Patents

Literature

97 results about "Minor metals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Minor metals is a widely used term in the metal industry that generally refers to metals which are a by-product of smelting a base metal. Minor metals do not have a real exchange, and are not traded on the London Metal Exchange (LME).

ICP-MS measuring method of trace metal impurities in high purity lead

InactiveCN101551357AEasy to operateAvoid pollutionMaterial analysis by electric/magnetic meansTotal solid contentMinor metals

The invention relates to an ICP-MS measuring method of trace metal impurities in high purity lead, which adopts a high-purity nitric acid dissolving sample and uses the electrolytic method to remove lead in the high purity nitric acid dissolving sample, and utilizes inductive coupled plasma mass spectrometer and adopts peak jumping mode to scan and test blank, work-curve standard solution and sample elements to be detected so as to obtain the content of the elements to be detected. The ICP-MS measuring method of trace metal impurities in high purity lead is convenient in operation and can effectively eliminate matrix effect caused by excessively high total solid content and avoid pollution during the preparation process of samples, thus greatly reducing memory effect and obviously increasing measuring accuracy. The ICP-MS measuring method of trace metal impurities in high-purity lead is applicable to the analysis and testing of the content of a plurality of trace metal impurities.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

Conversion type organic binding dry film lubricant and preparation thereof

InactiveCN101302459AGood lubrication effectExtended service lifeAdditivesBase-materialsLubricationChemistry

The invention provides convertible organic bonding dry film lubricant and a method for preparing the same, belonging to the lubrication technical field. The lubricant consists of macromolecular resins, solid lubricant, metallic conversion agent, talcum powder and dispersant. The method for preparing the convertible organic bonding dry film lubricant is as follows: firstly, the macromolecular resins are dissolved into a part of the dispersant to obtain macromolecular resin dispersion liquid; secondly, the solid lubricant, the talcum powder and the metallic conversion agent are dispersed into the other part of the dispersant and fully grinded to obtain the other dispersion liquid; thirdly, after the macromolecular resins are fully dissolved, the two parts of dispersion liquid are mixed and stirred at a high temperature, and the convertible organic bonding dry film lubricant is prepared. The lubricant provided by the invention can form a lubricating solid dry film on rustless or rusty metallic surface through synchronous implementation of conversion of metals and trace metal oxides and spray coating of the lubricant, and has the advantages of good bonding force with the metals, rust protection, lubrication, long service life, quick drying, convenient use and low cost; and the paint film can endure the high temperature of 200 DEG C and is particularly suitable for repair and maintenance of parts and components.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

ICP-AES detection method for trace element content in lead concentrate

InactiveCN109827952AAccurate contentAccurate measurementAnalysis by thermal excitationTrace metalCobalt

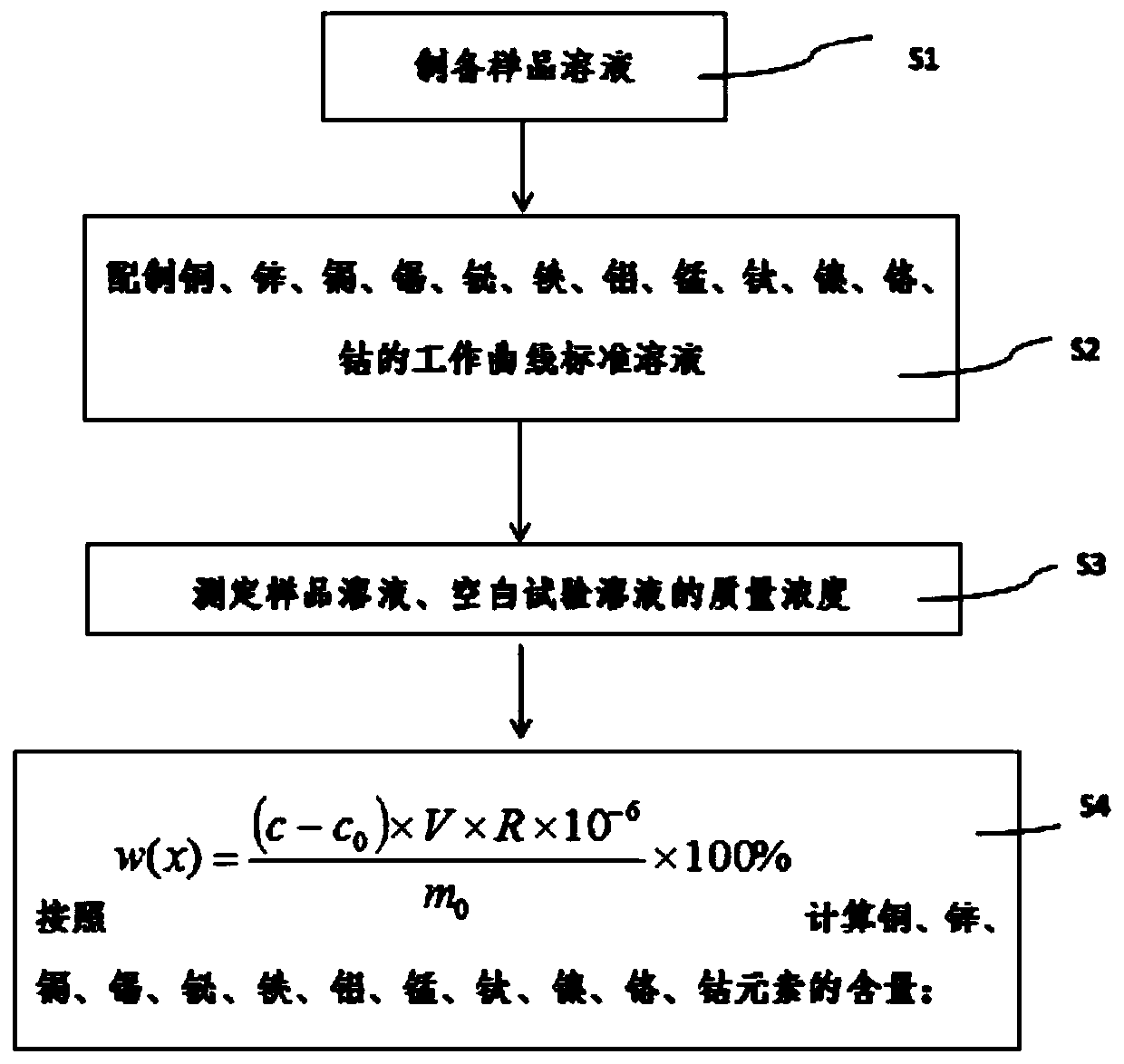

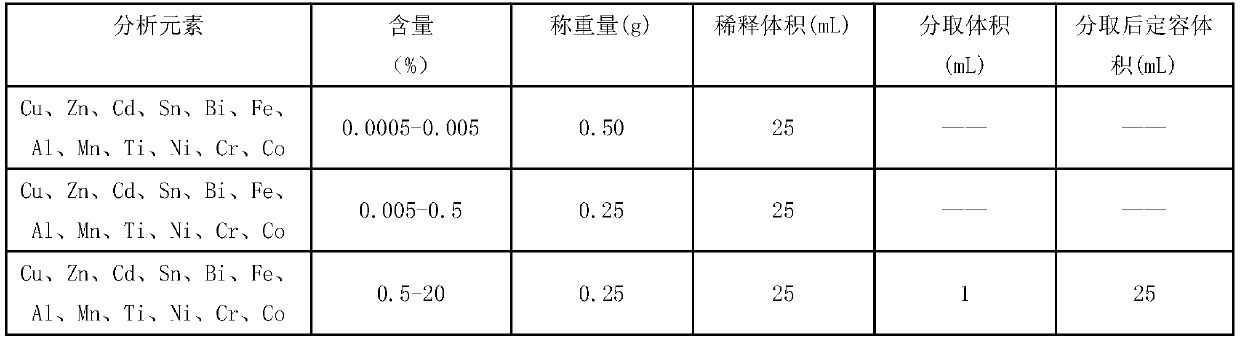

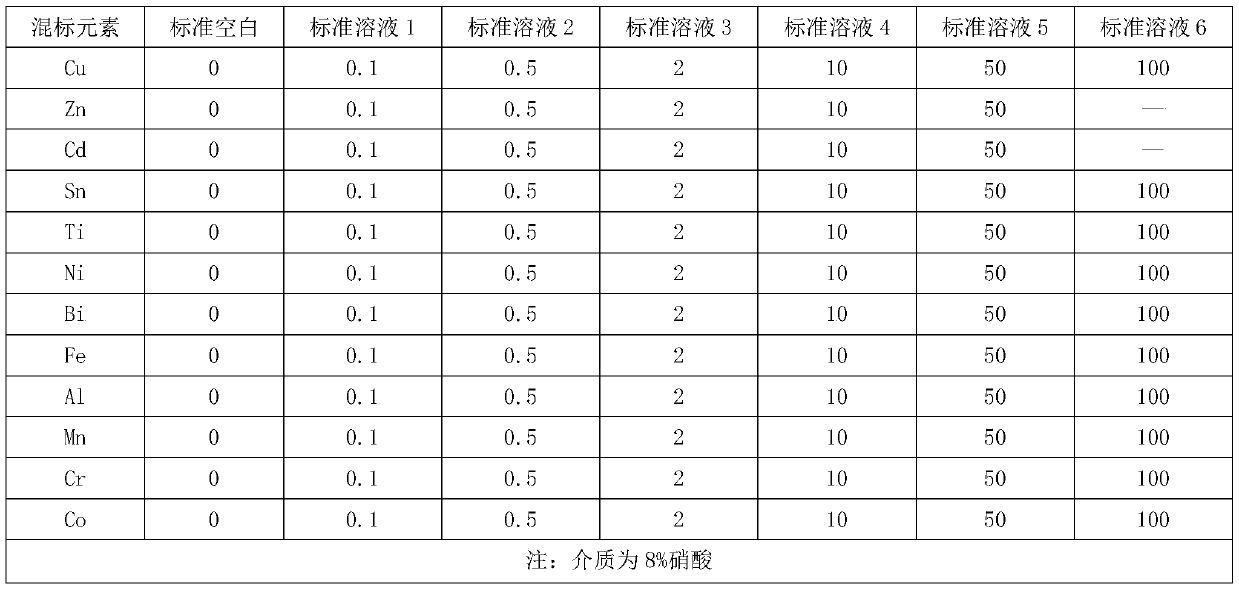

The invention relates to an ICP-AES detection method for trace element content in a lead concentrate. The trace elements comprise copper, zinc, cadmium, tin, antimony, iron, aluminum, manganese, titanium, nickel, chromium and cobalt elements. The objective of the invention is to solve the problems that the detection of multiple metal elements in the lead concentrate is not accurate, specially themeasurement for the content of the trace metal elements is not accurate. The method comprises the steps of: preparing a sample solution; preparing a working curve standard solution of copper, zinc, cadmium, tin, antimony, iron, aluminum, manganese, titanium, nickel, chromium and cobalt, measuring the mass concentrations of the sample solution and a blank test solution; and calculating the contentof the copper, zinc, cadmium, tin, antimony, iron, aluminum, manganese, titanium, nickel, chromium and cobalt elements according to formulas. The measurement result is accurate, the detection range islarge, the content of multiple trace elements is accurately measured, and the ICP-AES detection method can be widely applied to official testing institutions or third-party detection.

