Patents

Literature

158 results about "Carrier free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition: Free Carrier Free Carrier is an agreement used in international commerce according to which the obligation of seller gets fulfilled once the specified good has been delivered to the named airport, terminal or other places from which it will be transported though carrier.

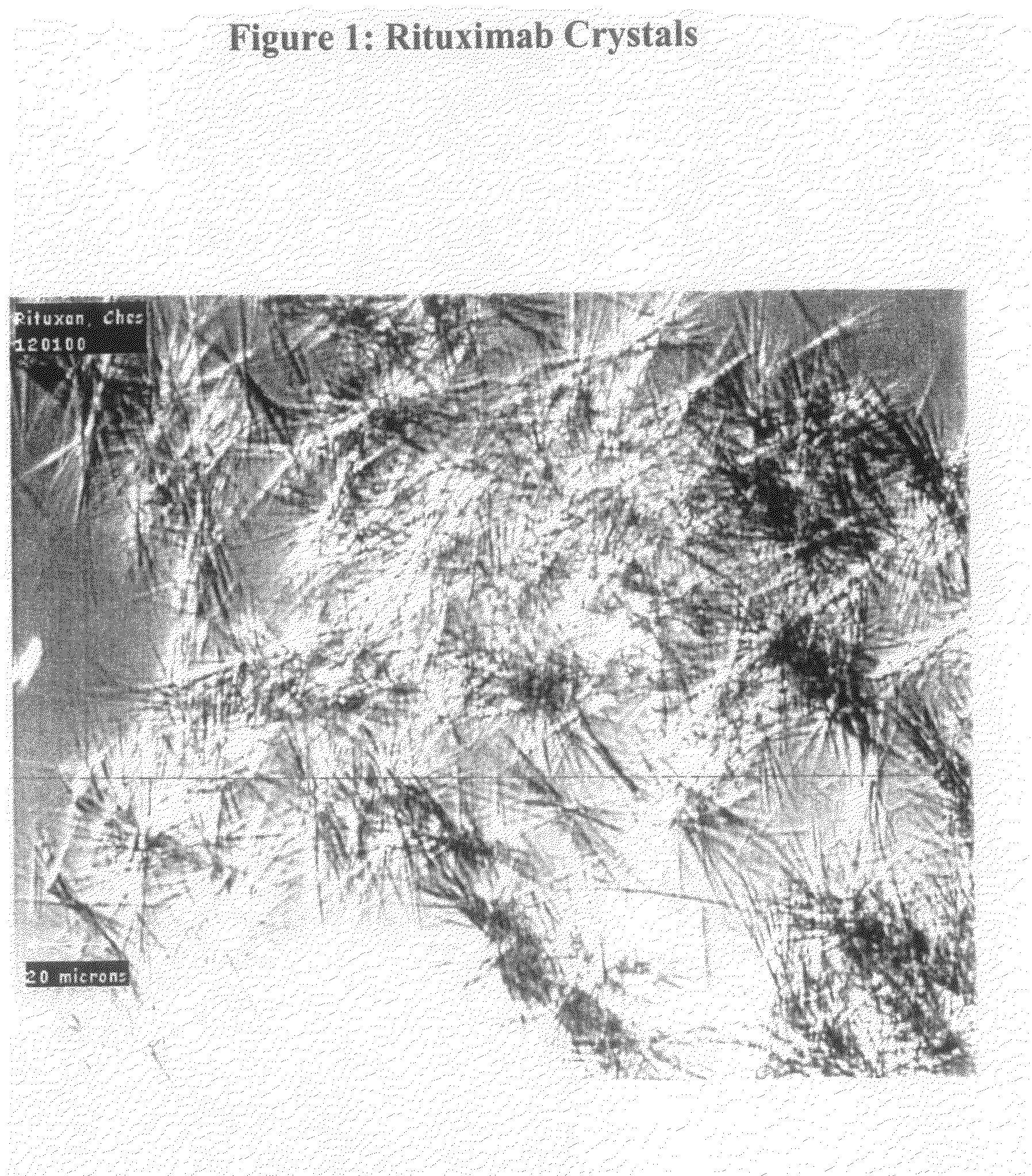

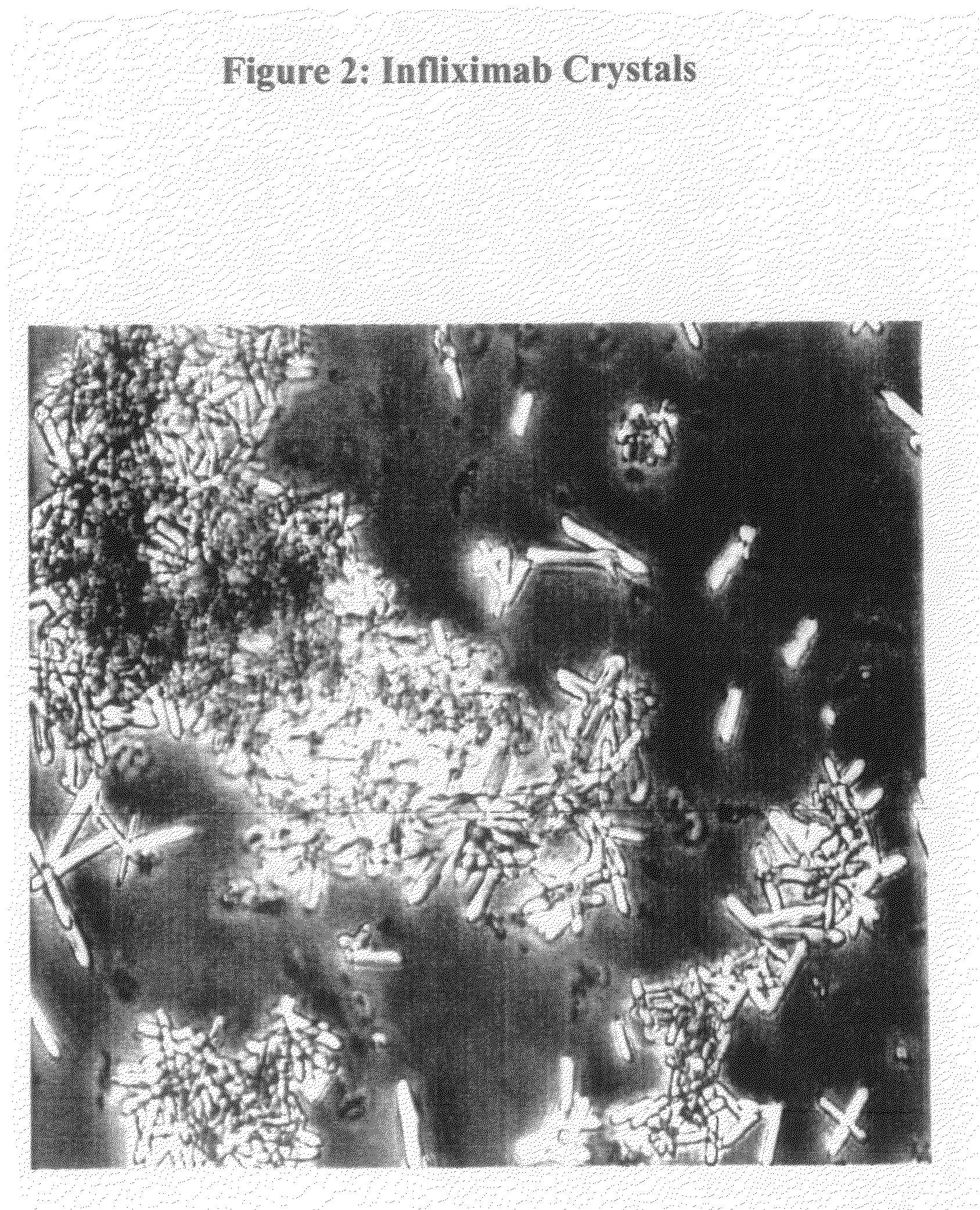

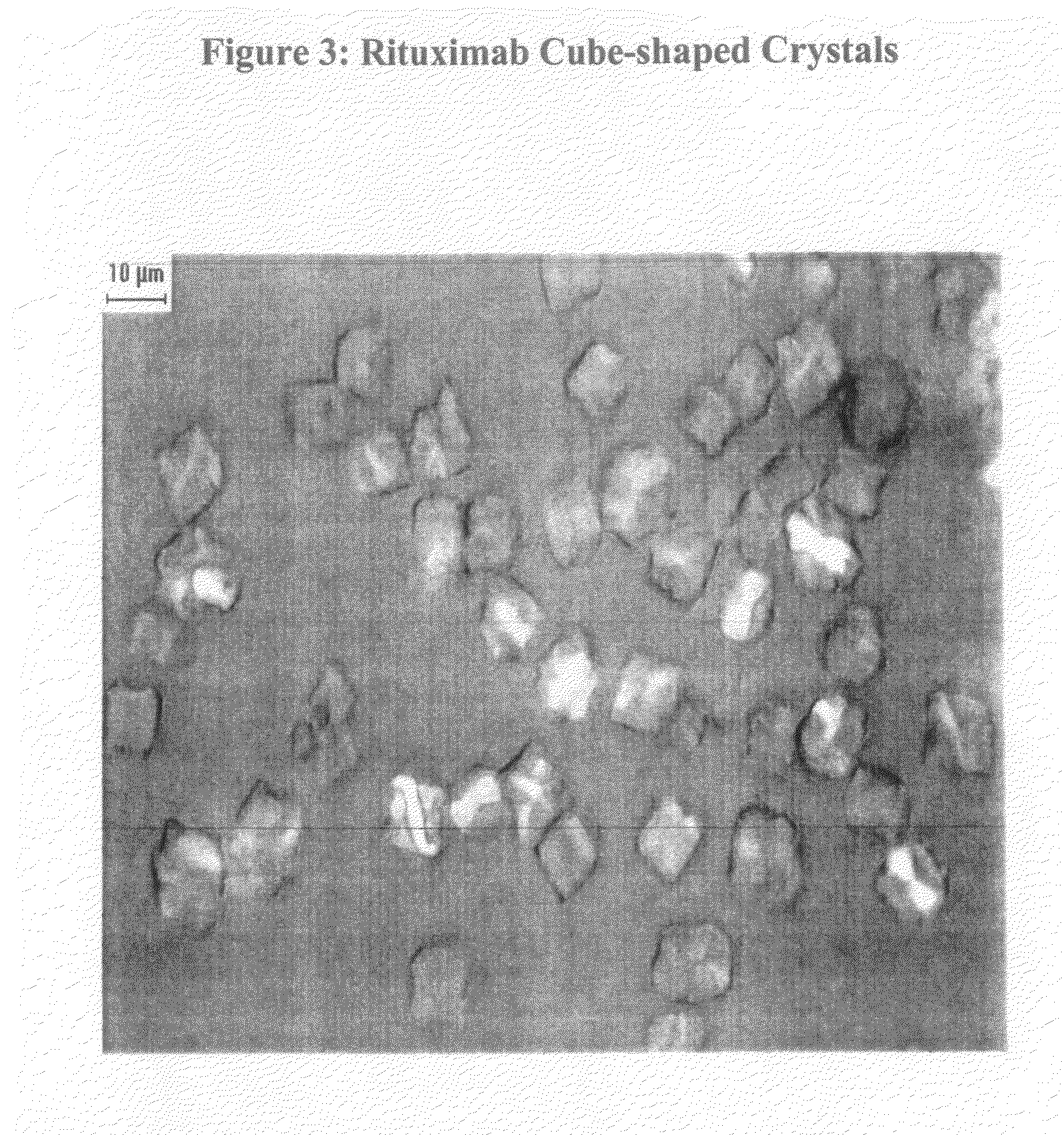

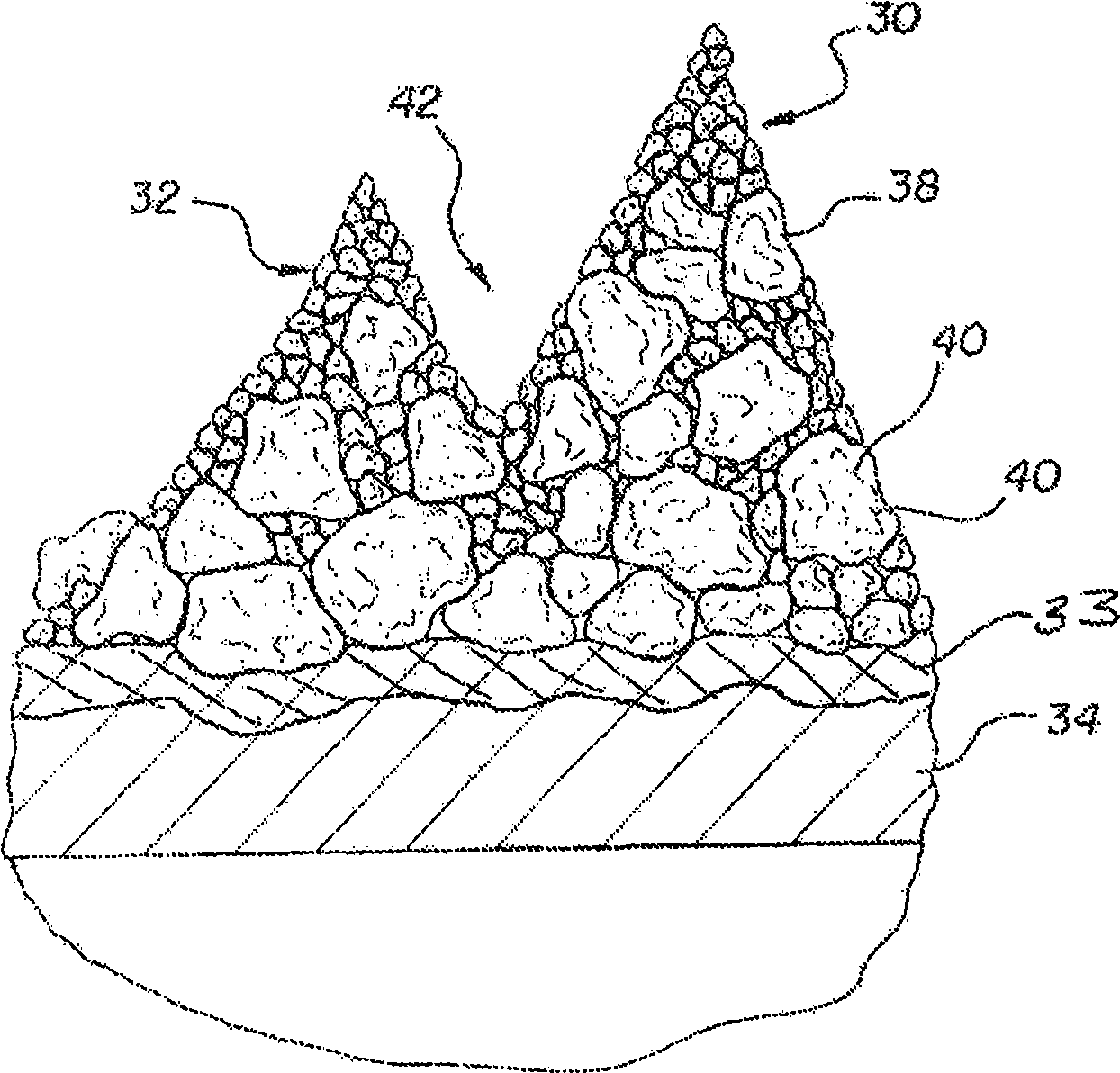

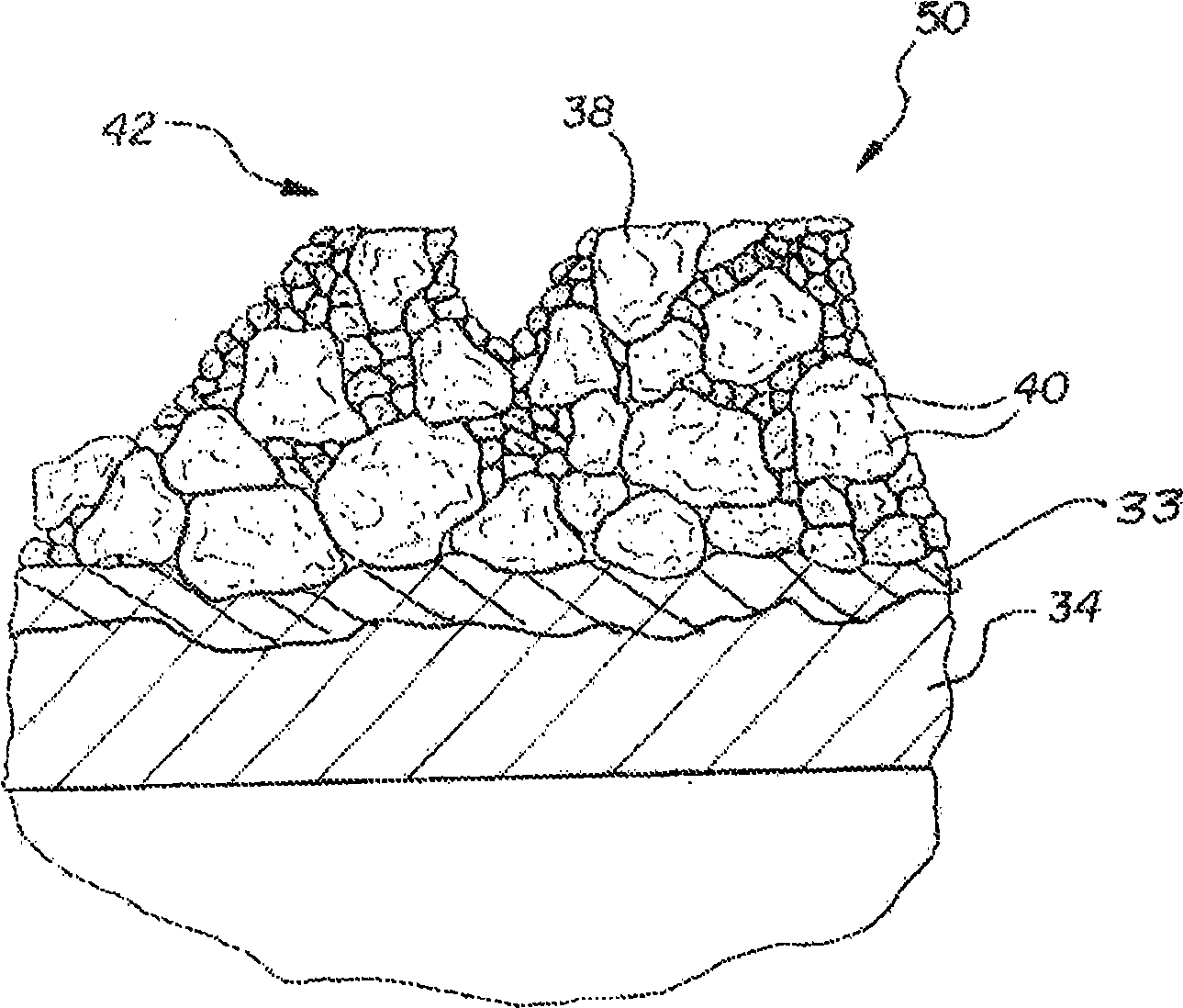

Crystals of whole antibodies and fragments thereof and methods for making and using them

InactiveUS20090093617A1Reduce releaseComposition is stableAntipyreticAnalgesicsHigh concentrationAntibody fragments

This invention relates to crystals of whole antibodies and fragments thereof, and formulations and compositions comprising such crystals. More particularly, methods are provided for the crystallization of high concentrations of whole antibodies, and fragments thereof, in large batches, and for the preparation of stabilized whole antibody crystals for use alone, or in dry or slurry formulations or compositions. This invention also relates to methods for stabilization, storage and delivery of biologically active whole antibody crystals. The present invention further relates to methods using whole antibody crystals, antibody fragment crystals, or compositions or formulations comprising such crystals for biomedical applications, including biological delivery to humans and animals. More particularly, whole antibody crystals or antibody fragment crystals, or crystal compositions or formulations thereof, are used as a carrier-free delivery system which can slowly release active whole antibodies or fragments thereof, to a subject, where and when they are needed.

Owner:AJINOMOTO ALTHEA INC

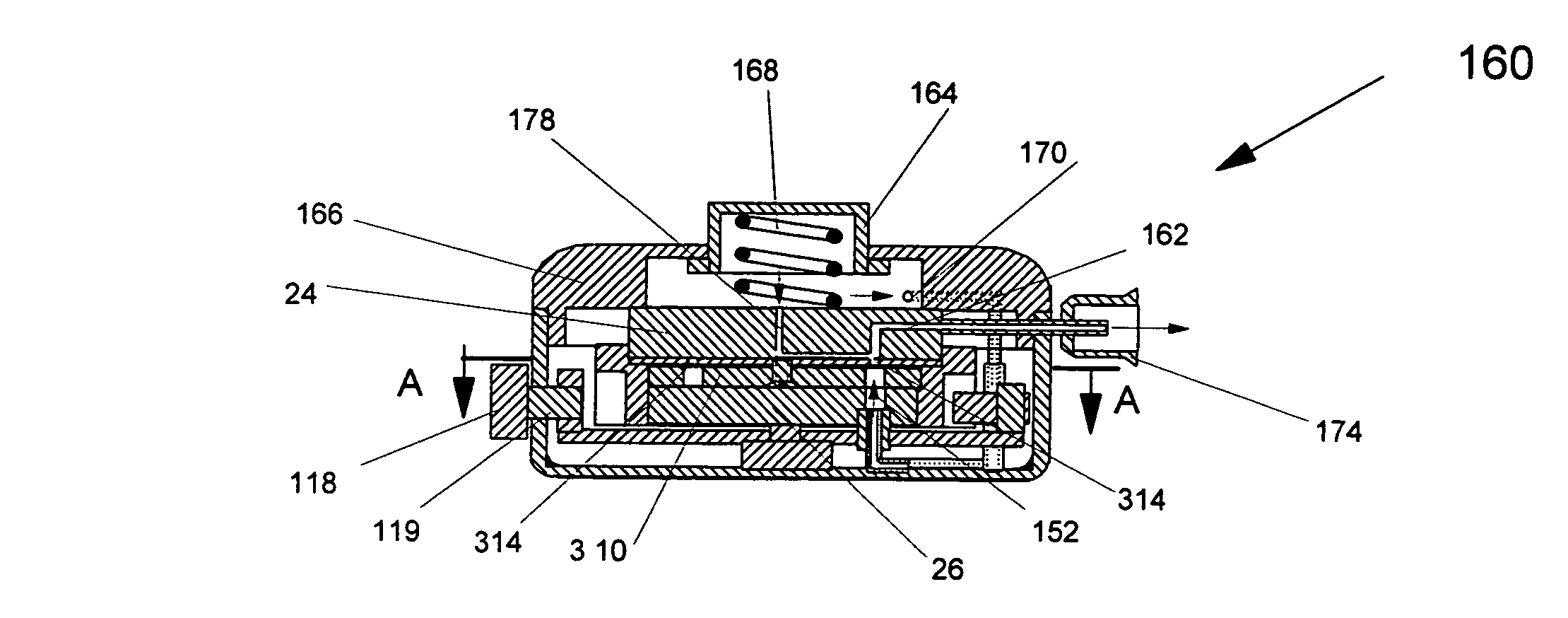

Dry powder inhaler

ActiveUS8037880B2Small accurate volumePrecise deliveryRespiratorsLiquid surface applicatorsUltra fineExcipient

A new dry powder inhaler is developed as a pulmonary medicine delivery device for dispersing precise tiny dosages (10 μg-50 mg) of pure carrier-free ultra-fine powdered medicament (<5 μm aerodynamics particle size) into a patient's lung. The powder is drawn from the blister cell and dispersed through an outlet tube assisted by two air streams. The first air stream goes through a the blister cell from its upstream side, to significantly fluidize the medicament in the dose to flow upward. The second one extracts the fluidized powder from downstream of the blister cell for further deagglomeration and dispersion of the medicament powder by shear force. The rotating multi-dose blister can hold up to 60 doses, which are pre-metered with pure ultra-fine powdered medicament. So that it has higher drug loading capability in small volumes, compared to most current dry powder inhalers, which usually use some excipient. The inhaler efficiently disperse the aerosolized medicament in the air stream to the deep interior of patient's lung. The fine particle fraction (<4.7 μm) is reported to reach as high as 80% using this inhaler.

Owner:NINGBO INHAL PHARMA CO LTD

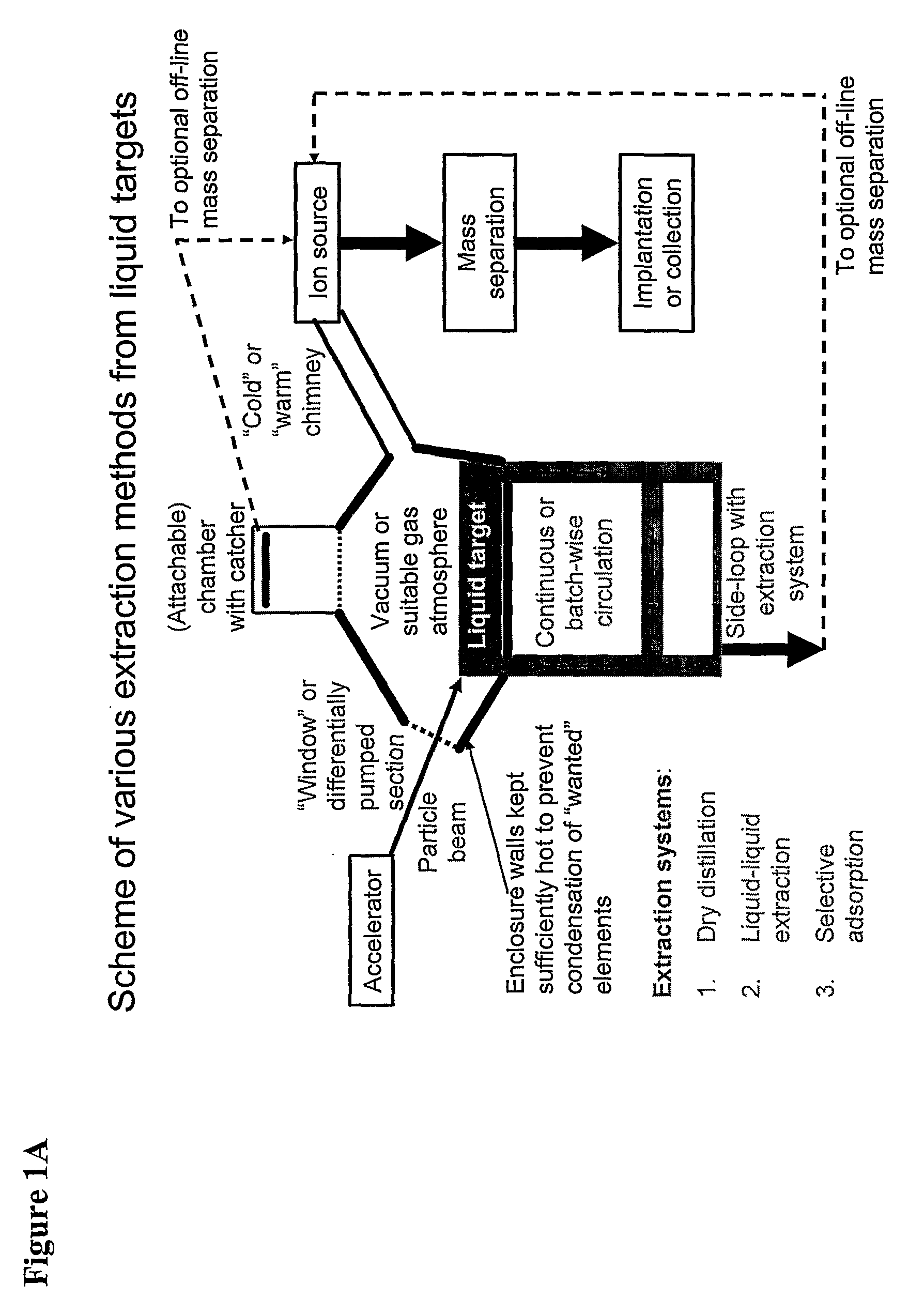

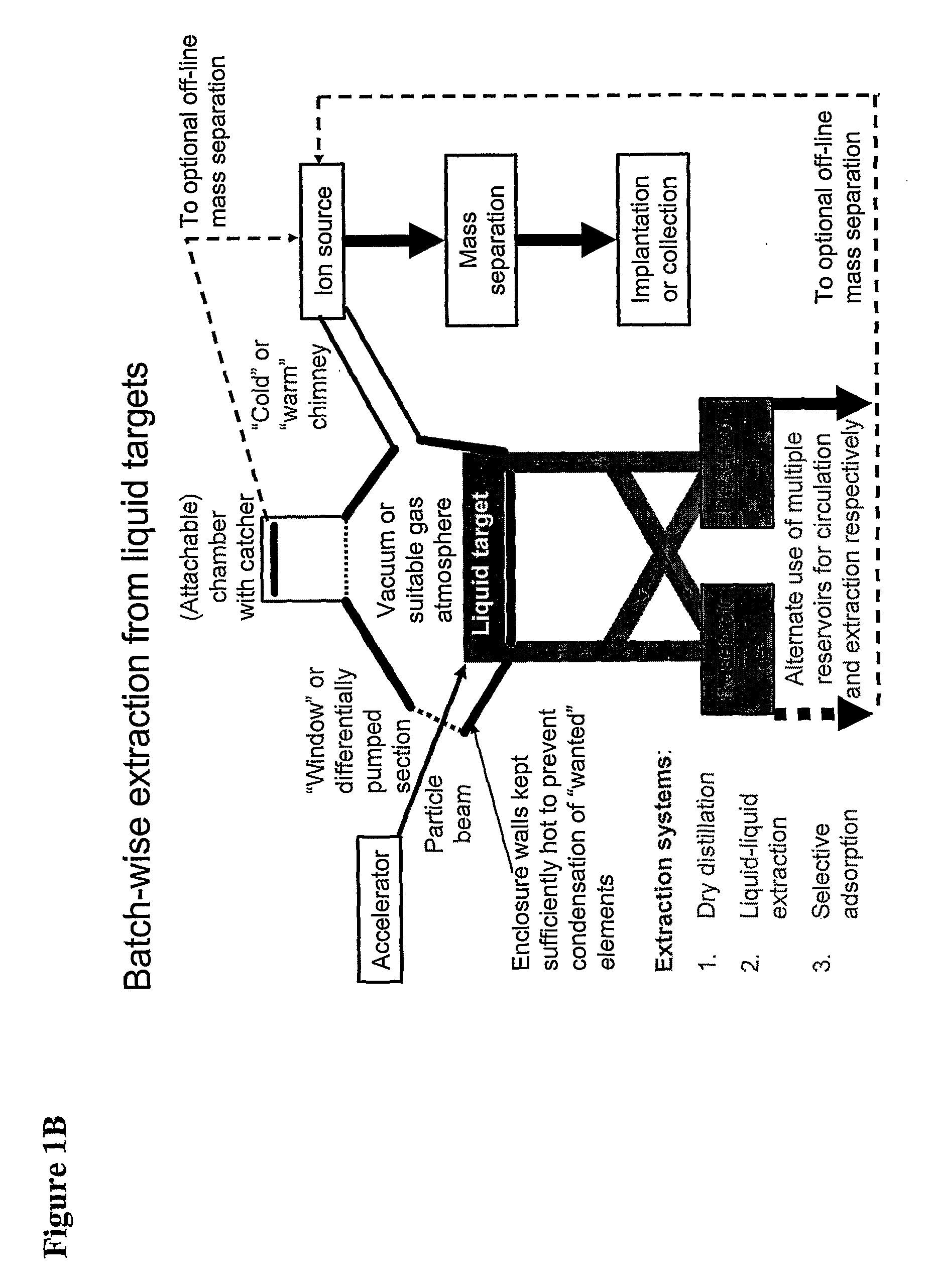

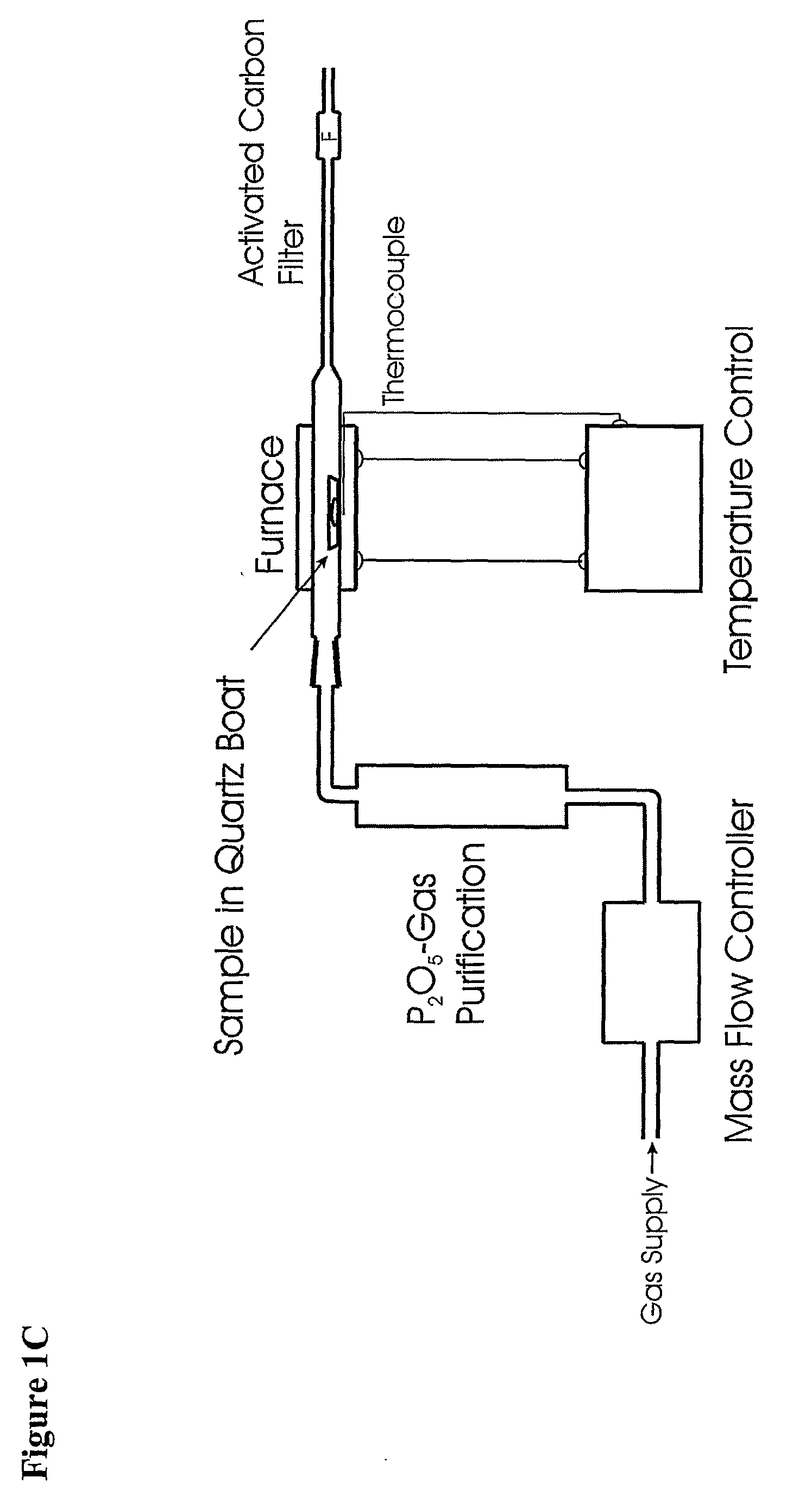

Method for Production of Radioisotope Preparations and Their Use in Life Science, Research, Medical Application and Industry

The present invention relates to an universal method for the large scale production of high-purity carrier free or non carrier added radioisotopes by applying a number of “unit operations” which are derived from physics and material science and hitherto not used for isotope production. A required number of said unit operations is combined, selected and optimised individually for each radioisotope production scheme. The use of said unit operations allows a batch wise operation or a fully automated continuous production scheme. The radioisotopes produced by the inventive method are especially suitable for producing radioisotope-labelled bioconjugates as well as particles, in particular nanoparticles and microparticles.

