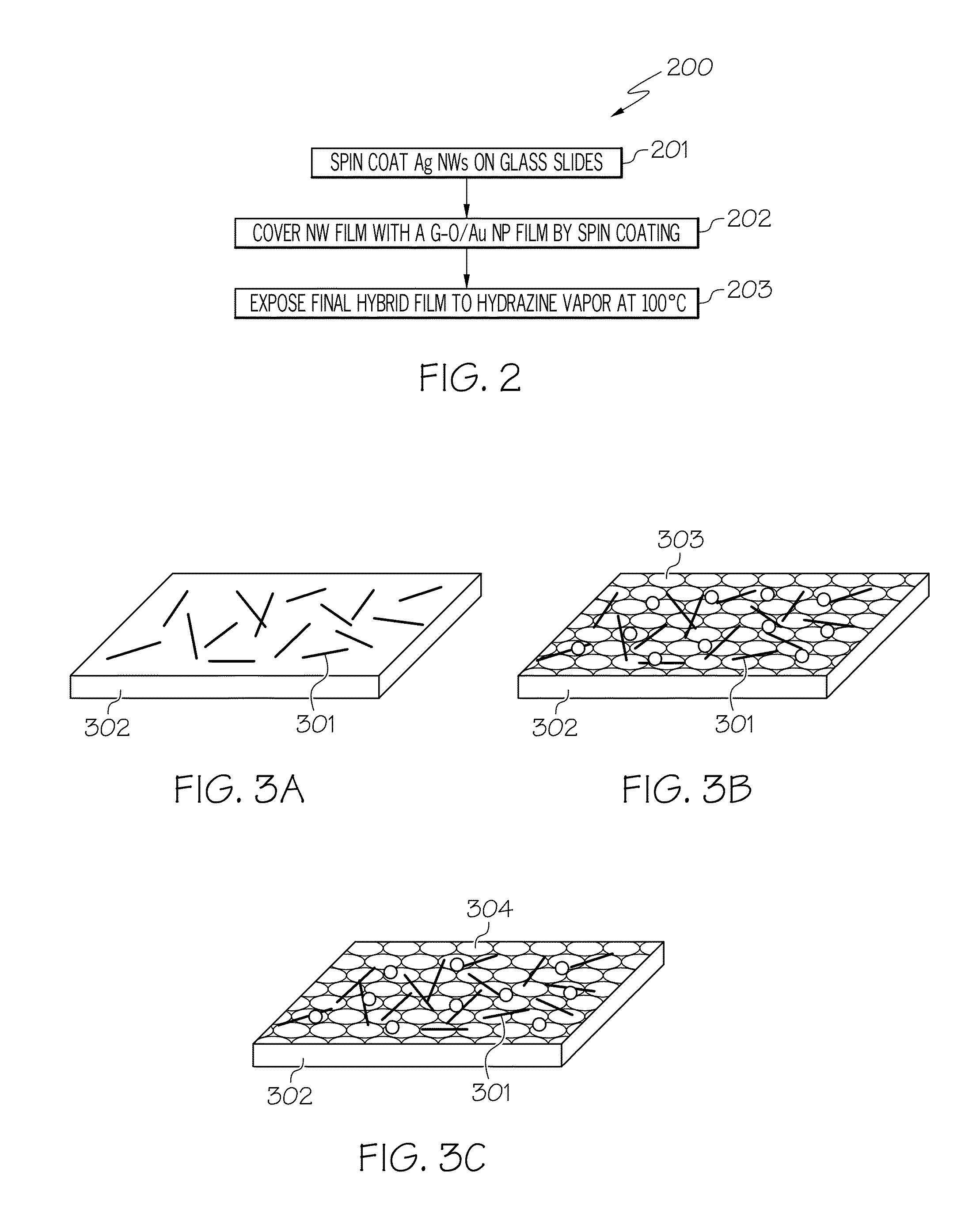

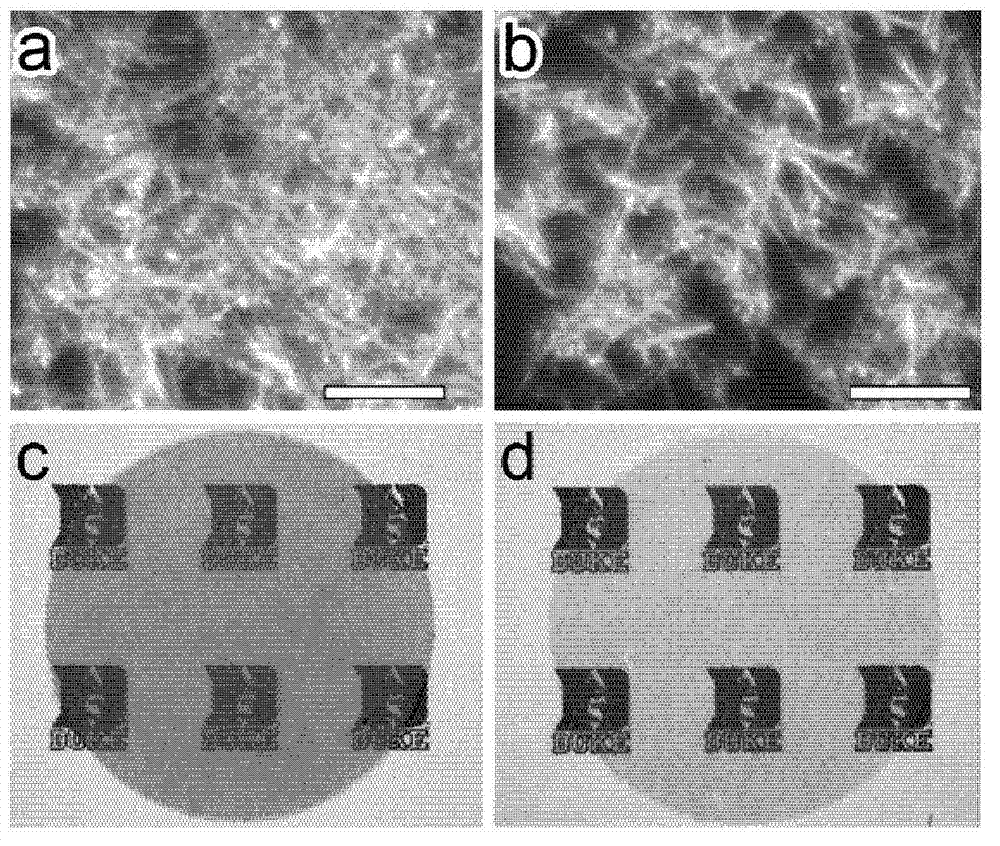

Graphene/metal nanowire hybrid transparent conductive films

A hybrid transparent conductive film, and methods for fabricating such hybrid transparent conductive films, involving the assembly of two-dimensional graphene-based materials with one-dimensional silver and / or copper nanowires with high optical transmittance and good electrical conductivity. The hybrid films are characterized by a good degree of control of the architecture at the nanoscale level, where the weakness(es) of each component are offset by the strengths of the other components. By rational design of the structure and using simple and locate-cost fabrication methods, hybrid films with sheet resistance of 26 ohm / sq and optical transmittance (at λ=550 nm) of 83% for reduced graphene oxide / silver nanowire films, and 64 ohm / sq and optical transmittance of 93.6% for monolayer graphene / silver nanowire films have been fabricated. These values are comparable to transparent conductive films based on indium tin oxide but are now able to be used in flexible electronics due to their good mechanical properties.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

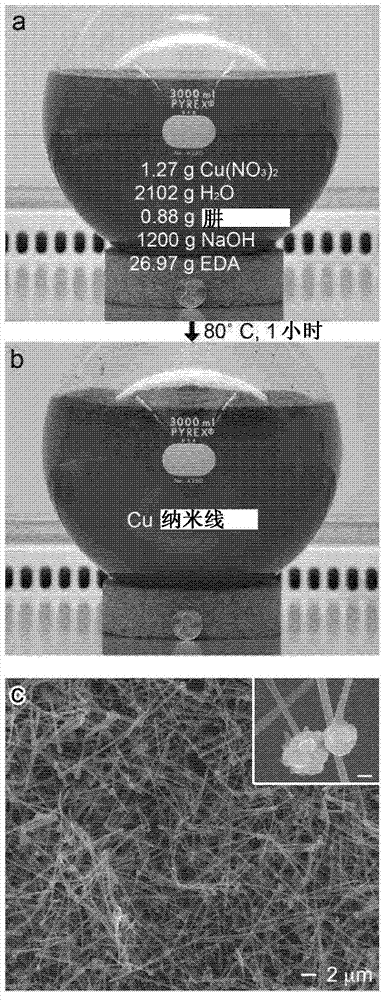

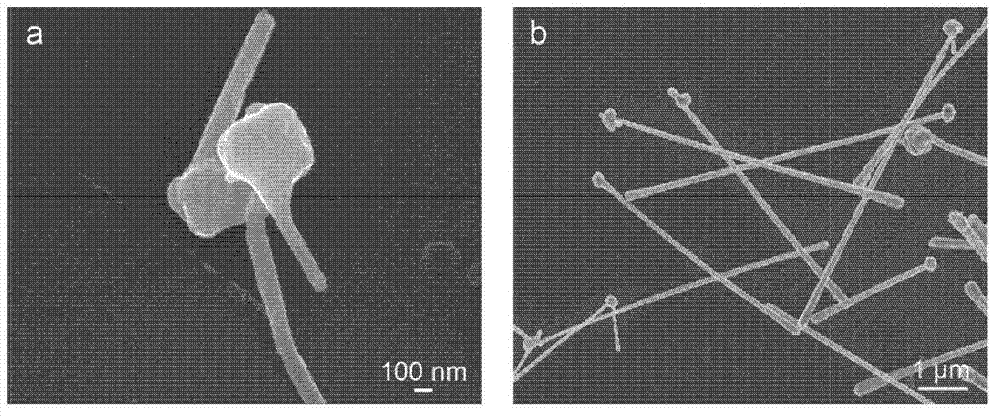

Compositions and methods for growing copper nanowires

InactiveCN102792385AMaterial nanotechnologyConductive layers on insulating-supportsGramCopper nanowires

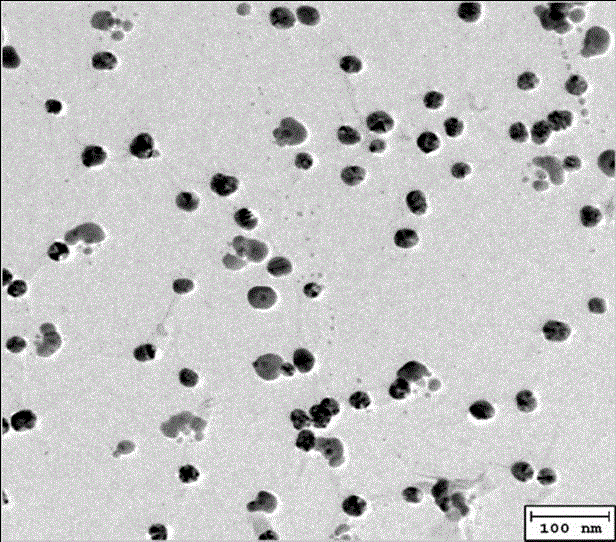

A method of synthesis to produce gram-scale quantities of copper nanowires in an aqueous solution, wherein the copper nanowires are dispersed in said solution. Copper nanowires grow from spherical copper nanoparticles within the first 5 minutes of the reaction. Copper nanowires can be collected from solution and printed to make conductive films (preferably <10,000 [omega] / sq) that preferably transmit greater than 60% of visible light.

Owner:DUKE UNIV

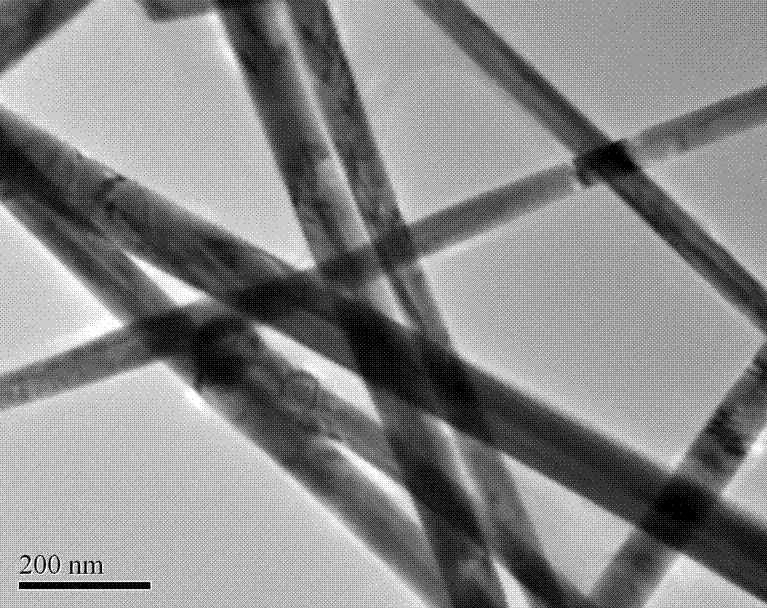

Liquid phase method for synthesizing one-dimensional super long Nano line of metal copper

ActiveCN1727523AImprove conductivityImprove thermal conductivityPolycrystalline material growthFrom normal temperature solutionsCopper saltMaterials science

A process for liquid-phase synthesis of ultra-long one-dimension copper nanowire includes such steps as proportionally mixing 2-valence copper salt, purified water and aliphatic alkylamine, stirring to become emulsion, filling it in pressure container, hydrothermal reaction at 100-200 deg.C for 4-72 hr, washing multiple times and filtering. The resultant copper nanowire has 10-500 nm in diameter and 10 to the power 6 in its length / diameter ratio.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