Owner:滕亚君

Preparation method of electronic grade tetraethoxysilane

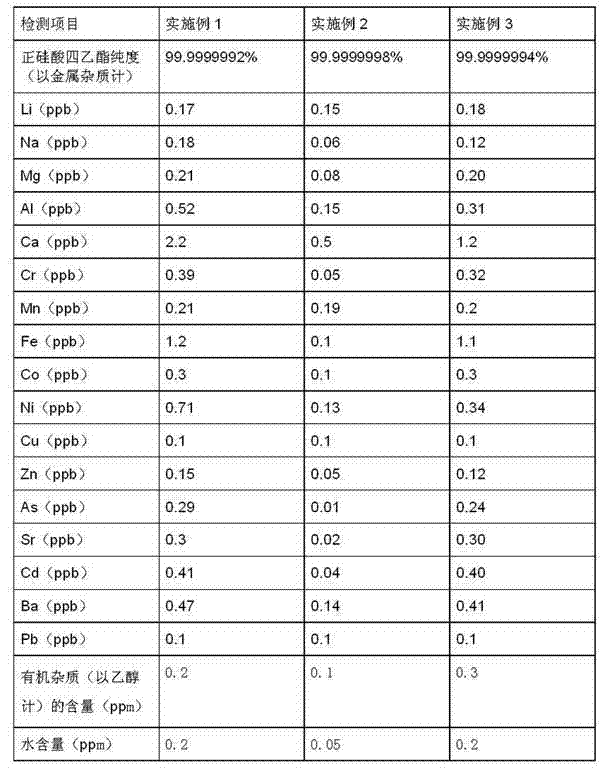

ActiveCN103772424AEfficient removalEase of mass productionSilicon organic compoundsMicropore FilterMinor metals

The invention relates to a preparation method of electronic grade tetraethoxysilane and particularly relates to a preparation method of electronic grade tetraethoxysilane for chemical vapor deposition in semiconductor industry. The preparation method comprises the steps of firstly complexing most of metal impurities in raw materials by using a complexing agent, and then filtering by using a microporous filter of 0.1 micron; passing through a cation exchange tower, a quartz plate type distillation tower and a sub-boiling distiller, strictly controlling temperature, and removing trace metal impurities, ethanol, other organic impurities and water. The preparation method provided by the invention adopts conventional purification equipment and has the advantages of convenience in operation, effect of being conductive to industrial large-scale production and low product cost.

Owner:贵州威顿晶磷电子材料股份有限公司

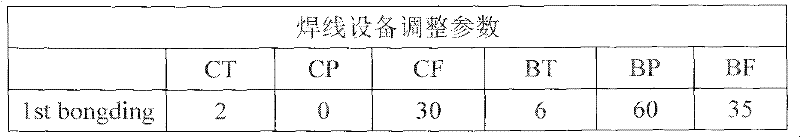

Surface palladium-plated bonding brass wire

ActiveCN102130067BUniform surfaceFully deformedSemiconductor/solid-state device detailsVacuum evaporation coatingMinor metalsSingle crystal

The invention discloses a surface palladium-plated bonding brass wire comprising a brass core taking brass as a main component and a palladium layer formed by plating on the brass core. The surface palladium-plated bonding brass wire is characterized in that trace metal for improving the extension performance is added in the brass core taking the brass as the main component; a single crystal is smelt and drawn to form a brass alloy core wire; the palladium is plated on the surface of the brass alloy core wire; and the surface palladium-plated bonding brass wire is formed in a superfine drawing manner. Compared with the prior art, the invention has the benefits that the surface palladium-plated bonding brass wire has better final plasticity deformation capability in the subsequent superfine drawing process without intermediate annealing; the percentage elongation of the surface palladium-plated bonding brass wire is at least 11 percent; the deformation of a palladium-plated layer in the pressure processing flow is consistent; the surface of the surface palladium-plated bonding brass wire is uniform, compact and complete, which is especially beneficial to full deformation during welding bonding, and thus the pulling strength and the reliability are improved. In addition, the cost of products can be controlled to be about 6 yuan / 100 meters and the products have high cost performance.

Owner:SICHUAN WINNER SPECIAL ELECTRONICS MATERIALS

Fe/pressed active carbon catalyst and preparation method thereof

InactiveCN101480614ASolve the catalytic activityAddressing Catalytic SelectivityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsActivated carbonMinor metals

The invention discloses a catalytic conversion agent of tar in gas for a biomass boiler, which consists of the following ingredients by weight percent: 0.1% to 0.3% of Na2CO3, 0.1% to 0.3% of K2CO3, 0.1% to 1% of Fe3O4, 0.5% to 0.8% of NaCl, 0.5% to 0.8% of KCl, 0.3% to 0.5% of KOH, 0.3% to 0.5% of NaOH, 0.1 to 1% of Ni(NO3)2 6H2O, 0.1 to 1% of KNO3, 0.1 to 0.5% of Ce(NO3)3 6H2O, 20% to 46% of dry attapulgite powder and 46% to 75% of dry dolomite powder, wherein the dry dolomite powder is the dry powder with the grain size not less than 325 meshes, the water content less than 1% and the CaCO3 / MgCO3 ratio ranging from 1 to 1.5, and the dry attapulgite powder has the grain size not less than 325 meshes, the water content is less than 1%, the content of MgO is not less than 23% and the content of SiO2 is not more than 56%. By using the catalyst, tar in biomass gasified gas can be converted into combustible small molecules, so as to reduce the hazard caused by tar remarkably.

Owner:BEIJING UNIV OF CHEM TECH

Method for improving methane yield by organic waste water anaerobic fermentation

InactiveCN101157937AIncrease productionImprove bioavailabilityWaste based fuelFermentationChemical industryTransformation efficiency

The invention relates to a method used for raising the output of marsh gas by using anaerobic fermentation of organic effluent water, which pertains to the technical field of biological treatment of effluent water. The invention adopts simulated organic effluent water or practical wastewater from chemical industry as treatment objects, by adding trace metal element Co and metal ion chelating agent to an anaerobic reactor to improve the biological availability of trace metal elements which are essential for methanogen and promote the growth and activity of methanogen, thereby, methane output and transformation efficiency of contaminating material of the system is improved. The method needs only extreme micro-amount of trace metal element Co and metal ion chelating agent, therefore, the invention is not only convenient to be manipulated with high efficiency and but also low in cost which leads the invention to be extensively applicable in engineering practice.

Owner:JIANGNAN UNIV

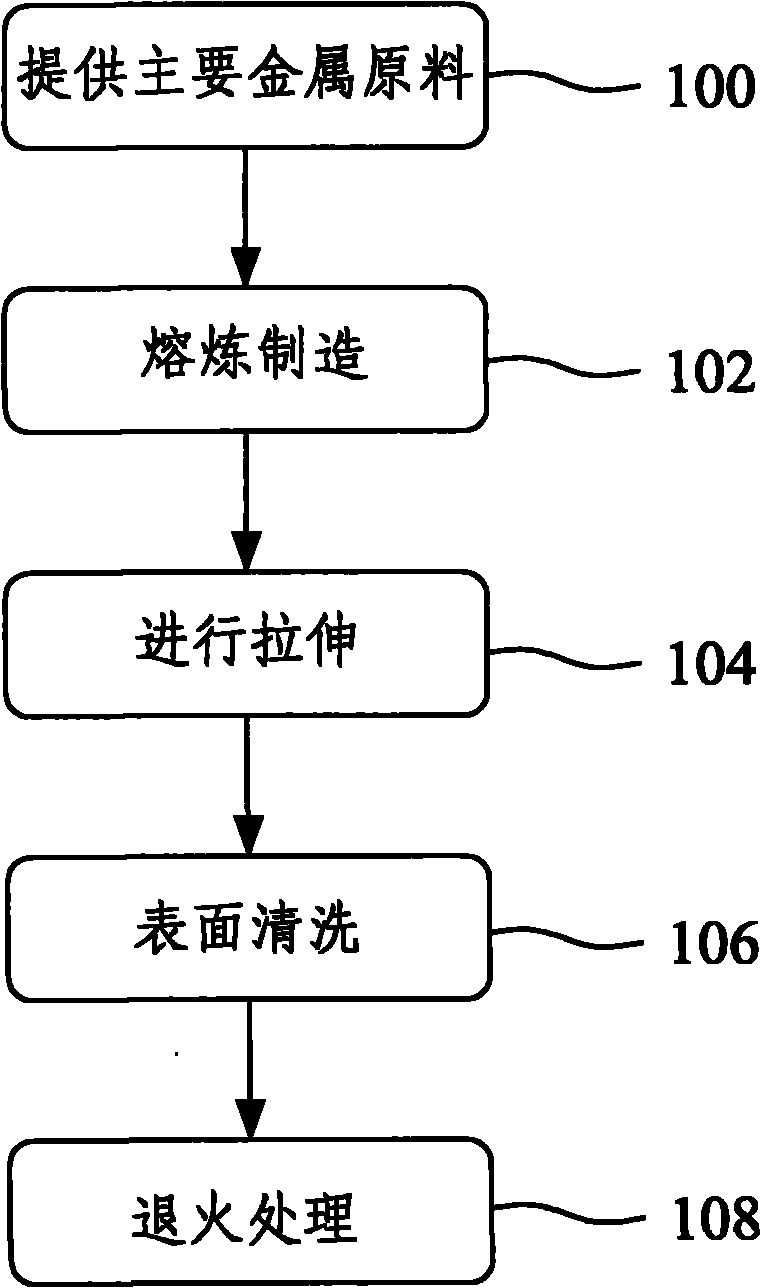

Gold-silver-palladium alloy single-crystal bonding wire and manufacturing method thereof

