Method for manufacturing high-strength magnesium alloy solder wire

A magnesium alloy, high-strength technology, used in welding equipment, metal processing equipment, welding media, etc., can solve the problems of unstable chemical properties, difficult to grasp the mechanical properties of weld metal, low melting point and boiling point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

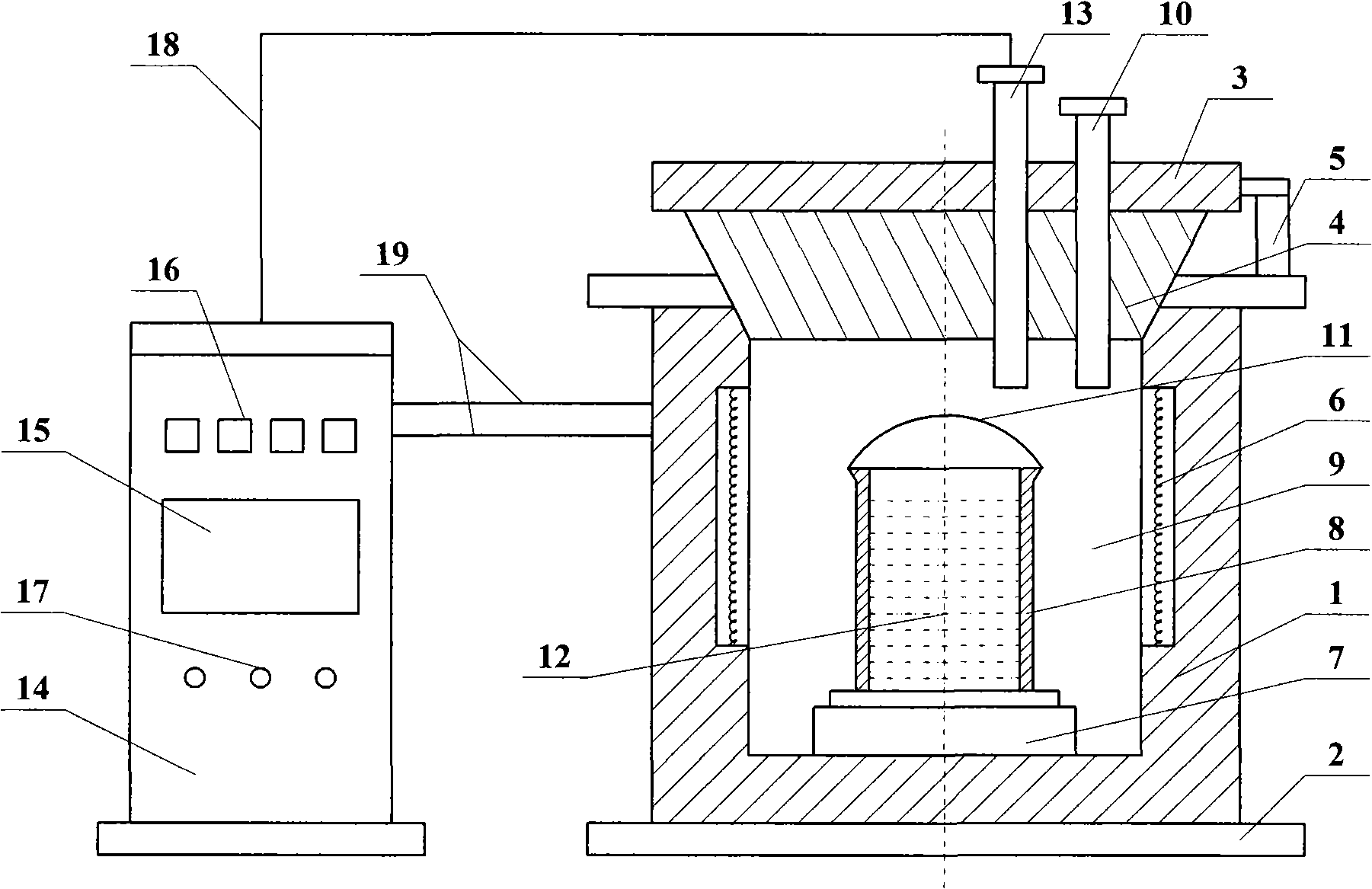

[0108] The present invention will be further described below in conjunction with accompanying drawing:

