Three-dimensional structure aerogel with copper nanowires coated with graphene and preparation method of three-dimensional structure aerogel and application of three-dimensional structure aerogel

A graphene-coated, copper nanowire technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor compression resilience and performance changes of materials, and achieve low cost, The effect of uniform pore distribution and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

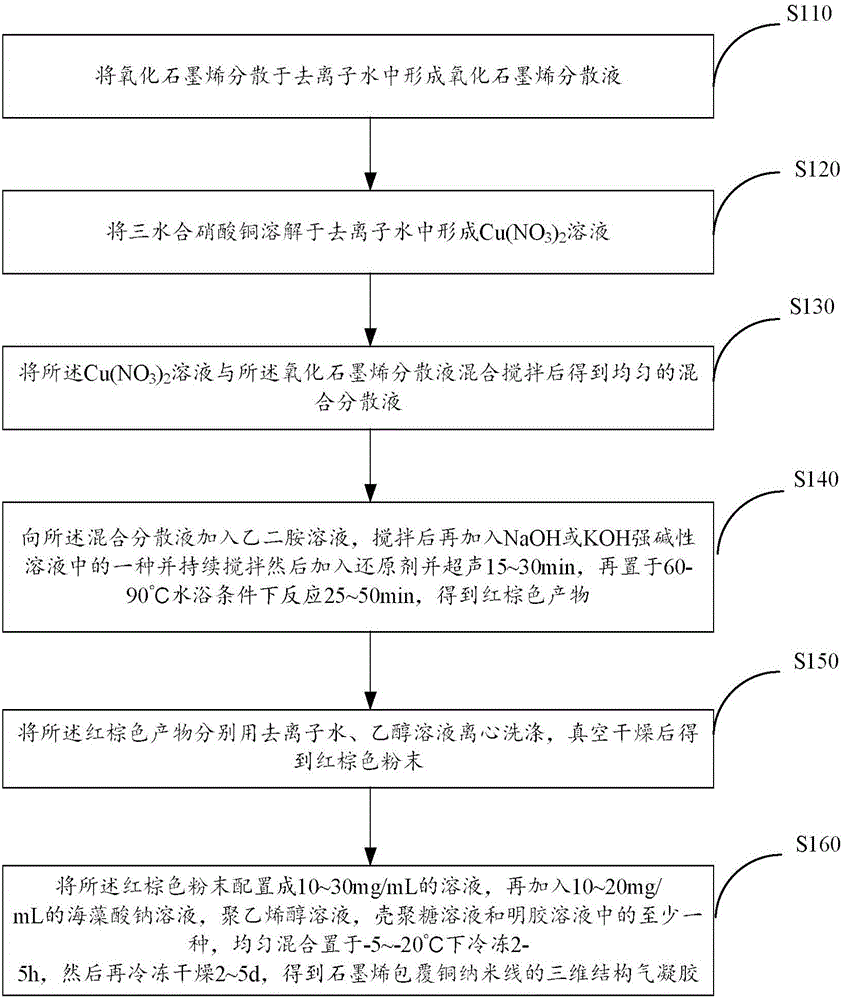

[0028] see figure 1 , the preparation method of the graphene-coated three-dimensional structure airgel of copper nanowire of one embodiment, comprises steps:

[0029] S110, dispersing the graphene oxide in deionized water to form a graphene oxide dispersion.

[0030] Specifically, the concentration of the graphene oxide dispersion is 1-5 mg / mL.

[0031] S120, dissolving copper nitrate trihydrate particles in deionized water to form Cu(NO 3 ) 2 solution.

[0032] Specifically, Cu(NO 3 ) 2 The concentration of the solution is 0.05-0.2 mol / L.

[0033] S130, the Cu(NO 3 ) 2 After the solution is mixed and stirred with the graphene oxide dispersion liquid, a uniform mixed dispersion liquid is obtained.

[0034] Specifically, 10-30 mL of 0.05-0.2 mol / L Cu(NO 3 ) 2 The solution is mixed with 5-15 mL of 1-5 mg / mL graphene oxide dispersion.

[0035] S140. Add an ethylenediamine solution with a mass fraction of 60%-99.5% to the mixed dispersion liquid, after stirring, add on...