InactiveCN103779308ALow priceReduce performanceSemiconductor/solid-state device detailsSolid-state devicesMinor metalsMetallic materials

Provided are a gold-silver-palladium alloy single-crystal bonding wire and a manufacturing method thereof. The main material of the gold-silver-palladium alloy single-crystal bonding wire is high-purity silver, and the gold-silver-palladium alloy single-crystal bonding wire further comprises gold, palladium, europium, lanthanum and other trace metal materials. The gold-silver-palladium alloy single-crystal bonding wire comprises, by weight, 98.713%-99.157% of the silver, 0.8%-1.2% of the gold, 0.04%-0.08% of the palladium, 0.002%-0.004% of the europium and 0.001%-0.003% of the lanthanum. The manufacturing method comprises the steps that the high-purity silver with the purity higher than 99.9999% is extracted and manufactured into silver alloy ingots, as-cast gold-silver-palladium alloy single-crystal main wires are manufactured, the single-crystal main wires are manufactured into single-crystal wires of around 1mm through a drawing mode, heat treatment is carried out on the single-crystal wires, and then gold-silver-palladium alloy single-crystal bonding wires of different specifications are manufactured through precise drawing, heat treatment and cleaning.

Owner:江西蓝微电子科技有限公司

Gold-plating gold and silver palladium alloy single-crystal bonding filament and manufacturing method thereof

InactiveCN103779309ALow priceImprove performanceSemiconductor/solid-state device detailsSolid-state devicesMinor metalsIngot

The invention provides a gold-plating gold and silver palladium alloy single-crystal bonding filament and a manufacturing method thereof. The bonding filament is mainly made of high-purity silver and comprises metal, palladium, europium, lanthanum and other trace metal materials. The bonding filament comprises, by weight, 97.713%-98.157% of silver, 1.8%-2.2% of gold, 0.04%-0.08% of palladium, 0.002%-0.004% of europium and 0.001%-0.003% of lanthanum. The manufacturing method of the gold-plating gold and silver palladium alloy single-crystal bonding filament comprises the steps that high-purity silver with the purity larger than 99.9999% is extracted, a silver alloy ingot is manufactured, a cast-condition gold and silver palladium alloy single-crystal bus is manufactured, the single-crystal bus is pulled to be a single-crystal filament which is about 1mm long, after thermal processing, a pure-gold protection layer is electroplated on the surface of the single-crystal filament, and gold-plating gold and silver palladium alloy single-crystal bonding filament of different specifications are manufactured after precise pulling, thermal processing and washing.

Owner:江西蓝微电子科技有限公司

Copper-based bonding wire with anti-oxidation coating and processing technology thereof

ActiveCN102332439ALow costCreate profit marginsSingle bars/rods/wires/strips conductorsSemiconductor/solid-state device detailsCeriumLanthanum

The invention provides a processing technology of an anti-oxidation coating of a copper-based bonding wire, which is characterized in that trace metal elements such as La (lanthanum), Ce (cerium) and Pt (platinum) are added to a copper base material to obtain a master alloy base material, and a gold layer is plated on a fine metal wire surface made of the master alloy base material so as to obtain the copper-based bonding wire, wherein the purities of the copper and the gold are over 99.99%. The invention also provides a manufacturing process of the copper-based bonding wire, comprising the following steps of: mixed smelting, drawing, washing, gold-plating, annealing, winding, packaging and the like. The copper-based bonding wire integrates the advantages of a copper bonding wire and a gold bonding wire, and has the characteristics of good resistance to oxidation and conductivity, low radian and price, improved hardness of a single copper material and the like. The copper-based bonding wire is packaged commonly, can be preserved for a long time at normal temperature, and is a substitute for an expensive gold bonding wire.

Owner:浙江佳博科技股份有限公司

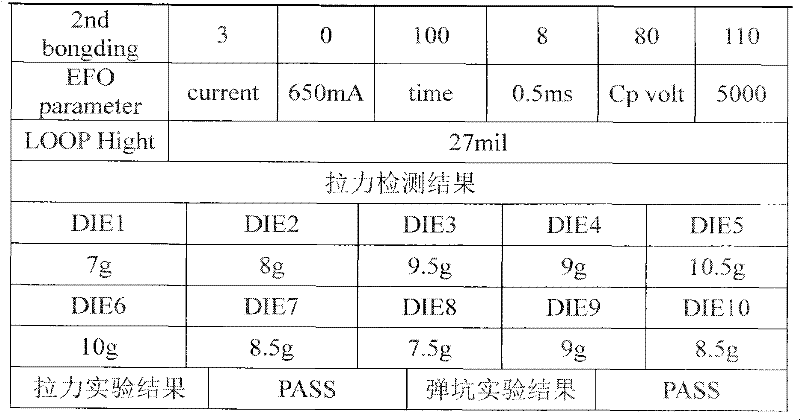

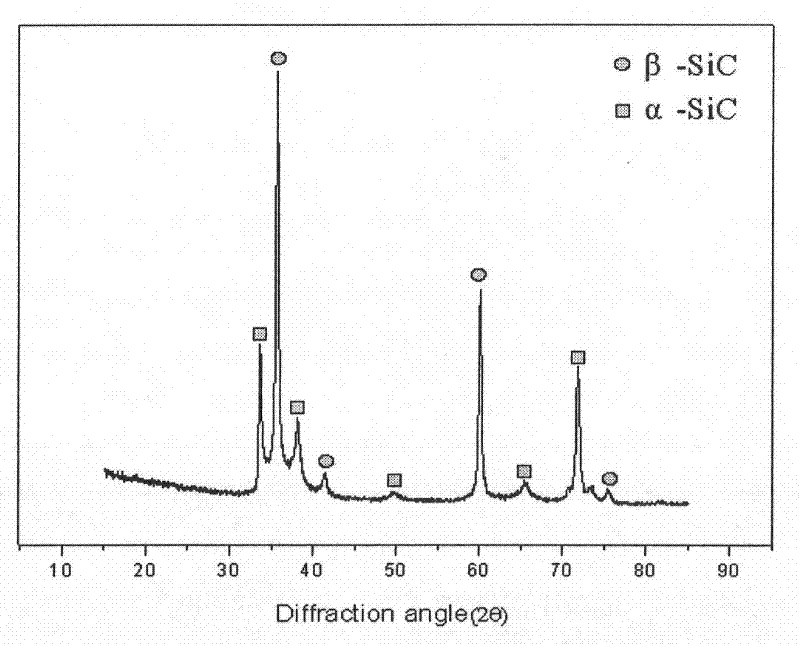

Method for preparing high-temperature resistant silicon carbide

The invention relates to a method for preparing high-temperature resistant silicon carbide. The method is technically characterized by comprising the following steps of: uniformly mixing liquid polycarbosilane and organic metal salt, crosslinking and curing, performing ball-milling, cracking at the temperature of between 900 and 1,100 DEG C, and performing high-heat treatment at the temperature of between 1,600 and 1,850 DEG C to obtain the crystalline silicon carbide containing a trace amount of metal elements. A SiO2 protection membrane which is obtained by performing high-temperature oxidation on the synthesized silicon carbide is SiO2 solid solution containing a trace amount of metal elements. The trace amount of metal elements reduces the activity of SiO2, and increases the conversion temperature of active and passive oxidation of the silicon carbide, so that the use temperature of the silicon carbide is increased. Compared with the prior art, the method has the advantages that: by introducing a trace amount of metal elements into the silicon carbide, the use temperature of the silicon carbide is increased from 1,700 to 1,800-1,850 DEG C, and equipment used by the preparationprocess is simple, safe and reliable, is easy to control and contributes to large-scale production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

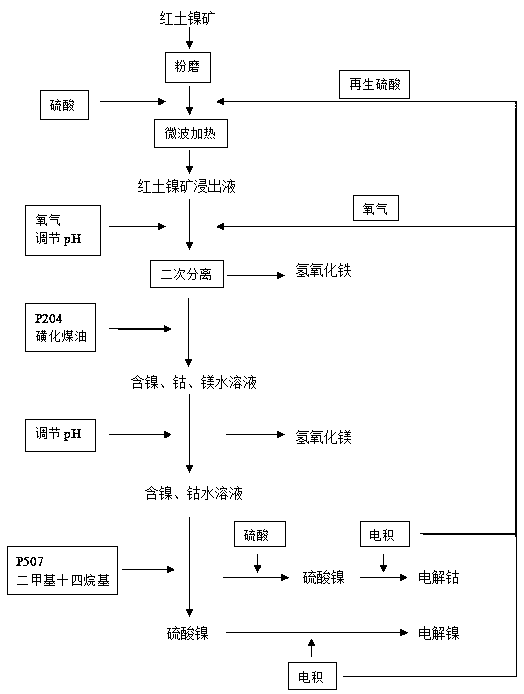

Treatment method for separating and extracting nickel, cobalt, magnesium and iron from laterite nickel ores

InactiveCN108486369APromote leachingImprove leaching ratePhotography auxillary processesProcess efficiency improvementCyclic processLiquid waste