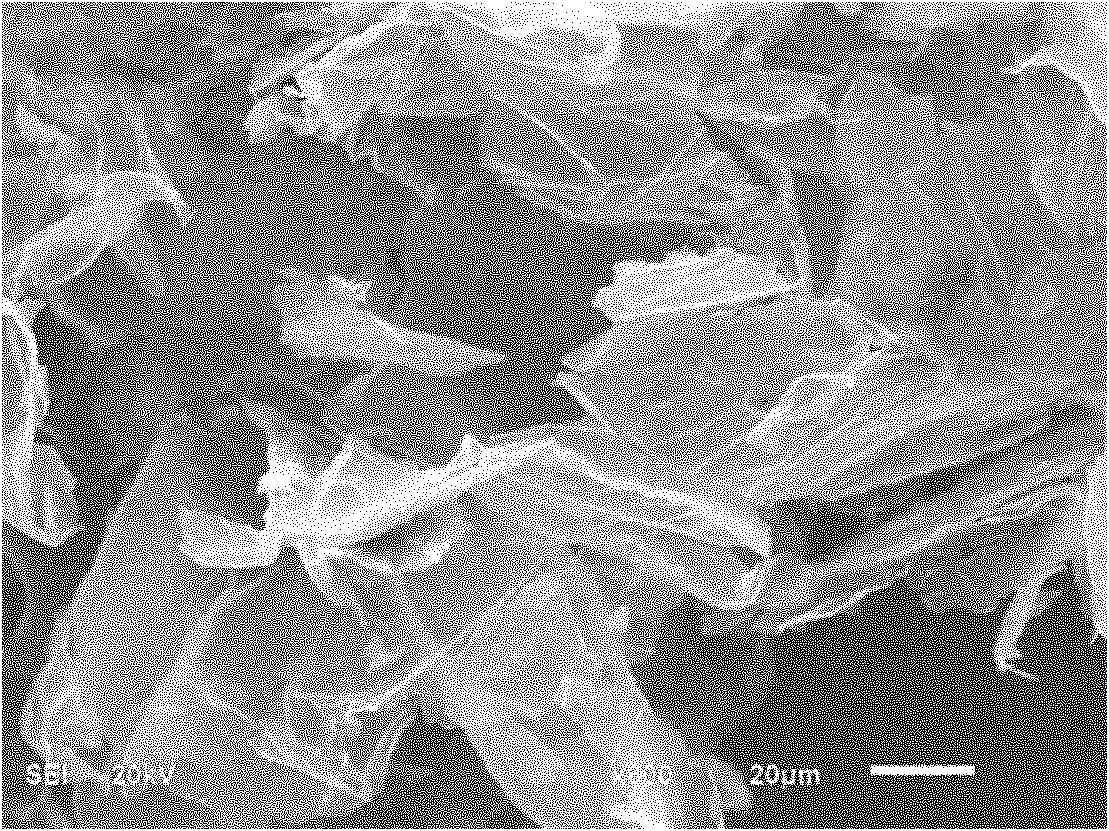

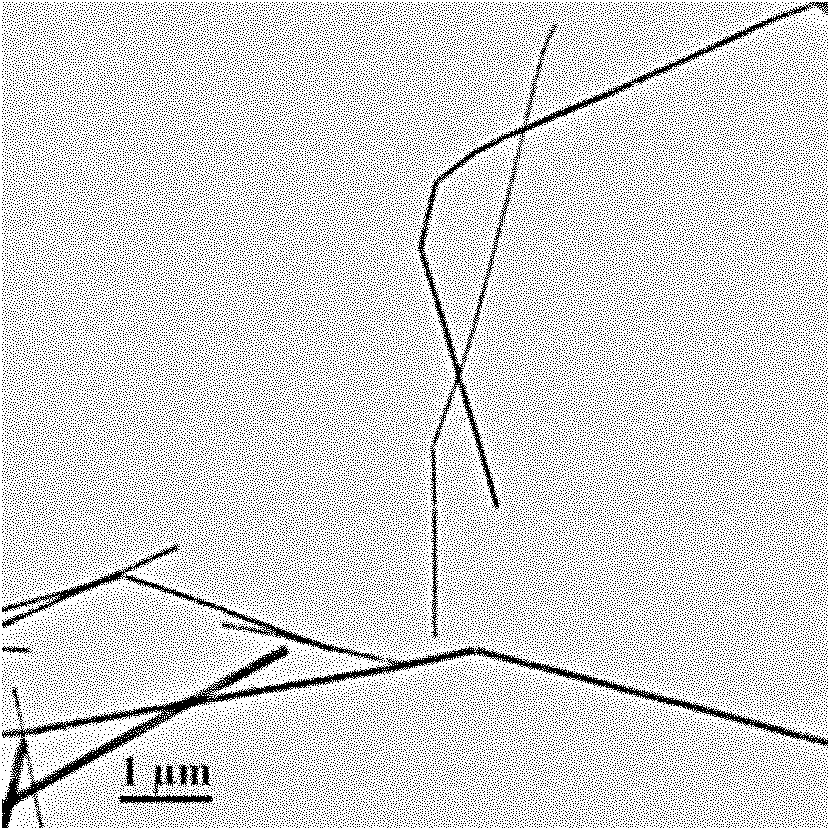

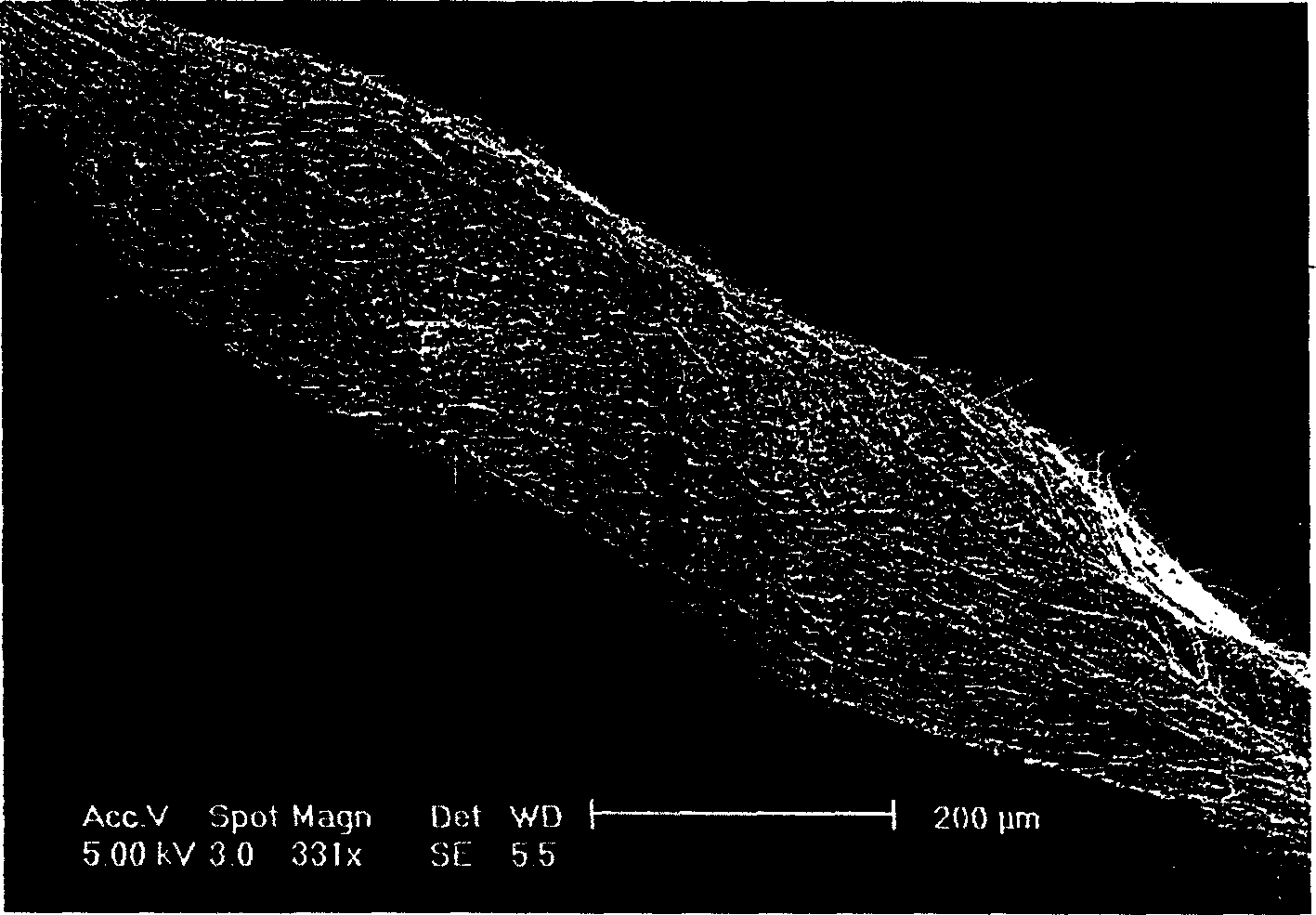

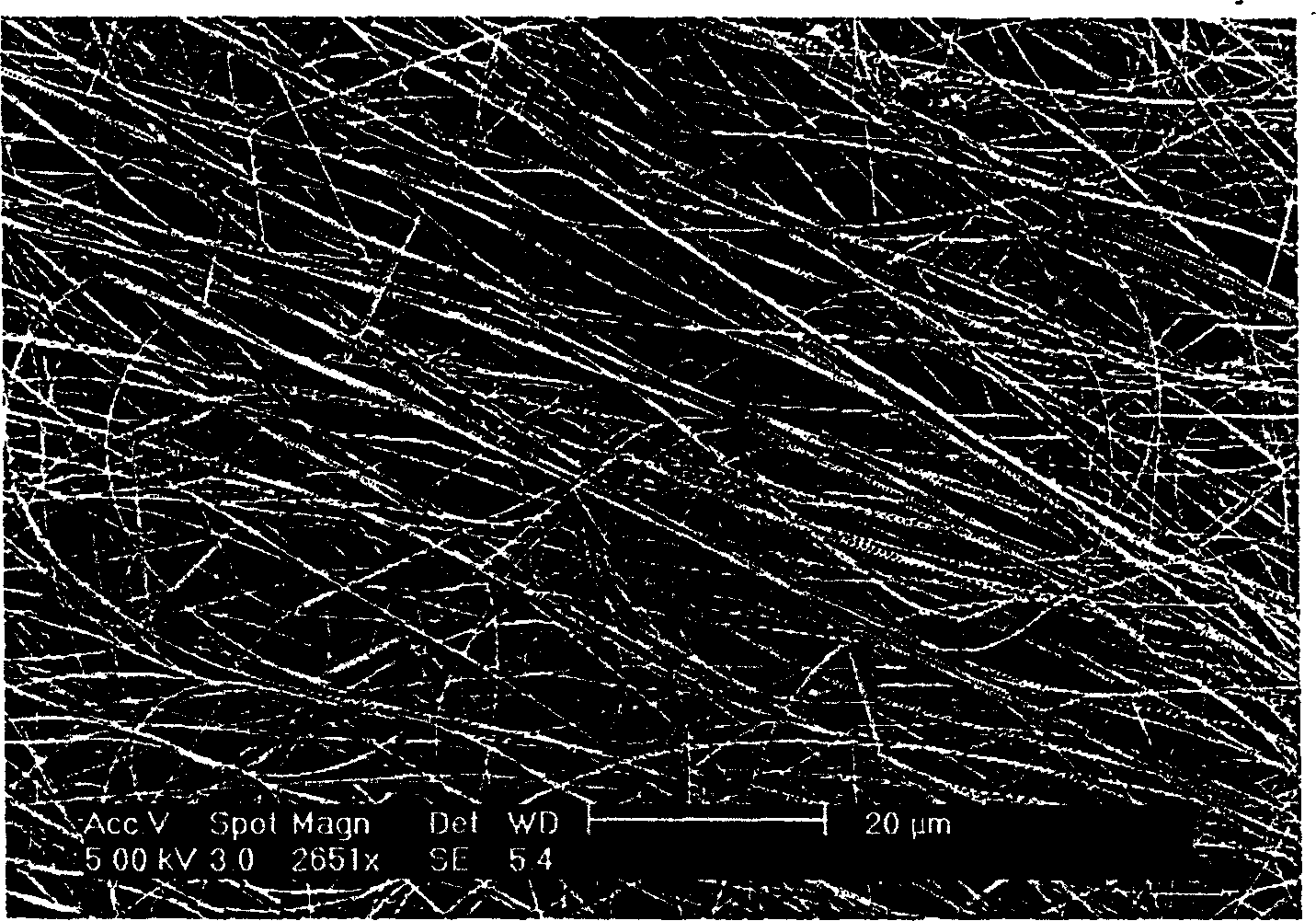

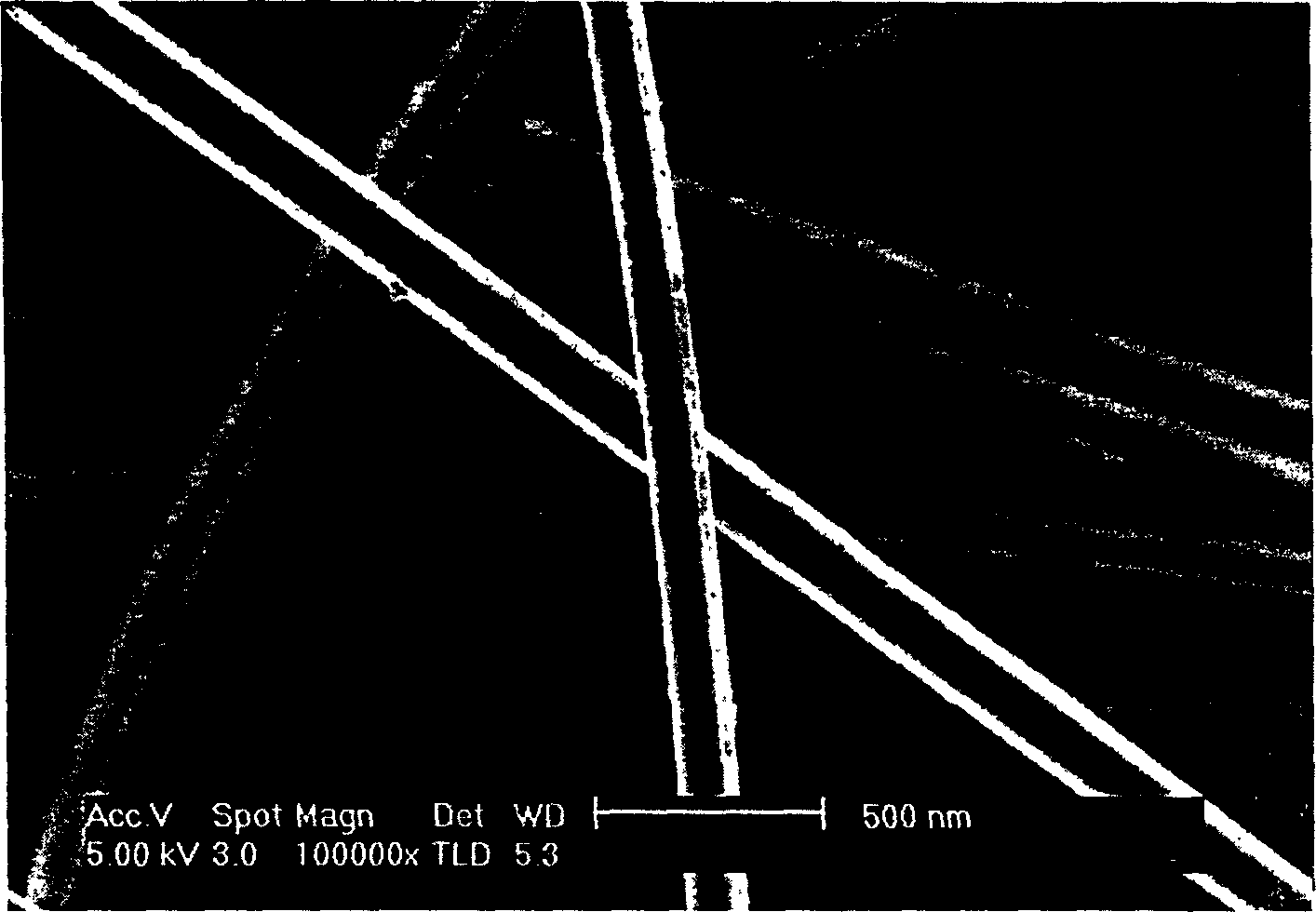

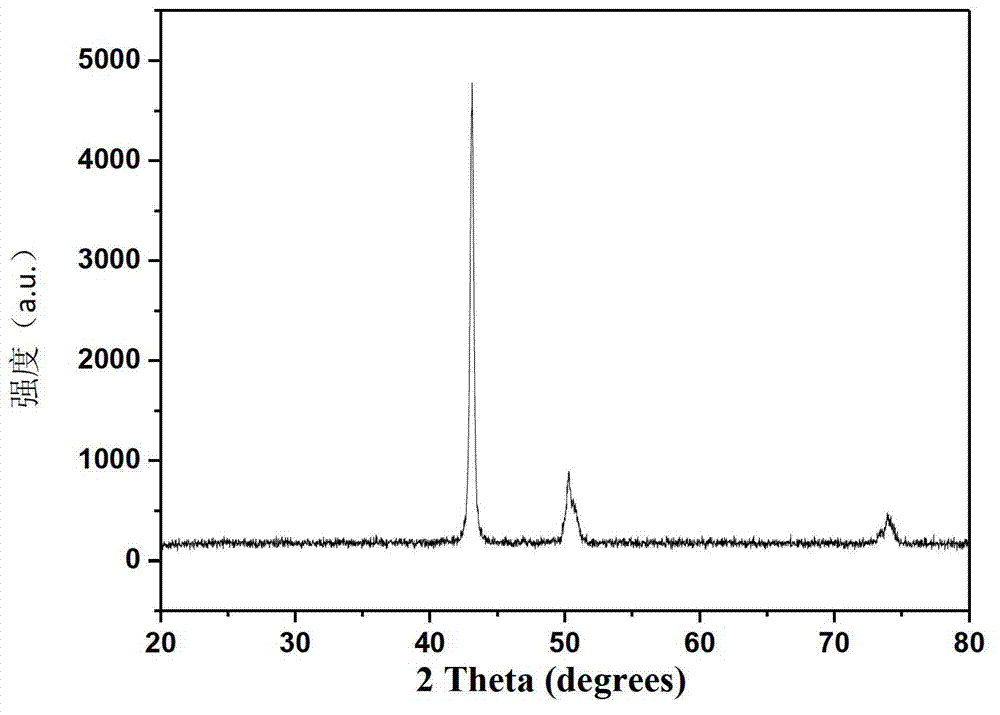

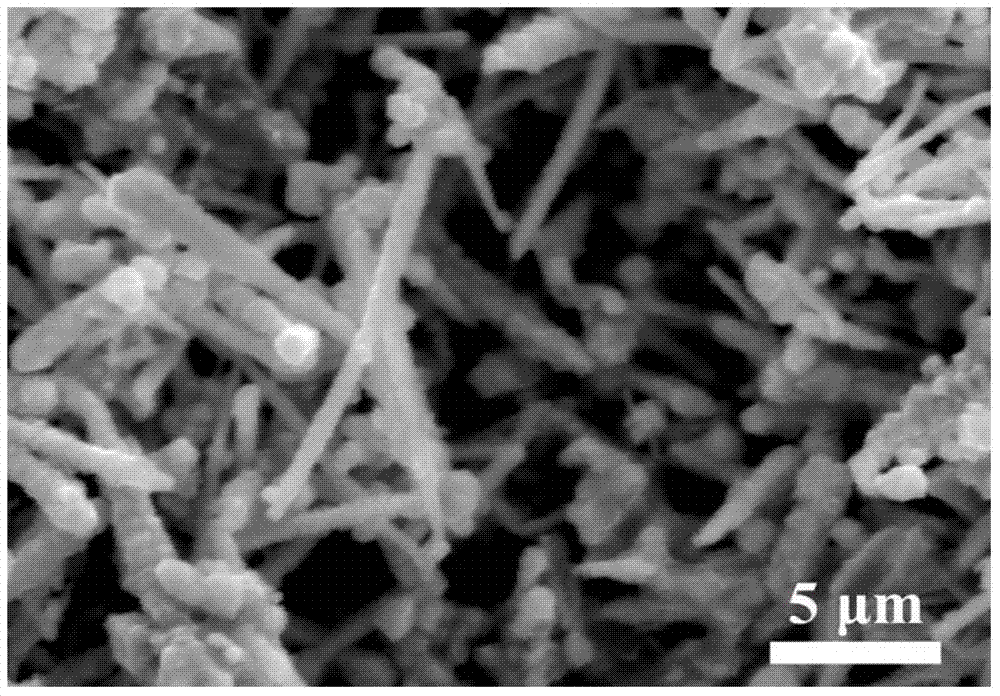

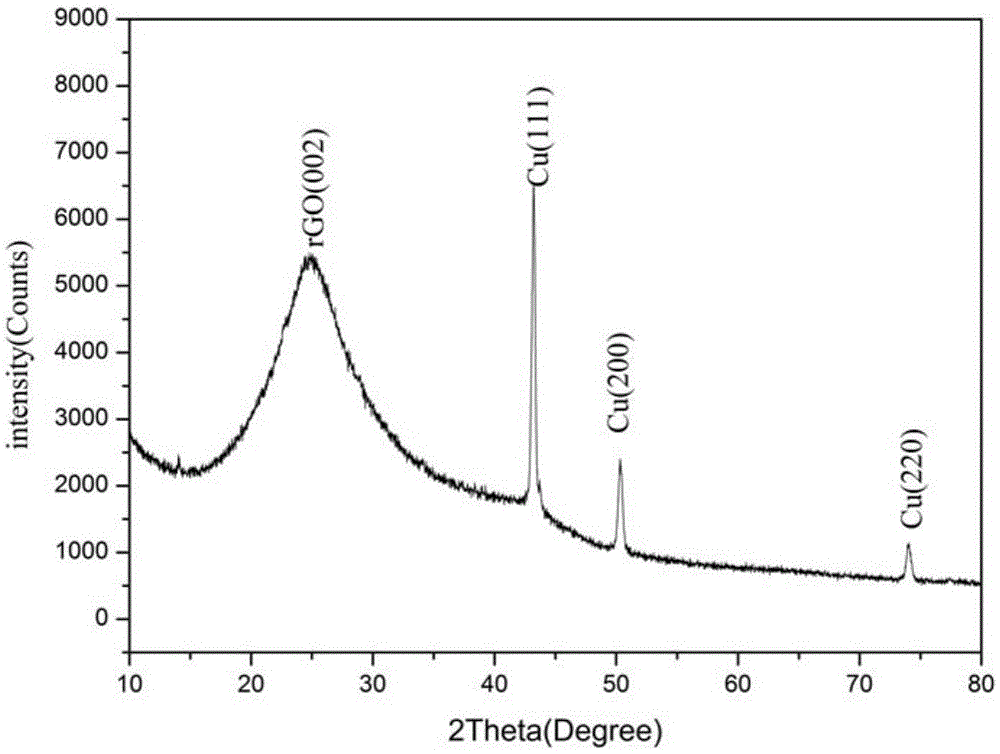

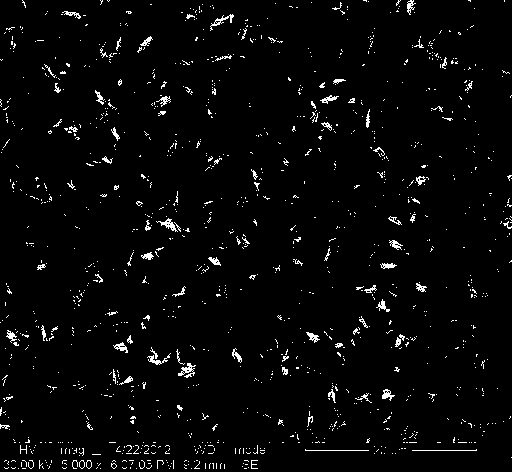