Owner:EUROPEAN ORGANIZATION FOR NUCLEAR RESEARCH +1

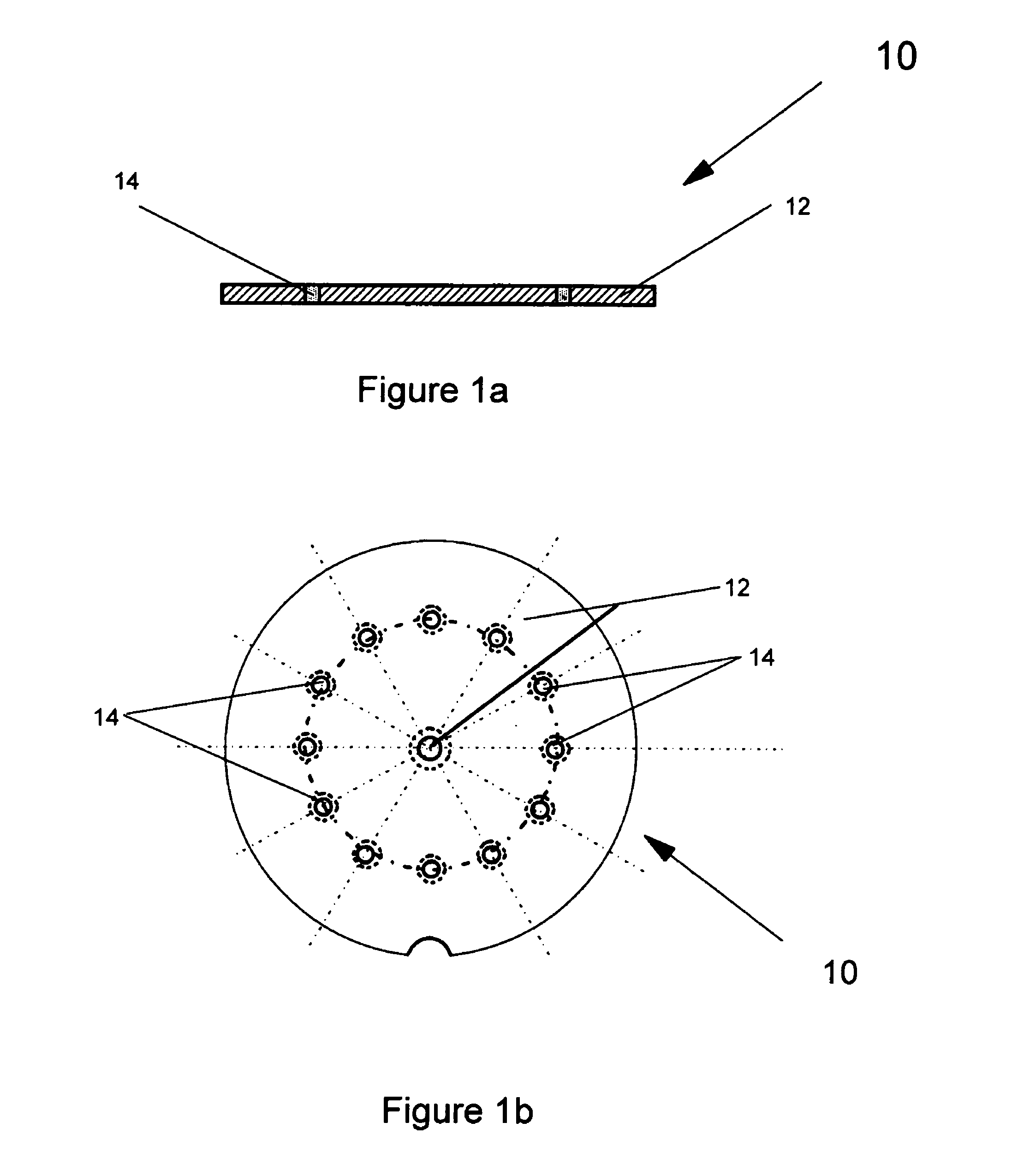

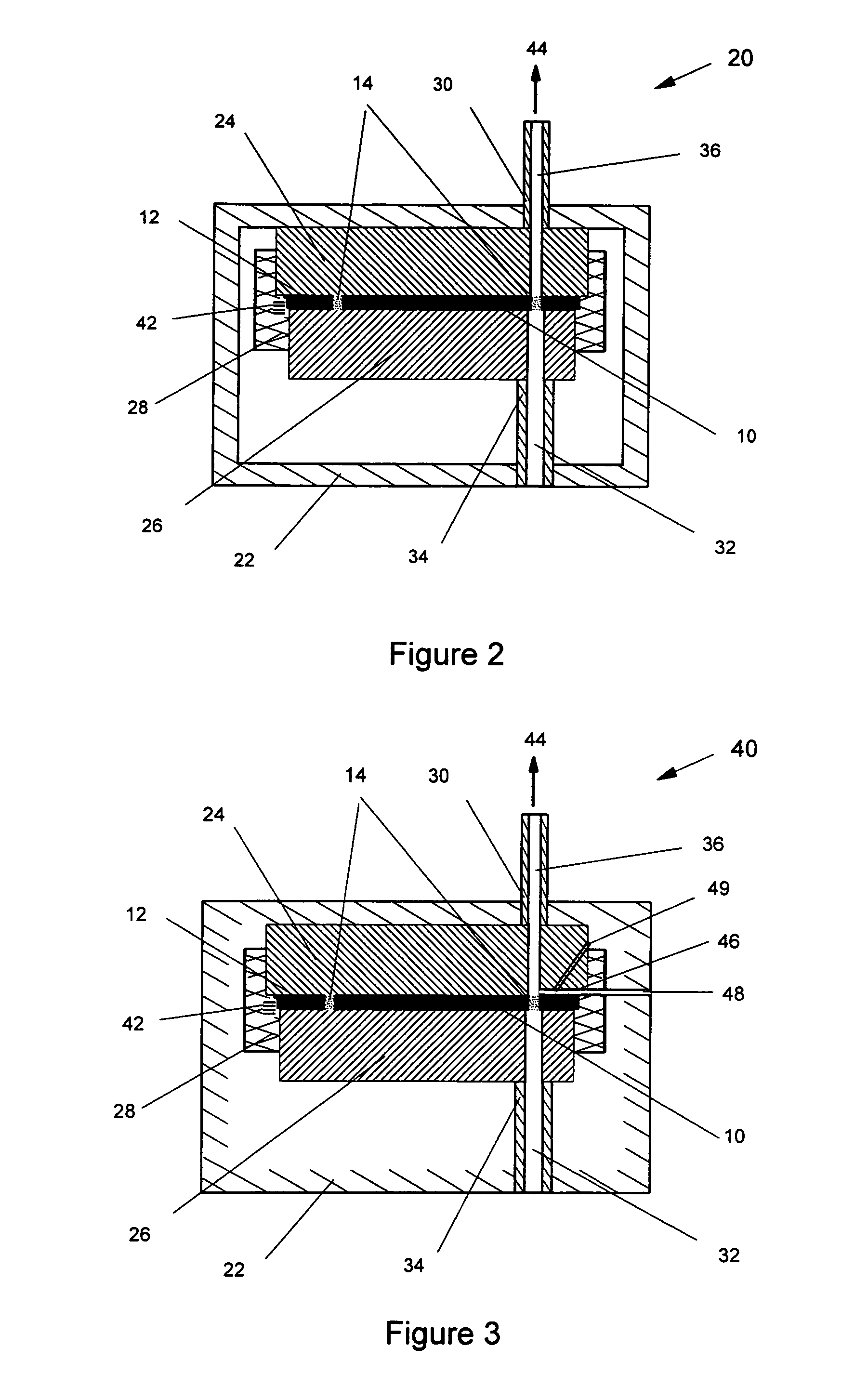

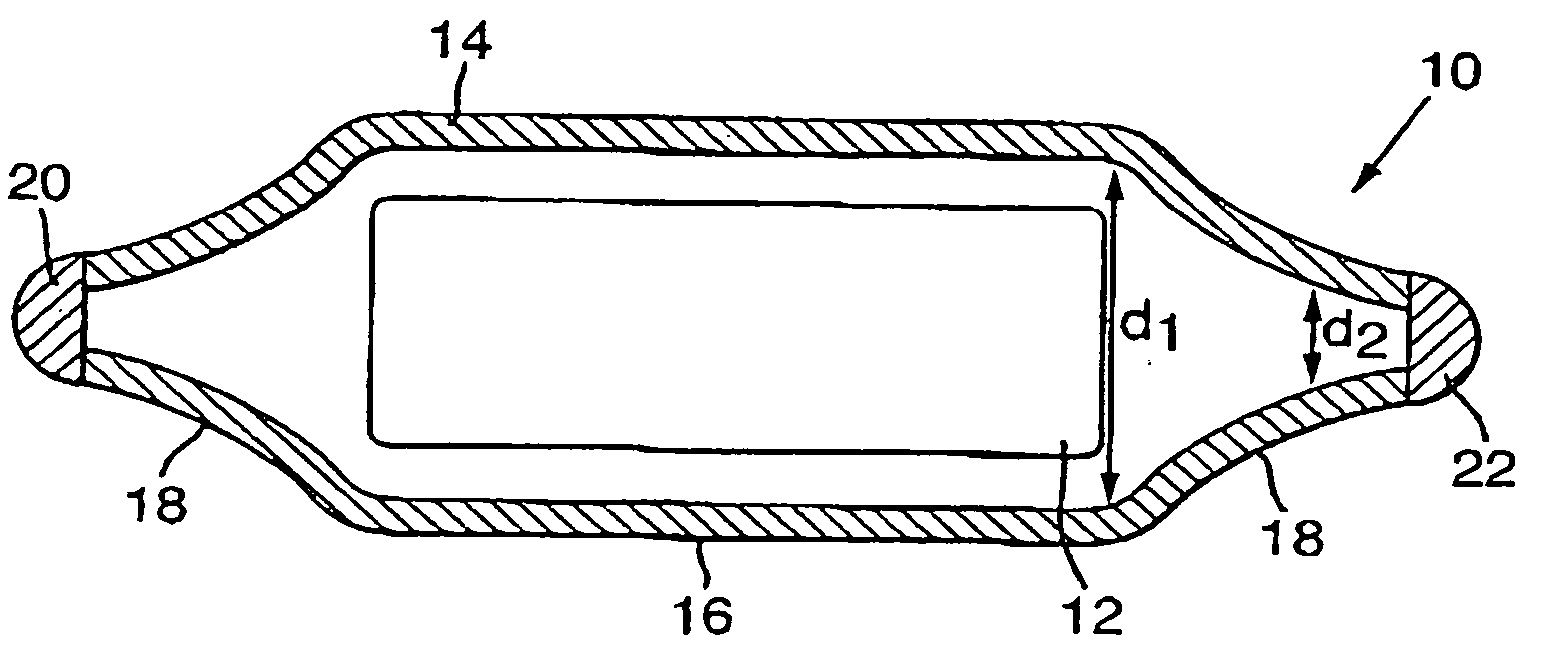

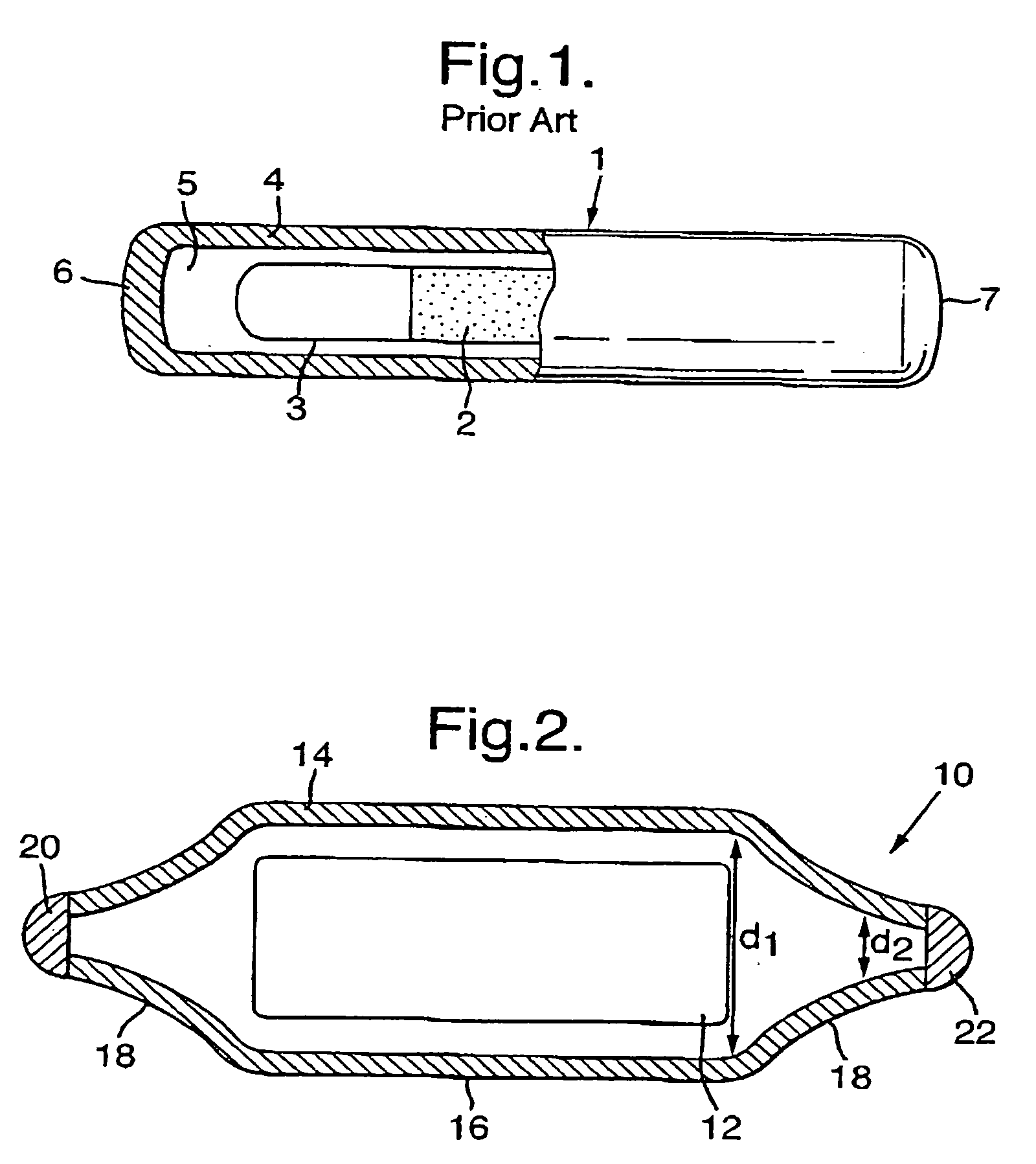

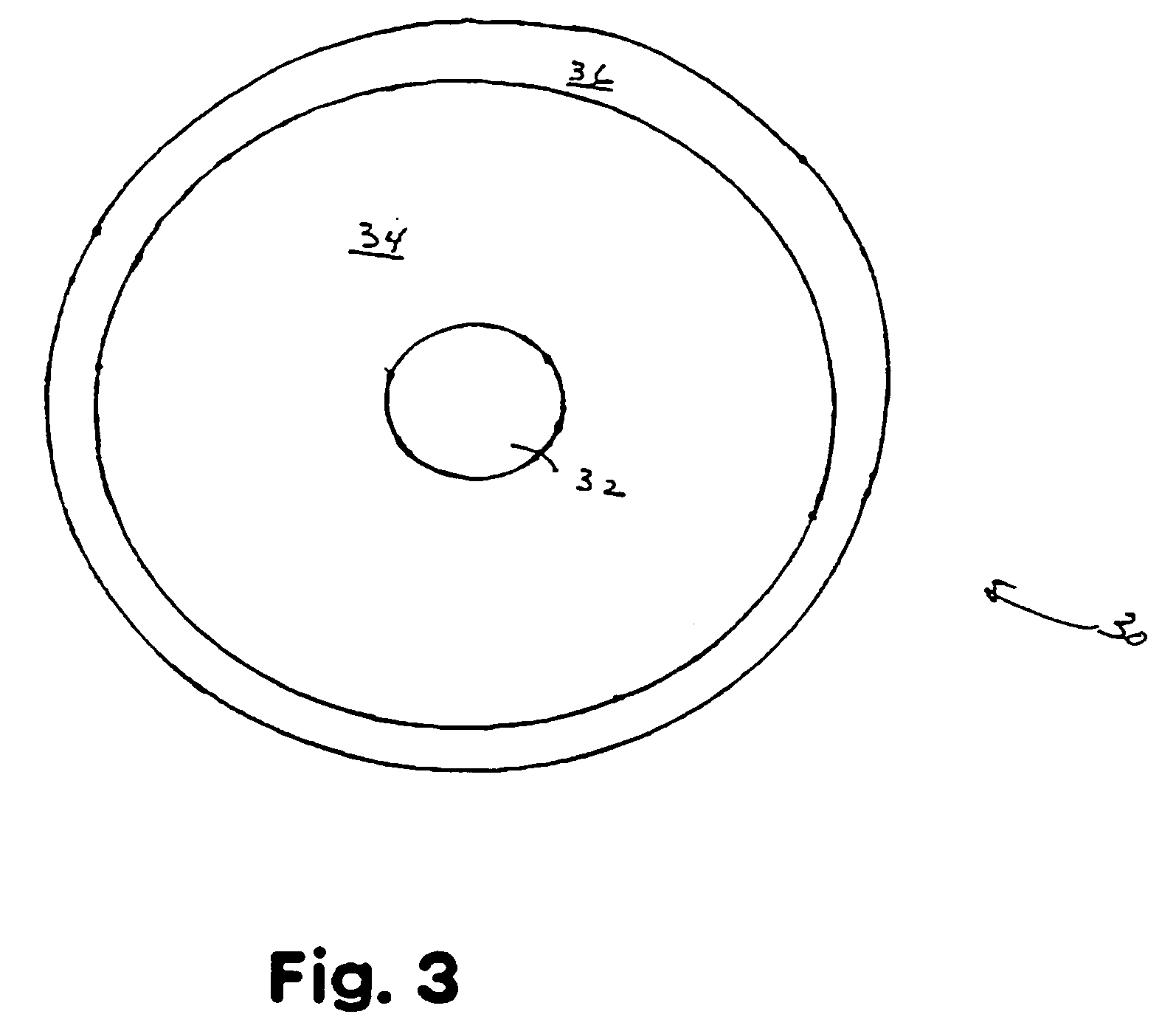

Carrier-free 103pd brachytherapy seeds

InactiveUS20060052654A1Uniform radiation dosePretreated surfacesRadioactive preparation formsBrachytherapyIsotope

A brachytherapy seed comprising (a) carrier-free 103Pd isotope, (b) a substrate for the carrier-free 103Pd radioisotope, and (c) a casing for encapsulating the carrier-free 103Pd-laden substrate, is disclosed.

