Expandable filler insert and methods of producing the expandable filler insert

An insert, polymer technology for thin material handling, transportation and packaging, superstructure, etc., that can solve problems such as sheet thickness limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

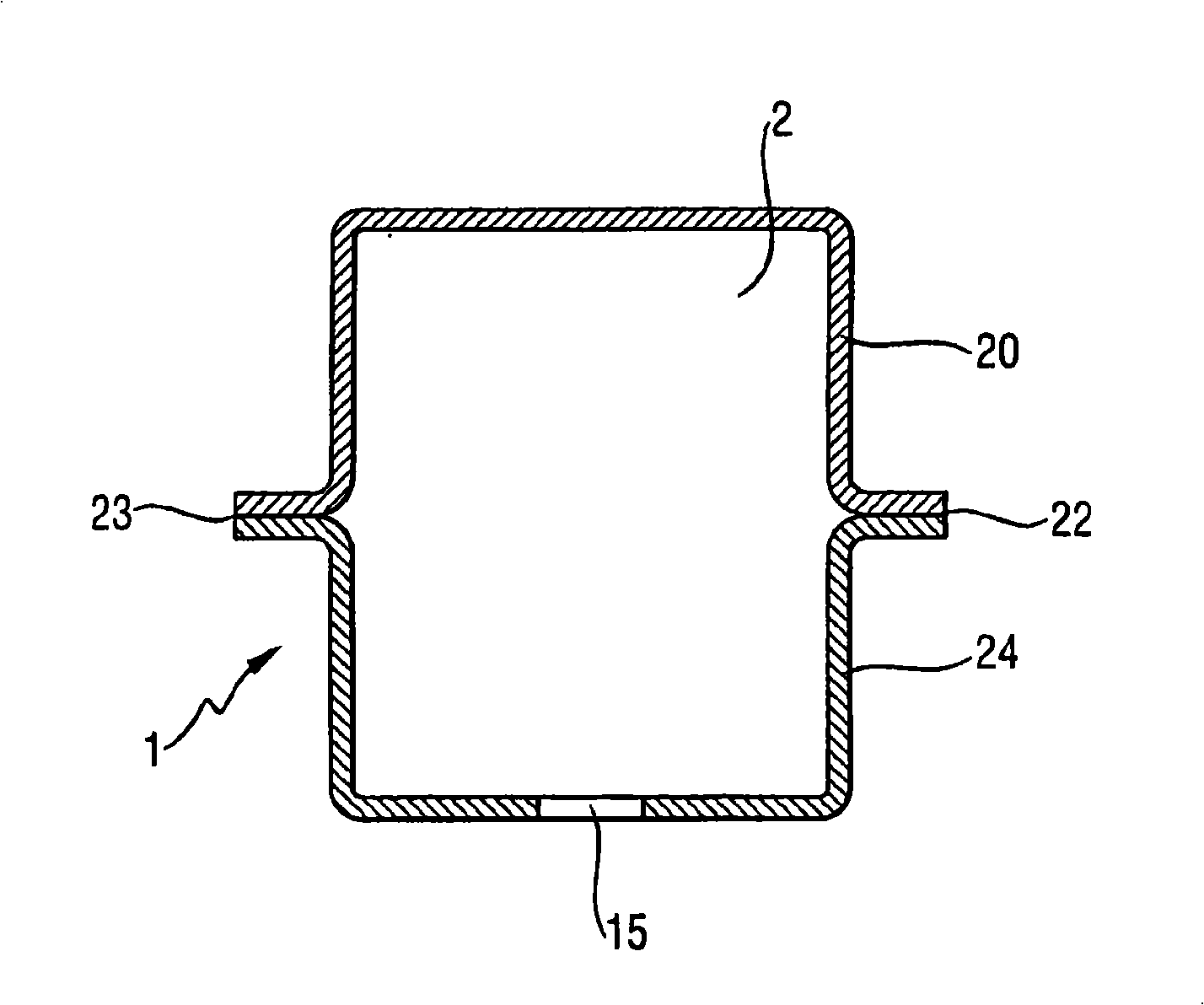

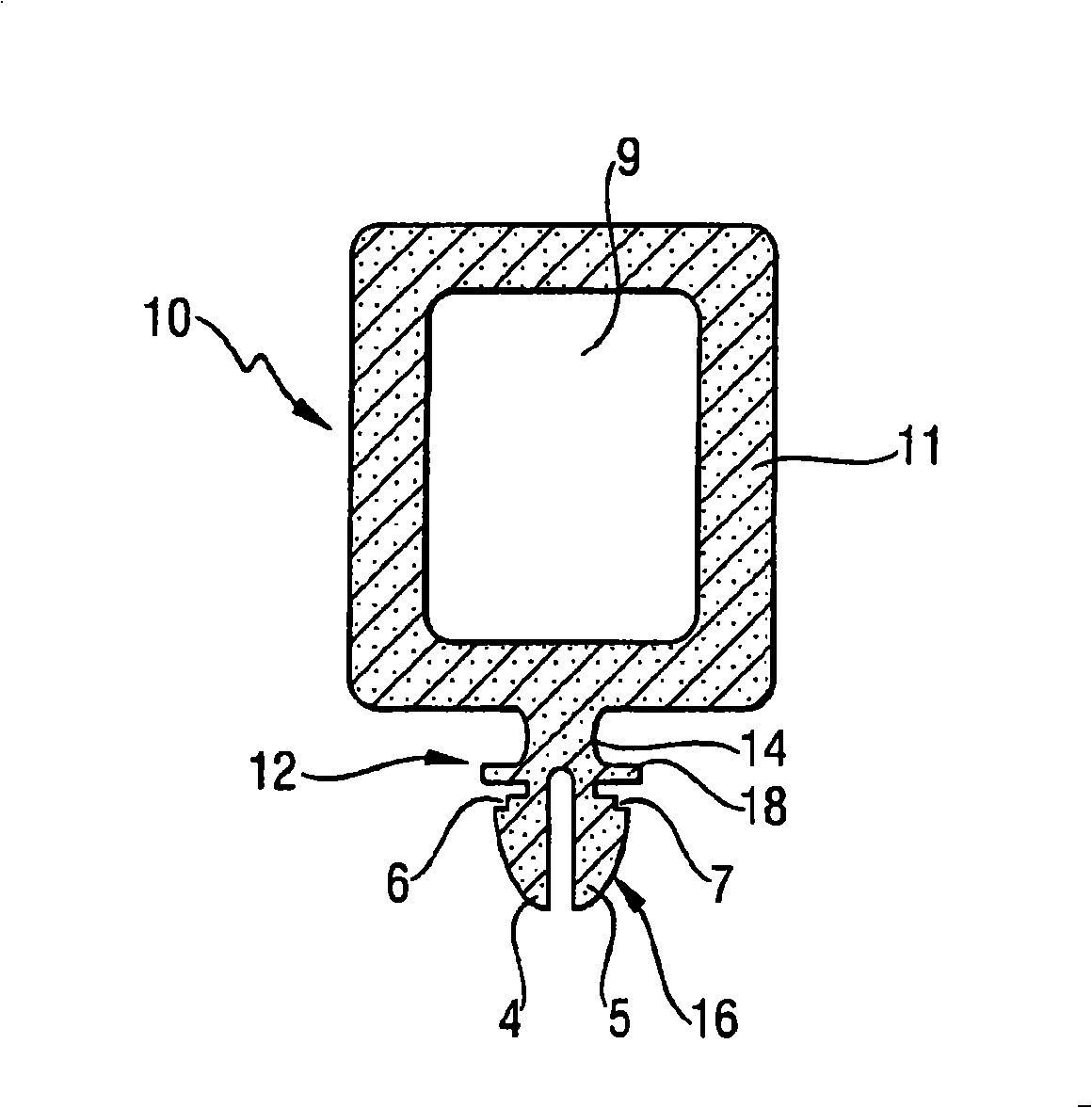

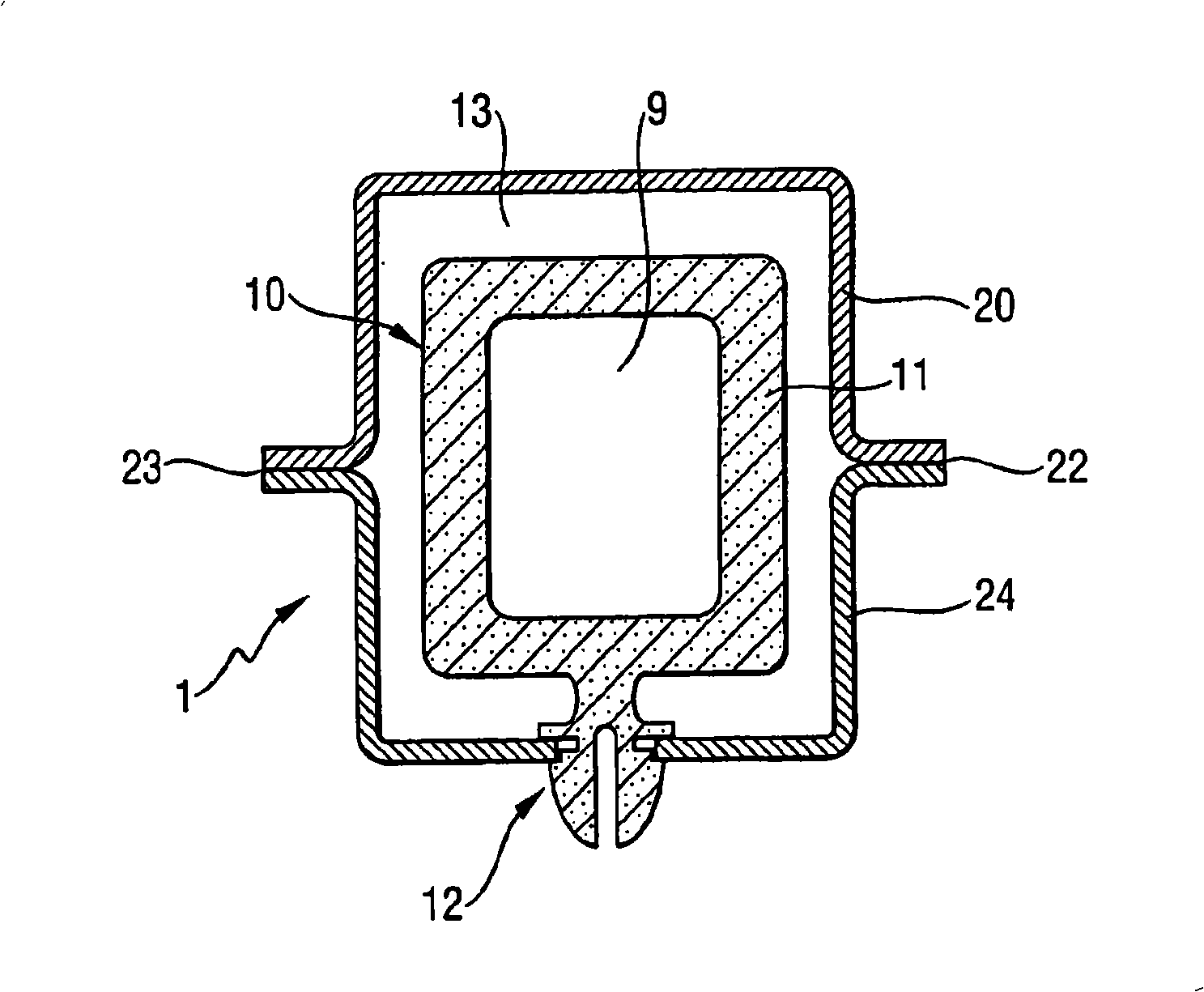

[0026] The present invention provides expandable filler inserts for filling or sealing hollow spaces or cavities. In addition, the present invention provides expandable filler inserts for filling or sealing hollow spaces or cavities of vehicle pillars. The present invention also provides a method for preparing expandable filler inserts by profile extrusion molding (also known as profile molding) or injection molding.

[0027] In an embodiment of the invention, an expandable filler insert is provided, for example for filling and / or sealing cavities such as cavities or hollow structures of pillars of vehicles such as automobiles. Expandable filler inserts comprising a self-supporting continuous structure with an internal space, the structure consisting of a polymer matrix comprising a) at least one polymer and / or polymer precursor and b) at least one latent blowing agent .

[0028]The continuous structure is fabricated to optionally have interior spaces (i.e. openings, viewed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com