Aluminum alloy anode material, and casting method and application thereof

An anode material, aluminum alloy technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low electrochemical activity, high hydrogen evolution overpotential, low anode utilization rate, etc. Good chemical properties and reasonable ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, the aluminum alloy anode material is cast from Pb, Sn, Ga, Ti, and Al, and the specific casting steps are as follows:

[0031] 1. Refined alloy:

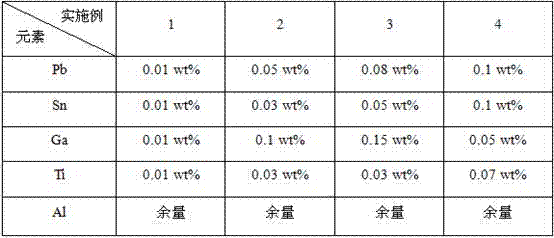

[0032] (1) According to the mass percentage of each component in Example 1 in Table 1, do the ingredients;

[0033] (2) Put a pure aluminum block with a purity of 99.99% into a pit furnace in multiple times and heat it to 750°C for melting;

[0034] (3) Afterwards, the four metal elements of Pb, Sn, Ga, and Ti that have been previously prepared are also added to the pit furnace;

[0035] (4) After all the components are completely melted, use a graphite rod to stir the molten aluminum alloy every 5 minutes and repeat it several times to make the metal elements in a uniform state;

[0036] (5) Finally, add hexachloroethane twice to remove the waste residue in the molten aluminum. The amount of hexachloroethane added is 8% of the total mass of the aluminum alloy.

[0037] 2. Casting:

[0038] (1) Coat a layer of release ...

Embodiment 2

[0042] In this embodiment, the aluminum alloy suitable for the aluminum-air battery is cast from Pb, Sn, Ga, Ti, and Al. The specific casting steps are as follows:

[0043] 1. Refined alloy:

[0044] (1) Make ingredients according to the mass percentage of each component in Example 2 in Table 1;

[0045] (2) Put a pure aluminum block with a purity of 99.99% into a pit furnace in multiple times and heat it to 700°C for melting;

[0046] (3) Afterwards, the four metal elements of Pb, Sn, Ga, and Ti that have been previously prepared are also added to the pit furnace;

[0047] (4) After all the components are completely melted, use a graphite rod to stir the molten aluminum alloy every 5 minutes and repeat it several times to make the metal elements in a uniform state;

[0048] (5) Finally, add hexachloroethane twice to remove the waste residue in the molten aluminum. The amount of hexachloroethane added is 6% of the total mass of the aluminum alloy.

[0049] 2. Casting:

[0050] (1) Coat a l...

Embodiment 3

[0054] In this embodiment, the aluminum alloy suitable for the aluminum-air battery is cast from Pb, Sn, Ga, Ti, and Al. The specific casting steps are as follows:

[0055] 1. Refined alloy:

[0056] (1) Make ingredients according to the mass percentage of each component in Example 3 in Table 1;

[0057] (2) Put a pure aluminum block with a purity of 99.99% into a pit furnace in multiple times and heat it to 700°C for melting;

[0058] (3) Afterwards, the four metal elements of Pb, Sn, Ga, and Ti prepared previously are also added to the pit furnace;

[0059] (4) After all the components are melted, use a graphite rod to stir the molten aluminum alloy every 5 minutes and repeat it many times to make the metal elements in a uniform state;

[0060] (5) Finally, add hexachloroethane twice to remove the waste residue in the molten aluminum. The amount of hexachloroethane added is 8% of the total mass of the aluminum alloy.

[0061] 2. Casting:

[0062] (1) Coat a layer of release agent on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com