Owner:MEDI PHYSICS IN

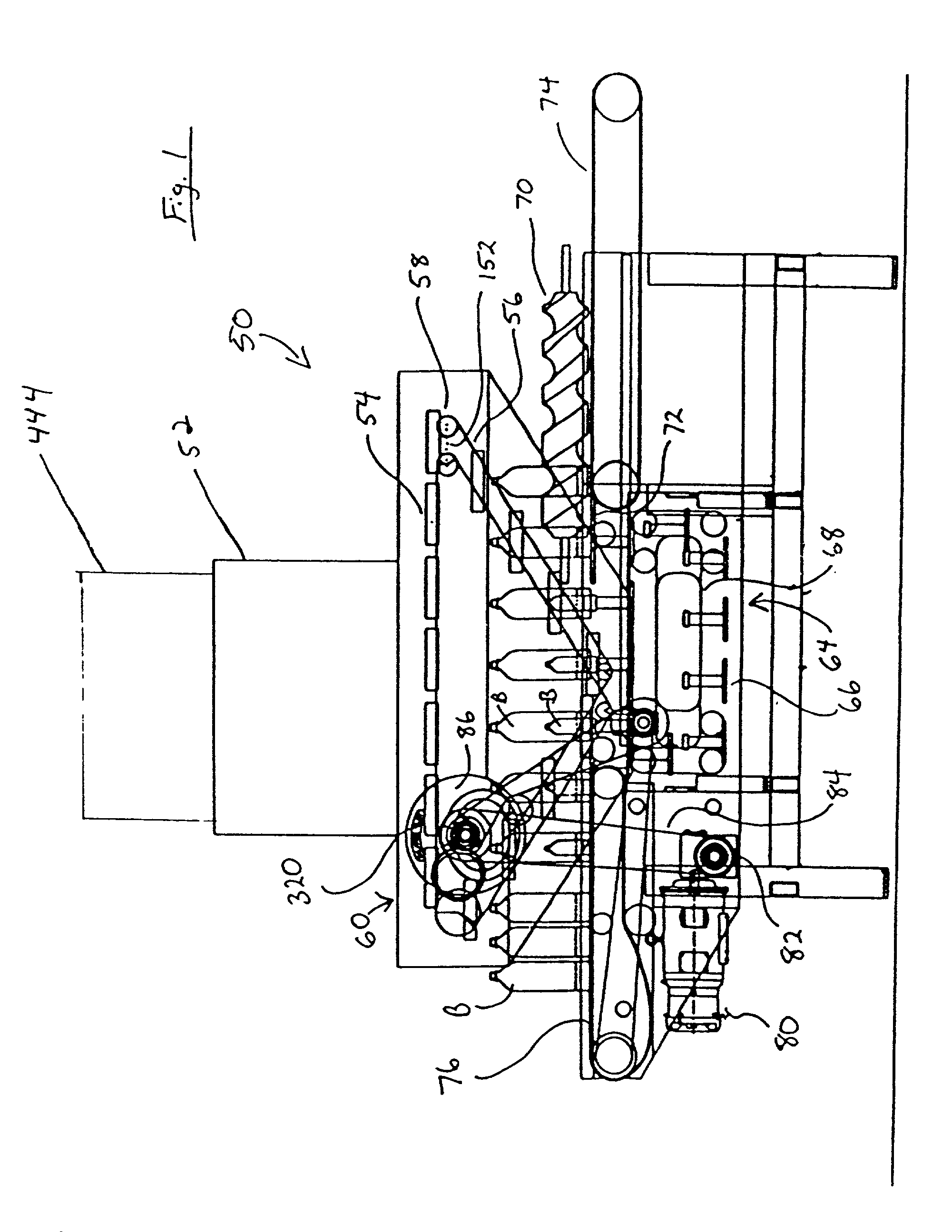

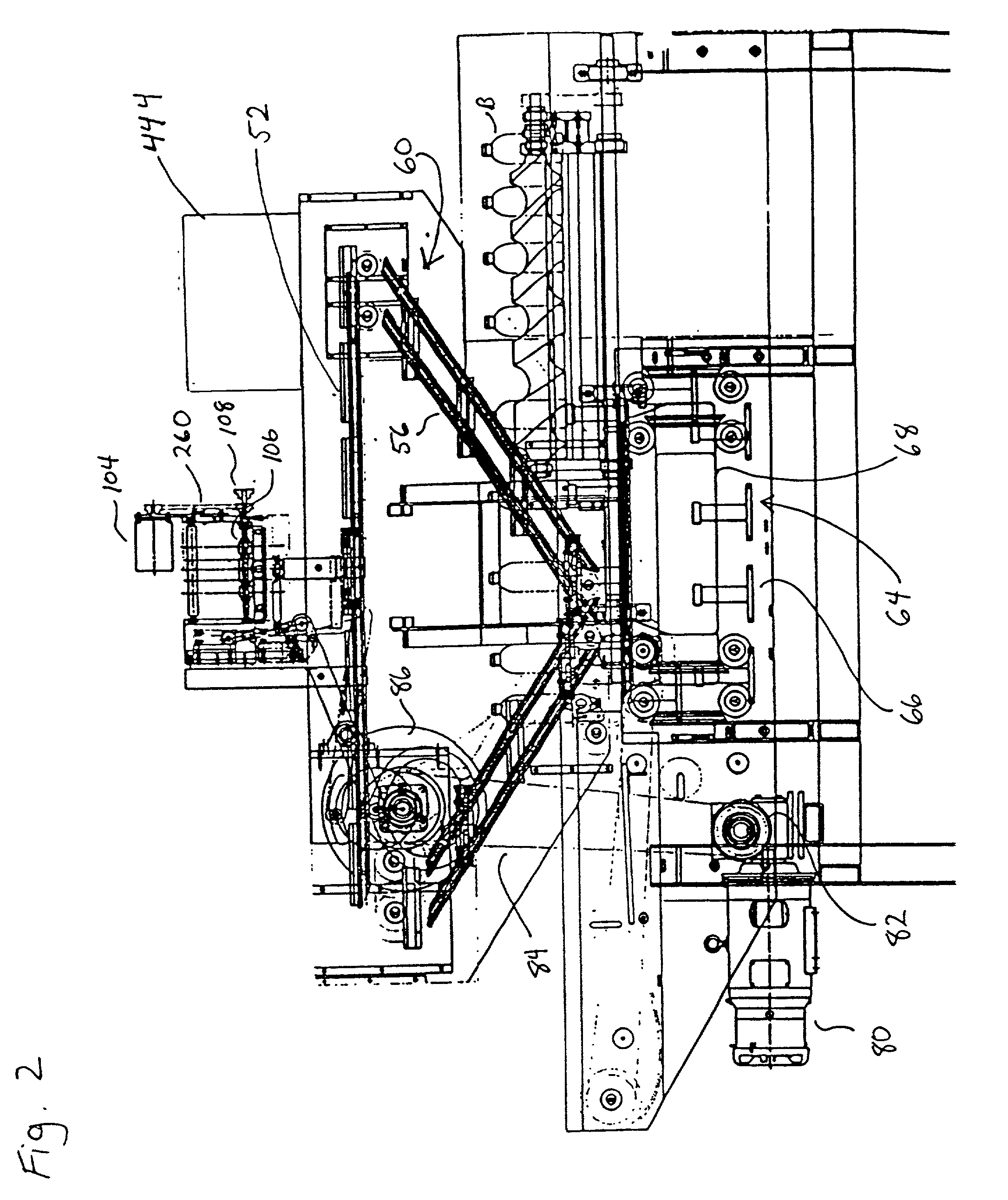

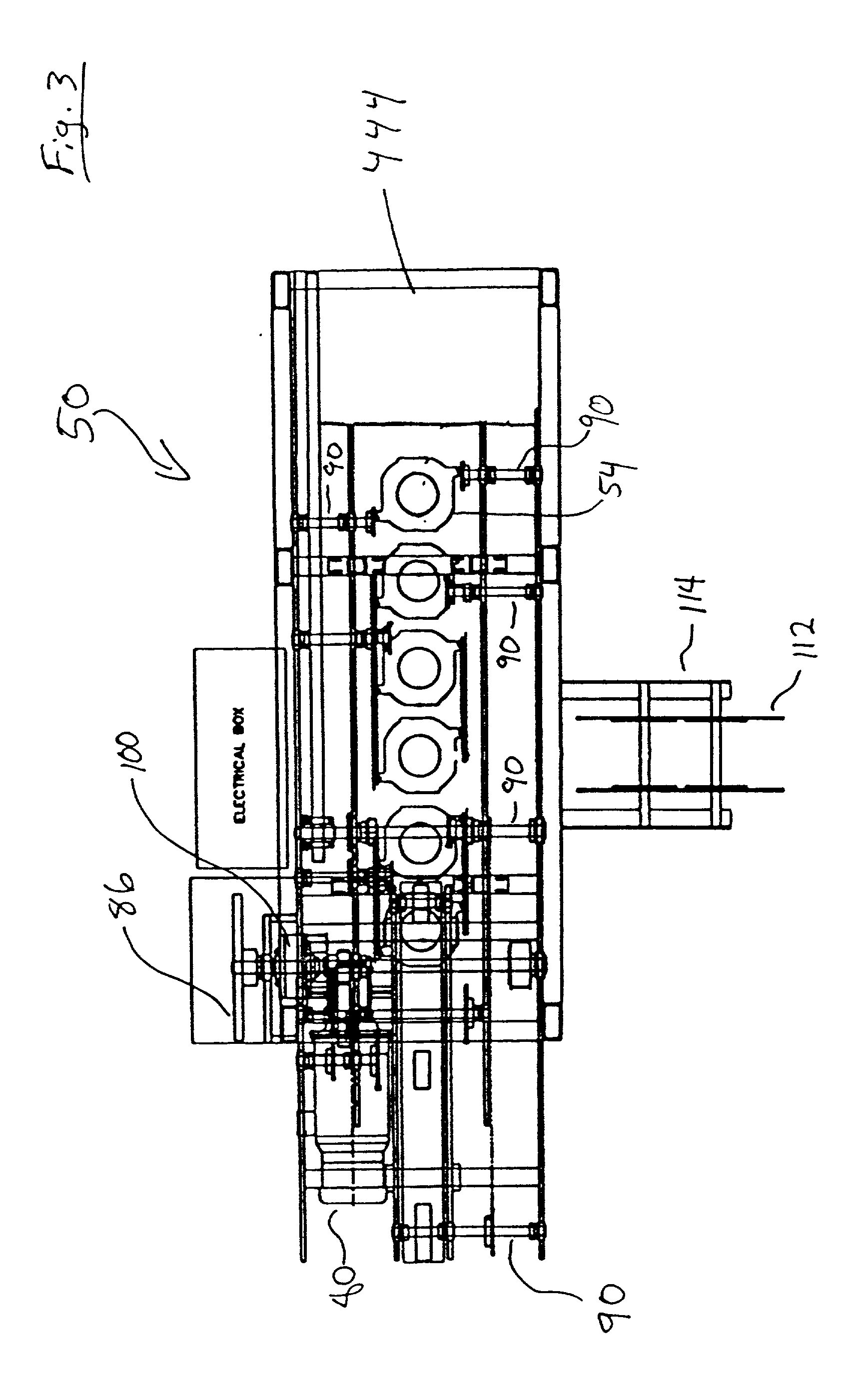

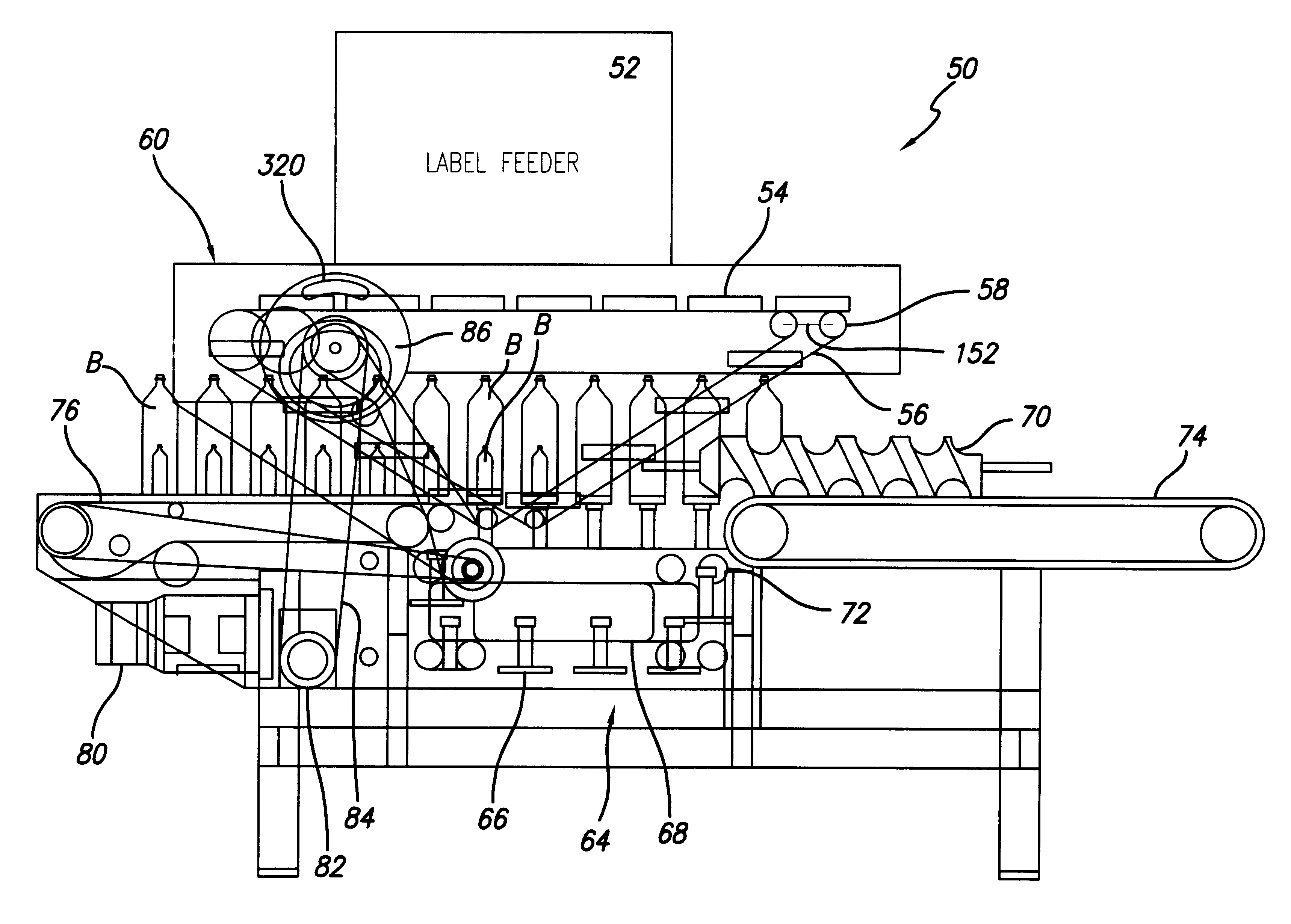

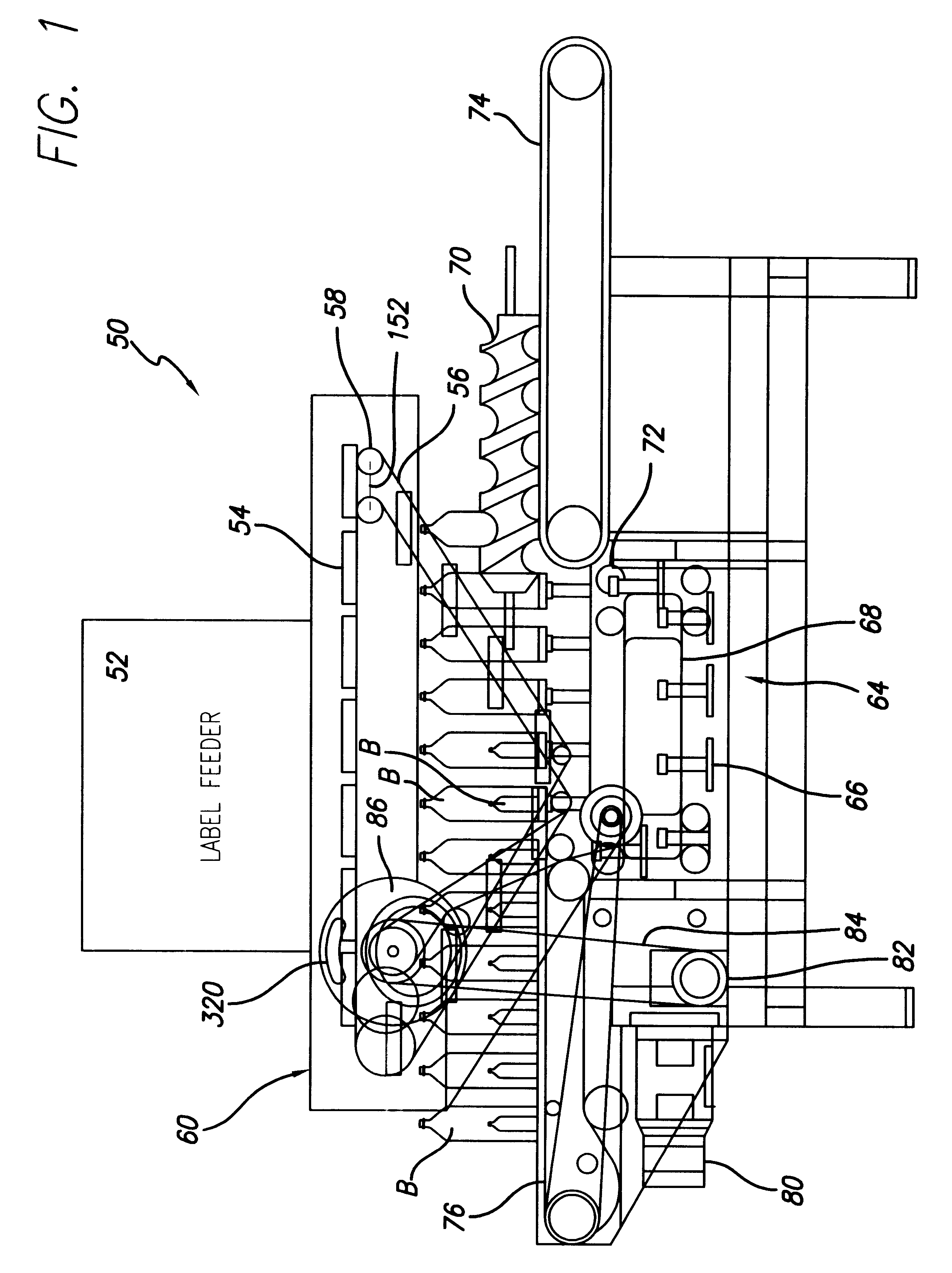

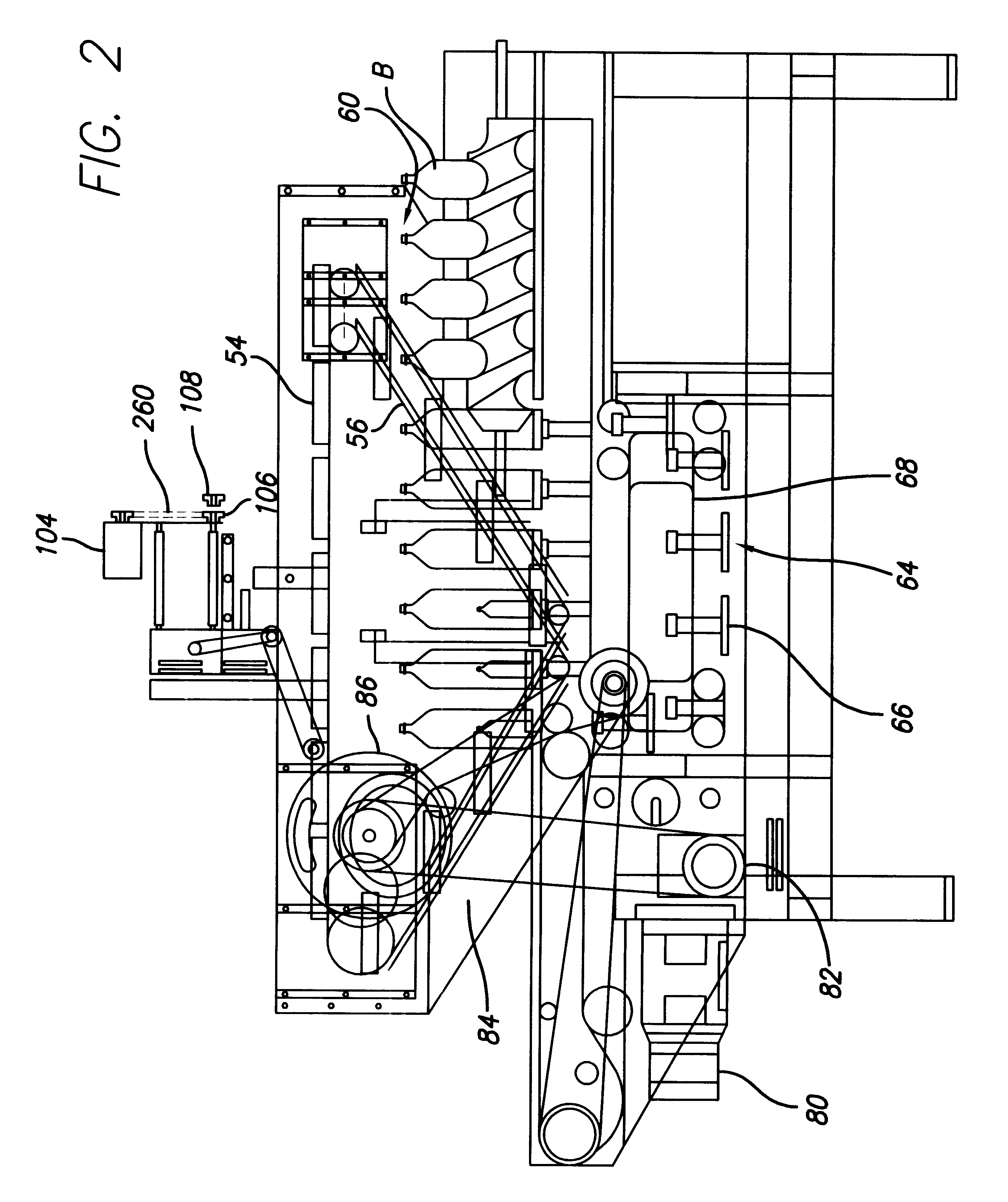

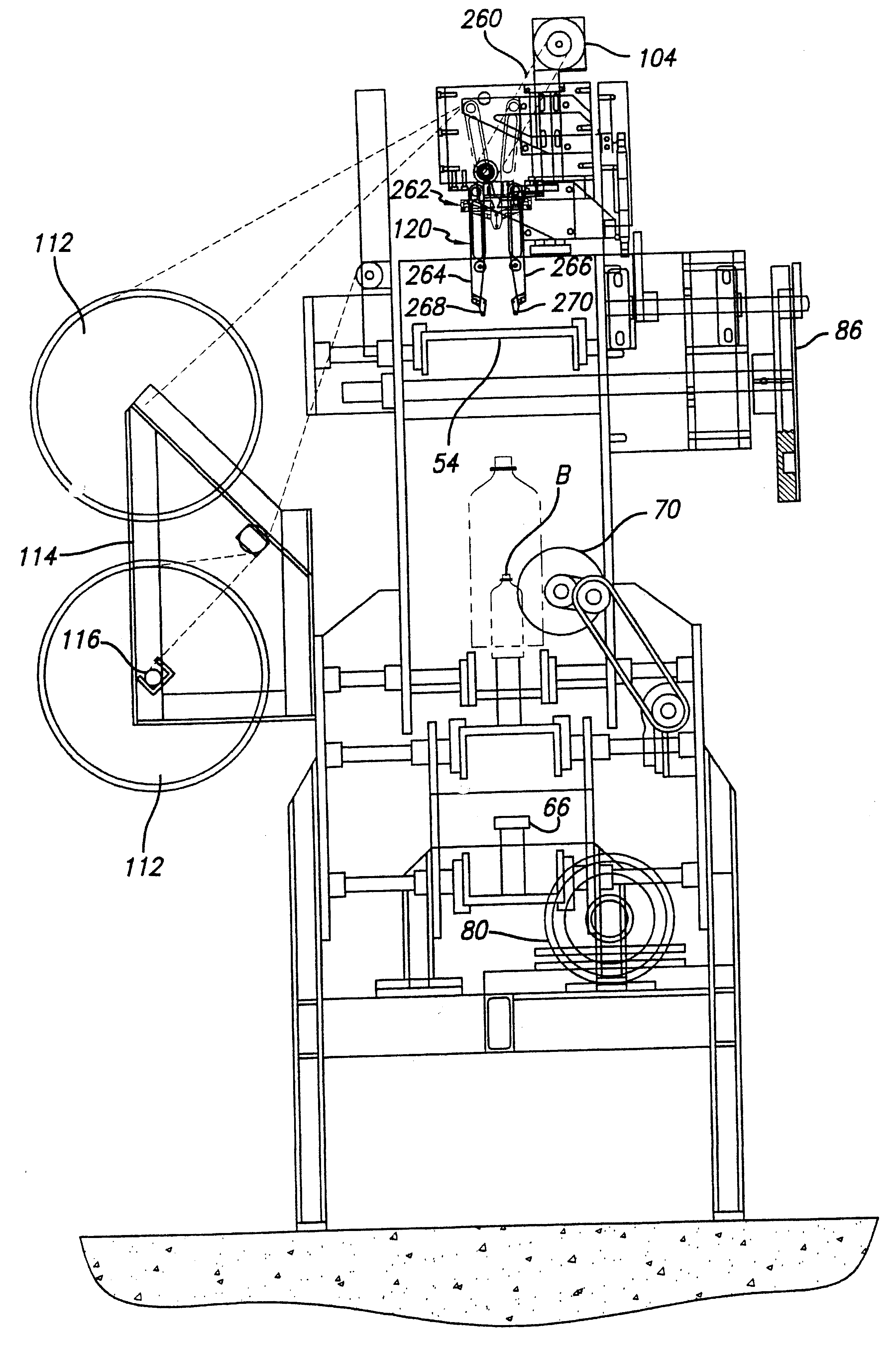

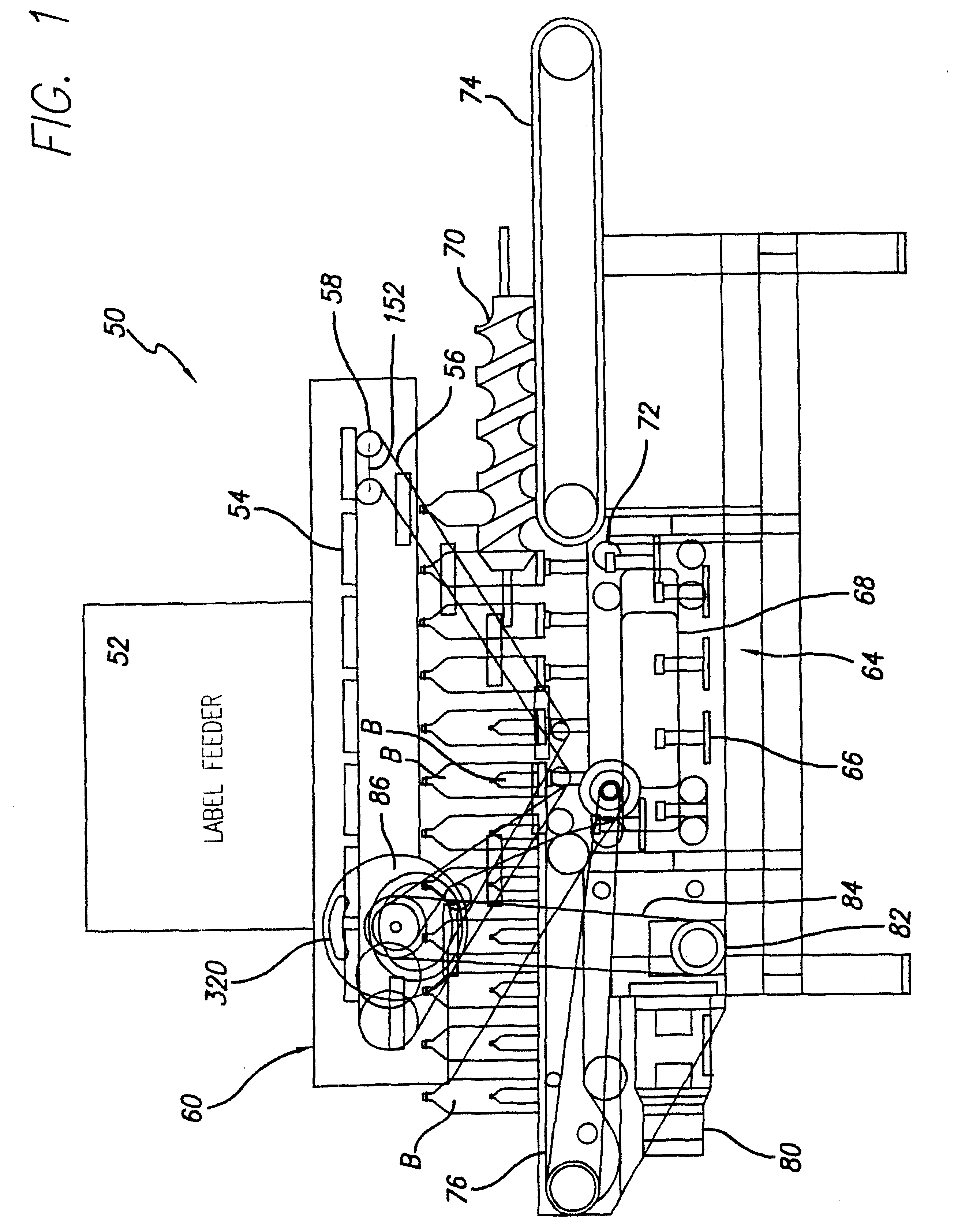

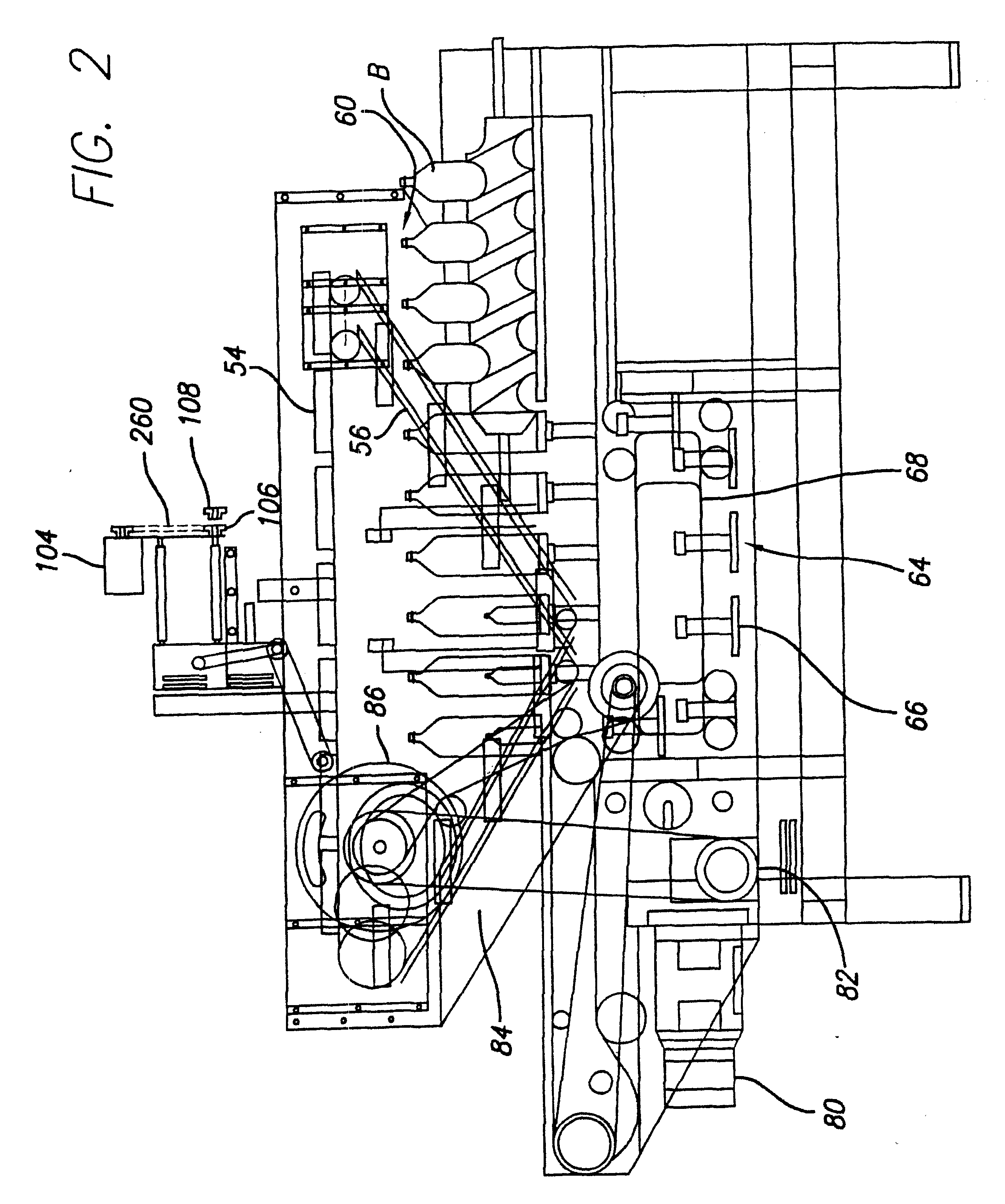

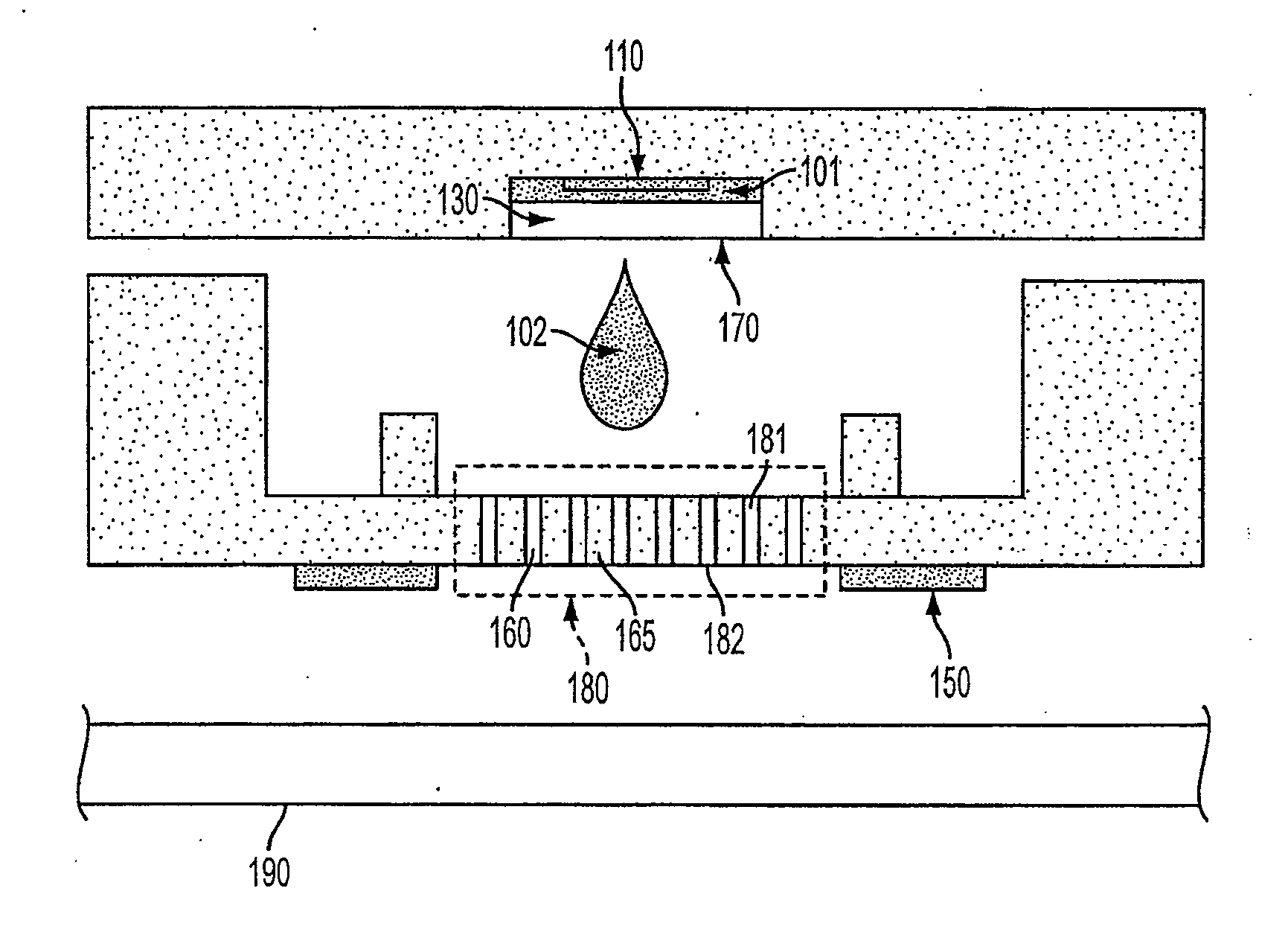

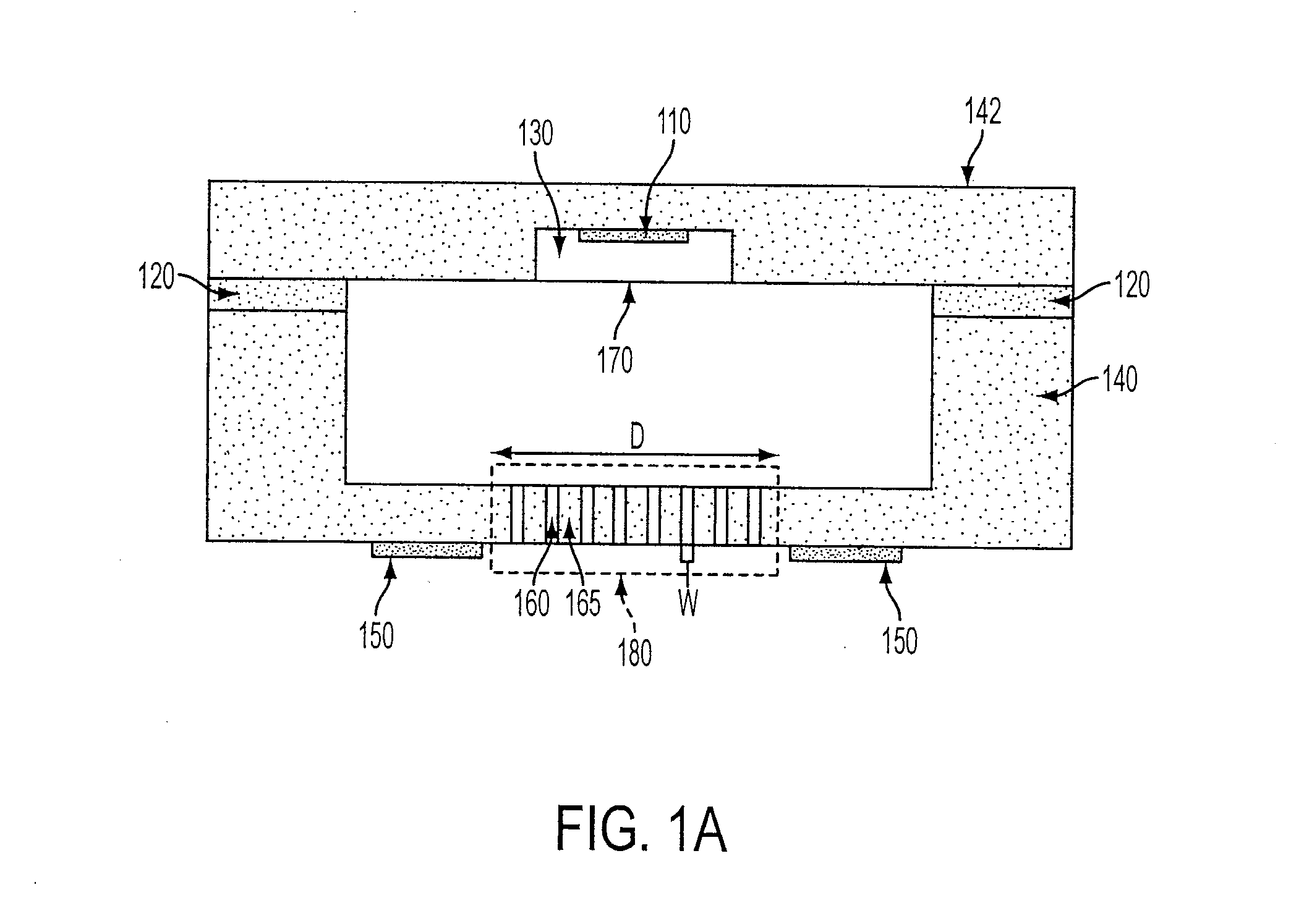

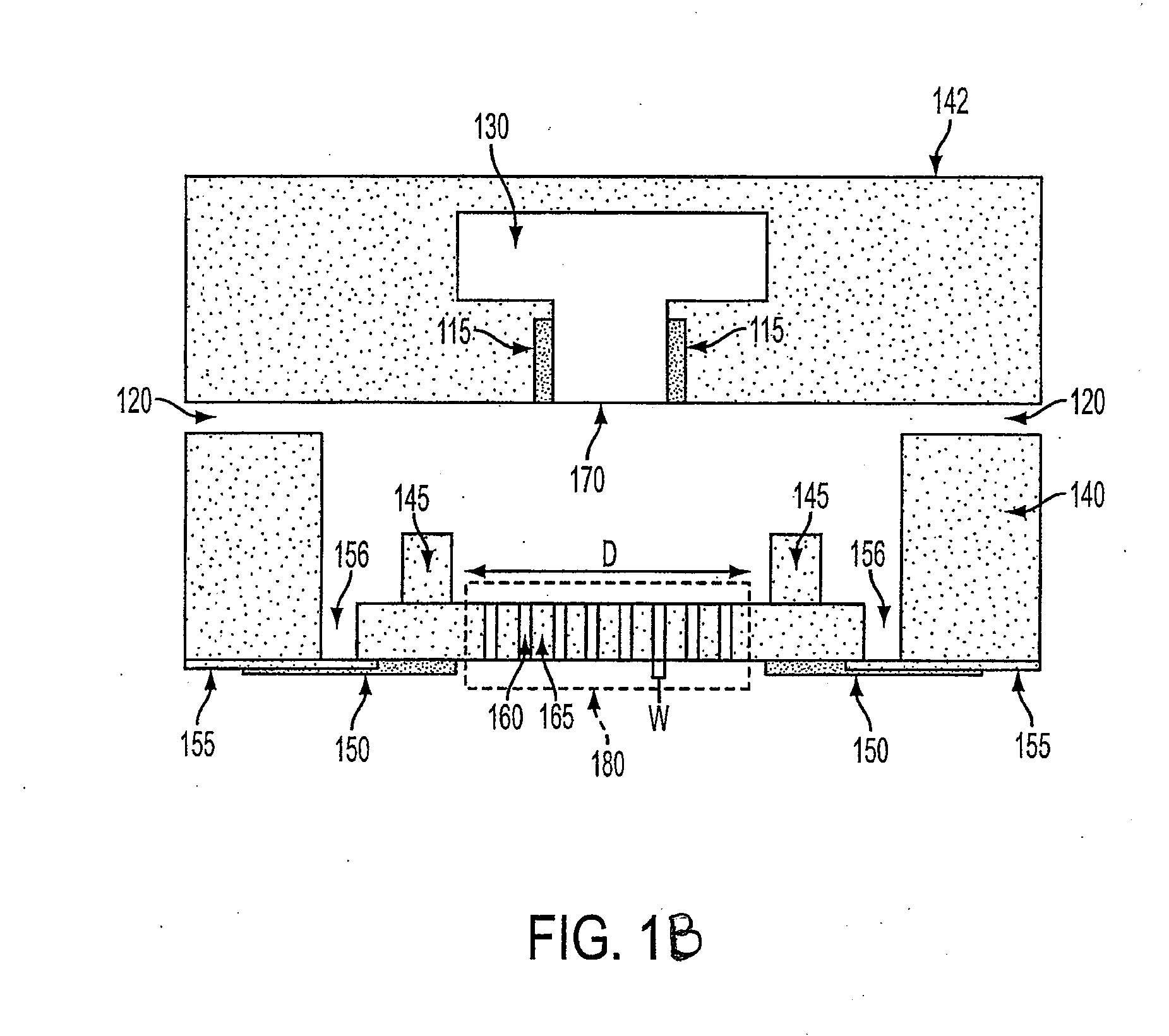

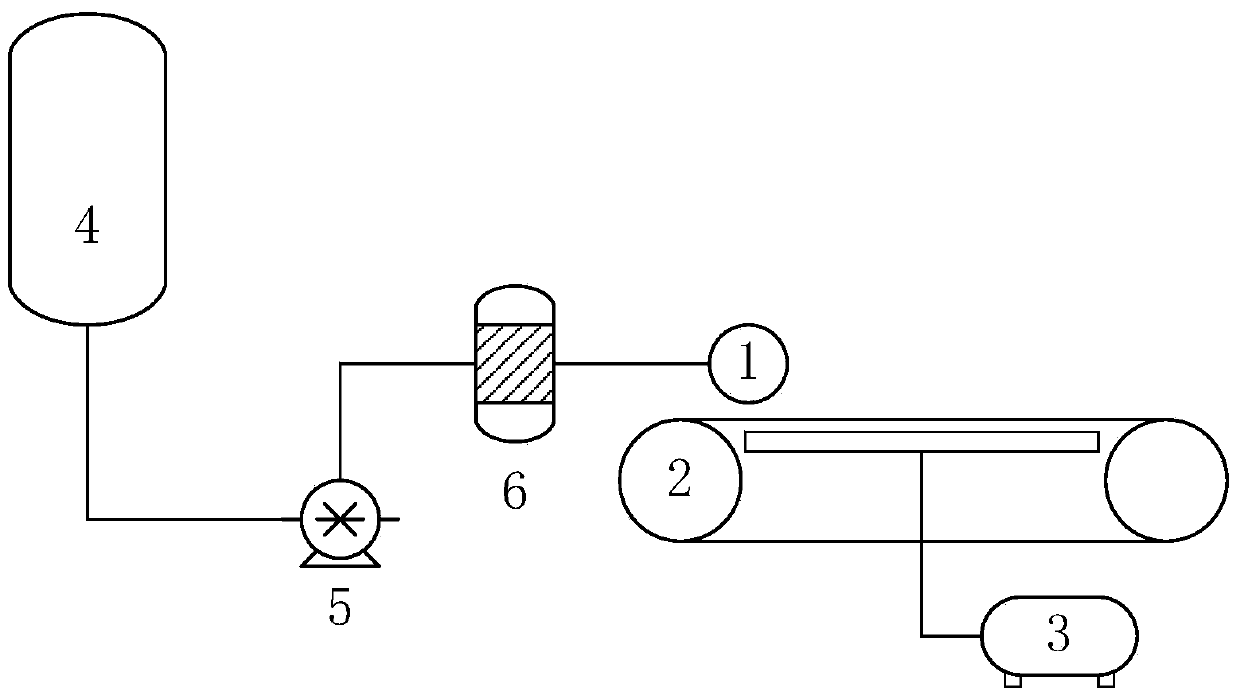

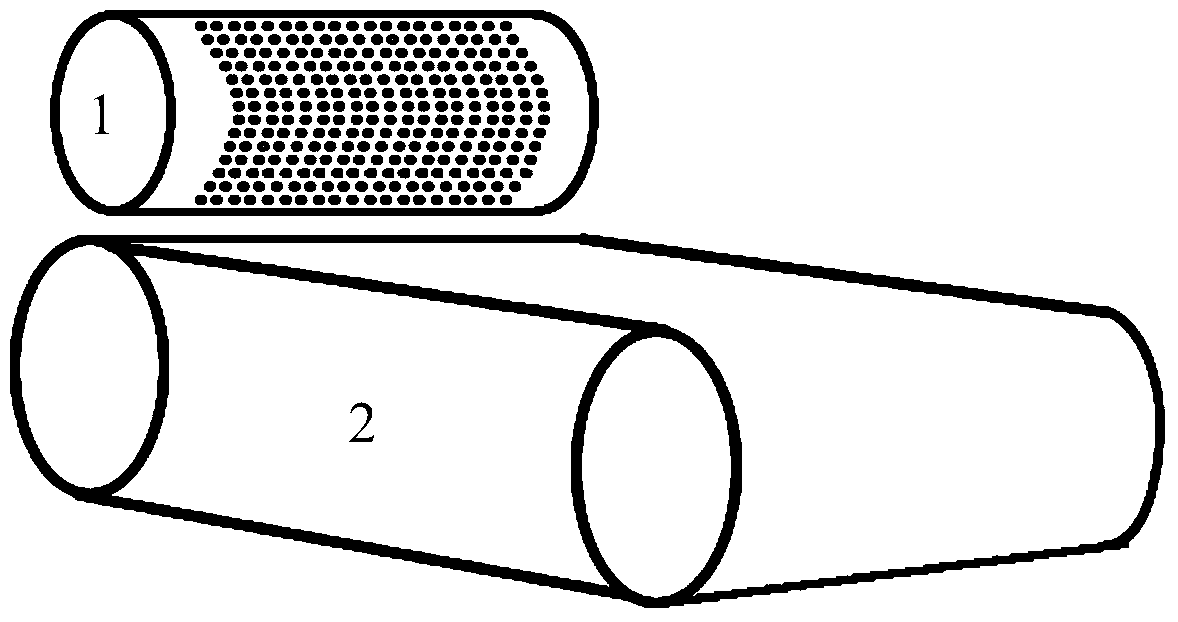

In-line continuous feed sleeve labeling machine and method

InactiveUS20010002614A1Wrappers shrinkageMechanical working/deformationUltrasonic weldingEngineering

An in-line continuous feed sleeve labeling machine labels containers, such as beverage containers, in an in-line fashion maintaining the elevation of the containers during their linear transport. The in-line continuous feed sleeve labeling machine of the present invention receives bottles in flood feeder or linear fashion. A timing screw or the like properly separates, and both spatially and temporally disposes, the containers for sleeving. The timing screw propels the containers onto a pedestal system. The pedestals of the pedestal system maintain their horizontal nature due to offset pivotable attachments to the track system upon which they travel. A sheet of film is unspooled from an unwind roll and passed through a tube forming apparatus that overlaps the edges of the film. The overlapping edges completing the tube enclosure are connected using ultrasonic welding or the like. The sleeve is then passed to an iris carrier. In coordinated fashion with the travel of the pedestal system, iris carriers carrying sleeves upon articulating radial arms descend upon the bottles. Once the label sleeve has reached the appropriate point (generally adjacent to the central portion of the bottle), the iris carrier allows the label sleeve to engage the central portion of the bottle. Frictional attachment or otherwise allows the finger rods of the iris carrier to pull away from the sleeve as the iris carrier continues to descend down towards the pedestal. The sleeve then becomes attached to or engaged by the bottle until the finger rods of the iris carrier free themselves from the sleeve label. A container stabilizer may provide lateral bottle support and aid the ensleevement process. The finger rods then dilate to better disengage the bottle as the iris carrier ascends up and away from the bottle. The bottle is then transported to an exit conveyor having been properly sleeved, while the iris carrier returns to transport another sleeve.