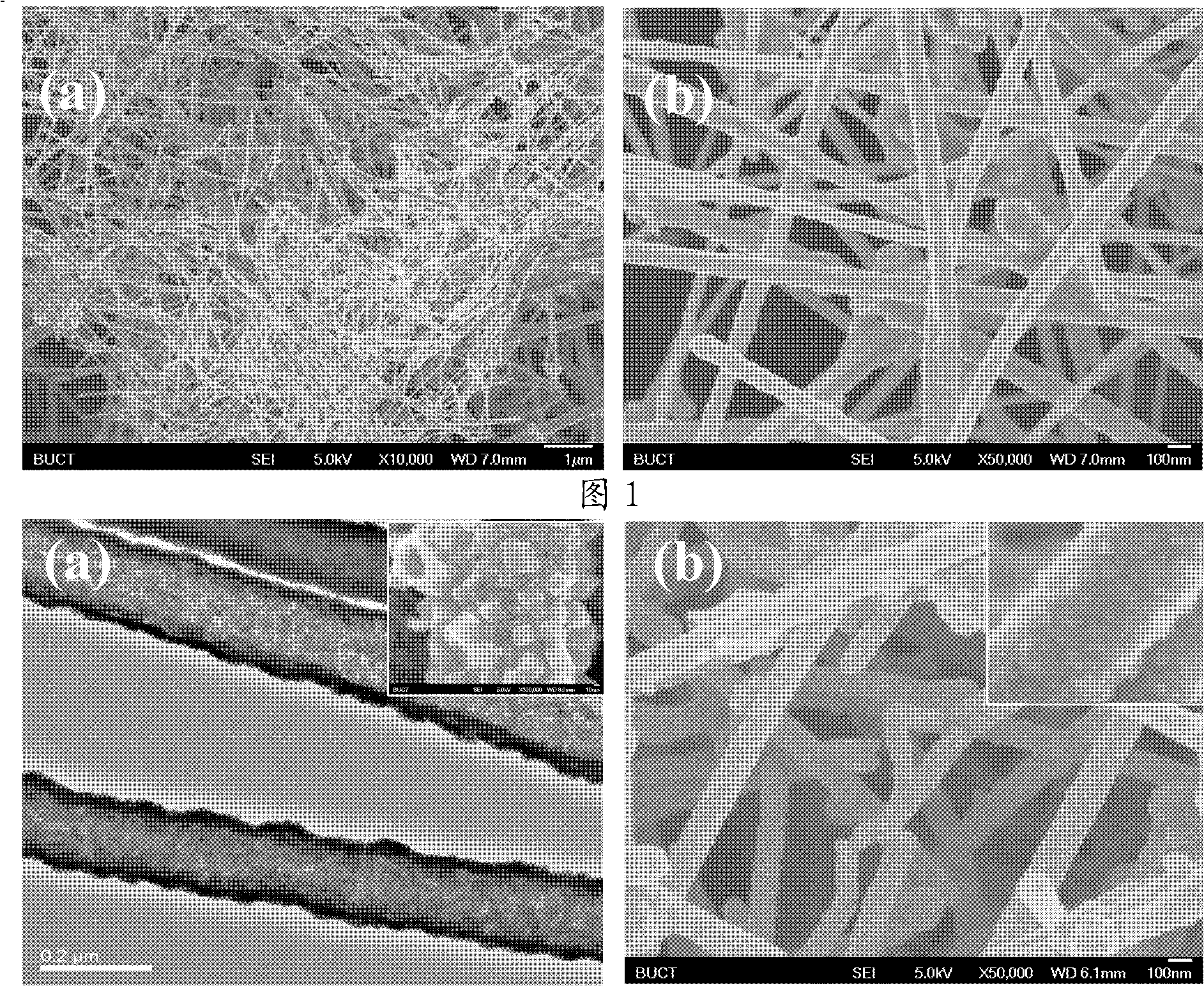

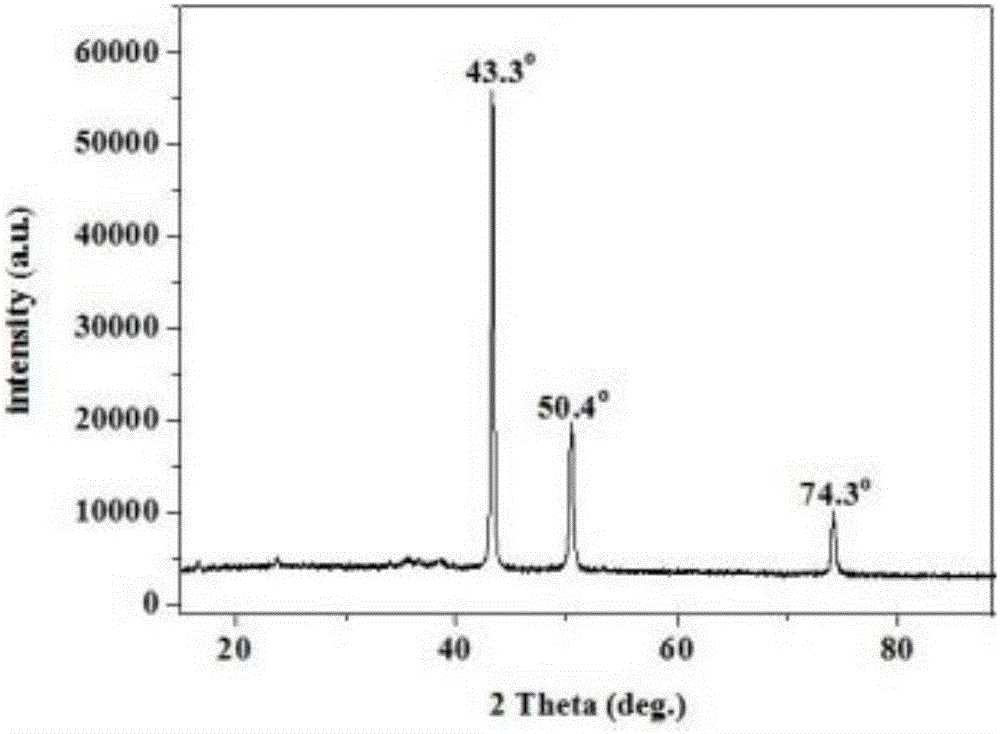

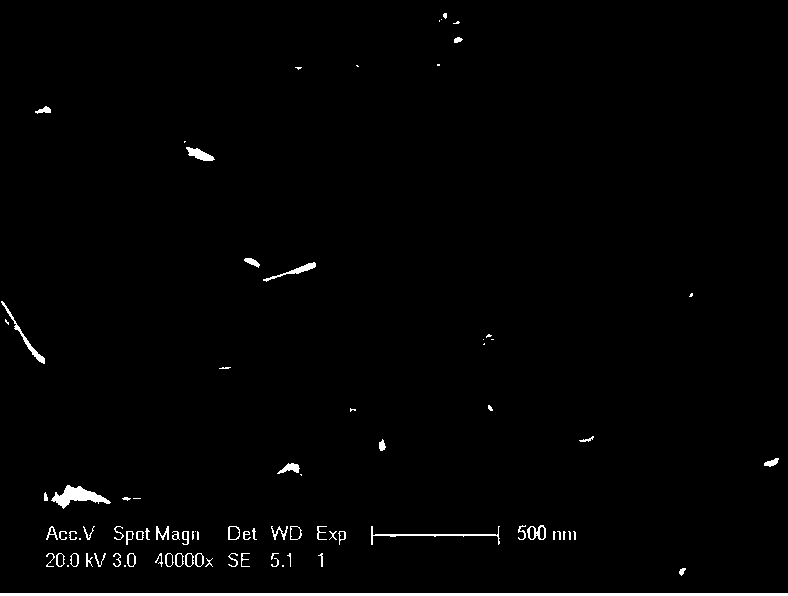

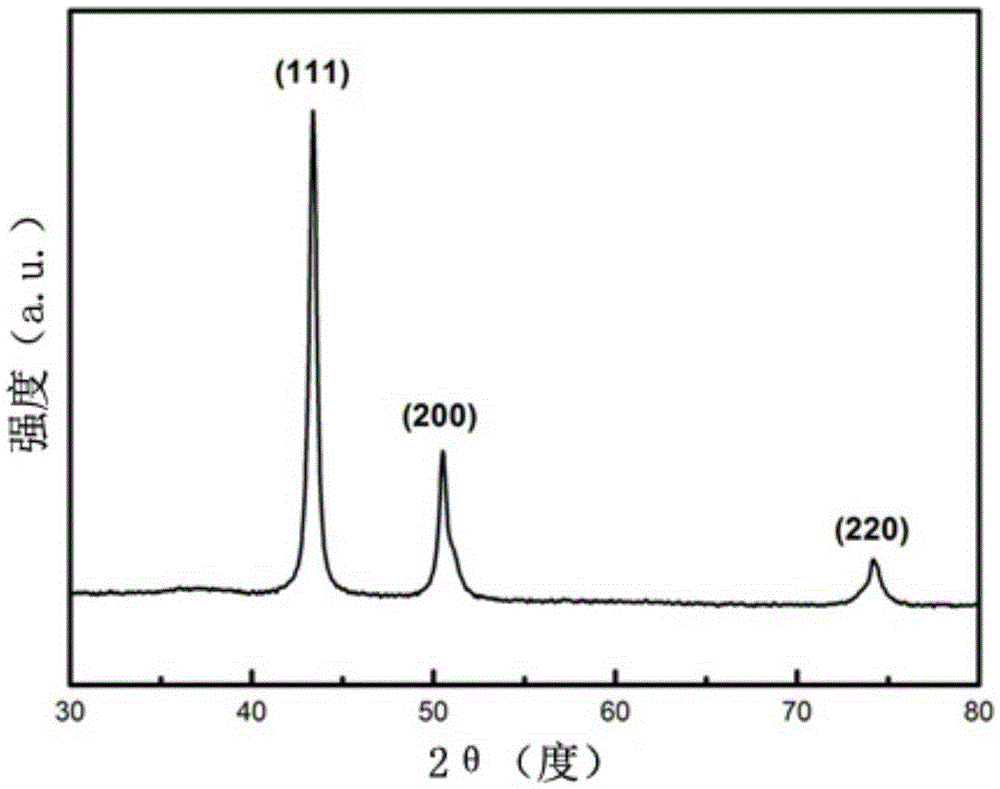

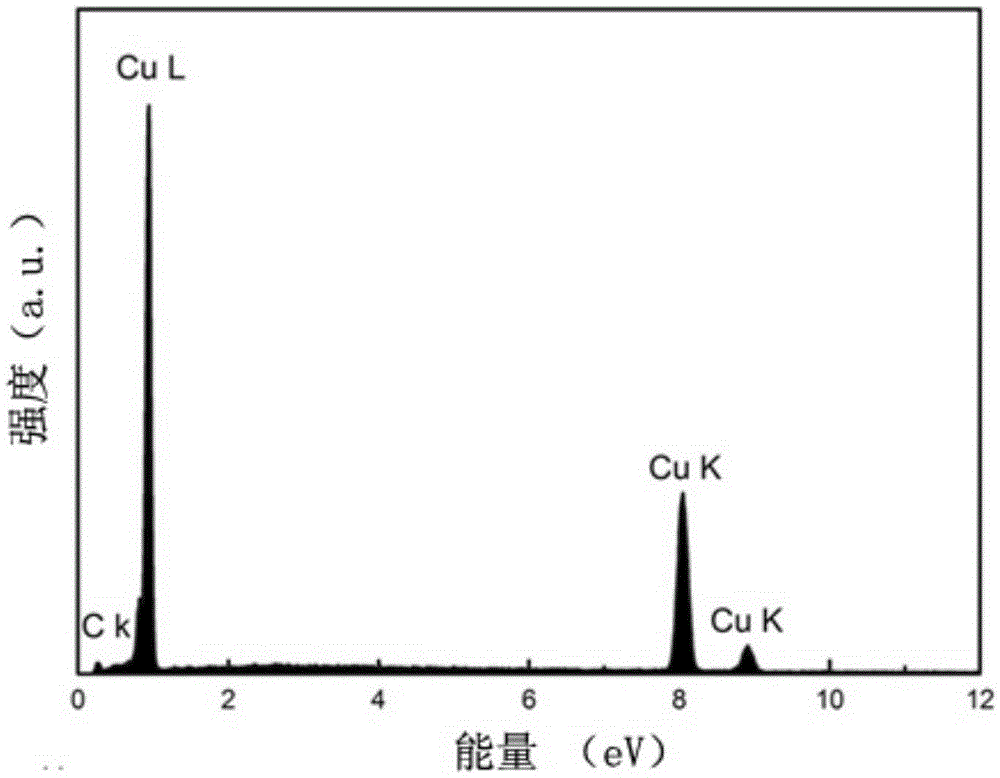

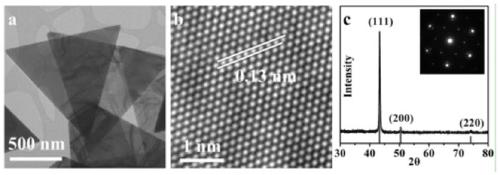

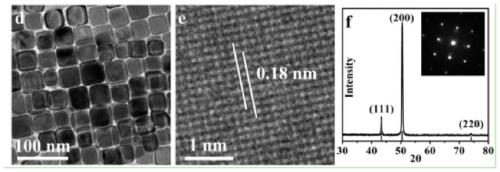

Preparation method of overlong copper nanowire and conductive copper nanowire film

