Method for preparing nano metal catalyst

A nano-metal and catalyst technology, which is applied in the field of metal catalyst preparation, can solve the problems of low economic benefit value and waste, and achieve the best reaction activity, improved activity, and good methanol selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with examples.

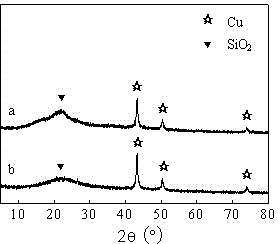

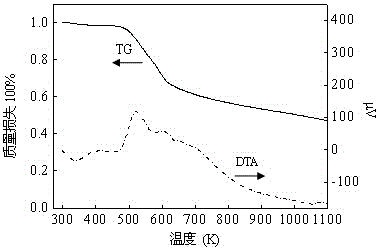

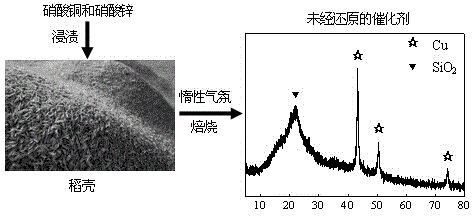

[0017] 1. Highly active metal Cu / Zn-SiO 2 Catalyst preparation method: using the impregnation method, a certain quality of Cu(NO 3 ) 2 ·3H 2 O (≥99%) and Zn(NO 3 ) 2 ·6H 2 O (≥99%) was dissolved in deionized water and then impregnated in the pores of a certain mass of rice husk. Wherein the molar ratio of Cu / Zn is 1 / 5-5 / 1, and the mass of Cu and Zn accounts for 5%-50% of the total mass of the catalyst. Dry the dried precursor in an oven at 120°C for 10 hours, then bake it at 150-400°C for 3-5 hours in an inert atmosphere (nitrogen, argon or helium, any one or a mixture of any proportion), the resulting Prepared Cu / Zn=1, Cu / ZnO-SiO with a mass fraction of 10% 2 Catalyst and catalyst C prepared by impregnation method IM-623-Reduction The catalyst characterization parameters and low-temperature methanol synthesis reactivity are shown in Table 1. where C 250 , C 300 and C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com