Owner:AXON LLC

In-line continuous feed sleeve labeling machine and method

An in-line continuous feed sleeve labeling machine labels containers, such as beverage containers, in an in-line fashion maintaining the elevation of the containers during their linear transport. The in-line continuous feed sleeve labeling machine of the present invention receives bottles in flood feeder or linear fashion. A timing screw or the like properly separates, and both spatially and temporally disposes, the containers for sleeving. The timing screw propels the containers onto a pedestal system. The pedestals of the pedestal system maintain their horizontal nature due to offset pivotable attachments to the track system upon which they travel. In coordinated fashion with the travel of the pedestal system, iris carriers carrying sleeves upon articulating radial arms descend upon the bottles. Once the label sleeve has reached the appropriate point (generally adjacent to the central portion of the bottle), the iris carrier allows the label sleeve to engage the central portion of the bottle. Frictional attachment or otherwise allows the finger rods of the iris carrier to pull away from the sleeve as the iris carrier continues to descend down towards the pedestal. The sleeve then becomes attached to or engaged by the bottle until the finger rods of the iris carrier free themselves from the sleeve label. A container stabilizer may provide lateral bottle support and aid the ensleevement process. The finger rods then dilate to better disengage the bottle as the iris carrier ascends up and away from the bottle. The bottle is then transported to an exit conveyor having been properly sleeved, while the iris carrier returns to transport another sleeve.

Owner:AXON LLC

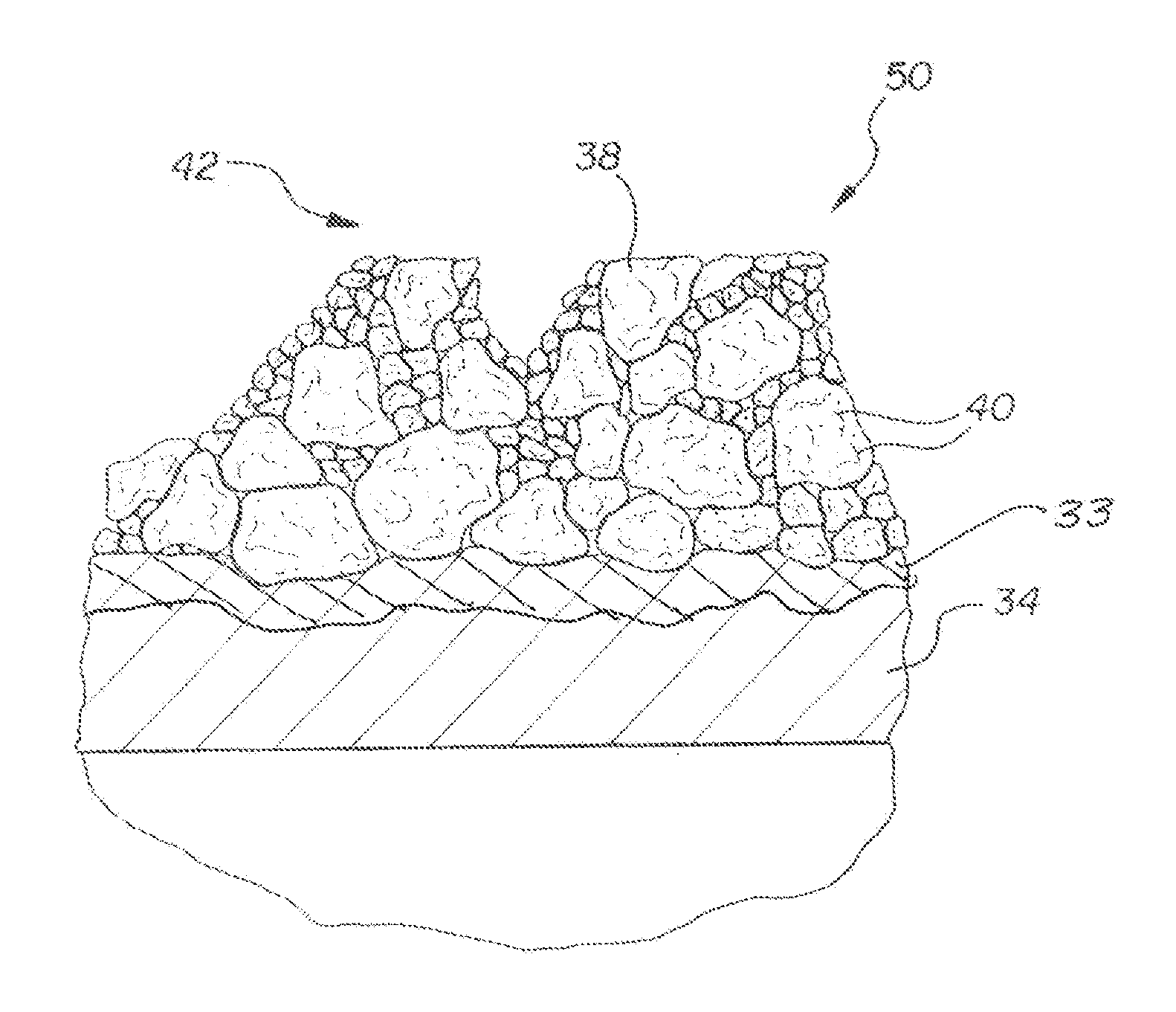

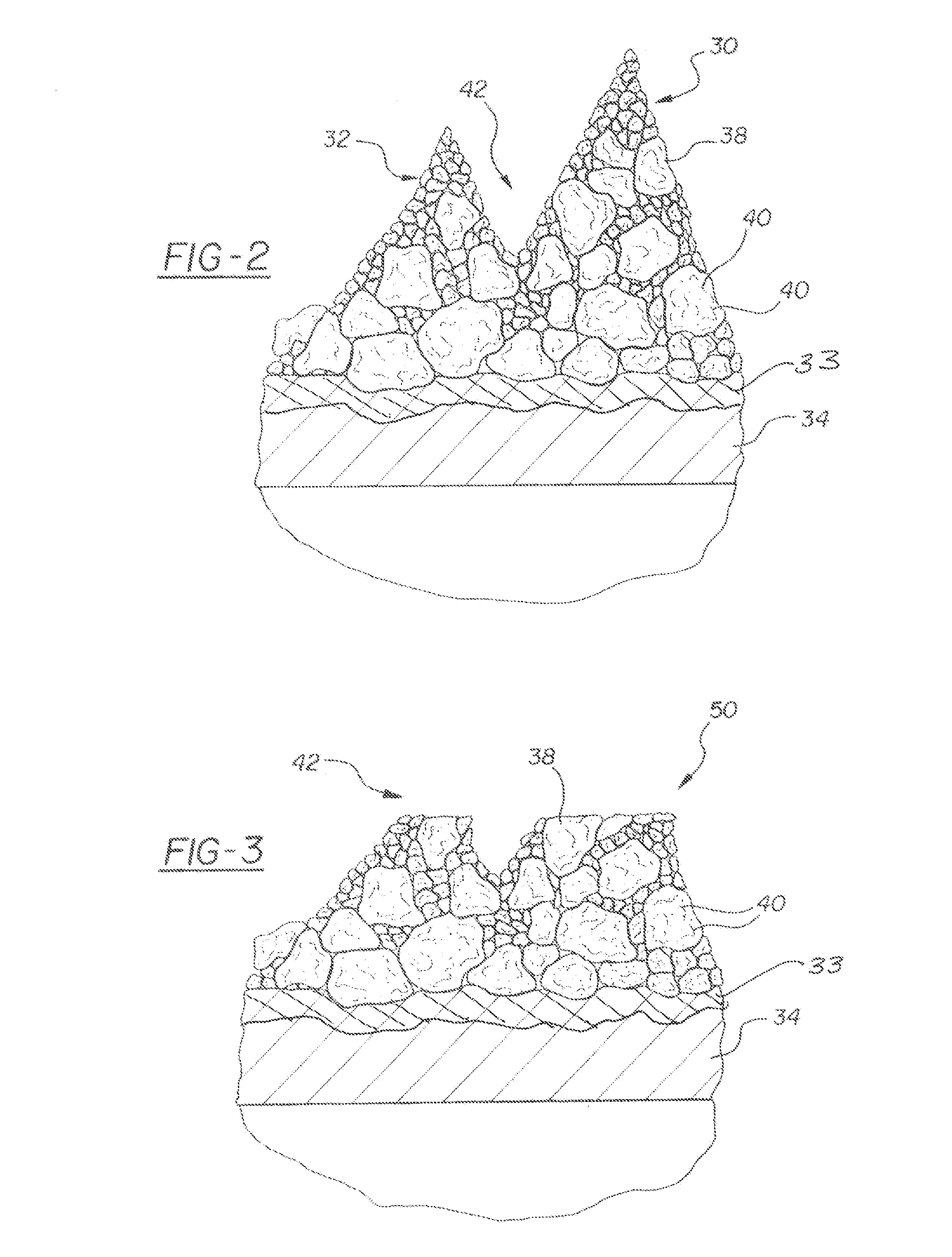

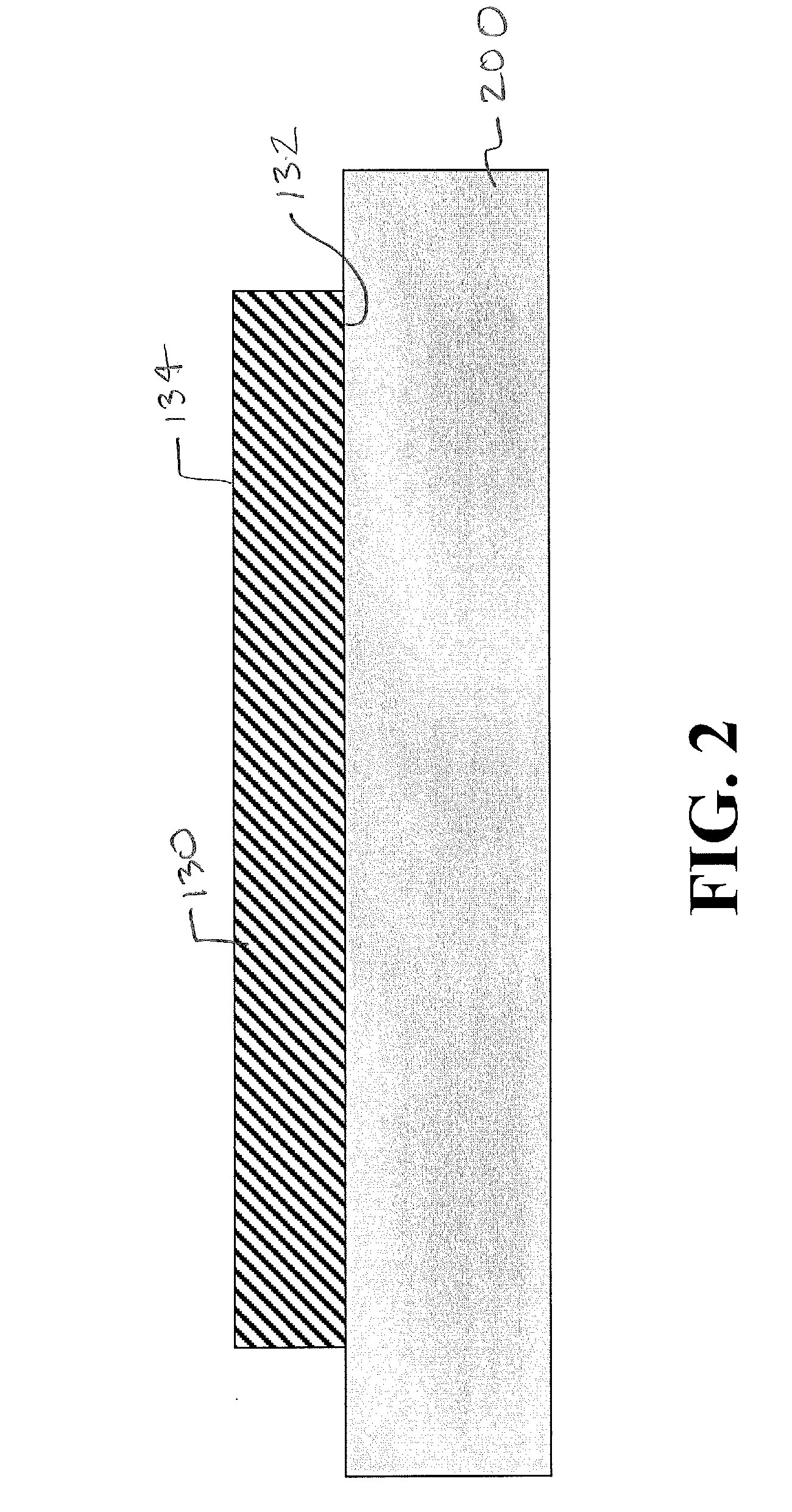

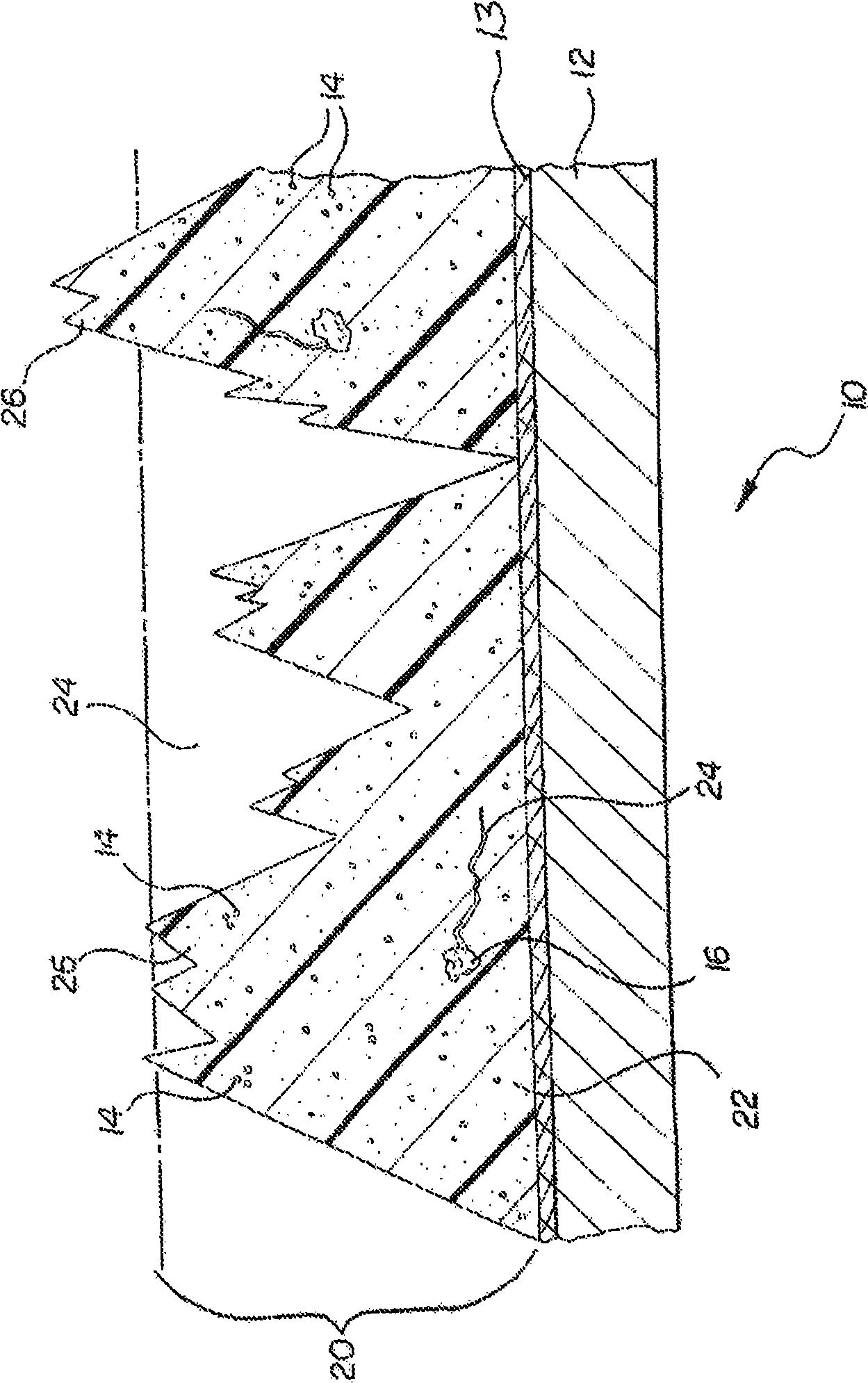

Abradable Dry Film Lubricant and the Method for Applying Same and Article Made Therefrom

An article with an abradable dry powder coating thereon comprises an abradably coated article with a substrate surface and having at least one coating of a liquid primer on the substrate surface and then coating with at least one abradable dry powder coating on the surface of the liquid primer. The sequence of layers may also be reversed, or additional layers may be useful. The abradable dry powder coating is formed of a dry powder coating composition including a thermoset resin having a cure temperature combined with at least one filler material, wherein the filler is formed of a material which does not melt substantially at or below the cure temperature of the resin, whereby an abradable coating results employing a filler to make the coating. A method of making a composition for coating an article with a coating curable into an abradable coating is also disclosed, comprising melt-mixing an evaporative carrier-free mixture of a dry powder thermoset resin having a cure temperature, to form a mass composite, wherein the filler is formed of a material which does not substantially melt at or below the cure temperature of the resin, cooling the mass composite, and breaking the cooled mass composite into powder particles, thereby forming the composite powder composition.

Owner:LINE 2 LINE INC

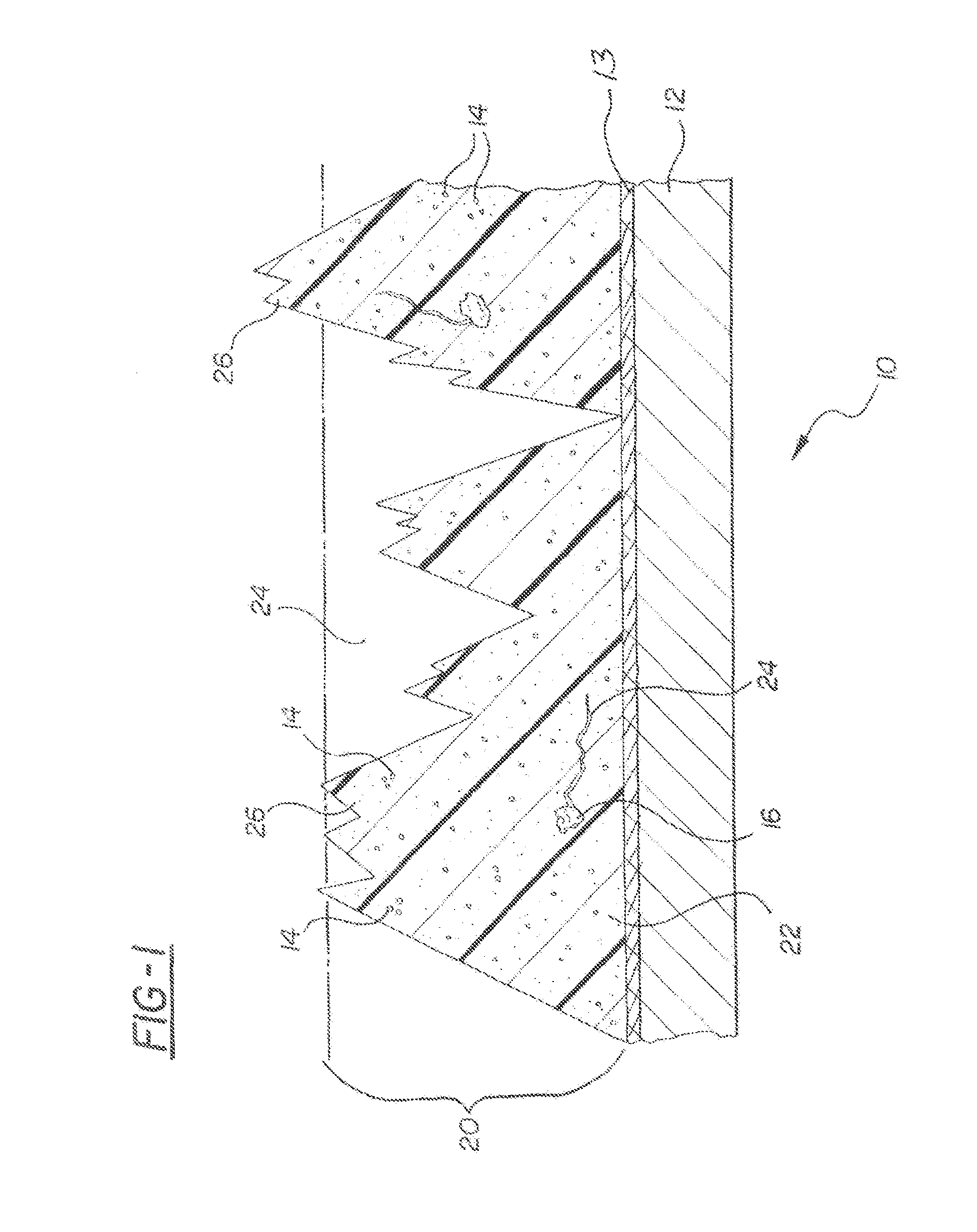

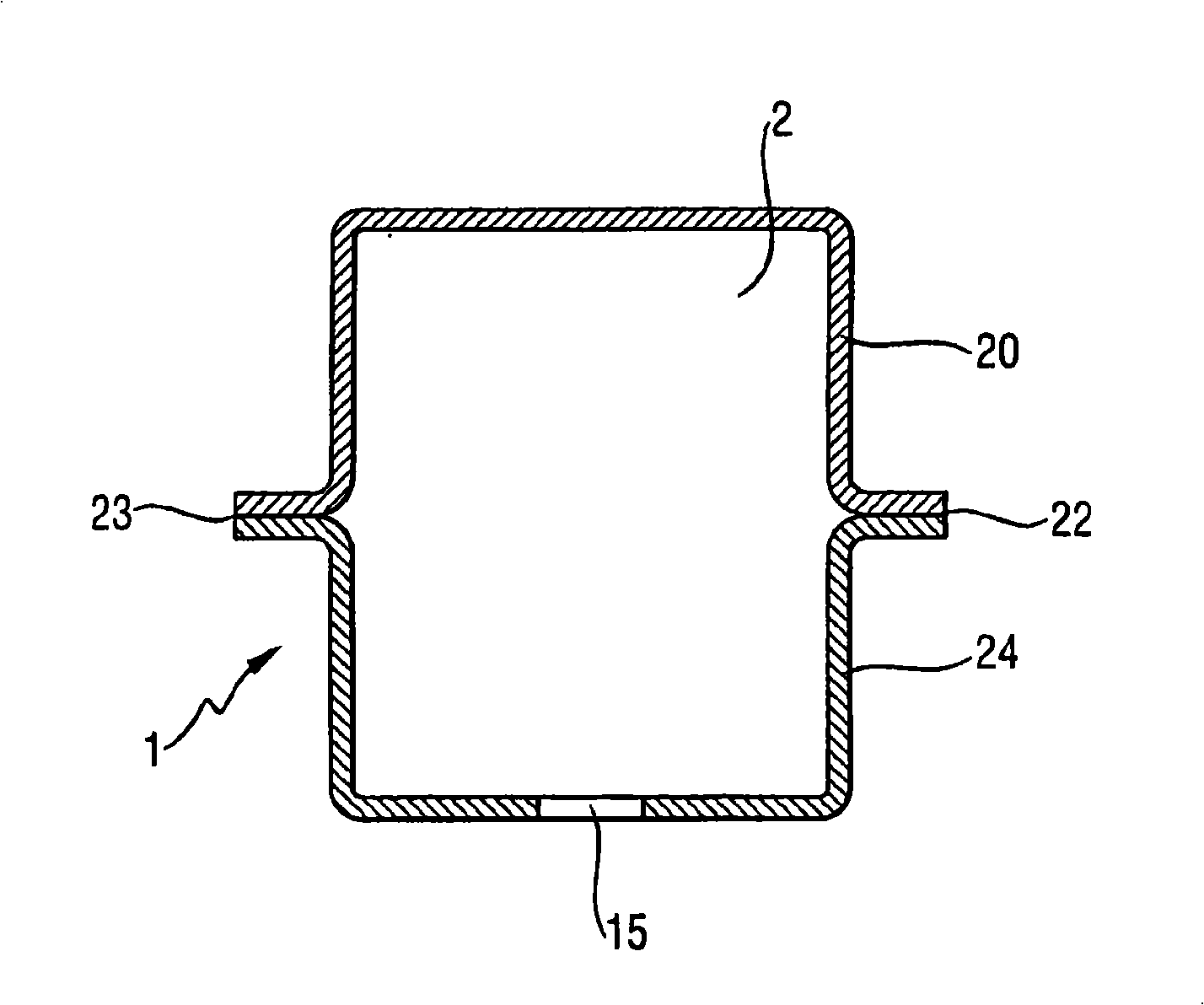

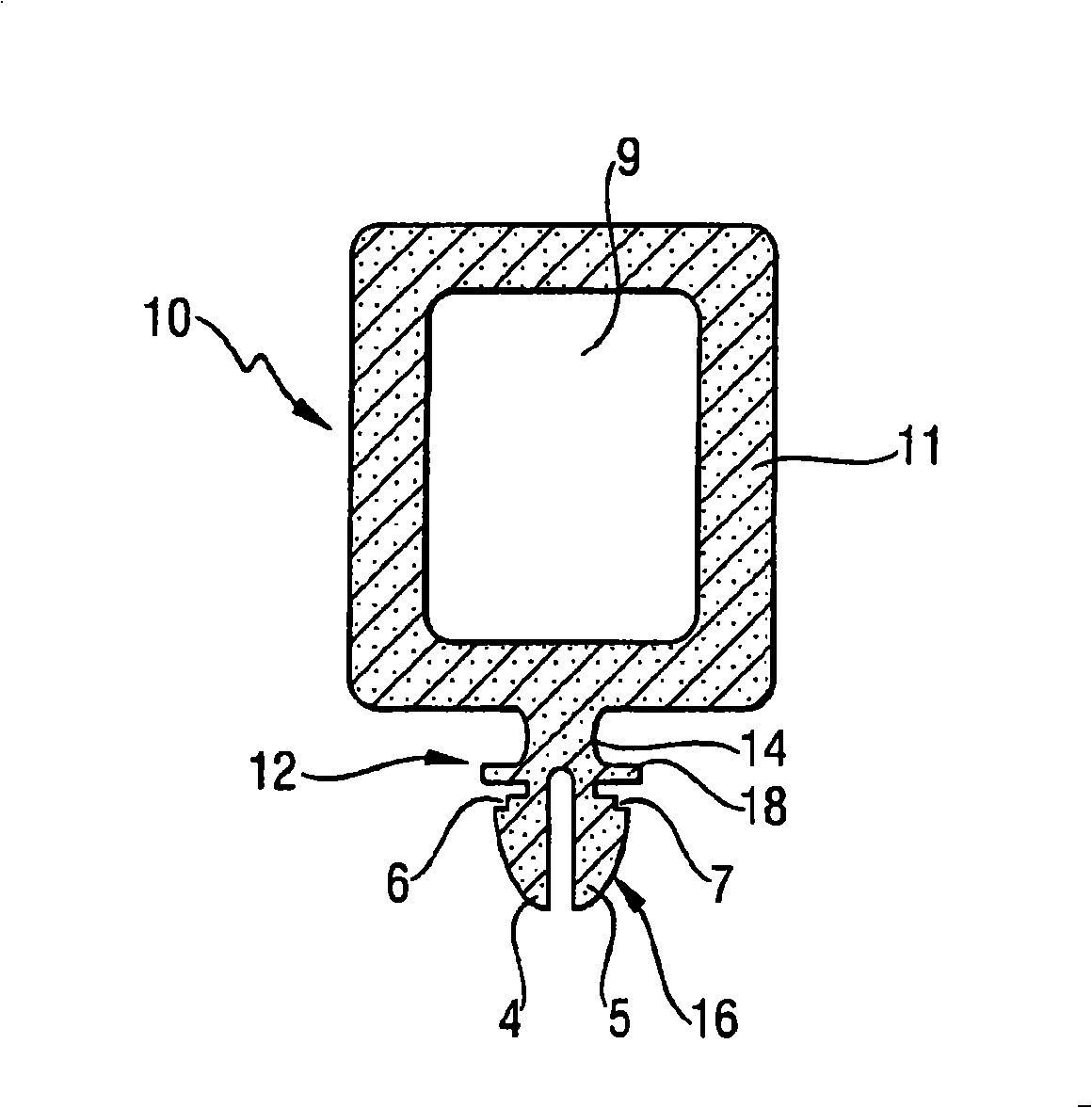

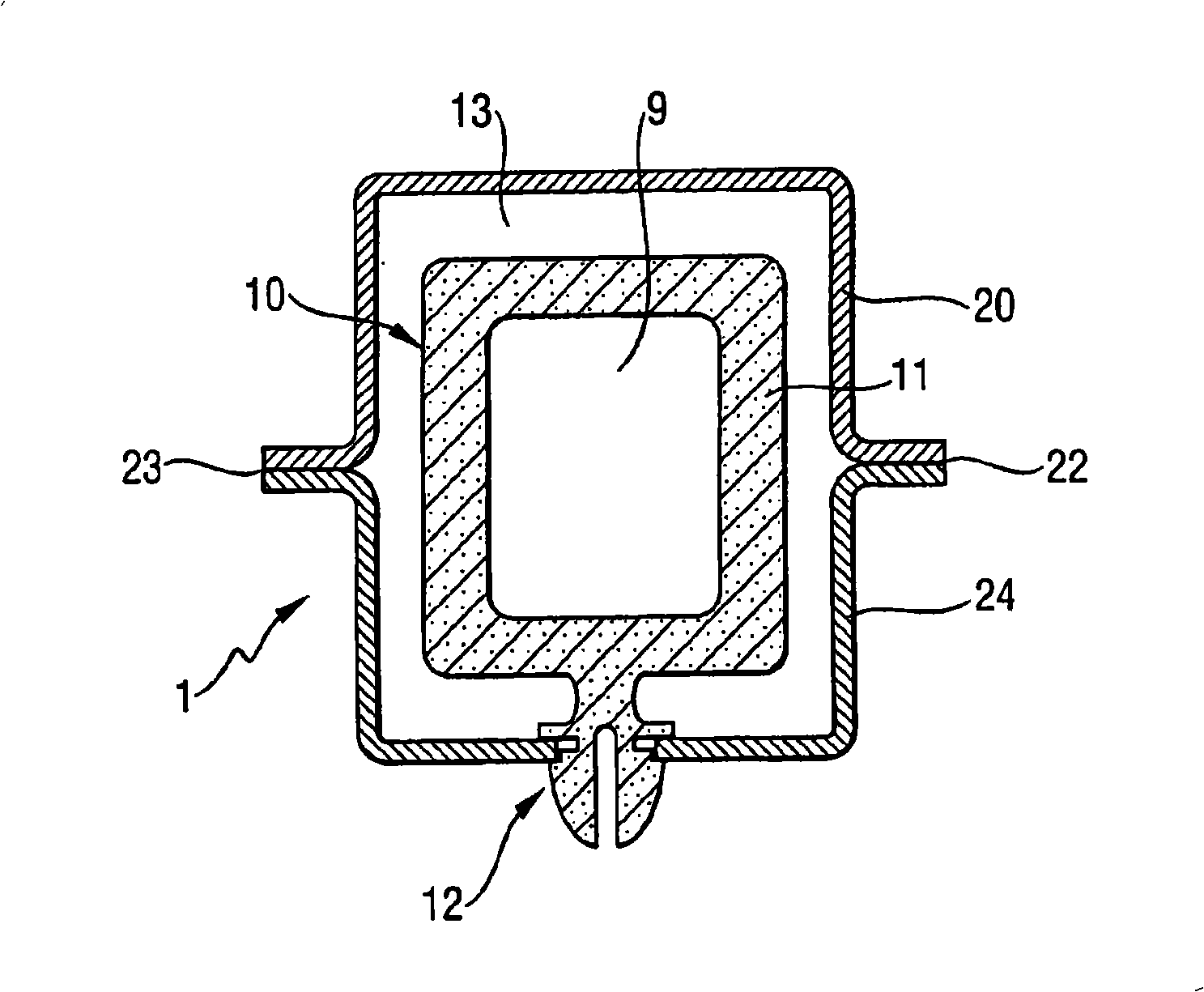

Expandable filler insert and methods of producing the expandable filler insert

A carrier-free expandable filler insert (10) for filling or sealing a hollow space or cavity (2) is provided. The insert comprises a self-supporting continuous structure (11) that may be produced by contour extrusion molding or injection molding a polymer matrix containing a polymer and / or polymer precursor and a latent blowing agent. The expandable filler insert is secured to the interior surface of a vehicle pillar (1), for example, using a fixing element (12) that may be integral with the self-supporting continuous structure, the polymer matrix thereafter being activated and expanded by heating.

