Carrier-free plastic master batch and preparation method and application of carrier-free plastic master batch

A plastic masterbatch and carrier-free technology, which is applied in the field of carrier-free plastic masterbatch and its preparation, can solve the problems of poor uniform dispersion, low dispersion degree of masterbatch, dispersing and powdering, etc., and achieve avoidance performance The effect of poor variation, low equipment requirements, and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

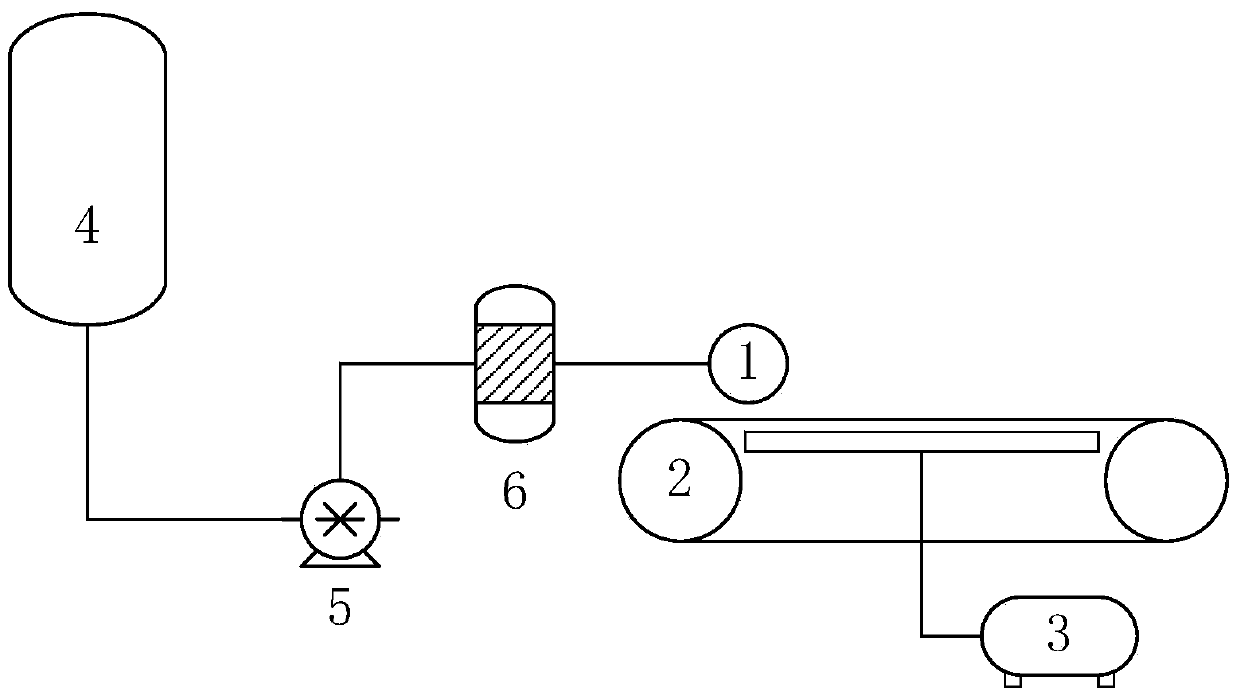

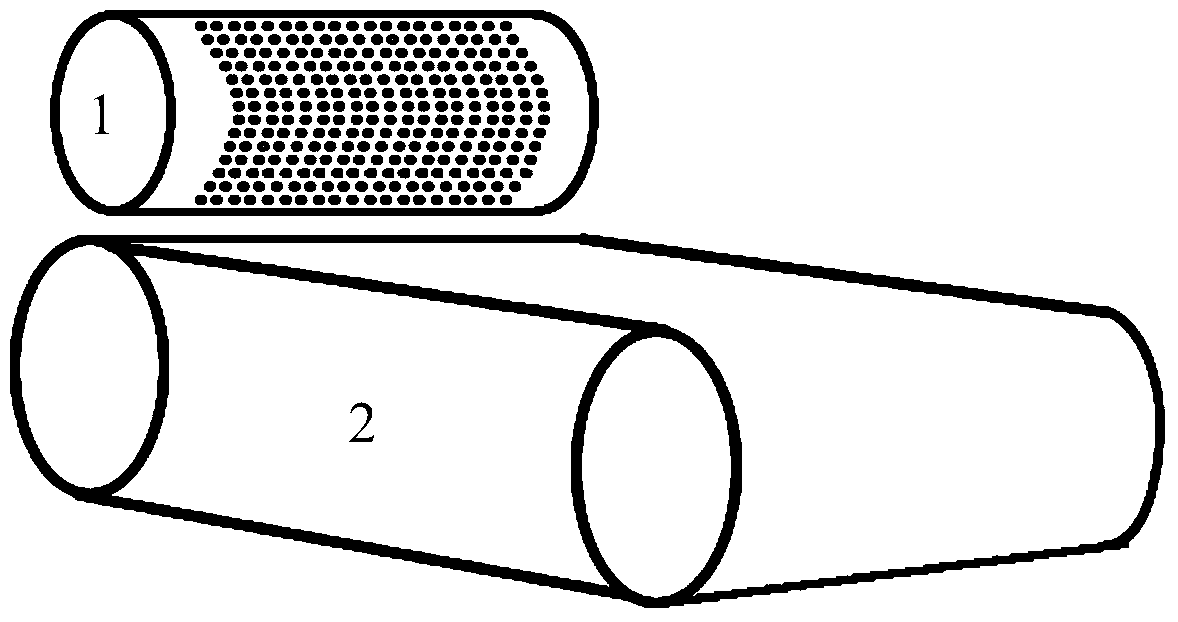

[0053] Utilize the above-mentioned granulation device of the present invention to prepare carrier-free plastic masterbatch (PP drawing color masterbatch): stearic acid, paraffin wax, polyethylene wax, polyethylene glycol, fatty acid bisamide (EBS hyperdispersant after modification) ), the toner is put into the heating kettle according to the mass ratio of 13:57:5:3:2:20, heated to 100°C and melted, and stirred for 10 minutes after they are completely melted. Cylindrical rotator, dripping from the side hole, dripping through free fall to the stainless steel circulation belt with cooling, cooling and solidification, to obtain 0.35 ~ 0.40 cm round masterbatch, the addition amount can be as low as 1.5wt when used %.

Embodiment 3