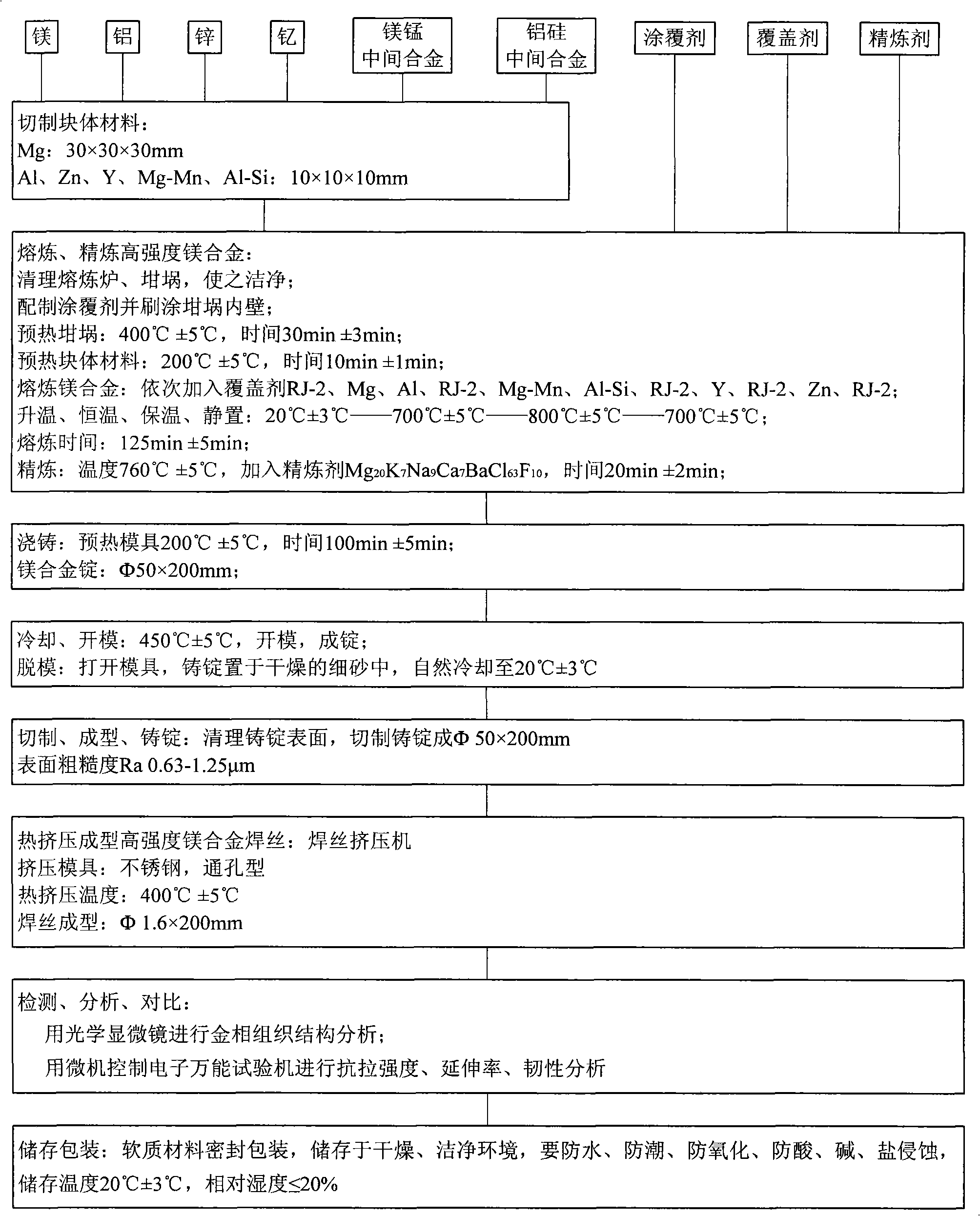

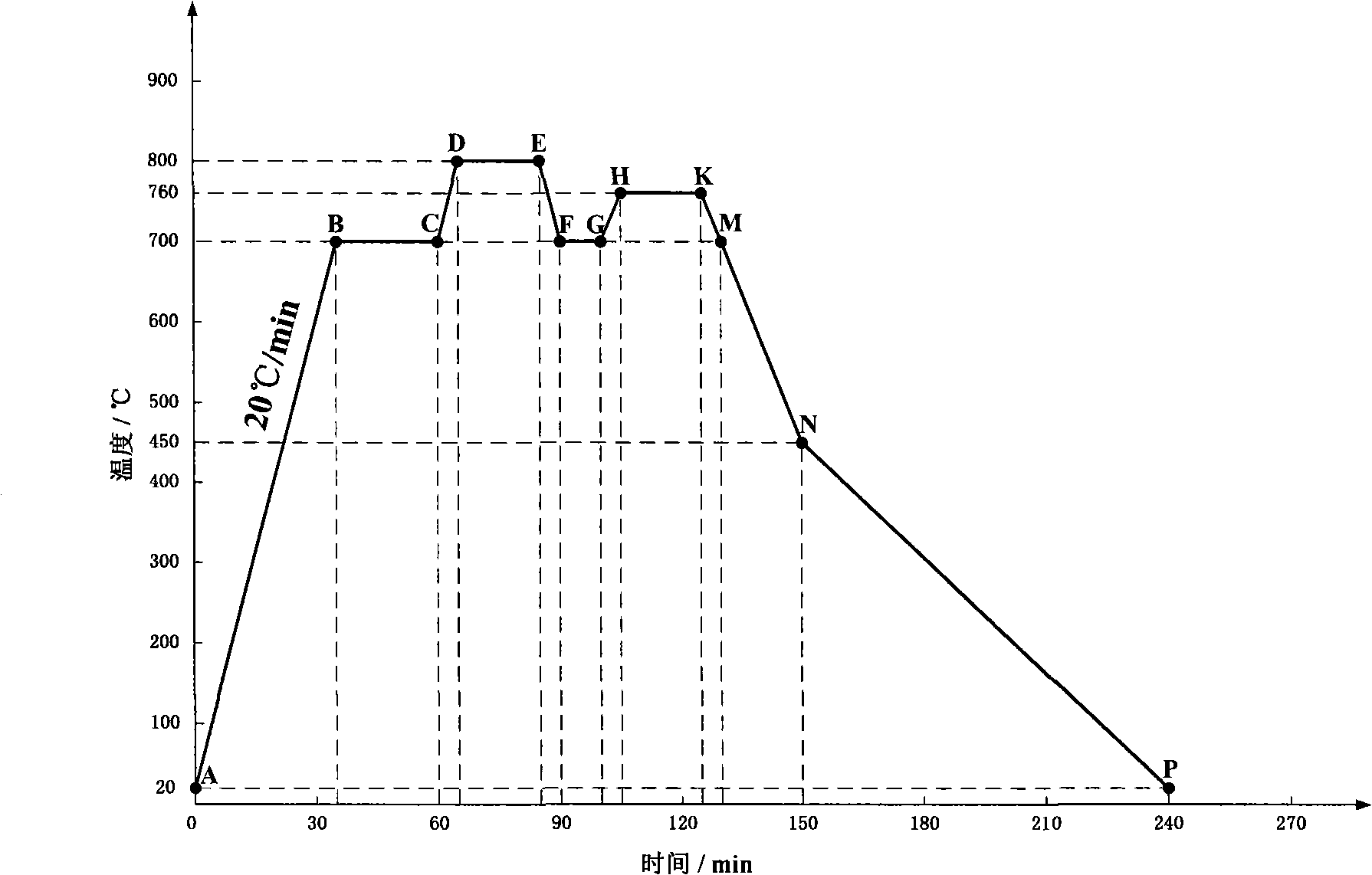

[0109] figure 1 As shown, it is a flow chart of the preparation process, which must be carried out in strict accordance with the preparation process and operated in sequence.

[0110] The proportion of chemical substances required for preparation is determined according to the preset range of values, with grams and milliliters as the unit of measurement, and for industrial production, with kilograms and liters as the unit of measurement, and calculated in proportion.

[0111] The magnesium, aluminum, zinc, yttrium, magnesium-manganese master alloy, and aluminum-silicon master alloy used in the preparation are all smelted and added in bulk, so pre-cutting is required.

[0112] The rare earth element yttrium used in the combination ratio and the magnesium-manganese master alloy and aluminum-silicon master alloy added in the form of master alloy can effectively increase the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com