Owner:HENKEL KGAA

Preparation method of carrier-free talcum powder master batch

ActiveCN101792536ASolve pollutionSolve problems such as poor compatibilityGranulation by material expressionDiameter ratioDiluent

The invention relates to a talcum powder, in particular to a preparation method of carrier-free talcum powder master batch. The preparation method of the carrier-free talcum powder master batch comprises the following steps of: preparation of additive: mixing diluent and binding agent according to a certain proportion, wherein the diluent accounts for 90-99 percent, and the binding agent accounts for 1-10 percent; treatment of the talcum powder: stirring and mixing the mixed additive and talcum powder, wherein the additive accounts for 15-35 percent, and the talcum powder accounts for 65-85%; molding of the talcum powder: putting the mixed talcum powder into an extruder for extruding at the normal temperature, controlling the pelleting pressure to be 1-2 MPa, the diameter of the extruded granule to be 1-5mm and the length-diameter ratio to be 1-4; and drying the extruded granules at 120-180 DEG C for 0.5-1h, and obtaining the product, wherein the percent is weight percent. The preparation method has the advantages of solving the environment problem caused by rising powder in the using process of the traditional talcum powder.

Owner:SHENYANG POLYTECHNIC UNIV +1

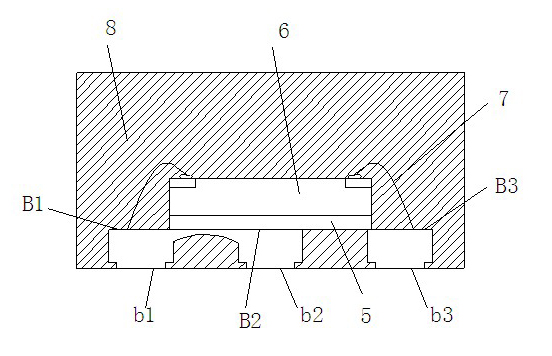

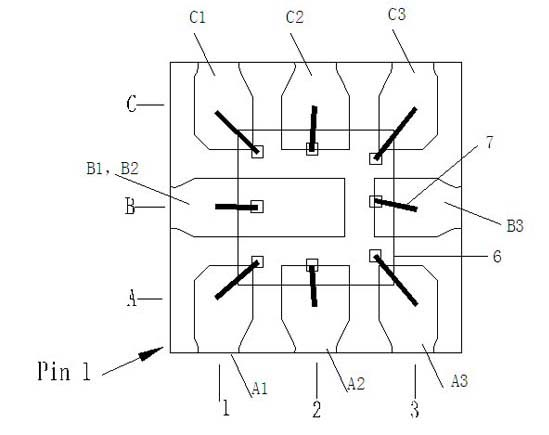

Carrier-free pin-free grid-array IC (Integrated Circuit) chip packaging part and production method thereof

ActiveCN102074541AImprove yieldIncrease profitSemiconductor/solid-state device detailsSolid-state devicesTriazineEngineering

The invention relates to a carrier-free grid-array IC (Integrated Circuit) chip packaging part and a preparation method thereof. The carrier-free grid-array IC chip packaging part comprises inner pins, IC chips, soldering pads, bonding lines and plastic-sealed bodies, wherein the inner pins are arranged into a multi-row matrix type on the front surface of the packaging part, and multiple rows of exposed round gold-plated contacts approximately to squares are arranged on the back surface of the packaging part; the IC chips are positioned on the upper surfaces of the inner pins, the inner pins and the IC chips are bonded through glue membranes, the soldering pads on the IC chips are connected with the inner pins through the bonding lines, and the glue membranes, the IC chips, the bonding lines and the edges of the inner pins are surrounded by the plastic-sealed bodies to form an integrated circuit. In the invention, since spherical array contacts approximately to squares are adopted, the structure is simple and flexible, and the radiating effect is good. The finished-product rate of a copper lead frame (L / F) is high, and the material cost is lowered. Since the copper lead frame (L / F) is adopted for replacing a ceramic baseplate, a PCB (Printed Circuit Board) baseplate or a BT (Bismaleimide Triazine) baseplate, the complicated layout design is saved, the designing and manufacturing cycle is shorter, the pilot production process is quickened, products are promoted to be on the market in advance, and the first market opportunity is obtained.

Owner:华天科技(南京)有限公司

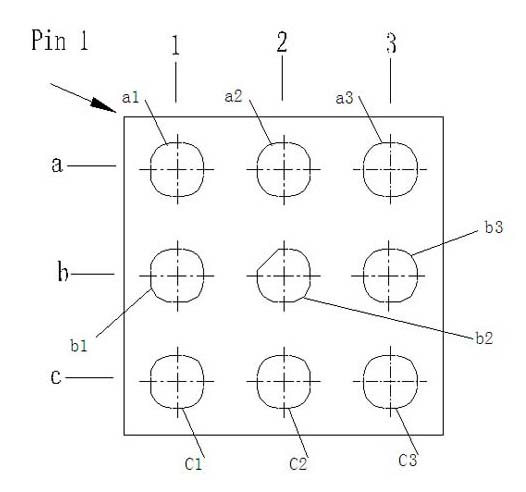

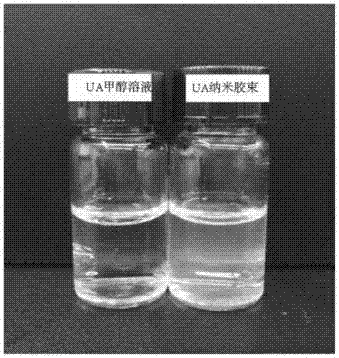

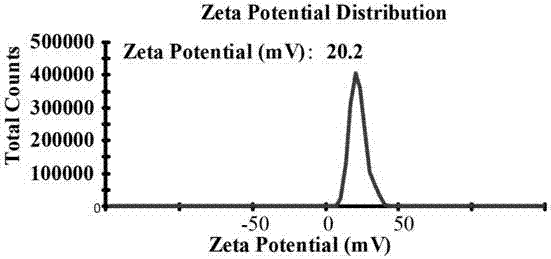

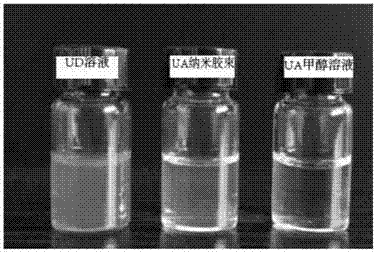

Carrier-free co-assembled tumor targeting anti-cancer nano medicine as well as preparation method and application thereof

InactiveCN107158014AGood tumor treatmentSolve complexityPowder deliveryOrganic active ingredientsTumor targetAptamer

The invention discloses a carrier-free co-assembled tumor targeting anti-cancer nano medicine as well as a preparation method and application thereof. The carrier-free dual anti-cancer nano medicine is prepared from a hydrophobic medicine, namely ursolic acid, together with board-spectrum anti-tumor medicines such as doxorubicin in water through co-assembling, in addition, a fluorescence labeling nucleic acid aptamer, a molecular target, an antibody or polypeptide and the like with tumor targeting functions are adsorbed to the surface of the medicine through mutual electrostatic functions, then the carrier-free co-assembled tumor targeting anti-cancer nano medicine with tumor targeting and tumor microenvironment response is prepared, a synergic anti-tumor function is achieved, diagnosis and treatment integration is achieved, particularly the medicine has outstanding functions in preventing tumor transfer, and more importantly the problems that a conventional nano carrier is complex in system, indefinite in in-vivo metabolism and the like are solved.

Owner:FUZHOU UNIV

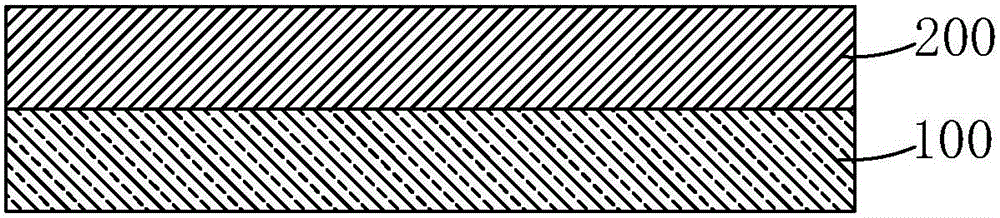

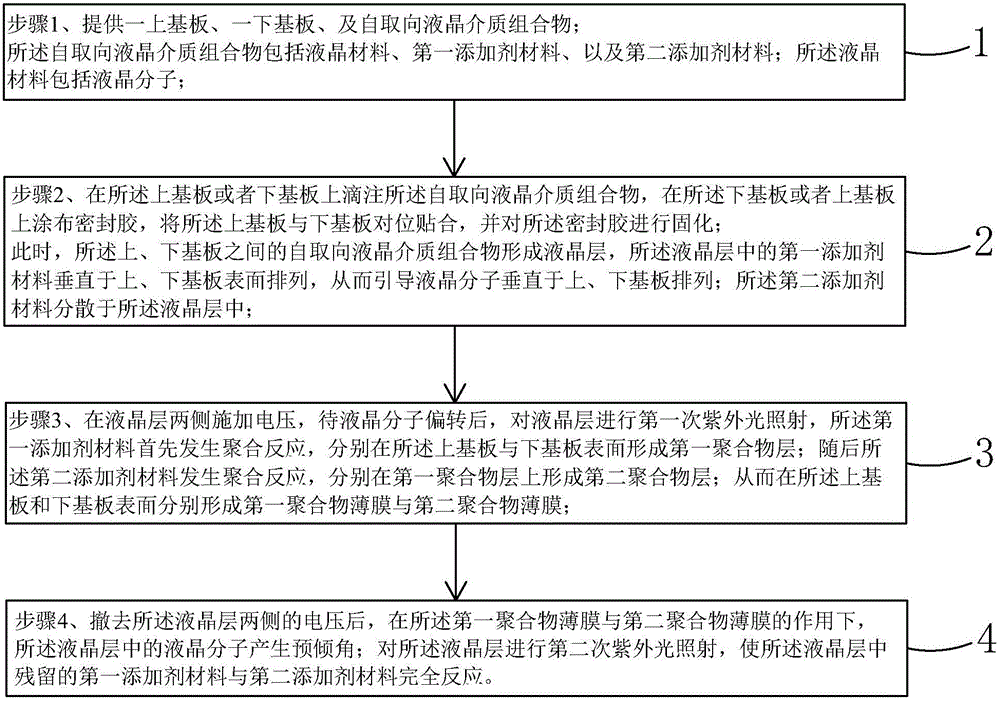

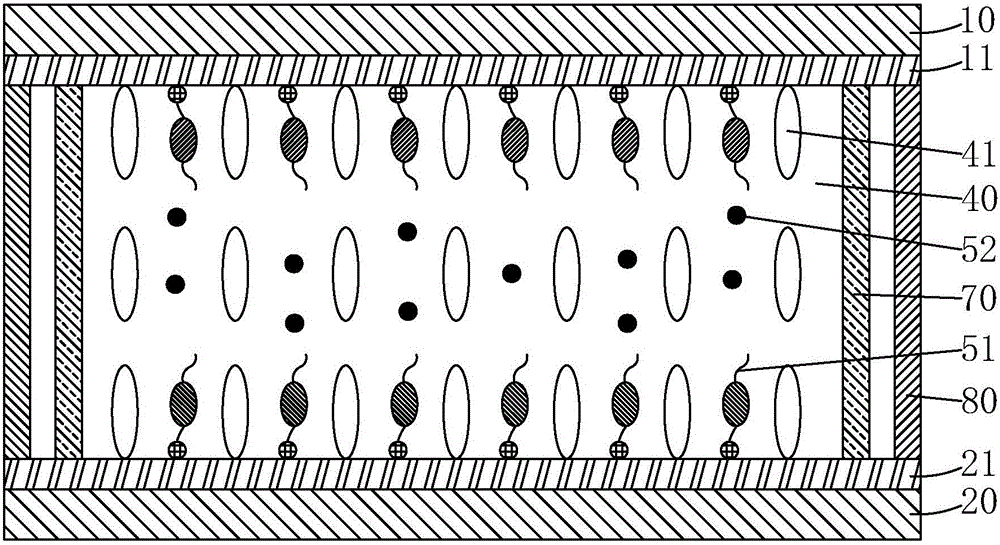

Self-oriented liquid crystal medium composition, liquid crystal display panel and its manufacturing method

ActiveCN106281364AEasy alignmentPrevent proliferationLiquid crystal compositionsNon-linear opticsElectrical polarityImpurity

The invention provides a self-oriented liquid crystal medium composition, a liquid crystal display panel and its manufacturing method. The self-oriented liquid crystal medium composition comprises a first additive material and a second additive material; the first additive material can be anchored on a base plate through a polar group and generates a polymerization reaction under the ultraviolet irradiation; a first polymer layer is formed on the surface of the base plate, and the second additive material has polymerization reaction subsequently; a second polymer layer is polymerized and formed on the surface of the first polymer layer, and the second polymer layer can make the liquid crystal molecule orient vertically; the first polymer layer can prevent impurities in a CF(carrier free) base plate and a TFT (thin film transistor) base plate from spreading to the liquid crystal. The manufacturing method of the liquid crystal display panel applies the self-oriented liquid crystal medium composition to realize the liquid crystal orientation, thus it omits the process of a traditional polyimide orientation film, saves production cost, improves the orientation effect of liquid crystal and promotes the panel reliability.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

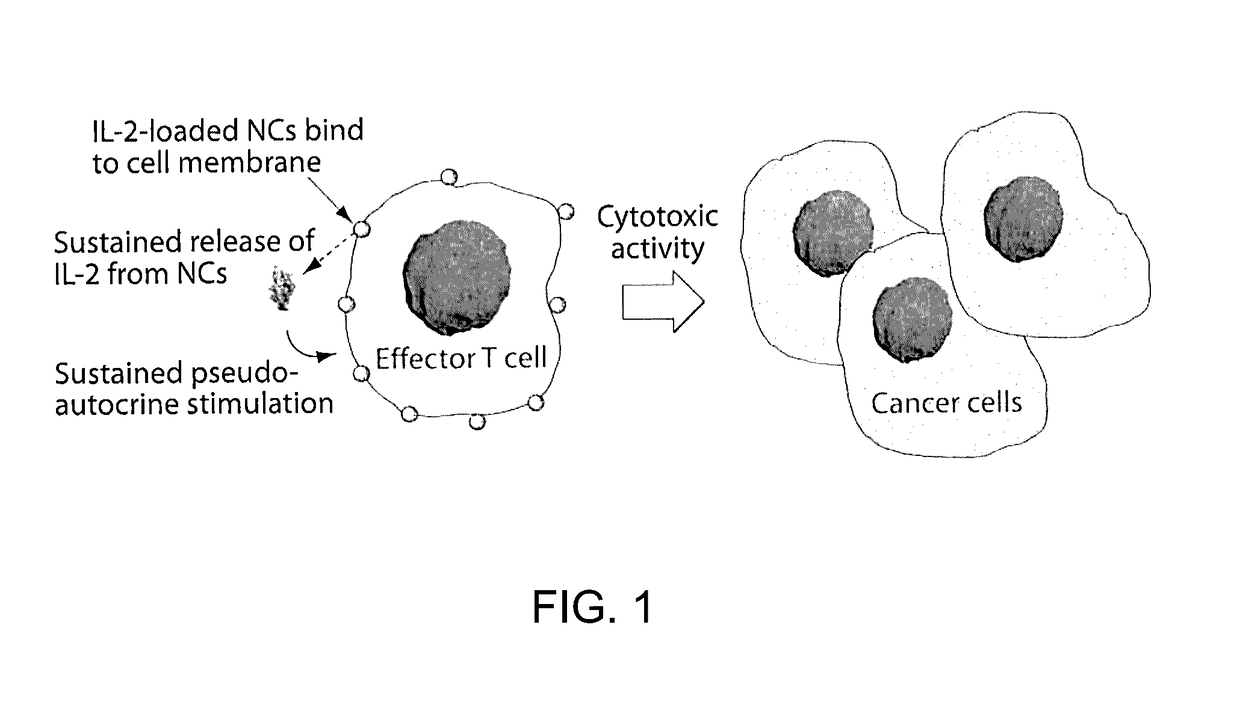

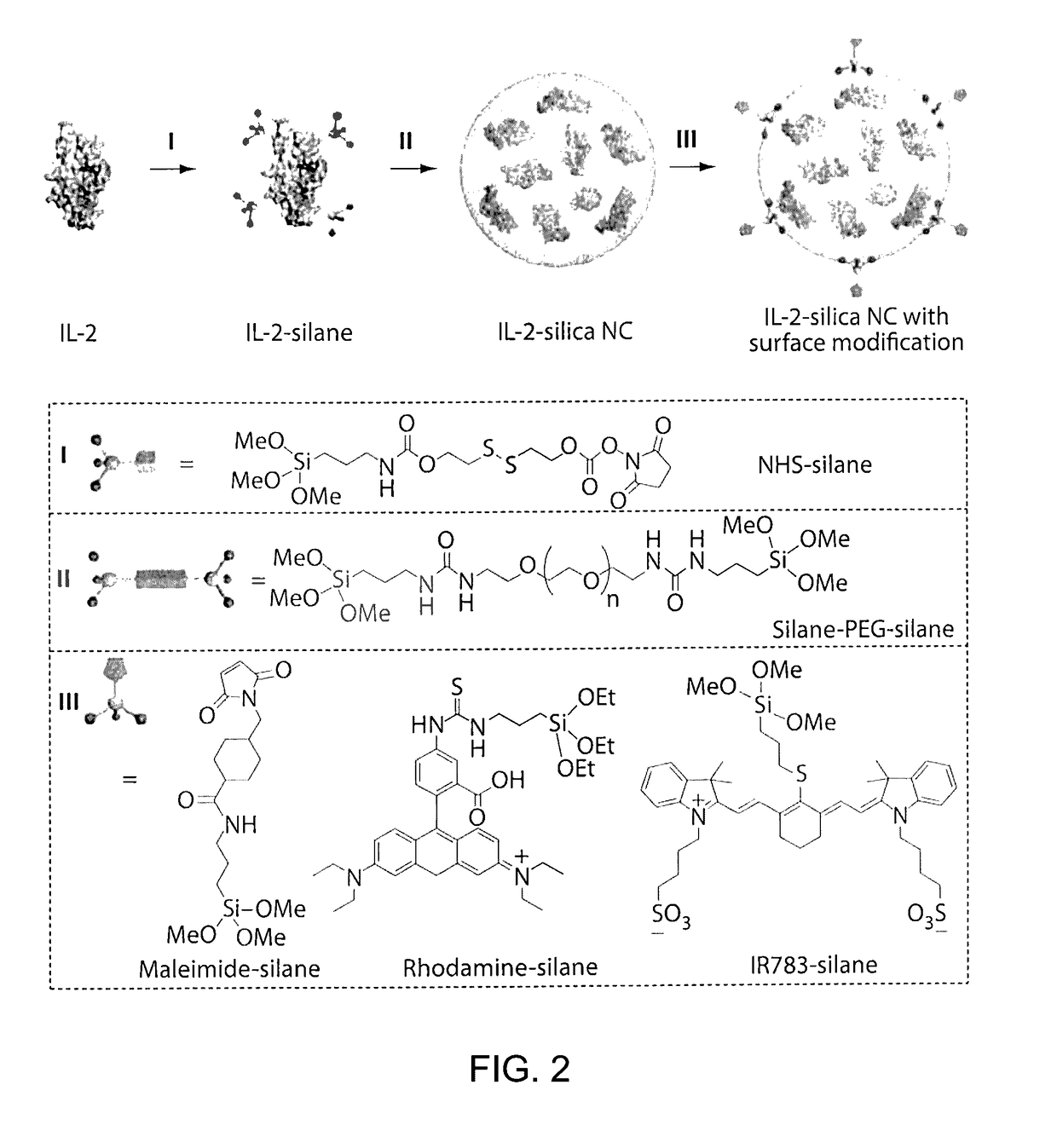

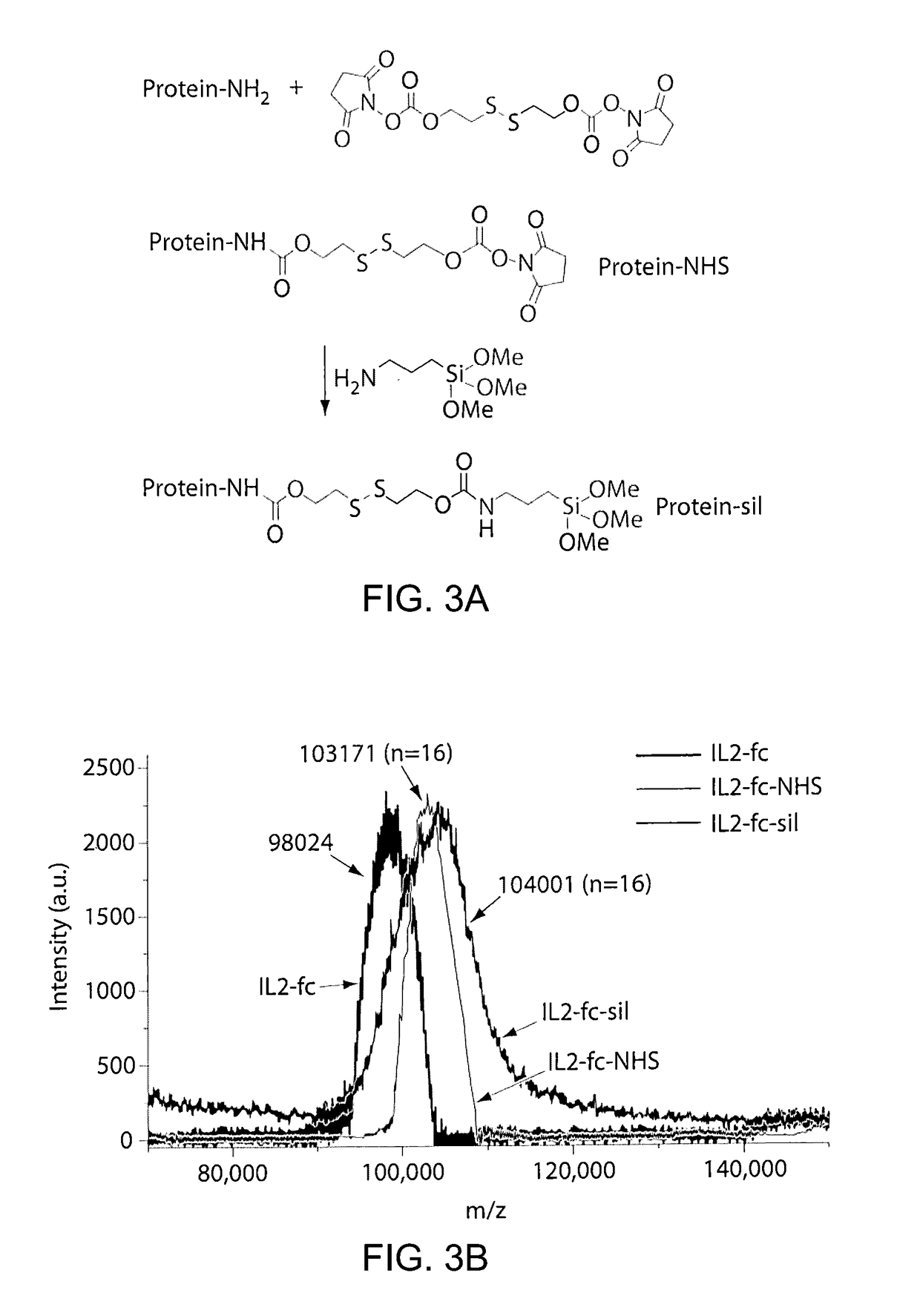

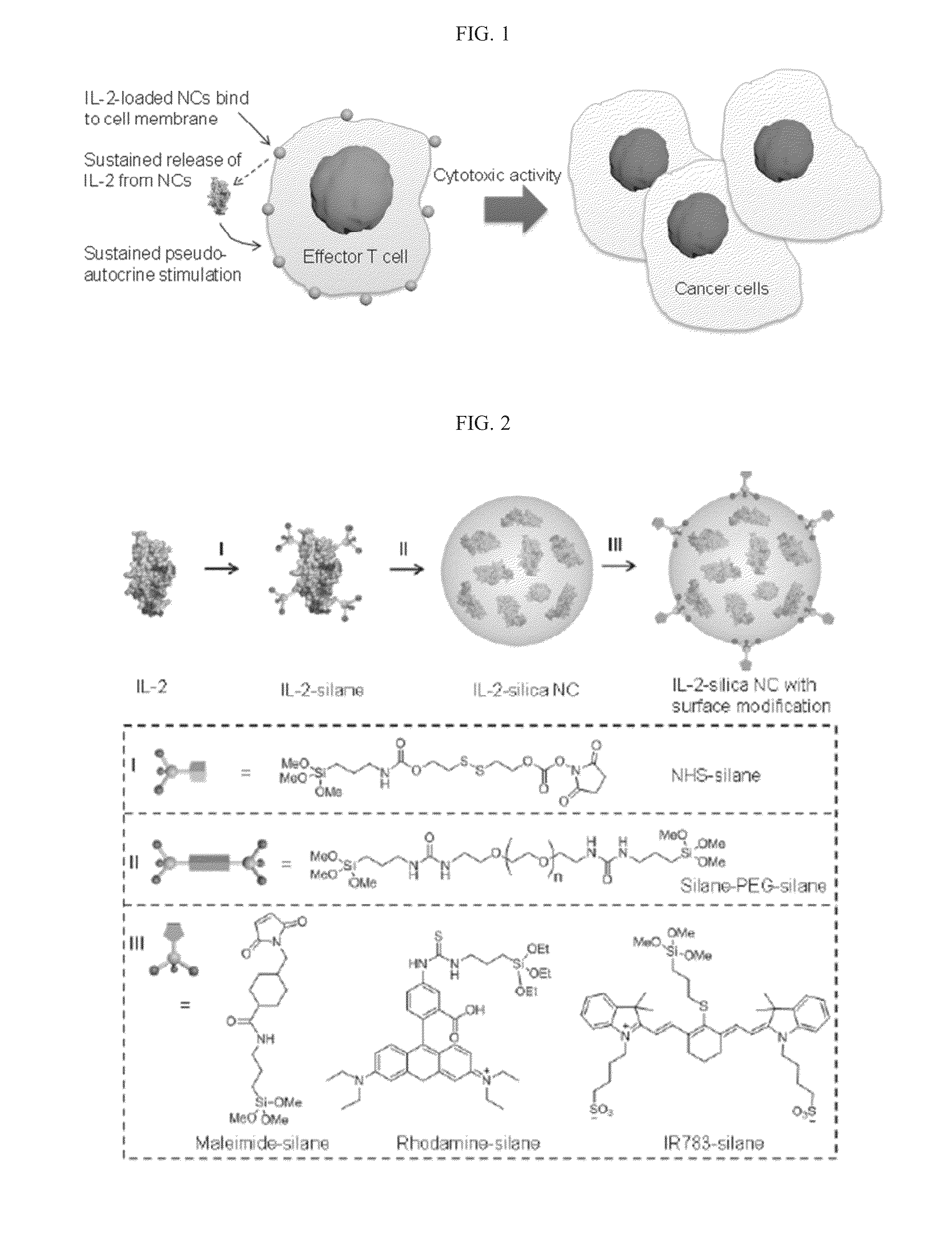

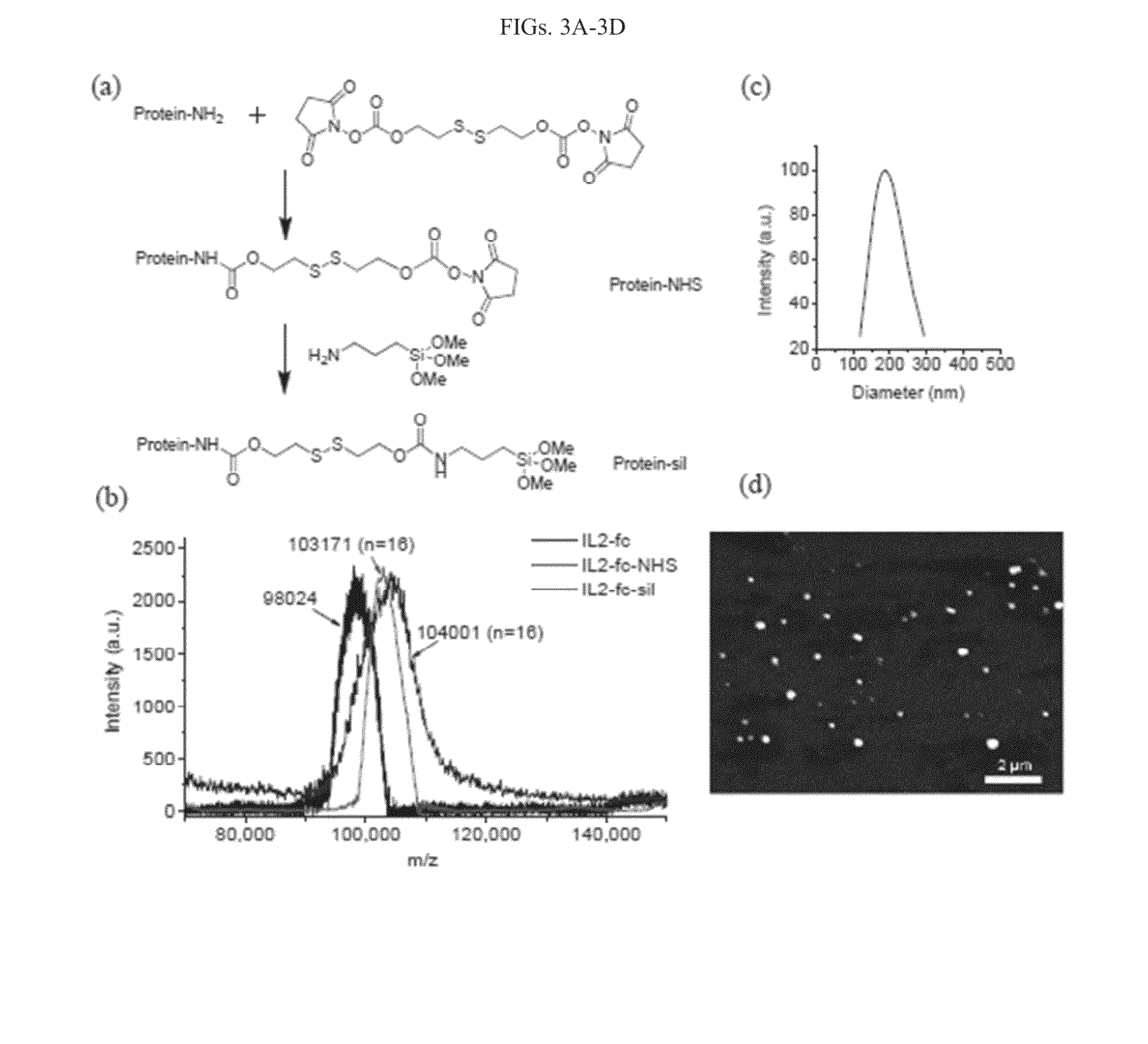

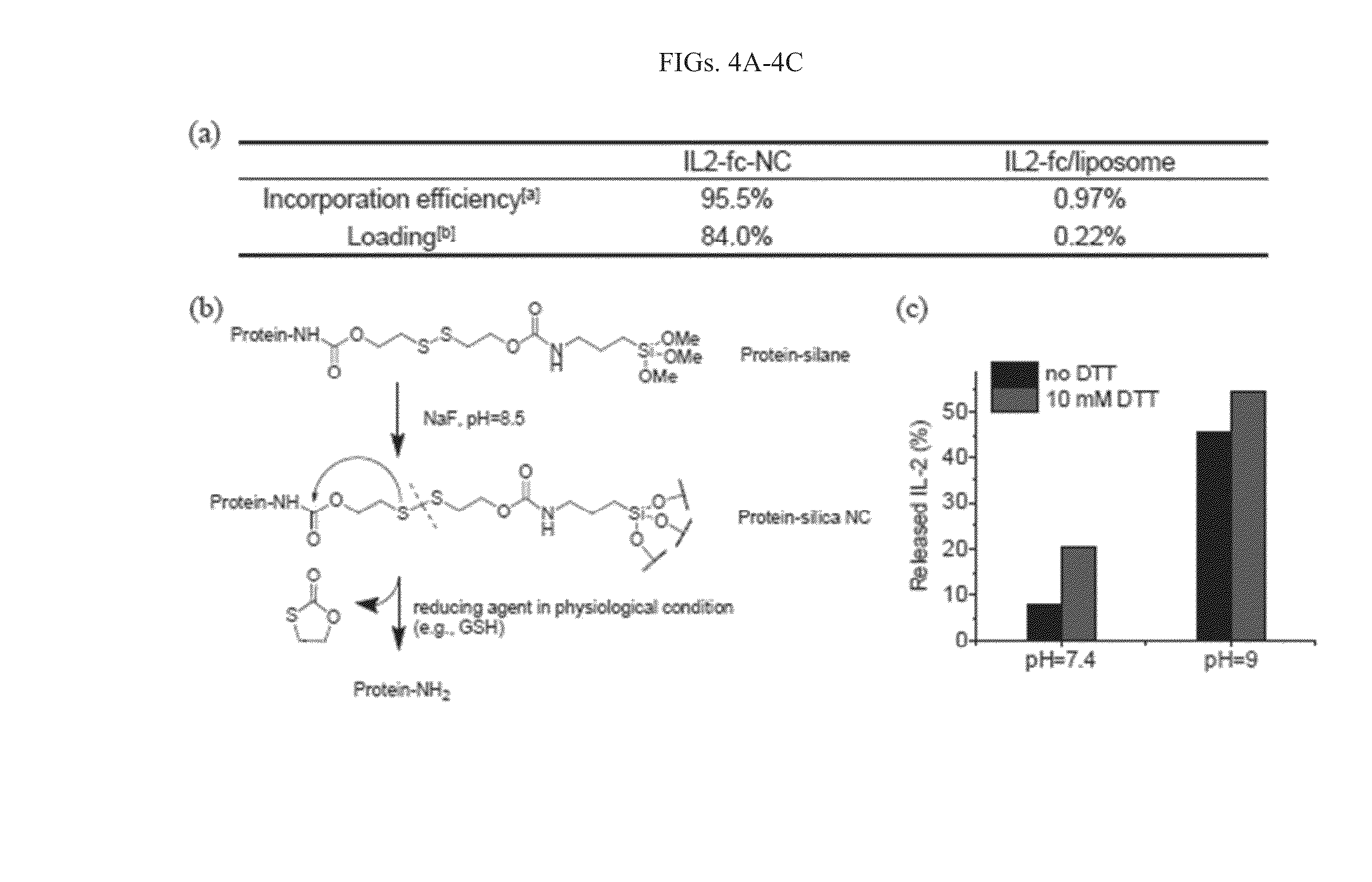

Carrier-free biologically-active protein nanostructures

ActiveUS9603944B2Improve integration efficiencyImprove loading efficiencyPeptide/protein ingredientsMetabolism disorderActive proteinNanoshell

The present disclosure provides compositions and methods for efficient and effective protein delivery in vitro and in vivo. In some aspects, proteins are reversibly crosslinked to each other and / or modified with functional groups and protected from protease degradation by a polymer-based or silica-based nanoshell.