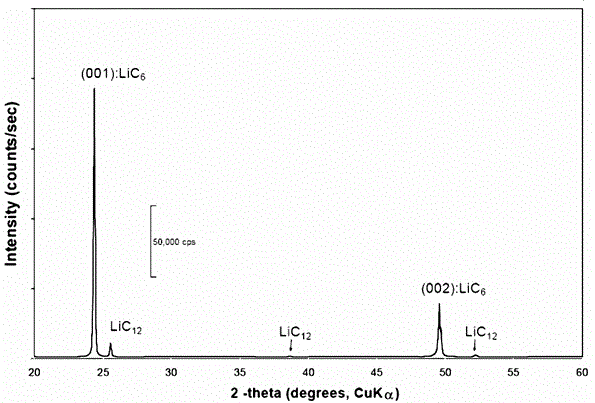

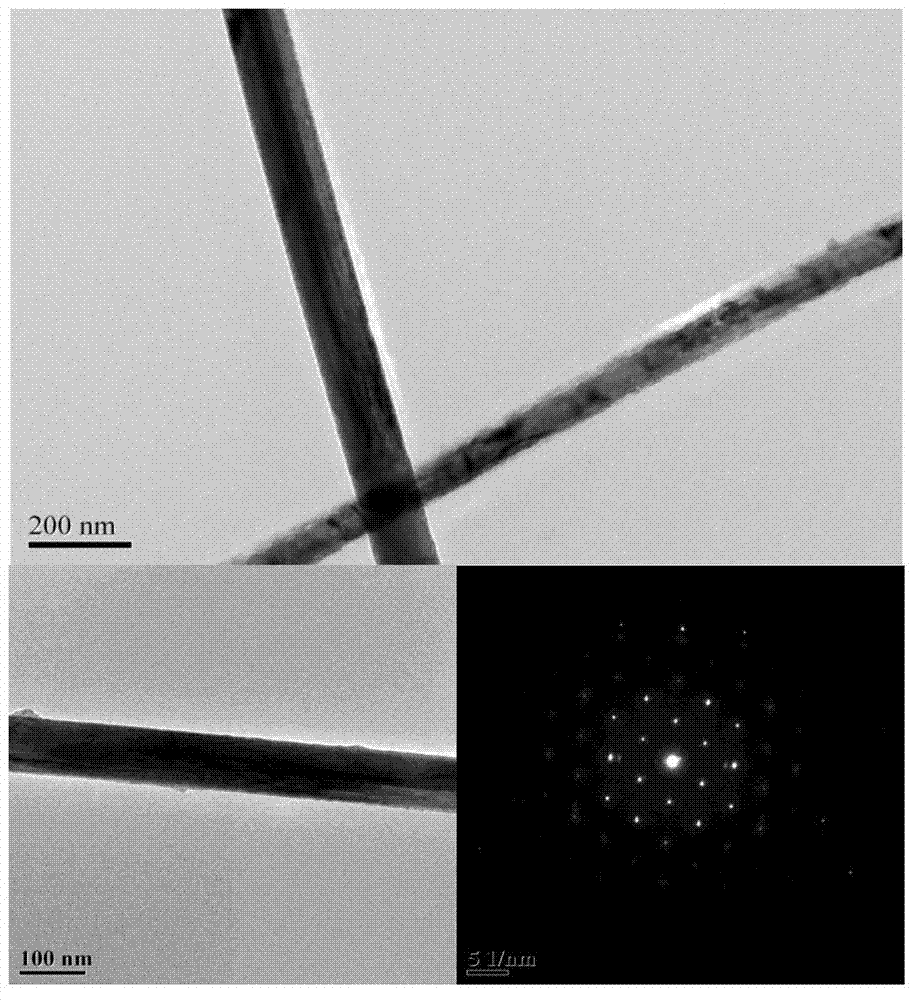

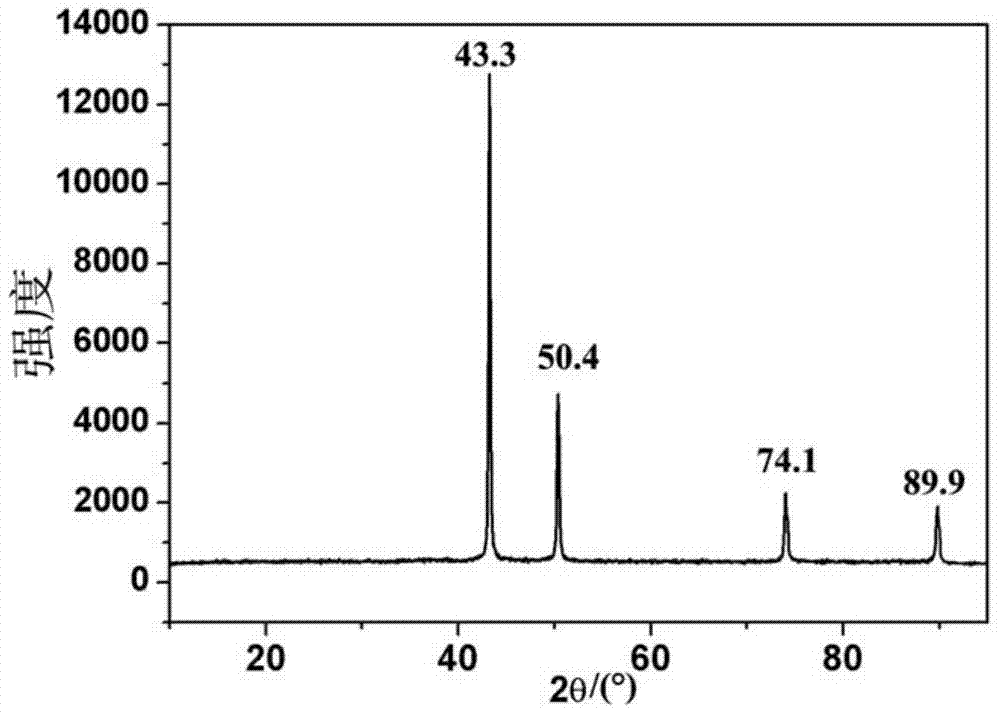

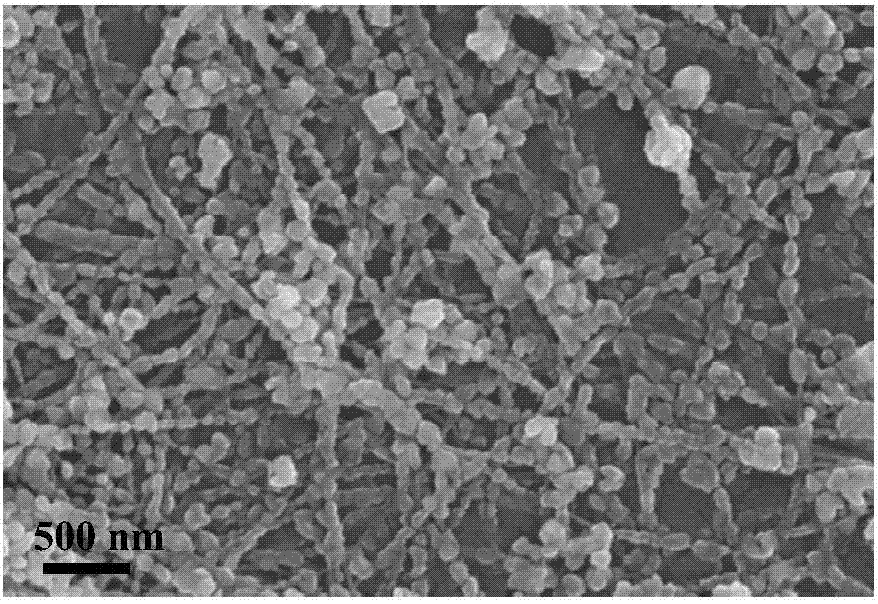

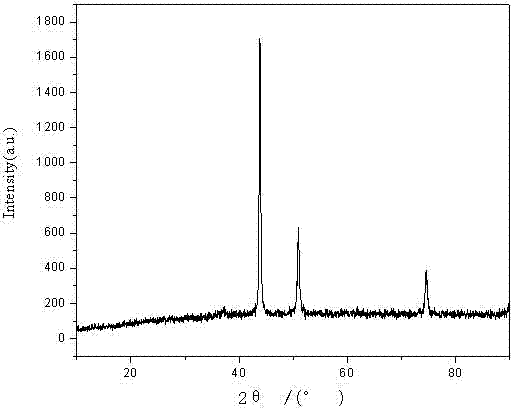

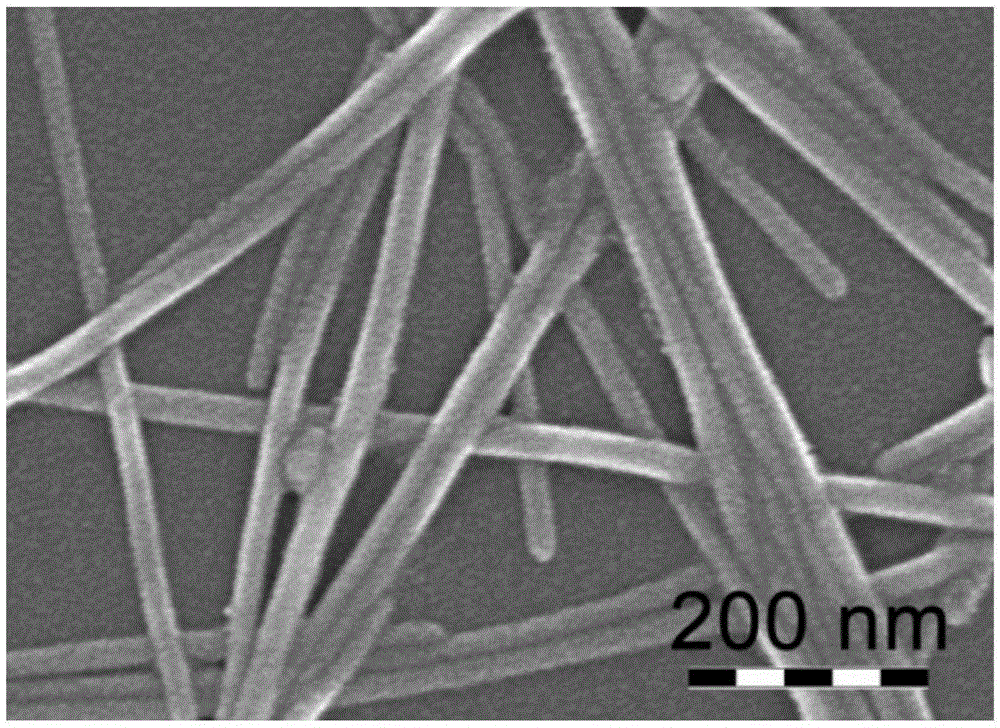

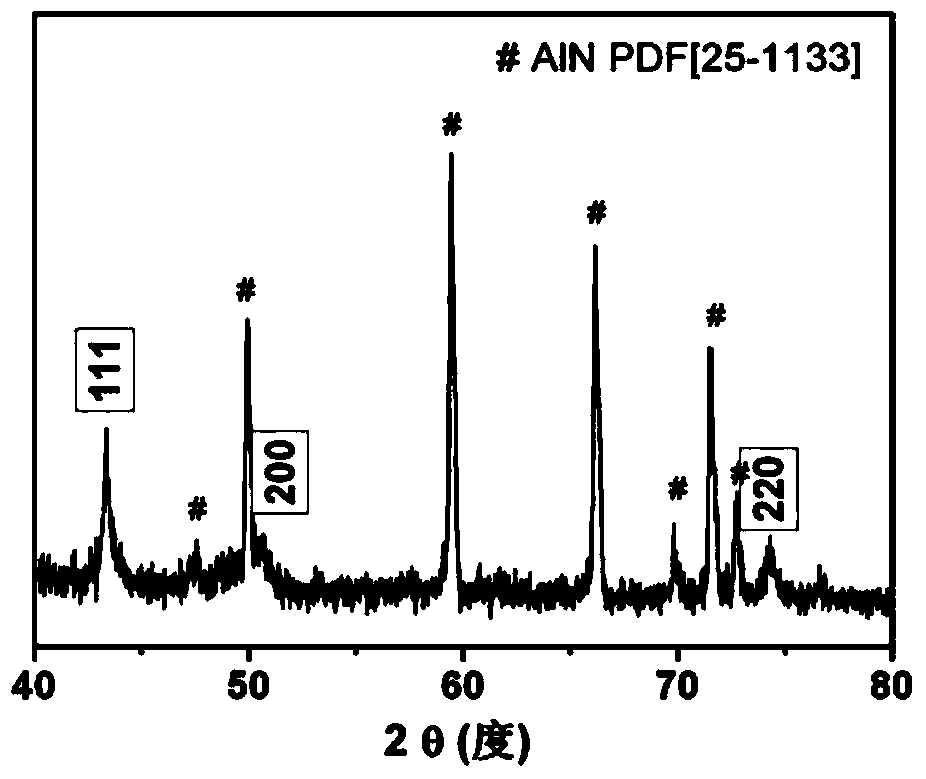

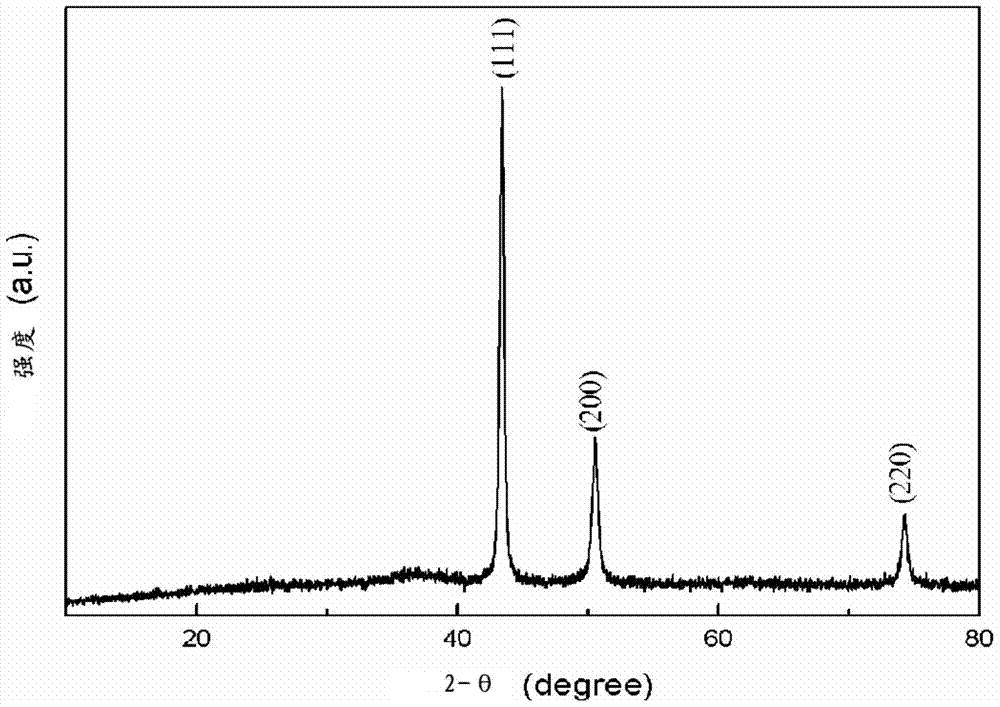

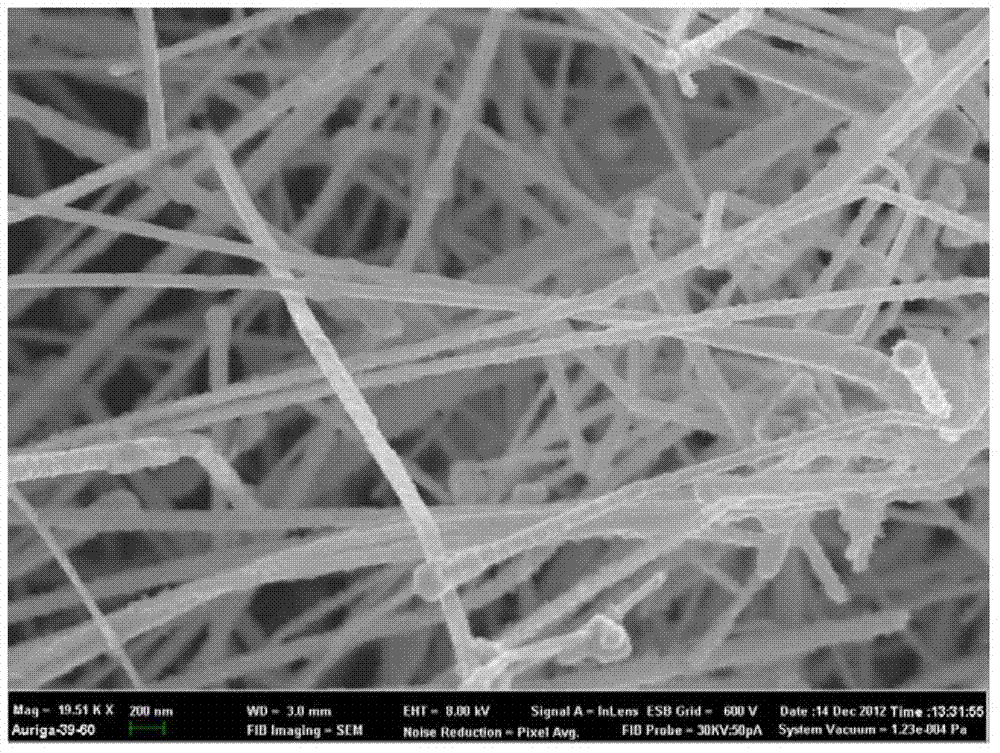

InactiveCN102787347AImprove performanceEasy to operatePolycrystalline material growthLiquid surface applicatorsX-raySingle crystal

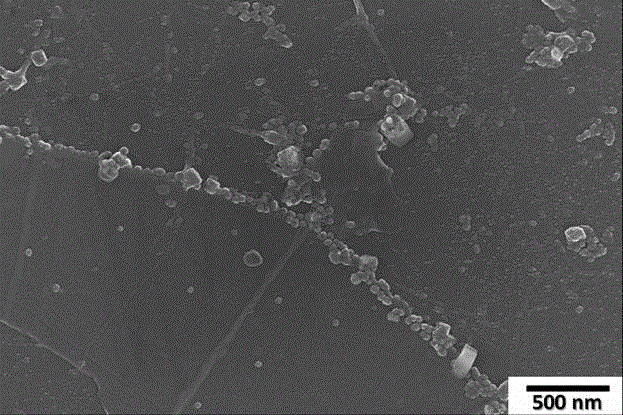

The invention discloses a preparation method of an overlong copper nanowire. The preparation method comprises steps as follows: (1) dissolving a cationic surfactant into a reducing organic solvent under a condition at 170-190 DEG C to obtain a solution A, wherein the reducing organic solvent is long-chain alkyl amine; (2) dissolving a copper source into the solution A completely, stirring to obtain a solution B; adding noble metal nanoparticles or a silicon sheet plated with the noble metal into the solution B to serve as a catalyst; reacting for 2-20 hours under the condition at 100-200 DEG C; and (3) after cooling the reaction system, taking out the solid and washing the solid by an organic solvent. The diameter of the copper nanowire prepared by the method is about 40-80nm, the length is about 300-1500 mu m; and the copper nanowire is a mono-crystalline copper nanowire grown along the [001] direction. The copper nanowire is proved by XRD (X ray diffraction). The method is simple to operate, the synthesized overlong copper nanowire is of a mono-crystalline structure and is easy to disperse, and a prepared conductive film is excellent in performance.

Owner:SHANGHAI NORMAL UNIVERSITY

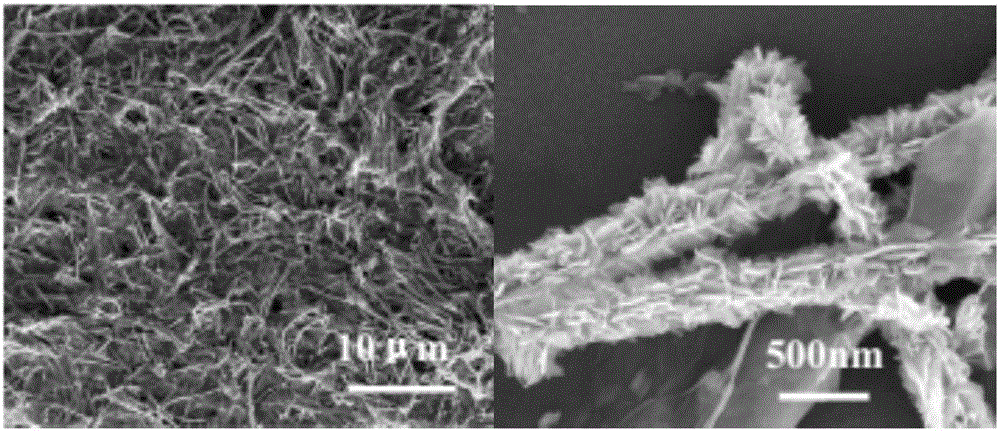

Method for preparing three-dimensional graphene-copper nanowire composite aerogel

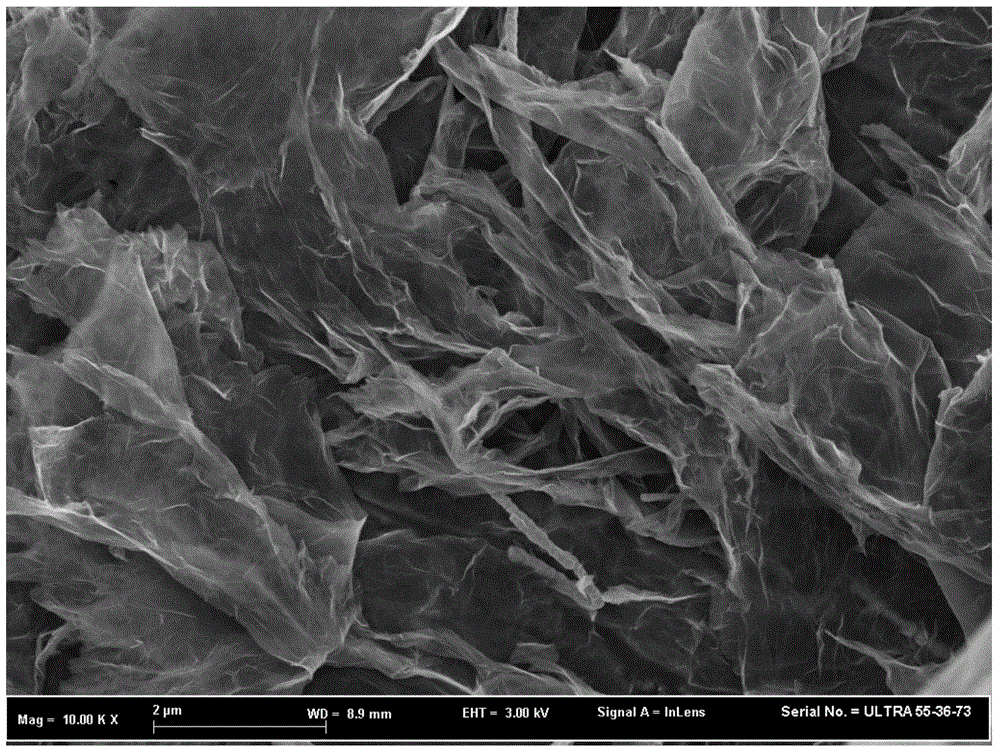

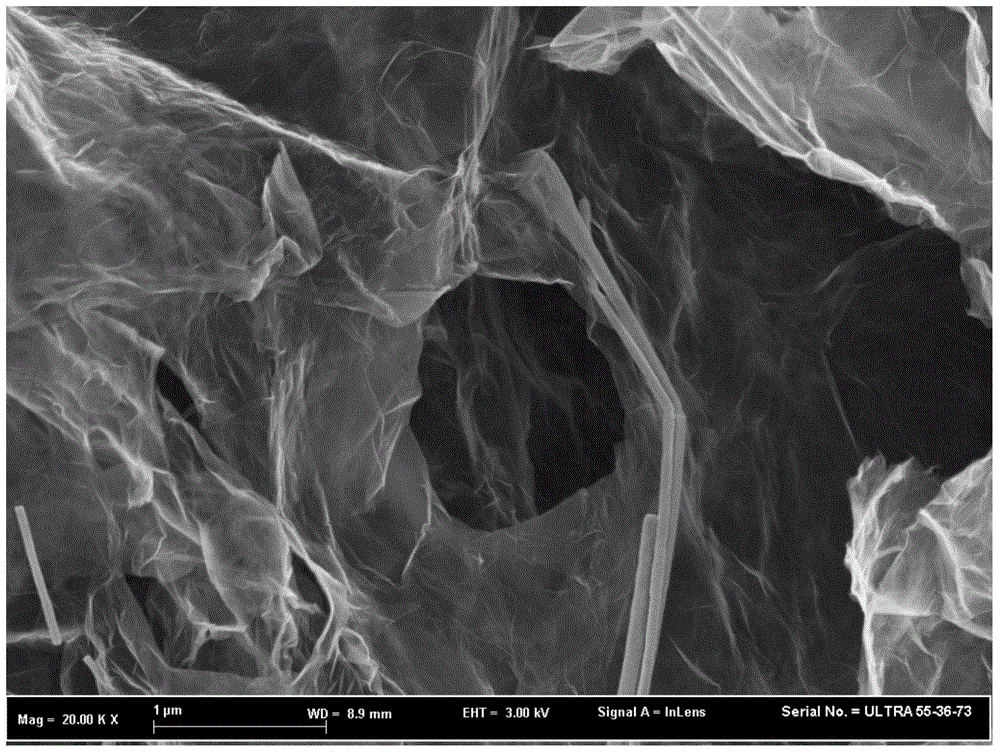

InactiveCN104801244AControllable sizeSimple processColloidal chemistry detailsFreeze-dryingCvd graphene

The invention discloses a method for preparing three-dimensional graphene-copper nanowire composite aerogel. The method comprises the following steps: first, preparing copper nanowires; mixing the copper nanowires and an oxidized graphene solution into an ethylene glycol solution; adding ascorbic acid which serves as a reducing agent; carrying out hydrothermal reaction to obtain three-dimensional graphene-copper nanowire composite hydrogel; finally, washing the three-dimensional graphene-copper nanowire composite hydrogel with a hydrazine hydrate solution which is 0.5 wt%; carrying out freeze-dry treatment to obtain the three-dimensional graphene-copper nanowire composite aerogel. The three-dimensional graphene-copper nanowire composite aerogel adopts a three-dimensional porous structure, and has the advantages of being high in compression performance, low in density, high in electric conductivity and the like.

Owner:ZHEJIANG SCI-TECH UNIV

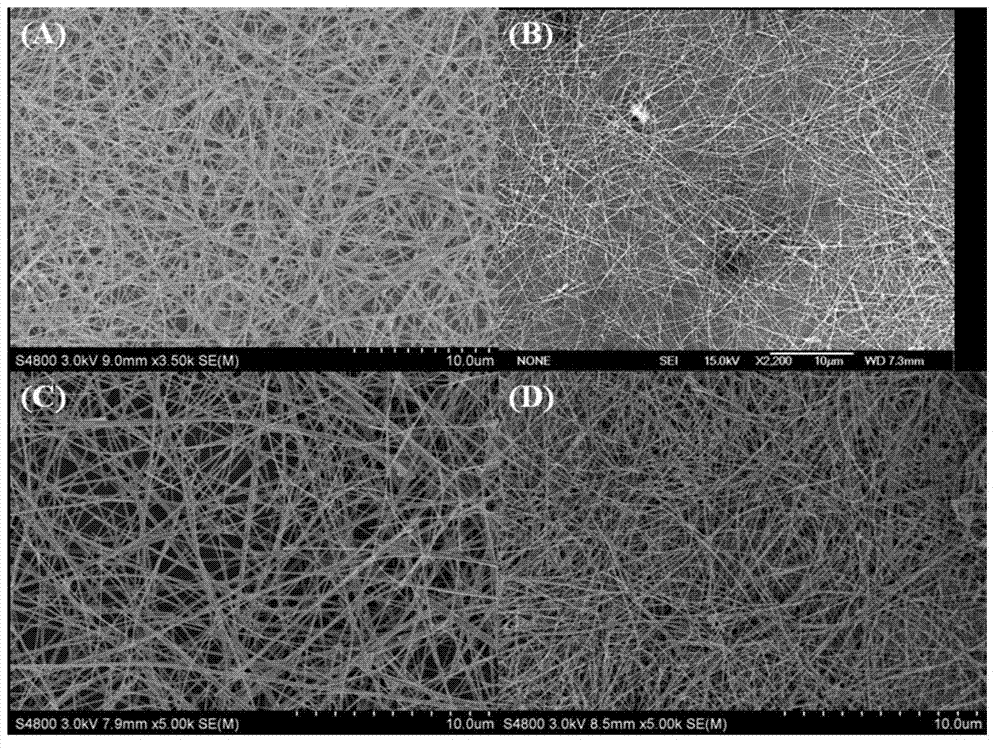

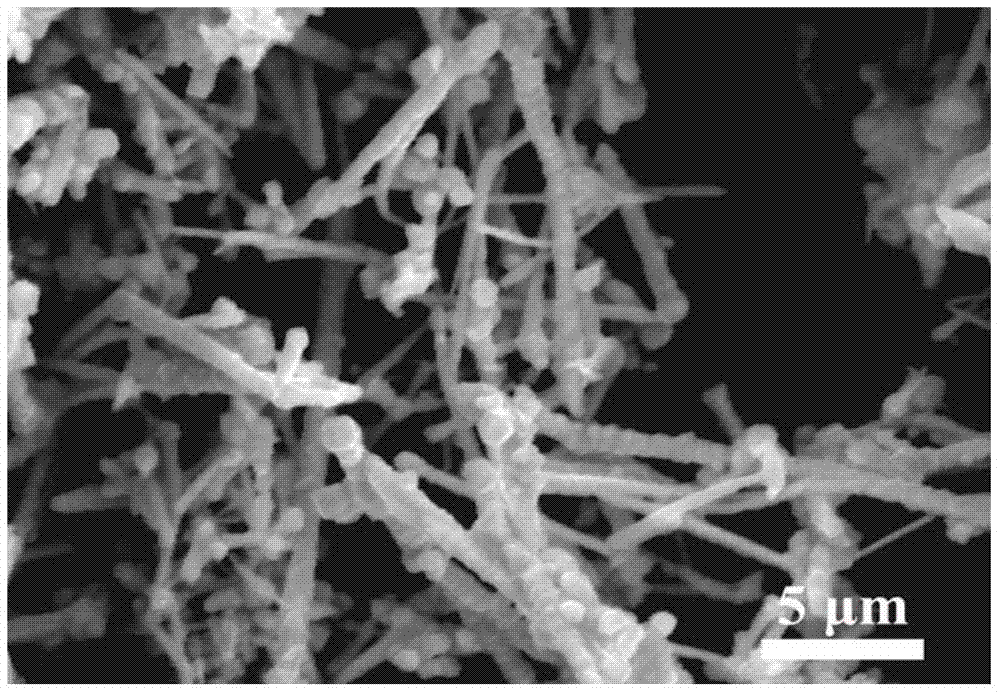

Copper nanowire and preparation method thereof

ActiveCN103658675AMeet savingsMeets requirementsMaterial nanotechnologyDispersityReaction temperature

The invention discloses a copper nanowire and a preparation method of the copper nanowire. The method comprises the steps that (1) a copper salt solution is added into an alkali solution, the two solutions are mixed, and the concentration of copper ions in the mixed solution ranges from 1*10<-7>mol / L to 1*10<-5>mol / L; (2) a mixed solution of a reducing agent and a dispersing agent is prepared and added into the mixed solution obtained in the step (1); (3) the copper salt solution is dropwise added into the solution obtained in the step (2) under the conditions of magnetic stirring or ultrasonic dispersing, and reaction is conducted for 0.5-6 hours at the temperature of 40-90 DEG C; (4) products obtained in the step (3) are centrifugally separated and washed, and then the copper nanowire is obtained. The copper nanowire obtained based on the preparation method has the good dispersity and inoxidizability, the particle sizes of the obtained products are uniform, the length of the prepared copper nanowire ranges from 3 micrometers to 15 micrometers, the diameter of the prepared copper nanowire ranges from 20nm to 100nm, and the maximum square resistance value can reach 10.1 ohm per square.

Owner:GUANGDONG TONESET SCI & TECH

Composite flexible transparent electrode of copper nanowires and poly (3, 4-ethylenedioxy group thiophene)-poly (styrene sulfoacid) and manufacturing method thereof

InactiveCN103440896AFix stability issuesImprove conductivityConductive layers on insulating-supportsOrganic conductorsComposite filmEthylenedioxy

The invention discloses a flexible transparent electrode and a manufacturing method of the flexible transparent electrode. The flexible transparent electrode is formed by compositing copper nanowires and poly (3, 4-ethylenedioxy group thiophene)-poly (styrene sulfoacid) (PEDOT: PSS) to form a conducting layer and attaching the conducting layer to a transparent polymer substrate. The flexible transparent electrode and the manufacturing method of the flexible transparent electrode solve the problems that a copper nanowire film is poor in stability and large in roughness, and the combination force between the copper nanowire film and the flexible substrate is poor. A copper nanometer wire and PEDOT: PSS composite film has the advantages of being high in conductivity, high in light transmittance, good in flexibility and the like. The obtained flexible transparent electrode has good application value in image sensors, solar cells, liquid crystal displays, organic electroluminescence displays, touch screen panels and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

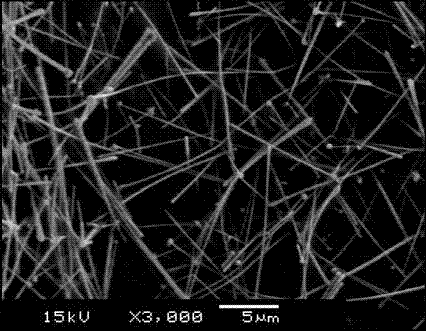

Method for massively preparing overlength copper nanowires

The invention relates to a method for massively preparing overlength copper nanowires. The method comprises the following steps of: using metal copper salt as a copper source; using alkyl aliphatic amine as a directing agent and a reducing agent; using polyethylene glycol and polyvinylpyrrolidone as an auxiliary agent; using mixed liquid of polyalcohol, water and dimethylformamide as a solvent; uniformly mixing several reactants and the solvent; transferring the mixture to a flask; and heating the mixture until the mixture is boiling and flowing back, and obtaining copper nanowires after a certain time. The copper nanowires have the advantages of uniform feature, high purity and good monodispersity; the cost is relatively lower, and the reversal device is simpler; the feature is controllable, and the size regulation range is wide, so that the large-scale production of the copper nanowires is realized, and the method has the industrialization prospect.