Embodiment 1

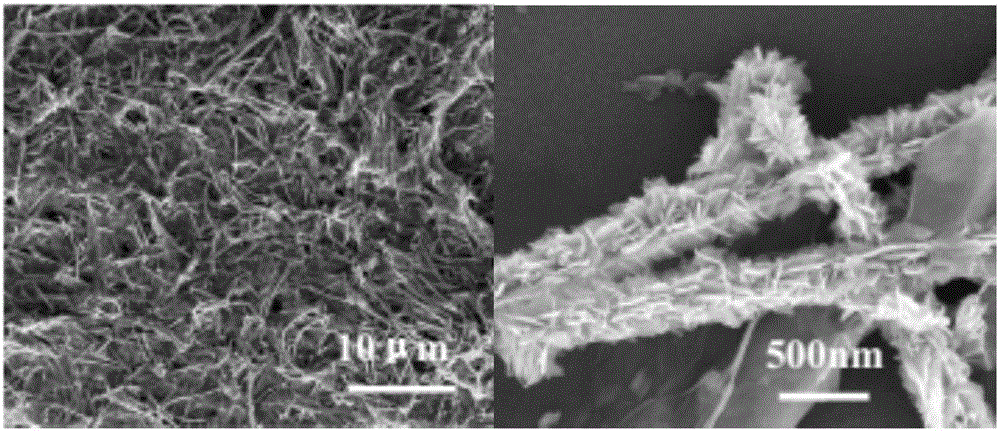

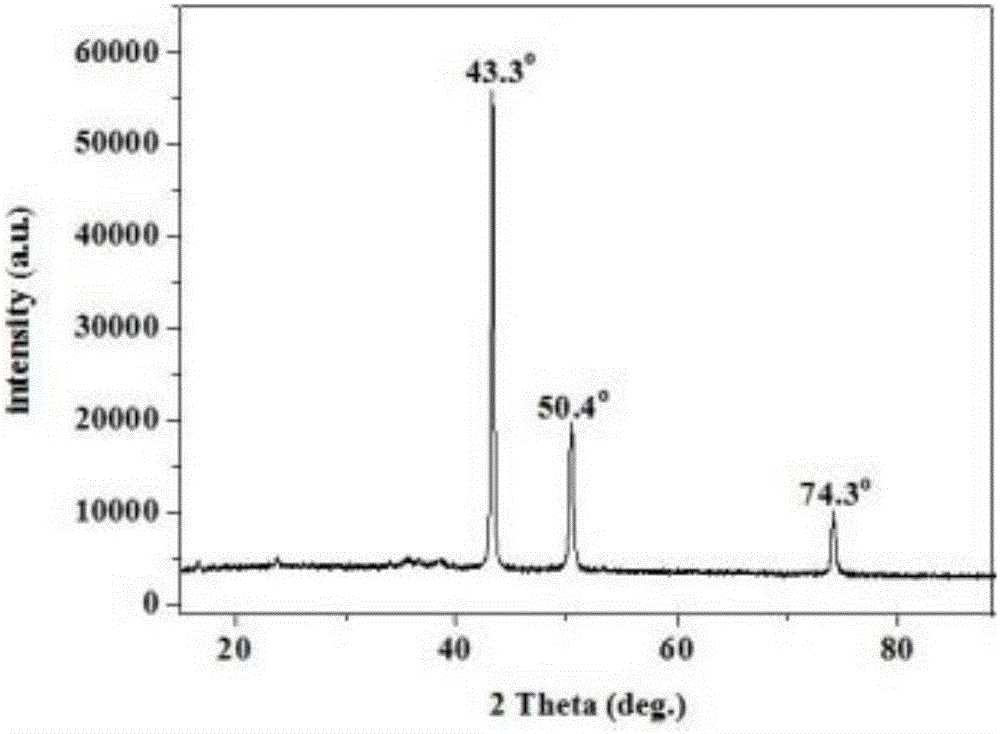

[0043] 20 mL of Cu(NO with a concentration of 0.05 mol / L 3 ) 2The solution was mixed evenly with 5 mL of graphene oxide aqueous solution with a concentration of 1 mg / mL. Then add 3mL of 80% ethylenediamine solution, stir for 20min, then add 250mL of 5mol / L NaOH solution and continue stirring for 45min, then add 0.3mL of 35% hydrazine hydrate solution, and sonicate for 25min, and the resulting solution is dissolved at 70 ℃ water bath conditions for 25min. After the reaction, a reddish-brown product will be obtained. The reddish-brown product was washed by centrifugation with deionized water and ethanol solution respectively, and the reddish-brown powder was obtained after vacuum drying.

[0044] Take an appropriate amount of reddish-brown powder, prepare a 10mg / mL solution, take 3 small bottles, and prepare polyvinyl alcohol solutions with a concentration of 10mg / mL, 15mg / mL, and 20mg / mL respectively. Take 3 beakers (marked A~C respectively) and add 1mL of 10mg / mL graphene-...

Embodiment 2

[0046] 20 mL of Cu(NO with a concentration of 0.1 mol / L 3 ) 2 The solution was mixed evenly with 5 mL of graphene oxide aqueous solution with a concentration of 2 mg / mL. Then add 4 mL of 99% ethylenediamine solution, stir for 20 min, then add 350 mL of 10 mol / L KOH solution and continue stirring for 45 min. Finally, 0.4 mL of 85% hydrazine hydrate solution was added and ultrasonicated for 25 min, and the resulting solution was reacted in a water bath at 80° C. for 30 min. After the reaction, a reddish-brown product will be obtained. The reddish-brown product was washed by centrifugation with deionized water and ethanol solution respectively, and the reddish-brown powder was obtained after vacuum drying.

[0047] Take an appropriate amount of reddish-brown powder and make it into a 20mg / mL solution. Take 3 small bottles and prepare sodium alginate solutions with concentrations of 10mg / mL, 15mg / mL and 20mg / mL respectively. Take 3 beakers (marked D~F respectively) and add 1mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com