Owner:MASSACHUSETTS INST OF TECH

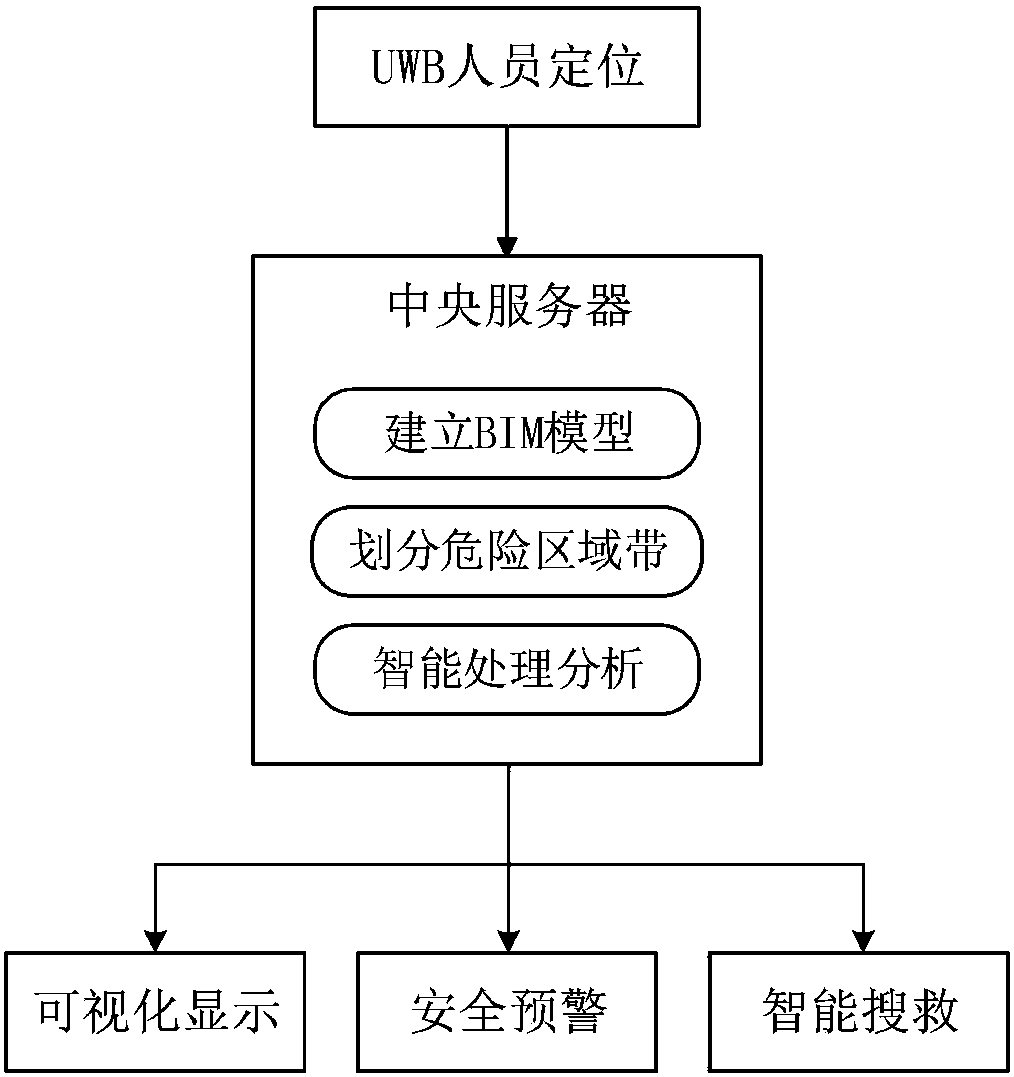

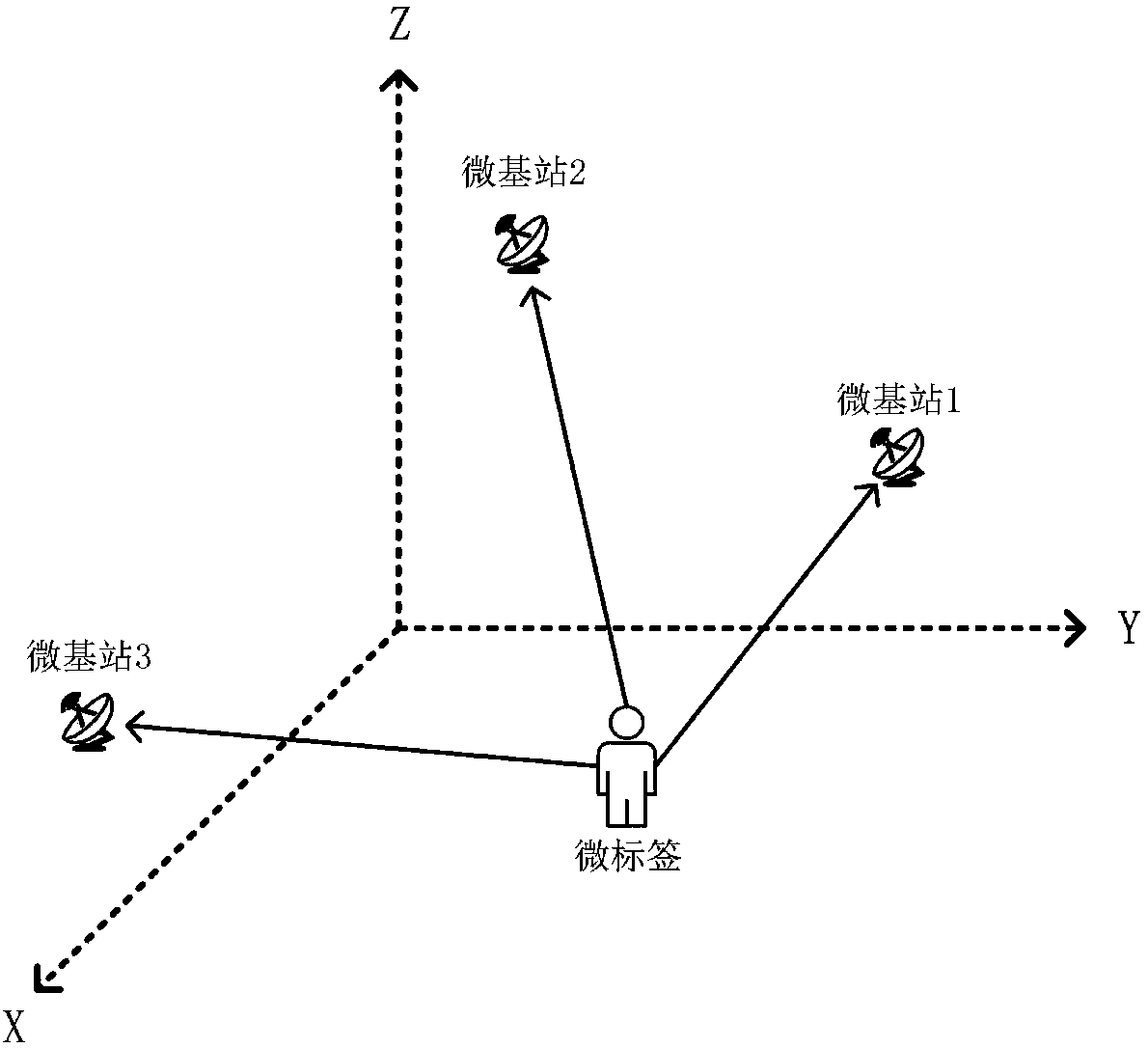

Building near-the-edge hole entrance safety management system and method based on BIM and UWB

InactiveCN108615204ATimely search and rescuePrecise positioningData processing applicationsDesign optimisation/simulationSafety management systemsCarrier signal

The invention discloses a building near-the-edge hole entrance safety management system and method based on BIM and UWB. The system comprises a UWB person positioning module, a central server, a visualization display module, a safety early warning module and an intelligent rescuing module. The UWB person positioning module achieves three-dimensional positioning of persons through the UWB carrier-free communication technology. The central server carries out data fusion on the person positioning information and a BIM model, and analyzes whether a worker is in a dangerous region. The visualization display module displays the accurate position of the worker in the BIM model. The safety early warning module carries out danger early warning prompting on the person. The intelligent rescuing module determines the shortest rescuing route for a person suffering from an accident and displays the shortest rescuing route on the BIM model. According to the invention, three-dimensional positions of the persons can be precisely positioned in real time; by carrying out comparison analysis with a preset dangerous region, voice early warnings are performed on construction workers, so occurrence of dangers is effectively avoided; reduction of casualties is facilitated; and intelligent safety management of construction sites is achieved.

Owner:BEIJING UNIV OF TECH

Carrier-free adhesive film

InactiveUS20100272943A1Easy to expandLow and substantially no VOC emissionCovering/liningsWallsAdhesiveEngineering

An adhesive system is provided that comprises a layer of adhesive without any adhesive carrier layer or screen or the like, covered on a first release surface and covered on the opposite side by a second release surface. Methods of forming the system and methods using the system to lay down a uniform layer of adhesive which can be used to secure various flooring materials are also provided.

Owner:W F TAYLOR

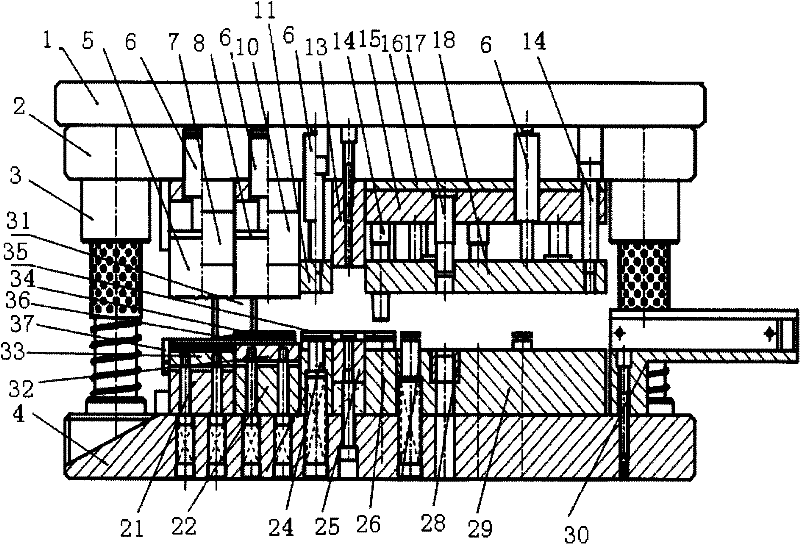

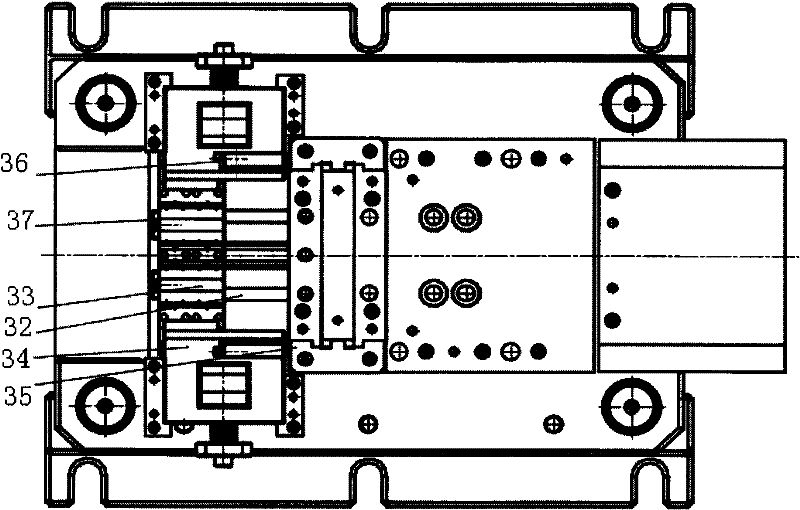

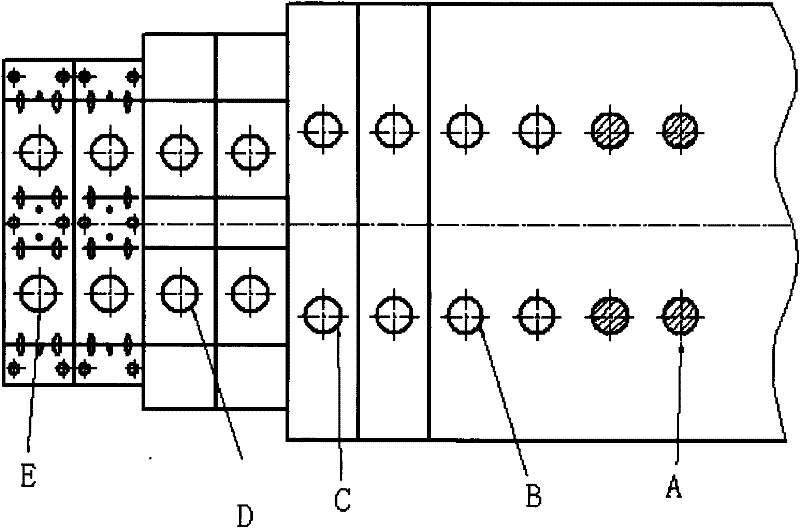

Carrier-free one-die two-piece forming method for bracket

The invention discloses a carrier-free one-die two-piece forming method for a bracket. The method comprises the following steps of: preparing a strip material, the size of which meets the requirement; placing the strip material on a special bracket carrier-free multi-station progressive forming die; completing formation and reshaping of the bracket on the special bracket carrier-free multi-station progressive forming die, thus obtaining two pieces on one die; and completing bracket formation when the bracket automatically falls from the die. The workpieces are bent, formed and reshaped by using the special bracket carrier-free (waste) multi-station progressive forming die. The utilization rate of the bracket material can be improved, the production efficiency can be improved, the production cost can be reduced, and the method has great practical value.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

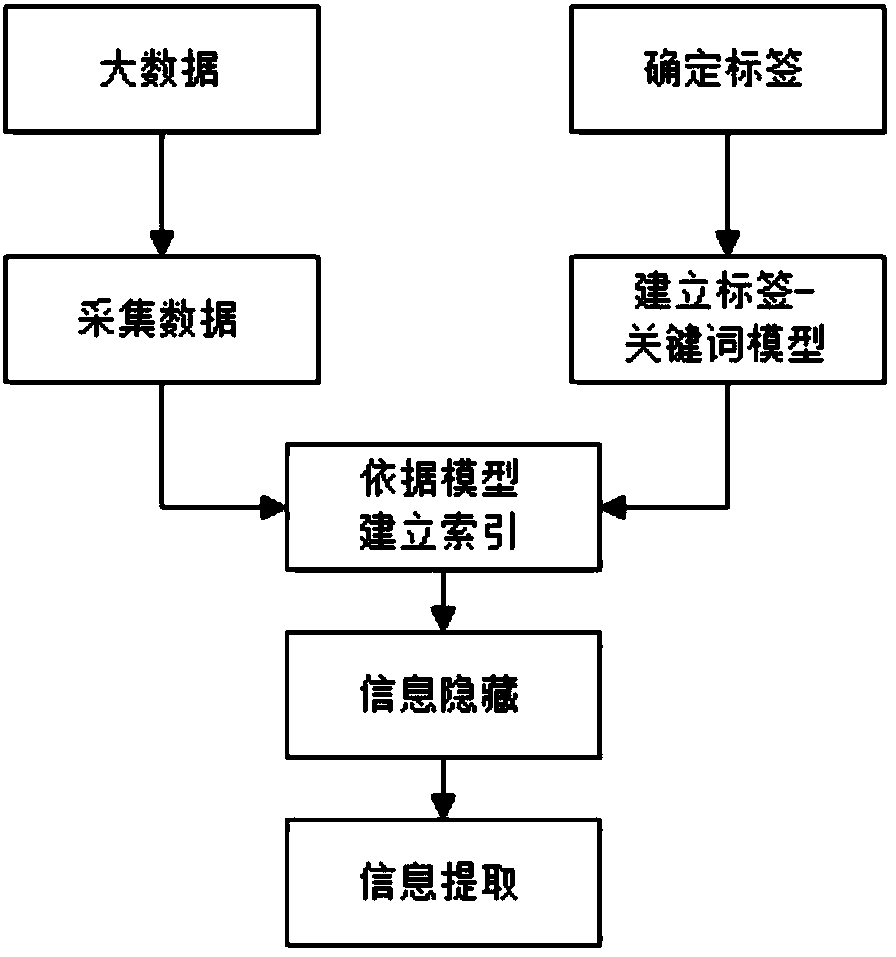

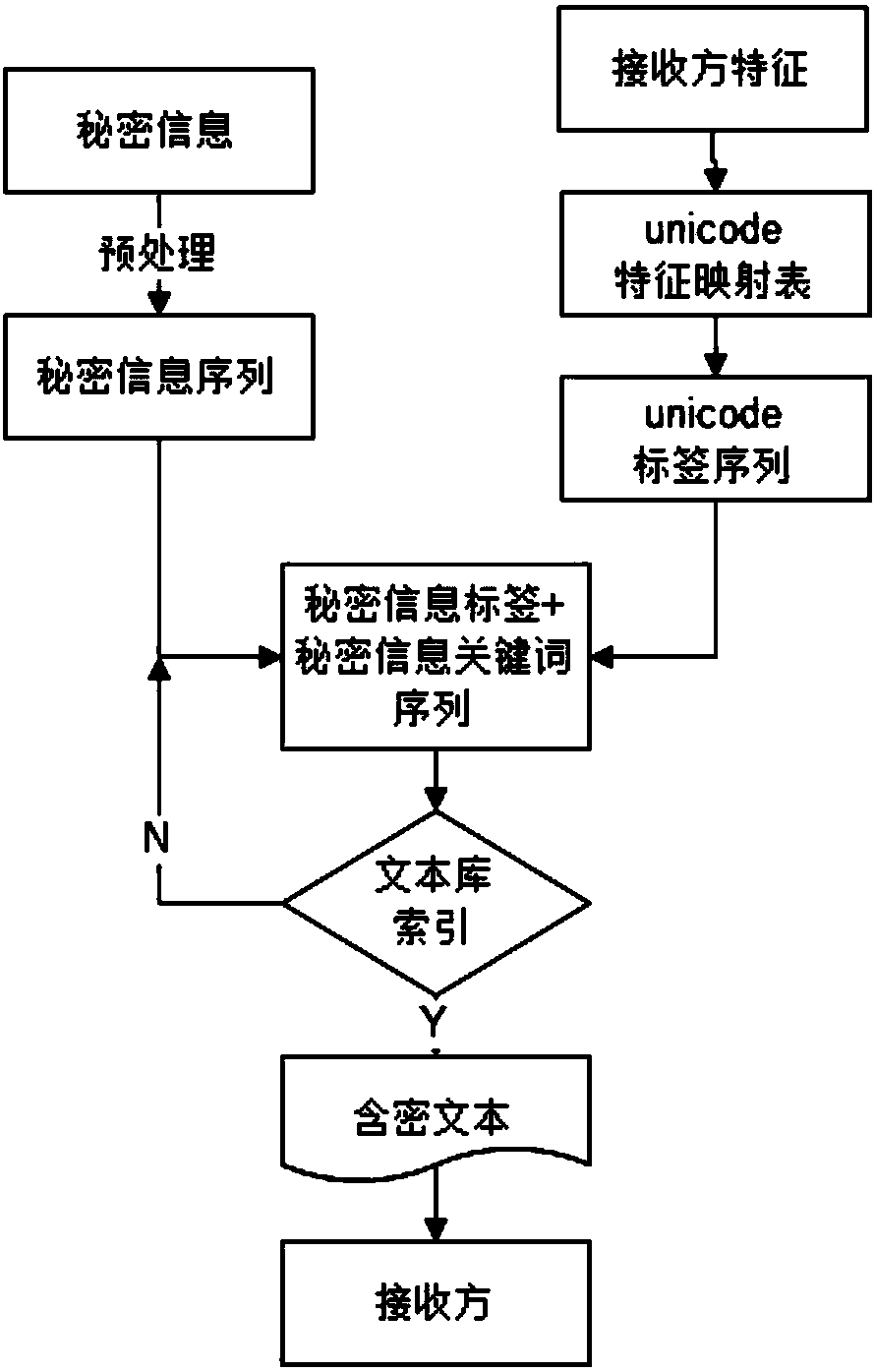

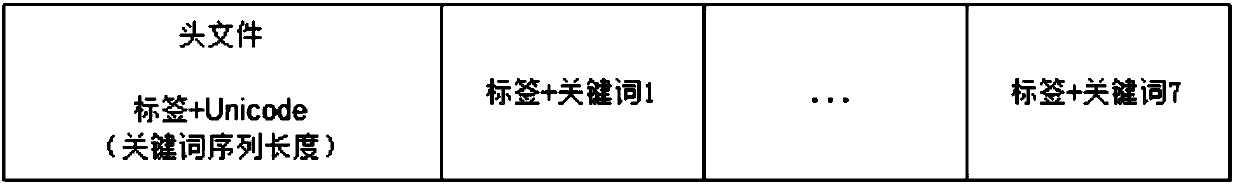

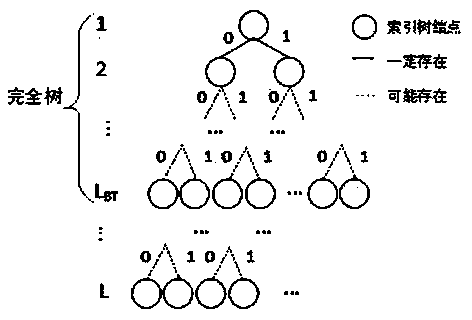

Text carrier-free information hiding method based on tag model

ActiveCN107609356AGuaranteed success rateIncrease hidden capacityTransmissionProgram/content distribution protectionChinese charactersTheoretical computer science

The invention provides a text carrier-free information hiding method based on a tag model. The method comprises the following steps that: collecting texts, and establishing indexes; hiding secret information: preprocessing the secret information to obtain the keyword sequence of the secret information; using the Unicode of Chinese characters as a secret information tag, and carrying out calculation according to the corresponding features of a receiver to obtain a secret information tag sequence; constructing a header file and a cipher containing text; through text index entries, selecting target text information corresponding to the header file and the cipher containing text one by one from a text library; and arranging all target text information in sequence, and sending the target text information to the receiver as a hidden text. By use of the method, while a hiding success rate is guaranteed, hiding capacity is improved.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

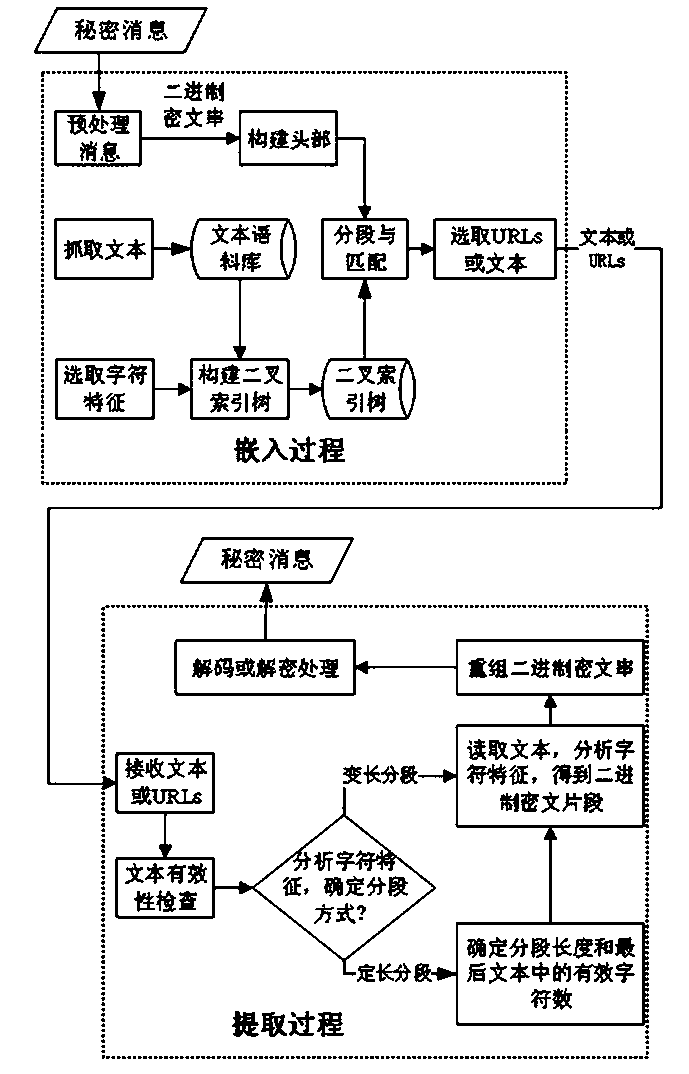

Carrier-free text steganography method based on character features

ActiveCN107947918AAvoid distortionNot easy to attract attentionKey distribution for secure communicationEncryption apparatus with shift registers/memoriesAlgorithmCiphertext

The invention discloses a carrier-free text steganography method based on character features. Binary digits are expressed through the character features; secret information is processed into a binaryciphertext string and then is packaged and segmented; mapping between texts and binary ciphertext string segments is established by taking abundant webpage texts in a network big data environment as candidate carriers; corresponding texts are found for the secret information through the mapping relationship; and the texts or the corresponding URLs are sent, thereby finishing secret information interaction. After a receiving end receives the texts, the character features of a first text are analyzed to obtain head information; a binary ciphertext segmentation mode and length are determined; thefollow-up text character features are analyzed to obtain binary ciphertext segments; the segments are recombined to form the complete binary ciphertext string; and decoding or decryption is carried out to obtain the secret information. The method has the advantages of high stealthiness, high expandability and high embedded capacity, and the application and development of a steganography technology in various fields are facilitated.