Owner:珠海纳金科技有限公司

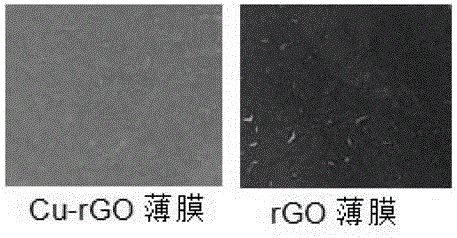

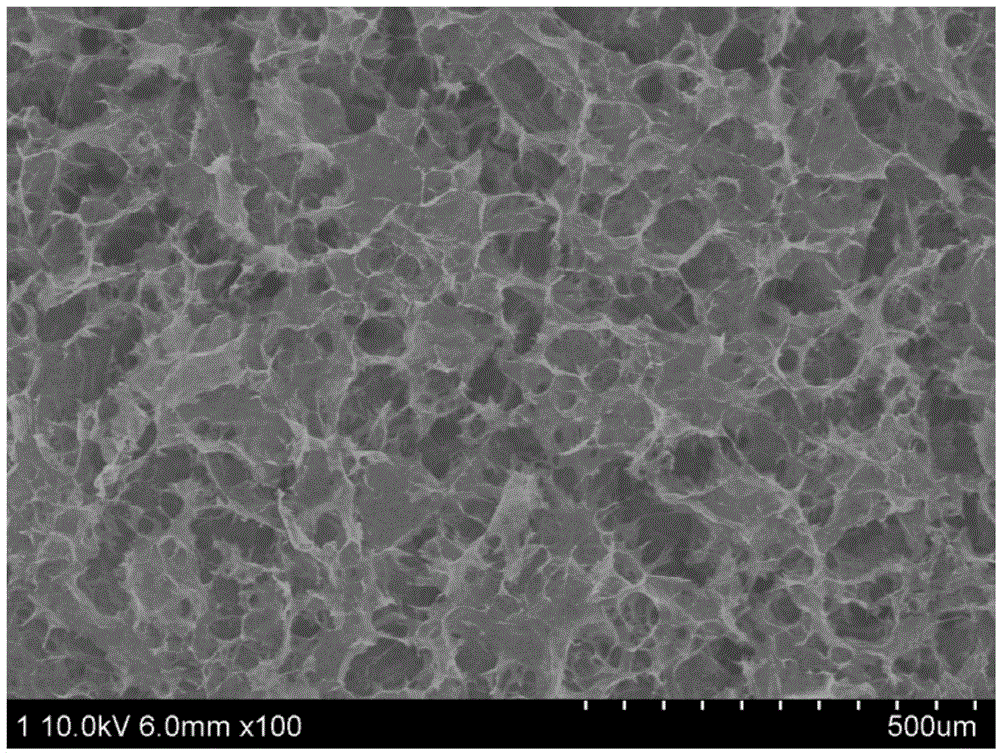

Preparation method and application of Cu nanowire-reduced graphene oxide three-dimensional porous film

InactiveCN105583408ALarge specific surface areaMild conditionsElectrical/magnetic solid deformation measurementComposite filmFiltration

The invention provides a preparation method of a Cu nanowire-reduced graphene oxide-PDMS composite strain sensor, and belongs to the field of reduced graphene oxide composite sensors. The preparation method comprises the steps that copper nanowires are added into graphene oxide containing ascorbic acid, Cu nanowire-reduced graphene oxide hydrogel is obtained after reducing, and a Cu nanowire-reduced graphene oxide film with the three-dimensional porous appearance is obtained through washing, stir-breaking and suction filtration film formation; and then liquid PDMS is poured, vacuum filtration is carried out to remove bubbles, the liquid PDMS is subjected to cross-linking and curing at the temperature of 70 DEG C, and finally the Cu nanowire-reduced graphene oxide-PDMS composite strain sensor is obtained. The composite film is large in specific surface area and excellent in electric conductivity and mechanical performance, and the preparation method of a Cu nanowire-reduced graphene oxide-PDMS composite is mild in condition, simple, practical, controllable in process parameter, low in cost and high in repeatability.

Owner:ZHEJIANG SCI-TECH UNIV

Three-dimensional copper nanowire array current collector for lithium ion battery and production method of three-dimensional copper nanowire array current collector

InactiveCN103531817AShorten the diffusion pathLow reaction temperatureElectrochemical processing of electrodesElectrode thermal treatmentElectrolysisHydrogen atmosphere

The invention relates to a three-dimensional copper nanowire array current collector for a lithium ion battery and a production method of the three-dimensional copper nanowire array current collector. The three-dimensional copper nanowire array current collector consists of a copper nanowire array growing on a copper surface. Red copper is employed as a cathode, a solution of sodium hydroxide or potassium hydroxide is employed as electrolyte, stainless steel is employed as an anode, and a saturated mercury chloride electrode is employed as a reference electrode. The production method comprises the following steps of (1) introducing inert gas into an electrolytic bath to remove oxygen, controlling the current density, and electro-oxidizing the cathode to form a Cu(OH)2 thin film on the surface of the red copper to obtain a Cu(OH)2 nanowire array; (2) placing the Cu(OH)2 nanowire array in a hydrogen atmosphere, thermally reducing the Cu(OH)2 nanowire array in a reactor, and naturally cooling to room temperature to obtain the three-dimensional copper nanowire array current collector. A product has high electrical conductivity and an ultra-large specific surface area, and can be produced at a low reaction temperature by simple procedures without a template; a three-dimensional Cu nanowire array has a controllable morphological structure and high uniformity.

Owner:山东玉皇盛世化工股份有限公司

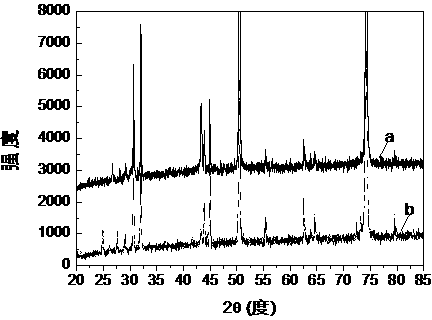

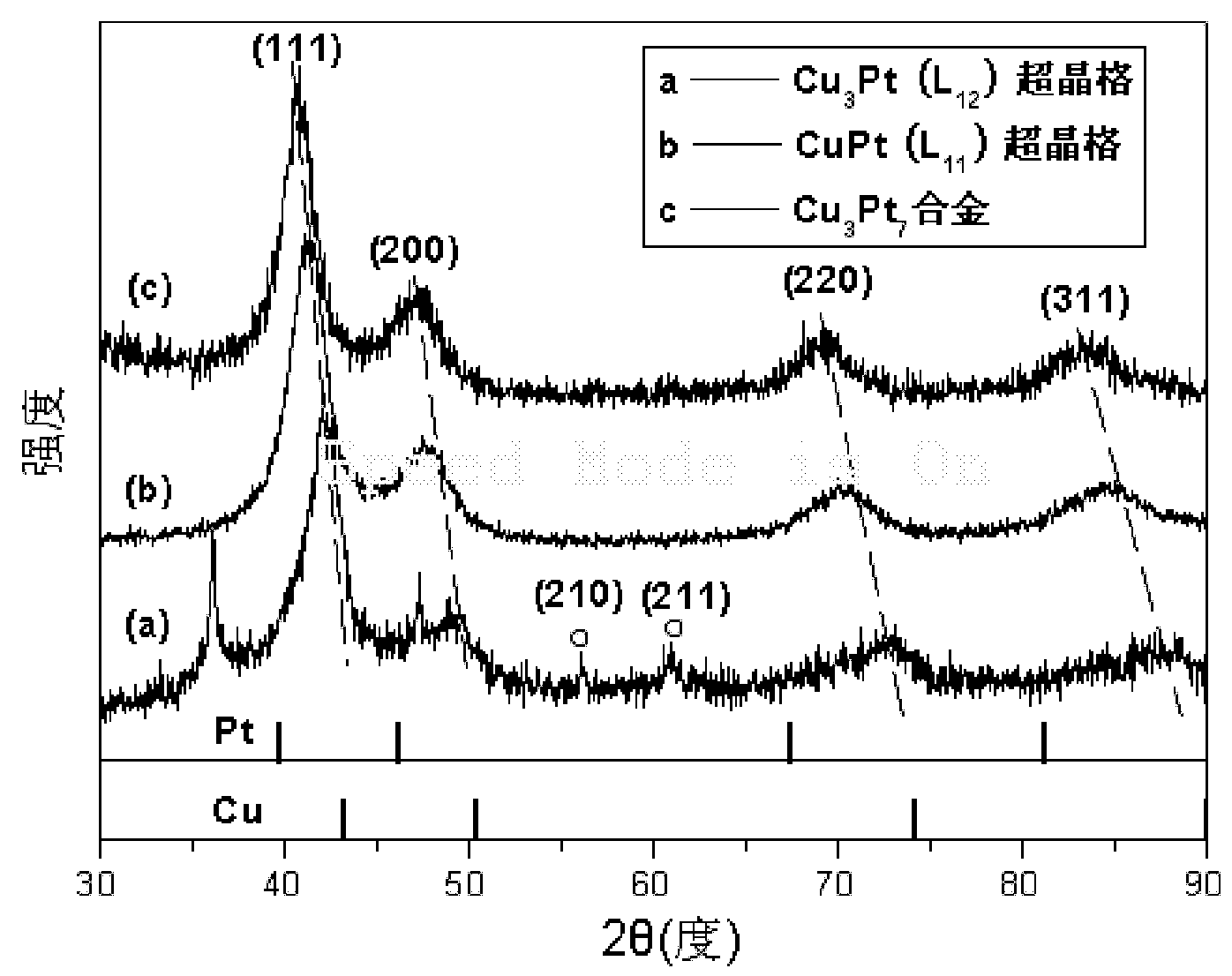

A kind of copper-platinum superlattice alloy nanotube and preparation method thereof

ActiveCN102277622AImprove conversion rateImprove responseMaterial nanotechnologyPolycrystalline material growthEthylenediamineCopper nitrate

The invention provides a copper-platinum superlattice alloy nano-tube and a preparation method thereof, and belongs to the technical field of alloy nano-tube preparation. The preparation method comprises the following steps: firstly, a sodium hydroxide solution is used as a pH regulating agent, anhydrous ethylenediamine is used as a morphological controlling agent, and a hydrazine hydrate solution is used as a reducing agent to reduce a copper nitrate solution to prepare a copper nano-wire; the copper nano-wire is treated with hydrochloric acid and water respectively and dried, and is dispersed in deionized water, in which nitrogen is introduced to remove oxygen; and a chloroplatinic acid solution is added to ensure the molar ratio of chloroplatinic acid to copper is 1:5 or 1:3, reaction is carried out for 20 to 60 minutes, and then filtering, cleaning and drying are carried out. The prepared copper-platinum superlattice alloy nano-tube has a hollow nano-tube structure with the lengthof between 3 and 5 mu m and an outer diameter of between 80 and 150 nm, and the alloy tube wall consists of alloy cubic particles with the particle diameter less than 20 nanometers. The preparation method has the advantages of simple condition, quick reaction and high product conversion rate.

Owner:BEIJING UNIV OF CHEM TECH

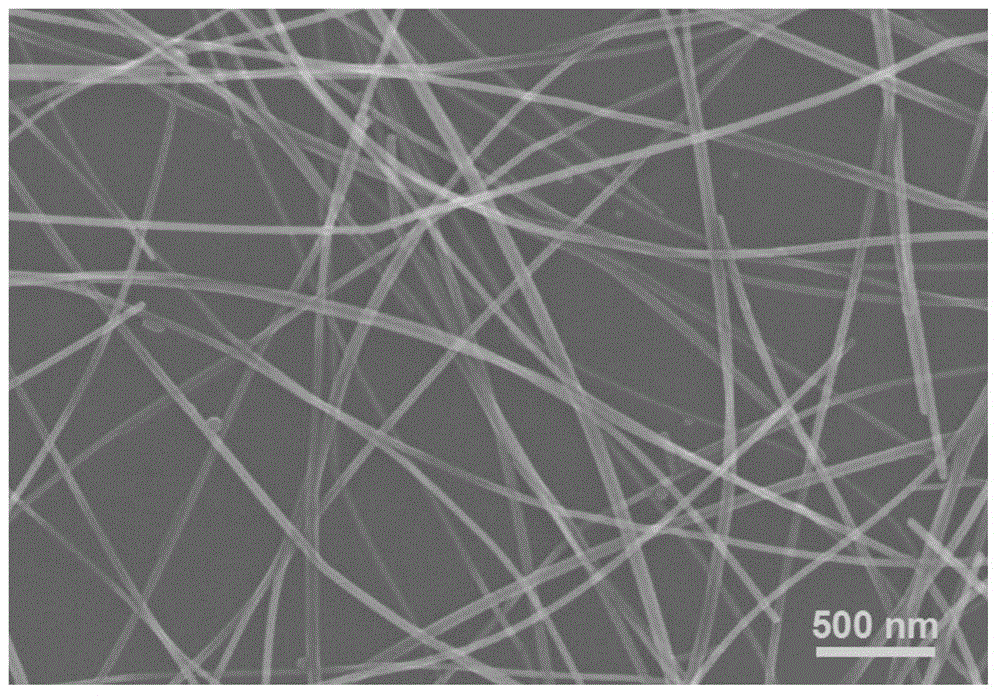

Preparation method for copper/silver nanowires of core-shell structures

ActiveCN105618785ACover tightlyUniform diameterMaterial nanotechnologyTransportation and packagingAlcoholThiourea

The invention discloses a preparation method for copper / silver nanowires of core-shell structures. The preparation method comprises the steps of 1, preparing the copper nanowires, cleaning the copper nanowires and then dispersing the copper nanowires into water; 2, adding thiourea into mixed liquid in the step 1 and fully stirring the thiourea and the mixed liquid; 3, preparing silver nitrate solutions, adding the silver nitrate solutios into the mixed liquid obtained in the step 2 drop by drop, and stirring the silver nitrate solutios and the mixed liquid in a light-shaded mode; 4, filtering and cleaning the mixed liquid obtained in the step 3 for obtaining the copper / silver nanowires of the core-shell structures. The copper / silver nanowires of the core-shell structures prepared through the method are compact copper-based nanowires coated with silver uniformly; silver shells are reduced and generated through copper, combination of the core-shell structures is tight, and the stability of the nanowires is good; the preparation method is simple, end products just need to be dispersed in ethyl alcohol for being stored, and the preparation and storage cost is low.

Owner:ZHEJIANG UNIV

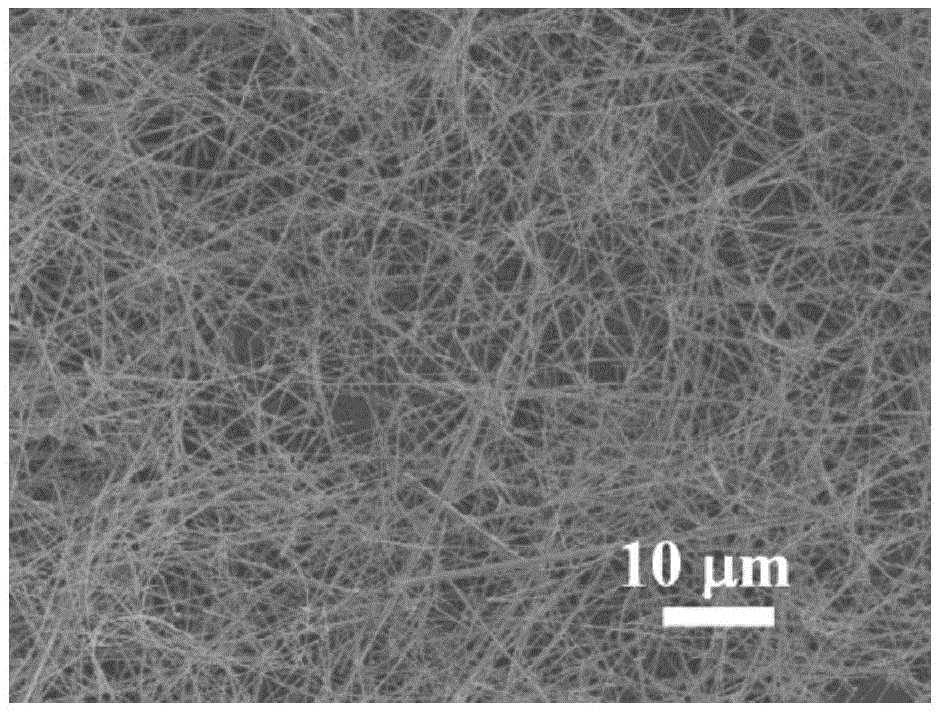

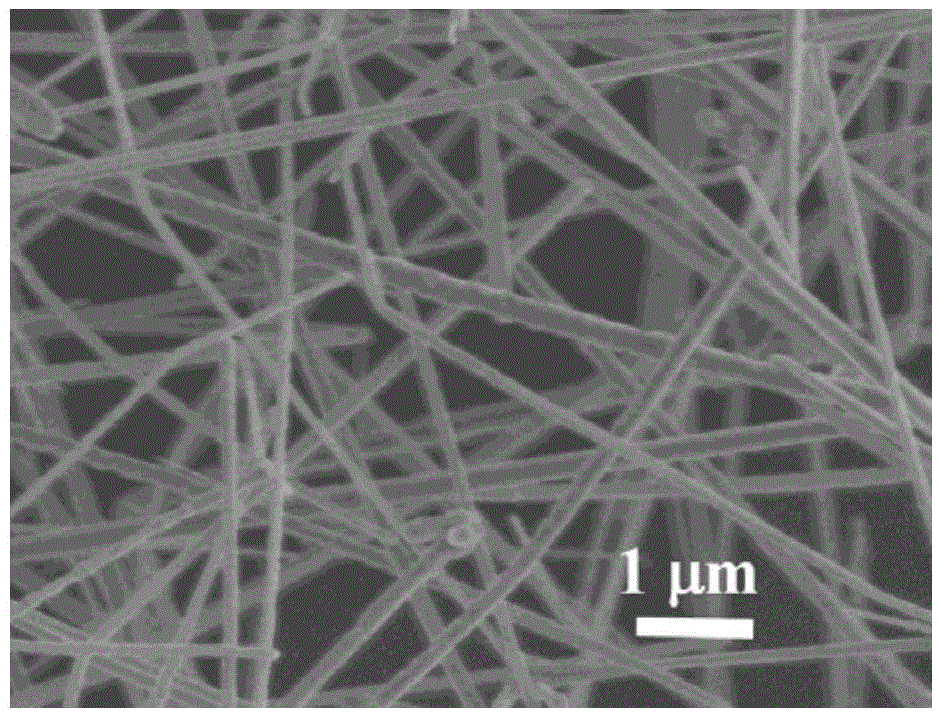

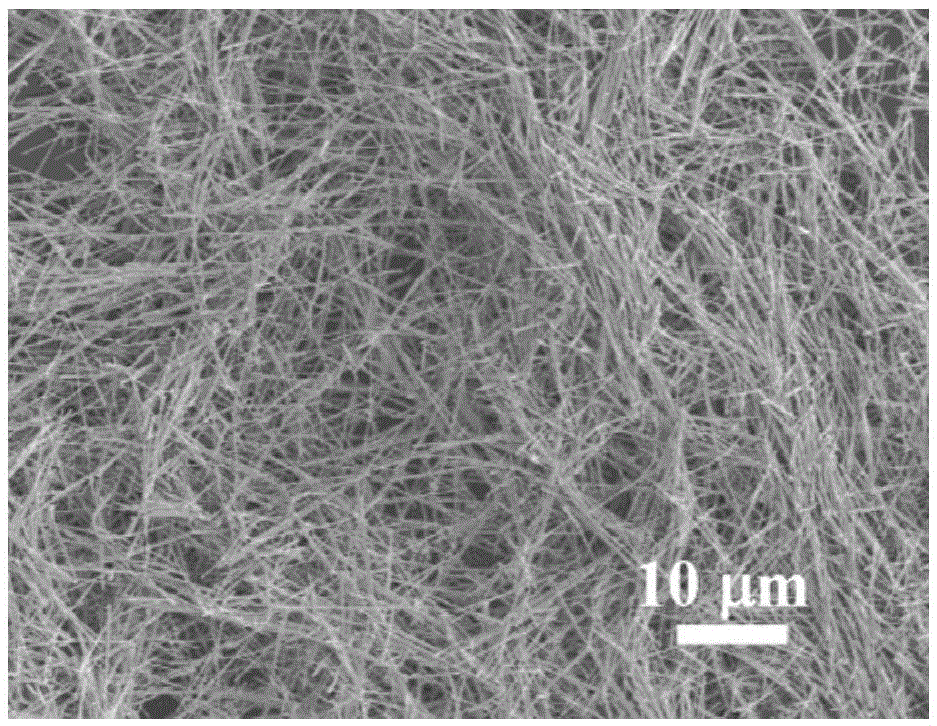

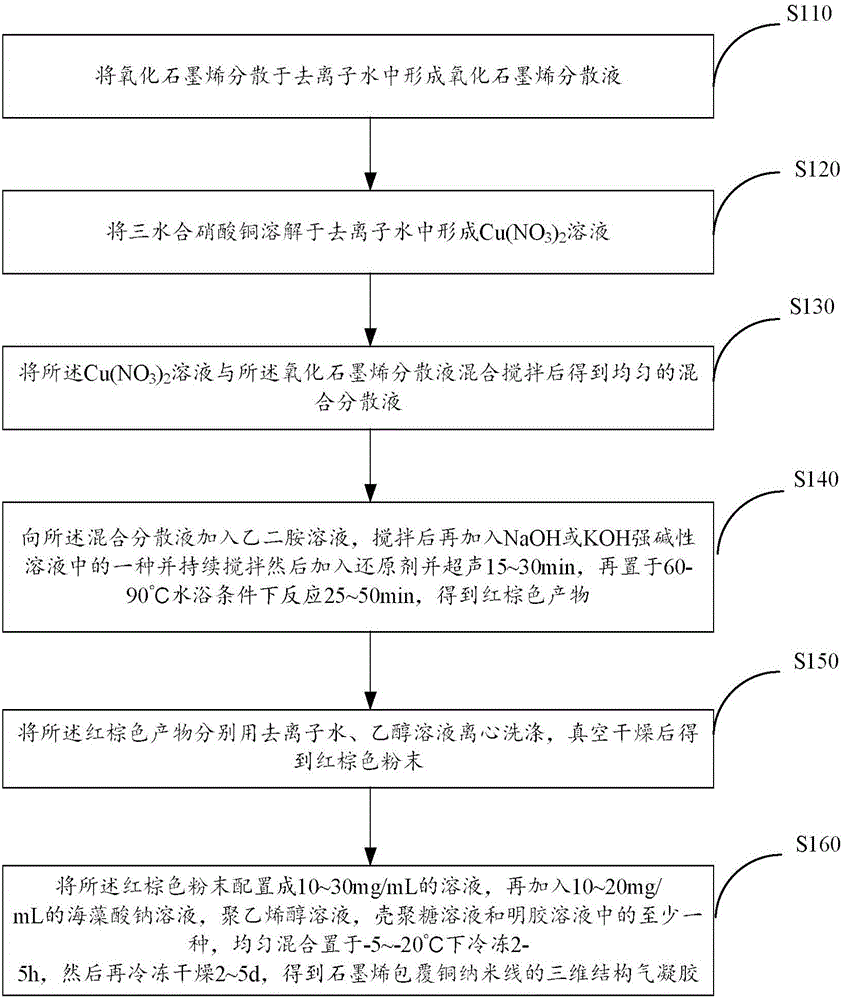

Three-dimensional structure aerogel with copper nanowires coated with graphene and preparation method of three-dimensional structure aerogel and application of three-dimensional structure aerogel