[0055] Utilize the above-mentioned granulation device of the present invention to prepare carrier-free plastic master batches (PE, PVC, EVA smooth master batches): fatty acid monoglyceride, stearate (zinc stearate), antioxidant (phenolic antioxidant) Oxygen agent), polyethylene glycol, slip agent (oleic acid amide) according to the mass ratio of 70:9:1:5:15, put them into the heating kettle, heat to 100 ℃ to melt, and stir for 10 minutes after all melt , continuously stirred and flowed into the cylindrical rotator full of holes through the conduit, and dropped to the stainless steel circulation belt with cooling through free fall, cooled and solidified, and obtained a round masterbatch of 0.35-0.45 cm, which can be applied to PE, As a smooth masterbatch in PVC or EVA, the addition amount can be as low as 1.5wt%.

Embodiment 4

[0057] Utilize the above-mentioned granulation device of the present invention to prepare carrier-free plastic master batch (smooth master batch): pentaerythritol stearate, stearate (zinc stearate), antioxidant (phenolic antioxidant, sub- Phosphate antioxidant compound), polyethylene glycol, slip agent (erucamide alone or erucamide and behenamide compounded at 2:1) according to 70:9:1:5:15 Put it into the heating kettle, heat it to 100°C to melt, stir for 10 minutes after all the melting, keep stirring, flow into the cylindrical rotator full of holes through the conduit, and drop to the stainless steel with cooling through free fall. Steel circulating belt, cooled and solidified to obtain a round masterbatch of 0.35-0.40 cm. It can be used for film materials such as PP, PET, BOPP, CPP, TPU or TPE, and the dosage can be as low as 2wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com