Owner:QINGDAO UNIV

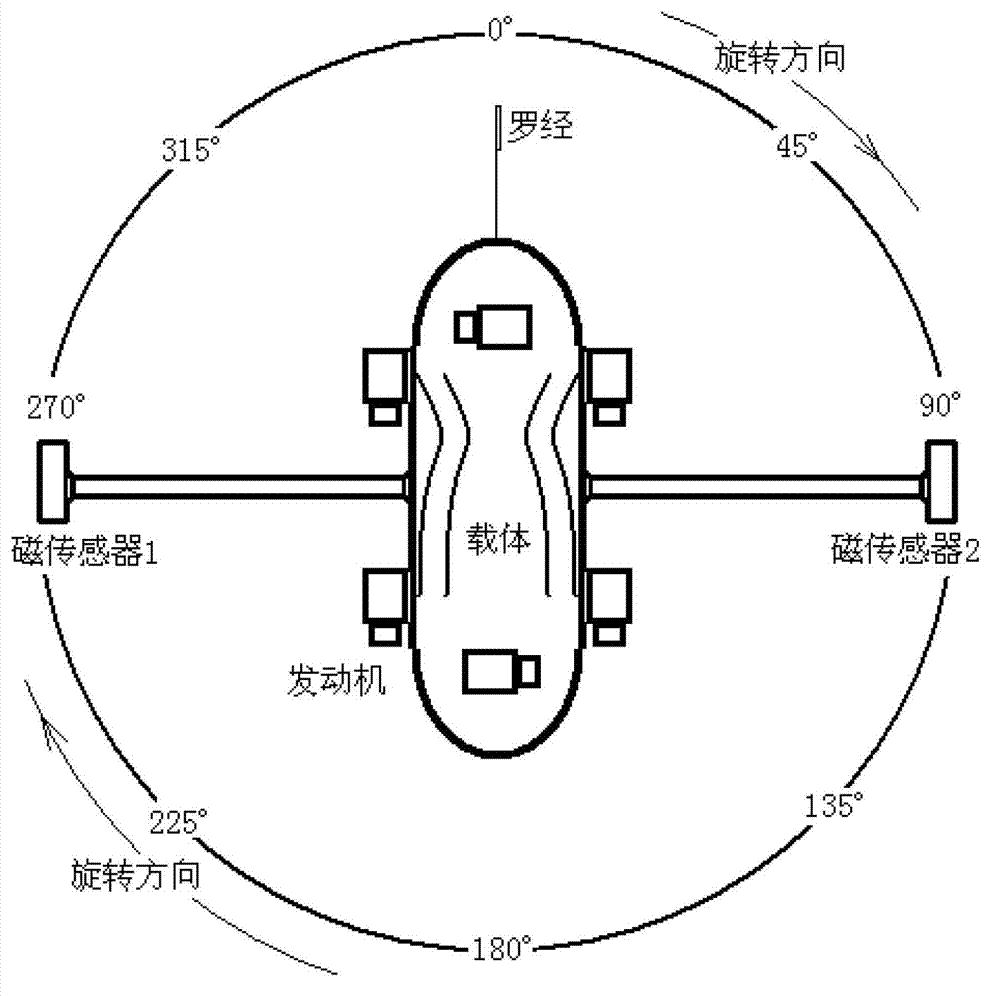

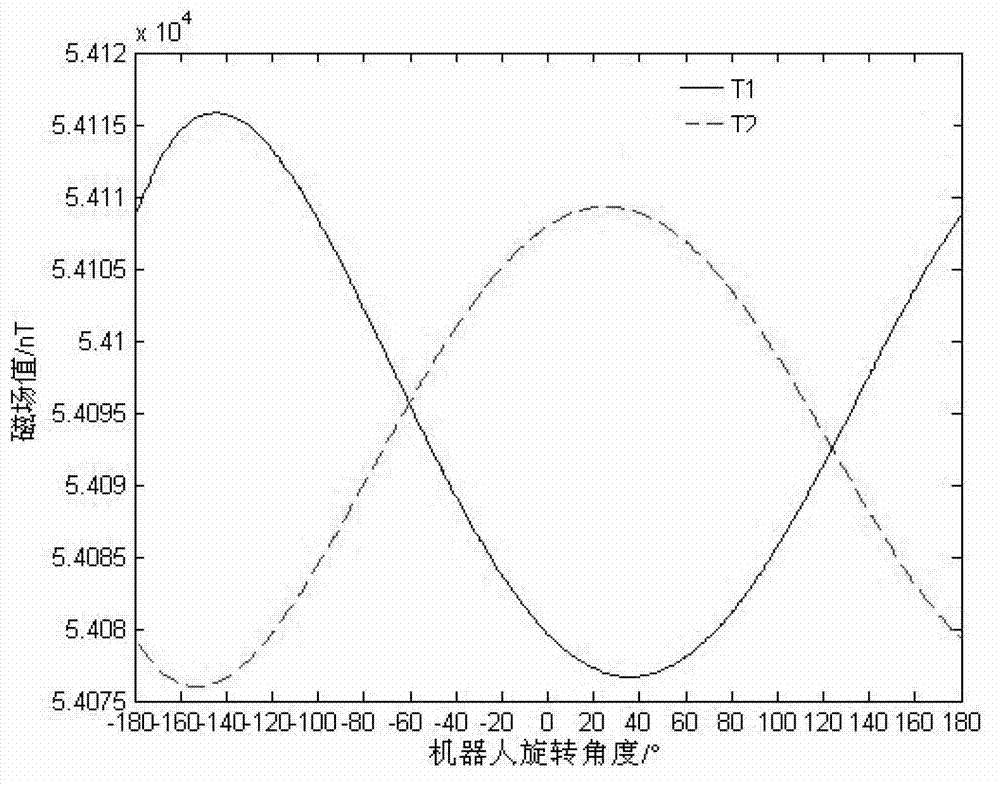

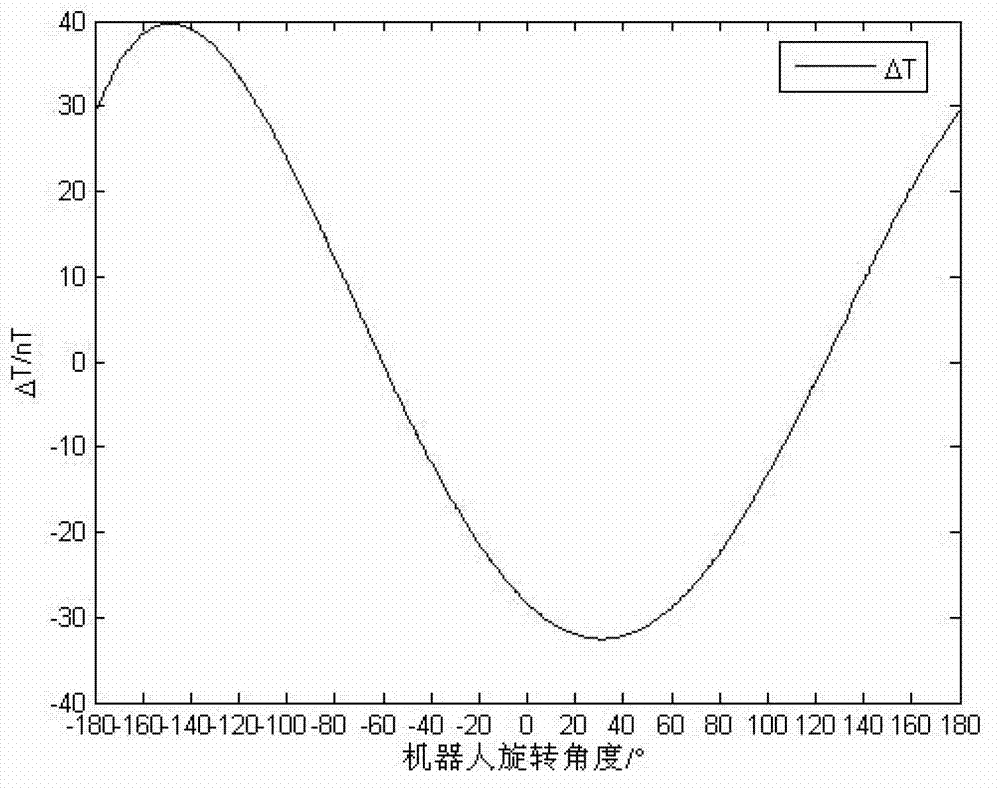

Method of eliminating influence of carrier magnetizing field on geomagnetic measurement

ActiveCN102927984AElimination of effects of geomagnetic measurementsImprove the accuracy of magnetic measurementNavigation by terrestrial meansContinuous measurementMagnetic measurements

The invention provides a method of eliminating influence of a carrier magnetizing field on geomagnetic measurement. The method is characterized in that two magnetic sensor linear arrays are carried on a carrier, a non-magnetic anomaly point A with a mild magnetic field change is selected within the scope of a space to be measured, a geomagnetic total field of the point A is measured under the carrier-free condition by utilizing an independent magnetic sensor, the carrier carried with the two magnetic sensor linear arrays is placed on the point A, a geometric center of the linear array is taken as an axis, the carrier is slowly rotated at a constant speed for one circle, a geomagnetic field value and the corresponding rotating angle are respectively continuously measured by the two magnetic sensors, the corresponding function curve of a difference and an angle is made, the geomagnetic total field on the point is subtracted by the magnetic field value of the linear array magnetic sensor, and the actual measurement geomagnetic field in the whole space to be measured is used for compensating the influence of the carrier magnetizing magnetic field. According to the invention, the linear array is formed by the two magnetic sensors, and a demagnetization method and a demagnetization algorithm of the rotating linear array are provided for complicated influence of the carrier on the magnetic measurement, so that the influence of the carrier on geomagnetic measurement is completed eliminated.

Owner:三亚哈尔滨工程大学南海创新发展基地

Carrier-free biologically-active protein nanostructures

ActiveUS20150110740A1Improve integration efficiencyImprove loading efficiencyPeptide/protein ingredientsAntibody mimetics/scaffoldsActive proteinIn vivo

The present disclosure provides compositions and methods for efficient and effective protein delivery in vitro and in vivo. In some aspects, proteins are reversibly crosslinked to each other and / or modified with functional groups and protected from protease degradation by a polymer-based or silica-based nanoshell.

Owner:MASSACHUSETTS INST OF TECH

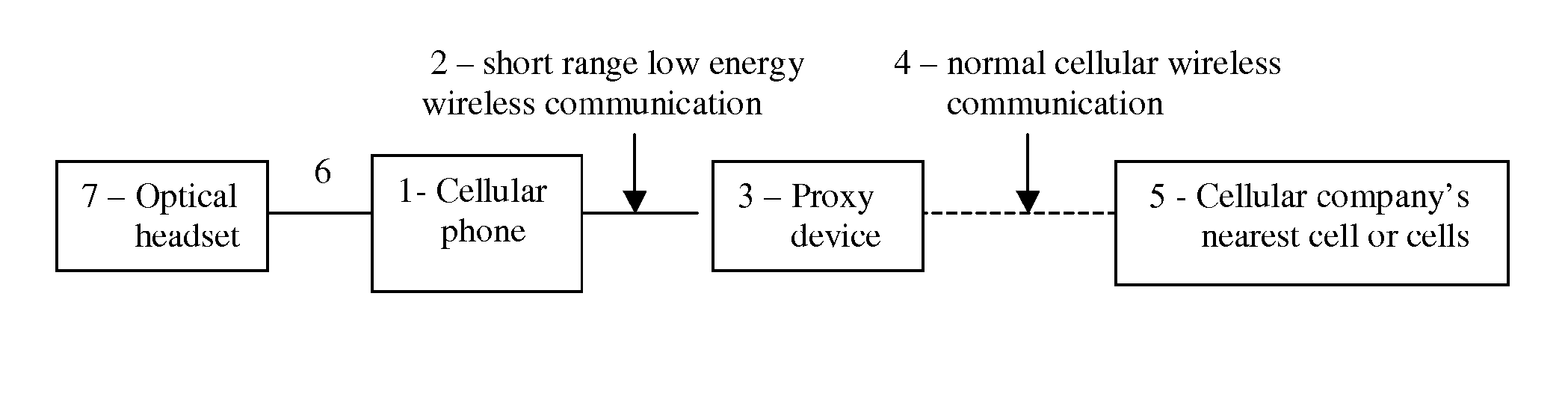

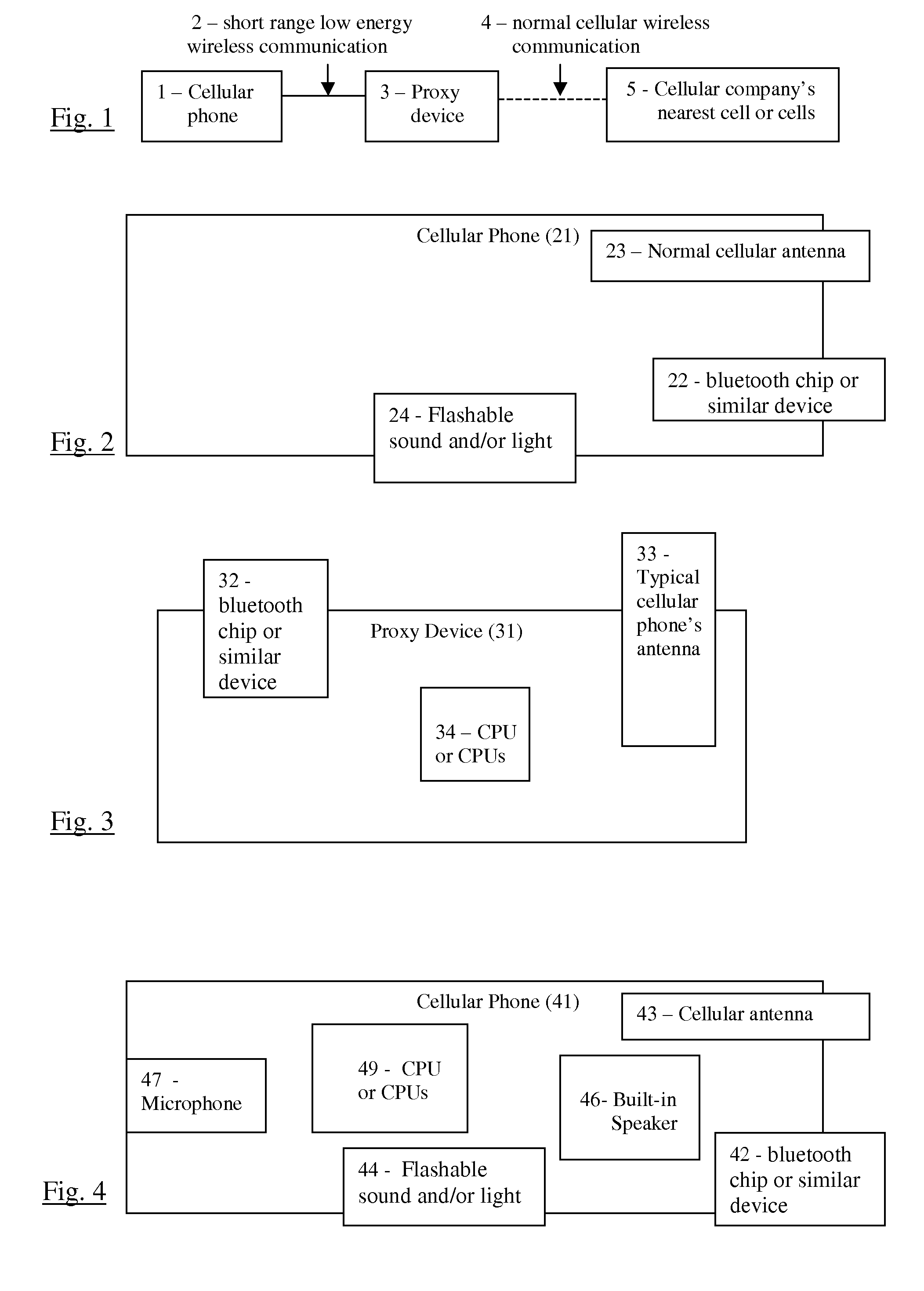

Cellular phone that exposes the user's brain to much less microwave radiation than ordinary cellular phones with the help of a proxy (intermediary) device.

InactiveUS20070224933A1Easy to replaceImprove privacyActive radio relay systemsElectromagnetic transmissionCarrier signalHeadphones

Cellular phones are becoming more common and popular amongst all sectors of the population for business and private conversations, including many children, with about a Billion users worldwide, and about 300,000 new joiners each day. There is much concern and there is already some accumulating evidence that the Microwave emission transmitted by the cellular antenna that is held close to user's head may have deleterious effects on the user, such as for example brain or eye cancer, and possibly even more so for children. One of the most common ways to try to avoid these problems has been the usage of personal earphones with microphone, but on Apr. 4, 2000 it was published worldwide that a research conducted by the “Which?” consumer Magazine in Britain found that in fact the earphone and its cable can act as an Antenna and also expose the user to the microwave radiation. The present invention solves the above problem in using earphones with cellular phones by a reverse and more sophisticated solution than short range wireless earphones, and also solves the problem that many people don't like using headsets at all. Another important variation is the use of short range low energy pulse-based carrier-free wireless communication (preferably UWB) between the two parts of the phone and / or between the phone and a headset and / or between the headset and the proxy.

Owner:MAYER YARON

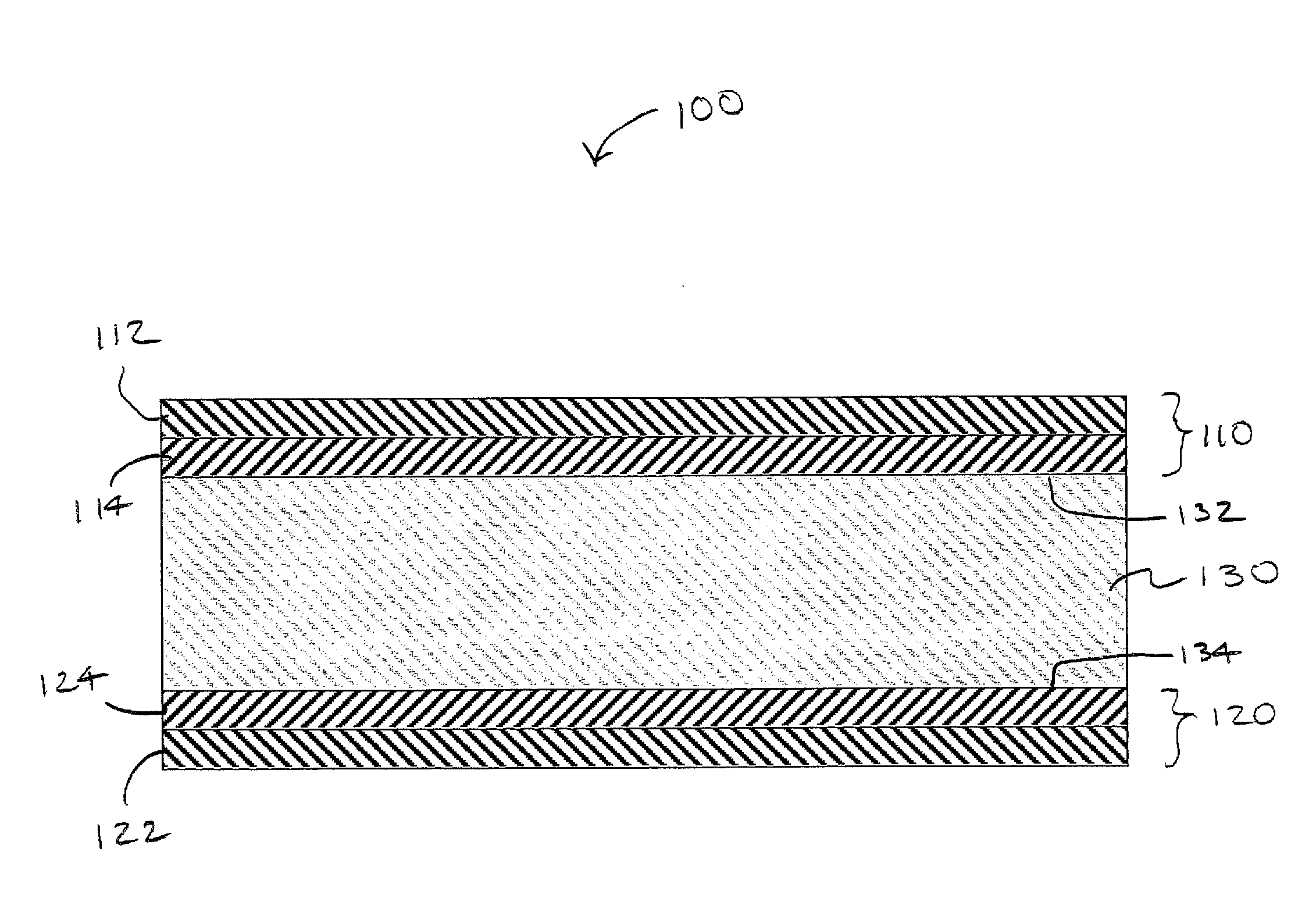

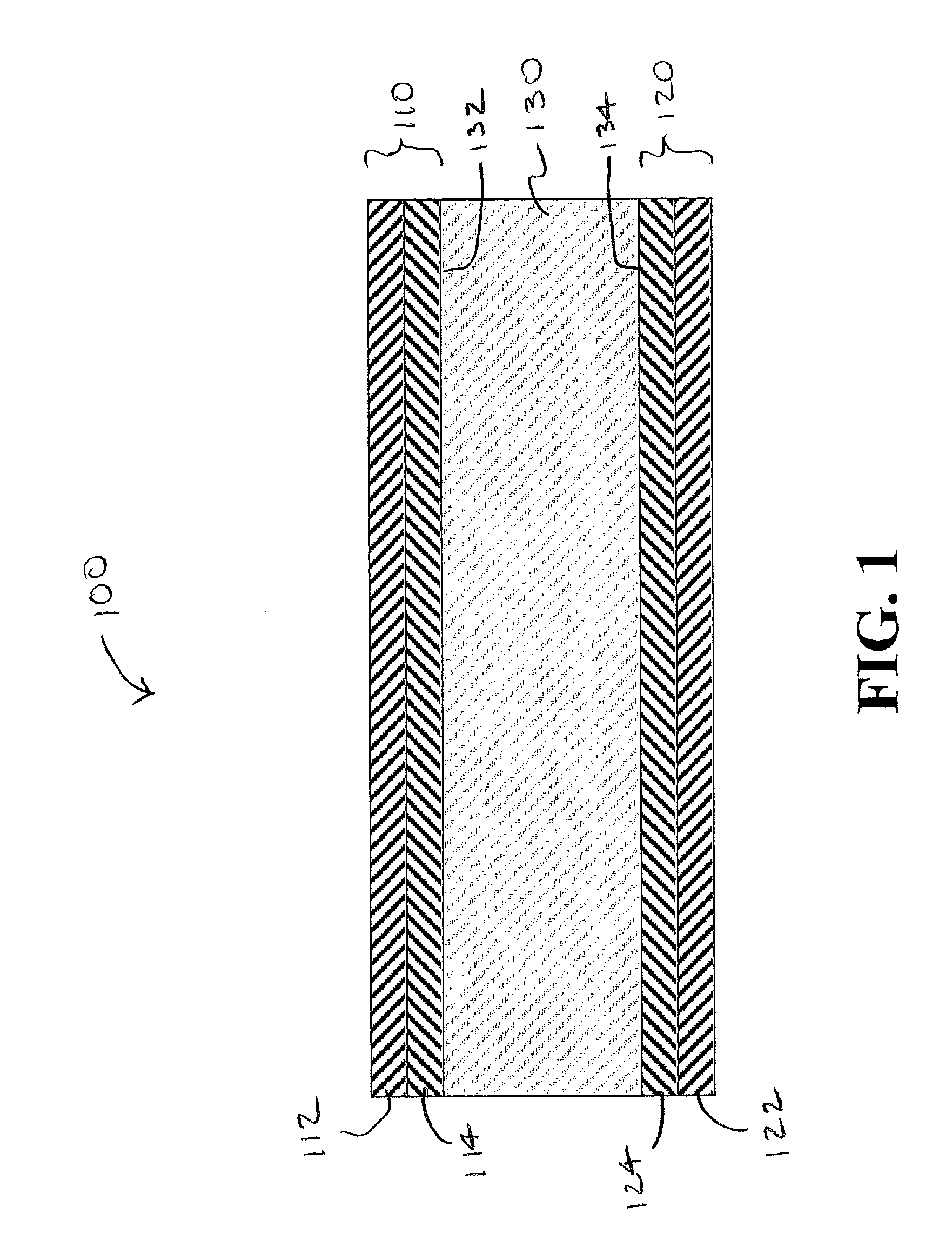

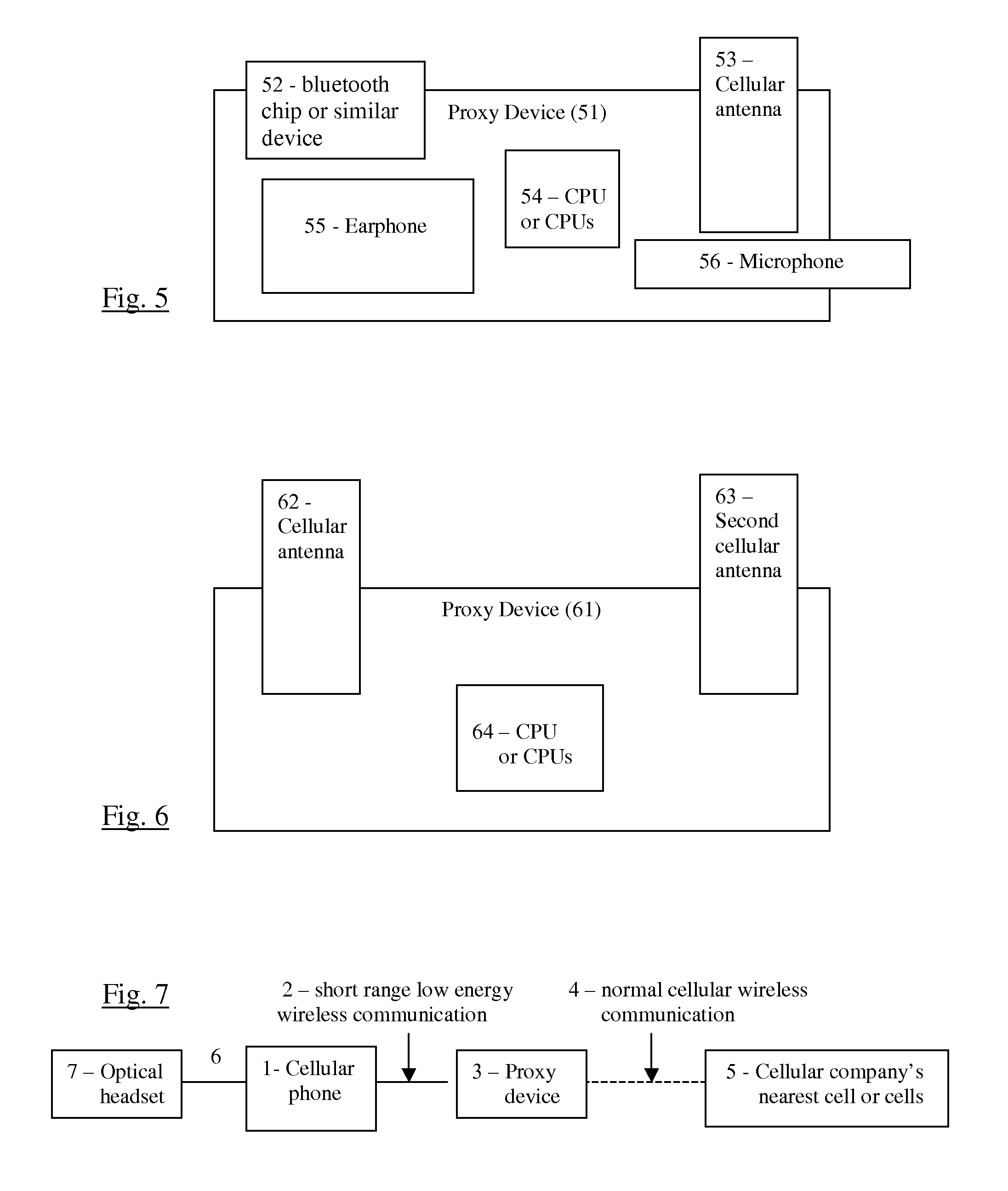

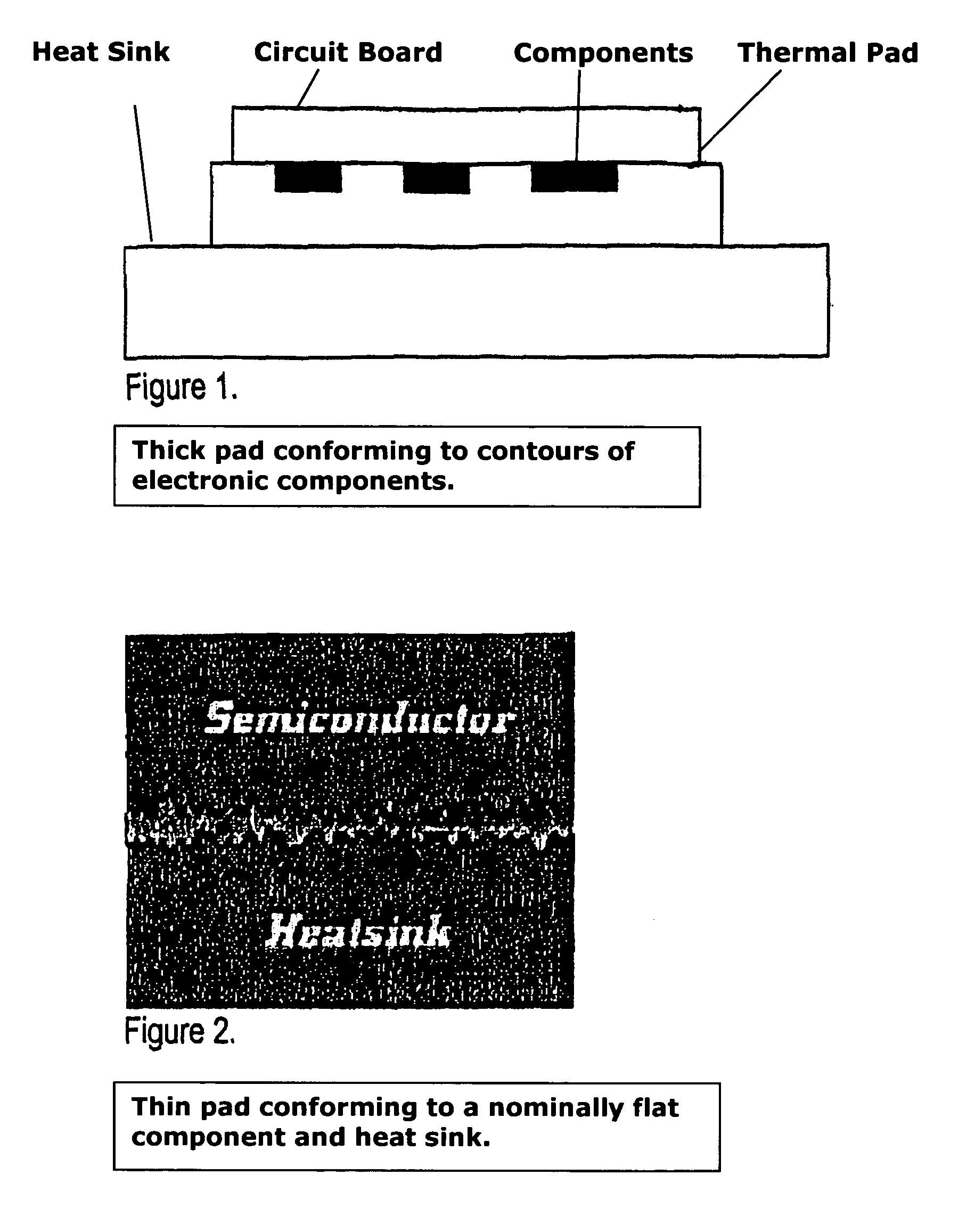

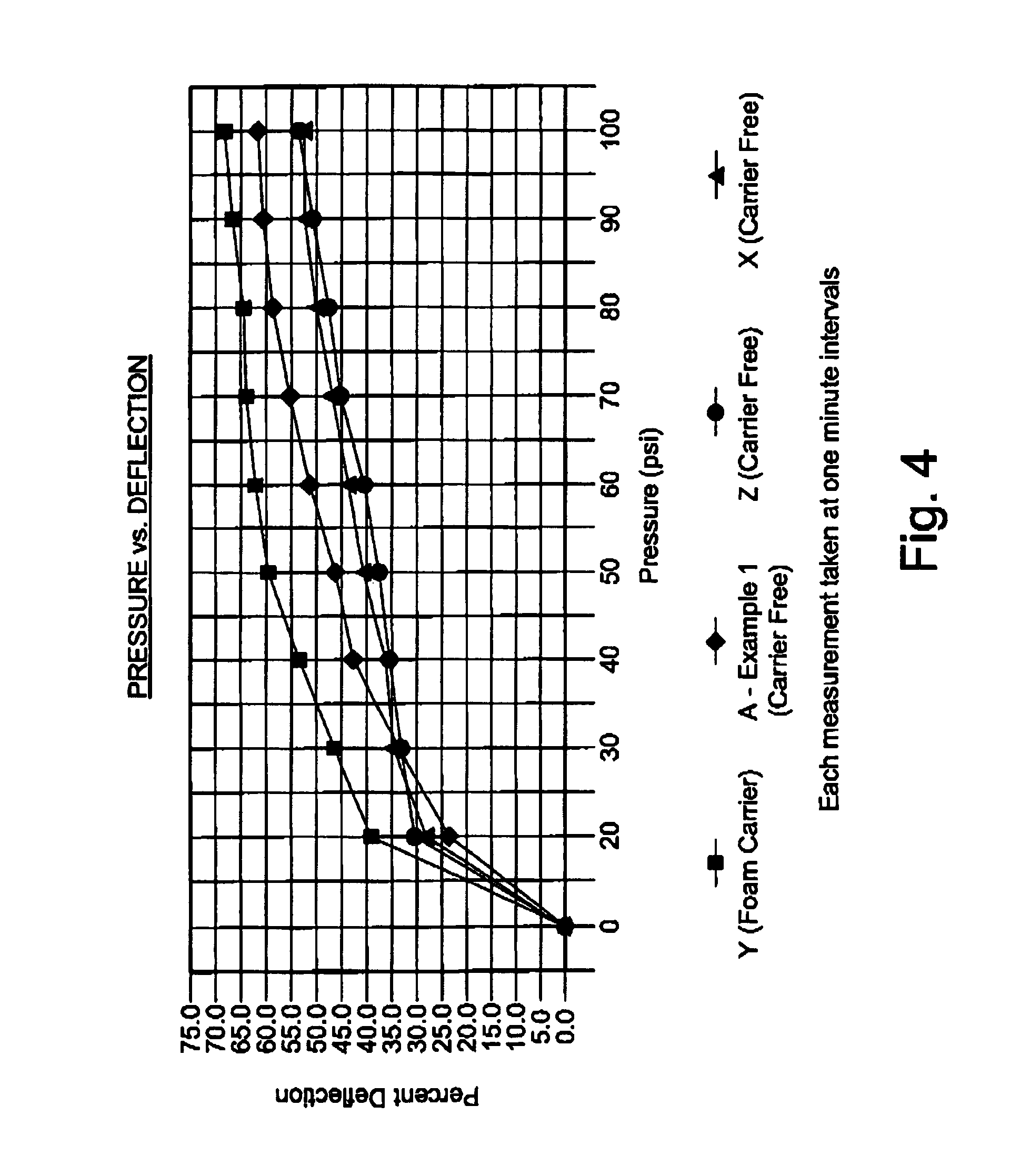

Silicone pads for electronics thermal management

A method of choosing a formulation for a carrier free pad having desired thermal conductivity and elastomeric properties therein which will produce a pad having a desirable thermal impedance. A combination of a vinyl functional fluid, hydrogen capped polysiloxane, cross linker and powder in the form of heat conductive particles with or without electrically insulating particles is utilized which is variable according to the desired thickness, elastomeric and thermal characteristics of the pad. Inhibitors and catalysts may be utilized to control reaction rate. The formulation enables one to more efficiently arrive at a final formulation for a thermal pad having the desired performance characteristics according to the job at hand.

Owner:LAIRD TECH INC

Method and Apparatus for Delivering Ink Material from a Discharge Nozzle

InactiveUS20120038705A1Efficient depositionImprove loading efficiencyInking apparatusSolid-state devicesCarrier fluidFilm material

The disclosure relates to a method for loading ink material into discharge nozzle having a non-discharge surface and a plurality of micropores. The, method includes the steps of providing a quantity of liquid ink material defined by a carrier fluid containing dissolved or suspended film material; delivering the quantity of liquid ink onto the discharge nozzle and directing a portion of the delivered ink into at least one micropore; flowing a pressurized gas over the surface to drive the delivered ink material into the least one nozzle; evaporating the carrier fluid from the delivered ink to form a substantially carrier-free ink material at the micropore; and dispensing the substantially carrier-free ink material from the nozzle. The surface can be configured to reject the ink and the plurality of nozzles are configured to receive the ink.

Owner:KATEEVA

Carrier-free plastic master batch and preparation method and application of carrier-free plastic master batch

The invention belongs to the technical field of plastic master batches, and discloses a carrier-free plastic master batch and a preparation method and an application of the carrier-free plastic master batch. The method comprises the following steps: mixing a plasticizer with an functional assistant; heating, melting and evenly stirring to obtain a mixture; adding the mixture to a granulating device so that the mixture freely falls off from holes of a cylindrical rotator, cooling and solidifying, so as to obtain the carrier-free plastic master batch, wherein the granulating device comprises the horizontally placed cylindrical rotator and a circulating band; holes are fully distributed on the side of the cylindrical rotator; and the circulating band is arranged below the cylindrical rotator. The carrier-free plastic master batch disclosed by the invention has the characteristic of strong general performance without addition of a plastic carrier; various functional assistants are good in dispersity; the obtained master batch is good in physical property, stable, and not easy to smash and disperse; high-speed kneading (or banburying) or single / dual screw extruder is not needed; and the problem of poor performance caused by secondary processing of traditional carrier master batches is avoided, thus the carrier-free plastic master batch can be widely applied to polyolefin and engineering plastics.

