Adhesive agent having adhesive blend of acrylate and styrene block copolymer

A technology of block copolymers and polyacrylates, which is applied in the direction of ester copolymer adhesives, hydrocarbon copolymer adhesives, film/sheet adhesives, etc., and can solve the problem of incompatibility of blends, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

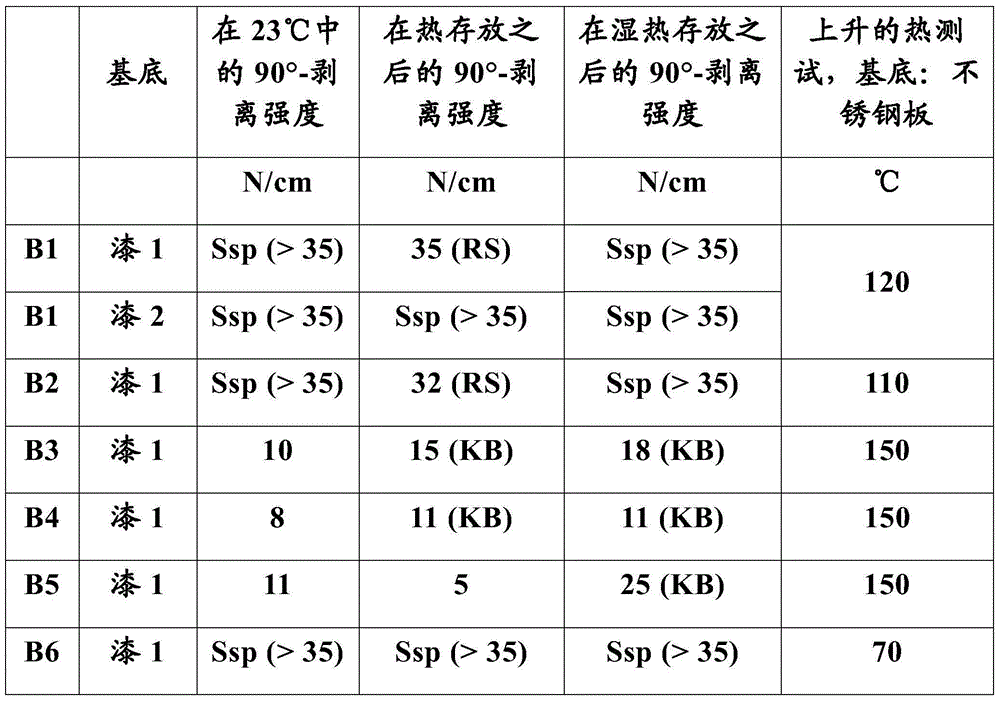

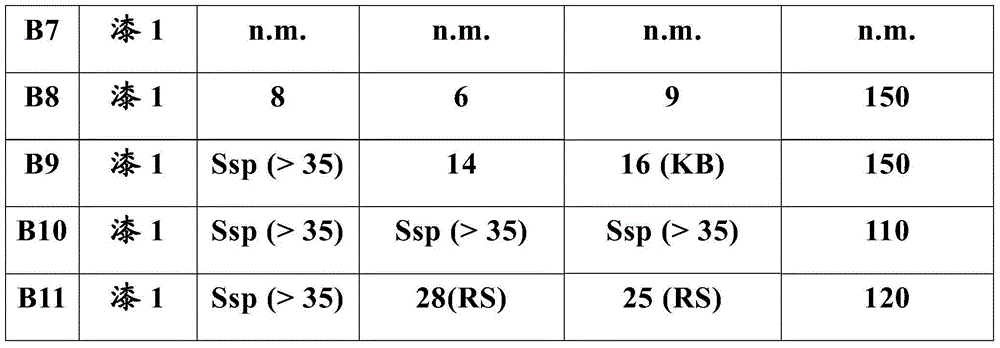

[0067] Example 1 (B1) :

[0068] 10.7 parts of Polymer 3, 21.2 parts of Resin 2 and 0.32 parts of AO1 were dissolved in solvent LM1, thus resulting in a solids content of approximately 55%. The mixture was supplied with a solution consisting of 65.1 parts of Polymer 1, 19.9 parts of Resin 1 and 16.3 parts of LM1.

[0069] The total mixture was mixed intensively for about 3 minutes at about 5000 U / min in a laboratory dissolver (Dispermat TU from the company VMA-Getzmann, with dissolution pan) so that a somewhat homogeneous dispersion was produced. The mixture was further worked up over 12 hours. 4.58 parts of crosslinker solution VM1 were mixed homogeneously into this mixture. The adhesive substance was applied to a siliconeized polyester film (thickness 50 μm) by means of a steel doctor blade, first dried at room temperature for 10 minutes and then dried in an air-circulating oven at 110° C. for 5 minutes. The thickness of the application is chosen such that after drying ...

example 2

[0070] Example 2 (B2) :

[0071] As Example 1, however using Polymer 2 instead of Polymer 1.

example 3

[0072] Example 3 (B3, comparative example) :

[0073] Neat Polyacrylate Adhesive: 100 parts Polymer 1 mixed with 7 parts V1 and coated, dried and coated onto a foam carrier as described above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com