InactiveCN105772741ASolve easy oxidationEasy to replyMaterial nanotechnologyHybrid capacitor electrodesWater bathsPolyvinyl alcohol

The invention relates to a preparation method of three-dimensional structure aerogel with copper nanowires coated with graphene. The method includes the steps that graphene oxide dispersion liquid and a Cu(NO3)2 solution are mixed to obtain mixed dispersion liquid; an ethylenediamine solution is added, then one of strong alkaline solutions such as NaOH and KOH is added, after a mixture is continuously stirred, a reducing agent is added, ultrasonic treatment is conducted for 15 min to 30 min, the mixture is then placed under the water bath condition at the temperature from 60 DEG C to 90 DEG C to react for 25 min to 50 min, and a reddish brown product is obtained; the reddish brown product is subjected to centrifugal washing and vacuum drying, so that reddish brown powder is obtained; a solution of 10 mg / mL to 30 mg / mL is prepared, at least one of a sodium alga acid solution of 10 mg / mL to 20 mg / mL, a polyvinyl alcohol solution, a chitosan solution and a gelatin solution is added, the solutions are evenly mixed and then placed in the environment at the temperature ranging from -5 DEG C to -20 DEG C to be frozen for 2 h to 5 h, freeze-drying is then conducted for 2 d to 5 d, and therefore the three-dimensional structure aerogel with the copper nanowires coated with the graphene is obtained. The invention further relates to the three-dimensional structure aerogel with the copper nanowires coated with the graphene and an application. The three-dimensional structure aerogel is unlikely to be oxidized and has good compression resilience performance.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Preparation method of antioxidant copper nanowires

ActiveCN107470609ALower redox potentialPrevent oxidationMaterial nanotechnologyTransportation and packagingOrganic solventAntioxidant

The invention provides a preparation method of antioxidant copper nanowires, and relates to the preparation method of metal nanowires. The preparation method is simple and low in cost, formic acid roots are modified or adsorbed on the surfaces of the copper nanowires, the stability of the copper nanowires is improved, and meanwhile, the electrical conductivity is not reduced. The preparation method comprises the following steps that the copper nanowires are added to dispersing agents, polar organic solvents and / or water are added then, and copper nanowire dispersing liquid is obtained by mixing; antioxidants are added to the obtained copper nanowire dispersing liquid to mix, and mixed liquid is obtained; the mixed liquid is put in a pressurized and heated sealing system to react; and the mixed liquid is subjected to liquid-solid separation after being cooled, and the copper nanowires subjected to antioxidant surface treatment, namely the antioxidant copper nanowires, are obtained after washing.

Owner:XIAMEN UNIV

Preparation method for copper nanowire

ActiveCN103084581AEasy to removeVolatilePolycrystalline material growthFrom normal temperature solutionsHydroxylaminePotassium hydroxide

The invention belongs to the technical field of novel function nanometer material preparation, and discloses a preparation method for a copper nanowire. Reducing agent is added to copper source on the premise that morphology control agent and chemical potential control agent are exist in water solution, and the copper nanowire are obtained after separation and under the condition that reaction is carried out for at least one hour in temperature of 25 DEG C to 100 DEG C, wherein the copper source is one or combination of copper hydroxide and copper oxide, the morphology control agent is one kind or combination of more than two kinds of polyethylene polyamine, the chemical potential control agent is one or combination of sodium hydroxide and potassium hydroxide, and the reducing agent is one or combination of hydrazine hydrate and hydroxylamine. The preparation method for the copper nanowire has the advantages of being simple in technology and device, cheap and easy-getting in raw materials, low in cost, high in productivity, suitable for large-scale industrial production, and the like. Prepared copper nanometers are uniform in diameter, diameters and lengths of the copper nanometers can be controlled through changing concentration of the morphology control agent and concentration and reaction temperature of the copper resource.

Owner:HENAN UNIVERSITY

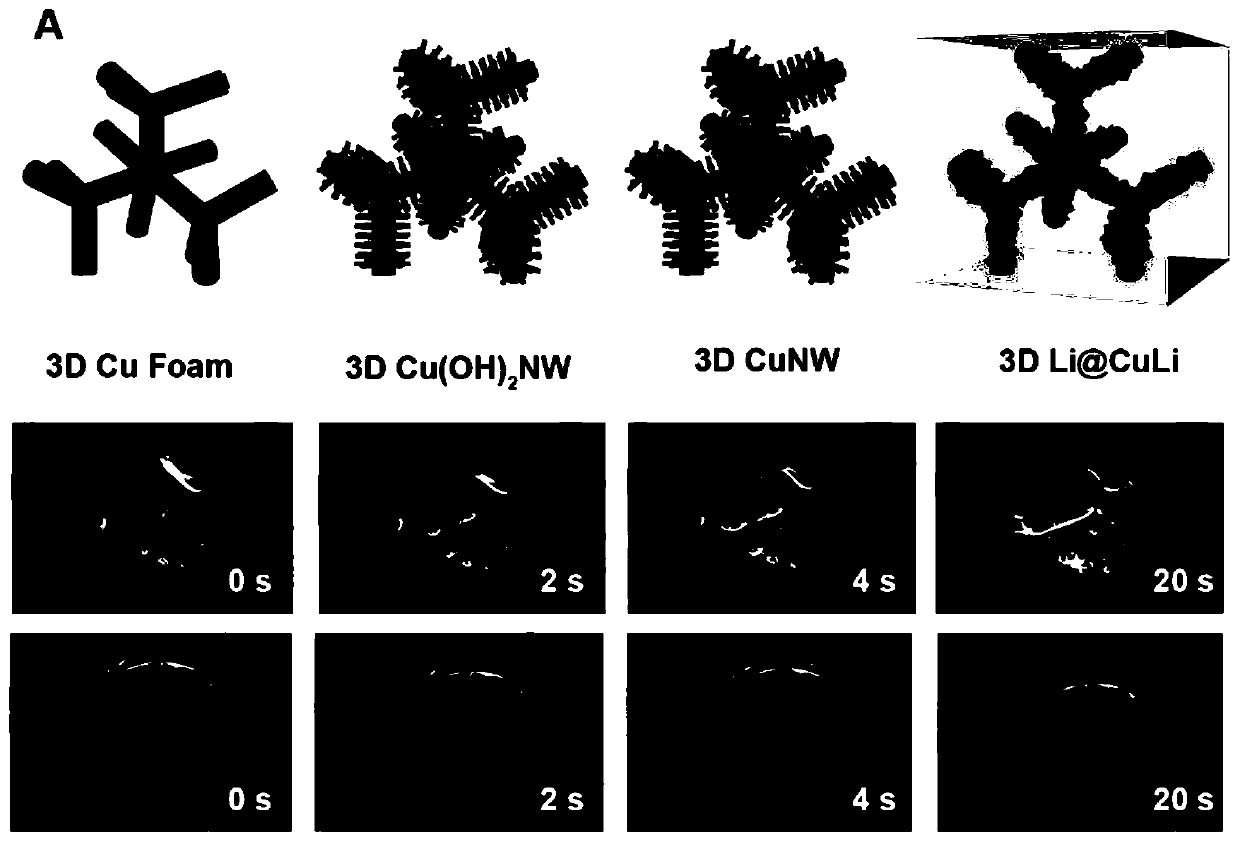

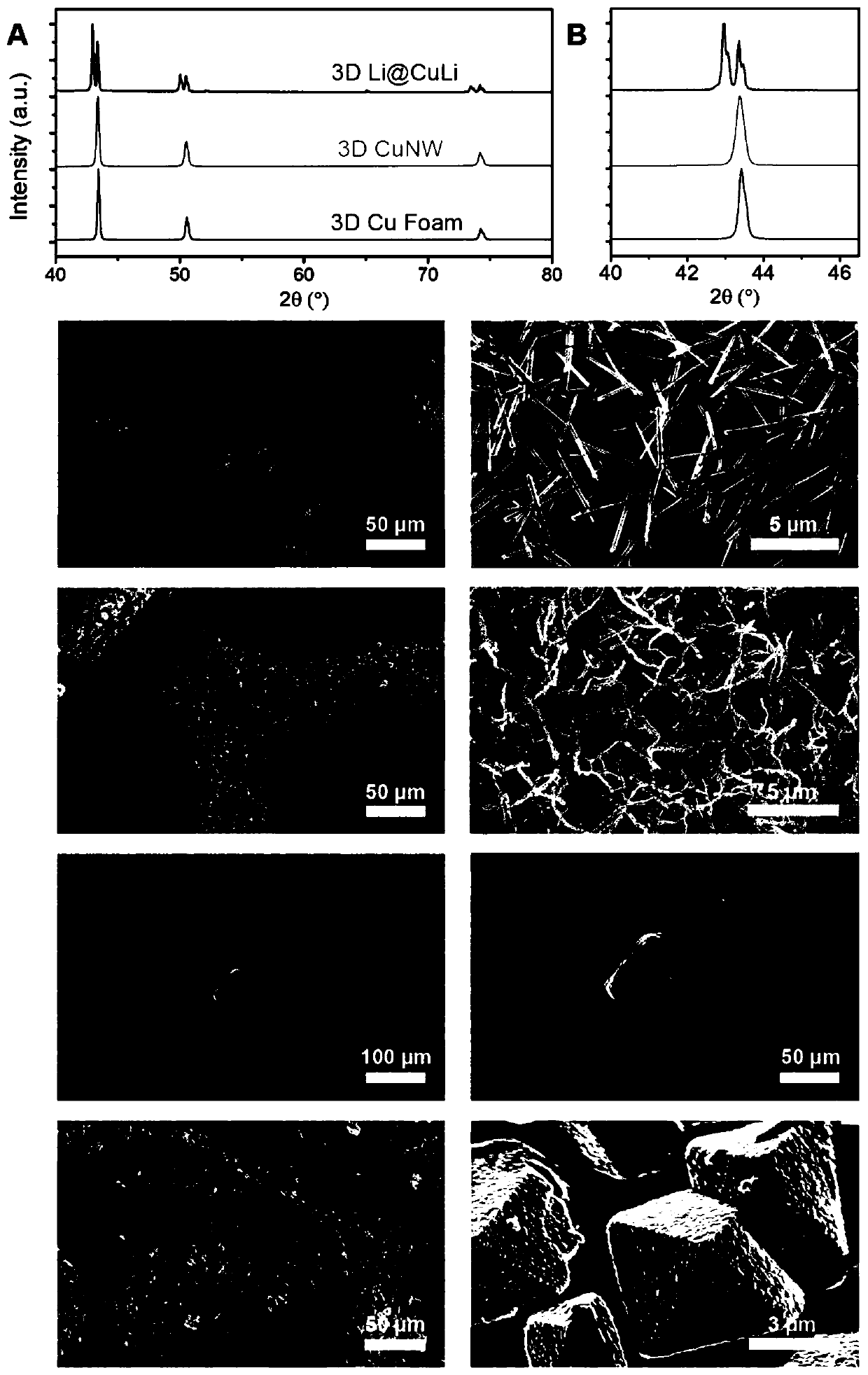

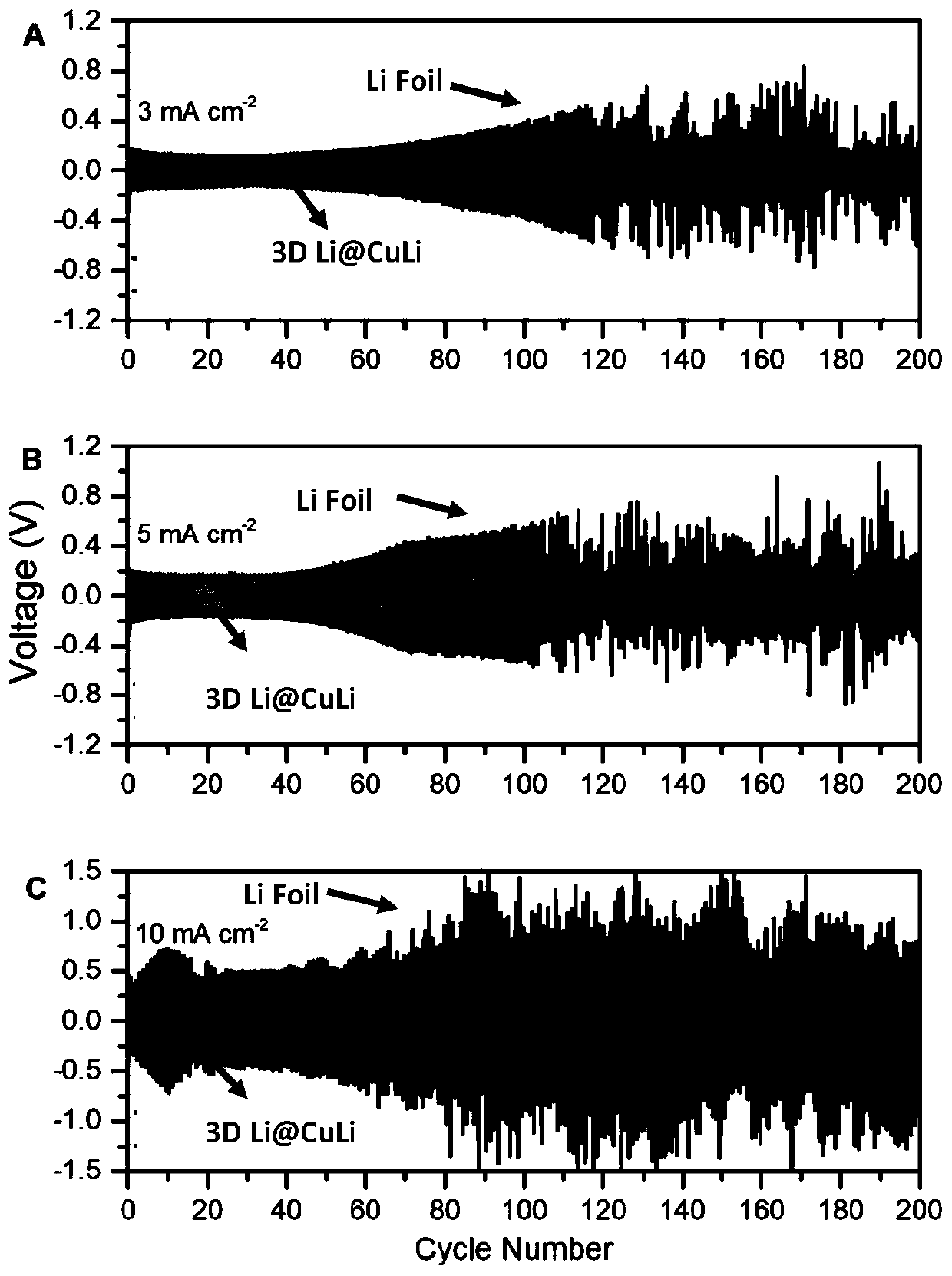

Three-dimensional metal lithium negative electrode and preparation method and application thereof

ActiveCN110061191AImprove cycle stabilityInhibition formationElectrode carriers/collectorsNegative electrodesHigh rateMetal framework

The present invention belongs to the technical field of lithium ion batteries, and particularly relates to a three-dimensional metal lithium negative electrode and a preparation method and an application thereof. The three-dimensional metal lithium negative electrode comprises a three-dimensional copper foam framework. Metal copper nanowires grow on the surface of the copper foam. By modifying thethree-dimensional (3D) copper foam framework with the copper nanowires, a surface with lithium affinity is obtained, thereby metal lithium is melted into the metal framework and the three-dimensionalmetal lithium negative electrode is realized. In addition, in the process of melting lithium, metal lithium reacts with copper to form Li-Cu alloy. The invention can inhibit the formation of dendritic lithium in the metal lithium negative electrode, and realizes a stable cycle of the metal lithium negative electrode. Compared with the conventional metal lithium plate, the present invention makesthe metal lithium battery have better cycle stability and higher rate performance, and is of great value for realizing the commercial application of metal lithium battery.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD +1

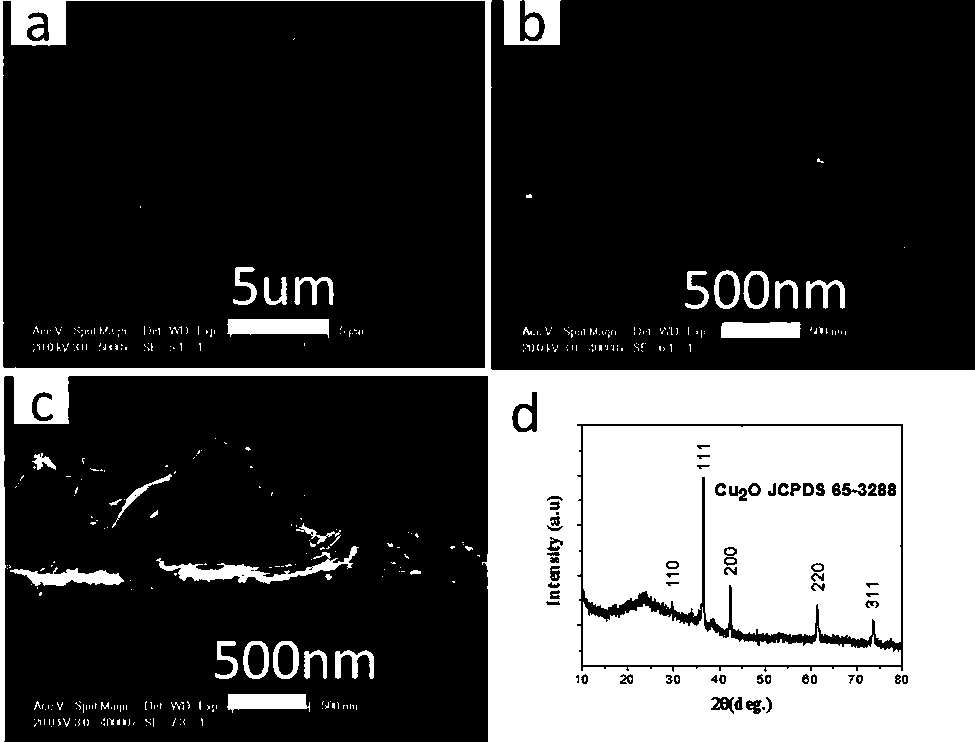

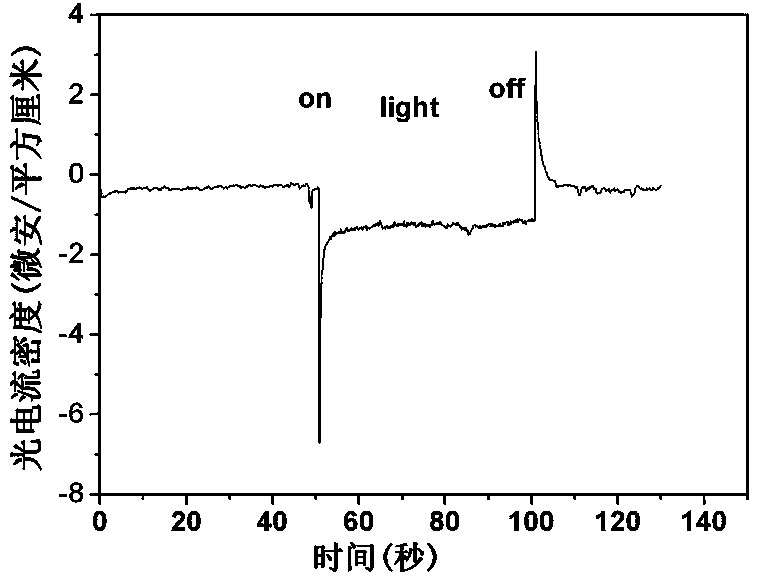

Cuprous oxide nanowire porous film as well as preparation method and application thereof

The invention belongs to the technical field of nano materials, relates to a photoelectric function material, and particularly relates to a cuprous oxide nanowire porous film as well as a preparation method and an application thereof. The cuprous oxide nanowire porous film is obtained by using copper thiocyanate film as a precursor to react with aqueous alkali. The copper oxide nanowire porous film provided by the invention can act as a photoelectric conversion material and also has wide use in the field of function materials and components.