Owner:王颖皓

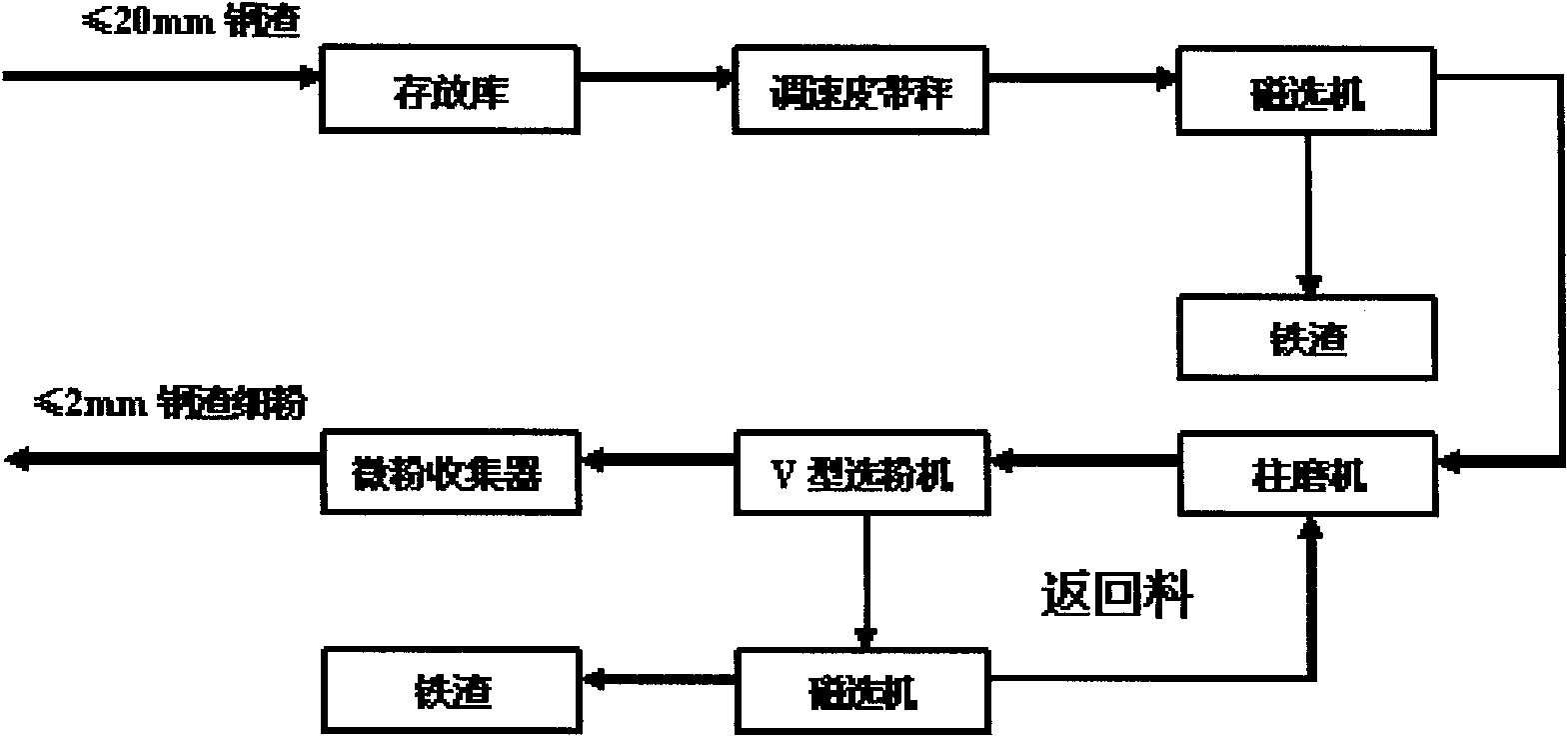

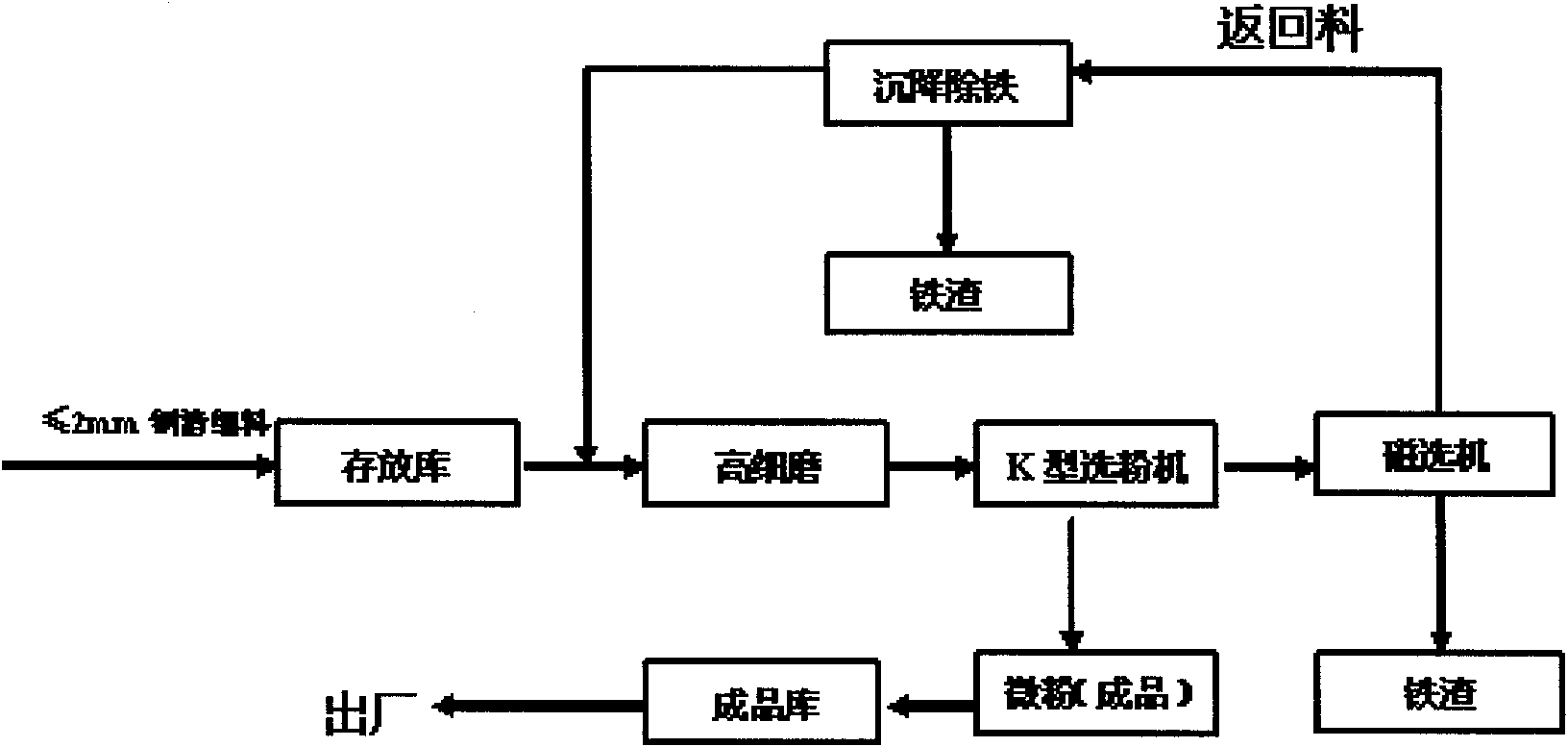

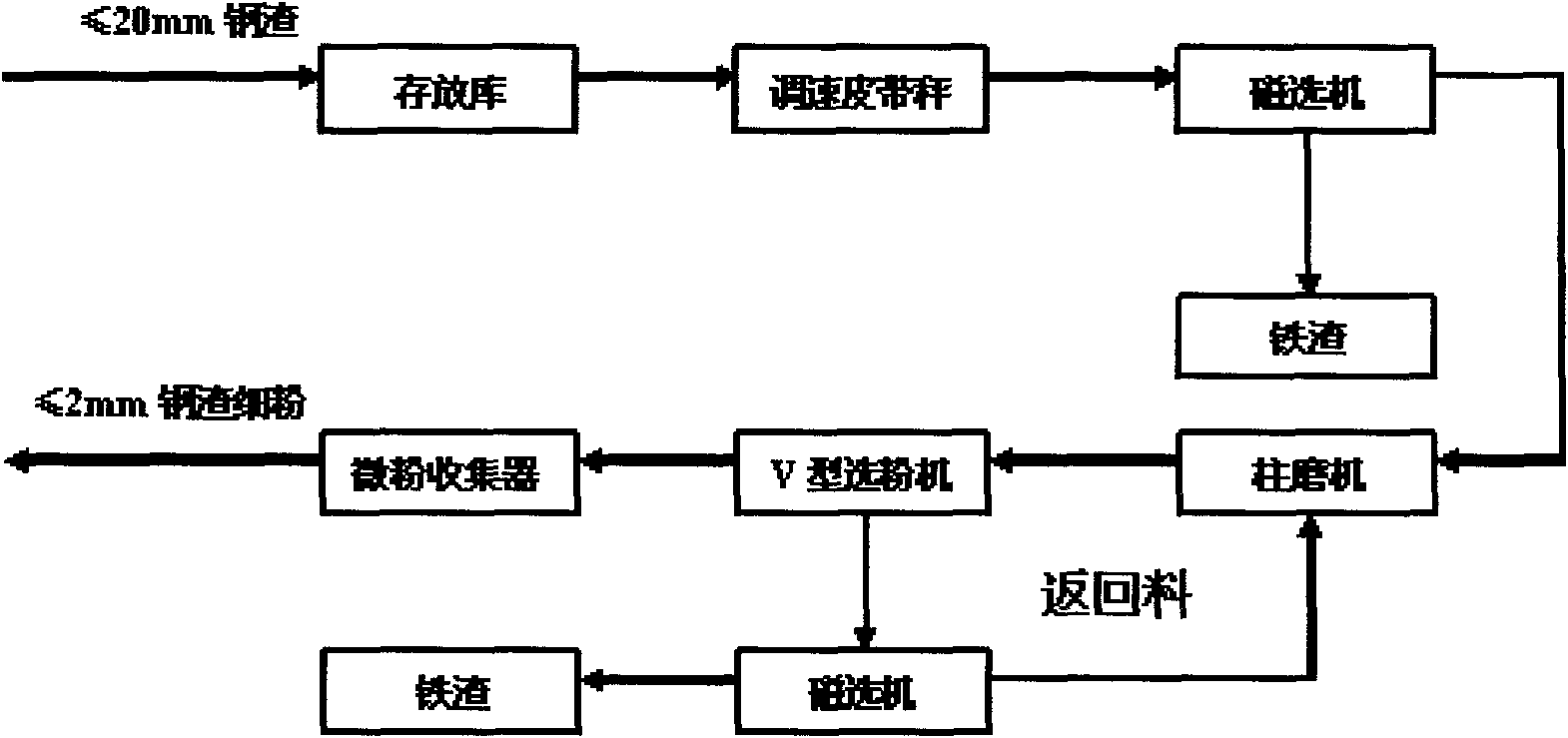

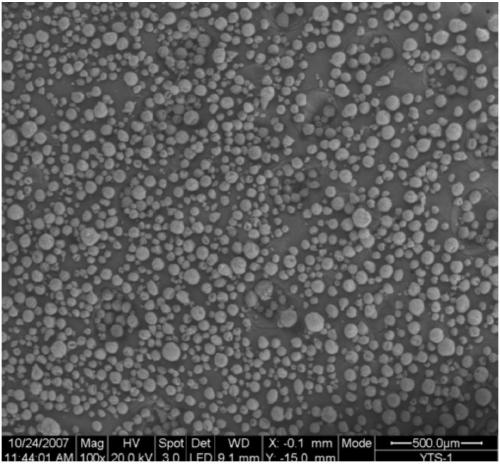

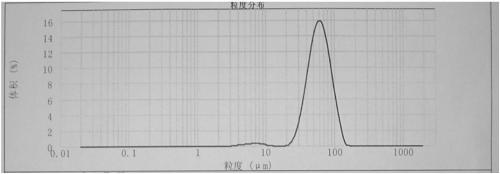

Preparation technology of superfine steel slag micropowder and production process

