Preparation method of electronic grade tetraethoxysilane

A tetraethyl orthosilicate, electronic-grade technology, applied in the direction of silicon organic compounds, can solve problems affecting the uniformity and flatness of the film layer, expensive gas chromatograph equipment, and reduce the insulation performance of the film layer, etc., to achieve low product cost , promote sustainable and stable development, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

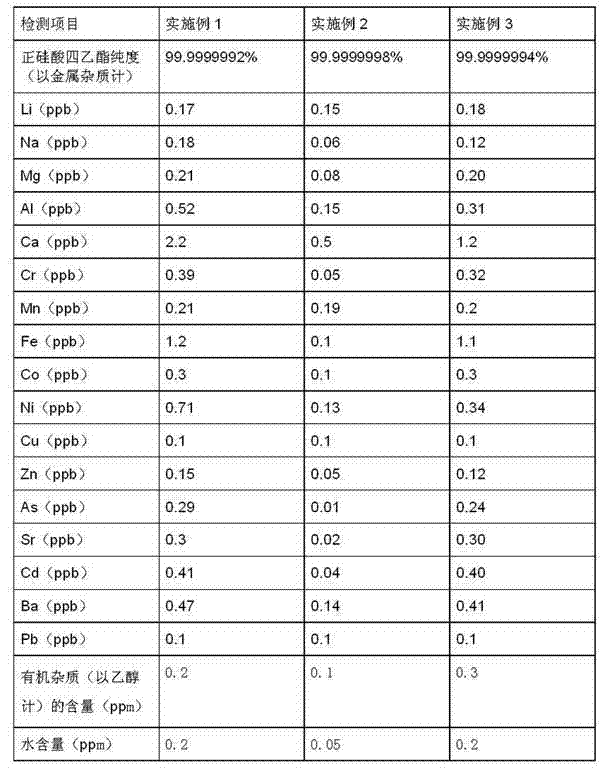

Embodiment 1

[0027] A preparation method of electronic grade tetraethyl orthosilicate: (1) Take 12kg of industrially synthesized crude tetraethyl orthosilicate in a 20L polytetrafluoroethylene container, add 0.36kg of analytically pure ethylenediaminetetraacetic acid complex mixture, fully mixed and stirred for 30 minutes, and then filtered with a 0.1 micron microporous filter; (2) Pass the collected filtrate through a cation exchange column device to further remove metal impurities and collect the filtrate; (3) Collect the filtrate The filtrate was added to a plate-type quartz distillation tower for distillation, and after 7 hours of total reflux, the fraction was collected from the top of the tower at 163°C; (4) The collected fraction was distilled through a sub-boiling distiller, and the voltage of the heating device of the sub-boiling distiller was adjusted , maintain the liquid surface temperature at 95°C, collect the distilled product at 95°C, and take samples for testing; (5) The obt...

Embodiment 2

[0031] A preparation method of electronic grade tetraethyl orthosilicate: (1) Take 12 kg of industrially synthesized crude tetraethyl orthosilicate in a 20L polytetrafluoroethylene container, add 0.72 kg of analytically pure ethylenediaminetetraacetic acid complex mixture, fully mixed and stirred for 45 minutes, and then filtered with a 0.1 micron microporous filter; (2) Pass the collected filtrate through a cation exchange column device to further remove metal impurities and collect the filtrate; (3) Collect the filtrate The filtrate was added to a plate quartz distillation tower for distillation, and after 10 hours of total reflux, the fraction was collected from the top of the tower at 165°C; (4) Distill the collected fractions through a sub-boiling still, and adjust the voltage of the heating device of the sub-boiling still , maintain the liquid surface temperature at 98°C, collect the distilled product at 98°C, and take samples for testing; (5) The obtained product is fill...

Embodiment 3

[0035] A preparation method of electronic grade tetraethyl orthosilicate: (1) Take 12kg of industrially synthesized crude tetraethyl orthosilicate in a 20L polytetrafluoroethylene container, add 1.2kg of analytically pure ethylenediaminetetraacetic acid complex mixture, fully mixed and stirred for 60 minutes, and then filtered with a 0.1 micron microporous filter; (2) Pass the collected filtrate through a cation exchange column device to further remove metal impurities and collect the filtrate; (3) Collect the filtrate The filtrate was added to a plate quartz distillation tower for distillation, and after 15 hours of total reflux, the fraction was collected from the top of the tower at 163°C; (4) Distill the collected fractions through a sub-boiling still, and adjust the voltage of the heating device of the sub-boiling still , maintain the liquid surface temperature at 90°C, collect the distilled product at 90°C, and take samples for testing; (5) The obtained product is filled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com