Owner:FUDAN UNIV

Method for preparing copper nanowires through oil-phase chemical reduction

InactiveCN105328206ANo other impuritiesLarge diameterMaterial nanotechnologyTransportation and packagingInorganic saltsOrganic solvent

The invention discloses a method for preparing copper nanowires through oil-phase chemical reduction. The method comprises: mixing a reducing organic solvent, a cationic surfactant, an inorganic salt catalyst and a copper source together to obtain a mixed liquid A; under the condition of protection with an inert atmosphere, heating the mixed liquid A at a temperature ranging from 40 to 100 DEG C and stirring until all solid reagents are completely dissolved to obtain a solution B; increasing a temperature of the solution B to the range of 170-200 DEG C and preserving heat, thereby obtaining a suspension C; and naturally cooling the suspension C to a room temperature, centrifuging, taking precipitate at the bottom for centrifugal washing by using an organic solvent, and obtaining red precipitate after washing, namely the copper nanowires. The method is simple and easy to implement; the copper nanowires prepared are regular in line form and uniform in dimension; the copper nanowires are made out of elementary substance copper without other impurities, and have diameters ranging from 15 to 35nm and lengths ranging from 5 to 20 microns; besides, the copper nanowires are controllable in morphology and thus are an excellent one-dimensional material.

Owner:BEIJING UNIV OF CHEM TECH

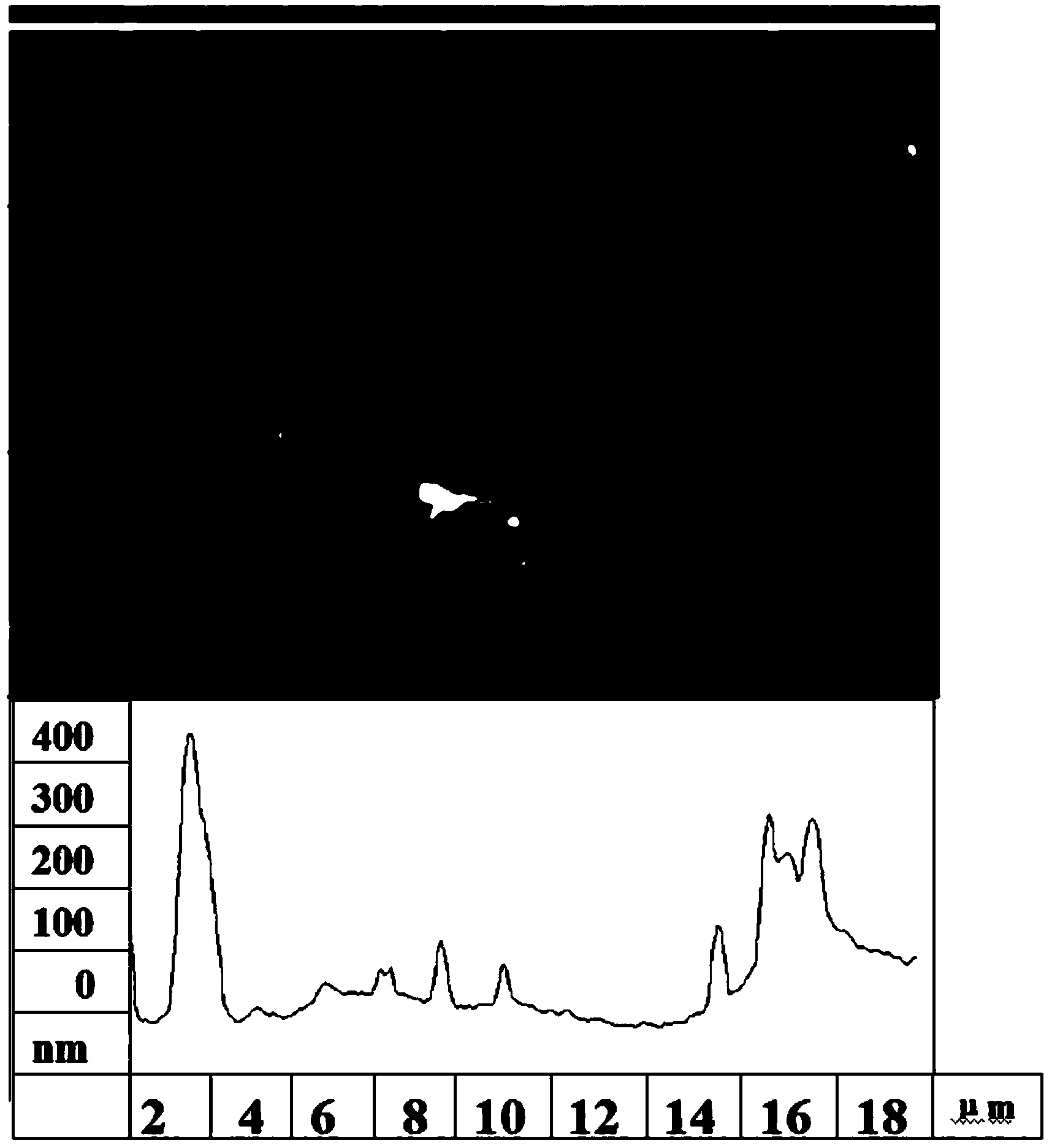

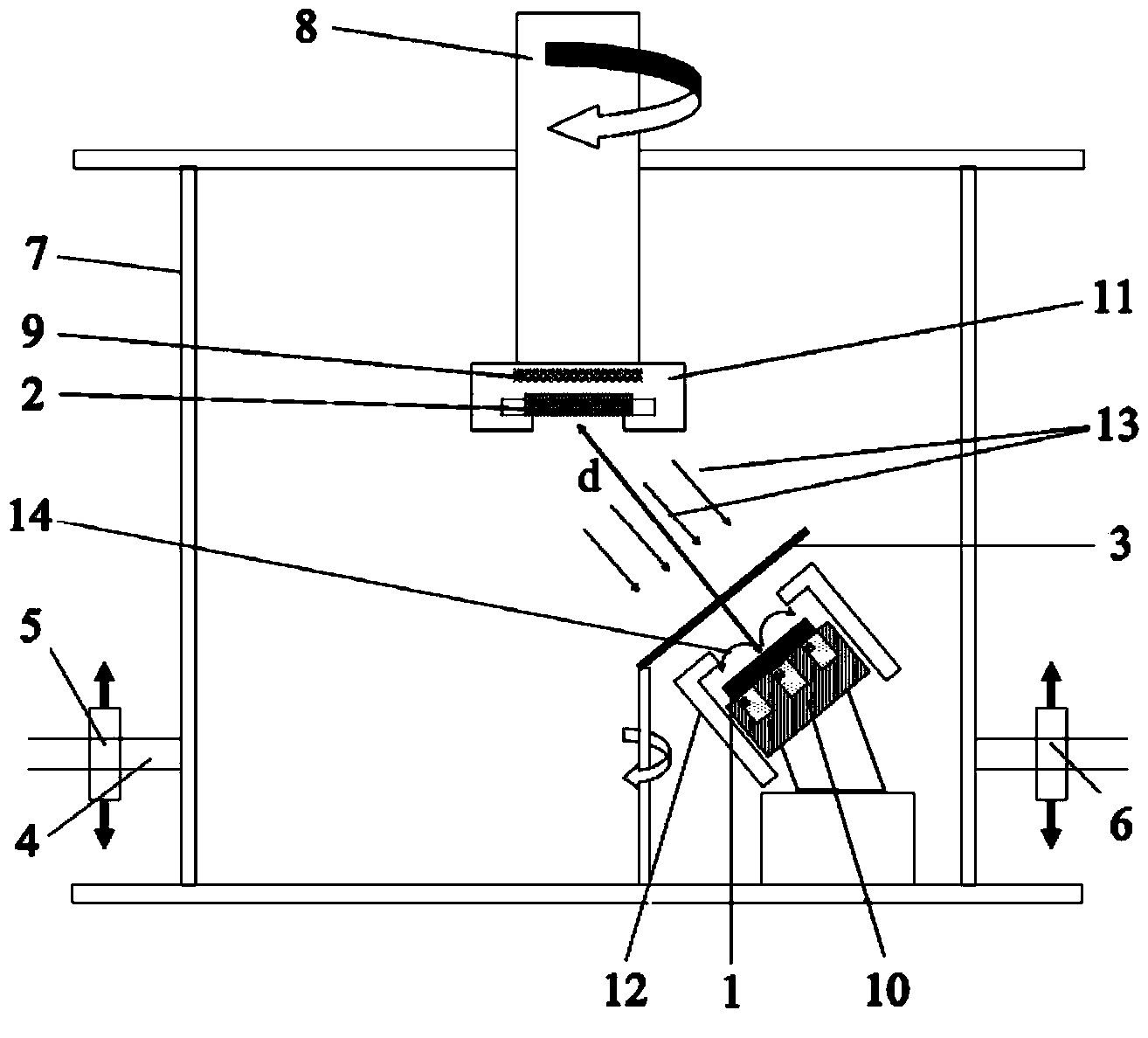

Preparation method of copper nanowire arrays with porous structure and film conductivity measuring method thereof

InactiveCN103510048AResistance/reactance/impedenceVacuum evaporation coatingVacuum chamberDc voltage

The invention provides a normal temperature preparation method of copper nanowire arrays. The method comprises the following steps: putting a copper target material in a direct current platform 1 in a vacuum chamber of a magnetron sputtering instrument, placing a substrate plate on a sample platform 2, modulating the distance between the sample platform 2 and the direct current platform 1 in a range of 50 to 90 mm; vacummizing the vacuum chamber until the vacuum degree of the vacuum chamber reaches 2.0*10<-4> to 4.0*10<-4> Pa; pumping argon gas into the vacuum chamber at the room temperature, adjusting the pressure of argon gas in a range of 1.0 to 2.0 Pa; applying a direct current voltage between a negative pole, which is tightly connected to the target material and a positive pole, which is tightly connected to the back of the substrate plate (namely a DC voltage), controlling the current to be in a range of 80 to 120 mA and the voltage to be in a range of 0.25 to 0.35 kV; carrying out deposition for 1 to 7 hours, turning off the direct current power supply, in-situ annealing for 20 minutes, and naturally cooling to the room temperature of 25 DEG C so as to prepare aluminium nitride, quartz or copper substrate coated with a copper nanowire array film. The copper nanowire arrays obtained by the preparation method have a uniform structure, effectively guarantee the even distribution of nano phase, and have the advantages of simple whole deposition technical process, low cost, and easiness in industrial production.

Owner:杭州知创新材料技术有限公司

CuO-MnO2 core-shell structured nanometer material and preparation method for same

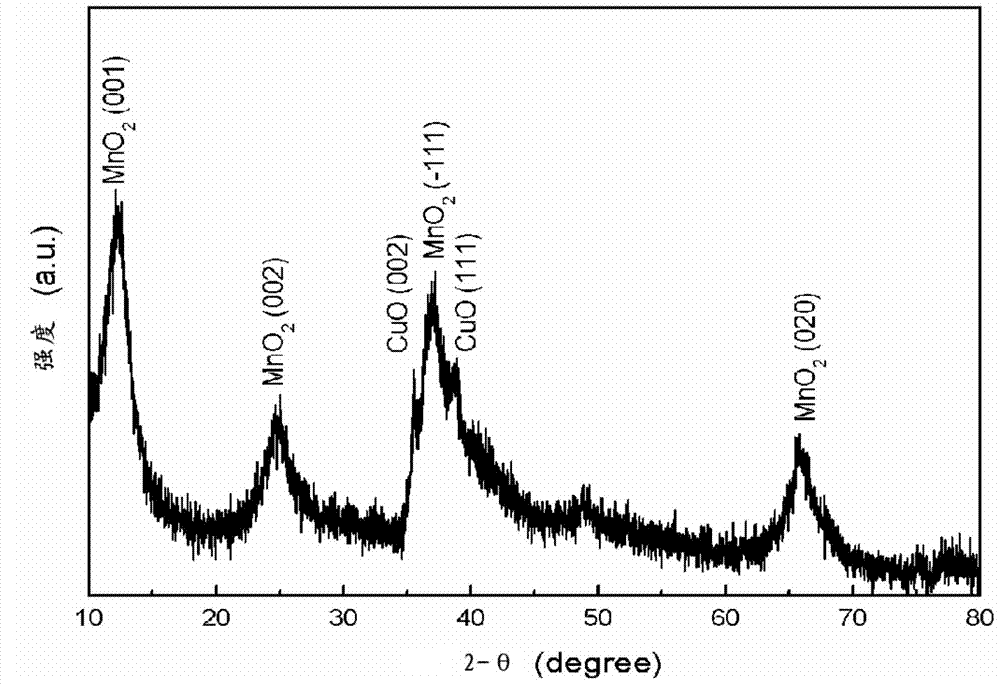

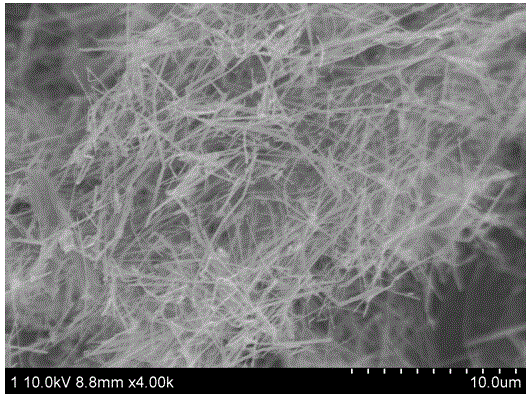

ActiveCN103500667AEasy transferFacilitated DiffusionMaterial nanotechnologyHybrid capacitor electrodesElectrochemical responseElectric capacity

The invention provides a preparation method for a CuO-MnO2 core-shell structured nanometer material. The preparation method comprises the following steps of dispersing copper nanowires into a solution of potassium permanganate, and performing hydrothermal reaction to obtain the CuO-MnO2 core-shell structured nanometer material, wherein the copper nanowires and the solution of potassium permanganate are subjected to oxidation-reduction reaction to form the CuO-MnO2 core-shell structured nanometer material with a mesoporous layered architecture and a larger specific surface area, a copper-wrapping copper oxide serves as a core of the material, and a manganese dioxide serves as a shell of the material. When the material with the structure is used as an electrode, the transmission and the diffusion of electrolyte ions during electrochemical reaction are facilitated, and more active sites for the oxidation-reduction reaction during charging and discharging reaction are formed, so that higher specific capacity and stable electrochemical cycling performance are ensured. Experimental results show that the CuO-MnO2 core-shell structured nanometer material has specific capacity of 250 to 276F / g, and the electric capacity can still be kept over 90 percent of original capacity after 1,000 cycles.

Owner:CHONGQING UNIV

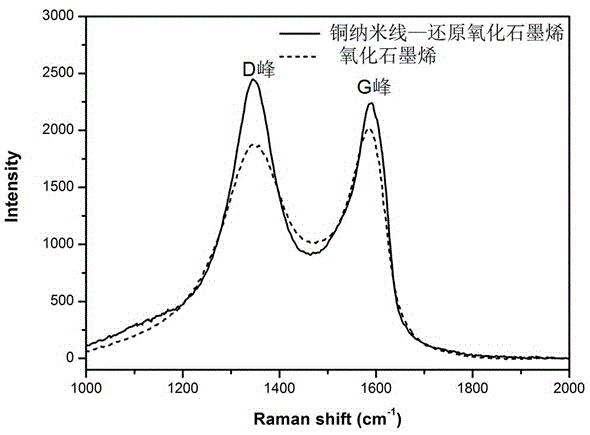

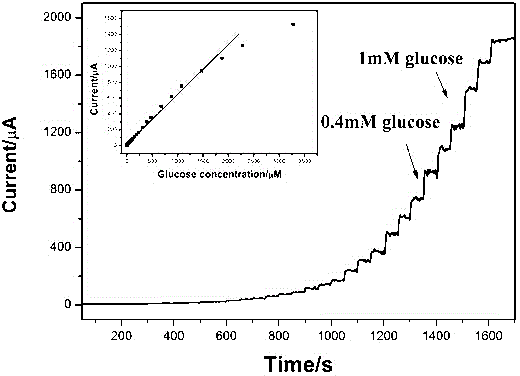

Preparation method of copper nanowire graphene composite-modified electrode, as well as applications thereof

ActiveCN104569097AAchieving electrocatalytic oxidationAvoid stabilityMaterial electrochemical variablesCvd grapheneCopper nanowires

The invention discloses a preparation method of a copper nanowire graphene composite-modified electrode, as well as applications thereof serving as a glucose electrochemical sensor. The preparation method mainly comprises the following steps: modifying ITO glass as an electrode by utilizing a copper nanowire graphene composite, preparing the copper nanowire graphene composite by adopting liquid phase reduction, evenly mixing with a Nafion solution, dropwise adding to the ITO glass, to obtain the copper nanowire graphene composite. The sensitive quantitative analysis determination can be performed to glucose by adopting a current-time curve through the electrochemical catalysis oxidization action of the modified electrode to the glucose. The preparation method is simple and easy, low in detection limit, and high in sensitivity, and the concentration of glucose can be fast detected.

Owner:上海睿骋实业有限公司

Nano-copper catalyst, preparation method thereof and application to synthesis of acetic acid or ammonia

ActiveCN110075843ARegular shapeClear structureOrganic compound preparationElectrolytic organic productionActive agentHigh energy

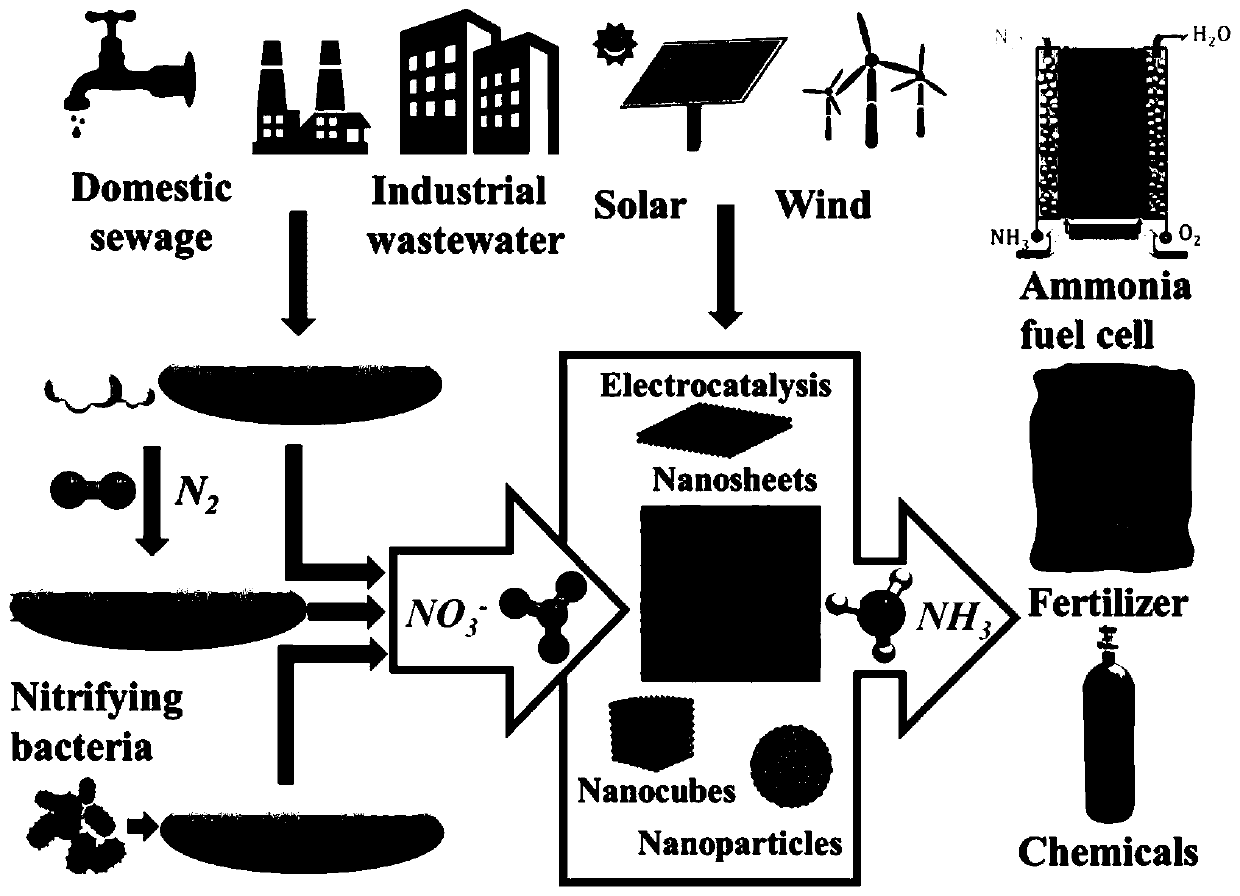

The invention discloses a nano-copper catalyst, a preparation method thereof and an application to synthesis of acetic acid or ammonia. The catalyst comprises a substrate and an active agent supportedon the substrate, wherein the active agent is a copper nanosheet with a [111] crystal plane exposed in a high proportion, a copper nano-polyhedron or a copper nanowire, and the supporting capacity ofthe active agent on the substrate is 0.1-3.0 mg / cm<2>. The active agent exists in air stably and has performance of selectively catalyzing carbon monoxide and carbon dioxide into acetic acid (acetate), and the yield is as high as 48%, that is, the active agent has industrial value; the copper nanomaterial with the [111] crystal plane exposed has performance of efficiently catalyzing various nitrates into ammonia, and both yield and selectivity can reach almost 100%. With the adoption of the catalyst, the problems of high energy consumption and high pollution of ammonia synthesis with a traditional Haber process and low efficiency of ammonia synthesis based on traditional electrochemical nitrogen reduction can be effectively solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