ActiveCN101880736AEfficient removalLow iron contentProcess efficiency improvementMagnetic separationMinor metalsSlag

The invention relates to a preparation technology of superfine steel slag micropowder and a production process thereof. Metal iron included in steel slag is separated and recycled for many times in circulation by selecting a column mill, a V-shaped powder separator and a magnetic separator as a pre-grinding closed cycle system; and trace metal iron included in superfine steel slag micropowder is separated and recycled for many times by selecting a high-fine mill, a K-type powder separator, a settling chamber and the magnetic separator to form a final-grinding closed cycle system. Accordingly, the prepared superfine steel slag micropowder has the specific surface area of larger than or equal to 600m<2> / kg, wherein the superfine steel slag micropowder with grain diameter smaller than 30 mu m accounts for more than 90 percent of the total mass and has the metal iron content of not more than 0.5 percent.

Owner:SHANGHAI HAILI NEW ENVIRONMENTAL PROTECTION BUILDING MATERIAL CO LTD

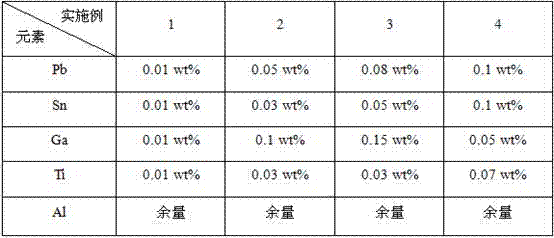

Aluminum alloy anode material, and casting method and application thereof

The invention discloses an aluminum alloy anode material, and a casting method and an application thereof. The aluminum alloy anode material is prepared through casting Pb, Sn, Ga, Ti and Al. The casting method concretely comprises the following steps: 1, refining alloy: (1) placing pure aluminum blocks in a shaft furnace in batches, and heating for melting the pure aluminum blocks; (2) adding trace metal elements into the high temperature shaft furnace after all the aluminum blocks are completely molten; (3) stirring all above components by a graphite rod after all the components are completely molten; and (4) adding hexachloroethane, and removing the waste residues in the molten aluminum; and 2, carrying out casting molding: (1) coating the internal surface of a die with a layer of a release agent, and carrying out heating and heat insulation; and (2) pouring the molten aluminum alloy into the die, and casting the aluminum alloy to form aluminum ingots. The aluminum alloy anode material has low overpotential and high hydrogen evolution overpotential, so an electrode made of the material has high electrochemical activity and high anode utilization efficiency during the running of a battery.

Owner:HARBIN INST OF TECH

Refining method for insect wax

InactiveCN101225345AImprove refining yieldHigh melting pointFatty substance recovery/refiningFatty substance recoveryWaxMinor metals

The invention discloses a refined method of Chinese wax, comprising 1) acid cleaning to removal impurity, which means acidic solution is adopted to removal the phospholipids and micro metal ion in the liquated raw wax; 2) adsorbing to decolor, which means the floridin and the silicon dioxide are adopted to decolor and removal the protein in the liquated raw Chinese wax under vacuum state. The refined method of Chinese wax has the advantages of simple technique and convention operation. The appearance of the made Chinese wax and the physicochemical index can reach the first wax standard set by < trading cooperative standards of P.R.C- Chinese wax [GH011-80] >, and also has the advantages of increasing the productive rate and the purity of the Chinese wax and lowering the productivity energy consumption.

Owner:THE RES INST OF RESOURCES INSECTS RIRI OF THE CHINESE ACADEMY OF FORESTRY

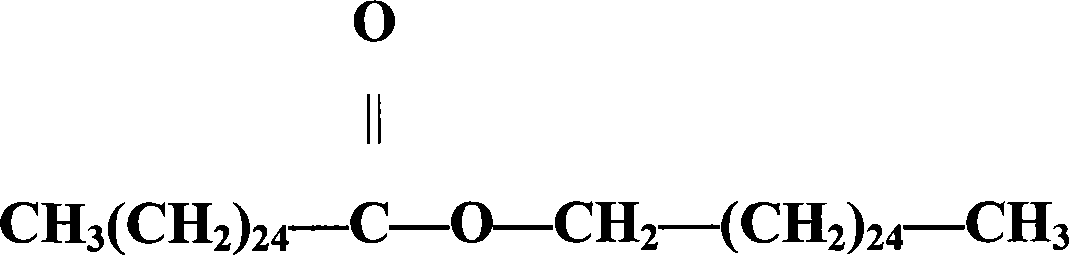

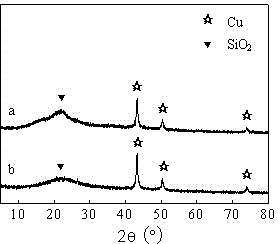

Method for preparing nano metal catalyst

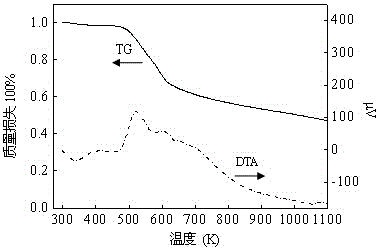

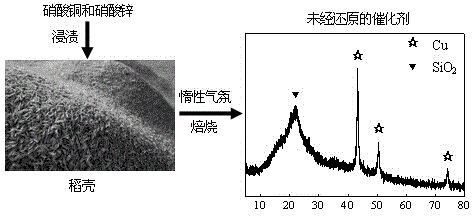

InactiveCN104941650AReduce consumptionHigh activityOrganic compound preparationHydroxy compound preparationMinor metalsTrace element

The invention discloses a method for preparing a nano metal catalyst, and relates to a catalyst preparation method. The method fully utilizes the elements such as silicon, carbon and trace metals contained in rice husks, uses SiO2 generated after calcinating a silicon source in the rick husks as a carrier of the catalyst, and uses organic matters and a carbon source as a reducing agent during the calcination of the catalyst. Under the condition of low temperature calcination, metal oxides can be reduced to a metal Cu simple substance through the reducing agent without additional reducing processes, so that energy is reduced; the trace element K contained in the rice husks is used as an auxiliary of the catalyst, so that the activity of the catalyst is remarkably improved; when being used in the low temperature methanol synthesis reaction, the catalyst shows good reaction activity and selectivity of methanol. According to the invention, the nano metal catalyst is a reduced state metal Cu-based catalyst, and no additional reducing process is required; the prepared catalyst shows relatively high Cu metal dispersion degree and relatively small metal Cu particles.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

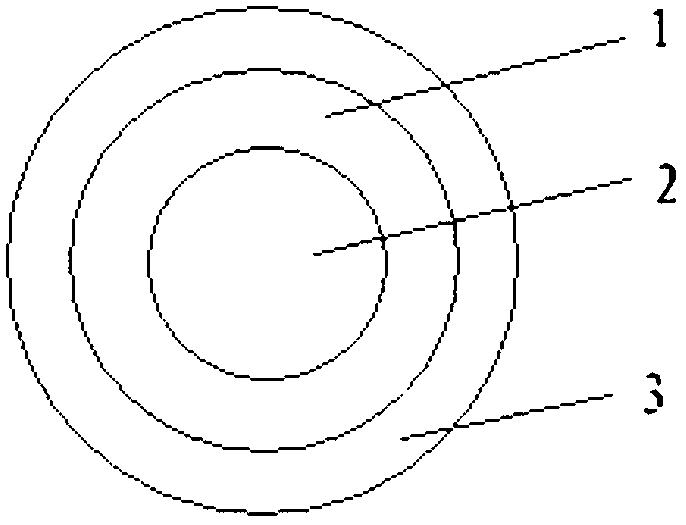

Manufacturing method of palladium-plated gold-plated double-plating bonding copper wire

InactiveCN103219249ASemiconductor/solid-state device detailsSolid-state devicesMinor metalsCopper wire

The invention discloses a double-plating bonding copper wire of a three-layer structure. The innermost layer of the copper wire is a copper core formed due to the fact that trace metal elements are added to high-purity copper, the surface of the copper core is plated with a pure-palladium conductive layer, and the surface of the pure-palladium conductive layer is plated with a pure-gold conductive layer. The trace metal elements include tin, magnesium and aluminum.

Owner:溧阳市虹翔机械制造有限公司

Copper alloy single-crystal bonding wire for microelectronic packaging and preparation method thereof

ActiveCN106992164AImprove antioxidant capacityGood ball formingSemiconductor/solid-state device detailsSolid-state devicesHost materialIngot

The invention provides a copper alloy single-crystal bonding wire for microelectronic packaging and a preparation method thereof. The bonding wire adopts high-purity copper as a main body material, and comprises micro-scale metal materials of silver, scandium, iron, titanium and the like. The bonding wire is composed by the following materials in weight percentage: 99. 9%-99. 95% of copper, 0.01-0.02% of silver, 0.01-0.02% of scandium, 0.001-0.015% of iron and 0.001-0.01% of titanium. The preparation method comprises the following steps: extracting the high-purity copper, the purity of which is larger than 99.99%; preparing a copper alloy ingot; preparing a cast copper alloy single crystal bus; drawing the single crystal bus into a single crystal wire, the diameter of which is about 1 mm, and then, carrying out heat treatment; and then, carrying out precision drawing, heat treatment and cleaning to prepare copper alloy single crystal bonding wires in different specifications.

