Self-oriented liquid crystal medium composition, liquid crystal display panel and its manufacturing method

A liquid crystal medium and composition technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of weak anchoring liquid crystal molecules, uneven alignment, and increased panel cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

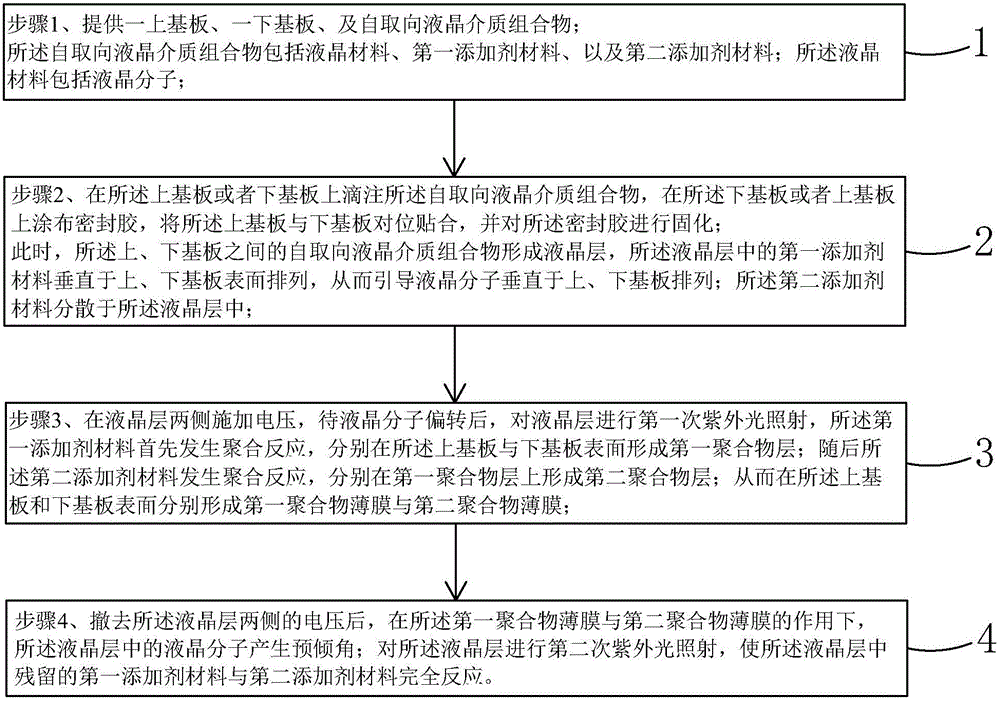

Method used

Image

Examples

specific Embodiment 1

[0129] The self-aligning liquid crystal medium composition includes a negative liquid crystal material, a first additive material, and a second additive material, the mass percentage of the negative liquid crystal material is 97%, and the mass percentage of the first additive material is 2- 2.5%, the mass percentage of the second additive material is 0.5-1%;

[0130] The first additive material includes

[0131] The second additive material includes

specific Embodiment 2

[0133] The self-orienting liquid crystal medium composition includes a negative liquid crystal material, a first additive material, and a second additive material, the mass percentage of the negative liquid crystal material is 97%, and the mass percentage of the first additive material is 1.5- 2.5%, the mass percentage of the second additive material is 0.5-1.5%;

[0134] The first additive material includes

[0135]

[0136] The second additive material includes

[0137]

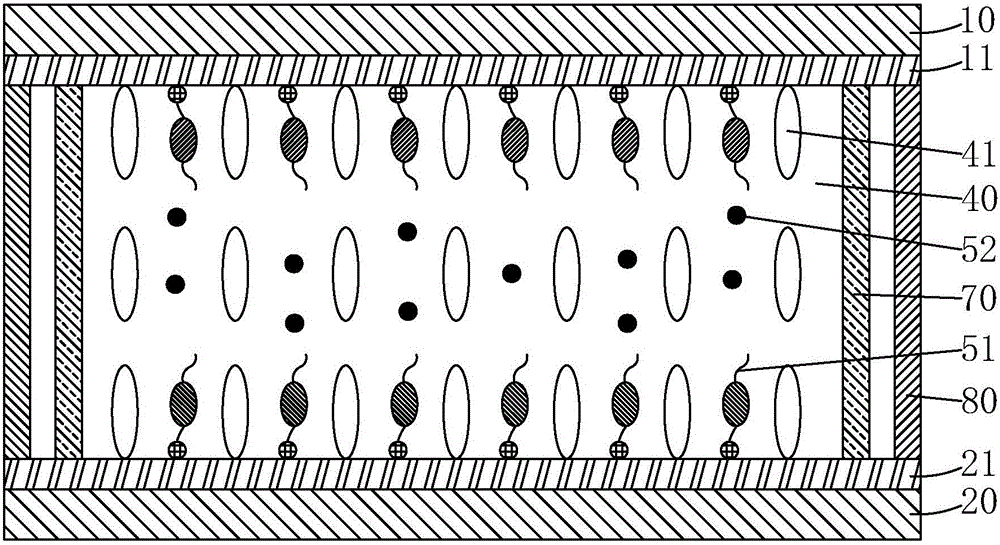

[0138]The above-mentioned self-aligning liquid crystal medium composition includes a first additive material and a second additive material, the first additive material contains both polar groups and polymerizable groups, and the second additive material only contains polymerizable groups group, the number of polymerizable groups in the first additive material is greater than the number of polymerizable groups in the second additive material, and the number of photosensitive groups per unit mass of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com