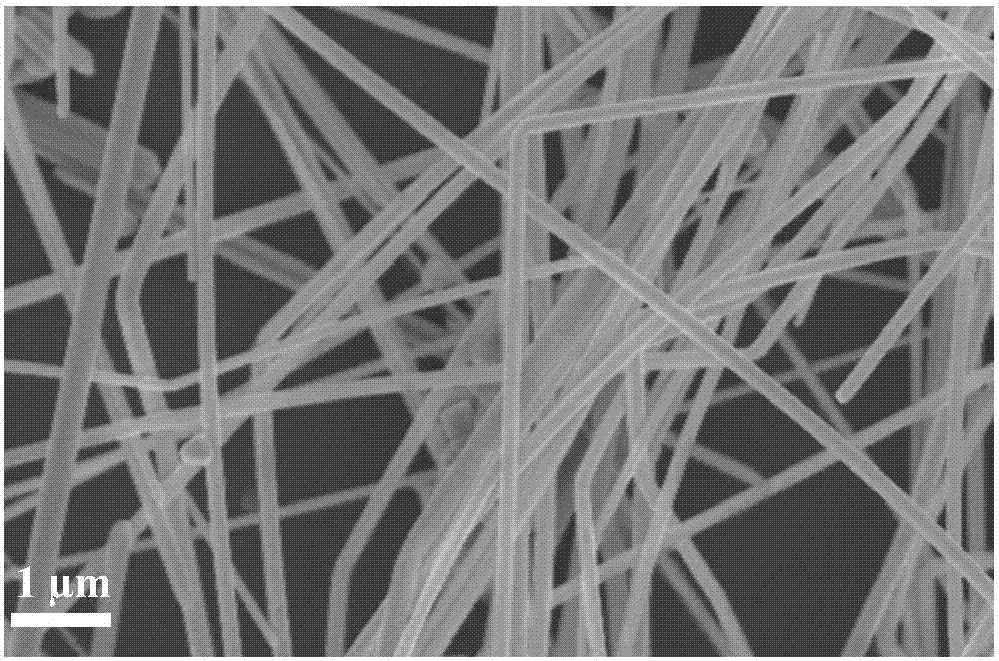

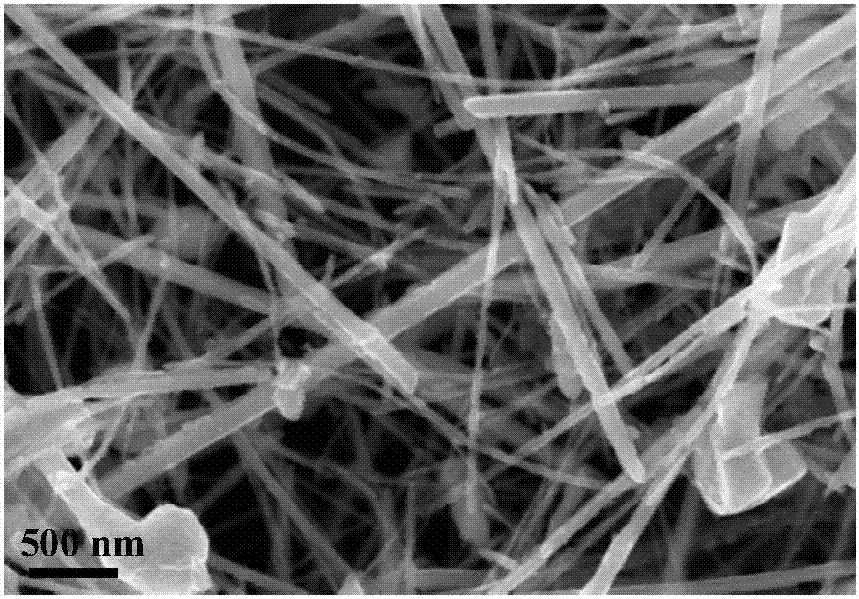

Copper nanowire preparation method and copper nanowire composite transparent conductive thin film

ActiveCN108695014AReduce manufacturing costSimple processConductive layers on insulating-supportsConductive materialPolymethyl methacrylateSurface roughness

The invention discloses a copper nanowire preparation method and a copper nanowire composite transparent conductive thin film. According to the copper nanowire preparation method, initial raw materials including water, octadecylamine, metal copper salt and vitamin C are adopted to prepare a copper nanowire of which the diameter ranges from 40 to 100 nm, of which the length ranges from 40 to 150 microns and of which the surface is smooth. The copper nanowire composite transparent conductive thin film comprises an upper polymethyl methacrylate layer, a copper nanowire layer, a lower polymethyl methacrylate layer and a transparent substrate which are distributed from top to bottom sequentially; the light transmittance of the copper nanowire composite transparent conductive thin film ranges from 40% to 90%; the square resistance of the copper nanowire composite transparent conductive thin film ranges from 5 to 200 ohm / cm<2>; and the surface roughness of the copper nanowire composite transparent conductive thin film ranges from 15 to 100 nm. The copper nanowire preparation method of the invention is low in cost and simple in process, and can produce super long copper nanowires in a batched manner. According to the copper nanowire composite transparent conductive thin film of the invention, a double-layer polymethyl methacrylate structure is adopted, and therefore, adhesion between acopper nanowire grid and a substrate can be improved, the surface roughness of the copper nanowire grid can be decreased, contact area between the copper nanowires is increased, and the copper nanowires can be insulated from the air, so that the copper nanowires can be prevented from being oxidized, and the conductivity and stability of the thin film can be improved.

Owner:威钛科技(东莞)有限公司

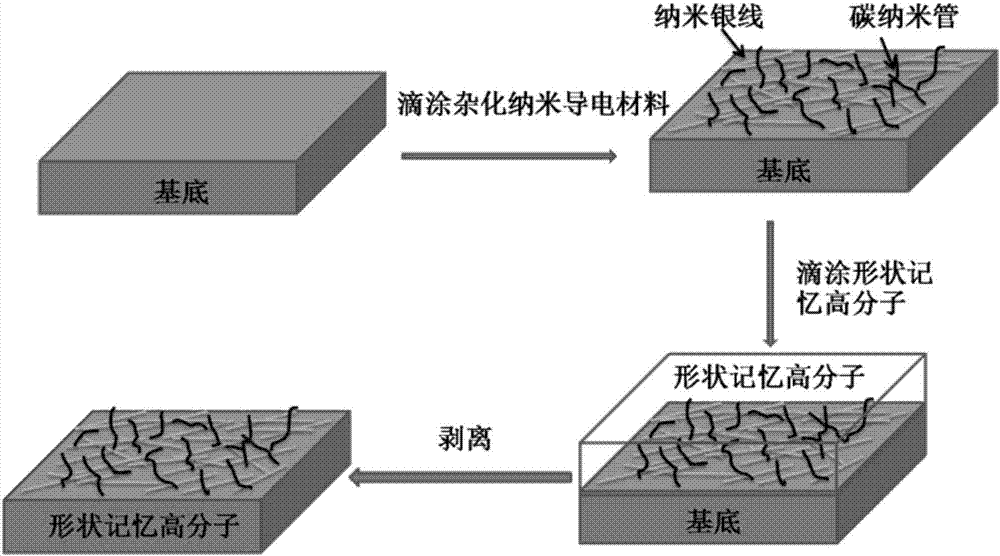

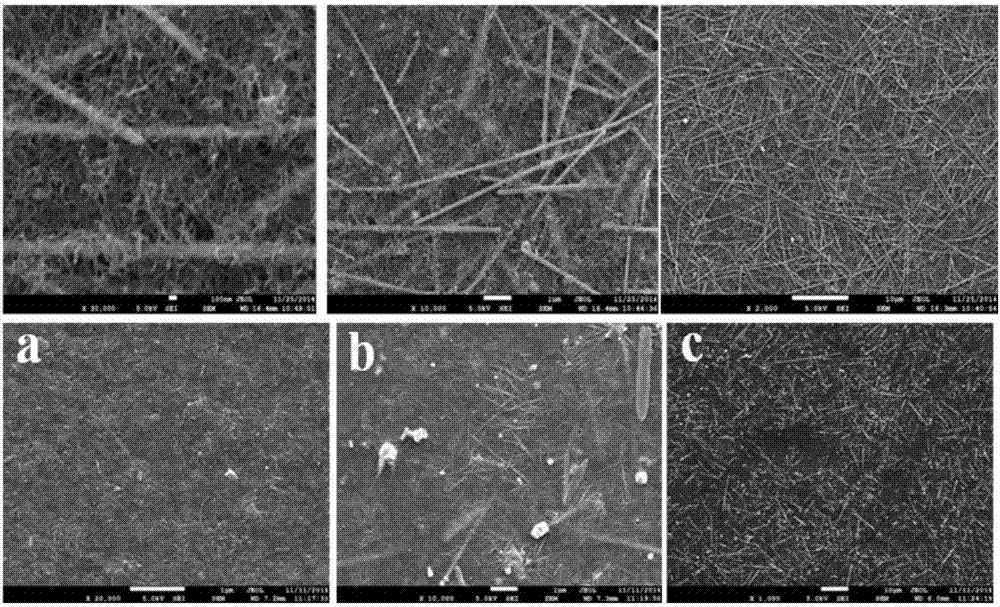

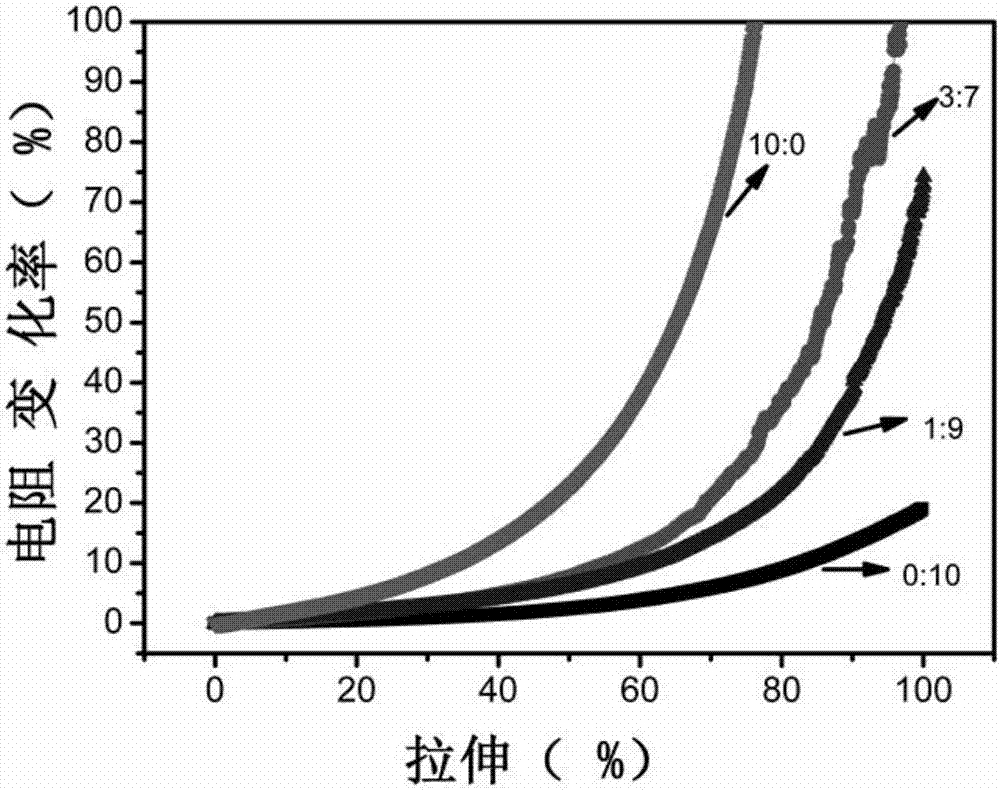

Adjustable strain-sensing high polymer with hybridized nano conducting material

Owner:GUANGDONG UNIV OF TECH

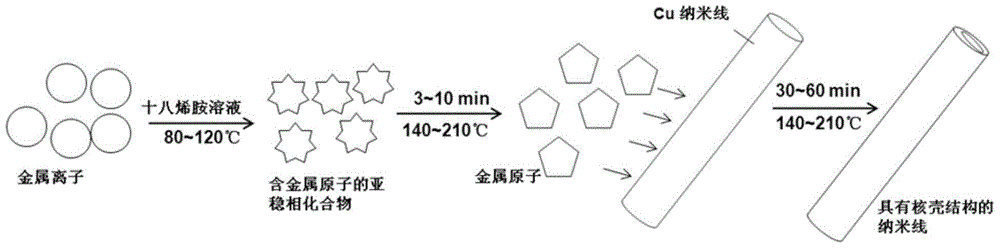

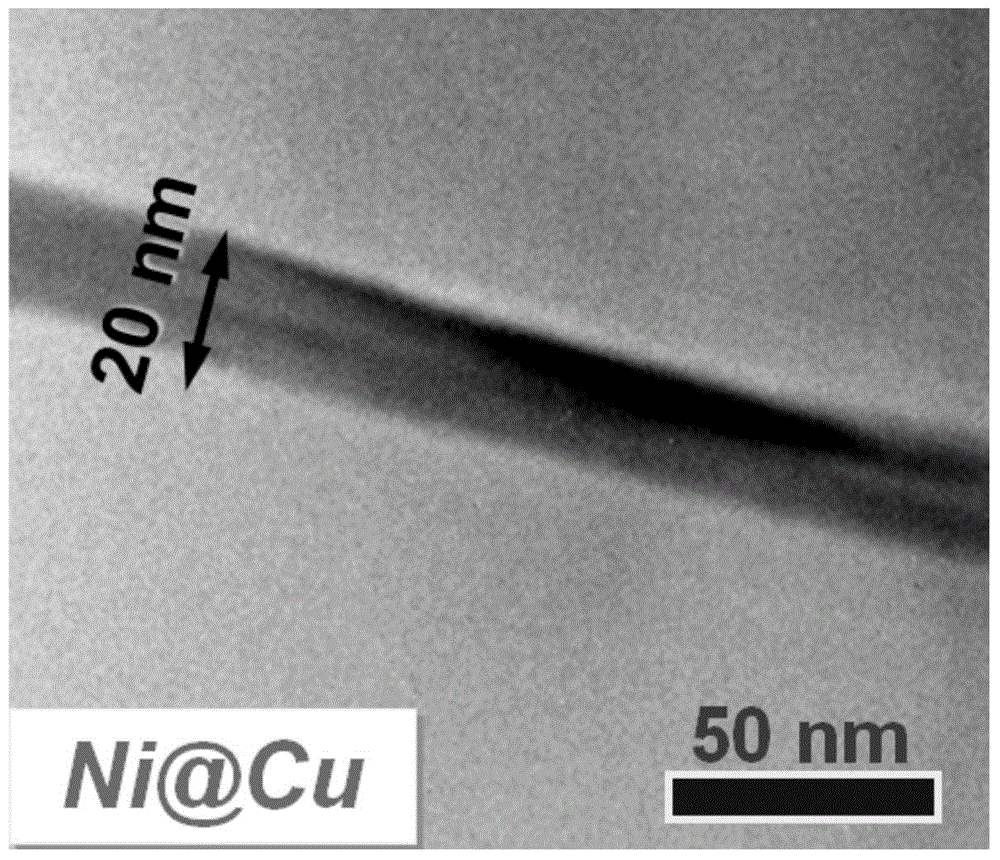

Method for preparing multifunctional core-shell nano-material by using alloy to wrap copper nanowires

ActiveCN104959626AImprove stabilityExcellent electrical propertiesMaterial nanotechnologyReaction temperatureAlloy

The invention discloses a method for preparing a multifunctional core-shell nano-material by using an alloy to wrap copper nanowires and relates to core-shell nano-materials. The Cu nanowires and metal organic salt are mixed and dissolved in an octadecene amine solution; a reaction vessel is heated, in a first stage, after the temperature of the solution in the reaction vessel is heated to 80-120 DEG C, N2 is pumped in, and the solution is heated for 10-20 min at a constant temperature; in a second stage, when the metal organic salt is acetylacetone nickel or acetylacetone zinc, the reaction temperature is 180-210 DEG C; when the metal organic salt is acetylacetone vanadium or acetylacetone titanium, the reaction temperature is 140-170 DEG C; when the reaction temperature reaches from 80-120 DEG C to a preset temperature, the solution is heated for 30-60 min at the constant temperature, and the reaction is finished; after the reaction solution is cooled, an n-hexane solution is added, ultrasound treatment is performed, the solution is transferred into a centrifugal tube to be subjected to centrifugation, the nanowire solid is deposited on the bottom of the centrifugal tube, and the Cu nanowires after being wrapped are obtained after the upper layer solution in the centrifugal tube is poured away.

Owner:XIAMEN UNIV

Conducting carbon fiber composite material as well as preparation method thereof

The invention relates to a conducting carbon fiber composite material as well as a preparation method thereof. The composite material comprises carbon fibers, an epoxy resin matrix material and inorganic nano-filler uniformly dispersed in the epoxy resin matrix material. The inorganic nano-filler consists of graphene and copper nanowires. The conducting performance of the carbon fiber composite material is effectively improved by means of the graphene and copper nanowires, so that the conductivity of the composite material is improved from 210S / cm to 6500S / cm.

Owner:JIAXING LONGSHINE CARBON FIBER PROD

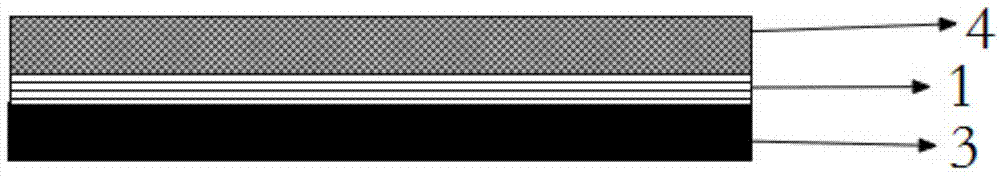

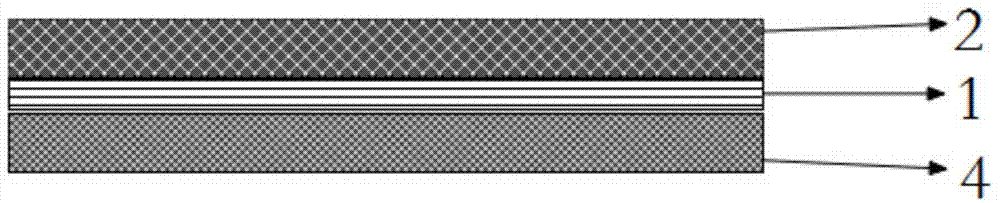

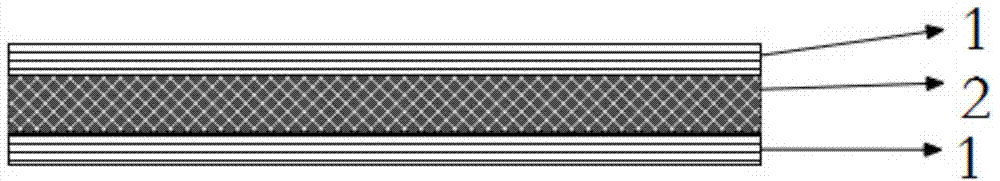

Flexible transparent conducting thin film based on graphene sandwich structure and preparation method thereof

InactiveCN104751934ALow costAvoid the disadvantage of being brittleCarbon-silicon compound conductorsCable/conductor manufactureFilm baseThin film solar cell

The invention discloses a flexible transparent conducting thin film based on a graphene sandwich structure. The flexible transparent conducting thin film is characterized by comprising at least two layers of graphene film layers and copper nano-wire layers which are alternately arranged between the adjacent graphene film layers. The flexible transparent conducting thin film provided by the invention is simple in preparation method, a traditional ITO (Indium Tin Oxide) transparent electrode can be replaced by the graphene / the copper nano-wire / the graphene sandwich structure with high transparency, high conductivity and flexibility, the defects that a traditional material is high in manufacturing cost and is likely to be crisped can be prevented, the efficiency and flexibility of a photoelectric device can be improved, the production cost of the photoelectric device can be reduced, and the transmission efficiency of electrons among graphene grains can be promoted by applying the copper nano-wires; meanwhile, compared with a graphene film, the conductivity of the transparent conducting thin film can be greatly improved, and the photoelectric conversion efficiency of a thin film solar cell can be improved.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com