Owner:江西蓝微电子科技有限公司

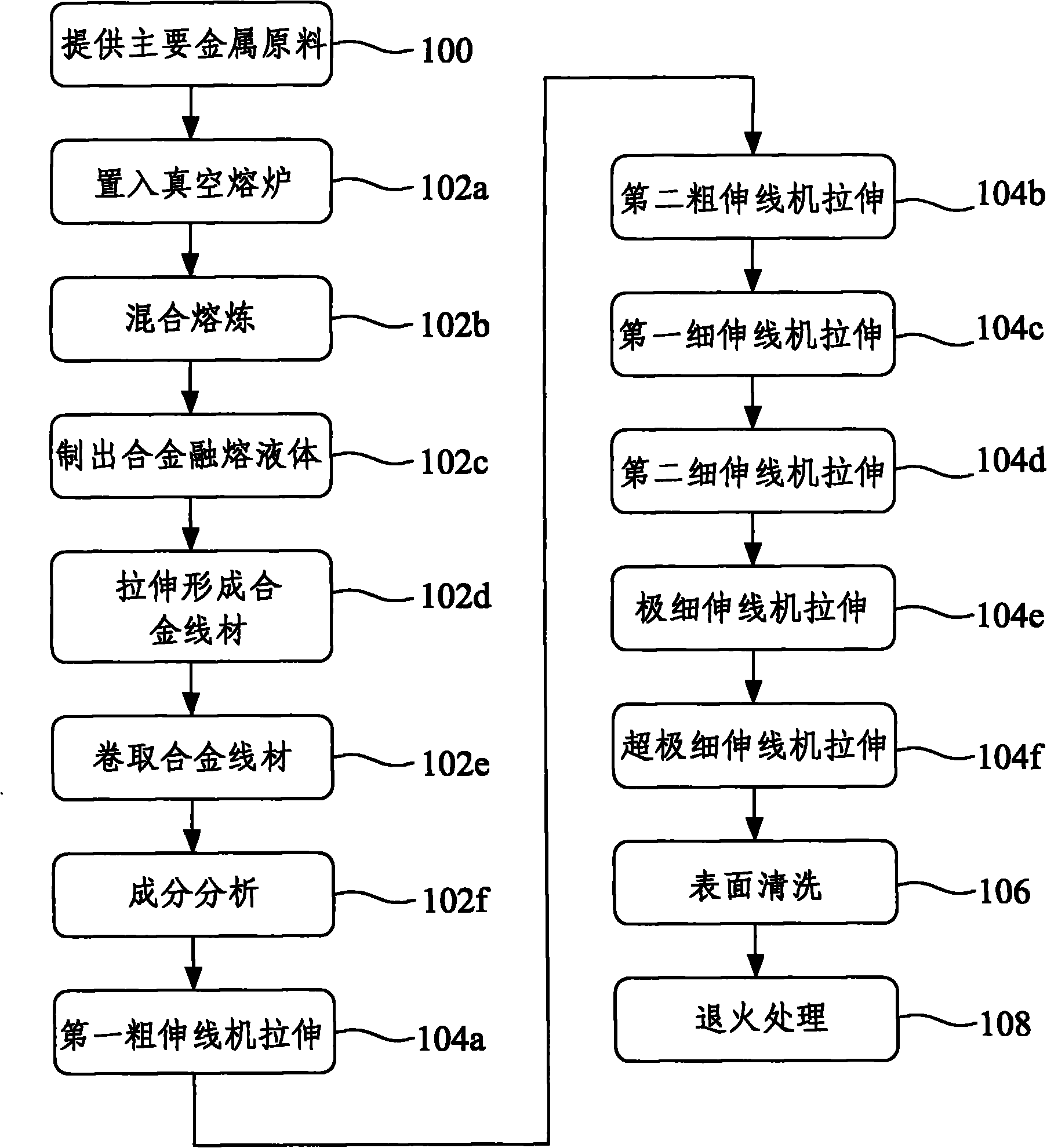

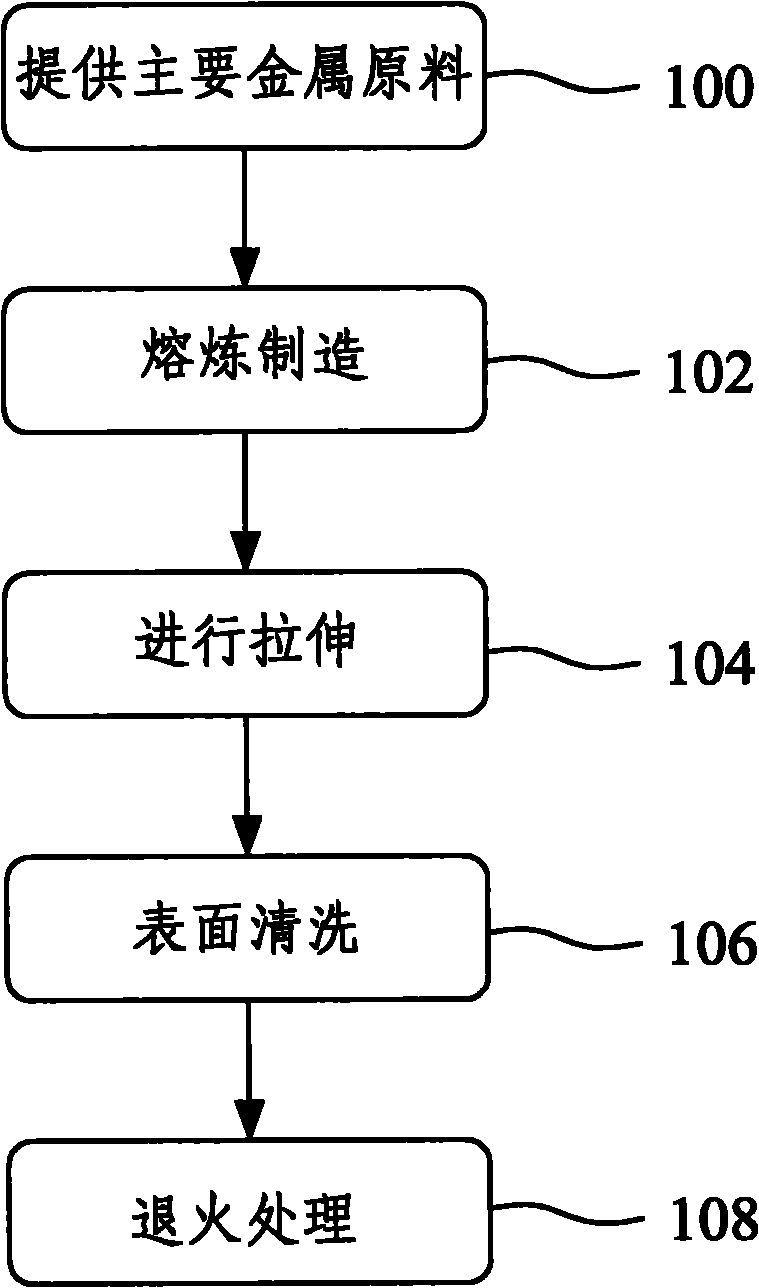

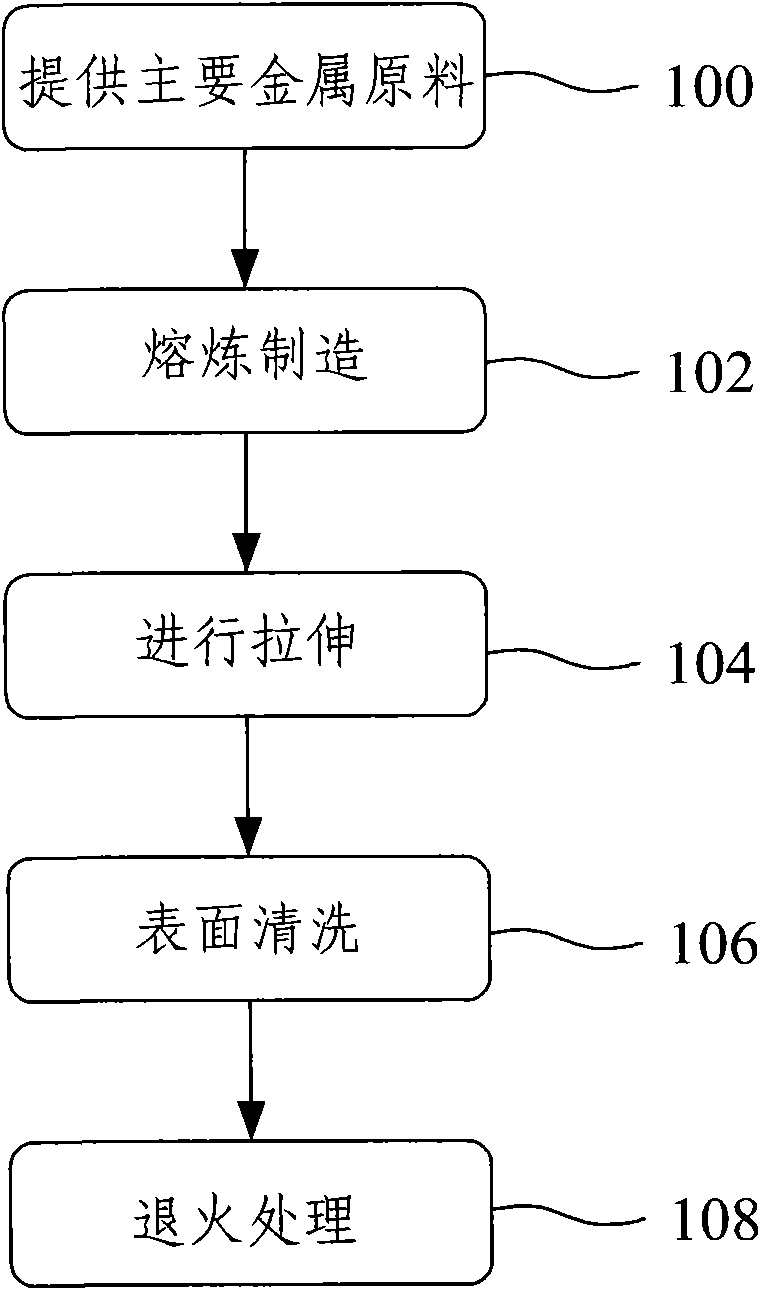

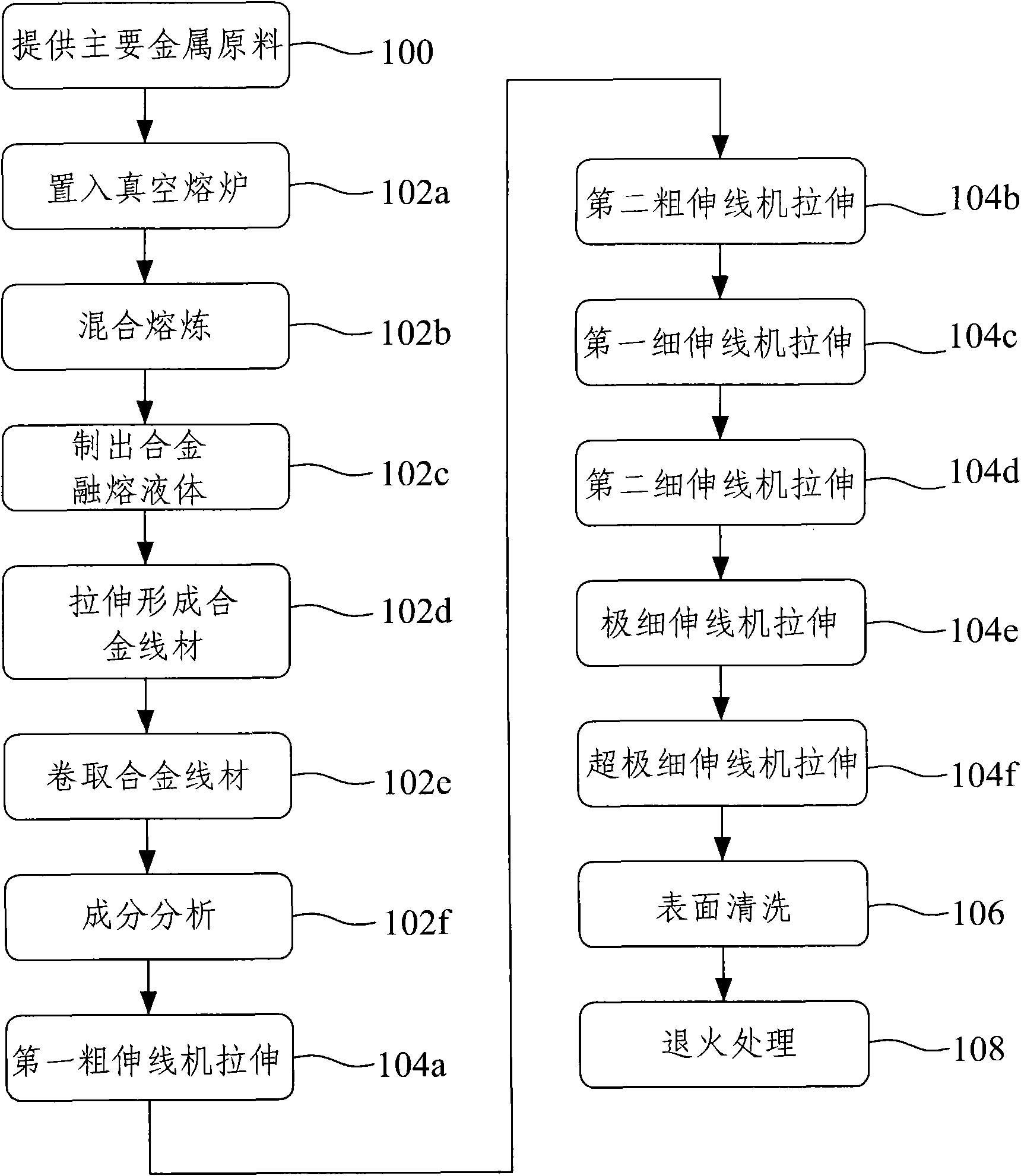

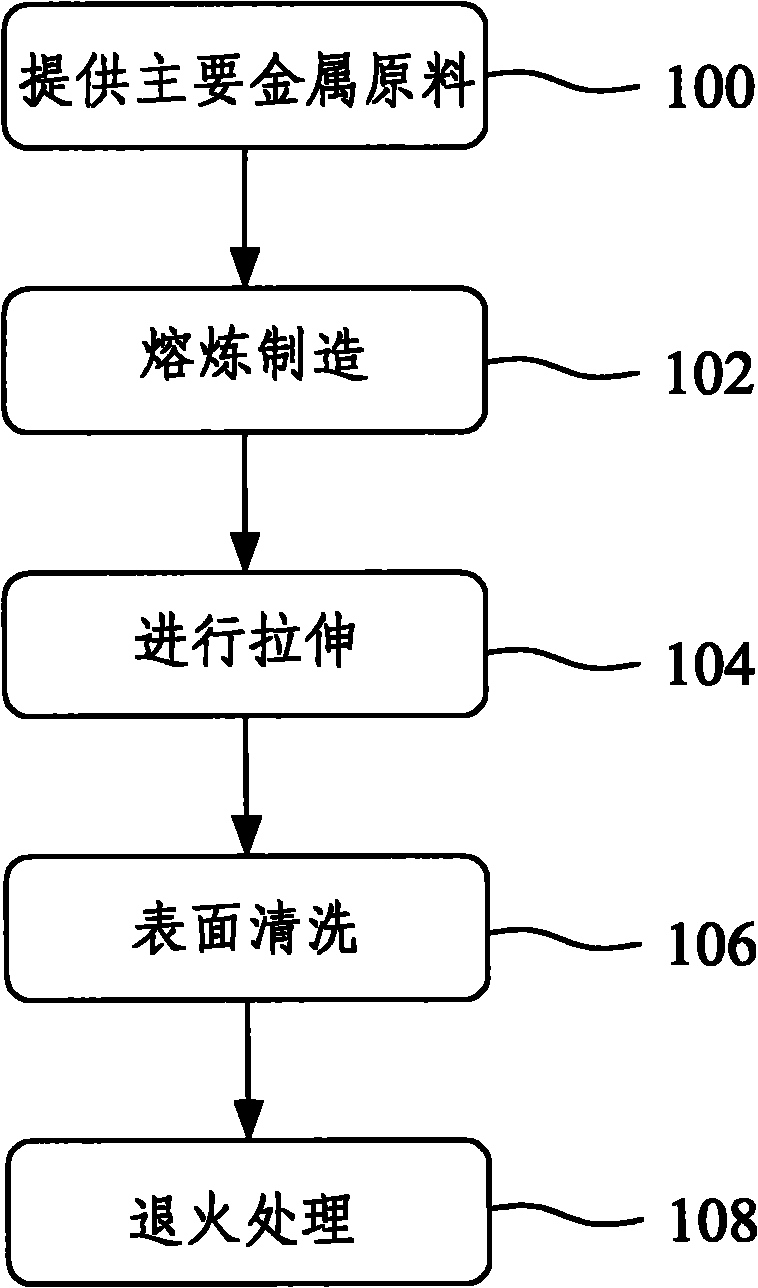

Composite gold wire and manufacture method thereof

The invention provides a manufacture method of a composite gold wire, comprising the steps of providing a main metal raw material containing a silver componnet; putting the main metal raw material in a vacuum melting furnace and carrying out mixing melting after adding a minor metal material containing a palladium component in the vacuum melting furnace and mixing to prepare a silver-palladium alloy melting liquid; then continuously casting and pulling and stretching the silver-palladium alloy melting liquid into a silver-palladium alloy wire rod; and at last, stretching the silver-palladium alloy wire rod into a silver-palladium alloy bonding wire with the preset wire diameter. The invention also provides the composite gold wire comprising the following ingredients in percentage by weight: 90.00-99.99 percent of silver and 0.01-10.00 percent of palladium. By dint of the silver-palladium alloy bonding wire prepared by mixing the two metal raw materials such as silver and palladium, the invention can not only achieve the effect of metal wire rods made of pure gold but also greatly reduce the cost.

Owner:李俊德

Preparation method of sludge ceramsite capable of slowly releasing trace metal elements including copper and nickel

InactiveCN104803661AEasy to prepareHigh removal rateCeramic materials productionClaywaresEpoxyChemical oxygen demand

A preparation method of sludge ceramsite capable of slowly releasing trace metal elements including copper and nickel is implemented as follows: sludge, coal ash and clay of a sewage plant are dried respectively and sieved with a 200-mesh sieve, 3-5 g of sludge, 6-8 g of coal ash and 8-10 g of clay are weighed and stirred uniformly, an appropriate amount of water is slowly