Owner:广州索润科技股份有限公司

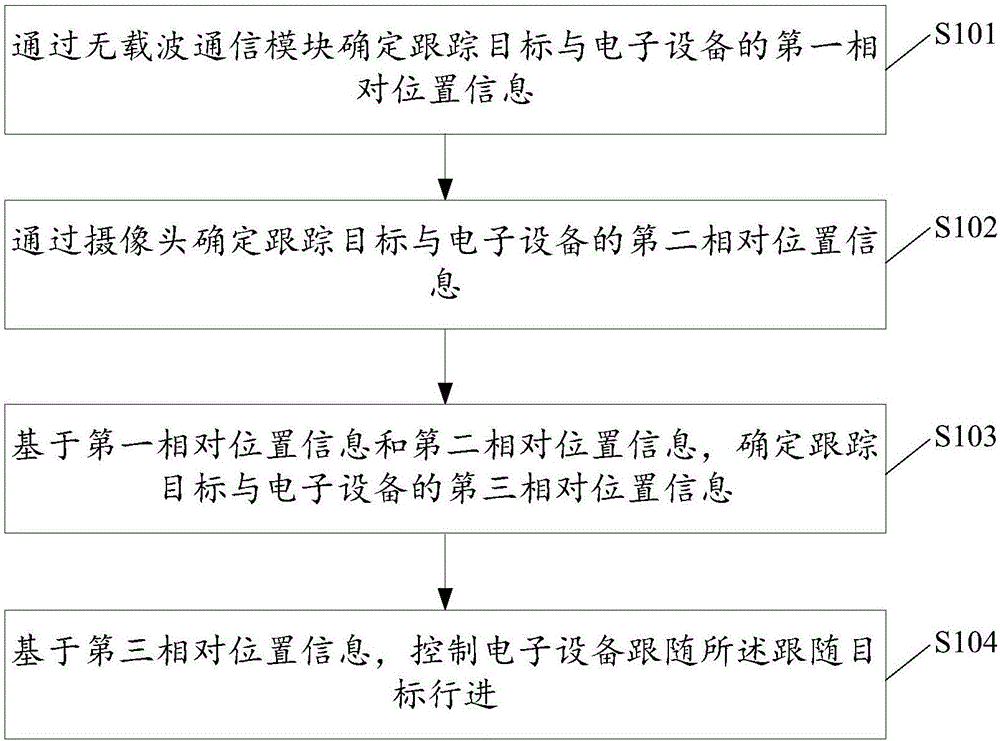

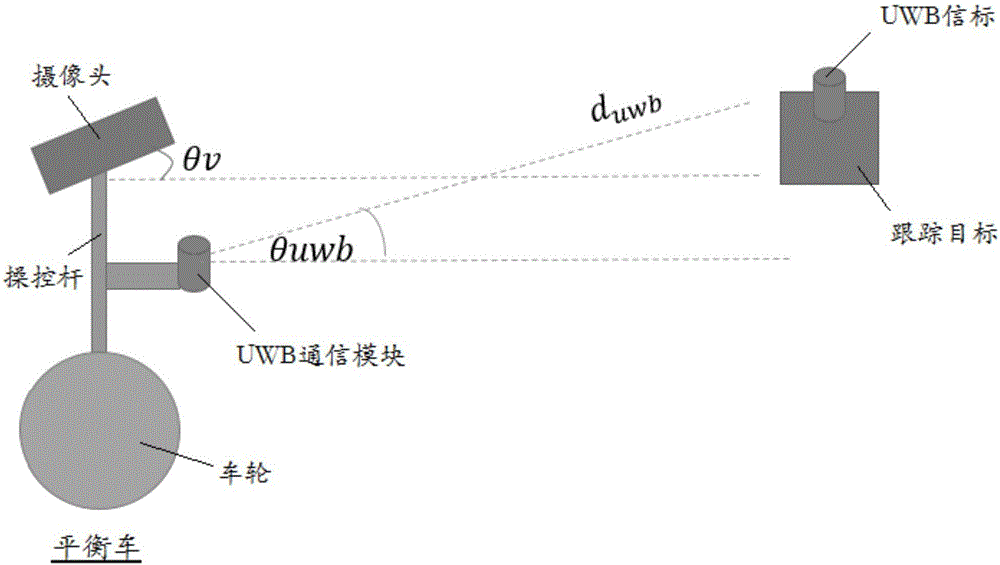

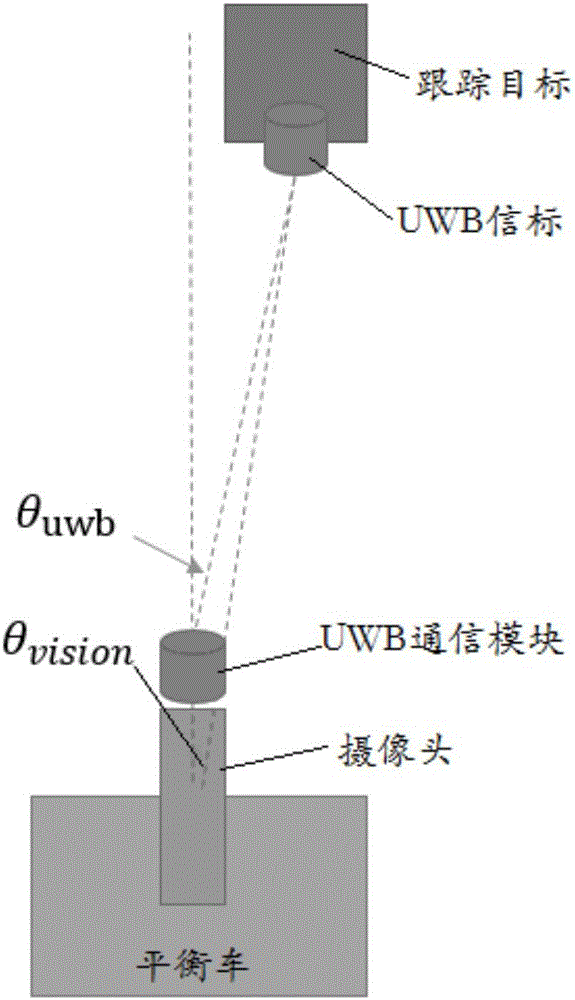

Method and device for tracking targets

ActiveCN106683123AImprove accuracyImage analysisPosition fixationComputer moduleElectronic equipment

The invention discloses a method for tracking targets. The method is applied to electronic equipment. A camera and a carrier-free communication module are arranged on the electronic equipment. The method includes determining first relative location information of the tracked targets and the electronic equipment by the aid of the carrier-free communication module; determining second relative location information of the tracked targets and the electronic equipment by the aid of the camera; determining third relative location information of the tracked targets and the electronic equipment on the basis of the first relative location information and the second relative location information; allowing the electronic equipment to track the tracked targets to advance under the control on the basis of the third relative location information. The method has the technical advantage that the stability and the robustness of the method for tracking the targets can be improved. The invention further discloses a device for tracking the targets.

Owner:NINEBOT (BEIJING) TECH CO LTD

Abradable dry film lubricant and the method for applying same and article made therefrom

InactiveCN101535420AEasy meshReduce contact stressShaftsBearing componentsSubstrate surfaceLubricant

An article with an abradable dry powder coating thereon comprises an abradably coated article with a substrate surface and having at least one coating of a liquid primer on the substrate surface and then coating with at least one abradable dry powder coating on the surface of the liquid primer. The sequence of layers may also be reversed, or additional layers may be useful. The abradable dry powder coating is formed of a dry powder coating composition including a thermoset resin having a cure temperature combined with at least one filler material, wherein the filler is formed of a material which does not melt substantially at or below the cure temperature of the resin, whereby an abradable coating results employing a filler to make the coating. A method of making a composition for coating an article with a coating curable into an abradable coating is also disclosed, comprising melt- mixing an evaporative carrier-free mixture of a dry powder thermoset resin having a cure temperature, to form a mass composite, wherein the filler is formed of a material which does not substantially melt at or below the cure temperature of the resin, cooling the mass composite, and breaking the cooled mass composite into powder particles, thereby forming the composite powder composition.

Owner:安德鲁·W·苏曼

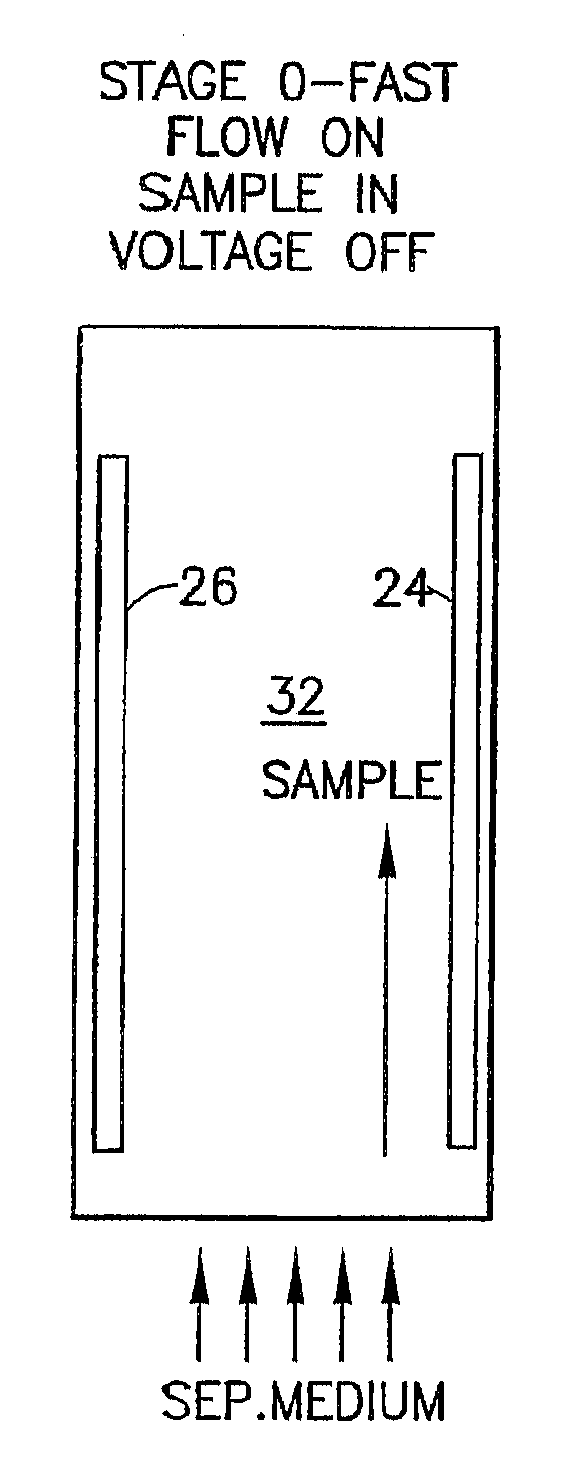

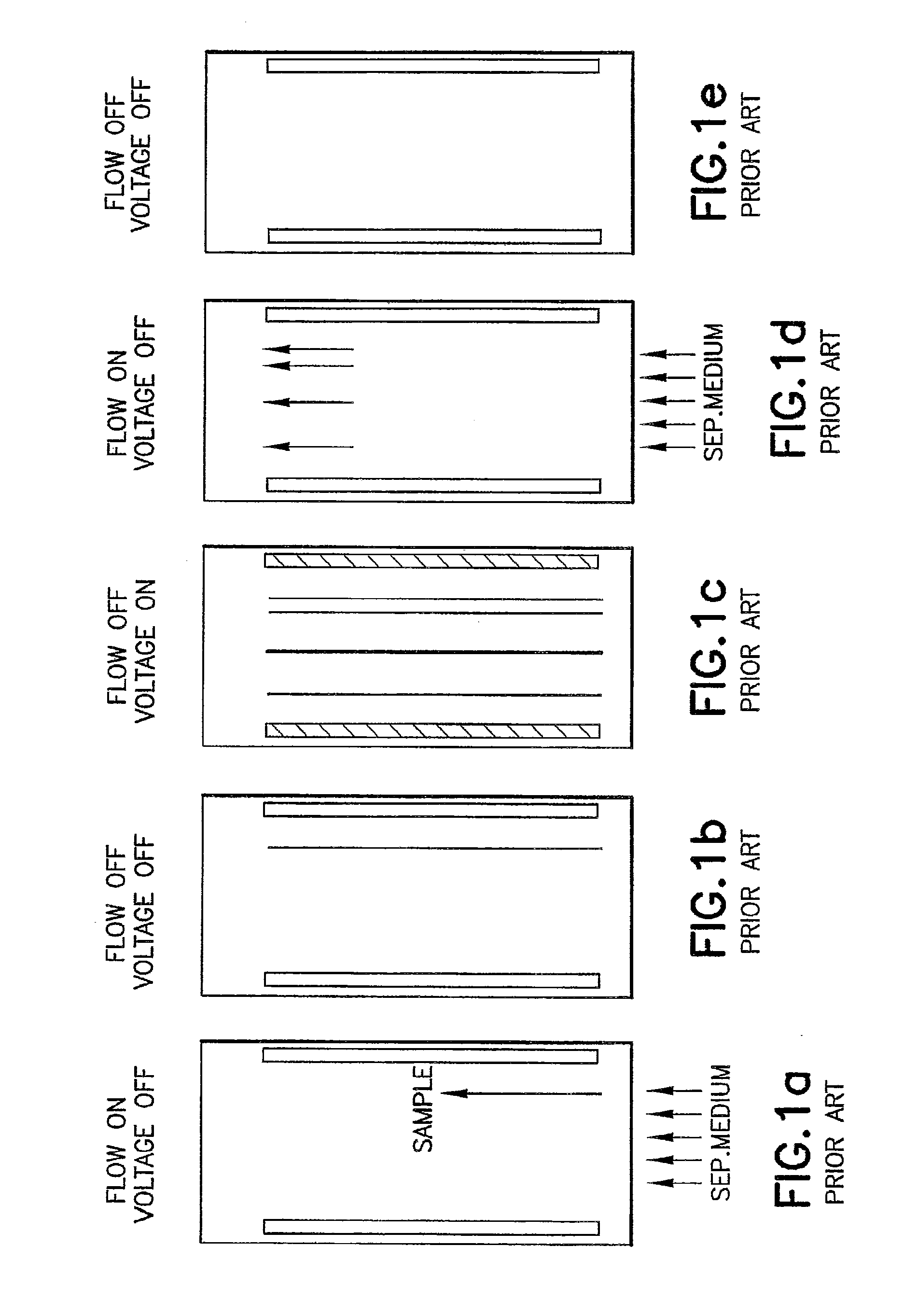

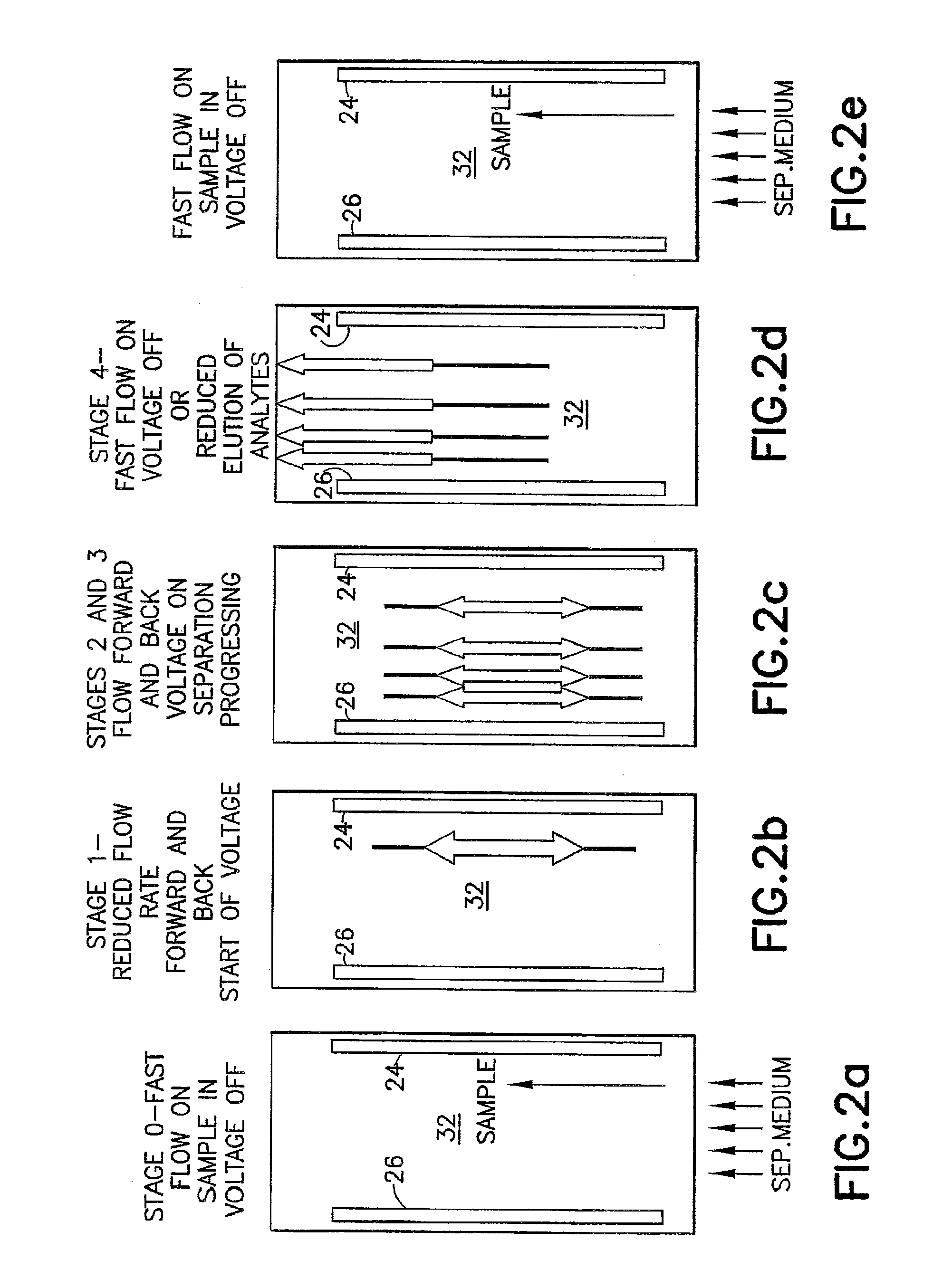

Methods and Apparatus for Carrier-Free Deflection Electrophoresis

ActiveUS20110174624A1Exclude influenceImprove separation qualitySludge treatmentVolume/mass flow measurementElectricityIsotachophoresis

Owner:BECTON DICKINSON & CO

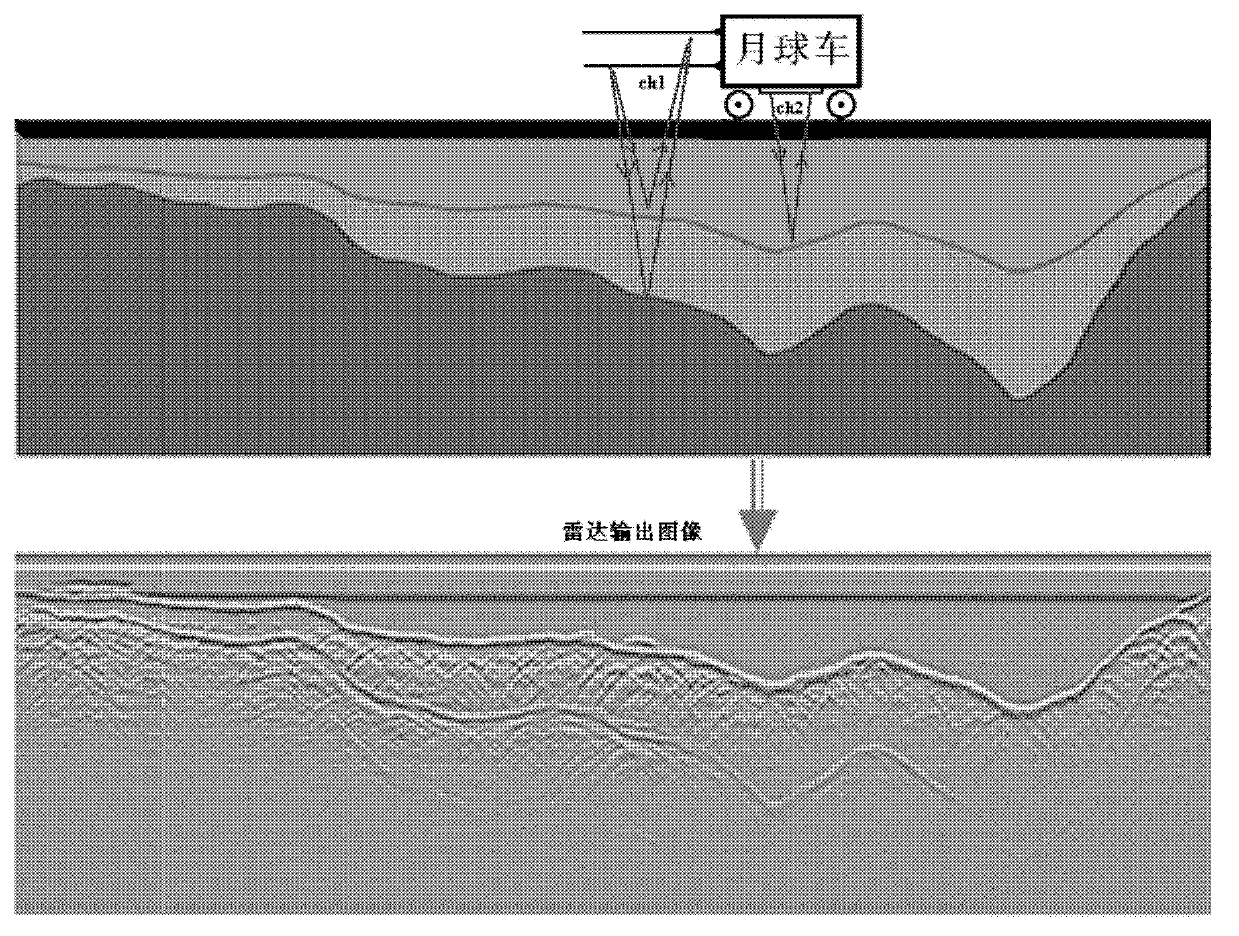

Method and system for detecting thickness of lunar soil and subsurface geological structure of moon

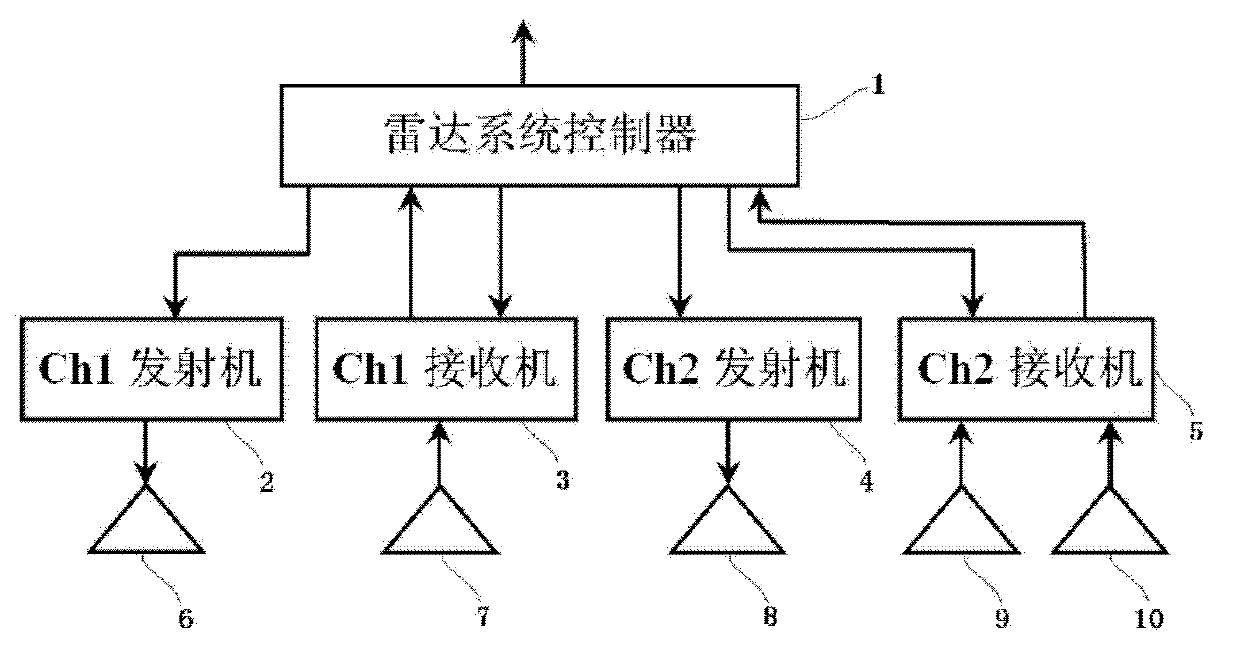

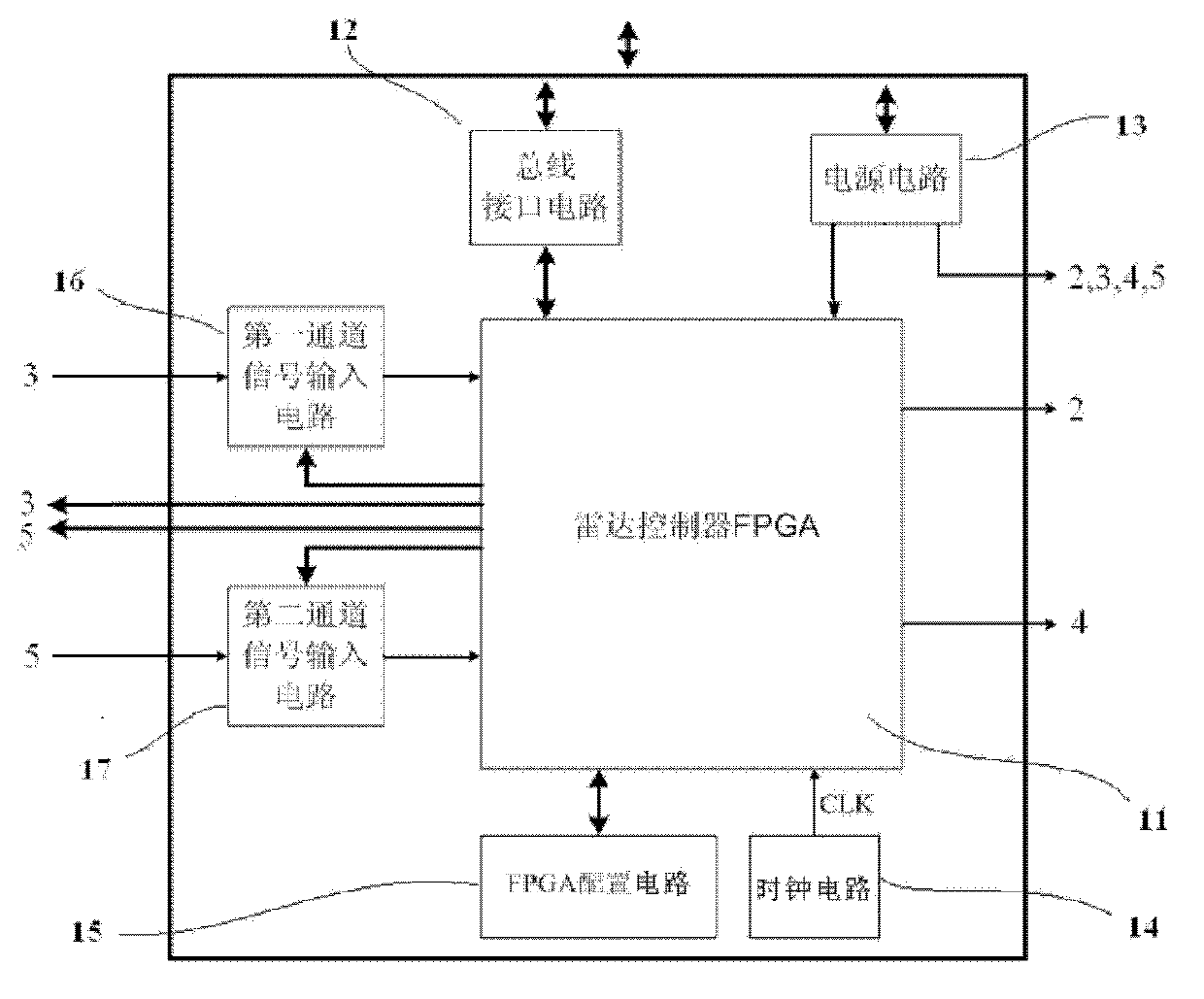

ActiveCN103630943AWorking frequency bandwidthReduce weightElectrical/magnetic thickness measurementsDetection using electromagnetic wavesRadar systemsGeomorphology

The invention discloses a method and system for detecting the thickness of lunar soil and the subsurface geological structure of the moon via an ultra-wide-band carrier-free pulse radar. A radar system includes two detection channels, wherein the first channel work at an HF / VHF waveband in a one-transmission-one-reception mode, and is used for detecting the geological structure of rocks at the subsurface of the moon; and the second channel works at a UHF waveband in a one-transmission-two-reception mode, and can accurately detect the thickness of the lunar soil layer. The ultra-wide-band carrier-free pulse radar is mounted on a moon rover and moves with the moon rover, and the two detection channels work alternatively, and respectively radiate and receive ultra-wide-band carrier-free pulses to complete detection for the thickness distribution of the lunar soil and the geologic structure of the rocks at the subsurface of the moon. Detected data is transmitted back to the earth, and the geologic structure of the rocks at the subsurface of the moon and the structure of the lunar soil layer are drawn on a display screen after processes as data filter and amplification.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

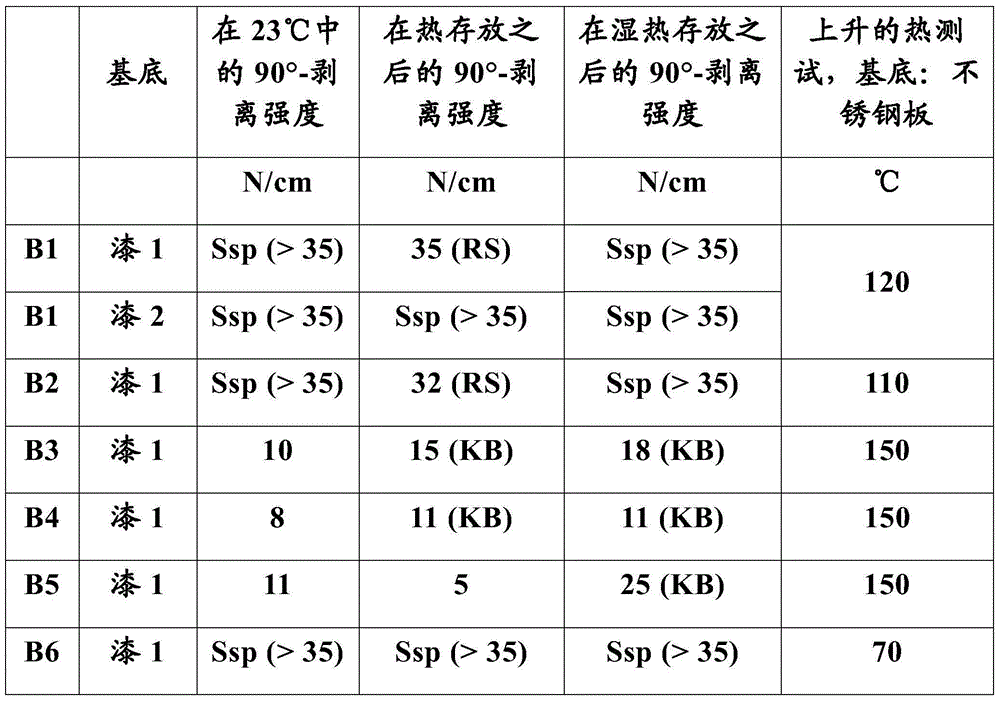

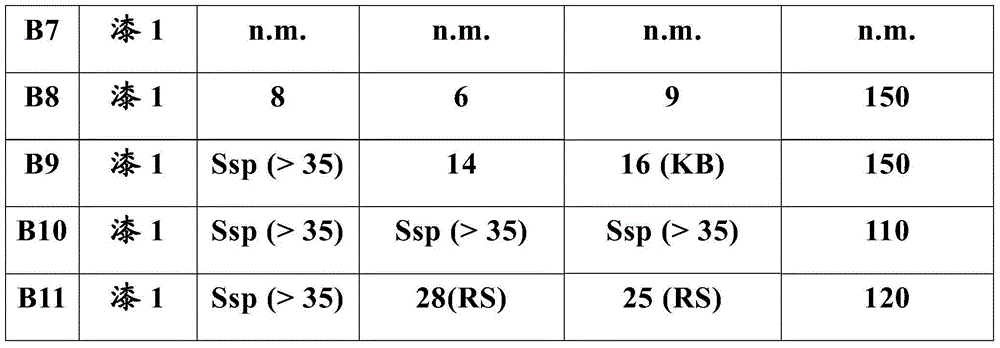

Adhesive agent having adhesive blend of acrylate and styrene block copolymer

The present invention relates to a carrier-based bonding adhesive agent, which is equipped for bonding adhesion on one or both sides or a carrier-free bonding adhesive agent, in the form of an adhesive strip or stamped part having a bonding adhesive consisting substantially of a blend of polyacrylate and a synthetic rubber as well as one or more adhesive resins. By comparison with previously known adhesive systems such an adhesive exhibits a significant improvement in adhesion on hard, non-polar surfaces such as for example new paint surfaces in the automobile industry.

Owner:LOHMANN GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com