added to the mixture and sufficiently stirred, the mixture is put in a press machine and subjected to extrusion forming, raw ceramsite with the diameter of 4-6 mm is obtained, dried at the temperature of 100 DEG C, preheated for 20 min and calcined at the temperature of 1,050 DEG C for 16 min, and the sludge ceramsite is prepared; the ceramsite is put into a mixed solution containing CuCl2 and NiCl2 to be soaked, then taken out and dried for standby application; a cladding material is prepared by mixing epoxy resin, acidamide resin, an ethanol solution and starch, soaked and well dried ceramsite is added and stirred, accordingly, the surface of the ceramsite is uniformly coated with the mixture and put in a drying oven to be dried, and the sludge ceramsite capable of slowly releasing the trace metal elements including copper and nickel is prepared. The ceramsite is applicable to anaerobic biological treatment of organic wastewater lack of trace metals Cu2+ and Ni2+, and the COD (chemical oxygen demand) removal rate of the wastewater can be increased by more than 12%.

Owner:SHENYANG LIGONG UNIV

Metal zipper with double-side color effect and production method thereof

The invention discloses a metal zipper with a double-side color effect and a production method thereof; a zipper teeth base material comprises 63-67% of copper, 33-37% of zinc, other trace metals, and colored layers with two different colors on surfaces and different-thickness organic protective layers coated according to different zipper types. The production method comprises the steps: chain teeth after chemical polishing are colored with a first color; then one face of each tooth is coated with a chemical protective layer with the thickness of 0.02-0.25 mm; and next the other face of each tooth has the color faded by a chemical deplating solution to expose a metal material and then is colored with a second color, and finally the other face is coated with the organic protective layer with the thickness of 0.02-0.25 mm.

Owner:深圳市联星服装辅料有限公司

Doping lithium iron phosphate material and preparation method and application thereof

ActiveCN101651198AUniform carbon contentImprove conductivityElectrode manufacturing processesActive material electrodesMinor metalsLithium iron phosphate

The invention discloses a doping lithium iron (II) phosphate material and a preparation method and an application thereof, belonging to the field of lithium ion battery. The chemical formula of the material is LiFe1-xMxPO4 / Cy, wherein, M represents doped element, namely one or more of Y, Al, Cr, Co and Ni, x is 0.003-0.005 and y is 1.22-3.06. Carbon and phosphorus elements of the material are fromthe same raw material so as to ensure the real molecular mixing of carbon and lithium iron (II) phosphate in the prepared material; in addition, trace doped metal can improve the conductivity of thelithium iron (II) phosphate. No conductive agent is needed to add in the material provided by the invention which has larger gram-capacity, and the invention is simple and practical and has large promotional value in the new material field of lithium ion secondary battery.

Owner:SHUANGDENG GRP

Absorbent for reducing trace metal content in deteriorated oil and production method thereof

InactiveCN103418339AReduce metal contentReduce trace metal contentOther chemical processesAluminium silicatesMinor metalsElectric power system

The invention discloses an absorbent for reducing trace metal content in deteriorated oil, which has been used in an electrical power system, and a production method thereof. The absorbent has the characteristics of non-toxicity, and combustion and explosion resistance, has the advantages of simple production technology, wide raw material sources, low production cost, environment-friendliness, good processing effect on waste oil, and high yield, is capable of saving a large amount of production cost for enterprises, and saves energy for nation.

Owner:STATE GRID CORP OF CHINA

Graphite felt treatment process

InactiveCN108615885ASimple processFinal product manufactureCell electrodesMinor metalsMicrowave oven

The invention discloses a graphite felt treatment process including steps of: 1) organic substance removal: annealing the graphite felt at 500-900 DEG C for 5-15 min; 2) removal common impurities: treating the graphite felt in a first solution (SC-1) at 70-80 DEG C for 5-10 min, and washing the graphite felt for 5-10 min in deionized water, then treating the graphite felt in a second solution (SC-2) at 70-80 DEG C for 5-10 min, and washing the graphite felt for 5-10 min in deionized water; (3) removal of stubborn trace metal impurities: treating the graphite felt in a microwave oven for 5-15 min. The treatment process is simple and can remove the organic substances and metal impurities from the graphite felt. The processed graphite felt can be used for producing zinc-bromine or zinc-iodinebatteries.

Owner:EAST CHINA NORMAL UNIV

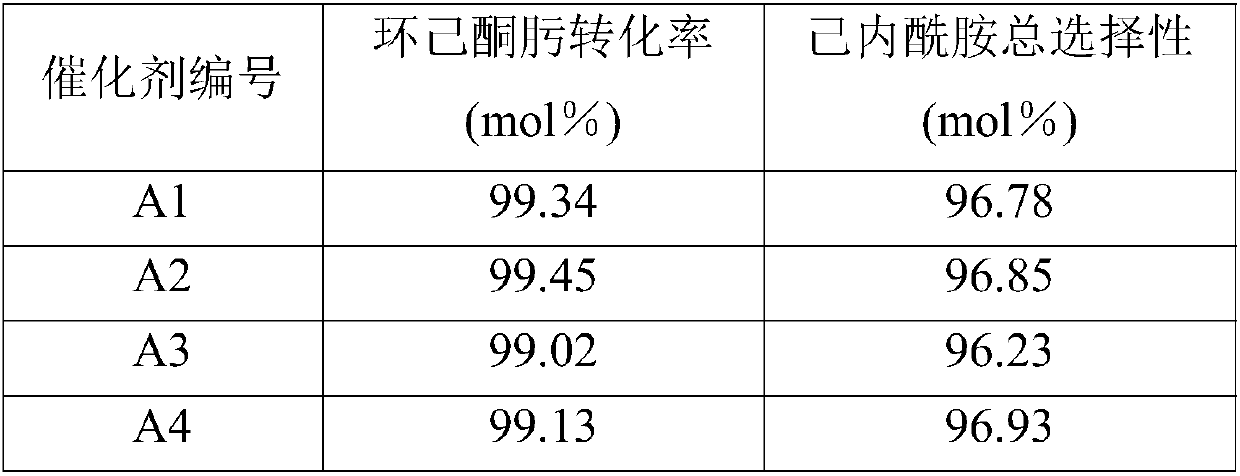

Microsphere Silicate-1 molecular sieve catalyst and preparation method thereof, and caprolactam preparation method

ActiveCN109718826AChange performanceHigh strengthLactams preparationMolecular sieve catalystsBeckmann rearrangementGas phase

The present invention relates to a Silicate-1 microsphere molecular sieve catalyst containing a trace amount of metal ions, and a preparation method thereof, and a method for preparing caprolactam from cyclohexanone oxime. According to the present invention, based on the weight of the dry base of the catalyst, the catalyst comprises 70-95 wt% of a Silicate-1 molecular sieve catalyst containing a trace amount of metal ions, and 5-30 wt% of a binder; the catalyst has a particle size of 40-150 [mu]m and a wear index K of less than 5; the Silicate-1 molecular sieve has a BET specific surface areaof 400-500 m<2> / g and a weight ratio of silicon oxide to metal ions of (5000-200000):1; and the catalyst has the low wear index, can be used for the vapor phase Beckmann rearrangement reaction of cyclohexanone oxime in a fluidized bed process, and can effectively increase the selectivity of caprolactam.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carbon based friction plates of powder metallurgy, and manufacturing technique

This invention discloses a carbon-based friction disk for producing brake by powder metallurgy. The carbon-based friction disk is composed of: specifically treated carbon powder 20-40 wt.%, copper 15-30 wt.%, iron 5-15 wt.%, tin 2-5 wt.%, silicon dioxide 3-10 wt.%, manganese 0.5-2 wt.%, and phenolic resin 2-5 wt.%. The carbon-based friction disk has such advantages as high friction strength, uniform properties, simple process and low energy consumption.

Owner:张雯

Microcrystal prepared from waste cinder

The invention provides a microcrystal prepared from waste cinder. The microcrystal is characterized in that: the microcrystal is prepared from the following raw materials by mass: 30 to 50 g of waste cinder, 10 to 28g of quartz, 12 to 25g of limestone, 6 to 15g of calcined soda, 1.3 to 3.0g of borax, 0.2 to 0.3g of zinc oxide, and 0.8 to 1.2g of sodium nitrate. The microcrystal has the advantages of high mechanical strength, high hardness, excellent wear-resisting property, acid-alkali resistance, and good chemical stability and thermal stability, and can be used in any severe environment, and also keeps the higher mechanical strength in high temperature environment; the microcrystal also has the advantages of no pore space, close texture, water resistance, no toxins, no dielectric and zero dielectric, no radioactivity, and safe use, and is a reasonable environmental protection building material; moreover, the microcrystal can be carved and is suitable for hot bending deformation, so that the microcrystal can be widely applied, and can be used for decoration on a cylinder, a plane, a curtain wall, kitchen ware, a high-grade document, furniture, a sauna bathroom and the like, and the production cost is reduced by more than 25 to 35 percent. Because the waste cinder contains various trace metal elements, various bright colors are prepared. Because a large amount of waste cinder is consumed, the key problem of environmental protection is solved.

Owner:谢海辉

Preparation method of high-corrosion-resistance sintered neodymium-iron-boron magnet

ActiveCN111403163AStrong magnetismReduce performanceInorganic material magnetismInductances/transformers/magnets manufactureTemperingMinor metals

The invention discloses a preparation method of a high-corrosion-resistance sintered neodymium-iron-boron magnet, and the methodcomprises the following steps: preparing a neodymium-iron-boron alloy cast sheet containing trace metal, and standing in dry air for 10-30 days to enable a neodymium-rich phase to fully absorb oxygen; performing hydrogen decrepitation, performingcooling to 35 DEG C afterdehydrogenation is finished; stoppingcooling, and standing for 30 to 120 minutes; introducing 20 to 100 ppm of pure oxygen into a hydrogen decrepitation reaction device;when the oxygen content is reduced to 10 ppm or below, performingcooling again, taking out the coarse powder, performing mixing, adding a lubricating agent and an antioxidant, not supplementing oxygen during jet milling, preparingfine powder, performing cold storage treatment on the fine powder, performing orientation forming, increasing the temperature to be less than or equal to 2 DEG C in the forming process, performing 180-300MPa cold isostatic pressing, and finally sintering, aging and tempering to obtain the high-corrosion-resistance neodymium-iron-boron magnet. According to the method, on the premise that the magnetic performance of the magnet is not reduced, the stability and corrosion resistance of the neodymium-rich phase of the sintered neodymium-iron-boron magnet are improved.

Owner:浙江凯文磁业有限公司

Acidity nanometer cobalt catalyst, preparation method and application thereof

InactiveCN101513616AHigh activityHigh selectivityHydrocarbon from carbon oxidesLiquid carbonaceous fuelsIsomerizationMinor metals

The invention provides an acidity nanometer cobalt catalyst, the main active constituent of which is Co and the accessory constituents of which are Zn, Mn and trace metals; the existence form of all constituents of the catalyst is as follows: (Co, Zn)O, (CoZn2)O4, Co3O4, ZnO, MnO, K2O, Na2O, and Li2O; the catalyst is carrier free acidity nanometer cobalt catalyst which is acidized, the average grain diameter of which is 3-18nm, the specific surface is 75-400m / g, and the average pore size is 4-20nm. The preparation process of the catalyst adopts a supercritical fluid drying technique, which causes the prepared catalyst is characterized by small grain diameter, big specific surface, small pore size and high activity. The catalyst is mainly used for synthesis gas CO+H2 which is directly transformed to prepare high isomerization clean fuel, and used for Fischer-Tropsch reaction of the synthesis gas preparing liquid hydrocarbon; wherein the conversion rate of CO reaches more than 78% and the isomerization product accounts for more than 53% of the total liquid hydrocarbon product.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com